Abstract

The rapid growth of electric vehicle (EV) adoption in Malaysia is projected to generate substantial volumes of end-of-life lithium-ion batteries, creating both environmental challenges and opportunities for repurposing into second-life batteries (SLBs). This study investigates the technical, economic, and regulatory feasibility of deploying SLBs for photovoltaic (PV) energy storage in petrol stations, an application aligned with the nation’s energy transition goals. Laboratory testing of Nissan Leaf ZE0 battery modules over a 120-day operation period demonstrated stable cycling performance with approximately 7% capacity fade, maintaining state-of-health (SOH) above 47%. A case study of a 12 kWp PV–SLB hybrid system for a typical Malaysian petrol station shows 45 kWh of usable storage, capable of offsetting a daily electricity demand of 45 kWh, reducing capital cost by 30–50% compared to new lithium-ion systems, and achieving 70–80% lifecycle CO2 emission reductions. The proposed architecture leverages SLBs’ suitability for slower, steady discharge to provide reliable nighttime operation and grid load relief, particularly in semi-urban and rural stations. Beyond technical validation, the paper evaluates economic benefits, environmental impacts, and Malaysia’s regulatory readiness, identifying gaps in certification standards, reverse logistics, and workforce skills. Strategic recommendations are proposed to enable large-scale SLB deployment and integration into hybrid PV–petrol station systems. Findings indicate that SLBs can serve as a cost-effective, sustainable energy storage solution, supporting Malaysia’s National Energy Transition Roadmap (NETR), advancing circular economy practices, and positioning the country as a potential ASEAN leader in battery repurposing.

1. Introduction

The rapid adoption of electric vehicles (EVs) in Malaysia is generating an increasing volume of end-of-life lithium-ion batteries, which can either pose environmental challenges or serve as a valuable resource for second-life applications. One promising application is the integration of second-life EV batteries (SLBs) with solar photovoltaic (PV) systems to support distributed energy needs at petrol stations. Petrol stations, totaling approximately 3530 outlets nationwide, consume an average of 45 kWh per day per station, creating a substantial cumulative load on Tenaga Nasional Berhad (TNB) and the national grid. The global shift toward electric mobility is accelerating significantly in response to climate change, energy security concerns, and air quality deterioration in urban environments [1]. Electric vehicles (EVs) have become a foundational component in this transition, supported by falling battery prices, policy incentives, and technological advancements. As EV adoption grows, so too does the number of lithium-ion batteries reaching their end of life (EOL) typically when their State of Health (SOH) declines below 70–80% of their initial capacity [2]. While these batteries may no longer be viable for vehicle propulsion, they retain sufficient capacity for lower-demand stationary energy storage applications, presenting a critical opportunity for reuse in the form of second-life batteries (SLBs).

Malaysia, like many countries in Southeast Asia, is at an inflection point. National initiatives such as the Low Carbon Mobility Blueprint 2021–2030, National Energy Transition Roadmap (NETR), and National Automotive Policy (NAP 2020) underscore the government’s commitment to sustainable transportation and grid decarbonization [3]. However, with the projected rise in EVs, the country must prepare for a parallel rise in battery waste and energy storage demand. Rather than relying solely on new batteries which are costly and resource-intensive to manufacture the repurposing of EV batteries presents a low-cost, low-carbon alternative aligned with Malaysia’s sustainability and industrial development goals [4].

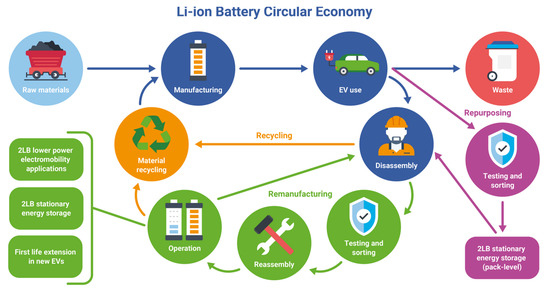

The concept of a circular economy for lithium-ion batteries lies at the heart of this opportunity. As illustrated in Figure 1, the circular battery economy promotes reuse, refurbishment, repurposing, and recycling, prolonging the value chain of EV batteries beyond their automotive life. Second-life applications, such as solar PV integration, off-grid energy storage, and backup systems, not only reduce capital expenditure but also defer the environmental impact associated with recycling or disposal [5]. This approach aligns with broader circular economy principles, enabling a more sustainable, resilient, and inclusive energy ecosystem.

Figure 1.

Li-ion Battery Circular Economy [6].

Malaysia has not provided detailed techno-economic modeling of SLB systems, nor examined the implications of Malaysia’s regulatory framework, climatic conditions, or battery assembly capacity. This paper investigates the technical, economic, regulatory, and industrial dimensions of developing a second-life battery infrastructure in Malaysia. It proposes a comprehensive roadmap for enabling SLB deployment across key sectors, supported by case studies, system designs, life-cycle analysis, and policy recommendations. By leveraging Malaysia’s existing strengths in electronics manufacturing and renewable energy integration, the country can position itself as a regional leader in second-life battery innovation and deployment, turning a future waste stream into a sustainable energy asset. The rest of the paper is structured as follows. Section 2 provides background on global trends and regulatory developments related to second-life battery (SLB) infrastructure, drawing lessons from the European Union, China, and the United States. Section 3 discusses the current state of Malaysia’s EV and battery ecosystem, covering adoption rates, projected volumes of end-of-life batteries, and national readiness. Section 4 outlines the technical considerations for SLB deployment, while Section 5 introduces the proposed SLB–PV hybrid architecture designed for the operational requirements of petrol stations. Section 6 evaluates the economic and environmental benefits of SLB integration, and Section 7 analyzes Malaysia’s policy and regulatory framework, highlighting gaps and proposing actionable instruments for effective implementation. Section 8 identifies the major challenges and provides strategic recommendations with clearly defined roles and timelines. Finally, Section 9 concludes the study by summarizing the key findings and emphasizing Malaysia’s opportunity to position itself as a regional leader in sustainable battery reuse across ASEAN.

2. Background and Global Context

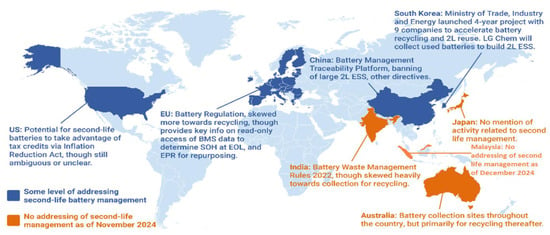

The global transition to electric mobility is accelerating, driven by the urgent need to decarbonize transportation systems and mitigate climate change. As electric vehicles (EVs) proliferate, the challenge of managing their end-of-life (EOL) lithium-ion batteries has emerged as a critical concern. Typically, EV batteries are deemed no longer suitable for vehicular use once their state-of-health (SoH) declines below 70–80% of their original capacity. However, these batteries often retain substantial usable capacity, rendering them viable for repurposing in stationary energy storage systems (ESS). Such second-life applications extend the operational lifespan of EV batteries, contribute to circular economy goals, reduce electronic waste, and provide cost-effective energy storage for renewable energy integration and grid support [7]. Globally, several countries have taken the lead in developing second-life battery (SLB) ecosystems. China is currently at the forefront, enabled by comprehensive government policies, a robust EV market, and advanced industrial capacity [8]. The “Interim Provisions on the Management of Power Battery Recycling for New Energy Vehicles” mandate full traceability of EV batteries, enabling repurposing initiatives by major companies such as CATL and BYD [9]. These firms are deploying SLBs in applications ranging from telecommunications backup systems and residential solar buffering to public transportation fleets, using real-time cloud-based BMS platforms. To visualize global trends, Figure 2 presents an overview of legislative activity related to second-life EV batteries by region. It highlights the geographic variation in regulatory maturity and deployment strategies.

Figure 2.

Second-Life EV Battery Legislative Activity by Region [6].

