Optimization of Embodied Energy and Construction Cost of Low-Income Housing in Urban India

Abstract

1. Introduction

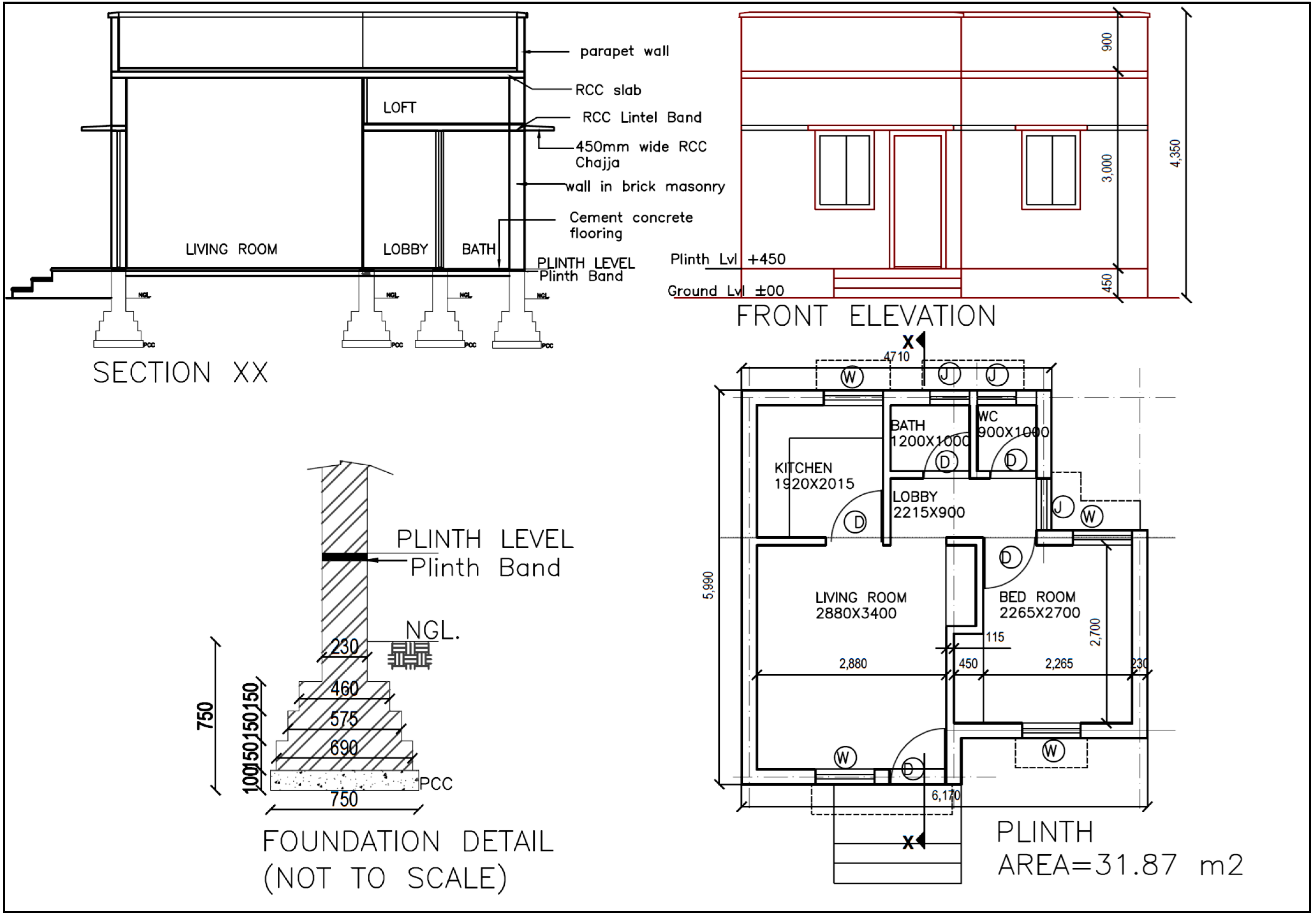

