1. Introduction

Industry 4.0 is reshaping modern manufacturing. The sector is undergoing a fundamental transformation, driven by intelligent automation and data-driven decision-making [

1]. McKinsey’s 2024 The State of AI report [

2] highlights the strategic advantage of Industry 4.0 technologies in manufacturing, where the seamless integration of digital processes enhances efficiency and competitiveness [

2]. According to the report [

2], 40% of surveyed organisations attribute more than 5% of their Earnings Before Interest and Taxes (EBIT) to these advancements, while top-performing firms, namely those deriving at least 20% of their EBIT from Industry 4.0, are 1.6 times more likely to increase their investment in these technologies by over 50% in the next three years [

2]. This pattern underscores how early adopters consolidate market leadership through continuous innovation. Companies that delay adoption risk falling behind, facing competitive disadvantages and long-term sustainability challenges. However, technological advancement alone is insufficient; manufacturing success depends on a well-integrated socio-technical system that aligns innovation with workforce development. While Industry 4.0 offers substantial economic benefits, its full potential relies on equipping workers with the skills to operate and optimise these systems [

1,

3]. Without this dual investment in technology and human capital, the transformative impact of Industry 4.0 will remain limited.

However, this alignment between technological advancement and workforce capability is not being universally achieved. Many manufacturing companies still struggle to balance technological progress with workforce skills. Employers often face a candidate pool of graduates who, despite favourable academic qualifications, lack the practical, hands-on expertise needed to navigate established manufacturing processes, troubleshoot technical issues, and optimise production with modern technologies [

4]. The gap between industry requirements and workforce capabilities is evident. A recent Deloitte study [

5] highlights that, if the skills shortage persists, nearly 1.9 million manufacturing jobs could go unfilled by 2033, leaving a significant portion of the 3.8 million new positions needed between 2024 and 2033 vacant, potentially hampering economic growth. This widening skills gap is exacerbated by shortcomings in current engineering education methods, which often fail to prepare students with the digital literacy and practical competencies essential for Industry 4.0. A significant issue is the prevalence of passive learning approaches, where students engage in lecture-based instruction with limited opportunities for hands-on practice [

6]. This traditional model frequently results in low engagement and poor knowledge retention, leaving students unprepared to apply theoretical concepts to real-world scenarios [

7]. Additionally, digital literacy gaps persist, as many engineering curricula lag in integrating advanced digital tools and Industry 4.0 technologies, leaving graduates underprepared for modern industrial environments.

Bridging this skills gap requires an educational paradigm shift, one that aligns teaching methodologies with industry needs. The concept of Education 4.0 has emerged in response, advocating for integrating advanced technologies to realign educational practices with Industry 4.0 demands [

6]. Education 4.0 promotes active, experiential learning, where students interact with digital tools and simulations to develop practical competencies. Central to this approach are Virtual Learning Factories (VLFs), enhanced by Mixed Reality (MR), which provide immersive, interactive environments replicating real-world manufacturing settings. VLFs move beyond traditional teaching methods, offering students a holistic and practical understanding of engineering principles while equipping them with the essential digital skills demanded by today’s industries [

8].

This study seeks to amalgamate established educational frameworks to tailor them specifically to the needs of stakeholders within engineering higher education. It aims to develop a MR-based framework that enhances engineering education through immersive learning. The proposed framework will be validated using a proof-of-concept MR learning environment that integrates VLFs, enabling students to engage with simulated manufacturing processes through structured, interactive tasks. Furthermore, this study will evaluate the effectiveness of the MR-based framework in improving student engagement and practical problem-solving skills, addressing current gaps in active learning. Finally, it will compare MR-enhanced learning with traditional engineering education methods and assess its potential scalability for broader implementation within higher education curricula.

To guide this study, the following research questions were formulated:

RQ1. What core components should a virtual learning framework for engineering education include to integrate Mixed Reality technologies within engineering education effectively?

RQ2. How can MR-based engineering educational platforms support the development of higher-order thinking skills, such as analysis, evaluation, and creation, in engineering students?

RQ3. How do immersive learning environments impact student engagement within the context of Industry 4.0 educational objectives?

2. Literature Review

The evident gap between the skills required by industry and those provided by academic programs underscores the urgent need to reform the current engineering education model to address this skills mismatch. This literature review highlights educational frameworks and technological advancements that support the development of an effective MR-based learning model.

2.1. Developing a Robust Educational–Technological Framework

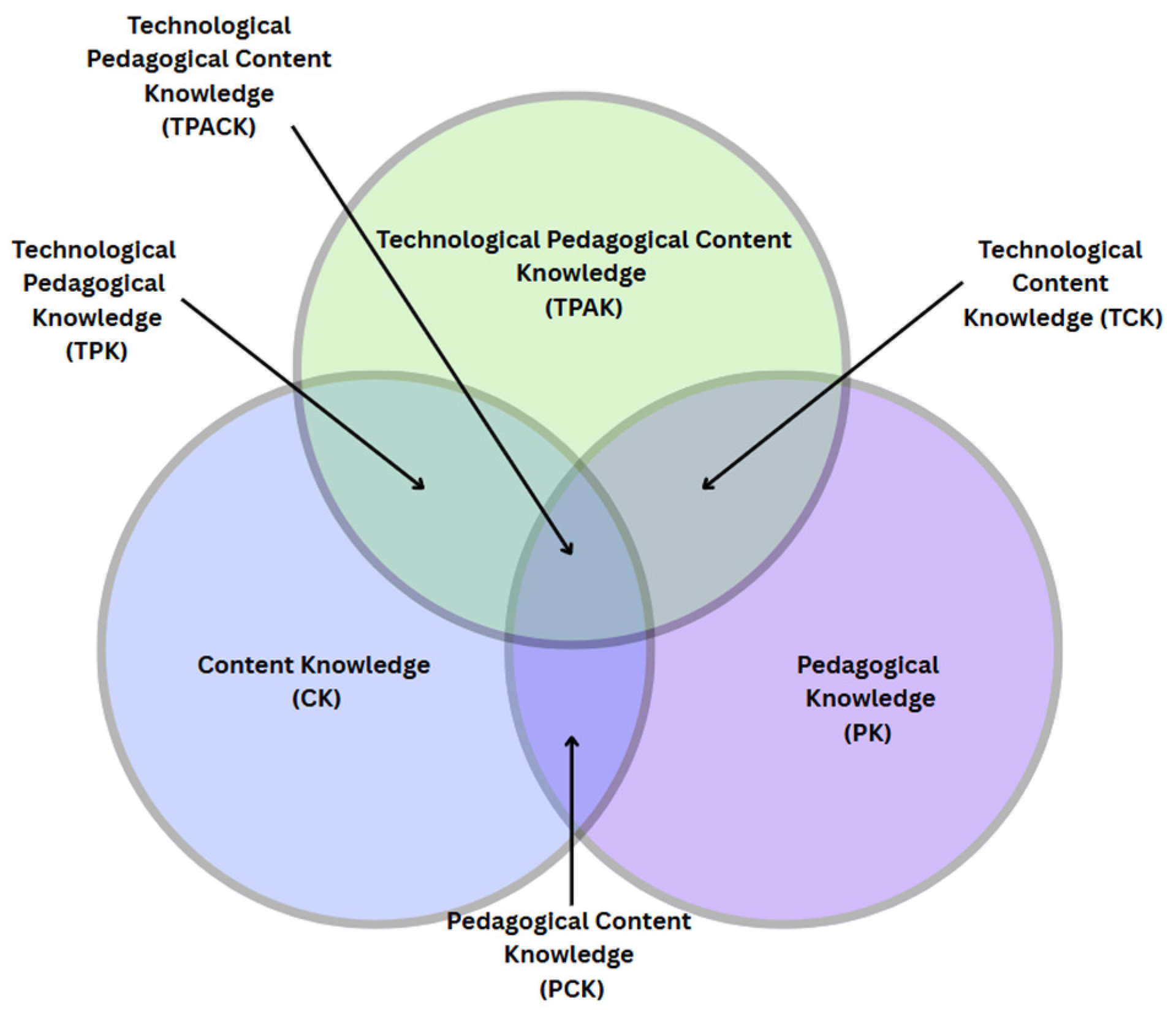

Technological Pedagogical Content Knowledge (TPACK) and the Substitution Augmentation Modification Redefinition (SAMR) model are foundational frameworks for integrating technology into education, each offering unique perspectives. As illustrated in

Figure 1, TPACK emphasises the intersection of three domains: technological, pedagogical, and content knowledge [

9]. Effective integration occurs when these domains align, ensuring that tools like MR and VLFs are used in ways that complement sound pedagogical practices and subject-specific requirements. TPACK is particularly relevant for this study, as it provides a structured approach to embedding emerging technologies into engineering education while aligning with established curricula [

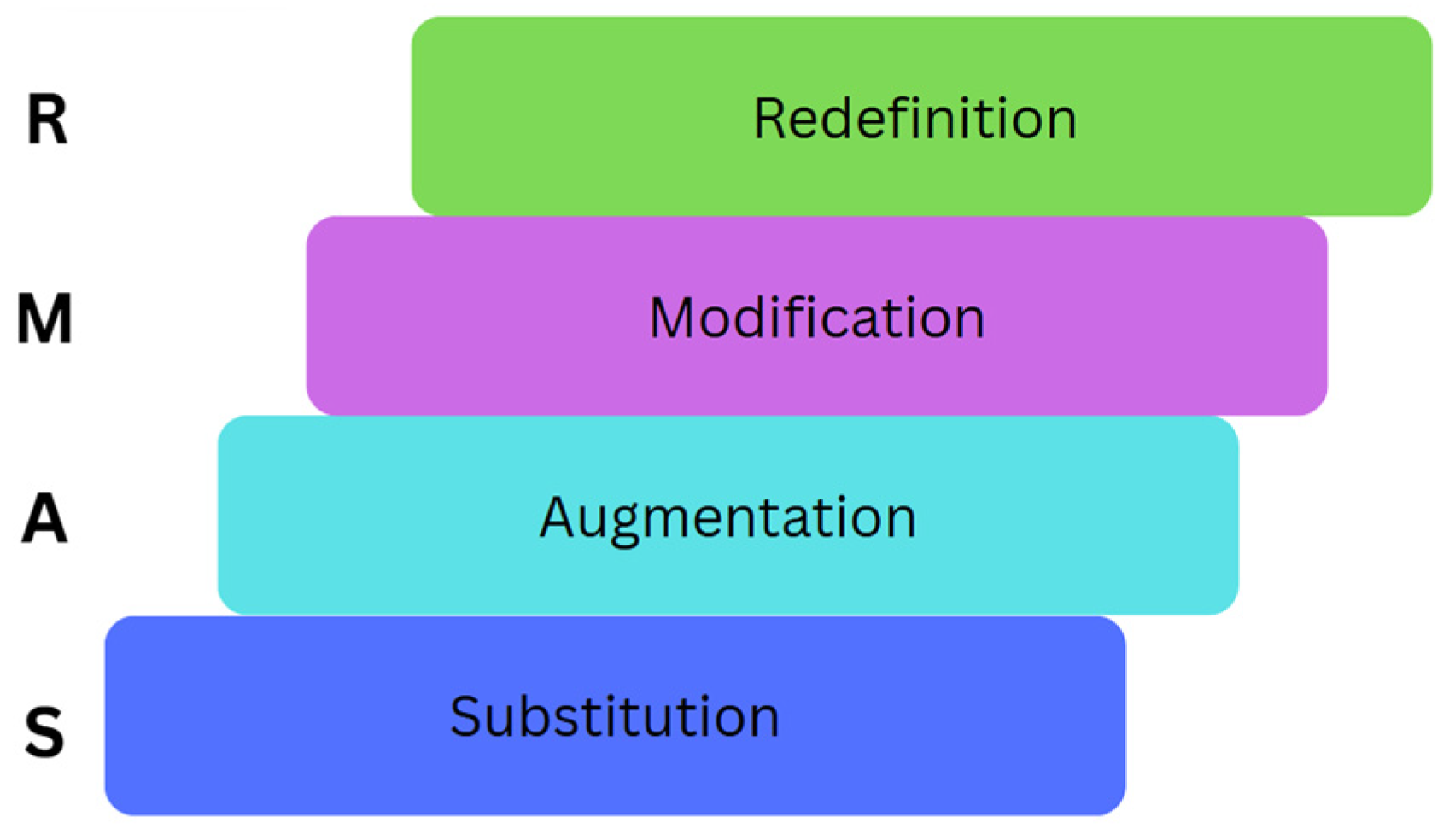

9]. In contrast, the SAMR model, depicted in

Figure 2, categorises technology use into four levels, Substitution, Augmentation, Modification, and Redefinition, highlighting the transformative potential of technology. While Substitution and Augmentation focus on enhancing traditional teaching methods, Modification and Redefinition encourage a complete reimagining of learning experiences, enabling new possibilities such as immersive, applied training environments [

10].

