Transforming Chiller Plant Efficiency with SC+BAS: Case Study in a Hong Kong Shopping Mall

Abstract

1. Introduction

- Investigate the optimized performance of the chiller plant in terms of energy and cost efficiency through the integration of SC and BAS.

- Provide practical insights for the application of SC+BAS in commercial buildings. By examining the real-world implementation in a typical shopping mall in Hong Kong, this study aims to offer actionable recommendations for facility managers and stakeholders seeking to enhance the sustainability and economic viability of their HVAC systems.

2. Literature Review

3. Methodology

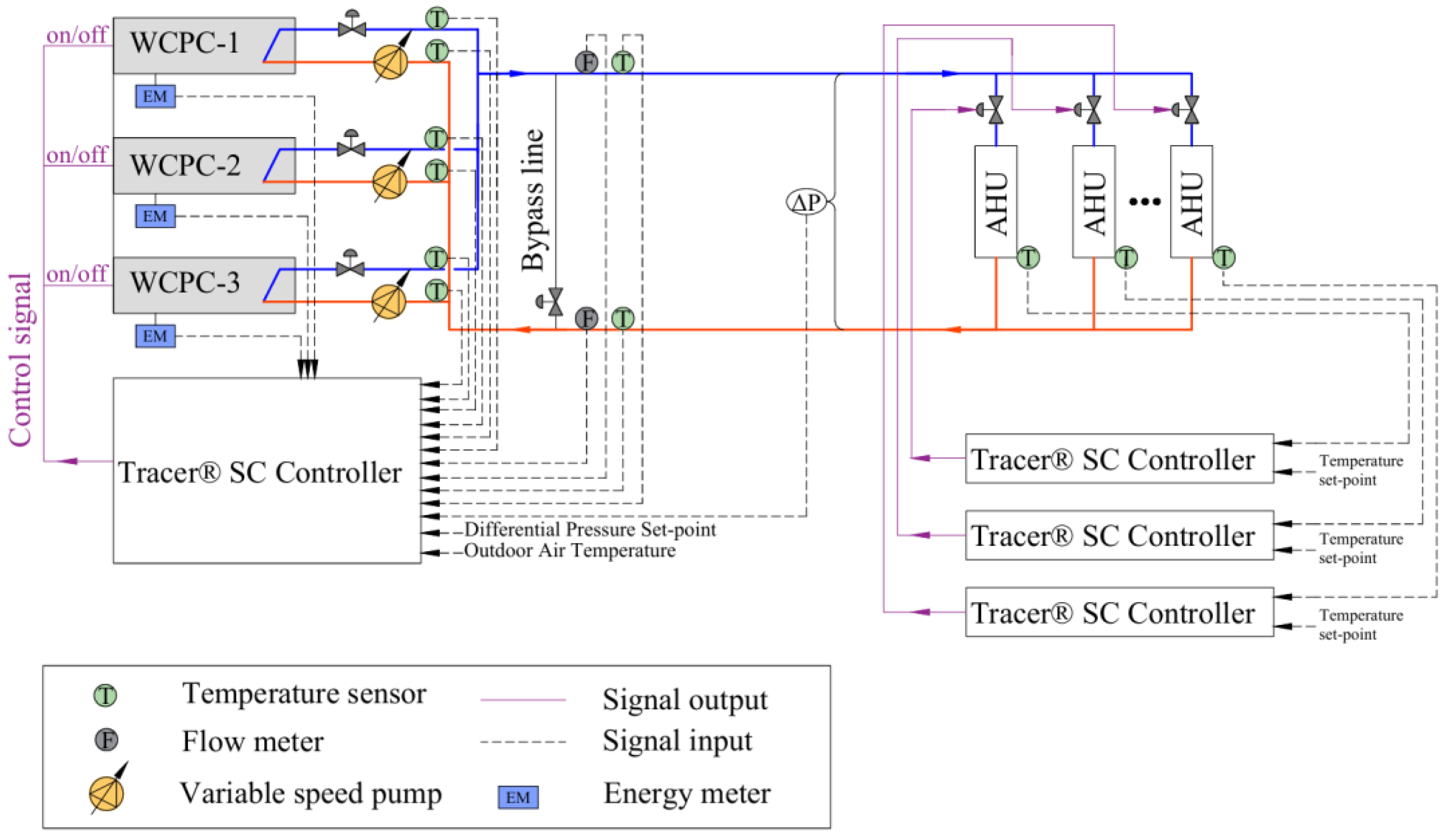

3.1. HVAC Plant Configuration and Instrumentation

3.2. Data Collection from Various Sources

3.3. Computation of Performance Parameters

3.3.1. Information from Control Panels of Chillers

- Cooling output of each chiller, Qch (kWh)where

- : water density (kg/m3)

- : chilled water flow rate in an hour ((m3/s) × h)

- cw: specific heat capacity of water with a value of 4.2 (kJ/(kg × K))

- Daily and monthly total cooling output of the entire chiller plant, Qtotal,d and Qtotal,m (kWh)where

- i: operating hour of the jth chiller, 1 £ i £ k

- j: 1 for chiller WCPC-1 and so forth, 1 £ j £ 3

- k: last operating hour according to the log data of energy meter, 1 £ k £ 24

- p: day of a month, 1 £ p £ n

- n: 31 for September and November; or 30 for October

- Daily and monthly total energy consumption of chillers, Wch,total,mwhere:

- P is the power in watts (W).

