Urban Sustainability in Construction: A Comparative Review of Waste Management Practices in Developed Nations

Abstract

1. Introduction

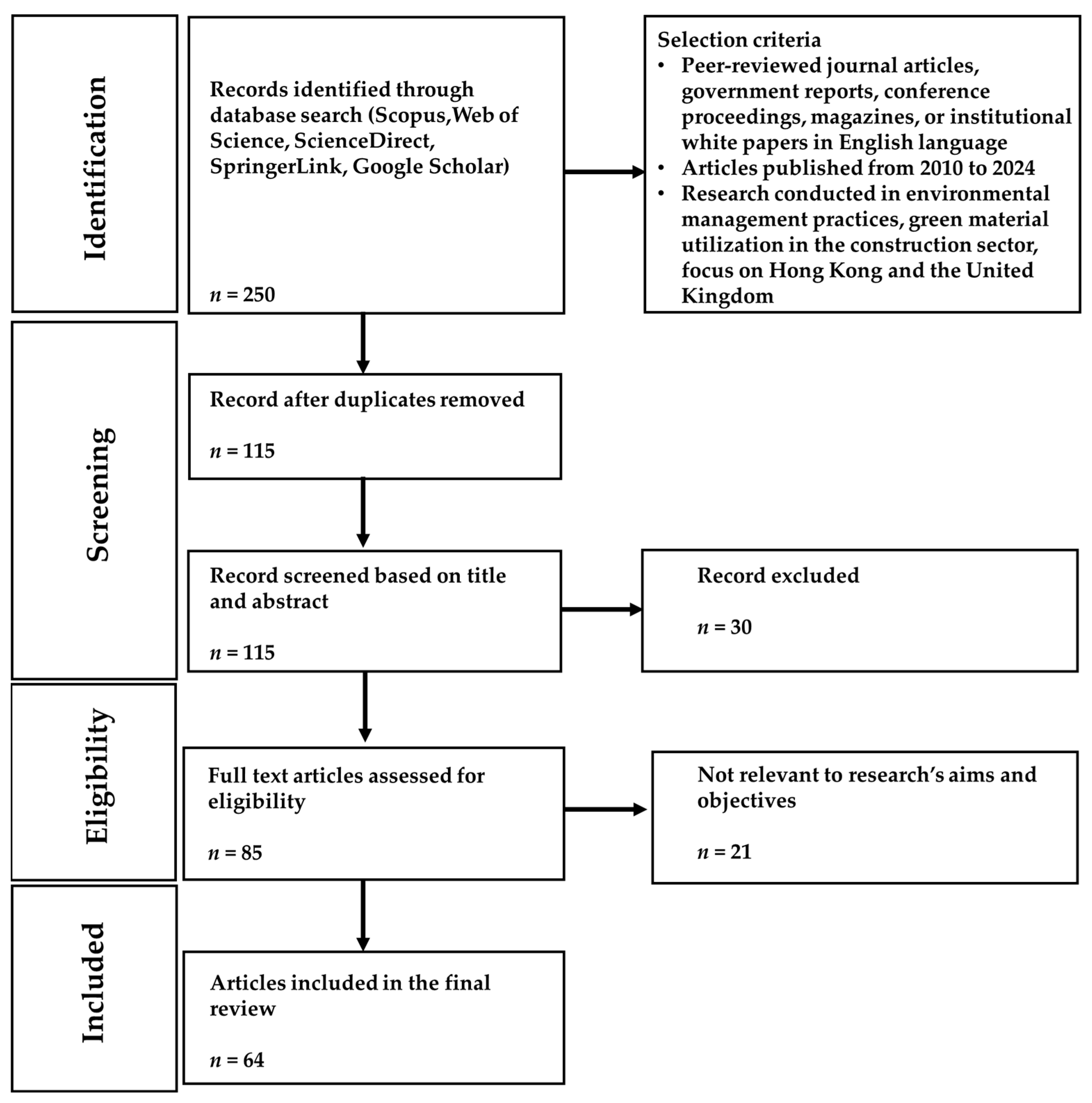

2. Methodology

3. Environmental Management Practices in Construction Industry

3.1. Status, Policy, and Environmental Management Practices in Hong Kong

3.1.1. Status and Issues in the Construction Sector of Hong Kong

3.1.2. Governmental Policy of Hong Kong

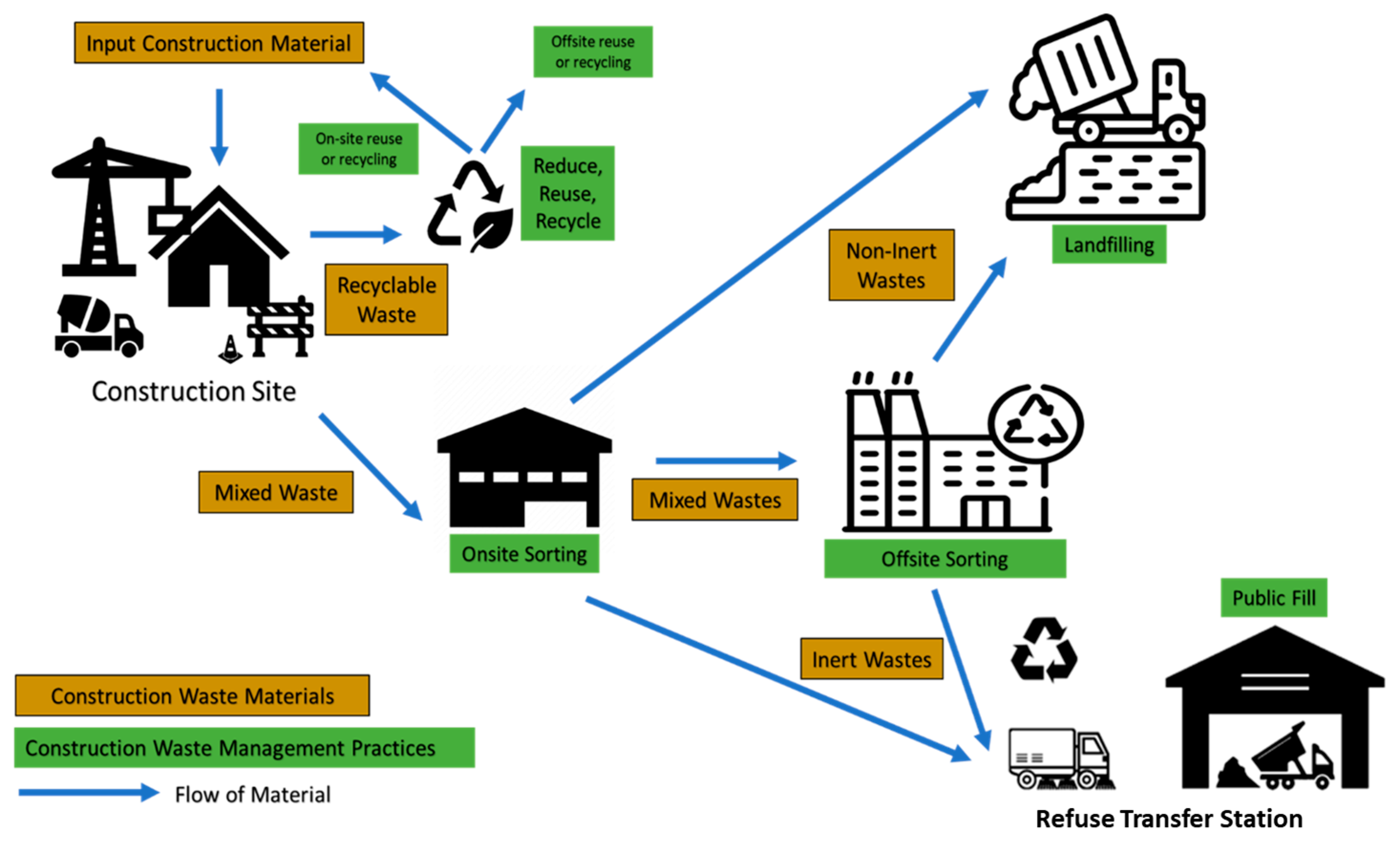

3.1.3. Environmental Management Practices in Hong Kong