Together, these frameworks shape the foundation of this study by addressing both the integration and the transformation of MR and VLFs in engineering education. TPACK ensures these technologies are integrated effectively within the pedagogical structure, while SAMR guides the exploration of their potential to redefine learning, bridging the gap between academic preparation and industry needs. However, tailoring these frameworks to the specific needs of engineering higher education requires a grounded understanding of the current state of the field. Recognising the unique challenges and gaps in engineering education, an investigation into the existing pitfalls is essential.

In comparison with similar MR-based implementations in STEM education, this study differentiates itself through its emphasis on human-centric, practice-oriented learning for industrial environments. For example, Cheng and Tsai [

13] found that Mixed Reality Virtual Field Trips significantly improved students’ motivation and reduced test anxiety in environmental science education. Similarly, Makransky et al. [

14] identified both the immersive benefits and cognitive challenges of VR-based learning environments. However, few studies have focused on developing Mixed Reality environments that place the student at the centre of the learning process, emphasising active engagement, experiential learning, and autonomy in navigating complex engineering concepts. By grounding this study’s MR development in both pedagogical theory and real-world manufacturing contexts, our approach offers a more novel and industry-aligned contribution to the field.

2.2. Pitfalls Within Established Pedagogical Approaches

While structured sessions like tutorials and lectures offer valuable guidance and conceptual clarity, they may fall short in facilitating experiential learning or fostering interdisciplinary problem-solving when not complemented with practical application [

15]. This model, rooted in history, fosters a reductionist approach by guiding students toward well-defined, single-solution problems [

15]. However, evolving industry demands have exposed its limitations, highlighting the need for a more flexible and adaptive educational framework [

15,

16]. As a result, educators are increasingly moving away from this rigid structure, recognising that the traditional model no longer sufficiently prepares students for the complexities of modern engineering challenges. This shift emphasises fostering creativity, knowledge exchange, and practical application, while moving beyond the constraints of Outcomes-Based Education (OBE) to promote continuous learning and real-world problem-solving [

17]. This shift aims to engage students actively and inspire self-directed learning, allowing them to apply concepts in real-world scenarios [

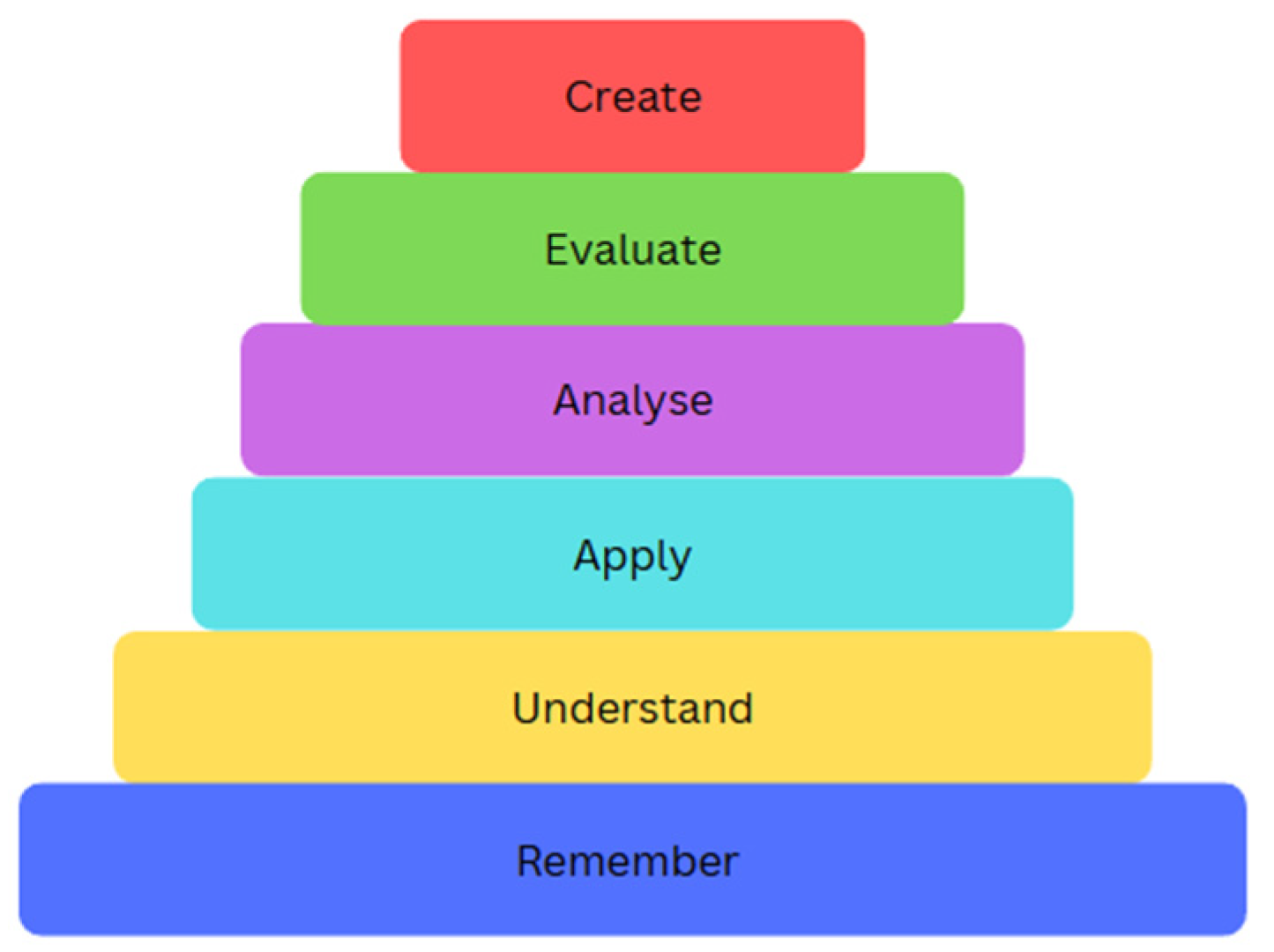

17]. The ultimate objective is to advance students from basic recall to higher levels of Bloom’s Taxonomy, shown in

Figure 3, where they can independently analyse, evaluate, and create solutions aligning with industry expectations [

18].

Despite structured learning outcomes, many higher education environments still prioritise instructor-led content delivery, which may limit opportunities for deeper cognitive engagement and critical thinking, particularly in engineering education [

6]. This passive learning environment is further compounded by a “fear of failure” culture, as noted by Foley et al. [

20], which discourages students from engaging in experimental problem-solving. Without hands-on work and opportunities for trial and error, students are reluctant to take risks or explore creative solutions, fearing failure. Edgar Dale’s Cone of Experience (

Figure 4) supports the need for active learning, showing that learners retain only about 10% of the information they read but remember up to 90% of what they actively do [

21]. Without experiential learning, students struggle to internalise and apply concepts effectively, limiting their preparedness for real-world engineering challenges.

Modular course structures are a barrier to effective learning in engineering education, often leading to knowledge fragmentation. The modularisation of courses divides the curriculum into small, independent units, each typically lasting a semester and contributing credits toward a final qualification [

23]. While modular programs are cost-effective and allow flexibility, especially within the lecture–lab model common in STEM, they often create a fragmented learning experience. Students encounter engineering concepts in isolation, limiting their ability to understand how these concepts interconnect to address complex, real-world challenges. This compartmentalisation hinders students’ capacity to synthesise knowledge across modules, ultimately reducing their readiness to tackle comprehensive engineering problems [

23].

As traditional engineering education faces challenges, technological advancements offer a promising solution. As society and technology advance together, education has evolved to meet new challenges, giving rise to Education 4.0 [

24]. This approach aligns with Industry 4.0, equipping students with skills for today’s complex technological landscape. Although not universally defined, Education 4.0 is a flexible framework designed to bridge gaps in traditional models and address issues like knowledge fragmentation and passive learning. It encourages higher education institutions to adapt curricula and teaching methods to meet the demands of a technology-driven workforce [

8]. With a clear understanding of the current challenges in education, it becomes essential that the proposed framework addresses knowledge fragmentation and passive learning. To achieve this, the framework must guide developers toward adopting technologies and Virtual Learning Factories rooted in the principles of Education 4.0. By doing so, it ensures the creation of immersive, industry-relevant learning experiences that effectively prepare students for the demands of a rapidly evolving technological landscape.

2.3. Bridging the Gaps with Technologies—Virtual Learning Factories

VLFs form part of the Education 4.0 paradigm, offering a transformative approach to engineering education. Unlike the traditional learning models that relied on physical field trips and rigid, modular structures, VLFs use MR to create flexible, immersive environments where students engage in hands-on, experiential learning accessible anytime, anywhere [

25]. A major benefit of VLFs is their shift from passive to active learning. Students become participants, rather than mere recipients, directly interacting with simulated industrial settings and applying problem-solving skills. This active engagement fosters a deeper understanding as students observe, decide, and adapt as they would in a real-world factory. VLFs also tackle knowledge fragmentation by presenting a holistic view of the simulated factory. This allows students to experience various engineering aspects, such as automation, quality control, and logistics, within a cohesive environment. This interconnected perspective helps students synthesise knowledge across disciplines, preparing them to address real-world challenges effectively. By promoting active participation and offering an integrated learning experience, VLFs help overcome key limitations of conventional education, equipping students for the demands of Industry 4.0 [

26,

27].

2.4. Gap Analysis and Framework Validation Method

Despite the pressing need to adapt educational practices to bridge the widening gap between academic institutions and modern industry demands, a significant research gap existed in establishing a validated framework that future researchers could use to develop their own MR engineering educational tools. This study aimed to fill this gap by thoroughly understanding the specific barriers within engineering education through a combination of the presented literature review and original data collection. Based on these findings, this research developed a robust framework, implemented a VLF with MR technology, and validated its effectiveness through rigorous testing. By focusing on specialised training aligned with Industry 4.0 requirements, this framework not only supported workforce readiness but also provided a foundational model for future researchers to advance MR-based educational approaches, fostering a new generation of engineers prepared to meet the demands of modern manufacturing.