- VL is the line voltage in volts (V) = 380 (V)

- IL is the line current in amperes (A).

- cos(ϕ) is the power factor = 0.89

- d.

- Daily energy consumption from control panels, Wch,panel,d (kWh)

- e.

- Overall coefficient of performance (COP) of chiller plant based on control panels, COPpanel,d

3.3.2. Information from Energy Meters

- Daily total energy consumption from energy meters CH1, CH2, and CH3, Wch,total,d (kWh)

- Overall COP of operating chillers based on energy meters CH1, CH2, and CH3, COPch,d

3.4. Data Handling and Assumption

Daily Cooling Output

3.5. Data Collection Frequency

- Power Consumption: measured by the electricity meters installed on the chillers.

- Temperature: high-precision temperature sensors tracked inlet and outlet water temperatures.

- Flow Rate: flow sensors put on the pipes measured chilled water flow rates.

3.6. Preliminary Analysis and Data Organization

- Data Cleaning: using data analysis tools to find missing values and anomalies and remove them.

- Preliminary Analysis: Monthly total energy consumption, operating time, and load demand were calculated. Trends in energy consumption, operating time, and load demand were plotted to provide a preliminary understanding of the data.

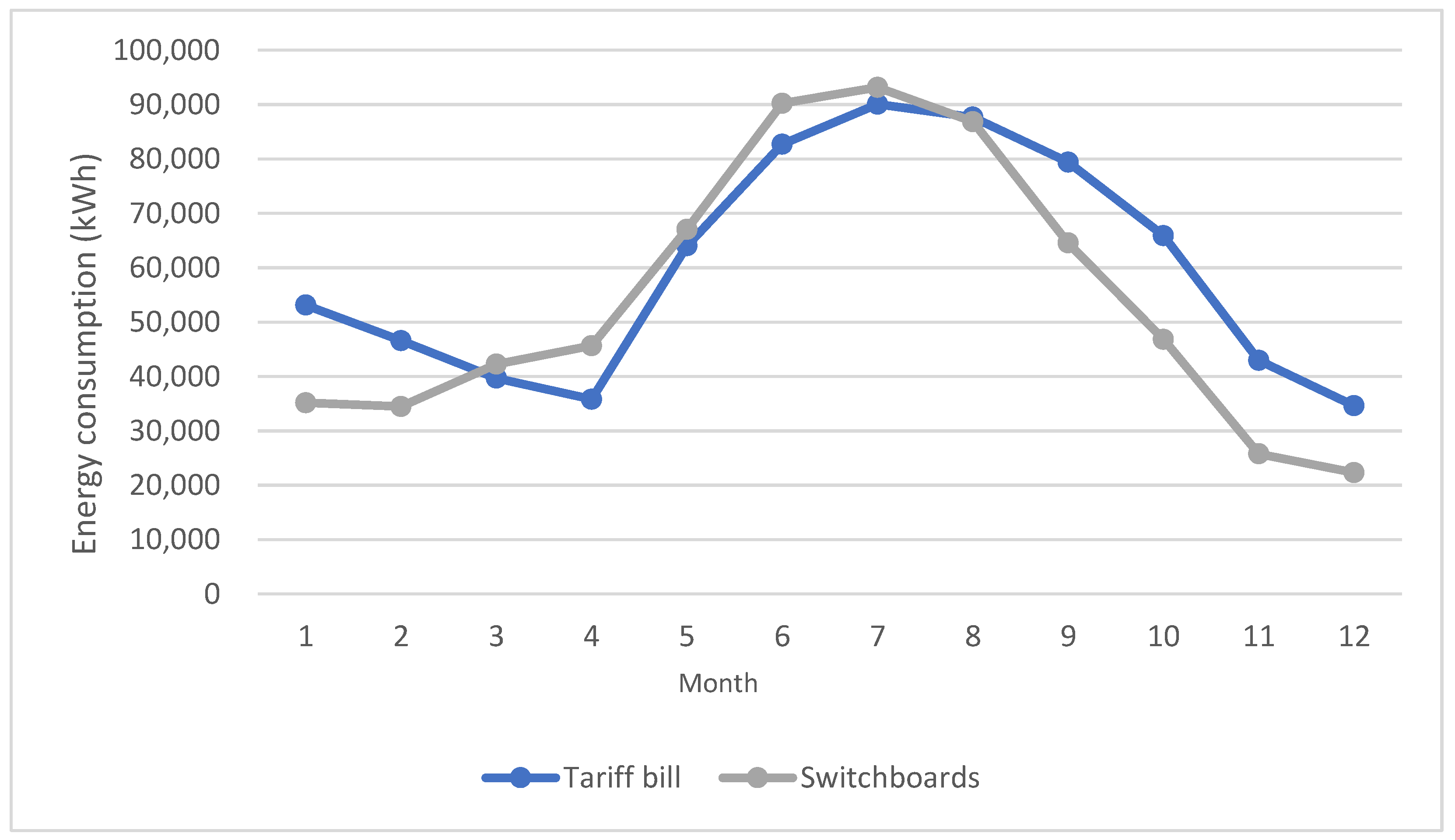

3.7. The Energy Consumption of the Chiller Plant

- Manual recording of equipment operation;

- Electricity consumption from tariff bill;

- Energy consumption data from switchboards of chiller plant.