By contrast, the United States adopts an innovation-driven approach, with the SLB market shaped by pilot projects, academic-industry partnerships, and utility-led trials. For example, Nissan’s 4R Energy has deployed second-life batteries in grid-support and emergency power systems, while the U.S. Department of Energy (DOE) funds research into SoH estimation tools, safety protocols, and system integration standards [10]. The European Union (EU) focuses on regulatory standardization and sustainability. The recently revised EU Battery Regulation mandates SoH disclosure, labeling of reused batteries, and performance verification [11]. Collaborative programs such as ReLIB (Recycling and Reuse of Lithium-Ion Batteries) and EUCAR have been established to develop modular SLB applications for commercial and residential energy storage. Countries like Germany, with high levels of renewable energy penetration, have actively deployed SLBs into decentralized solar and wind networks to stabilize the grid.

From a technical perspective, the worldwide deployment of SLB systems has driven innovations in battery management systems (BMS), state-of-health (SoH) and remaining useful life (RUL) estimation, and power electronics. These technologies facilitate the safe reuse of heterogeneous battery modules, which often vary significantly in terms of chemistry (e.g., NMC, LFP), capacity, and degradation behavior. The integration of AI and machine learning into BMS platforms has enhanced predictive accuracy and remote diagnostics, allowing scalable deployment across both grid-tied and off-grid applications. Economically, second-life batteries offer considerable advantages over new lithium-ion storage systems. Capital expenditures for SLB-based stationary storage can be reduced by up to 40%, while life-cycle assessments suggest a 30–50% lower environmental footprint compared to direct recycling. This is largely attributed to avoided resource extraction and deferred recycling processes, particularly for critical materials such as lithium, cobalt, and nickel. Table 1 summarizes the comparative development status of SLB frameworks across major global regions, including China, the EU, the U.S., Japan, South Korea, and Malaysia.

Table 1.

Global Comparison of Second-Life Battery Development [12].

For Malaysia, these global trends offer a strategic framework to develop a localized SLB ecosystem. With EV adoption projected to increase in line with the Low Carbon Mobility Blueprint 2021–2030 and the National Energy Transition Roadmap (NETR), Malaysia has the opportunity to leverage second-life batteries for rural electrification, renewable energy buffering, and microgrid applications [2]. Local strategies must account for distinct conditions, including Malaysia’s tropical climate, diverse grid accessibility, and growing solar PV deployment [13]. By learning from mature international models and prioritizing early investments in SLB standards, diagnostics, and reuse infrastructure, Malaysia can position itself as a regional leader in second-life battery innovation, enhancing energy resilience, environmental stewardship, and economic competitiveness.

3. Current State of EV and Battery Ecosystem in Malaysia

Malaysia’s electric vehicle (EV) and battery ecosystem is undergoing a dynamic early-stage expansion, guided by key national frameworks such as the Low Carbon Mobility Blueprint 2021–2030, the National Energy Transition Roadmap (NETR), and the National Automotive Policy (NAP 2020) [13]. These strategies aim to increase EV adoption, reduce carbon emissions associated with transportation, and localize high-value activities in the energy storage and battery manufacturing supply chain.

Electric vehicle (EV) adoption in Malaysia has experienced substantial growth in recent years. According to the Malaysian Automotive Association (MAA), battery electric vehicle (BEV) sales surged by 286% in 2023, reaching 10,159 units, compared to just 2631 units in 2022. Similarly, hybrid vehicle sales increased by 40%, from approximately 20,000 units in 2022 to around 28,000 in 2023. Despite EVs comprising less than 1% of the total vehicle stock, the government has set an ambitious target of achieving 800,000 cumulative EVs on the road by 2030, supported by plans to install 10,000 public charging stations. These trends are reflected in Table 2, which summarizes key performance indicators in the Malaysian EV and battery landscape.

Table 2.

EV and Battery Ecosystem in Malaysia [14].

Alongside increasing EV adoption, Malaysia faces an emerging challenge: the accumulation of end-of-life (EOL) lithium-ion batteries [15]. With an average EV battery lifespan of 8–10 years, the volume of EOL batteries is expected to grow substantially over the next two decades. Based on projections by the Malaysia Automotive, Robotics and IoT Institute (MARii), approximately 40,000 depleted EV batteries will require processing by 2030, increasing to 330,000 by 2040, and reaching 870,000 by 2050 [14]. This underscores the urgency of establishing national infrastructure for battery collection, diagnostics, repurposing, and recycling. The estimated cumulative volume of depleted batteries, shown in Table 3, provides a clear timeline indicating when Malaysia must scale its second-life battery (SLB) infrastructure to prevent waste and capture circular economy value.

Table 3.

Projected Cumulative Depleted EV Batteries in Malaysia [14].

Malaysia’s battery infrastructure is currently limited to pack-level assembly and system integration, with no full-cycle cell manufacturing or industrial-scale recycling operations. However, the country possesses latent strengths in electronics manufacturing, logistics, and power electronics, making it a strong candidate for regional leadership in SLB repurposing and export [3]. Malaysia’s ports (e.g., Port Klang, Penang, Johor) and free trade access to ASEAN markets provide a unique opportunity to position itself as a hub for battery logistics and second-life system integration. This could include exporting SLB-powered microgrid solutions, telecom energy systems, and modular solar + battery kits to neighboring countries such as Indonesia, Laos, Myanmar, and Cambodia. In summary, while Malaysia’s EV and battery ecosystem is still maturing, the convergence of policy support, market growth, and industrial capability presents a timely opportunity to build a second-life battery economy that is both technically viable and economically strategic. Table 4 shows the research gaps with solutions on Repurposing EV Batteries for PV Energy Storage in Malaysia.

Table 4.

Research Gap on Repurposing EV Batteries for PV Energy Storage in Malaysia.

4. Technical Considerations for Second-Life Batteries and Infrastructure Requirements

The deployment of second-life electric vehicle (EV) batteries in Malaysia necessitates a multidisciplinary approach encompassing battery diagnostics, electrical integration, system architecture, and lifecycle management. Second-life battery (SLB) applications are fundamentally different from their first-use environments, demanding tailored technical infrastructure to ensure performance, safety, and economic viability. The following outlines the key technical considerations and infrastructure requirements to enable large-scale SLB deployment in Malaysia’s energy and transport ecosystems.

4.1. Battery Diagnostics and State of Health (SOH) Assessment

Battery Accurately assessing the State of Health (SOH) is the foundational step in determining the usability of SLBs. Unlike new batteries, SLBs exhibit varying levels of degradation influenced by operating temperature, charge/discharge cycles, depth of discharge, and cell balancing history [16]. The standard SOH is calculated as

where is the battery’s capacity at time , is the original nominal capacity.

Another critical performance parameter is capacity fade, which can be quantified as:

where is the remaining capacity, is the initial capacity at the start of the battery’s life, is the capacity fade due to aging and degradation, which can be a function of cycle count, temperature, and other environmental factors.

Additionally, the measurement of internal resistance is essential, as an increase in resistance reduces the battery’s efficiency and generates excess heat during operation. The internal resistance can be modeled using the following equation:

where is the power lost as heat due to internal resistance, is the current flowing through the battery, is the internal resistance, which increases with battery aging and usage.

Malaysia’s proposed SLB testing centers must be equipped with electrochemical impedance spectroscopy (EIS), ultrasound diagnostics, and machine learning (ML)-based SOH prediction models to efficiently triage batteries. Table 5 shows the Common Diagnostic Methods for SOH Assessment.

Table 5.

Common Diagnostic Methods for SOH Assessment.

4.2. Standardization and Modular Architecture

A major technical challenge confronting Malaysia’s second-life battery (SLB) sector is the lack of standardization in EV battery design [3]. Battery packs vary widely depending on the original equipment manufacturer (OEM), with differences in cell chemistry, voltage levels, communication protocols, mechanical dimensions, and thermal control strategies [17]. These variations make it technically complex to repurpose used batteries into consistent and scalable second-life energy storage systems. For example, while Nissan Leaf batteries typically use a prismatic format with a 360 V nominal voltage and lithium manganese oxide chemistry, Tesla models incorporate cylindrical nickel-cobalt-aluminum oxide (NCA) cells operating at 350–400 V, while Chinese manufacturers like BYD often use LFP cells with lower voltage profiles. This heterogeneity complicates the design of modular, interoperable systems suitable for Malaysia’s solar PV, telecom, or rural electrification use cases [24].