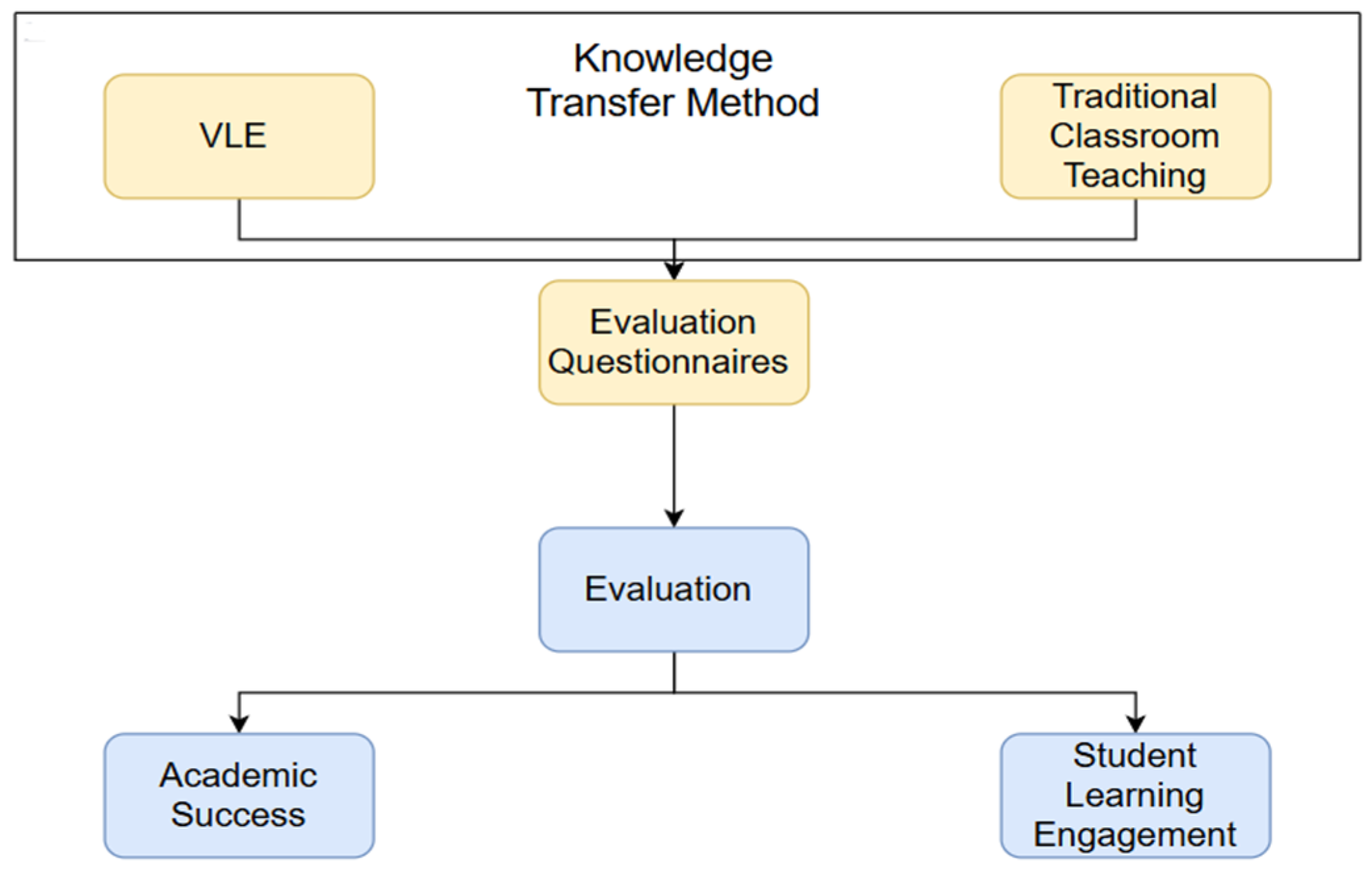

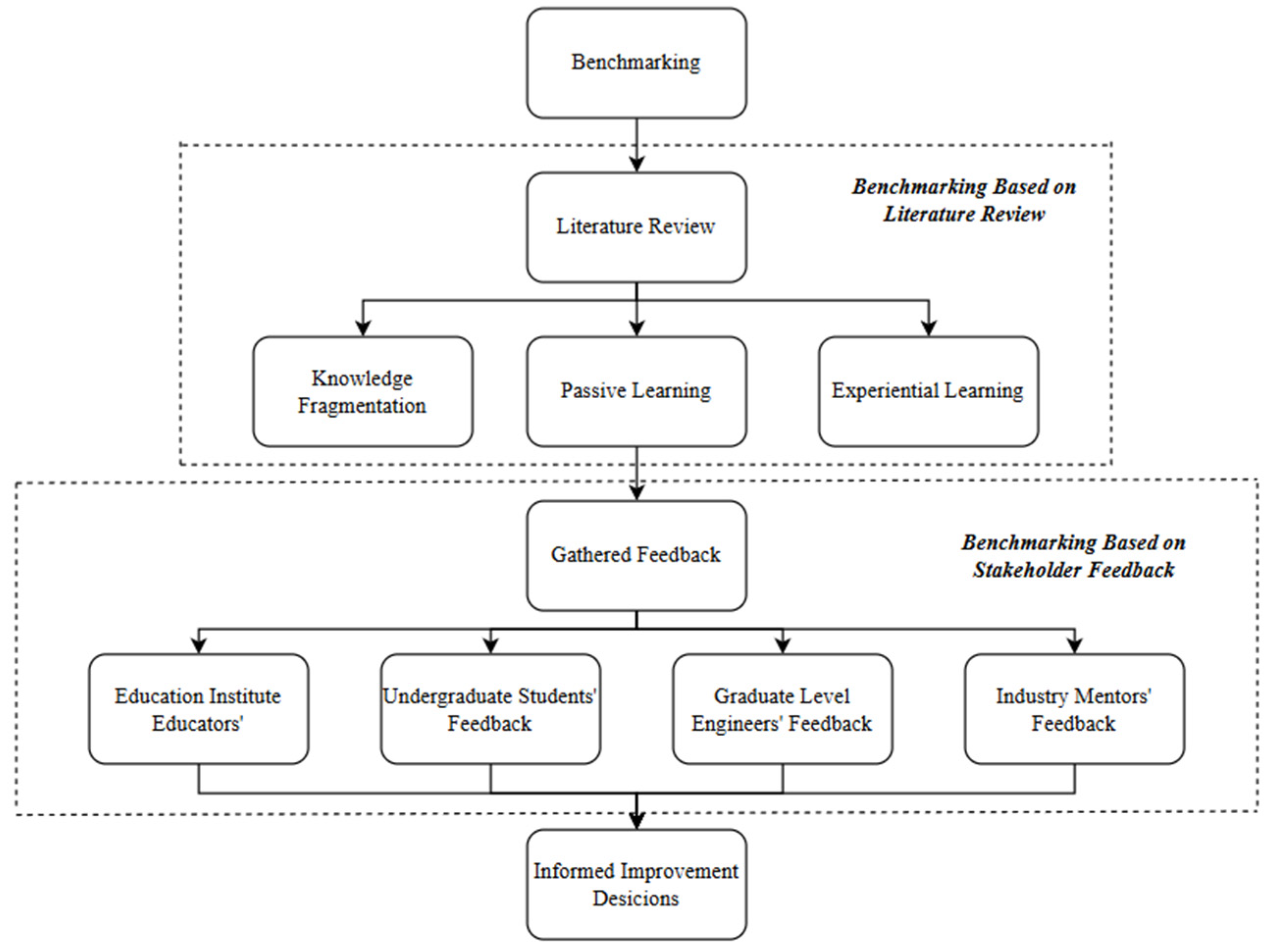

The framework was validated through the approach illustrated in

Figure 5. This involved having students answer identical questions but with different modes of learning (traditional teaching vs. MR-based learning). By comparing the results, we assessed which method led to higher academic success and engagement. This approach enabled us to evaluate the effectiveness of the framework in enhancing knowledge transfer and student outcomes.

3. Development of MR-Educational Framework

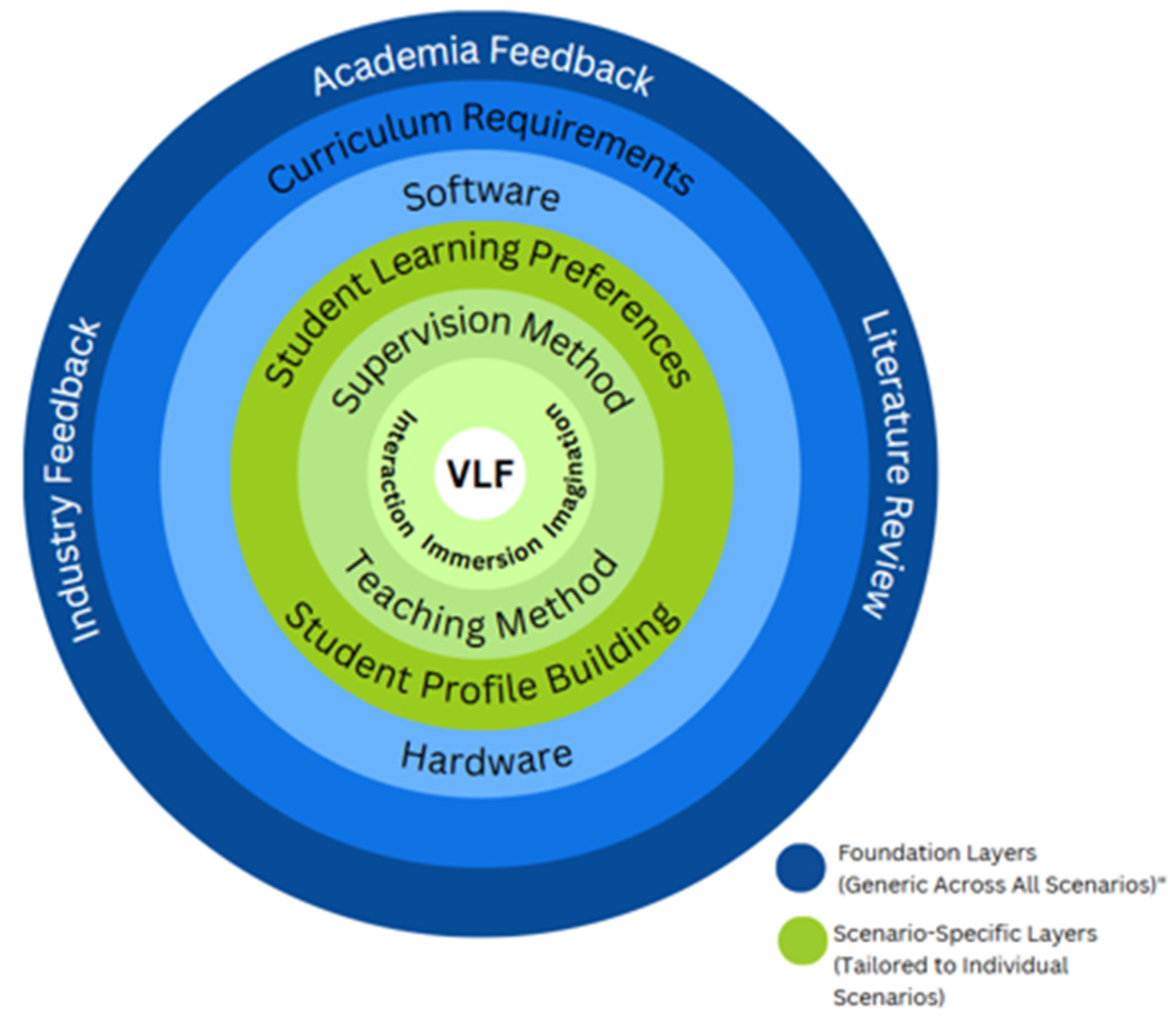

The framework, depicted in

Figure 6, is structured as concentric circles, with each layer contributing to the development of an effective VLF. The outermost blue layers represent foundational elements, including curriculum requirements and the selection of software and hardware. These layers ensure the VLF is grounded in stakeholder feedback from academia and industry, addressing knowledge gaps and aligning with accredited curriculum standards. This alignment guarantees that the VLF meets both educational and practical demands.