- Manual Recording of Equipment Operation.

- b.

- Electricity Consumption from Tariff Bills.

- c.

- Energy Consumption Data from Chiller Plant Switchboards.

3.8. Control Strategy Prior to and After SC+BAS Implementation

3.8.1. Control Strategy Prior to SC+BAS Implementation

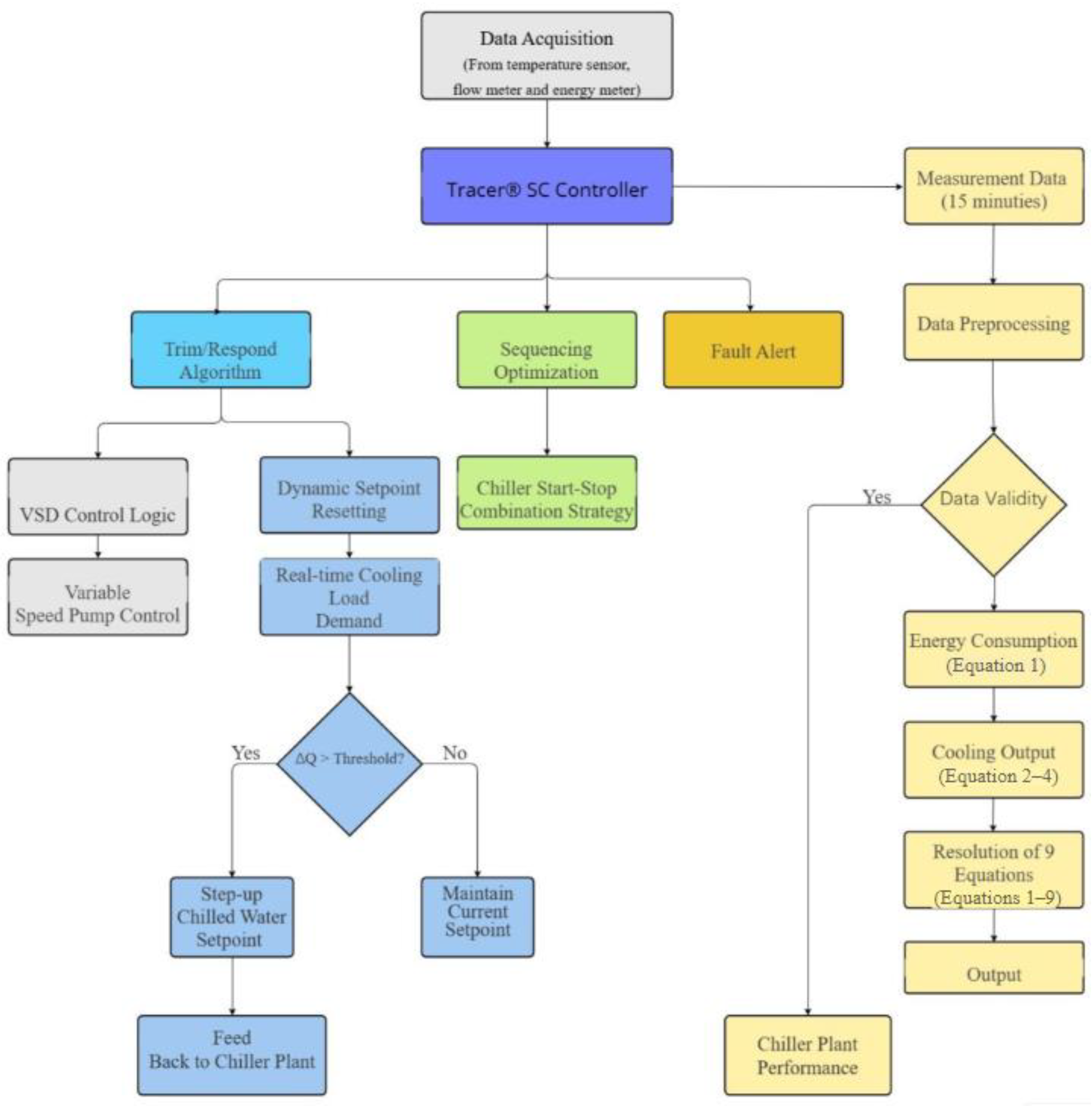

3.8.2. Optimized Control Strategy with SC+BAS Implementation

- Trim/Respond (T/R) Algorithm: This algorithm dynamically adjusts the setpoints for the chilled water temperature and flow rate based on real-time feedback from the sensors. The system continuously monitors the cooling load and adjusts the setpoints to maintain optimal performance while minimizing energy consumption.

- Chiller Sequencing: The SC+BAS system optimizes the sequencing of the chillers based on the actual cooling demand. It dynamically adds or removes chillers from operation to match the load, ensuring that only the necessary number of chillers are running at any given time. This reduces energy waste and improves overall efficiency [31].

- Variable Speed Drives (VSD): The optimized control strategy integrates VSD technology for the pumps and fans, allowing them to operate at variable speeds based on the actual load. This flexibility significantly reduces energy consumption compared to fixed-speed systems.

- Real-Time Monitoring and Adjustments: The SC+BAS system continuously monitors key parameters such as temperature, flow rate, and power consumption. It uses this data to make real-time adjustments, ensuring that the system always operates at peak efficiency.