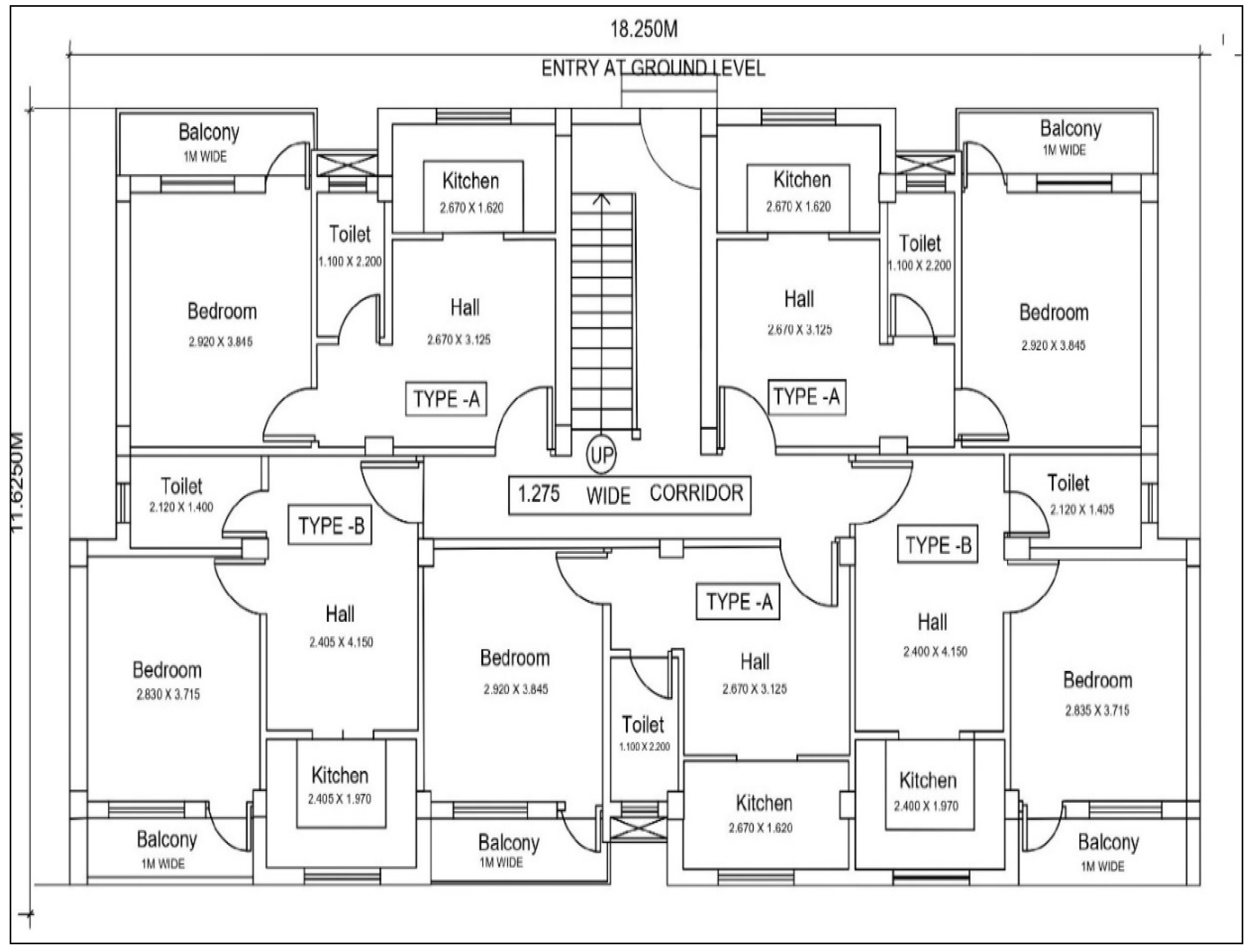

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations of Building Materials