To overcome this challenge, second-life battery modules must be decoupled from original packs, re-tested, and reassembled into standardized enclosures. These enclosures should follow uniform physical and electrical specifications, including voltage, form factor, and thermal properties. Moreover, Malaysia ought to adopt open-source Battery Management System (BMS) architectures capable of supporting heterogeneous battery chemistries, enabling real-time balancing, safe cutoff control, and thermal monitoring across diverse SLB arrays. A national SLB module standard led by SIRIM, the Energy Commission, and key automotive stakeholders should be introduced to define unified connector types, voltage ratings, enclosure dimensions, and communication protocols to ensure plug-and-play compatibility.

Malaysia’s mature electronics manufacturing ecosystem, particularly in Penang, Selangor, and Johor, offers the capability to mass produce modular BMS controllers, standardized enclosures, and SLB retrofitting kits. These components are essential for scaling second-life battery use in microgrids, petrol station systems, and off-grid telecom towers. Table 6 below compares the key technical characteristics of common EV battery types in Malaysia, highlighting the importance of convergence toward a unified second-life system standard. Technical Variation in Common EV Battery Packs in Malaysia is shown in Table 6.

Table 6.

Technical Variation in Common EV Battery Packs in Malaysia [25].

The variety in voltage levels, thermal interfaces, and communication protocols among major EVs necessitates hardware and software abstraction layers in second-life applications. The development and local manufacturing of standardized SLB module kits will be critical to Malaysia’s ability to deploy energy storage systems at scale across rural, commercial, and industrial applications.

4.3. Power Electronics and Grid Integration

In both grid-connected and off-grid applications, second-life battery (SLB) systems require a robust suite of power electronics to ensure safe, stable, and efficient operation [18]. These include inverters to convert DC energy from SLBs into grid-compliant AC for utility or local use; DC/DC converters that regulate voltage levels across variable load profiles and maintain compatibility with hybrid solar photovoltaic (PV) systems; hybrid controllers that orchestrate the interaction between SLBs, PV arrays, diesel generators, and the utility grid; and protection circuits equipped with sensors to monitor and mitigate risks such as overcurrent, overvoltage, short circuits, and thermal overload. These power interfaces not only improve system reliability but also allow dynamic energy balancing, load prioritization, and fault tolerance in hybrid renewable systems. Malaysia’s well-established solar energy sector featuring players like Solarvest, Plus Xnergy, and GSPARX—offers a strong foundation for localizing the design and manufacture of these components. This is particularly important for SLB deployment in community microgrids in rural Sabah and Sarawak, off-grid telecom towers, and commercial battery energy storage systems (BESS) for peak shaving and time-of-use optimization [26]. The integration of SLBs with adaptable power electronics will play a central role in enabling scalable, modular energy solutions that align with Malaysia’s distributed energy and rural electrification goals, as illustrated in Table 7.

Table 7.

Power Electronics for SLB Applications.

4.4. Thermal Management and Climate Adaptation

Malaysia’s tropical climate, characterized by consistently elevated ambient temperatures ranging from 25 °C to 40 °C, presents a significant challenge to the longevity, reliability, and safety of second-life battery (SLB) systems [3]. Elevated temperatures accelerate electrochemical degradation, reduce state-of-health (SOH), and increase the risk of thermal runaway, particularly in SLBs with inconsistent cell conditions or impaired cooling from their first life. Effective thermal management in this context must balance energy efficiency, cost-effectiveness, and operational safety [27]. In many applications, especially rural or off-grid systems, passive thermal strategies are preferred due to their low maintenance and power requirements [13]. These include aluminum heat sinks, ventilated enclosure designs, and thermal insulation materials to buffer ambient heat and improve dissipation. For high-load environments or regions with elevated temperatures, active cooling strategies such as low-power forced-air fans, phase-change material (PCM)-based systems, or hybrid cooling triggers are recommended, activating when preset thermal thresholds are exceeded. Additionally, IoT-enabled thermal monitoring should be incorporated for real-time temperature sensing, with automatic load reduction or disconnection protocols in case of overheating. Phase Change Materials (PCMs) provide effective thermal management in tropical climates by absorbing heat during the day and releasing it at night, reducing cooling loads and improving indoor comfort. Case studies in Singapore show that PCM-enhanced walls and building envelopes lower energy consumption year-round. In Thailand, PCM integration with air conditioning systems increases efficiency, reduces costs, and promotes healthier indoor environments [28]. Overall, PCMs offer a practical, energy-efficient solution for sustainable building design in hot and humid regions. In addition to PCM-based thermal management, advanced photovoltaic (PV) technologies, such as semi-transparent perovskite solar cells (ST-PSCs), can further enhance system performance by simultaneously generating electricity and mitigating heat. Studies on PV system design for urban petrol stations provide practical strategies for deployment and integration [29,30].

In the proposed SLB system, thermal management is achieved through passive cooling using heat sinks and ventilated enclosures, supplemented by real-time temperature monitoring at the cell, module, and enclosure levels. Temperature data were recorded at one-minute intervals during charge/discharge cycling and under worst-case ambient conditions of 40 °C. The maximum observed module temperature remained within manufacturer-specified limits, with a calculated thermal margin of approximately 10–12 °C, demonstrating a sufficient safety buffer against thermal runaway. A simplified lumped-capacitance thermal model further validated that even under continuous high-power operation, module temperatures remain within safe limits. To mitigate risks associated with cell mismatch and thermal propagation, modules were pre-characterized for capacity and internal resistance variations, and enclosures were compartmentalized to isolate potential failures. Fire-retardant materials compliant with UL94 V-0 rating and venting pathways for hot gases are incorporated, with additional fire-suppression strategies recommended for operational deployment. The system design is consistent with IEC 62619 and UL1973 standards, and all thermal, overcurrent, and enclosure safety measures are either tested or planned for verification against these standards. Table 8 presents thermal management strategies for SLB deployment in Malaysia.

Table 8.

Thermal Management Strategies for SLB Deployment in Malaysia.

4.5. Safety, Compliance, and Certification

Second-life batteries (SLBs) intrinsically pose latent safety risks owing to their previous deployment in electric vehicles, which may result in internal shorts, degraded or unstable cells, compromised thermal integrity, and potential fire hazards. To ensure reliable and safe operation, SLB systems should integrate a combination of active and passive safety mechanisms. These include real-time Battery Management System (BMS)-controlled disconnection mechanisms to isolate faulty modules, voltage and temperature fail-safes that prevent overcharge or thermal stress, modular fault isolation techniques to contain localized failures, and advanced thermal runaway detection algorithms. To facilitate safe SLB deployment and cultivate public and commercial confidence, Malaysia must adopt and harmonize its regulatory framework with globally recognized battery safety standards, such as IEC 62619 for Li-ion cell safety in industrial use, UL 1973 for stationary battery system certification, and ISO 26262 for functional safety in automotive electronics [25]. Establishing a dedicated national SLB certification and testing laboratory, potentially hosted at SIRIM or Universiti Teknologi Malaysia (UTM), is essential for certifying repurposed batteries for domestic use and export within ASEAN and beyond. Such an initiative would also help position Malaysia as a regional leader in battery reuse standards and compliance technologies. Key safety standards for SLB certification are summarized in Table 9.

Table 9.

Key Safety Standards for SLB Certification.