3.9. Climatic Context

4. Data Collection and Analysis

4.1. Analysis of Measurement Results

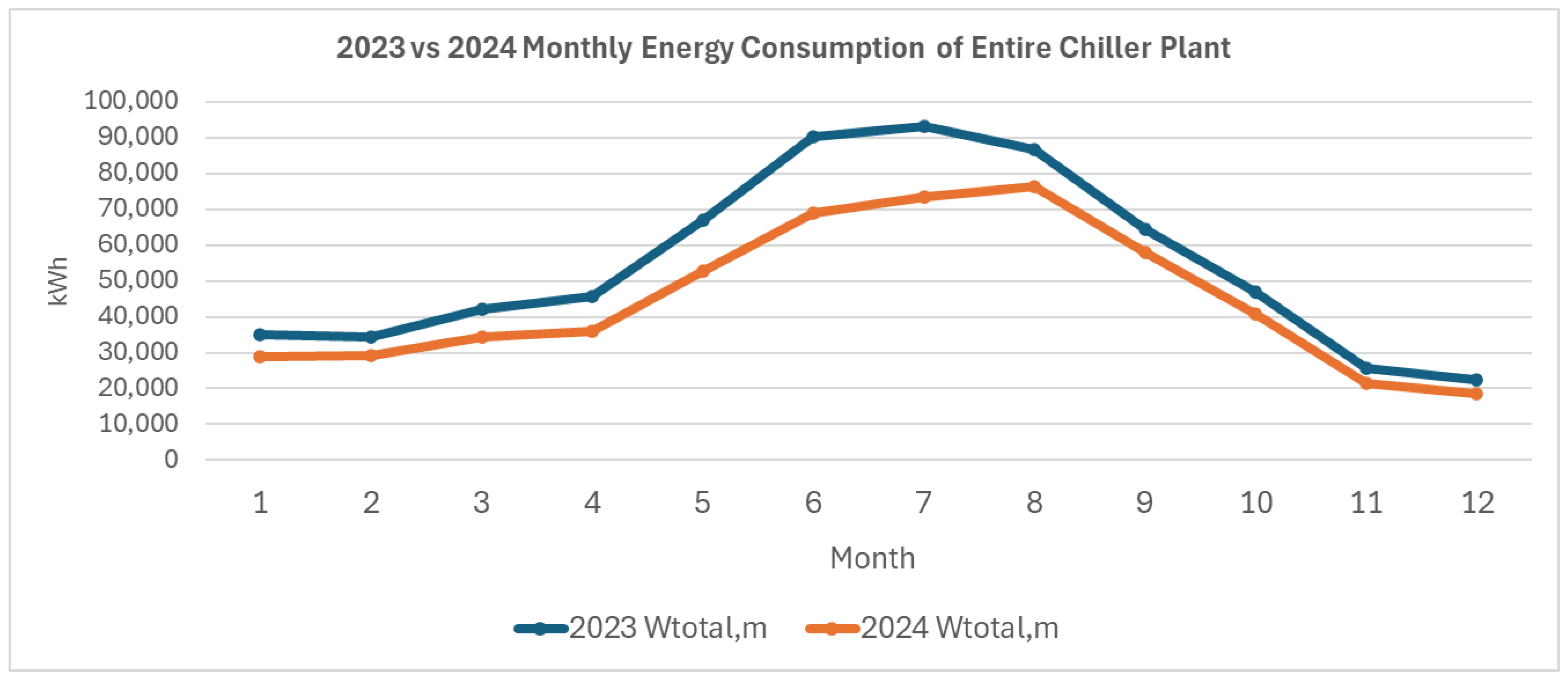

4.1.1. Monthly Results and Summary

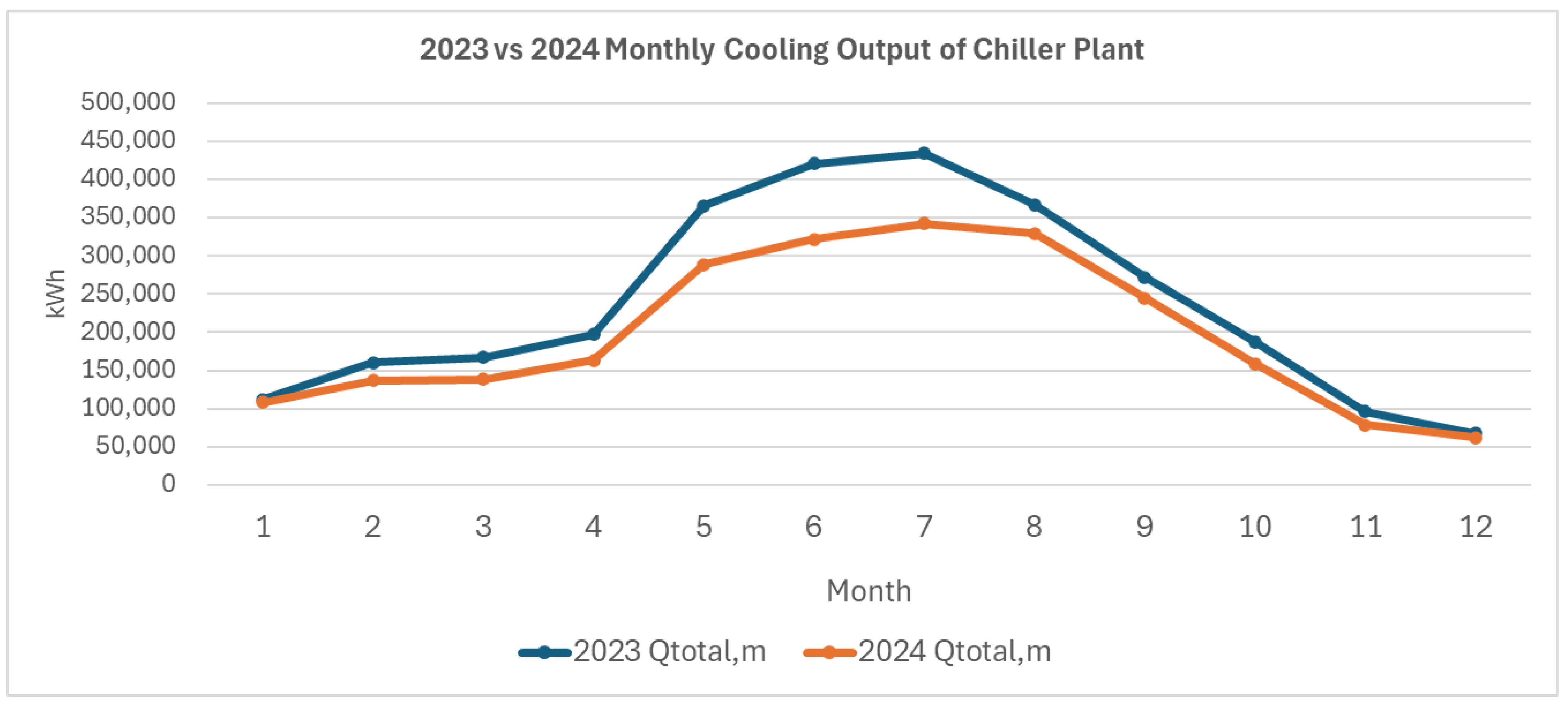

- Monthly cooling output of chiller plant, Qtotal,m (kWh);

- Monthly energy consumption of entire chiller plant, Wtotal,m (kWh);

- Monthly overall COP of chiller plant, COPm;

- Difference of monthly energy consumption between 2023 and 2024, DW (kWh);

- Difference of monthly cooling output between 2023 and 2024, DQ (kWh);

- Ratio of monthly 2024 energy consumption to 2023 energy consumption, Re.

4.1.2. Changes in Electricity Consumption

4.1.3. Changes in Cooling Load

4.1.4. Changes in System Efficiency (COP)

4.1.5. Energy Savings

4.1.6. Cost–Benefit Analysis

5. Discussion

5.1. Savings Through the Integration of SC+BAS

5.1.1. Advanced Monitoring and Control of Chiller Operations

5.1.2. Chilled Water Temperature Reset Methods

5.1.3. Variable Speed Drive (VSD) Technology Integration

5.1.4. Demand-Based Cooling Strategies

5.1.5. Improved Maintenance Procedures and Predictive Control

5.2. Recommended Enhancement Initiatives

5.2.1. Optimization of Chiller Sequencing and Load Balancing

5.2.2. Implementation of Demand-Based Cooling Strategies

5.2.3. Optimizing Chiller Plant Maintenance and Operation

6. Conclusions

Limitations and Future Research Directions