3.2. Status, Policy and Environmental Management Practices in the UK

3.2.1. Status and Issues in the Construction Sector of the UK

3.2.2. Governmental Policy of the UK

3.2.3. Environmental Management Practices in the UK

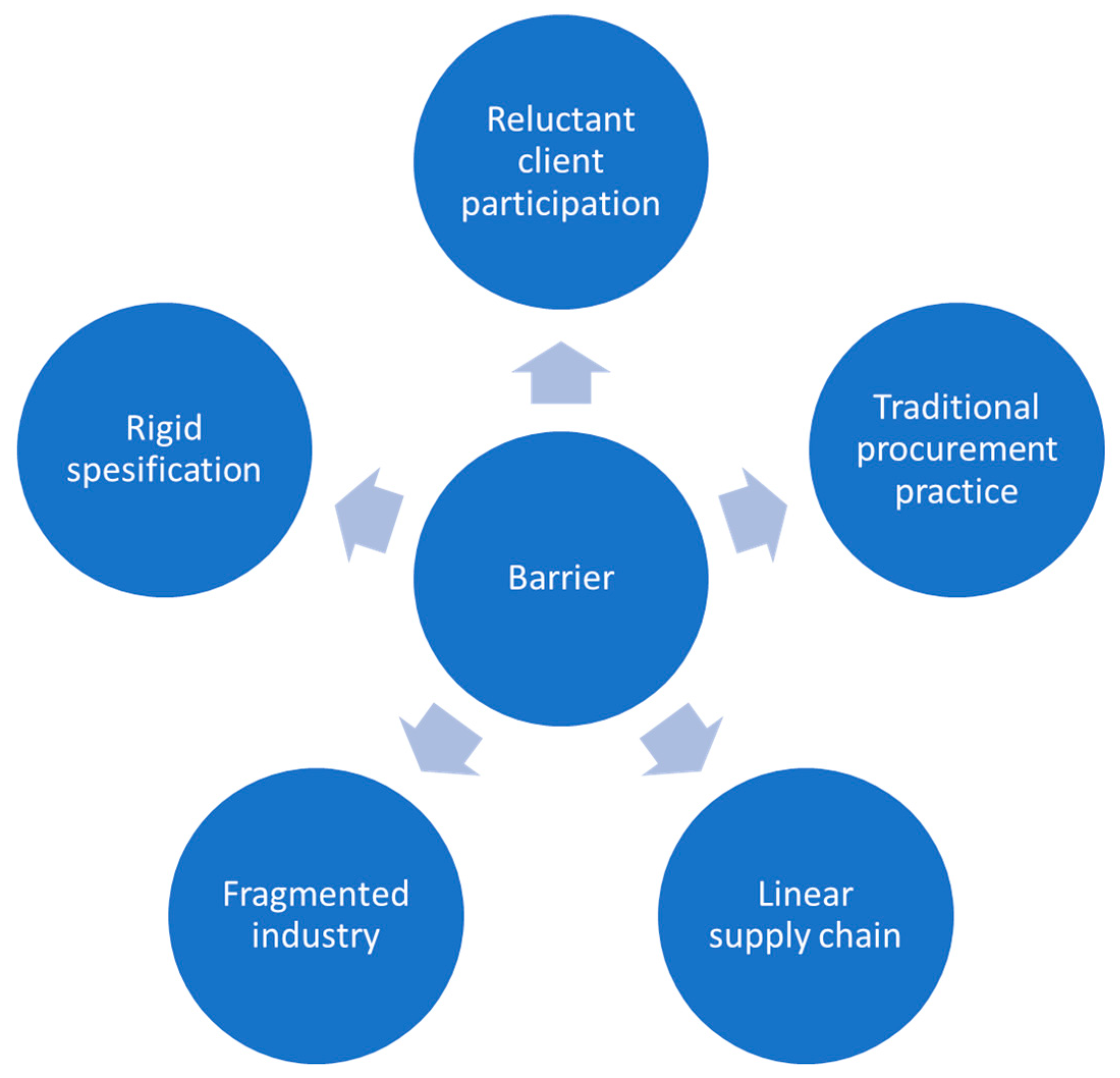

3.2.4. Proposing Environmental Management Practice

4. Green Materials for Construction

4.1. Recycled Plastic Lumber

4.2. Eco-Concrete

4.3. Recovered Steel

5. Green Materials Technologies

5.1. Green Roof

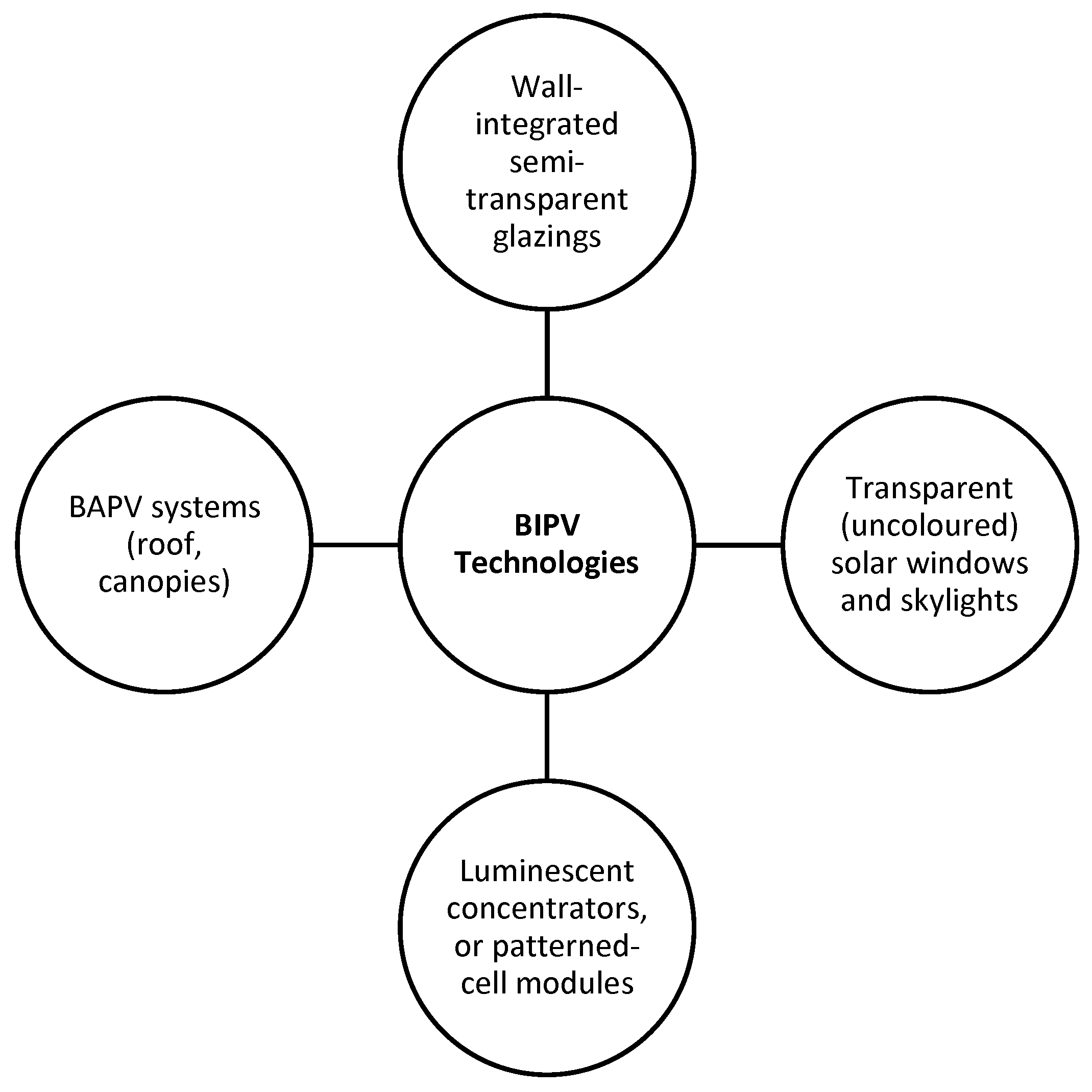

5.2. Building Integrated Photovoltaic (BIPV)

6. Future Policy Direction

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alaloul, W.S.; Musarat, M.A.; Rabbani, M.B.A.; Iqbal, Q.; Maqsoom, A.; Farooq, W. Construction sector contribution to economic stability: Malaysian GDP distribution. Sustainability 2021, 13, 5012. [Google Scholar] [CrossRef]

- Hatema, Z.M.; Kassemc, M.A.; Alic, K.N.; Khoiryd, M.A. A New Perspective on the Relationship Between the Construction Industry Performance and The Economy Outcome—A Literature Review. J. Kejuruter 2022, 34, 191–200. [Google Scholar] [CrossRef]