The inner green layers focus on scenario-specific elements, such as student learning preferences, teaching methods, and supervision approaches. These layers tailor the VLF to individual student needs, offering personalised learning experiences through features like skill-level selection (beginner, intermediate, or expert). Teaching methods are adapted to the chosen difficulty level, with beginners receiving step-by-step guidance and advanced learners engaging in independent problem-solving. Supervision mechanisms, such as progress tracking, ensure targeted support and adaptability.

At the core of the framework lies the VLF, which integrates all the layers into a cohesive system. Leveraging MR, the VLF emphasises immersion, imagination, and interaction. The students engage in realistic, hands-on environments, visualise complex concepts, and interact with virtual objects, receiving immediate feedback. This approach not only enhances learning but also prepares students for real-world engineering challenges. In summary, the framework provides a holistic approach to engineering education, balancing foundational requirements with personalised learning experiences. It ensures that the VLF is both academically rigorous and practically relevant, meeting the evolving needs of academia and industry.

4. Developing the VLF Proof of Concept

4.1. Stakeholder Feedback: The Key Findings

The first layer of the framework, which is benchmarking, serves as its foundation and will be detailed in this section. The strategy followed to benchmark the current engineering education model is laid out in

Figure 7. While the literature review, already presented, provides critical insights into long-standing trends and challenges in engineering education, it is less sensitive to capturing real-time shifts and emerging issues. To address this, surveys were conducted to complement the literature review with up-to-date data collection. The structure of this questionnaire was designed based on Bloom’s Taxonomy, ensuring it identifies what is needed to reach the higher levels of learning. This approach allows the data collected to align with cognitive objectives, facilitating a deeper understanding of how to enhance knowledge delivery effectively. Benchmarking is essential for identifying areas of improvement in engineering education, as it helps develop a comprehensive understanding of the current educational situation. This process clarified existing strengths and weaknesses, ensuring that proposed enhancements are based on actual needs in knowledge delivery.

This study, therefore, gathered first hand insights from crucial stakeholder groups:

Undergraduate engineering students.

Graduate engineering students.

Higher institute educational educators.

Manufacturing industry mentors.

The feedback was collected via a distributed questionnaire completed by 42 undergraduate and newly graduated engineers, along with 42 educators and industry mentors. This significant sample size not only adds credibility to our findings but also strengthens and expands upon the preliminary information gathered, providing a well-rounded view of the barriers impacting engineering education. Collected in 2024, these data offer a timely snapshot of current educational practices, complementing the literature review by capturing up-to-date perspectives directly from stakeholders. This ensures that our framework is based on the most current insights, making it directly applicable to addressing today’s educational challenges in engineering. The ethical approval for the study was granted by the Faculty Research Ethics Committee of the University of Malta. The REDP form (ENG-2024-00004) was formally acknowledged on 11 March 2024

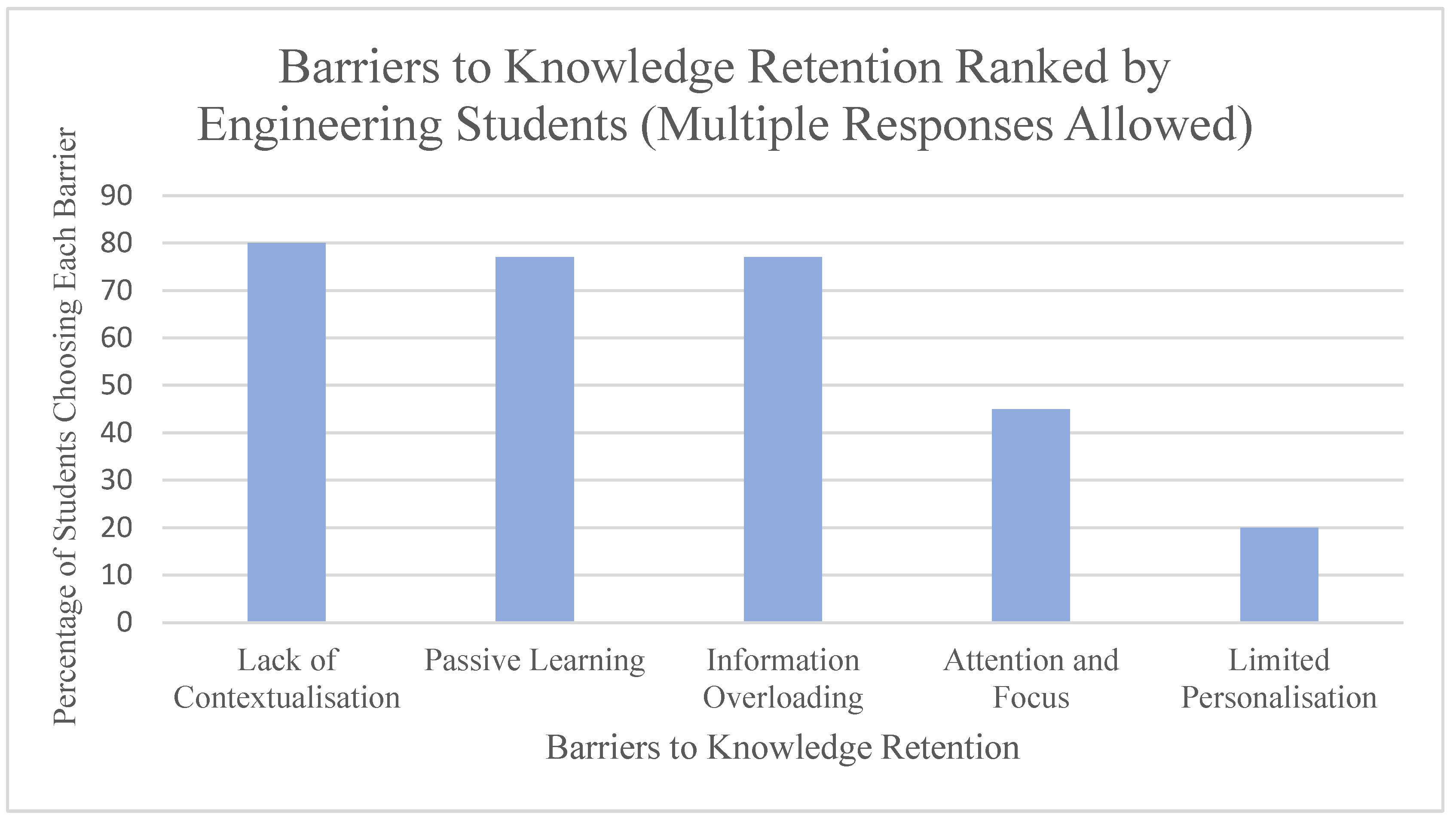

The student feedback revealed that traditional lecture-based instruction often challenges their ability to contextualise and retain knowledge. Specific concerns included information overload, limited personalisation, and insufficient linkage to real-world engineering contexts (

Figure 8). These barriers align with the literature, which highlights the passive nature of such approaches and their inability to foster meaningful engagement. Educators echoed these concerns, emphasising that logistical and resource constraints further exacerbate the lack of hands-on learning opportunities. Field trips, which were historically essential for contextualising theoretical knowledge, have become increasingly unfeasible due to financial and operational challenges. This highlights the potential use of MR and VLFs as effective alternatives, offering immersive and contextual learning experiences that can address these limitations. By simulating real-world scenarios in a controlled and accessible manner, MR and VLFs could serve as a practical solution to bridge the gap left by the decline in field trip opportunities, sparking a discussion on how these technologies can transform traditional approaches to experiential learning. Hence, the design of the MR-based application will need to intentionally address the learning barriers identified in

Figure 8, such as information overload, limited personalisation, and disconnection from real-world scenarios, by incorporating features that promote engagement, clarity, and contextual relevance, as recommended by [

26].

At the intermediate levels of Bloom’s Taxonomy, “Applying” and “Analysing”, the disconnect between theoretical knowledge and practical application emerged as a key concern. Approximately 70% of the students indicated that their current education does not sufficiently prepare them to apply learned concepts in real-world situations. Similarly, 61% expressed frustration with the lack of opportunities to engage in hands-on engineering tasks. Educators and industry mentors reinforced these concerns, noting that many students enter the workforce without the practical problem-solving skills required for professional practice. They highlighted project-based assessments and experiential learning as critical tools for bridging this gap. This is where VLFs demonstrate their potential, offering a structured form of experiential learning that allows students to apply their knowledge in realistic, simulated environments, fostering a deeper understanding and enabling them to tackle complex engineering challenges in a safe yet practical context.

As students advance to higher-order learning, “Evaluating” and “Creating”, they face additional barriers to developing critical thinking and innovation skills. Modularised course structures, time constraints, and a fear of failure were cited by students as significant obstacles to creative exploration. These challenges were echoed by mentors, who observed a lack of opportunities for students to experiment, compare solutions, and make informed judgments in a supportive environment. Since VLFs offer students a holistic view of engineering processes, they provide an opportunity to simulate the operations of a factory, allowing students to experience real-world complexities and challenges in a safe, controlled setting. By immersing learners in simulated real-world scenarios, the VLF approach facilitates the application of theoretical knowledge in complex, practice-based tasks, supporting the development of critical thinking and innovation

A striking outcome of the feedback is the alignment between students and educators in recognizing the limitations of current educational practices and the potential of technology-driven solutions. This shared perspective not only highlights the overlapping needs of both groups but also makes the requirements for improvement clearer, as many of these align for students and educators alike. The reinforcement from both sides underscores the urgency to address these needs and implement practical solutions. Furthermore, with 81% of students expressing enthusiasm for integrating MR and VLFs, it becomes easier to move forward with these technologies, as there is already strong interest and willingness from a significant majority of the student body. This alignment paves the way for the seamless integration of MR and VLFs to overcome barriers and enhance engagement effectively.

With a comprehensive framework in place, we can now develop a learning scenario that mirrors environments typical engineering students may encounter in industry. This foundation allows us to progress to selecting suitable game-generating software and MR hardware, as well as developing a proof-of-concept application. This application will serve as a benchmark to evaluate the effectiveness of both the learning environment and the framework itself, ensuring that our approach provides a meaningful and practical learning experience.