- Multi-Building Validation: Replicate this study across diverse commercial buildings (e.g., offices, hotels) and climatic regions to develop scalable energy-saving benchmarks for SC+BAS.

- AI Integration: Explore hybrid “SC+BAS+AI” frameworks (e.g., embedding reinforcement learning for setpoint optimization, as in Qiu et al. [37]), building on our recommendation in Section 5.2.1. Pilot data from Hong Kong’s MTR suggest potential for more than 8% additional savings.

- Holistic Sustainability Metrics: Extend analysis to non-energy benefits (e.g., maintenance cost reduction, equipment lifespan extension, thermal comfort quantification) to strengthen cost–benefit arguments for SC+BAS adoption. Addressing these directions will advance the role of data-driven automation in achieving carbon-neutral urban infrastructure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SC+BAS | Supervisory Control plus Building Automation System |

| COP | Coefficient of Performance |

| VSD | Variable Speed Drive |

| ANN | Artificial Neural Network |

| HVAC | Heating, Ventilation, and Air Conditioning |

| AI | Artificial Intelligence |

| CPC | Chiller Plant Control |

| T/R | Trim/Respond |

| VSD | Variable Speed Drives |

References

- Trane. Product Catalog Tracer SC+ System Controller with the Tracer Synchrony User Interface. 2021. Available online: https://www.tranehk.com/files/Products/BAS-PRC087D-EN%2020Aug2021.pdf (accessed on 24 January 2025).