- Jiang, Q. Analysis on the relationship between GDP and construction based on the data of UK and China. In Proceedings of the International Conference on Education Technology and Management Science (ICETMS), Nanjing, China, 8–9 June 2013; pp. 1296–1299. [Google Scholar] [CrossRef][Green Version]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Hasan, R.; Rakib, M.F.H.; Rahman, M. Quantification of Construction Waste through BIM. J. Technol. Manag. Bus. 2022, 9, 62–77. [Google Scholar] [CrossRef]

- Finnveden, G.; Ekvall, T.; Arushanyan, Y.; Bisaillon, M.; Henriksson, G.; Gunnarsson Östling, U.; Söderman, M.L.; Sahlin, J.; Stenmarck, Å.; Sundberg, J.; et al. Policy Instruments towards a Sustainable Waste Management. Sustainability 2013, 5, 841–881. [Google Scholar] [CrossRef]

- Cheng, C.; Zhou, Y.; Zhang, L. Sustainable Environmental Management Through a Municipal Solid Waste Charging Scheme: A Hong Kong Perspective. Front. Environ. Sci. 2022, 10, 919683. [Google Scholar] [CrossRef]

- Jia, A.Y.; Zhang, Y.; Shen, J. Modular integrated construction as a development strategy for post-COVID urban sustainability: The case of Hong Kong. Front. Sustain. Cities 2025, 7, 1553276. [Google Scholar] [CrossRef]

- Bao, Z.; Lee, W.M.; Lu, W. Implementing on-site construction waste recycling in Hong Kong: Barriers and facilitators. Sci. Total Environ. 2020, 747, 141091. [Google Scholar] [CrossRef]

- Evangelinos, K.I.; Allan, S.; Jones, K.; Nikolaou, I.E. Environmental management practices and engineering science: A review and typology for future research. Integr. Environ. Assess. Manag. 2014, 10, 153–162. [Google Scholar] [CrossRef]

- Lu, W.; Tam, V.W. Construction waste management policies and their effectiveness in Hong Kong: A longitudinal review. Renew. Sustain. Energy Rev. 2013, 23, 214–223. [Google Scholar] [CrossRef]

- Research and Market. United Kingdom Green Construction Industry Databook Series—Market Size & Forecast (2016–2025) by Value and Volume Across 40+ Market Segments in Residential, Commercial, Industrial, Institutional and Infrastructure Construction—Q2 2021 Update. 2021. Available online: https://www.researchandmarkets.com/reports/5504486/united-kingdom-green-construction-industry#rela0-4747876 (accessed on 25 December 2024).

- Osmani, M. Construction waste minimization in the UK: Current pressures for change and approaches. Procedia Soc. Behav. Sci. 2012, 40, 37–40. [Google Scholar] [CrossRef]

- Osmani, M. Integration of Waste Minimisation Strategies into the Design Process of Buildings. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2015. Available online: https://core.ac.uk/download/pdf/288371785.pdf (accessed on 4 February 2025).

- David Gardiner & Associates, LLC. Green Building and the Finance Sector: An Overview of Financial Institution Involvement in Green Buildings in North America; United Nation Environment Programme Finance Initiative (UNEPFI): Geneva, Switzerland, 2010; Available online: https://www.unepfi.org/publications/green-buildings-and-the-finance-sector-an-overview-of-financial-institution-involvement-in-green-buildings-in-north-america/ (accessed on 15 January 2025).

- Grand View Research. Green Concrete Market Analysis, Market Size, Application, Analysis, Regional Outlook, Competitive Strategies, and Segment Forecasts, 2015 to 2022. Available online: https://www.grandviewresearch.com/industry-analysis/green-concrete-market (accessed on 13 January 2025).

- Liu, X.; Liu, S. Green Technology Innovation, Capital-Factor Allocation, and Manufacturing-Export Resilience. Sustainability 2024, 16, 1246. [Google Scholar] [CrossRef]

- Keles, H.; Yayla, O.; Tarinc, A.; Keles, A. The Effect of Environmental Management Practices and Knowledge in Strengthening Responsible Behavior: The Moderator Role of Environmental Commitment. Sustainability 2023, 15, 1398. [Google Scholar] [CrossRef]

- Tam, V.W.-Y.; Lu, W. Construction Waste Management Profiles, Practices, and Performance: A Cross-Jurisdictional Analysis in Four Countries. Sustainability 2016, 8, 190. [Google Scholar] [CrossRef]

- Chang, T.W.; Kumar, D. Overview of Environmental Management Practice for Construction in Malaysia. Civ. Sustain. Urban Eng. 2021, 1, 15–25. [Google Scholar] [CrossRef]

- Hall, J.N. Briefing: A practical initiative for the construction industry. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2010; Volume 163, pp. 181–183. [Google Scholar] [CrossRef]

- Au, L.S.; Ahn, S.; Kim, T.W. System Dynamic Analysis of Impacts of Government Charges on Disposal of Construction and Demolition Waste: A Hong Kong Case Study. Sustainability 2018, 10, 1077. [Google Scholar] [CrossRef]

- Organisation for Economic Cooperation and Development (OECD). OECD Environmental Performance Reviews: United Kingdom 2022; OECD Environmental Performance Reviews; OECD Publishing: Paris, France, 2022. [Google Scholar] [CrossRef]

- International Trade Administration (ITA). Hong Kong—Country Commercial Guide: Hong Kong and Macau Construction Industry. International Trade Administration, U.S. Department of Commerce, January 2022. Available online: https://www.trade.gov/country-commercial-guides/hong-kong-and-macau-construction-industry (accessed on 30 January 2025).