4.2. Grounding in Curriculum Requirements

To address the pressing educational needs and challenges in engineering education, a comprehensive analysis of curriculum requirements was conducted. This analysis was informed by stakeholder feedback, which identified a wide range of learning outcomes essential for preparing students to meet the demands of modern manufacturing. The learning outcomes indicated by knowledge facilitator stakeholders are as follows:

Enabling product visualisation.

Learning about Lean manufacturing and process optimisation.

Learning about quality control.

Health and safety training.

Learning about robotics and automation.

Given the breadth of these learning outcomes, four distinct learning scenarios were selected as the building blocks of the VLF. These scenarios, which form part of the Mechanical Engineering curriculum at the University of Malta (accredited by IMechE and RINA), include the following:

Fixed position layout.

Functional layout.

Flow line layout.

Cellular layout.

These scenarios were chosen because they represent key shop floor arrangements in manufacturing, addressing spatial, operational, and process-related challenges. By focusing on these scenarios, the VLF ensures that students gain practical, hands-on experience in environments that mirror real-world industrial settings. This framework addresses the most pressing educational needs and challenges by aligning the curriculum requirements with stakeholder-identified learning outcomes and leveraging MR technology. It provides students with the skills and knowledge necessary to excel in Industry 4.0, while also offering a scalable and adaptable model for future educational innovations.

4.3. Selection of Software and Hardware

The Unity game engine emerged as the optimal choice for our development needs. Unity’s selection was based on several key advantages that align closely with the objectives of our VLF:

Extensive AR capabilities with a flexible interface: the VLF needs to support both 2D and 3D augmentation, allowing for a versatile display of various learning scenarios [

27].

Intuitive, user-centric interface: featuring drag-and-drop functionality, the interface enables rapid prototyping and development with minimal coding, focusing on enhancing engineering education rather than on complex MR development [

28].

Cross-platform support and forward compatibility: This feature ensures compatibility across a range of devices and operating systems, enhancing accessibility. By supporting multiple platforms, the VLF is well-suited for adoption by various educational institutions, with regular updates ensuring it remains aligned with advancements in AR and VR [

28].

Strong Community and asset Library: access to a broad selection of prefabs and pre-built assets minimises the need for extensive coding and custom asset creation, streamlining development and allowing for a greater emphasis on educational content [

27].

These features make Unity ideal for developing a versatile, adaptable, and future-ready VLF. Unity’s capabilities align well with current educational needs while allowing for evolution alongside emerging teaching methods in engineering higher education.

A comparative analysis of current MR headsets identified the Meta Quest 3 as the top choice for MR development. As a standalone device, it avoids the need for additional hardware like PCs or gaming consoles, significantly reducing setup complexity and system costs. This independence from external devices is especially valuable in educational settings, where scaling across multiple users or classrooms becomes more practical and economical. Educational institutions can implement the technology without requiring substantial investments in computing infrastructure, making large-scale deployments more feasible within standard educational budgets.

With a high resolution of 2064 × 2208 and a 120 Hz refresh rate, the headset ensures sharp visuals and smooth performance, essential for immersive learning experiences [

28]. The wireless design enhances mobility and user comfort, removing physical limitations that could hinder learning activities. This untethered functionality, combined with an accessible price, makes it well suited for broad adoption in educational contexts. Additionally, as the most recently released model (October 2023) among the devices analysed, the Meta Quest 3 reflects the latest MR technology, promising extended viability and future software support over older models, such as the HTC Vive or Oculus Rift [

29]. While the Microsoft HoloLens, often regarded as a premium MR headset, was considered during the selection process, its significantly higher cost made it less suitable for this educational context [

29]. Therefore, the Meta Quest 3 was deemed as the most practical, forward-looking choice for developing a VLF, balancing high-end capabilities with accessibility and cost-effectiveness.

5. Development of Framework Validation Material

5.1. VLF Development

For the scope of this study, a single learning scenario VLF was developed: the cellular layout. In this section, and as illustrated in

Figure 6, the green layers of the framework were followed, guiding decisions on a learning scenario basis. The chosen scenario was a cellular layout overlaid in a real-life lab setting using MR, providing an authentic experience and enabling students to engage with automation systems and production cells in a realistic context. MR offers a compelling advantage over being solely focused on either AR or VR because it integrates both technologies’ strengths, creating a more versatile and effective learning environment. This approach allows students to interact within a familiar physical space, grounding their learning in settings that resemble industry environments.

As highlighted by the student-reported barriers in

Figure 8, such as information overload and limited real-world context, the design of the MR-based learning environment aimed to support meaningful learning by reducing the cognitive load and enhancing retention through immersive, structured, and context-rich interactions [

26]. This approach aligns with recommendations in the literature on educational application design [

30]. The learning scenario was developed with a beginner-level audience in mind, ensuring that content delivery follows a clear, step-by-step approach. This beginner-level focus directly influences the teaching method layer, which, in this case, adopts a structured and instructional approach to guide students through the tasks sequentially, ensuring task completion before advancing. The step-by-step method aligns with the student learning preferences and student profile building layers of the framework, as these layers must cater to varying difficulty levels, such as beginner, medium, and hard, in future, fully developed VLFs. As the difficulty level increases, the instructional approach can gradually shift towards a more supervision-based method. For higher-order tasks, audio instructions, designed to engage multiple senses and enhance cognitive processing, can be provided initially. As learners become more familiar with the scenario, the supervision method would allow them greater freedom to explore, experiment, and interact with the environment independently, fostering self-directed learning and promoting the application of knowledge in more dynamic contexts.

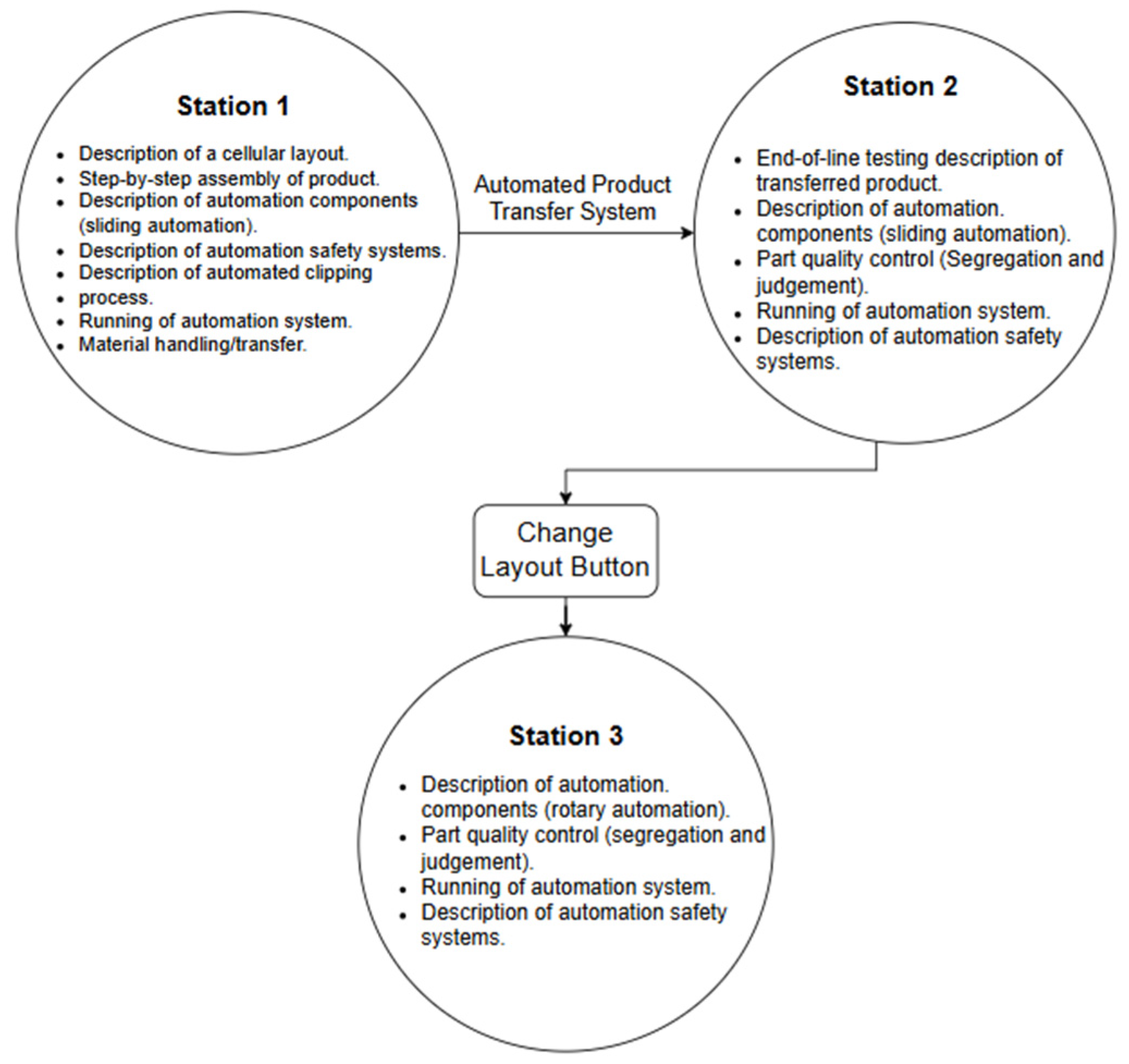

In the cellular layout, the students engaged with the manufacturing process of a product, as depicted in

Figure 9, with each station designed to carry out specific operations.

Figure 10 provides an overview of this learning scenario, highlighting the various subjects covered within this layout, which will be discussed in greater detail throughout this section. The process starts at Station 1, where the product undergoes a clipping procedure, an essential step in the assembly process. Upon completion, the product is automatically transferred to Station 2 through an automated transfer system, ensuring a smooth and continuous flow between the stations. At Station 2, the product is subjected to end-of-line testing to verify that it meets the established quality standards.

Additionally, students can press the “Change Layout” button, which reveals an alternative version of the production cell. In this variation, Station 3 consolidates the previously performed actions from Stations 1 and 2, combining the clipping process and the end-of-line testing into a single, integrated station. This alternative layout allows the students to examine a more streamlined workflow and analyse its efficiency compared to the original setup.