4.6. Digital Infrastructure: Monitoring, Control, and Traceability

With the increasing deployment of second-life batteries (SLBs) across grid-connected and remote energy systems, the need for robust digital infrastructure becomes essential for ensuring lifecycle visibility, operational safety, and regulatory compliance. Digitization enables SLBs to be continuously monitored, intelligently managed, and traceable from reuse to recycling. Core components include smart Battery Management Systems (BMS) capable of real-time logging of key metrics such as State of Health (SOH), State of Charge (SOC), voltage, and temperature, ensuring early detection of faults and degradation [2]. These systems are complemented by cloud-based analytics platforms that consolidate performance data from multiple SLB units, supporting predictive maintenance, Remaining Useful Life (RUL) estimation, and operational optimization across distributed energy networks. Additionally, blockchain or distributed ledger technologies can be employed to provide tamper-proof records of each battery’s reuse cycle, ownership transfers, warranty status, and recycling eligibility especially critical in multi-party supply chains. As SLBs evolve into networked energy assets, cybersecurity and data governance become imperative. Malaysia must enforce standards for end-to-end data encryption, secure edge-layer firmware on BMS controllers, and transparent data ownership policies, particularly for systems deployed in public utilities, telecom, and fleet sectors. With the national expansion of 5G, IoT, and smart grid platforms, Malaysia is well-positioned to pioneer secure SLB telemetry architectures that support urban energy resilience, rural electrification, and ASEAN-wide SLB trade. Digital Infrastructure Components for SLB Systems is shown in Table 10.

Table 10.

Digital Infrastructure Components for SLB Systems.

4.7. Infrastructure and Ecosystem Development for Scalable SLB Deployment

The effective nationwide deployment of second-life battery (SLB) systems in Malaysia necessitates strategic alignment with the nation’s industrial geography, technical competencies, and regional energy demands. A decentralized yet coordinated infrastructure is essential to manage the entire SLB lifecycle from collection and testing to integration and deployment [3]. State-of-Health (SOH) testing and refurbishment centers should be established in key industrial hubs such as Selangor, Penang, and Johor, leveraging existing electronics manufacturing clusters and logistics networks. In contrast, deployment zones should focus on underserved and energy-insecure regions such as rural Sabah, Sarawak, and Orang Asli communities, where SLB-based microgrids can have the greatest socio-economic impact. The local assembly of modular SLBs, inverters, and thermal enclosures can be efficiently supported through Penang’s well-established EMS (Electronics Manufacturing Services) ecosystem, which is already equipped for small-batch, high-value electronic production. Furthermore, national skill development must be prioritized through the establishment of technical training and certification programs at institutions such as UNITEN, Universiti Teknologi Malaysia (UTM), and MARA colleges, focusing on battery diagnostics, repurposing, and safe deployment. Malaysia’s second-life battery ecosystem must address the full lifecycle from diagnostics to repurposing and real-time control. Strategic deployment of SOH testing, modular standards, climate-adapted enclosures, and secure BMS-cloud platforms will enable scalable, export-ready SLB applications. These efforts directly support Malaysia’s goals in energy resilience, grid decentralization, and regional leadership in sustainable technologies. By institutionalizing technical excellence in SLB reuse, Malaysia can unlock long-term economic, environmental, and industrial benefits.

5. SLB–PV Hybrid Architecture Design for Petrol Station

Petrol stations in Malaysia, totaling approximately 3530 outlets, typically consume around 45 kWh per day each, equivalent to an average continuous demand of about 1.9 kW, to power fuel pumps, lighting, air conditioning, refrigeration, signage, and air compressor systems. Extrapolating this average, the national total daily electricity consumption is estimated at 158,850 kWh, placing a substantial demand on Tenaga Nasional Berhad (TNB) and the national grid. Integrating solar photovoltaic (PV) systems with second-life electric vehicle (EV) batteries (SLBs) can significantly enhance energy resilience and reduce operational costs. Solar panels generate clean, renewable electricity during daylight hours, while SLBs provide cost-effective energy storage to supply power during peak hours or nighttime, mitigating reliance on TNB electricity and buffering against rising energy tariffs. The integration of second-life electric vehicle (EV) batteries (SLBs) with solar photovoltaic (PV) systems offers a cost-effective, sustainable energy solution for powering petrol station infrastructure in Malaysia. Given the country’s high solar irradiance (4.5–5.0 kWh/m2/day) and consistent tropical temperatures (25–40 °C), SLB-PV hybrid systems are well-suited for remote and semi-urban petrol stations that face unreliable grid access or seek operational energy cost reduction. A typical mid-sized petrol station consumes approximately 45 kWh per day, distributed across core functions such as fuel pump operation, LED lighting, refrigeration, signage, and air compressor systems. The breakdown of daily energy consumption is detailed in Table 11.

Table 11.

Daily energy usage for Petrol Pump.

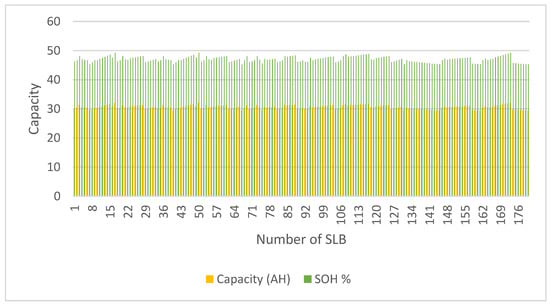

To meet this demand, a 12 kWp rooftop solar PV array consisting of 27 panels rated at 450 W each can generate sufficient daily energy under average conditions. This is coupled with a battery energy storage system (BESS) made from repurposed EV batteries to store excess solar power for nighttime or cloudy-day use. Using Nissan Leaf ZE0 battery modules, which offer 65 Ah nominal capacity at 7.6 V nominal voltage, and calculating an average State of Health (SoH) of 51.13%, a total of approximately 180 modules are required to provide a 45 kWh usable energy reserve, as calculated below:

where 33.24 Ah represents the average battery capacity at time , measured using the Arbin Battery Tester as described in [16].

The Average SOH is

Putting the value in Equation (4),

A total of 180 Nissan Leaf ZE0 modules (7.6 V, 65 Ah) were sourced from six decommissioned vehicles (2013–2016 models, 80,000–120,000 km, 7–9 years old). Defective modules (swelling, leakage, cracks) were excluded after initial open-circuit voltage and capacity screening. Laboratory tests were conducted at 25 ± 2 °C using an Arbin BT2000 Battery Tester, with surface temperatures monitored by thermocouples. Each module was cycled for 120 days (120 cycles) under a constant-current, constant-voltage (CC–CV) protocol: charge at 0.5 C (≈32.5 A) to 8.4 V (cutoff at 0.05 C), discharge at 0.5 C to 6.0 V, with 30 min rest between phases. Electrochemical impedance spectroscopy (EIS) was performed before and after cycling (Gamry Reference 3000, 10 mHz–100 kHz, 10 mV perturbation).

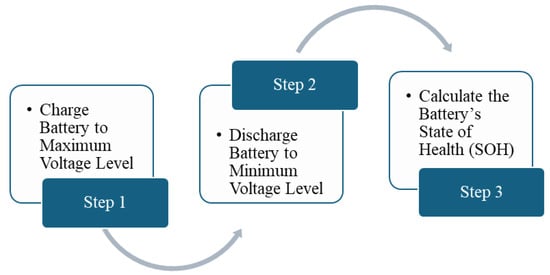

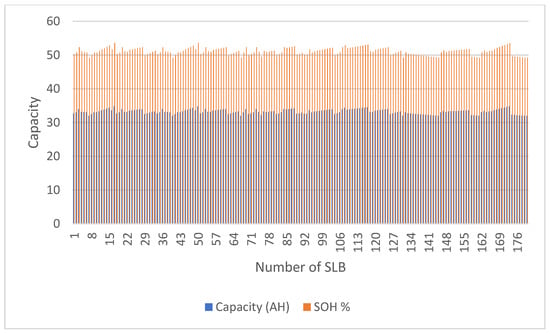

Figure 3 illustrates the sequential steps involved in measuring the State of Health (SOH) of batteries. These steps are intricately connected, as both SOH and capacity metrics work together to provide a comprehensive understanding of battery performance, enabling effective management and insightful analysis throughout the battery’s lifecycle. Figure 4 shows Capacity test for SLB’s Nissan Leaf ZE0 battery with a fleet of 180 using the ARBIN Battery Tester. As SOH declines, available capacity reduces proportionally, emphasizing the importance of accurate SOH diagnostics in determining second-life viability.

Figure 3.

Step for state of health (SOH) measurement.

Figure 4.

Capacity test for SLB’s Nissan Leaf ZE0 battery with a fleet of 180.