- Textor, C. Number of People Employed in Hong Kong’s Construction Industry 2013–2020; Statista: Hamburg, Germany, 2021. [Google Scholar]

- Ann, T.W.; Poon, C.S.; Wong, A.; Yip, R.; Jaillon, L. Impact of construction waste disposal charging scheme on work practices at construction sites in Hong Kong. Waste Manag. 2013, 33, 138–146. [Google Scholar] [CrossRef]

- Environmental Protection Department (EPD). Monitoring of Solid Waste in Hong Kong, Waste Statistics for 2020. Hong Kong Waste Reduction Website, 2021. Available online: https://www.wastereduction.gov.hk/sites/default/files/resources_centre/waste_statistics/msw2020_eng.pdf (accessed on 4 February 2025).

- Tang, L.; Fan, L.; Ni, M.; Shen, L. Environmental impact assessment in Hong Kong: A comparison study and lessons learnt. Impact Assess. Proj. Apprais. 2016, 34, 254–260. [Google Scholar] [CrossRef]

- Environmental Protection Department (EPD). Monitoring of Solid Waste in Hong Kong, Waste Statistics for 2010. Hong Kong Waste Reduction Website, 2011. Available online: https://www.wastereduction.gov.hk/sites/default/files/resources_centre/waste_statistics/msw2010_eng.pdf (accessed on 8 June 2025).

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; Klyuev, S.; Chulkova, I.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Azevedo, A. Design Strategy for Recycled Aggregate Concrete: A Review of Status and Future Perspectives. Crystals 2021, 11, 695. [Google Scholar] [CrossRef]

- Dorich, J.; Li, Y.; Reklaoui, L.; Steeves, M. Sustainable Solutions in the Construction Industry of Hong Kong. Worcester Polytechnic Institute, Digital WPI, 2013. Available online: https://api.semanticscholar.org/CorpusID:204691998 (accessed on 15 January 2025).

- Anaç, M.; Gumusburun Ayalp, G.; Karabeyeser Bakan, M. A Roadmap for Reducing Construction Waste for Developing Countries. Sustainability 2024, 16, 5057. [Google Scholar] [CrossRef]

- Botchway, E.A.; Asare, S.S.; Agyekum, K.; Salgin, B.; Pittri, H.; Kumah, V.M.A.; Dompey, A.M.A. Competencies Driving Waste Minimization during the Construction Phase of Buildings. Buildings 2023, 13, 971. [Google Scholar] [CrossRef]

- Papargyropoulou, E.; Preece, C.; Padfield, R.; Abdullah, A.A. Sustainable construction waste management in Malaysia: A contractor’s perspective. In Proceedings of the Management and Innovation for a Sustainable Built Environment, Amsterdam, The Netherlands, 20–23 June 2011; Available online: https://www.scribd.com/document/510762023/Sustainable-Construction-Waste-Management-in-Malaysia-A-Contractor-s-Perspective (accessed on 15 February 2025).

- De Silva, M.; Paris, R. Delivering Crossrail, UK: A holistic approach to sustainability. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2015; Volume 168, pp. 151–158. [Google Scholar] [CrossRef]

- Ghumra, S.; Glass, J.; Frost, M.W.; Watkins, M.; Mundy, J. Materials and energy assessment in Ceequal transport projects. In Proceedings of the Institution of Civil Engineers-Transport; Thomas Telford Ltd.: London, UK, 2011; Volume 164, pp. 153–164. [Google Scholar] [CrossRef]

- Arts, J.; Faith-Ell, C. New governance approaches for sustainable project delivery. Procedia Soc. Behav. Sci. 2012, 48, 3239–3250. [Google Scholar] [CrossRef]

- Salah, M.; Elmasry, M.; Mashhour, I.; Amer, N. A framework for assessing sustainability of construction projects. Clean. Eng. Technol. 2023, 13, 100626. [Google Scholar] [CrossRef]

- Sansom, M.; Avery, N. Briefing: Reuse and recycling rates of UK steel demolition arisings. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2014; Volume 167, pp. 89–94. [Google Scholar] [CrossRef]

- Islam, N.; Sandanayake, M.; Muthukumaran, S.; Navaratna, D. Review on Sustainable Construction and Demolition Waste Management—Challenges and Research Prospects. Sustainability 2024, 16, 3289. [Google Scholar] [CrossRef]

- Department for Environment, Food and Rural Affairs (DEFRA). Construction, Demolition, and Excavation Waste Generation Estimate: England. 2010. Available online: https://www.gov.uk/government/statistical-data-sets/env23-uk-waste-data-and-management (accessed on 31 January 2025).

- Ahmed, S.; El-Sayegh, S. Critical Review of the Evolution of Project Delivery Methods in the Construction Industry. Buildings 2021, 11, 11. [Google Scholar] [CrossRef]

- Molenaar, K.R.; Sobin, N.; Antillón, E.I. A synthesis of best-value procurement practices for sustainable design-build projects in the public sector. J. Green Build. 2010, 5, 148–157. [Google Scholar] [CrossRef]

- Negi, P.; Thakur, G.; Singh, R.; Gehlot, A.; Thakur, A.K.; Gupta, L.R.; Priyadarshi, N.; Twala, B. Perception of lean construction implementation barriers in the indian prefabrication sector. Heliyon 2024, 10, e36458. [Google Scholar] [CrossRef]

- Brummitt, N.A.; Araujo, A.C. The UK’s 25 Year Plan for the Environment and the Convention on Biological Diversity: Gaps, Synergies and Opportunities. Sustainability 2024, 16, 2975. [Google Scholar] [CrossRef]

- Vagtholm, R.; Matteo, A.; Vand, B.; Tupenaite, L. Evolution and Current State of Building Materials, Construction Methods, and Building Regulations in the U.K.: Implications for Sustainable Building Practices. Buildings 2023, 13, 1480. [Google Scholar] [CrossRef]