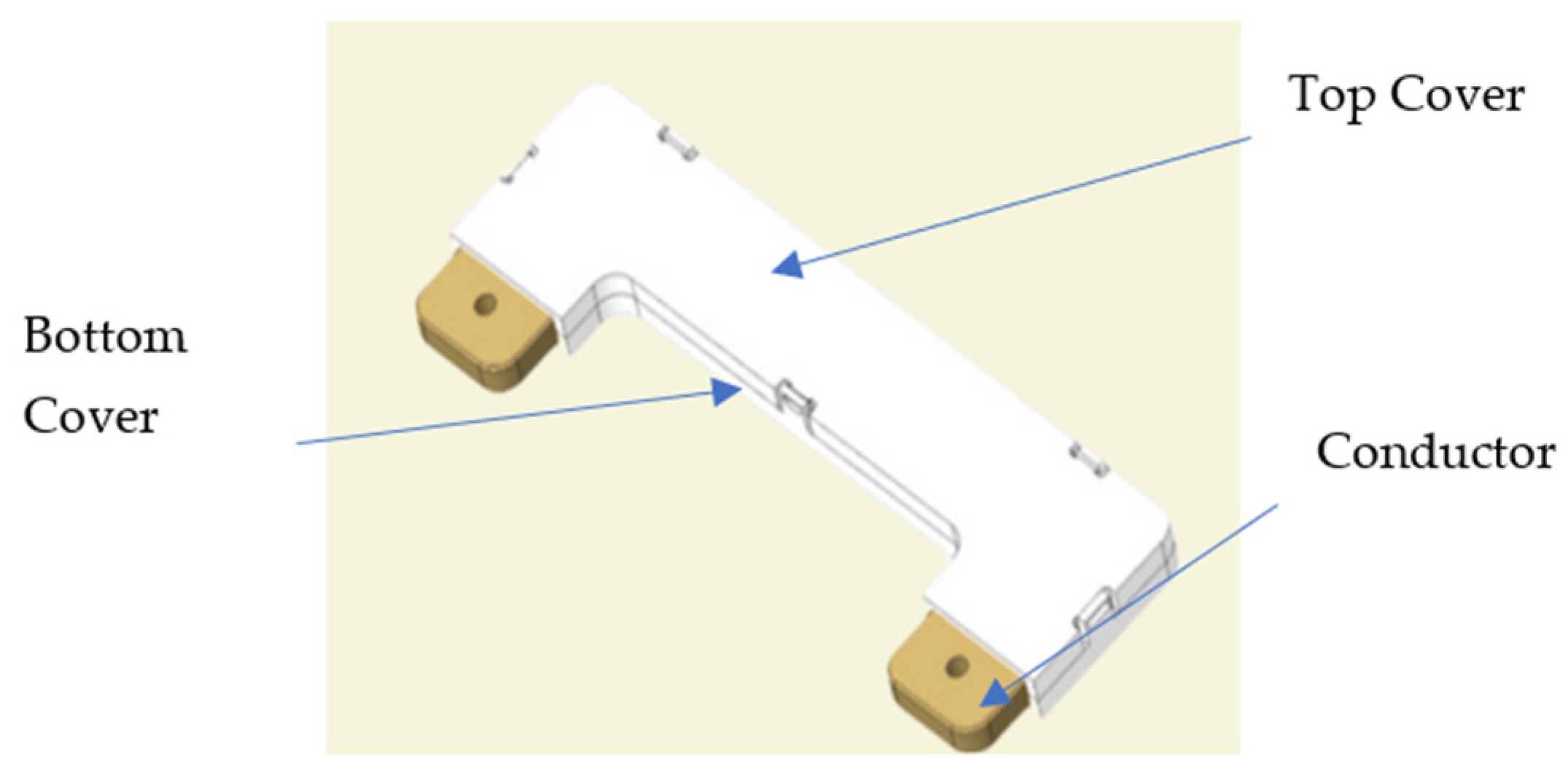

5.1.1. Product Visualisation

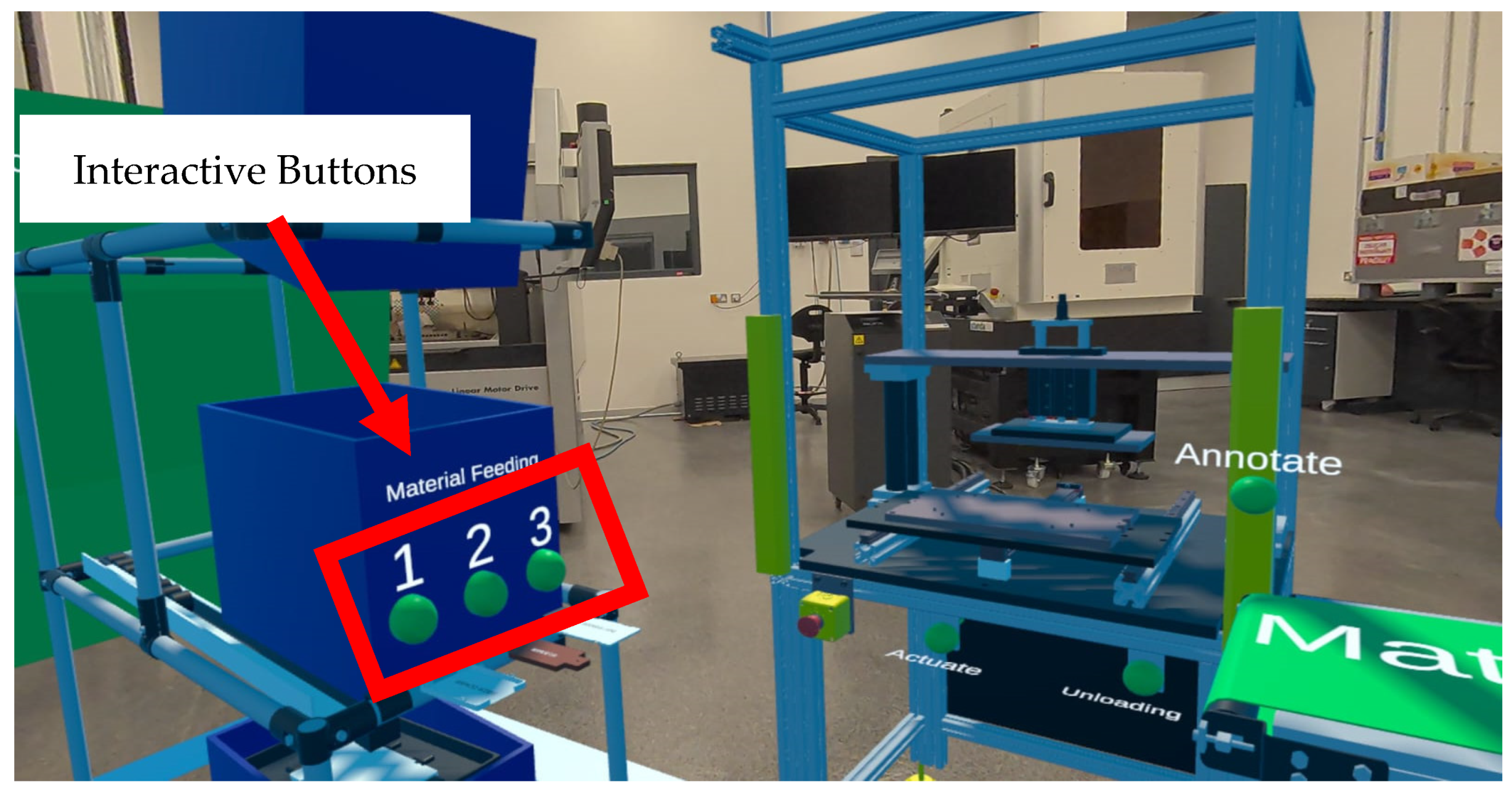

At Station 1, the students are introduced to both product visualisation and the assembly process, providing them with a practical understanding of how individual components are combined to create the final product. The interactive assembly process revolves around three buttons, each corresponding to a specific product component: the bottom cover, the Conductor, and the top cover. These buttons are displayed within the virtual environment, offering an intuitive way for students to grasp their functionality. As illustrated in

Figure 11, the buttons are visually connected to their respective busbar subcomponents, serving as a clear reference throughout the assembly process. The assembly sequence replicates real-world manufacturing processes by enforcing a specific order of operations. The students start by selecting the bottom cover, guided by voice instructions that explain its importance. Once positioned, they proceed to select the copper busbar, with the accompanying audio detailing its properties and function. Finally, the students add the top cover to complete the assembly. This step-by-step process reinforces the correct assembly order while improving product visualisation and interactivity. As each component is selected, the virtual environment simulates its placement, allowing the students to observe how the parts fit together.

5.1.2. Lean Manufacturing and Process Optimisation

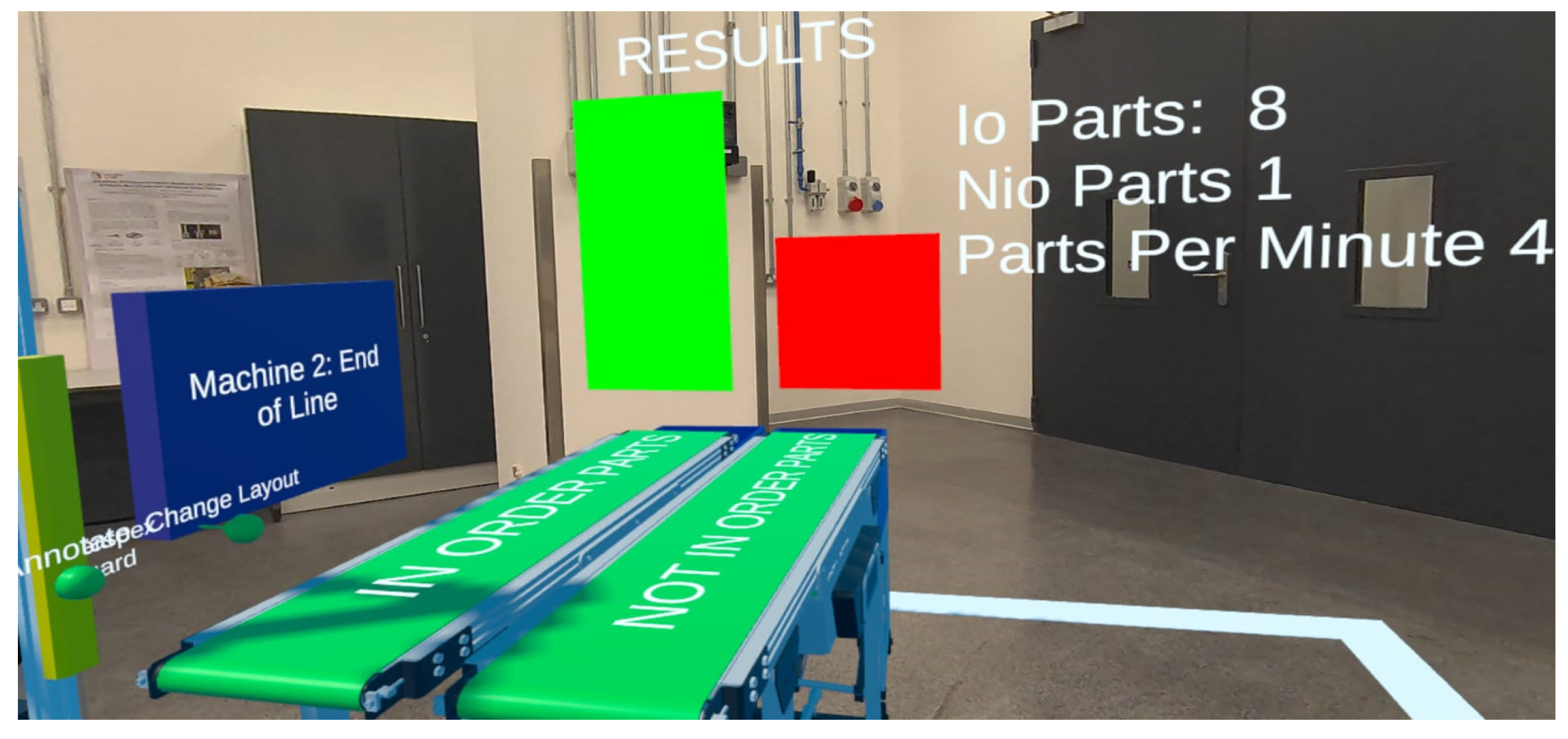

The developed learning scenario allows the students to compare production methods using either Stations 1 and 2 or the integrated approach at Station 3. Real-time Key Performance Indicators, KPIs, generated through DT capabilities, provide insights into process efficiency, quality control, and performance metrics. As shown in

Figure 12, the students can visualise KPIs, such as the parts produced per minute and the part quality, to compare the two configurations. This hands-on experience demonstrates how DT supports performance monitoring and optimisation, bridging classroom theory with real-world manufacturing practices. Such real-time data and performance insights would typically be inaccessible during traditional field trips, let alone within a classroom setting, highlighting the added value of this immersive MR-based approach.