References

- Asif, M.; Muneer, T.; Kelley, R. Life cycle assessment: A case study of a dwelling home in Scotland. Build. Environ. 2007, 32, 1391–1394. [Google Scholar] [CrossRef]

- Keoleian, G.A.; Blanchard, S.; Reppe, P. Life-cycle energy, costs, and strategies for improving a single-family house. J. Ind. Ecol. 2000, 4, 135–156. [Google Scholar] [CrossRef]

- IPCC (Intergovernmental Panel on Climate Change). Climate Change 2007: Mitigation, Contribution of Working Group III to the Fourth Assessment Report of the IPCC. 2007. Available online: https://www.ipcc.ch/site/assets/uploads/2018/03/ar4_wg3_full_report-1.pdf (accessed on 1 November 2019).

- Srilakshmi, S. Embodied Energy Analysis. Archit. Time Space People 2013, 13, 34–42. [Google Scholar]

- Bansal, D.; Minocha, V.K.; Kaur, A. Embodied energy, CO2e, and construction cost of Indian housing: Model of low-rise versus high-rise development. J. Archit. Eng. 2021, 27, 04021017. [Google Scholar] [CrossRef]

- Hu, S.; Yan, D.; Guo, S.; Cui, Y.; Dong, B. A survey on energy consumption and energy usage behavior of households and residential building in urban China. Energy Build. 2017, 148, 366–378. [Google Scholar] [CrossRef]

- UNEP Sustainable Building and Construction Initiative. The Kyoto Protocol, the Clean Development Mechanism, and the Building and Construction Sector: A Report for the UNEP Sustainable Buildings and Construction Initiative; UNEP/Earthprint: Hertfordshire, UK, 2008. [Google Scholar]

- Huovila, P. Buildings and Climate Change: Status, Challenges, and Opportunities; UNEP: Panama City, Panama, 2007. [Google Scholar]

- Tiwari, P. Energy efficiency and building construction in India. Build. Environ. 2001, 36, 1127–1135. [Google Scholar] [CrossRef]

- NBO (National Building Organization). Housing data. Available online: http://nbo.nic.in/pdf/housing_data_table.pdf (accessed on 11 March 2021).

- Census of India. Housing data of Urban and Rural. Available online: https://censusindia.gov.in/nada/index.php/catalog/42617 (accessed on 2 March 2020).

- Roy, D.; Meera, M.L. Housing for India’s Low-Income Urban Households: A Demand Perspective. 2020, Working Paper, No. 402, Indian Council for Research on International Economic Relations (ICRIER), New Delhi. Available online: https://hdl.handle.net/10419/242881 (accessed on 21 December 2021).

- Report of The Technical Group (11th Five-Year Plan: 2007-12) on Estimation of Urban Housing Shortage. Available online: http://mhupa.gov.in/ministry/housing/HOUSINGSHORTAGE-REPT.pdf (accessed on 5 April 2020).

- Sengupta, N.; Roy, S.; Guha, H. Assessing embodied GHG emission reduction potential of cost-effective technologies for construction of residential buildings of Economically Weaker Section in India. Asian J. Civ. Eng. 2018, 19, 139–156. [Google Scholar] [CrossRef]

- MoHUA (Ministry of Housing and Urban Affairs). Annual Report 2014–15. Available online: http://mohua.gov.in/upload/uploadfiles/files/3Annual_Report_2014_15_MHUPA_English.pdf (accessed on 11 May 2021).

- Prime Minister Awas Yojna. Available online: https://pmay-urban.gov.in/ (accessed on 19 January 2023).

- MoHUA (Ministry of Housing and Urban Affairs). Affordable Housing. 2019. Available online: http://mohua.gov.in/w_new/AffordableHousing.pdf (accessed on 11 May 2021).