- Rhodes, O.; Rostami, A.; Khodadadyan, A.; Dunne, S. Response Strategies of UK Construction Contractors to COVID-19 in the Consideration of New Projects. Buildings 2022, 12, 946. [Google Scholar] [CrossRef]

- Santos, F.A.d.; Canto, L.B.; Silva, A.L.N.d.; Visconte, L.L.Y.; Pacheco, E.B.V. Processing and Properties of Plastic Lumber. In Thermosoftening Plastics; Evingür, G.A., Pekcan, Ö., Achilias, D.S., Eds.; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Yu, A.T.W.; Wong, I.; Wu, Z.; Poon, C.-S. Strategies for Effective Waste Reduction and Management of Building Construction Projects in Highly Urbanized Cities—A Case Study of Hong Kong. Buildings 2021, 11, 214. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Darko, A.; Ameyaw, E.E. Strategies for promoting green building technologies adoption in the construction industry—An international review. Sustainability 2018, 10, 1746. [Google Scholar]

- Bonomo, P.; Chatzipanagi, A.; Frontini, F. Overview and analysis of current BIPV products: New criteria for supporting the technological transfer in the building sector. VITRUVIO Int. J. Archit. Technol. Sustain. 2015, 67–85. [Google Scholar] [CrossRef]

- Pagliaro, M.; Ciriminna, R.; Palmisano, G. BIPV: Merging the photovoltaic with the construction industry. Prog. Photovolt. Res. Appl. 2010, 18, 61–72. [Google Scholar] [CrossRef]

- Bonomo, P.; Frontini, F. Building Integrated Photovoltaics (BIPV): Analysis of the Technological Transfer Process and Innovation Dynamics in the Swiss Building Sector. Buildings 2024, 14, 1510. [Google Scholar] [CrossRef]

- Strong, S. Building Integrated Photovoltaics (BIPV). Whole Building Design Guide, 2016. Available online: https://stg.wbdg.org/resources/building-integrated-photovoltaics-bipv (accessed on 25 February 2025).

- Abass, F.; Ismail, L.H.; Wahab, I.A.; Elgadi, A.A. A review of green roof: Definition, history, evolution and functions. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 713, p. 012048. [Google Scholar] [CrossRef]

- Chong, J.H.; Liu, M.S.; Hernandes, E.; Albescu, M. Implementation of Green Materials in Construction Management System in Malaysia. Civ. Sustain. Urban Eng. 2023, 3, 51–69. [Google Scholar] [CrossRef]

- Cascone, S. Eco-Innovative Construction: Integrating Green Roofs Design within the BIM Framework. Sustainability 2024, 16, 1967. [Google Scholar] [CrossRef]

- Liu, K.; Minor, J. Performance evaluation of an extensive green roof. In Proceedings of the Presentation at Green Rooftops for Sustainable Communities, Washington, DC, USA, 5–6 May 2005; pp. 1–11. Available online: https://www.academia.edu/download/7265468/Performance_evaluation_of_an_extensive_green_roof.pdf (accessed on 10 January 2025).

- Reddy, P.; Gupta, M.S.; Nundy, S.; Karthick, A.; Ghosh, A. Status of BIPV and BAPV system for less energy-hungry building in India—A review. Appl. Sci. 2020, 10, 2337. [Google Scholar] [CrossRef]

- Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Recent developments in solar energy-harvesting technologies for building integration and distributed energy generation. Energies 2019, 12, 1080. [Google Scholar] [CrossRef]

- Medio, S. Photovoltaic Design Integration at Battery Park City, New York. Buildings 2013, 3, 341–356. [Google Scholar] [CrossRef]

- Zuo, J.; Zhao, Z.-Y. Green building research–current status and future agenda: A review. Renew. Sustain. Energy Rev. 2014, 30, 271–281. [Google Scholar] [CrossRef]

- Darko, A.; Zhang, C.; Chan, A.P.C. Drivers for green building: A review of empirical studies. Habitat Int. 2017, 60, 34–49. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Chileshe, N.; Zuo, J.; Baroudi, B. Adopting global virtual engineering teams in AEC Projects: A qualitative meta-analysis. Constr. Innov. 2015, 15, 491–507. [Google Scholar] [CrossRef]

| Regulation | Year | Policy | Ref. |

|---|---|---|---|

| Waste Disposal Ordinance | 1980 | Legislation waste generation in construction sites. Framework for managing onsite waste from generation to disposal. Prohibit use of any premises as waste disposal area unless permitted by Director of Environmental Protection. Amendment in 2003 to accommodate construction waste disposal charging scheme and waste crime. | [11] |

| 10-Year Plan | 1989 | Aim to minimize construction waste and other environmental pollution issues. | [11] |

| Green Manager Scheme | 1994 | Appoint Green Managers from all governmental departments to look after green-housekeeping-related matters. Focus on water and energy saving. | [11] |

| Waste Disposal Regulations | 1995 | Introduced charge payment for disposal of wastes (chemical waste and construction solid waste) at landfills. | [11] |

| Waste Disposal (Designated Waste Disposal Facility) Regulation | 1996 | Ensure the upkeep of orderly conduct within places used for waste disposal activities. Prevent the evasion of service charges of waste disposal. | [11] |

| Waste Reduction Framework Plan | 1998 | Reduce, reuse, and recycling aspects (materials management).Milestones include extend landfill useful life, reduce quantity of waste, conserve non-renewable materials, increase recycling practices, persuade the public on the true cost of waste management, and encourage efficient on-site and off-site waste management operation. | [11] |

| Landfill Charging Scheme | 1999 | Based on principles of “Polluter Pays” and “User Pays”. | [11] |

| “Construct for Excellence” report | 2001 | Responsible for implementation: Construction industry Review Committee and the Departments of Buildings, Lands, and Planning. Promote the use of recycled and green building materials in the design and construction operation to reduce construction waste. | [19] |