5.1.3. Quality Control

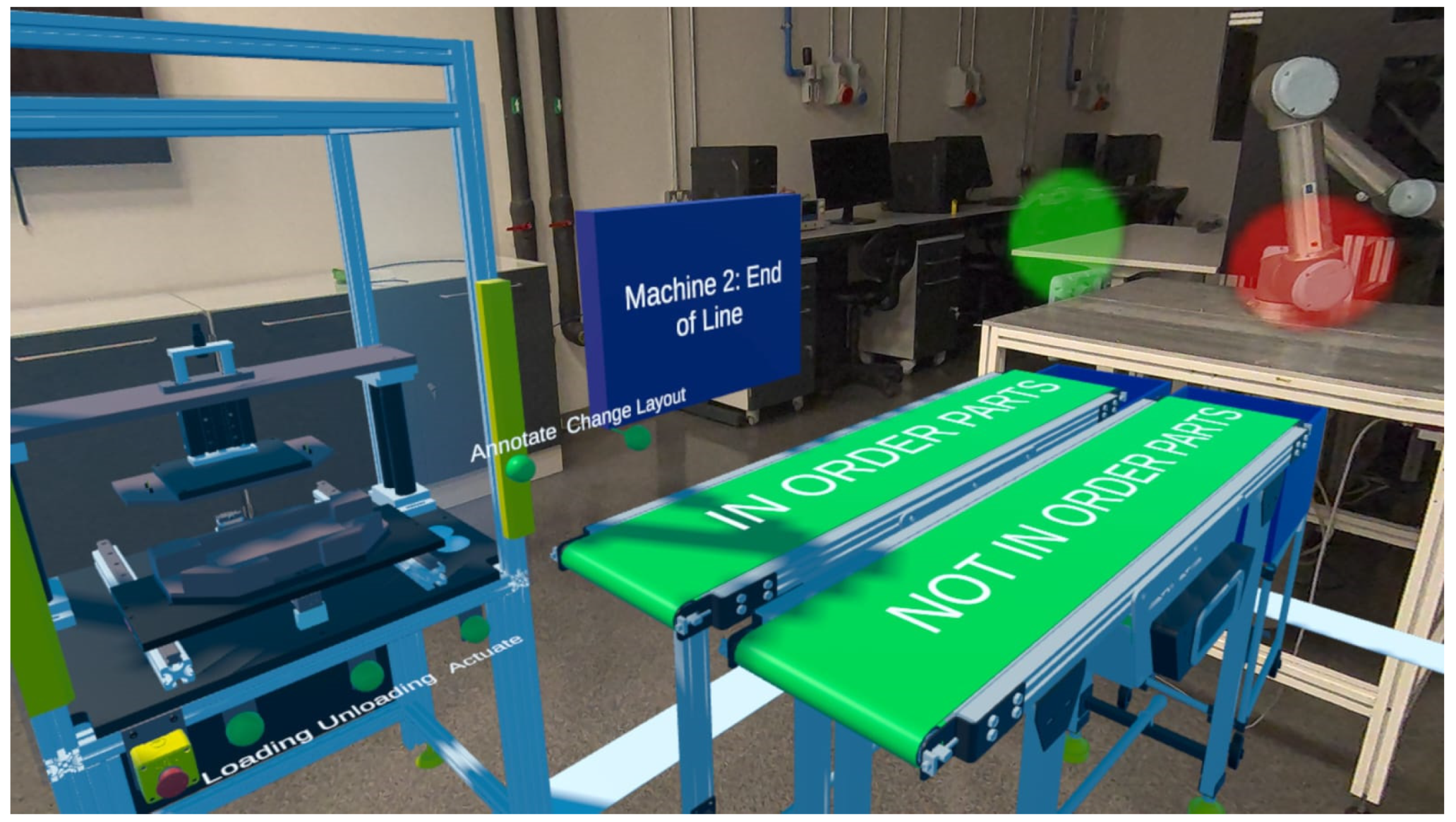

Quality control is a key aspect of the learning experience, particularly at the end-of-line stages in Stations 2 and 3. These stations feature a colour-coded indicator system to display the part status: a green light signals parts that meet quality standards, while a red light indicates defective parts. Beyond the visual cues, the virtual environment demonstrates how the parts are automatically sorted based on their quality results. As shown in

Figure 13, the parts passing the quality check (in order—IO) are sent to one conveyor, while the defective parts (not in order—NIO) are directed to a separate conveyor. This process highlights the importance of quality assurance in manufacturing, allowing the students to virtually produce NIO parts and learning about part segregation without wasting resources.

5.1.4. Health and Safety—Robotics and Automation

The annotate button is a key feature designed to enhance students’ understanding of robotics and automation. When activated, it labels the core components of the automation system, as shown in

Figure 14. This feature helps the students identify essential elements, like pneumatics, rails, and carriages, along with brief descriptions of their functions and interactions within the system. Safety is also a focal point when using the annotate function. It highlights critical safety features, such as light curtains, Perspex guards, and emergency stop buttons. The students learn how light curtains use optical sensors to stop machines if someone enters the protected zone, while Perspex guards serve as physical barriers to prevent accidental contact with moving parts. The annotation also explains the role of emergency stop buttons in immediately halting machine operations, reinforcing the importance of these components in ensuring a safe manufacturing environment.

5.2. Traditional Teaching

The second teaching method used for comparison with the VLF-based learning is the traditional classroom approach, designed to align with the same educational objectives as the VLF. To ensure a fair and unbiased comparison, the traditional teaching materials were carefully developed to deliver an equivalent learning experience. The content was presented through PowerPoint slides, accompanied by voice-over explanations for each slide. This format ensures consistency in the information provided while eliminating potential variations that might arise with live or asynchronous instruction. The use of pre-recorded voice-overs guarantees that all the participants receive the same level of detail and clarity, maintaining consistency across all the sessions. This structured and uniform approach allows for a reliable evaluation of the VLF’s effectiveness when compared to conventional teaching methods.

6. Comparative Analysis

In order to gauge the effectiveness of the VLF learning experience for the cellular layout, questionnaires were developed to assess student learning outcomes based on Bloom’s Taxonomy. The questions were designed to measure key aspects, such as knowledge retention, comprehension, and application. Standardised answers were implemented to ensure consistent and objective grading, minimising the potential for any bias.

Forty participants were voluntarily recruited for the study, comprising final-year undergraduate engineering students from the University of Malta and first-year graduate engineers currently working within the industry. The participants were randomly assigned into two groups of 20: one engaged with the Mixed Reality-based Virtual Learning Factory (MR-VLF), while the other followed a traditional lecture-based learning approach. Care was taken to balance the academic backgrounds and gender representation across both groups to enhance the comparability of outcomes

As shown in

Table 1, the participant distribution was evenly balanced, ensuring a fair comparison between the two teaching methods and allowing for more reliable insights into the educational impact of the VLF approach.

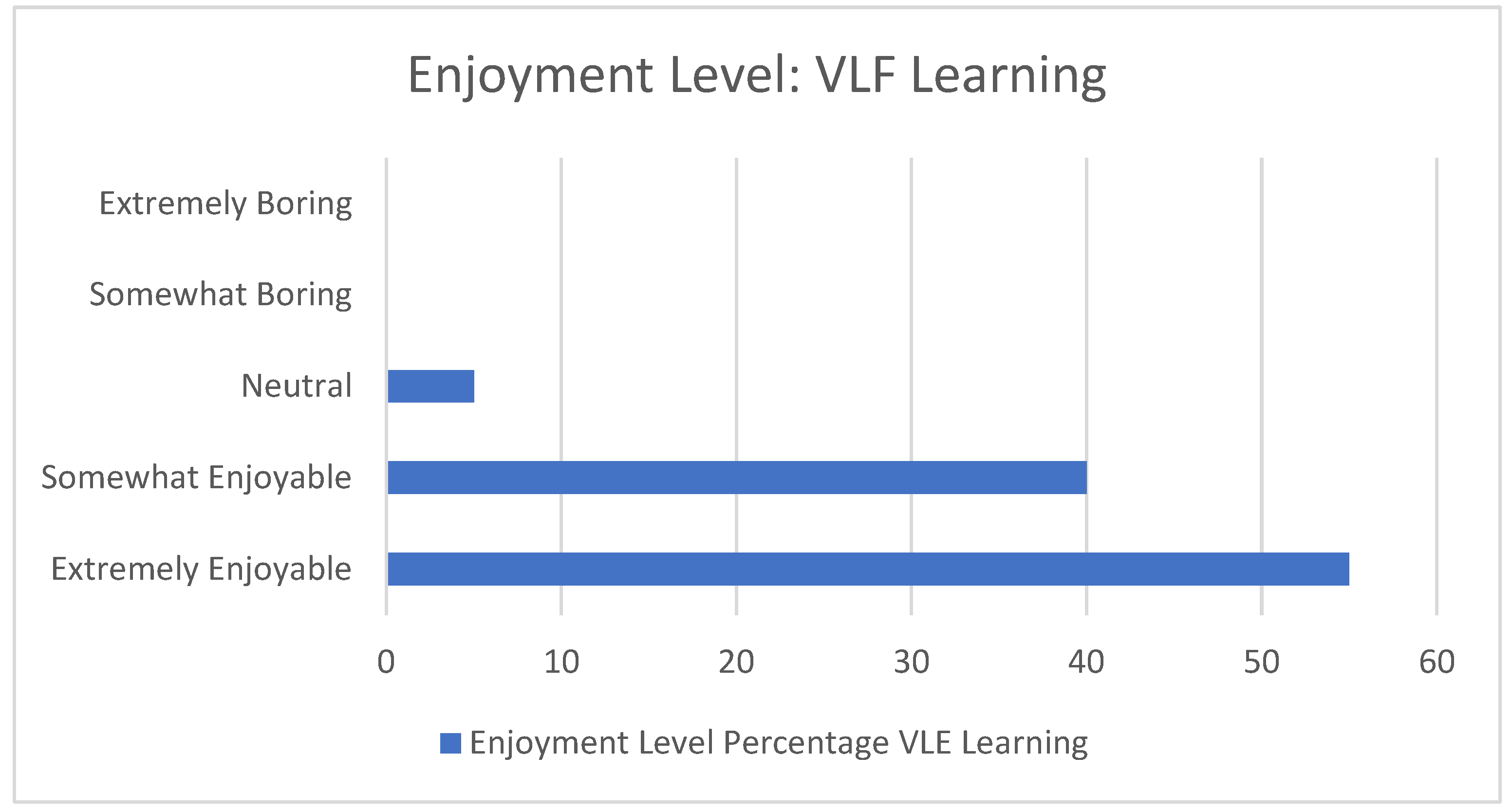

Student enjoyment was measured using a 5-point Likert scale ranging from “Extremely Boring” to “Extremely Enjoyable”. The results are presented as descriptive statistics to compare the perceived engagement between the groups. The results of the study indicate a significant difference in the student engagement between the VLF and the traditional learning methods, as shown in

Figure 15 and

Figure 16. The students in the VLF group reported higher enjoyment levels, with 65% rating the session as “Extremely enjoyable” and 30% as “Somewhat enjoyable”. In contrast, only 9.5% of the traditional learning group found the experience “Somewhat enjoyable”, while over 50% rated it as “Somewhat boring”. No participants in the traditional group rated the session as “Extremely enjoyable”. These findings align with those of Soliman et al. [

31], who highlighted that immersive VR environments in engineering education significantly enhance student engagement, leading to improved understanding and performance. Furthermore, our results are supported by the work of Halabi [

32], who demonstrated that immersive VR enhanced engagement, problem-solving, and project implementation.