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle embodied energy analysis of residential buildings: A review of literature to investigate embodied energy parameters. Renew. Sustain. Energy Rev. 2017, 79, 390–413. [Google Scholar] [CrossRef]

- Bansal, D.; Vijay K, M.; Arvinder, K. Initial or recurring embodied energy: Importance in Indian affordable housing. J. Build. Eng. 2022, 49, 104072. [Google Scholar] [CrossRef]

- Talakonukula, R.; Ravi, P.; Karunesh, K.S. Life cycle energy analysis of a multifamily residential house: A case study in Indian context. Open J. Energy Effic. 2013, 2, 34–41. [Google Scholar]

- Utama, A.; Gheewala, S.H. Life cycle energy of single landed houses in Indonesia. Energy Build. 2008, 40, 1911–1916. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Bansal, D.; Minocha, V.K.; Kaur, A.; Dakwale, V.A.; Ralegaonkar, R.V. Reduction of embodied energy and construction cost of affordable houses through efficient architectural design: A case study in Indian scenario. Adv. Civ. Eng. 2021, 1, 5693101. [Google Scholar] [CrossRef]

- Bureau of Energy Efficiency. Energy Conservation Building Code, BEE-ECBC. Available online: https://beeindia.gov.in/sites/default/files/BEE_ECBC%202017.pdf (accessed on 11 March 2020).

- Devi, P.; Palaniappan, S. A case study on life cycle energy use of residential building in Southern India. Energy Build. 2014, 80, 247–259. [Google Scholar] [CrossRef]

- Devi, P.; Palaniappan, S. Life cycle energy analysis of a low-cost house in India. Int. J. Constr. Educ. Res. 2019, 15, 256–275. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Winistorfer, P.; Chen, Z.; Lippke, B.; Stevens, N. Energy consumption and greenhouse gas emissions related to the use, maintenance, and disposal of a residential structure. Wood Fiber Sci. 2005, 37, 128–139. [Google Scholar]

- Ramesh, S. Appraisal of vernacular building materials and alternative technologies for roofing and terracing options of embodied energy in buildings. Energy Procedia 2012, 14, 1843–1848. [Google Scholar] [CrossRef][Green Version]

- Baird, G.; Alcorn, A.; Haslam, P. The energy embodied in building materials-updated New Zealand coefficients and their significance. Trans. Inst. Prof. Eng. N. Z. Civ. Eng. Sect. 1997, 24, 46–54. [Google Scholar]

- Reddy, B.V.; Jagadish, K.S. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H.; De Myttenaere, K. Multi-scale life cycle energy analysis of a low-density suburban neighbourhood in Melbourne, Australia. Build. Environ. 2013, 68, 35–49. [Google Scholar] [CrossRef]

- Praseeda, K.I.; Reddy, B.V.; Mani, M. Embodied energy assessment of building materials in India using process and input–output analysis. Energy Build. 2015, 86, 677–686. [Google Scholar] [CrossRef]

- Chani, P.S.; Najamuddin; Kaushik, S.K. Comparative analysis of embodied energy rates for walling elements in India. J. Inst. Eng. (India) Archit. Eng. Div. 2003, 84, 47–50. [Google Scholar]

- Das, P.K. A Sustainability Impact-Assessment Tool for Selected Building Technologies in Rural India-The Case of Andhra PRADESH Education Project. Ph.D. Thesis, School of Architecture, Planning and Landscape, Newcastle University, Newcastle upon Tyne, UK, 2006. [Google Scholar]

- Debnath, A.; Singh, S.V.; Singh, Y.P. Comparative assessment of energy requirements for different types of residential buildings in India. Energy Build. 1995, 23, 141–146. [Google Scholar] [CrossRef]

- Shukla, A.; Tiwari, G.N.; Sodha, M.S. Embodied energy analysis of adobe house. Renew. Energy 2009, 34, 755–761. [Google Scholar] [CrossRef]

- Chaudhary, A.; Akhtar, A. Template for Evaluating Cradle-to-Site Environmental Life Cycle Impacts of Buildings in India. ACS Environ. Au 2022, 3, 94–104. [Google Scholar] [CrossRef] [PubMed]