| Joint Practice Note (JPN) | 2001 | JPN1 (2001) and JPN2 (2007) were published on reducing construction waste. They provide exemption of site coverage or gross floor area (GFA) calculation for builders to increase the use rate of prefabricated external walls. The 2011 revision introduce an overall cap of 10% GFA exemptions for qualified features. | [19] |

| Practical Note on Recycled Aggregate | 2003 | To eliminate the uncertainty of using recycled aggregates under the guidelines for recycling construction waste, the use of reusable aggregates should be promoted and standards and guidelines for their use should be developed. Technical guidelines apply to concrete for both prescribed and planned mixes. | [19] |

| Waste Management Plan and Pay for Safety and Environment Scheme | 2003 | This is highlighted in the circular “Construction Site Waste Management” from the Environment, Transport and Labour Office. | [19] |

| Recycling Pilot Plant | 2004 | Established in Tuen Mun, inert waste is processed into recycled aggregates for road construction and as raw materials for the production of asphalt and small concrete structures. Between 2004 and 2006, public projects began using recycled aggregates. | [19] |

| Trip Ticket System (TTS) | 2004 | The system was introduced in 1999 and expanded in 2004 to combat illegal waste disposal. Destinations and routes are tracked and monitored. | [19] |

| Construction Waste Disposal Charging Scheme | 2005 | Promote the sorting, reduction, and resource utilization of construction waste. Two external sorting facilities (Tuen Mun and Tseung Kwan O) have been set up. | [19] |

| Best Practice Guide | 2009 | Published by the Hong Kong Construction Association for reference by frontline management teams when dealing with environmental issues (including site waste management). | [19] |

| Construction Waste Management Tool | Developer Description | Ref. |

|---|---|---|

| SMARTWaste | Collects and organizes data on the types and quantities of waste generated on construction sites. Helps create site-specific waste management plans that can inform future waste control strategies. | [31] |

| Net Waste Tool | Estimates the amount of waste that will be generated during construction activities, aiding in planning and management. | [31] |

| BreMap | Assists waste producers and users in finding the nearest recycling centers, reclamation facilities, and landfill sites, and it sources for locally reclaimed and recycled materials. | [14] |

| Webfill | An online marketplace designed to promote the reuse of construction waste by facilitating the exchange of surplus materials. | [14] |

| SWMP Tracker | A digital tool for compiling and analyzing data from Site Waste Management Plans (SWMPs). | [34] |

| ConstructCLEAR | Integrates and simplifies processes for managing SWMPs, carbon reporting, waste procurement, and ensuring regulatory compliance. | [34] |

| Building Research Establishment Environmental Assessment Method (BREEAM) | Civil Engineering Environmental Quality Assessment and Award Scheme (CEEQUAL) | Ref. |

|---|---|---|

| Certification scheme for environmental assessment of building (local spatial planning projects and infrastructure projects) | Improvement of sustainability in public works and civil engineering projects via self-evaluation and rewards. | [36,37,38,39] |

| Often used building sustainability performance measures in the UK since its introduction in 1990. | Launched in 2015 with the support of industry organizations. | [36,37] |

| Ten categories of environmental criteria for sustainability assessment. | Twelve categories of environmental criteria for sustainability assessment. | [36,38] |

| A range of schemes for assessment that cover different requirements of building types. | A range of awards for projects involved in assessment: whole project award, client and design award, construction only award, etc. | [36,38] |

| The total score is a sum of various category scores that are weighted to achieve a pass (30%), good (45%), very good (55%), excellent (70%), and exceptional (85%) rating. | Pass (30%), good (40%), very good (60%), and excellent (75%) are the grades of reward. Give incentives to clients or developers to improve upon best practices. | [36,39] |

| Assessment is conducted independently and credible by government. | Assessment and award process involves project assessor and a verifier. | [36,38] |

| Policy | Remark | Effect | Ref. |

|---|---|---|---|

| Producer Responsibility Obligations (Packaging Waste) Regulations | For construction industry with GBP 2 million or more of turnover and handle 50 tons of packaging waste per year. Companies obliged to recover packaging waste. | The company collaborates with product manufacturers and supply chains to implement recyclable/returnable packaging as a means to reduce waste. | [13,23,31] |

| Landfill tax | Tax for active waste is 32 GBP/ton (2008) increased to 48 GBP/ton (2010). Tax for inactive waste is 2.5 GBP/ton (2008). | Impose considerable costs for industry that produce waste and use waste management contractors. Develop the culture of recycling and recovering onsite waste. | [13,23,31] |

| Aggregates Levy | 1.95 GBP/ton (2008). | Improved financial incentive for secondary and recycled aggregates. More purchase consideration and increased on-site reuse. A higher standard of supply for secondary and recycled aggregates used in high-value projects. | [13,23,31] |

| Hazardous Waste (England and Wales) Regulations 2005 | Requirement for identification and classification of hazardous waste. Pre-treatment of hazardous waste before landfill, particularly in situ treatment. Company needs to register site with Environment Agency if the activities producing 200 kg or more of hazardous waste per year. | An increase in the cost of hazardous waste disposal from C&D waste. | [13,23,31] |

| Waste Strategy for England 2007 by Defra | A vision to reduce waste production across the supply chain, promote close loop industry through reuse and recycling, and improve economics of reuse and recycling industry. Mission to halve landfilled construction wastes (including excavation component), requirement of construction client to include strategy is contractual for measurement and improvement in construction project in value GBP 1 million by 2009 and achieve waste-neutral construction. | Culture of joint working between government and industry. Client emphasizes enhanced resource efficiency. The market for reclaimed and recycled materials expanded. | [13,23,31] |