- Hong, S.H.; Kim, S.H.; Kim, G.M.; Kim, H.L. Experimental evaluation of BZ-GW (BACnet-ZigBee smart grid gateway) for demand response in buildings. Energy 2014, 65, 62–70. [Google Scholar] [CrossRef]

- Li, Y.; Hong, S.H. BACnet–EnOcean smart grid gateway and its application to demand response in buildings. Energy Build. 2014, 78, 183–191. [Google Scholar] [CrossRef]

- Moosavi, S.A.; Asgari, M.; Kamel, S.R. Developing a comprehensive BACnet attack dataset: A step towards improved cybersecurity in building automation systems. Data Brief 2024, 57, 111192. [Google Scholar] [CrossRef] [PubMed]

- Elamanov, S.; Son, H.; Flynn, B.; Yoo, S.K.; Dilshad, N.; Song, J. Interworking between modbus and internet of things platform for industrial services. Digit. Commun. Netw. 2024, 10, 461–471. [Google Scholar] [CrossRef]

- Elehwany, H.; Gunay, B.; Ouf, M.; Cotrufo, N.; Venne, J. Evaluating common supply air temperature setpoint reset strategies with varying occupancy patterns and behaviours. Build. Environ. 2024, 266, 112129. [Google Scholar] [CrossRef]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. ASHRAE Guideline 36-2018: High-Performance Sequences of Operation for HVAC Systems; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2018; Available online: https://kh.aquaenergyexpo.com/wp-content/uploads/2023/02/High-Performance-Sequences-of-Operation-for-HVAC-Systems.pdf (accessed on 10 February 2025).

- Van Roosmale, S.; Hellinckx, P.; Meysman, J.; Verbeke, S.; Audenaert, A. Building Automation and Control Systems for office Buildings: Technical Insights for Effective Facility Management—A Literature review. J. Build. Eng. 2024, 97, 110943. [Google Scholar] [CrossRef]

- Kang, W.H.; Yoon, Y.; Lee, J.H.; Song, K.W.; Chae, Y.T.; Lee, K.H. In-situ application of an ANN algorithm for optimized chilled and condenser water temperatures set-point during cooling operation. Energy Build. 2021, 233, 110666. [Google Scholar] [CrossRef]

- Fong, K.; Hanby, V.; Chow, T. HVAC system optimization for energy management by evolutionary programming. Energy Build. 2005, 38, 220–231. [Google Scholar] [CrossRef]

- Thu, K.; Saththasivam, J.; Saha, B.B.; Chua, K.J.; Murthy, S.S.; Ng, K.C. Experimental investigation of a mechanical vapour compression chiller at elevated chilled water temperatures. Appl. Therm. Eng. 2017, 123, 226–233. [Google Scholar] [CrossRef]

- Schibuola, L.; Scarpa, M.; Tambani, C. Variable speed drive (VSD) technology applied to HVAC systems for energy saving: An experimental investigation. Energy Procedia 2018, 148, 806–813. [Google Scholar] [CrossRef]

- Wang, L.; Greenberg, S.; Piette, M.A.; Meier, A.; Fiegel, J. Data analysis and modeling of an all-variable speed water-cooled chiller plant. In Proceedings of the ASHRAE Annual Conference; American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE): Atlanta, GA, USA, 2015; Available online: https://www.ashrae.org (accessed on 13 February 2025).

- Liu, Z.; Tan, H.; Luo, D.; Yu, G.; Li, J.; Li, Z. Optimal chiller sequencing control in an office building considering the variation of chiller maximum cooling capacity. Energy Build. 2017, 140, 430–442. [Google Scholar] [CrossRef]

- Building Authority. Code of Practice for Overall Thermal Transfer Value in Buildings; Building Authority: Hong Kong, 1995. Available online: https://www.bd.gov.hk/doc/en/resources/codes-and-references/code-and-design-manuals/OTTV1995_e.pdf (accessed on 14 February 2025).

- Pompei, L.; Nardecchia, F.; Viglianese, G.; Rosa, F.; Piras, G. Towards the Renovation of Energy-Intensive Building: The Impact of Lighting and Free-Cooling Retrofitting Strategies in a Shopping Mall. Buildings 2023, 13, 1409. [Google Scholar] [CrossRef]

- United Nations Framework Convention on Climate Change (UNFCCC). The Paris Agreement. 2021. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 30 May 2025).

- de Kleijne, K.; Hanssen, S.V.; van Dinteren, L.; Huijbregts, M.A.J.; van Zelm, R.; de Coninck, H. Limits to paris compatibility of CO2 capture and utilization. One Earth 2022, 5, 168–185. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Global Warming of 1.5 °C: An IPCC Special Report on the Impacts of Global Warming of 1.5 °C Above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change. 2018. Available online: https://www.ipcc.ch/sr15/ (accessed on 30 May 2025).

- Dhanda, K.K.; Hartman, L.P. The ethics of carbon neutrality: A critical examination of voluntary carbon offset providers. J. Bus. Ethics 2011, 100, 119–149. [Google Scholar] [CrossRef]

- Hong Kong Special Administrative Region. Energy Saving Plan for Hong Kong’s Built Environment 2015~2025+; Environment Bureau, Development Bureau, Transport and Housing Bureau: Hong Kong, 2015. Available online: https://www.eeb.gov.hk/sites/default/files/pdf/EnergySavingPlanEn.pdf (accessed on 30 May 2025).

- Hong Kong Special Administrative Region. Hong Kong’s Climate Action Plan 2030+; Environment Bureau: Hong Kong, 2017; Available online: https://www.hkgbc.org.hk/eng/engagement/file/ClimateActionPlanEng.pdf (accessed on 30 May 2025).

- Building Department. Practice Note for Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-67: Energy Efficiency of Buildings Building (Energy Efficiency) Regulation; Building Department: Hong Kong, 2024. Available online: https://www.bd.gov.hk/doc/en/resources/codes-and-references/practice-notes-and-circular-letters/pnap/APP/APP067.pdf (accessed on 30 May 2025).