- Jyosyula, S.K.R.; Surana, S.; Raju, S. Role of lightweight materials of construction on carbon dioxide emission of a reinforced concrete building. Mater. Today Proc. 2020, 27, 984–990. [Google Scholar] [CrossRef]

- Kurian, R.; Kulkarni, K.S.; Ramani, P.V.; Meena, C.S.; Kumar, A.; Cozzolino, R. Estimation of carbon footprint of residential building in warm humid climate of India through BIM. Energies 2021, 14, 4237. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of a residential building with different envelopes and climates in Indian context. Appl. Energy 2012, 89, 193–202. [Google Scholar] [CrossRef]

- Bansal, D.; Minocha, V.K.; Kaur, A. Componentwise-embodied energy analysis of affordable houses in India. Asian J. Civ. Eng. 2020, 21, 137–145. [Google Scholar] [CrossRef]

- Rawal, R.; Shukla, Y.; Shivani, S.; Nathani, S.; Kumar, S.; Asrani, S. Developing an Embodied Energy Database for Construction Materials in India. In Proceedings of the Energise 2023—Lifestyle, Energy Efficiency, and Climate Action, Goa, India, 31 October–4 November 2023; pp. 136–145, Alliance for an Energy Efficient Economy. [Google Scholar] [CrossRef]

- BIS (Bureau of Indian Standards). National Building Code. Delhi, India. Available online: https://www.bis.gov.in/standards/technical-department/national-building-code/ (accessed on 19 January 2023).

- Saka, A.B.; Chan, D.W. Knowledge, skills and functionalities requirements for quantity surveyors in building information modelling (BIM) work environment: An international Delphi study. Archit. Eng. Des. Manag. 2020, 16, 227–246. [Google Scholar] [CrossRef]

- Development Alternatives, Energy in Building Materials: Final Report. BMTPC. Available online: www.bmtpc.org (accessed on 15 March 2019).

- Central Public Works Department (CPWD), Plinth Rates. Available online: https://cpwd.gov.in/Publication/PLINTH_AREA_RATES_2019.pdf (accessed on 5 November 2020).

- Hammond, G.; Jones, C. Inventory of Carbon and Energy, ver. 20. 2011. University of Bath. Available online: https://greenbuildingencyclopaedia.uk/wp-content/uploads/2014/07/Full-BSRIA-ICE-guide.pdf (accessed on 15 March 2019).

- BMTPC (Building Materials and Technology Promotion Council). Vulnerability Atlas of India, 3rd Edition. 2020. Available online: www.bmtpc.org (accessed on 5 November 2020).

| No. | Building Component | Detailed Specifications |

|---|---|---|

| 1 | Structure | Load-bearing, G + 3 Structure |

| 2 | Wall | 230 mm thick brick masonry in mortar of cement and coarse sand in 1:6 proportion |

| 3 | Roof | 115 mm thick flat reinforced cement concrete (RCC) roof with concrete of M25 grade and with TMT Fe 500D-grade reinforcement, 1% by volume of RCC |

| 4 | Flooring | 40 mm thick Plain Cement Concrete (PCC) of M15 grade |

| 5 | Skirting/Dado | 12 mm thick, 100 mm/1200 mm high, in mortar of cement and coarse sand in 1:6 proportion |

| 6 | Plaster/Rendering | 12/15 mm thick with in mortar of cement and coarse sand in 1:6 proportion |

| 7 | Terrace finishing | 100 mm thick (average) with brick tiles and mud phuska (treatment with clay and mud to reduce solar heat gain) |

| 8 | Parapet | 900 mm high, 115 mm thick brick masonry in mortar of cement and coarse sand in 1:4 proportion |

| 9 | Joinery | Mild steel frames with steel grills and float glass (4 mm thick) panels |