Overall, these results indicate a substantial difference in the perceived engagement between the two teaching methods, suggesting that the VLF approach may offer advantages in learner engagement under the tested conditions. While these results demonstrate a strong initial engagement with the MR-based learning approach, it is important to acknowledge that the novelty effect may diminish over time. As noted in the literature, technological obsolescence and the lack of ongoing innovation in virtual environments can reduce learner enthusiasm in the long term [

33]. However, this remains an open question that will require longitudinal studies to assess over time, as such technologies may eventually become embedded in everyday educational practice, at which point the initial novelty may give way to sustained utility.

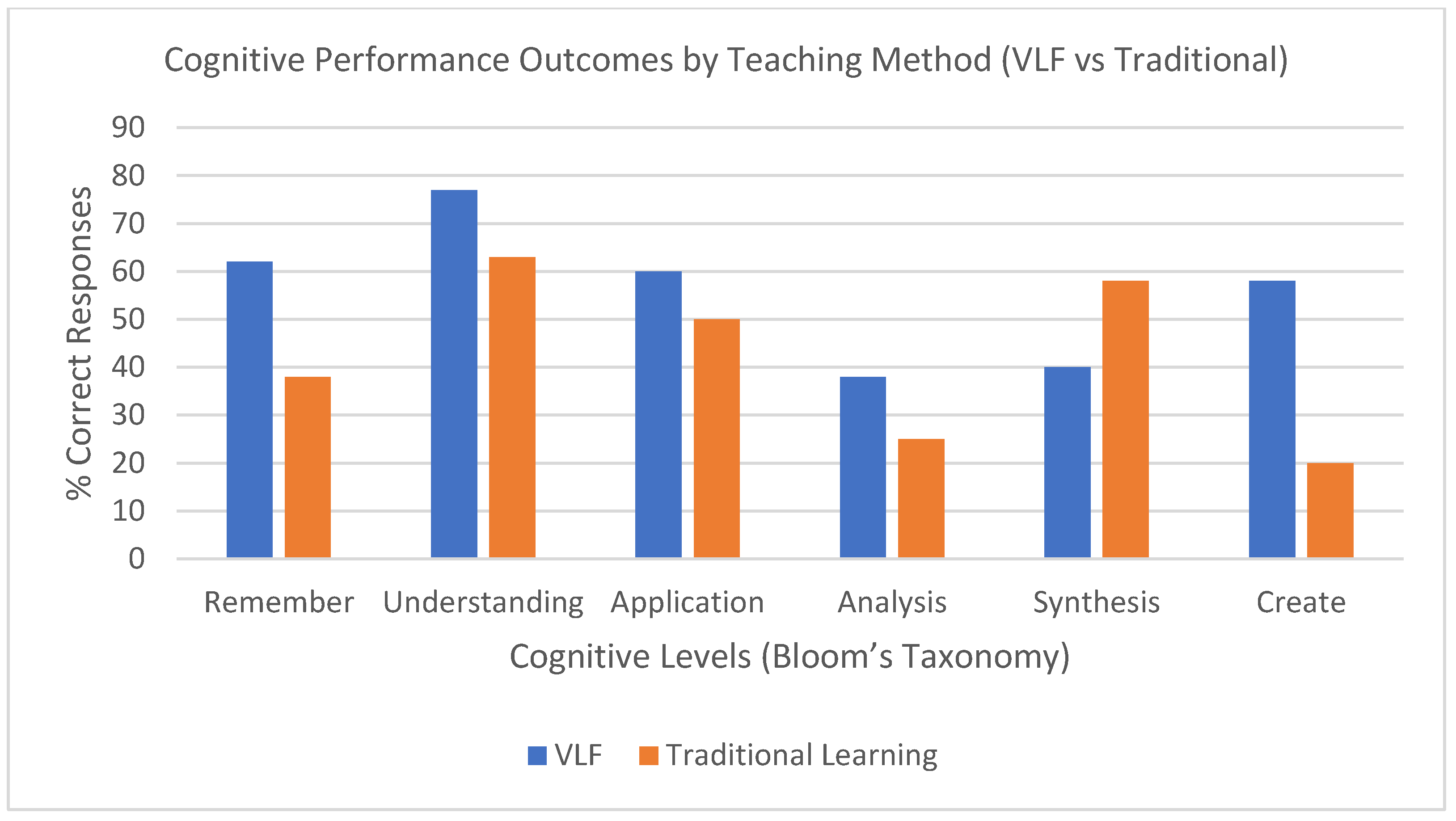

This heightened engagement is critical because it fosters a deeper level of focus and interaction, which lays the foundation for improved learning outcomes. With the students more actively involved in the learning process, the VLF demonstrates its potential not only to enhance knowledge retention but also to prepare learners to reach higher levels of Bloom’s Taxonomy. While

Table 2 provides a detailed numerical comparison,

Figure 17 visually highlights these differences, making it easier to discern performance trends across the cognitive domains.

The results presented in

Figure 17 and

Table 2 illustrate the differences in performance between the students who engaged with the VLF and those who followed traditional classroom-based learning, across the various cognitive levels defined by Bloom’s Taxonomy. The data clearly demonstrate a consistent performance advantage for the VLF group across most of the cognitive domains, with particularly significant improvements observed in the higher-order cognitive tasks. A key observation from the results is the notable improvement in the VLF group’s performance in higher-order cognitive skills, particularly in the application, analysis, and creation levels.

The VLF group outperformed the traditional learning group by margins ranging from 9% to 15% across these categories. The pronounced improvement was seen in the creation category, where the VLF group demonstrated a 15% higher success rate compared to the traditional group. This suggests that the immersive and interactive nature of the VLF fosters creative problem-solving by allowing students to visualise, manipulate, and experiment with complex engineering processes in a way that traditional methods cannot easily replicate.

In addition to the gains in higher-order thinking, the VLF group also displayed stronger performance in intermediate cognitive tasks like understanding and application. For instance, the VLF group achieved a 10% higher score in understanding and an 8% improvement in application when compared to the traditional learning group. This indicates that the interactive, hands-on nature of the VLF helps bridge the gap between theoretical knowledge and practical application, promoting a deeper understanding of the content.

While both groups performed similarly in remembering, a foundational cognitive level, the VLF group maintained a slight advantage. This suggests that, although traditional methods can effectively support basic recall, they become less effective as the cognitive complexity increases. The immersive and engaging characteristics of the VLF appear to support not only knowledge retention but also the development of the cognitive processes necessary for deeper learning.

Interestingly, the only cognitive domain where the traditional group outperformed the VLF group was in synthesis, where a 3% performance difference was observed in favour of the traditional learners. This result may suggest that tasks at the synthesis level, which often require the integration of various pieces of knowledge, can still be effectively supported by structured, linear teaching approaches like traditional presentations.

Overall, the findings highlight the capacity of the VLF to enhance cognitive engagement and improve learning outcomes across a broad range of cognitive levels. The ability to interact with virtual components and visualise real-time processes seems to contribute significantly to student learning, particularly in tasks involving application, analysis, and creation. These results strongly support the integration of immersive learning tools like the VLF into educational frameworks to better prepare students for the cognitive demands of modern engineering practices.

7. Conclusions

This study introduces a novel Mixed Reality-based learning framework tailored for engineering education, developed through a combination of research analysis and stakeholder input from academia and industry. Its originality lies in merging pedagogical models (Bloom’s Taxonomy, TPACK, SAMR) with practical, immersive learning environments grounded in real-world production contexts. The framework aims to equip students with the applied skills and cognitive adaptability required by Industry 4.0, offering a structured yet flexible approach to transforming technical education. The findings of this study highlight the significant potential of VLFs augmented by MR in addressing critical gaps in engineering education. While traditional learning methods can effectively support foundational knowledge acquisition, they often struggle to engage learners and foster the higher-order cognitive skills required in modern industry. The comparative analysis between the VLF and traditional methods demonstrates that the VLF enhances student engagement and supports cognitive progression through Bloom’s Taxonomy, particularly in the areas of application, analysis, and creation.

The results offer the initial validation of the proposed MR-based learning framework, demonstrating its potential in guiding the design and implementation of immersive educational experiences. By incorporating established pedagogical models, such as TPACK and SAMR, the framework ensures both instructional soundness and alignment with current industry demands. While the sample size in this study is relatively small, the findings serve as an exploratory evaluation of the framework’s feasibility and impact. Future studies with larger and more diverse cohorts will be essential to confirm these early trends and assess the generalisability across broader educational settings. The feedback gathered from the literature and stakeholder engagement further reinforces the framework’s adaptability to evolving teaching and learning needs. Despite these promising results, this study reveals some limitations that warrant attention. The relatively small sample size limits the generalisability of the findings, suggesting the need for larger, more diverse groups in future research. Additionally, the study focused primarily on short-term learning outcomes, leaving long-term knowledge retention unexamined. Further studies should assess the durability of learning gains over extended periods. Longitudinal research can help distinguish between these short-term effects and genuine learning improvements. Future studies with larger sample sizes could also provide the opportunity to gather more comprehensive data and perform inferential statistical testing, enabling statistically backed potential correlations between increased engagement and academic performance. Establishing such connections would offer clearer insights into how immersive MR-based learning environments influence cognitive engagement and knowledge retention across different educational contexts.

Looking ahead, scaling this MR-based learning framework for broader educational use presents several challenges. Since scaling MR-enhanced learning environments may require ongoing investment in faculty training, technical support, and infrastructure, barriers could be present in widespread adoption. Integrating the VLF into coursework requires careful alignment with existing learning objectives to ensure relevance and consistency. The training of academic staff is essential, as educators need to develop the technical and pedagogical skills to effectively use MR technologies in their teaching. Industry partnerships also offer significant potential for growth by ensuring the VLF remains aligned with real-world practices and emerging industry trends. Furthermore, future iterations of MR-based VLFs should expand collaborative and multi-user functionalities, enabling students to engage in team-based industrial problem-solving. By leveraging the concept of the metaverse, students can immerse themselves in a virtual factory environment that mirrors the dynamics of real-world production, operating continuously and generating an abundance of production data for analysis. This approach not only enhances students’ understanding of industrial processes but also prepares them to interpret and apply real-time data in complex manufacturing scenarios.

Overall, this study demonstrates the potential of MR-based VLFs to transform engineering education by providing immersive, interactive, and cognitively engaging learning experiences. The findings support the further development and integration of these technologies into educational frameworks to better prepare students for the demands of Industry 4.0.