| Sustainable Construction Strategy 2007 by BERR | Aim to establish a joint government and industry strategy towards sustainable industry Consultation of the targets for England Waste Strategy. Targets to zero net waste at construction site level by 2015, zero waste to landfill by 2020, and halve onsite construction waste quantity. | Manufacturers consider resource efficiency within lifecycles. Tackle waste through integrated supply chains. Specification of resource efficiency by designers or architects. | [13,23,31] |

| Site Waste Management Plans (SWMPs) | Compulsory from April 2008 for projects over GBP 300,000. | Effective management of on-site waste through appropriate planning and monitoring. Observed ongoing reduction in fly-tipping incidents. | [13,23,31] |

| Code for Sustainable Homes (CSH) | For house builders to meet environmental standards. Rating for all new homes commenced from May 2008. Voluntary codes. | [13,23,31] |

| Technology | Green Roof | Building Integrated Photovoltaic (BIPV) | Ref. |

|---|---|---|---|

| Functionality | Minimize heat flow that enhances indoor thermal comfort, reducing the energy demand for space cooling in a building and achieving energy efficient design. | Develop building surfaces as active solar collectors to supply clean, safe, economical, and decentralized power. | [17,51,52,53,54,55] |

| Types | Extensive green roof Semi-Intensive green roof Intensive green roof | Two major types of solar cells that make up the array of interconnecting cells of BIPV: inorganic silicon semiconductors and inorganic nanocrystalline salts deposited as thin films on a substrate. Various types of building components for BIPV, like roofs, facades, and skylights. | [17,51,52,53,54,55] |

| Example Project | The Solaire, New York Villa Mairea, Finland Monastery of La Tourette, France Rockefeller Center in New York | Terrace in Battery Park City, New York AstroPower’s Headquarters, Newark Delaware The Solaire, New York | [17,51,52,53,54,55] |

| Pros (Main) | Rainfall runoff reduction. Aesthetic benefit. Reduce surface heat flux. | Energy production Weather protection Noise protection Material savings Thermal insulation Daylight modulation | [17,51,52,53,54,55] |

| Cons | Considerable cost to install and maintain the system. | Power efficiency. Design lack of standardization that restricts implementation in few countries. | [17,51,52,53,54,55] |

| Benefit | Description | Ref. |

|---|---|---|

| Environmental Benefit | Act as natural air filtration. Act as carbon sink and oxygen source. Control and reduce sound reflection. Reduce ambient temperature by 0.3–3 degrees C compared to conventional roof. Shield against acid rain and UV rays. | [55,58] |

| Economic Benefit | Reduce energy consumption by shade, insulation, evaporation, and an increase in thermal mass. Enhance the energy efficiency of structures. In response to a rise in temperature, a green roof is less susceptible to contraction than other construction materials. Provide thermal comfort by absorbing shortwave radiation and cooling the ambient temperature, therefore mitigating the urban heat island effect that is prevalent in cities and towns. The thermal insulation provided by a green roof against UV radiation oscillations and diurnal stress extends the roof’s lifespan. | [55,58] |

| Social Benefit | Places for recreation and rest. Great for human health and wellbeing (psychological impact) Enhance living environment. Offer environment for rare or imperiled species. | [55,58] |

| Case Study | Residential Building in Battery Park City, New York. | AstroPower Headquarters—A Solar Cell Manufacturer in Newark, Delaware. | Ref. |

|---|---|---|---|

| BIPV Technology | Front façade equipped with an 11 kW_p BIPV solar system. A total of 11 rows of standard solar modules mounted horizontally and tilted towards the sun in front of the brick façade building. (Passive solar heating.) Semi-transparent canopy PV module at the entrance of the building. Landscaped flat roof. | A 30 kW_p BIP façade covering front face of building. A 310 kW PowerGuard system covering the roof of manufacturing plant of building. Insulated glass PV technology as sunshades in façade that create a large skylight above the entrance of lobby. | [52,54,61] |

| Functionality | BIPV façade supplying 5% of building base electricity consumption. Passive solar system contributes the dominant portion of green power supply for the building. | Supply the total electricity consumption of entire administrative offices. PowerGuard systems provide thermal insulation that help protect roofing membrane from harsh UV radiation. Blue tinted insulation glass window offers optimum light within a working climate. | [52,54,61] |

| Structural design | By using TEDLAR encapsulation technology, the PV laminates made into custom shape to adapt to building dimensions in standard glass. The modules integrated into cassette façade system, which is an external cladding system to provide a skin or layer that eases installation. | BIPV façade constructed from aluminum façade system with custom sized TEDLAR PV laminates (glass) mounted into supporting structure. Ballasted PowerGuard System that enables mechanical attachment to the structure without any penetration, enhancing roof warranties. Integrate the multi-crystalline solar cells into PV modules through glazing technology to form a uniform blue appearance. | [52,54,61] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadibarata, T.; Kristanti, R.A. Urban Sustainability in Construction: A Comparative Review of Waste Management Practices in Developed Nations. Urban Sci. 2025, 9, 217. https://doi.org/10.3390/urbansci9060217

Hadibarata T, Kristanti RA. Urban Sustainability in Construction: A Comparative Review of Waste Management Practices in Developed Nations. Urban Science. 2025; 9(6):217. https://doi.org/10.3390/urbansci9060217

Chicago/Turabian StyleHadibarata, Tony, and Risky Ayu Kristanti. 2025. "Urban Sustainability in Construction: A Comparative Review of Waste Management Practices in Developed Nations" Urban Science 9, no. 6: 217. https://doi.org/10.3390/urbansci9060217

APA StyleHadibarata, T., & Kristanti, R. A. (2025). Urban Sustainability in Construction: A Comparative Review of Waste Management Practices in Developed Nations. Urban Science, 9(6), 217. https://doi.org/10.3390/urbansci9060217