| 10 | CC Gola/Khurrah/Coping | CC Gola (over-the-deck treatment at junction of parapet wall and roof slab to prevent seepage) in PCC of M15 grade. Khurrah (rainwater spout)/coping (PCC over parapets to protect it from rainwater) |

| Construction Materials | Unit | Size (mm) | EEV(MJ)/Unit | Rates (INR)/Unit | Rates (INR)/Unit |

|---|---|---|---|---|---|

| Fired Clay Bricks | Nos | 230 × 115 × 75 | 4.70 | 5.20/Nos | - |

| Cements | Bag | 50 Kg Bags | 342.50 | 285.00/Bags | - |

| Steel | Kg | - | 35.10 | 37.30/Kg | - |

| Sand | Quintal (Q *) | - | 15.00 | 80.00/Q * | 1200/Cum |

| Aggregate | Quintal (Q *) | - | 40.00 | 74.20/Q * | 1300/Cum |

| Hollow CC Blocks | Nos | 400 × 200 × 200 | 11.20 | 35.00/Nos | - |

| AAC Blocks | Nos | 400 × 200 × 200 | 11.52 | 41.60/Nos | - |

| Fa-L-G Blocks | Nos | 300 × 200 × 150 | 7.92 | 22.50/Nos | - |

| Solid CC Blocks | Nos | 300 × 200 × 150 | 10.37 | 32.40/Nos | - |

| HF SEB Blocks | Nos | 230 × 220 × 115 | 6.05 | 11.64/Nos | - |

| HF Fly Ash Blocks | Nos | 230 × 220 × 115 | 5.32 | 10.47/Nos | - |

| No. | Design Typology | Plinth–Carpet Area Ratio | Construction Cost (INR)/Plinth Area (Sqm) | Materials Cost (INR)/Plinth Area (Sqm) | Embodied Energy (MJ)/Plinth Area (Sqm) | Units on a Floor |