This ensures adequate energy storage for nighttime operations and load peaks. The PV array sizing is calculated using:

Putting the Value in Equation (5),

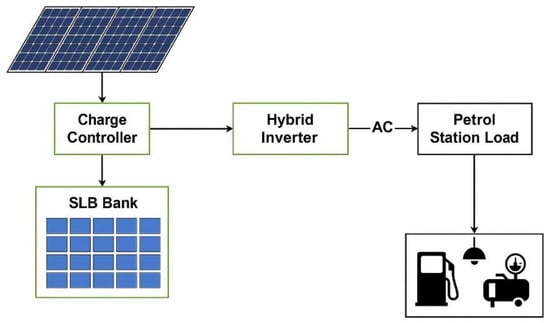

This system integrates hybrid inverters (10–15 kW), MPPT charge controllers, and a modular control interface to enable seamless operation across solar, second-life battery (SLB), and grid sources. The SLB modules are passively cooled using heat sinks and ventilated enclosures, while an IoT-based battery management system (BMS) provides real-time monitoring of performance and thermal conditions. This configuration enhances energy resilience for rural or semi-urban petrol stations, particularly in regions such as Sabah, Sarawak, or underserved areas in Peninsular Malaysia, as illustrated in Figure 5.

Figure 5.

System Architecture of SLB–PV Hybrid Petrol Station.

The 150 V system consists of 180 Nissan Leaf ZE0 modules, arranged in 20 modules per series string and 9 parallel strings, yielding a nominal voltage of 152 V and an approximate capacity of 585 Ah. Module-level monitoring via a CAN-based BMS tracks voltage, state-of-charge, and temperature, while fuses and DC isolators ensure operational safety. Passive or active balancing maintains uniform module performance, and the multi-string layout directly interfaces with the hybrid inverter (10–15 kW, MPPT 150–600 V), with DC-DC converters optionally employed for voltage adjustment. Table 12 shows the System Components Overview.

Table 12.

System Components Overview.

Over a 120-day testing period, second-life battery (SLB) modules were evaluated in the laboratory using the ARBIN Battery Tester to simulate operational conditions of a petrol station PV–SLB hybrid system. The results showed an approximate 7% reduction in capacity, corresponding to a decline in State of Health (SOH) from 51% to around 47%. Despite this degradation, the batteries maintained stable voltage profiles and reliable cycling performance without abnormal thermal behavior. In the petrol pump scenario, where daily energy demand is approximately 45 kWh, the tested SLB system continued to deliver sufficient usable storage capacity to meet operational loads. These results highlight that although SOH gradually decreases, SLBs remain technically viable for petrol station applications when integrated with proper battery management systems (BMS), thermal controls, and periodic diagnostics. Figure 6 shows the capacity test results for SLBs after 120 days of operation.

Figure 6.

Capacity test for SLBs after 120 days of operation.

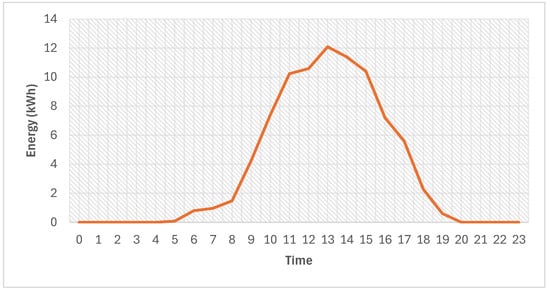

At the SLB-powered petrol station, solar PV peaks around midday (11–12 kWh), as shown in Figure 7, but evening demand arrives after sunlight fades. Second-life batteries bridge this gap by storing surplus daytime energy for later use. Seasonal patterns shape performance output dips in the monsoon months of November–January due to clouds and rain, while March–April and July–August bring clearer skies and higher generation, ensuring steady, green charging year-round.

Figure 7.

Average hourly PV energy production across a day.

Malaysia’s expanding solar industry, strengthened by local pioneers such as Solarvest and Plus Xnergy, provides a strong foundation for sourcing photovoltaic modules, hybrid inverters, and advanced control systems domestically. Complementing this, established electronics manufacturing hubs in Penang and Selangor offer the technical capacity for integrating and assembling second-life battery (SLB) modules, battery management systems (BMS), and enclosure units at scale. When deployed in semi-urban and rural petrol stations, PV–SLB hybrid systems deliver more than just reliable power; they foster local energy autonomy, reduce dependence on diesel generators, and strengthen national resilience against grid vulnerabilities.

Framed within the broader urban energy transition, this approach exemplifies how circular economy practices and renewable energy integration can reshape critical urban infrastructure. By extending the useful life of EV batteries, hybrid PV–SLB systems provide a cost-effective and environmentally responsible pathway for ensuring resilient energy access across diverse geographies. More importantly, they enable petrol stations as pivotal nodes in both urban and peri-urban mobility networks to evolve into sustainable, decentralized energy hubs. In doing so, Malaysia positions itself at the forefront of a just and inclusive transition, aligning local innovation with national decarbonization goals while advancing the resilience of urban energy systems.

6. Economic and Environmental Benefits of Integrating SLBs

The integration of second-life batteries (SLBs) presents a significantly lower capital and lifecycle expenditure compared to new lithium-ion battery energy storage systems. While the average cost of new systems typically ranges between USD 250–350/kWh, repurposed SLBs can reduce this figure by 30–60%, resulting in system-level costs of approximately USD 100–180/kWh, depending on the application and repurposing process [20]. This cost reduction makes SLBs particularly attractive for applications that do not demand high energy density or extended cycle life, such as solar microgrids, rural telecom backup systems, and hybrid petrol stations. By lowering the financial barrier to energy storage deployment, SLBs enable wider adoption of renewable energy and decentralized power solutions.

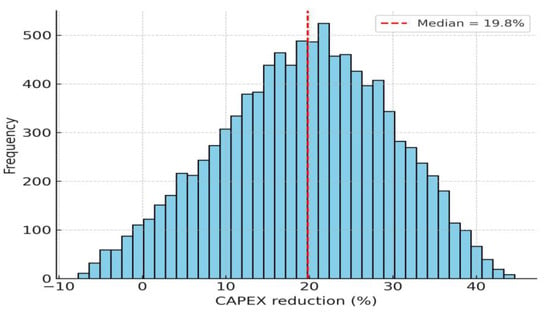

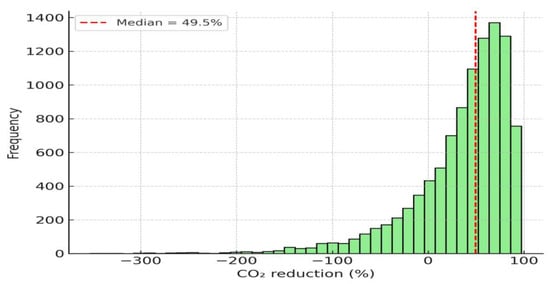

To account for variability, a Monte Carlo sensitivity analysis (10,000 iterations) was performed, with results shown in Figure 8. The distribution indicates that SLBs achieve a median capital expenditure (CAPEX) reduction of 19.8%, with an interquartile range of 12–28% and a broader 5th–95th percentile interval of 2–36%. Although slightly below the 30–50% savings commonly reported in earlier studies, higher reductions remain achievable in scenarios where new battery pack prices are elevated and repurposing costs minimized. Overall, SLBs provide a robust pathway to reducing upfront costs and improving the economic feasibility of small- and medium-scale PV–battery systems in Malaysia and similar contexts.

Figure 8.

Distribution of CAPEX reduction (%) when using SLB vs. new batteries.