- Electrical and Mechanical Services Department (EMSD). Code of Practice for Building Energy Audit; EMSD: Hong Kong, 2012. Available online: https://www.emsd.gov.hk/beeo/en/pee/EAC_2012.pdf (accessed on 31 May 2025).

- Standard 90.1-2022; Energy Standard for Sites and Buildings Except Low-Rise Residential Buildings. American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2022. Available online: https://www.ashrae.org/technical-resources/bookstore/standard-90-1 (accessed on 31 May 2025).

- Chartered Institution of Building Services Engineers. Energy Efficiency in Buildings: Guide F; CIBSE: London, UK, 2012; Available online: https://www.cibse.org/knowledge-research/knowledge-portal/guide-f-energy-efficiency-in-buildings-2012/?id=a0q20000008I7oTAAS (accessed on 31 May 2025).

- Electrical and Mechanical Services Department (EMSD). Code of Practice for Energy Efficiency of Building Services Installation; EMSD: Hong Kong, 2024. Available online: https://www.emsd.gov.hk/beeo/en/pee/BEC_2024_ENG.pdf (accessed on 31 May 2025).

- BEAM Society Limited. BEAM Plus New Buildings Version 2.0; Hong Kong Green Building Council: Hong Kong, 2019; Available online: https://www.beamsociety.org.hk/ (accessed on 31 May 2025).

- Sweden Green Building Council. BREEAM-SE New Construction v6.0 Technical Manual 1.1; Sweden Green Building Council: Stockholm, Sweden, 2023; Available online: www.breeam.com (accessed on 31 May 2025).

- U.S. Green Building Council. LEED v4 for Building Design and Construction; U.S. Green Building Council: Washington, DC, USA, 2019; Available online: https://www.usgbc.org/sites/default/files/LEED%20v4%20BDC_07.25.19_current.pdf (accessed on 31 May 2025).

- Lu, S.; Zhou, S.; Ding, Y.; Kim, M.K.; Yang, B.; Tian, Z.; Liu, J. Exploring the comprehensive integration of artificial intelligence in optimizing HVAC system operations: A review and future outlook. Results Eng. 2025, 25, 103765. [Google Scholar] [CrossRef]

- Hong Kong Observatory. Climate Change in Hong Kong—Temperature. 1995–2024. Available online: https://www.hko.gov.hk/en/climate_change/obs_hk_temp.htm (accessed on 6 June 2025).

- CLP Power Hong Kong Limited. Non-Residential Electricity Tariff Schedule; CLP Power Hong Kong Limited: Hong Kong, 2023; Available online: https://www.clp.com.hk/content/dam/clphk/documents/tariff-adjustment-20221/TariffTable%20-%20English-(2023-01-01).pdf (accessed on 31 May 2025).

- CLP Power Hong Kong Limited. Non-Residential Electricity Tariff Schedule; CLP Power Hong Kong Limited: Hong Kong, 2024; Available online: https://www.clp.com.hk/content/dam/clphk/documents/tariff-adjustment-2024/TariffTable2024_ENG.pdf (accessed on 31 May 2025).

- CLP Holdings. 2024 Annual Report; CLP Holdings: Hong Kong, 2024; p. 43. Available online: https://www.clpgroup.com/content/dam/clp-group/channels/investor/document/3-3-financial-reports/2024/e_2024%20Annual%20Report.pdf (accessed on 31 May 2025).

- Suen, A.T.Y.; Ying, D.T.W.; Choy, C.T.L. Application of artificial intelligence (AI) control system on chiller plant at MTR station. HKIE Trans. 2022, 29, 90–97. [Google Scholar] [CrossRef]

- Qiu, S.; Li, Z.; Fan, D.; He, R.; Dai, X.; Li, Z. Chilled water temperature resetting using model-free reinforcement learning: Engineering application. Energy Build. 2021, 255, 111694. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Refrigeration Capacity | 1054 | kW |

| Total Power Input | 180.3 | kW |

| Design COP (100% Load) | 5.85 | - |

| Chilled Water Flow Rate | 50.2 | L/s |

| Chilled Water ΔT | 5 | °C |

| Condenser Water Flow Rate | 59.5 | L/s |

| Condenser Water ΔT | 5 | °C |

| Part-Load COP (70% Load) | 5.65 | - |

| Months | 2023 | 2024 | DW | DQ | Re | ||||

|---|---|---|---|---|---|---|---|---|---|

| Qtotal,m | Wtotal,m | COPm | Qtotal,m | Wtotal,m | COPm | kWh | kWh | ||

| Jan | 111,877 | 35,160 | 3.18 | 107,786 | 28,823 | 3.74 | 6337 | 4091 | 0.820 |

| Feb | 160,422 | 34,481 | 4.65 | 136,597 | 29,180 | 4.68 | 5301 | 23,825 | 0.846 |

| Mar | 167,324 | 42,269 | 3.96 | 138,680 | 34,365 | 4.04 | 7904 | 28,644 | 0.813 |

| Apr | 197,295 | 45,677 | 4.32 | 163,074 | 36,074 | 4.52 | 9603 | 34,221 | 0.790 |

| May | 365,191 | 67,062 | 5.45 | 288,450 | 52,800 | 5.46 | 14,262 | 76,741 | 0.787 |