|---|---|---|---|---|---|---|

| 1 | A1 | 1.42 | 11,927.16 | 4076.70 | 3558.06 | 8 |

| 2 | A2 | 1.47 | 11,487.56 | 3993.45 | 3483.36 | 12 |

| 3 | A3 | 1.34 | 12,902.10 | 4637.34 | 4048.83 | 4 |

| 4 | A4 | 1.40 | 12,272.83 | 4388.28 | 3831.47 | 4 |

| 5 | A5 | 1.41 | 12,092.39 | 4312.85 | 3766.21 | 4 |

| 6 | A6 | 1.44 | 11,477.83 | 4046.48 | 3528.23 | 12 |

| 7 | A7 | 1.46 | 11,371.10 | 4028.09 | 3511.74 | 12 |

| 8 | A8 | 1.38 | 11,108.88 | 3928.48 | 3429.99 | 4 |

| 9 | A9 | 1.50 | 11,684.46 | 4147.22 | 3620.30 | 6 |

| 10 | A10 | 1.54 | 12,406.63 | 4552.34 | 3966.77 | 7 |

| 11 | A11 | 1.51 | 13,294.85 | 4906.98 | 4290.29 | 2 |

| 12 | A12 | 1.46 | 11,219.80 | 3989.92 | 3477.91 | 12 |

| 13 | A13 | 1.30 | 11,684.69 | 4161.10 | 3634.69 | 4 |

| 14 | A14 | 1.36 | 10,687.47 | 3753.78 | 3276.09 | 4 |

| 15 | A15 | 1.55 | 12,236.02 | 4477.61 | 3904.63 | 6 |

| 16 | A16 | 1.62 | 11,507.40 | 4189.72 | 3651.60 | 4 |

| 17 | A17 | 1.56 | 12,518.13 | 4583.78 | 4005.69 | 2 |

| 18 | A18 | 1.33 | 11,928.50 | 4301.93 | 3751.28 | 8 |

| 19 | A19 | 1.38 | 12,332.31 | 4547.92 | 3967.89 | 4 |

| 20 | A20 | 1.43 | 11,759.53 | 4269.52 | 3724.90 | 6 |

| 21 | A21 | 1.44 | 11,287.00 | 4097.48 | 3570.92 | 12 |

| 22 | A22 | 1.31 | 10,269.58 | 3592.60 | 3135.80 | 8 |

| 23 | A23 | 1.48 | 10,336.23 | 3633.63 | 3168.57 | 8 |

| 24 | A24 | 1.51 | 12,350.00 | 4638.66 | 4039.82 | 12 |

| 25 | A25 | 1.35 | 10,443.51 | 3732.01 | 3254.44 | 8 |

| 26 | A26 | 1.41 | 10,880.51 | 3962.96 | 3457.44 | 3 |

| 27 | A27 | 1.39 | 11,692.36 | 4342.83 | 3785.25 | 12 |

| 28 | A28 | 1.42 | 11,023.18 | 4025.70 | 3506.76 | 12 |

| 29 | A29 | 1.46 | 11,241.31 | 4167.20 | 3637.30 | 3 |

| 30 | A30 | 1.54 | 11,760.95 | 4535.06 | 3962.85 | 6 |

| Average | 1.44 | 11,639.48 | 4200.72 | 3664.97 | 6.97 |

| Variables | Coefficients | Standard Error | t Stat | p-Value |

|---|---|---|---|---|

| Intercept | 1.1852 | 12.4865 | 0.0949 | 0.9251 |

| Plinth–carpet area ratio | −5.2447 | 7.0527 | −0.7436 | 0.4640 |

| Cost of construction (INR)/plinth area (sq.m.) | 0.0025 | 0.0023 | 1.1146 | 0.2756 |

| Cost of materials (INR)/plinth area (sq.m.) | 0.8681 | 0.0054 | 161.1469 | 0.0000 |

| Number of units on a floor | −0.7275 | 0.1499 | −4.8539 | 0.0001 |

| Low-Cost Housing Construction Materials | Single-Story House | Two-Story House | Three-Story House | Average Construction Cost |

|---|---|---|---|---|

| Burnt Clay Bricks | 4758.55 | 3924.41 | 4004.02 | 4229.00 |

| Hollow CC Blocks | 4520.92 | 3607.99 | 3688.12 | 3939.01 |

| AAC Blocks | 4883.28 | 3883.68 | 3956.25 | 4241.07 |

| Fal G Blocks | 4879.90 | 3881.11 | 3953.75 | 4238.25 |

| Solid CC Blocks | 5883.34 | 4644.56 | 4696.27 | 5074.73 |

| HF SEB Blocks | 4319.60 | 3454.82 | 3539.14 | 3771.19 |

| HF Fly Ash Blocks | 4146.95 | 3323.94 | 3411.85 | 3627.58 |

| Construction Material | Embodied Energy (MJ per sqm of Plinth Area) | |||

|---|---|---|---|---|

| Single-Story House | Two-Story House | Three-Story House | Average Embodied Energy | |

| Burnt Clay Bricks | 3937.13 | 3227.70 | 3281.36 | 3482.06 |

| Hollow CC Blocks | 2317.06 | 1932.48 | 2038.97 | 2096.17 |

| AAC Blocks | 2344.47 | 1953.33 | 2059.25 | 2119.02 |

| Fal G Blocks | 2514.75 | 2082.89 | 2185.25 | 2260.96 |

| Solid CC Blocks | 2762.88 | 2271.67 | 2368.86 | 2467.80 |

| HF SEB Blocks | 2606.10 | 2152.39 | 2252.85 | 2337.11 |

| HF Fly Ash Blocks | 2498.57 | 2070.57 | 2173.28 | 2247.47 |

| No. | Construction Material | Initial Embodied Energy (MJ/sqm) | % of Initial Embodied Energy of 3 Components | Recurring Embodied Energy of 3 Components (MJ/sqm) | % of Recurring Embodied Energy of 3 Components to Total | ||||