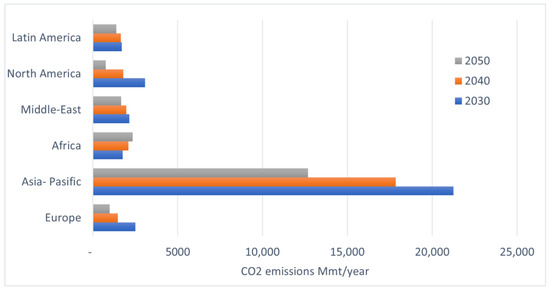

In parallel, SLBs deliver substantial lifecycle environmental benefits by extending the usable lifespan of existing EV batteries and delaying recycling or disposal. Manufacturing a new lithium-ion battery emits 70–200 kg CO2-eq/kWh, whereas repurposing batteries for second-life use requires only 5–60 kg CO2-eq/kWh, corresponding to a 70–80% reduction in lifecycle emissions [31]. Environmental performance, however, depends on the chosen LCA allocation method. Original manufacturing emissions are distributed across both automotive and stationary use phases. Under this conservative approach, benefits vary widely and may be modest or even negative if the second-life system delivers relatively little additional throughput. This optimistic approach assumes that using SLBs avoids production of equivalent new batteries for stationary storage, with only repurposing emissions added. In Figure 9 Monte Carlo results show median lifecycle CO2 reductions of 74%, with a 5th–95th percentile range of 48–94%, consistent with the majority of published SLB LCA studies.

Figure 9.

Distribution of lifecycle CO2 reduction.

From an environmental standpoint, SLBs play a pivotal role in waste minimization and carbon footprint reduction. Extending battery life delays entry into energy-intensive recycling or disposal streams, mitigating premature e-waste generation. These environmental savings are particularly relevant in Malaysia, where large-scale cell manufacturing is limited and most batteries are imported with high embedded carbon

A unique advantage of SLBs in petrol station applications is their ability to provide slower-power charging support. Unlike high-performance EV batteries that are optimized for fast charging and high cycle life, SLBs due to their reduced energy density and cycle limitations are best suited for slower, steady discharge profiles. Petrol stations can strategically use SLBs to buffer solar PV generation during the day and supply evening or overnight slow charging for EVs, reducing strain on the national grid. This approach not only maximizes the remaining useful life of repurposed batteries but also ensures cost-effective, reliable, and safe operation. For stations located in semi-urban or rural areas, slower SLB-powered charging aligns well with user demand patterns, where charging times are less critical compared to urban fast-charging hubs.

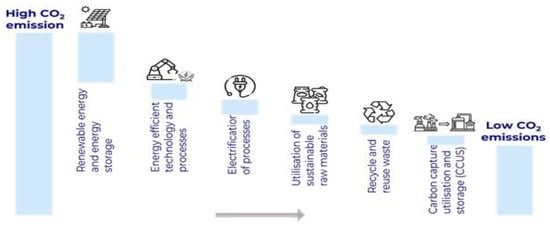

Figure 10 illustrates global projections of CO2 emissions from battery manufacturing between 2030 and 2050, underscoring the urgency of adopting circular battery pathways to avoid escalating emissions [32]. In line with the national Push for Net Zero mission, SLB deployment contributes to Malaysia’s decarbonization strategy by complementing renewable energy integration, waste management practices, and efficiency measures [33]. Figure 11 further outlines the transition pathway from conventional high-carbon battery production toward low-emission reuse and circular economy models, positioning SLBs as a cornerstone in the country’s green industrial transition [31].

Figure 10.

CO2 emissions forecast worldwide from 2030 to 2050.

Figure 11.

Decarbonization Pathway from High to Low CO2 Emissions.

Beyond cost and carbon benefits, SLBs generate multi-tiered sustainability impacts. Figure 12 highlights their broader contributions: enhancing resource efficiency, lowering lifecycle emissions, and aligning with Malaysia’s low-carbon development targets at the national level. For the EV industry, SLB adoption ensures long-term sustainability by addressing end-of-life battery waste through reuse and repurposing. For academia, it creates fertile ground for advancing research in repurposing techniques, thermal management, and energy optimization. Finally, on a societal scale, SLB-powered systems can extend clean, reliable, and affordable electricity access to rural and underserved communities, thereby improving quality of life while strengthening the resilience of local energy systems.

Figure 12.

The multi-tiered sustainability benefits of SLBs.

7. Policy and Regulatory Framework for Urban PV–SLB Hybrid Systems

The deployment of second-life EV batteries (SLBs) for PV–SLB hybrid petrol stations in Malaysia requires a coherent regulatory framework that ensures safety, reliability, and alignment with the country’s urban energy transition goals. While current initiatives such as the National Energy Transition Roadmap (NETR) and the National Automotive Policy (NAP 2020) outline broad support for EV adoption and renewable integration, they lack explicit provisions for second-life battery reuse, certification, and hybrid PV–SLB deployment in urban infrastructure [3]. Addressing this gap is essential to scale SLB-powered energy storage in petrol stations, which form critical nodes in Malaysia’s urban energy landscape.

7.1. Regulatory Gaps and Global Alignment

Malaysia’s current regulatory framework for batteries primarily addresses waste management, electrical safety, and hazardous material handling under instruments such as the Environmental Quality Act 1974 and general SIRIM standards [34]. However, there are no dedicated mechanisms for evaluating, certifying, or monitoring second-life batteries (SLBs) across sectors such as energy storage, telecom infrastructure, or off-grid microgrids. This regulatory gap creates uncertainty for investors, manufacturers, and energy operators, and may pose environmental or safety risks if SLBs are improperly handled.

In contrast, international markets are rapidly advancing SLB regulation. The European Union’s Battery Regulation (EU) 2023/1542 mandates second-life traceability, minimum performance requirements, and recyclability benchmarks [21]. China enforces strict producer responsibility requirements and has developed national platforms for battery data tracking under the Ministry of Industry and Information Technology (MIIT) [22]. In the United States, pilot projects funded by the Department of Energy (DOE) and supported by UL standards are promoting SLB deployment with specific testing protocols and performance metrics [35].

To align with these global best practices, Malaysia can adopt measures such as digital battery passports, standardized State of Health (SOH) thresholds for second-life eligibility, mandatory SLB testing through accredited laboratories, and cross-sector producer responsibility mandates [3]. Establishing clear criteria for SLB classification, testing, and reuse will enhance investor confidence, support system integrators, and ensure safe integration of SLBs into urban petrol stations, while enabling compatibility with international markets.

7.2. Proposed Policy Instruments for Malaysia

To develop a comprehensive SLB ecosystem, Malaysia should deploy a suite of policy instruments designed to address technical, industrial, and environmental priorities. First, a dedicated SLB regulatory framework should be introduced, covering classification, safety testing, reuse certification, and lifecycle reporting. This framework should be formulated in partnership with SIRIM, the Energy Commission, and the Department of Environment. Second, the government should mandate reverse logistics and battery collection schemes through which EV dealerships and importers are responsible for channeling used batteries to licensed facilities for testing and repurposing. Third, green public procurement policies can incentivize demand by requiring SLB-based systems in government solar or backup energy projects. These can be supported by tax incentives, subsidies, or carbon credits for early adopters. In addition, R&D grants and industrial funding mechanisms should be allocated to support local assembly of modular SLB systems, BMS units, and standardized enclosures especially within high-tech zones in Penang, Selangor, and Johor. Lastly, Malaysia should actively engage with international standards bodies (ISO, IEC) and regional platforms such as ASEAN to help shape and adopt harmonized SLB standards that can enable cross-border commerce and technology dissemination.

7.3. Strategic Positioning in the Urban Energy Transition

The integration of PV–SLB hybrid systems into Malaysia’s urban energy transition offers both technical and economic advantages. Petrol stations, located at high-traffic urban nodes, can serve as distributed energy hubs that alleviate grid stress, provide backup power during outages, and contribute to decarbonization targets. By embedding SLB standards into NETR implementation and aligning with international regulations, Malaysia can ensure that SLB-powered systems are not only safe and efficient but also export-ready for the wider ASEAN market. SWOT Analysis of Malaysia’s Regulatory Readiness for PV–SLB Hybrid Petrol Stations is shown in Table 13.

Table 13.

SWOT Analysis of Malaysia’s Regulatory Readiness for PV–SLB Hybrid Petrol Stations.

In summary, the policy and regulatory framework for PV–SLB hybrid petrol stations must evolve beyond general EV and renewable energy policies to specifically address second-life battery repurposing, certification, and integration in urban settings. A proactive regulatory approach will allow Malaysia to transform battery waste into strategic energy assets, strengthen its urban energy resilience, and position itself as a regional leader in sustainable battery reuse.