| Jun | 420,849 | 90,232 | 4.66 | 321,640 | 69,100 | 4.65 | 21,132 | 99,209 | 0.766 |

| Jul | 433,965 | 93,179 | 4.66 | 342,024 | 73,442 | 4.66 | 19,737 | 91,941 | 0.788 |

| Aug | 366,754 | 86,855 | 4.22 | 329,061 | 76,470 | 4.30 | 10,385 | 37,693 | 0.880 |

| Sep | 272,259 | 64,544 | 4.22 | 245,034 | 57,826 | 4.24 | 6718 | 27,225 | 0.896 |

| Oct | 187,732 | 46,832 | 4.01 | 158,560 | 40,972 | 3.87 | 5860 | 29,172 | 0.875 |

| Nov | 96,088 | 25,768 | 3.73 | 78,803 | 21,374 | 3.69 | 4394 | 17,285 | 0.829 |

| Dec | 67,536 | 22,331 | 3.02 | 61,700 | 18,662 | 3.31 | 3669 | 5836 | 0.836 |

| Energy and Cost Savings Analysis | ||||

|---|---|---|---|---|

| Metric | 2023 | 2024 | Δ Amount | Rate of Change |

| Annual Consumption, kWh | 654,389.47 | 539,088.26 | −115,301.21 | −17.6% |

| Annual Cost, HKD | $674,675.54 | $571,433.56 | −103,241.98 | −15.3% |

| Year 2023 (Without SC+BAS) | Year 2024 (with SC+BAS) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Water-Cooled Chiller Designation & its Capacity | WCPC-1 | WCPC-2 | WCPC-3 | Sub-Total Power, kWh of WCPC-1, 2 & 3 of Each Month in 2023 | WCPC-1 | WCPC-2 | WCPC-3 | Sub-Total Power, kWh of WCPC-1, 2 & 3 of Each Month in 2024 | 2023 vs. 2024 Variance (%) | ||

| 300 TR | 300 TR | 300 TR | 300 TR | 300 TR | 300 TR | ||||||

| Operating Power of each Month | Jan | 8438.41 | - | 26,721.60 | 35,160 | Jan | 20,176.10 | - | 8646.90 | 28,823 | −18.0% |

| Feb | 22,412.70 | - | 12,068.30 | 34,481 | Feb | 20,426.00 | 8754.00 | - | 29,180 | −15.4% | |

| Mar | 31,279.10 | 10,989.90 | - | 42,269 | Mar | - | 25,773.80 | 8591.20 | 34,365 | −18.7% | |

| Apr | 32,927.40 | - | 12,749.60 | 45,677 | Apr | 25,251.80 | - | 10,822.20 | 36,074 | −21.0% | |

| May | 30,237.80 | 23,814.60 | 13,009.60 | 67,062 | May | 23,760.30 | - | 29,039.70 | 52,800 | −21.3% | |

| Jun | 38,729.30 | 31,452.70 | 20,050.00 | 90,232 | Jun | 29,022.70 | 24,835.90 | 15,241.40 | 69,100 | −23.4% | |

| Jul | 42,862.30 | 28,114.90 | 22,201.80 | 93,179 | Jul | 33,048.90 | 25,702.70 | 14,690.40 | 73,442 | −21.2% | |

| Aug | 36,517.10 | 30,338.50 | 19,999.40 | 86,855 | Aug | 32,117.40 | 28,246.80 | 16,105.80 | 76,470 | −12.0% | |

| Sep | 29,044.80 | 21,005.20 | 14,494.00 | 64,544 | Sep | 26,021.70 | 20,820.40 | 10,983.90 | 57,826 | −10.4% | |

| Oct | 33,892.30 | 12,939.70 | - | 46,832 | Oct | - | 10,243.00 | 30,729.00 | 40,972 | −12.5% | |

| Nov | 17,522.20 | 8245.80 | - | 25,768 | Nov | 5,343.50 | 16,030.50 | - | 21,374 | −17.1% | |

| Dec | 15,855.10 | 6475.90 | - | 22,331 | Dec | 13,063.40 | 5598.60 | - | 18,662 | −16.4% | |

| Variance | ∑ Jan to Dec | [a] Annual operating Power in 2023 | 654,389.47 | ∑ Jan to Dec | [b] Annual operating Power in 2024 | 539,088.26 | −17.6% | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alan, F.M.-L.; Nelson, L.B. Transforming Chiller Plant Efficiency with SC+BAS: Case Study in a Hong Kong Shopping Mall. Urban Sci. 2025, 9, 253. https://doi.org/10.3390/urbansci9070253

Alan FM-L, Nelson LB. Transforming Chiller Plant Efficiency with SC+BAS: Case Study in a Hong Kong Shopping Mall. Urban Science. 2025; 9(7):253. https://doi.org/10.3390/urbansci9070253

Chicago/Turabian StyleAlan, Fong Ming-Lun, and Li Baonan Nelson. 2025. "Transforming Chiller Plant Efficiency with SC+BAS: Case Study in a Hong Kong Shopping Mall" Urban Science 9, no. 7: 253. https://doi.org/10.3390/urbansci9070253

APA StyleAlan, F. M.-L., & Nelson, L. B. (2025). Transforming Chiller Plant Efficiency with SC+BAS: Case Study in a Hong Kong Shopping Mall. Urban Science, 9(7), 253. https://doi.org/10.3390/urbansci9070253