|---|---|---|---|---|---|---|---|---|---|

| Total | Plastering/Rendering | Flooring | Terracing | Total of 3 Components | |||||

| Churn out Rates | 3 Times | 4 Times | 9 Times | ||||||

| 1 | Burnt Clay Bricks | 3390.03 | 144.36 | 212.43 | 156.19 | 512.98 | 15% | 2688.53 | 79% |

| 2 | Hollow CC Blocks | 2060.03 | 148.18 | 187.56 | 69.16 | 404.9 | 20% | 1817.24 | 88% |

| 3 | AAC Blocks | 2081.81 | 148.18 | 187.56 | 70.55 | 406.29 | 20% | 1829.74 | 88% |

| 4 | Fal G Blocks | 2217.15 | 148.18 | 187.56 | 79.17 | 414.91 | 19% | 1907.28 | 86% |

| 5 | Solid CC Blocks | 2414.37 | 148.18 | 187.56 | 91.73 | 427.47 | 18% | 2020.36 | 84% |

| 6 | HF SEB Blocks | 2289.76 | 148.18 | 187.56 | 82.8 | 418.54 | 18% | 1939.94 | 85% |

| 7 | HF Fly Ash Blocks | 2204.29 | 148.18 | 187.56 | 78.31 | 414.05 | 19% | 1899.58 | 86% |

| Average | 18% | 2014.67 | 85% | ||||||

| No. | Construction Material | Cost of Construction (INR/sqm) | Share of Initial Cost of 3 Components to Total | Recurring Cost of 3 Components | Share of Recurring Cost of 3 Components to Total | ||||

|---|---|---|---|---|---|---|---|---|---|

| Total | Plastering/Rendering | Flooring | Cost of Terracing | Total of 3 Components | |||||

| Churn out Rates | 3 Times | 4 Times | 9 Times | ||||||

| 1 | Burnt Clay Bricks | 4124.31 | 208.44 | 427.67 | 165.27 | 801.38 | 19% | 3823.42 | 93% |

| 2 | Hollow CC Blocks | 3823.61 | 212.78 | 340.1 | 147.87 | 700.74 | 18% | 3329.52 | 87% |

| 3 | AAC Blocks | 4111.62 | 212.78 | 340.1 | 166.2 | 719.07 | 17% | 3494.52 | 85% |

| 4 | Fal G Blocks | 4108.93 | 212.78 | 340.1 | 166.03 | 718.9 | 17% | 3492.96 | 85% |

| 5 | Solid CC Blocks | 4906.49 | 212.78 | 340.1 | 216.79 | 769.67 | 16% | 3949.85 | 81% |

| 6 | HF SEB Blocks | 3663.59 | 212.78 | 340.1 | 137.7 | 690.57 | 19% | 3238.01 | 88% |

| 7 | HF Fly Ash Blocks | 3526.71 | 212.78 | 340.1 | 128.95 | 681.82 | 19% | 3159.27 | 90% |

| Average | 18% | 3498.22 | 87% | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bansal, D.; Byahut, S.; Bansal, Y. Optimization of Embodied Energy and Construction Cost of Low-Income Housing in Urban India. Urban Sci. 2024, 8, 146. https://doi.org/10.3390/urbansci8030146

Bansal D, Byahut S, Bansal Y. Optimization of Embodied Energy and Construction Cost of Low-Income Housing in Urban India. Urban Science. 2024; 8(3):146. https://doi.org/10.3390/urbansci8030146

Chicago/Turabian StyleBansal, Deepak, Sweta Byahut, and Yashika Bansal. 2024. "Optimization of Embodied Energy and Construction Cost of Low-Income Housing in Urban India" Urban Science 8, no. 3: 146. https://doi.org/10.3390/urbansci8030146

APA StyleBansal, D., Byahut, S., & Bansal, Y. (2024). Optimization of Embodied Energy and Construction Cost of Low-Income Housing in Urban India. Urban Science, 8(3), 146. https://doi.org/10.3390/urbansci8030146