8. Challenges and Recommendations

Despite the robust policy impetus and technological potential of second-life battery (SLB) systems in Malaysia, several key challenges must be addressed to unlock scalable, safe, and economically viable deployment. One major challenge is the fragmented regulatory landscape, which currently lacks clear legal definitions and technical standards for SLB reuse, certification, and system integration [36]. In the absence of a cohesive framework, manufacturers and operators face uncertainties in safety compliance, cross-sector deployment, and warranty liability [37]. Another major bottleneck is the skills gap in battery diagnostics, battery management system (BMS) design, and energy storage integration. A recent evaluation by domestic energy training institutions indicates that less than 8% of Malaysia’s technical workforce has formal exposure to advanced battery systems, and less than 5% have hands-on experience in BMS design, firmware, or SOH analysis [38]. This shortage constrains the country’s ability to assemble, maintain, and certify SLB units, particularly for mission-critical applications like microgrids, telecom infrastructure, and transport.

Additionally, logistical and technical infrastructure for reverse logistics, SOH testing, and modular repurposing is still in early development [23]. Many used EV batteries remain uncollected or exported for processing abroad, representing a missed opportunity for domestic value creation and job generation. Lastly, public awareness and market confidence in SLB systems remain low due to safety concerns and the absence of performance standards, which limits demand among commercial and government users. To address these challenges, a coordinated national strategy is required. Table 14 shows actionable recommendations aligned with responsible agencies and realistic implementation timelines that can help accelerate SLB ecosystem readiness in Malaysia.

Table 14.

Recommended Actions to Overcome SLB Deployment Challenges in Malaysia.

In summary, Malaysia is well-positioned to lead in second-life battery deployment within the ASEAN region, but this will require decisive actions across regulation, workforce development, infrastructure, and public engagement [23]. Implementing these recommendations in a phased and coordinated manner will allow the country to transform battery waste into national value, supporting clean energy, industrial innovation, and long-term energy resilience

9. Conclusions

The transition toward electric mobility and renewable energy presents both challenges and opportunities for Malaysia. As EV adoption accelerates, end-of-life lithium-ion batteries could either become an environmental burden or be repurposed as valuable second-life batteries (SLBs) for stationary energy storage. This study demonstrates that repurposing EV batteries for photovoltaic (PV) applications provides substantial benefits, including 30–60% lower capital costs and 70–80% reductions in lifecycle CO2 emissions compared to new systems. A case study of petrol stations, which collectively consume approximately 158,850 kWh daily nationwide, shows that an SLB–PV hybrid system can reliably offset the average 45 kWh per station demand, reducing dependency on Tenaga Nasional Berhad (TNB) while lowering operational costs. Laboratory testing of Nissan Leaf ZE0 battery modules over a 120-day cycle validated their technical viability, with stable performance, manageable 7% capacity fade, and state-of-health (SOH) remaining above 47%. The proposed SLB–PV hybrid architecture leverages Malaysia’s high solar irradiance, enabling stations to generate renewable electricity during daylight hours and store excess for nighttime or peak demand. Beyond technical feasibility, this approach advances circular economy goals by extending battery lifespans, mitigating waste, and supporting national sustainability objectives.

Successful large-scale deployment requires advancements in SOH diagnostics, standardized modular pack designs, robust power electronics, and thermal management tailored to Malaysia’s tropical climate. Additionally, digital traceability, reverse logistics networks, regulatory standards, and workforce training are essential to ensure safe and scalable adoption. Leveraging its strong electronics manufacturing base, Malaysia is well-positioned to establish itself as a regional hub for SLB repurposing, supporting both domestic energy resilience and ASEAN-wide clean energy growth. In conclusion, SLB–PV hybrid systems offer a technically robust, economically viable, and environmentally sustainable pathway for decarbonizing petrol station operations while strengthening Malaysia’s energy transition and positioning the nation as a leader in second-life battery innovation.

Author Contributions

Conceptualization, M.T.S.; methodology, M.T.S.; validation, M.T.S. and M.A.Q.; formal analysis, M.T.S., M.A.Q. and G.R.; investigation, M.T.S., M.A.Q. and S.K.; data curation, M.T.S., M.A.Q. and G.R.; writing—original draft, M.T.S.; writing—review and editing, M.T.S., S.K. and M.A.Q.; visualization, M.T.S. and M.A.Q.; supervision, G.R. All authors have read and agreed to the published version of the manuscript.

Funding

The funding for this project was provided by the Multimedia University under the post-doctoral research fellowship scheme, with the grant number MMUI/250012. Appreciation is also extended to the Research Management Center (RMC) of MMU for covering the article processing charges (APC).

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors gratefully acknowledge the support provided by the Multimedia University, Malaysia, for facilitating laboratory resources and technical assistance throughout this research. The authors would also like to thank the Deanship of Scientific Research at Shaqra University for supporting this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ruggieri, R.; Ruggeri, M.; Vinci, G.; Poponi, S. Electric mobility in a smart city: European overview. Energies 2021, 14, 315. [Google Scholar] [CrossRef]

- Sarker, M.T.; Haram, M.H.S.M.; Shern, S.J.; Ramasamy, G.; Al Farid, F. Second-life electric vehicle batteries for home photovoltaic systems: Transforming energy storage and sustainability. Energies 2024, 17, 2345. [Google Scholar] [CrossRef]

- Sarker, T.; Haram, M.H.S.M.; Shern, S.J.; Ramasamy, G.; Al Farid, F. Readiness of Malaysian PV system to utilize energy storage system with second-life electric vehicle batteries. Energies 2024, 17, 3953. [Google Scholar] [CrossRef]

- Riffat, S.; Ahmad, M.I.; Shakir, A. Eco-cities: Sustainable urban living. In Sustainable Energy Technologies and Low Carbon Buildings; Springer: Cham, Switzerland, 2024; pp. 259–309. [Google Scholar]

- Ahmad, S.; Hasan, S.M.N.; Hossain, S.; Uddin, R.; Ahmed, T.; Mustayen, A.G.M.B.; Hazari, R.; Hassan, M.; Parvez, S.; Saha, A. A Review of Hybrid Renewable and Sustainable Power Supply System: Unit Sizing, Optimization, Control, and Management. Energies 2024, 17, 6027. [Google Scholar] [CrossRef]

- Nichols, C.; Holland, A. Li-ion Battery Recycling Market 2025–2045: Markets, Forecasts, Technologies, and Players. 2025. Available online: https://www.idtechex.com/en/research-report/li-ion-battery-recycling-market/1090 (accessed on 1 August 2025).

- Kostenko, G.; Zaporozhets, A.; Babak, V.; Uruskyi, O.; Titko, V.; Denisov, V. Second-Life EV Batteries Application in Energy Storage Systems for Sustainable and Resilient Power Sector. In Systems, Decision and Control in Energy VII: Volume II: Power Engineering and Environmental Safety; Springer: Cham, Switzerland, 2025; pp. 3–24. [Google Scholar]

- Hu, S.; Liu, Z.; Tan, Y.; Cheng, X.; Chen, Z.; Long, Z. The status quo and future trends of new energy vehicle power batteries in China—Analysis from policy perspective. Energy Rep. 2022, 8, 63–80. [Google Scholar] [CrossRef]

- Yang, J.; Jiang, Q.; Zhang, J. Bridging the regulatory gap: A policy review of extended producer responsibility for power battery recycling in China. Energy Sustain. Dev. 2025, 86, 101697. [Google Scholar] [CrossRef]

- Akram, M.N.; Abdul-Kader, W. Repurposing Second-Life EV Batteries to Advance Sustainable Development: A Comprehensive Review. Batteries 2024, 10, 452. [Google Scholar] [CrossRef]

- Gianvincenzi, M.; Marconi, M.; Mosconi, E.M.; Favi, C.; Tola, F. Systematic review of battery life cycle management: A framework for European regulation compliance. Sustainability 2024, 16, 10026. [Google Scholar] [CrossRef]

- Patel, A.N.; Lander, L.; Ahuja, J.; Bulman, J.; Lum, J.K.H.; Pople, J.O.D.; Hales, A.; Patel, Y.; Edge, J.S. Lithium-ion battery second life: Pathways, challenges and outlook. Front. Chem. 2024, 12, 1358417. [Google Scholar] [CrossRef]

- Sarker, M.T.; Haram, M.H.S.M.; Ramasamy, G.; Al Farid, F.; Mansor, S. Solar photovoltaic home systems in Malaysia: A comprehensive review and analysis. Energies 2023, 16, 7718. [Google Scholar] [CrossRef]

- Mail, M.; Malaysia’s Auto Industry Hits Record 816,747 Units in 2024. 2025. Available online: https://www.malaymail.com/news/money/2025/01/21/malaysias-auto-industry-hits-record-816747-units-in-2024/164070 (accessed on 1 August 2025).

- Bahrudin, F.I.; Daud, N.; Harun, I.; Aizamddin, M.F.; Shaffee, S.N.A.; Mahat, M.M. A Malaysian Perspective on Lithium-Ion Batteries Recycling. In IGEC Transactions, Volume 1: Energy Conversion and Management; Springer: Cham, Switzerland, 2023; pp. 39–52. [Google Scholar]

- Haram, M.H.S.M.; Sarker, T.; Ramasamy, G.; Ngu, E.E. Second life EV batteries: Technical evaluation, design framework, and case analysis. IEEE Access 2023, 11, 138799–138812. [Google Scholar] [CrossRef]

- See, K.W.; Wang, G.; Zhang, Y.; Wang, Y.; Meng, L.; Gu, X.; Zhang, N.; Lim, K.C.; Zhao, L.; Xie, B. Critical review and functional safety of a battery management system for large-scale lithium-ion battery pack technologies. Int. J. Coal Sci. Technol. 2022, 9, 36. [Google Scholar] [CrossRef]

- Hassan, A.; Khan, S.A.; Li, R.; Su, W.; Zhou, X.; Wang, M.; Wang, B. Second-life batteries: A review on power grid applications, degradation mechanisms, and power electronics interface architectures. Batteries 2023, 9, 571. [Google Scholar] [CrossRef]

- Lai, X.; Yao, J.; Jin, C.; Feng, X.; Wang, H.; Xu, C.; Zheng, Y. A review of lithium-ion battery failure hazards: Test standards, accident analysis, and safety suggestions. Batteries 2022, 8, 248. [Google Scholar] [CrossRef]

- Kostenko, G. Cluster based deployment of second life ev batteries for reliable and sustainable backup power solution in power systems. Syst. Res. Energy 2025, 2025, 40–60. [Google Scholar] [CrossRef]

- Kostenko, G.; Zaporozhets, A. World experience of legislative regulation for lithium-ion electric vehicle batteries considering their second-life application in power sector. Syst. Res. Energy 2024, 2, 97–114. [Google Scholar] [CrossRef]

- Sarker, M.T.; Al Qwaid, M.; Ramasamy, G.; Haram, M.H.S.M. Performance Evaluation of Second-Life EV Batteries for Off-Grid Solar Energy Storage System. IEEE Access 2025, 13, 148365–148373. [Google Scholar] [CrossRef]

- Mahboubi, A.; Miyangaskary, M.K.; Keivanpour, S.; Lamghari, A. The Sustainable Shared Reverse Logistics Framework: A Blueprint for EV Battery Recovery. Circ. Econ. Sustain. 2025, 10, 1–23. [Google Scholar] [CrossRef]

- Ahmad, M.S.; Mansor, N.N.; Mokhlis, H.; Naidu, K.; Mohamad, H.; Ramadhani, F. Demand Response Program towards Sustainable Power Supply: Current Status, Challenges, and Prospects in Malaysia. IEEE Access 2025, 13, 34706–34731. [Google Scholar] [CrossRef]

- Muzir, N.A.Q.; Mojumder, M.R.H.; Hasanuzzaman, M.; Selvaraj, J. Challenges of electric vehicles and their pro-spects in Malaysia: A comprehensive review. Sustainability 2022, 14, 8320. [Google Scholar] [CrossRef]

- Zahari, N.E.M.; Mokhlis, H.; Mubarak, H.; Mansor, N.N.; Sulaima, M.F.; Ramasamy, A.K.; Zulkapli, M.F.; Bin Ja’aPar, M.A.; Jaafar, M.; Marsadek, M.B. Integrating solar PV, battery storage, and demand response for industrial peak shaving: A systematic review on strategy, challenges and case study in Malaysian food manufacturing. IEEE Access 2024, 12, 106832–106856. [Google Scholar] [CrossRef]

- Azizighalehsari, S.; Venugopal, P.; Singh, D.P.; Soeiro, T.B.; Rietveld, G. Empowering Electric Vehicles Batteries: A Comprehensive Look at the Application and Challenges of Second-Life Batteries. Batteries 2024, 10, 161. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Uthaichotirat, P.; Sangpet, T.; Sisomphon, K.; Newlands, M.; Siripanichgorn, A.; Chindaprasirt, P. Thermal properties of lightweight concrete incorporating high contents of phase change materials. Constr. Build. Mater. 2019, 207, 431–439. [Google Scholar] [CrossRef]

- Chen, J.; Brunner, A.-D.; Cogan, J.Z.; Nuñez, J.K.; Fields, A.P.; Adamson, B.; Itzhak, D.N.; Li, J.Y.; Mann, M.; Leonetti, M.D.; et al. Pervasive functional translation of noncanonical human open reading frames. Science 2020, 367, 1140–1146. [Google Scholar] [CrossRef] [PubMed]

- Spampinato, C.; Calogero, G.; Mannino, G.; Valastro, S.; Smecca, E.; Arena, V.; La Magna, P.; Bongiorno, C.; Fazio, E.; Alberti, A. A Sputtered Gig-Lox TiO2 Sponge Integrated with CsPbI3: EuI2 for Semitransparent Perovskite Solar Cells. J. Phys. Chemistry. C Nanomater. Interfaces 2025, 129, 16338. [Google Scholar] [CrossRef]

- Pesaran, A.; Roman, L.; Kincaide, J. Electric Vehicle Lithium-Ion Battery Life Cycle Management; (No. NREL/TP-5700-84520); National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2023. [Google Scholar]

- Rehman, S.; Al-Greer, M.; Burn, A.S.; Short, M.; Cui, X. High-Volume Battery Recycling: Technical Review of Challenges and Future Directions. Batteries 2025, 11, 94. [Google Scholar] [CrossRef]

- Maka, A.O.; Ghalut, T.; Elsaye, E. The pathway towards decarbonisation and net-zero emissions by 2050: The role of solar energy technology. Green Technol. Sustain. 2024, 2, 100107. [Google Scholar] [CrossRef]

- Choong, J.E. (2019). Quantification of Potential Environmental Impacts of Electricity Generation from The Wood Wastes Using Life Cycle Assessment Approach/Choong Joo Ee. Ph.D. Thesis, University of Malaya, Kuala Lumpur, Malaysia.

- Blair, N.; Schiek, A.; Burrell, A.; Keyser, M.; Deadman, A.; Ellerington, I.; Govaerts, L.; Mulder, G.; Hendrick, P.; Polfliet, T.; et al. Global Overview of Energy Storage Performance Test Protocols; U.S. Department of Energy, Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2021. [Google Scholar]

- Umair, M.; Hidayat, N.M.; Ali, N.H.N.; Nasir, N.S.M.; Hakomori, T.; Abdullah, E. A Review of Malaysia’s Current State and Future in Electric Vehicles. J. Sustain. Dev. Energy, Water Environ. Syst. 2024, 12, 1120522. [Google Scholar] [CrossRef]

- Sarker, T.; Al Qwaid, M.; Shern, S.J.; Ramasamy, G. AI-Driven Optimization Framework for Smart EV Charging Systems Integrated with Solar PV and BESS in High-Density Residential Environments. World Electr. Veh. J. 2025, 16, 385. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Othman, A.M.; Abdussami, M.R. Review of battery management systems (BMS) development and industrial standards. Technologies 2021, 9, 28. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).