Factories of the Future in Digitization of Industrial Urban Areas

Abstract

1. Introduction

- Digital Twin Technology:

- ○

- Digital twins create virtual replicas of physical assets and processes, enabling real-time monitoring, simulation, and optimization.

- ○

- They facilitate predictive maintenance, reduce downtime, and enhance operational efficiency.

- Building Information Modeling (BIM):

- ○

- BIM integrates all aspects of a building’s lifecycle, from design and construction to operation and maintenance.

- ○

- It provides a collaborative platform for stakeholders to manage and share data efficiently.

- Internet of Things (IoT):

- ○

- IoT devices collect and transmit data from various sensors and equipment, enabling real-time monitoring and control.

- ○

- They support automation, remote monitoring, and smart analytics.

- Artificial Intelligence (AI) and Machine Learning (ML):

- ○

- AI and ML algorithms analyze data to provide insights, optimize processes, and support autonomous decision-making.

- ○

- They enhance predictive analytics, improve quality control, and drive innovation in manufacturing.

- Identify the research gap in the integration of advanced manufacturing systems with urban environments.

- Develop a detailed framework for the integration of digital twin and BIM technologies in FoF.

- Propose actionable strategies for embedding FoF within Smart City infrastructure.

- Assess the challenges and opportunities in the integration process.

- Evaluate the economic, social, and environmental impacts of integrating FoF into urban contexts.

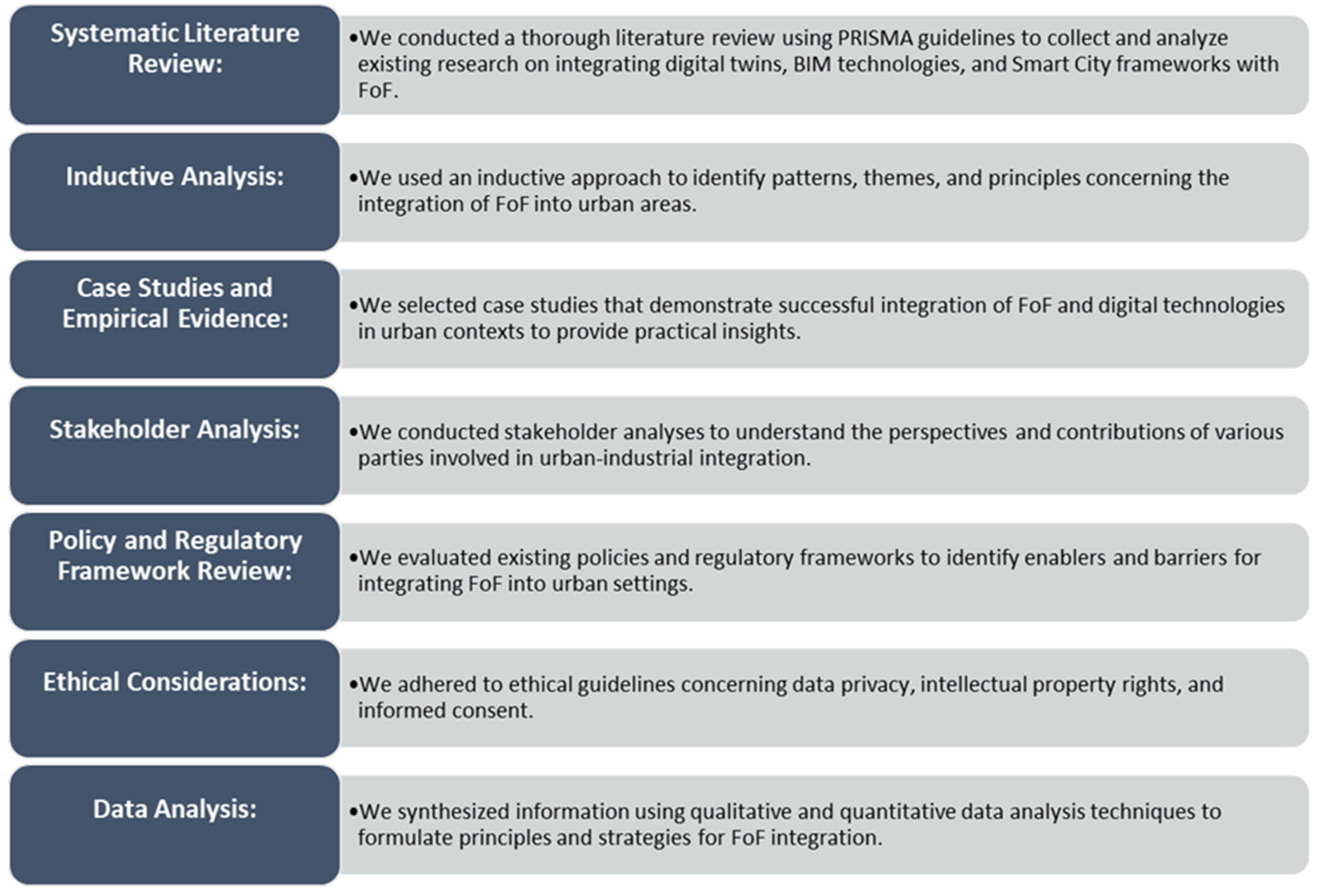

2. Materials and Methods

- Assessment and Planning:

- ○

- Conduct a comprehensive assessment of the current manufacturing infrastructure and capabilities.

- ○

- Develop a detailed implementation plan, including timelines, resource allocation, and risk management strategies.

- Technology Integration:

- ○

- Integrate advanced manufacturing technologies such as IoT devices, AI, and machine learning algorithms.

- ○

- Implement digital twin technologies to create real-time virtual models of manufacturing processes and assets.

- Pilot Testing and Validation:

- ○

- Conduct pilot tests to validate the integrated technologies and their interoperability within the manufacturing environment.

- ○

- Use BIM and digital twin simulations to predict improvements in resource efficiency and carbon emissions reduction.

- Scaling and Optimization:

- ○

- Scale up successful pilot tests to full-scale production.

- ○

- Continuously monitor and optimize manufacturing processes using real-time data and predictive analytics.

- Workforce Training and Development:

- ○

- Provide comprehensive training programs for the workforce to operate and maintain new technologies.

- ○

- Develop new skill sets required for managing digital manufacturing systems.

3. Results

- Identification of Initial Topics:During our initial analysis, we identified a broad range of topics related to the integration of FoF into urban contexts. These topics included:

- Interoperability challenges between digital twins and urban systems

- The need for sustainability-driven design principles in urban manufacturing

- The emerging role of BIM in dynamic urban planning

- Economic impacts of digital transformation

- Social implications of technological integration

- Policy and regulatory challenges

- Technological advancements in AI and IoT

- Workforce development and training needs

- Data privacy and security concerns

- Criteria for Selection:To narrow down the list of topics, we applied specific criteria:

- Frequency of Mention: How often each topic was mentioned in the literature and stakeholder interviews.

- Relevance to Research Goals: The extent to which each topic aligned with our research objectives of integrating FoF into Smart Cities.

- Alignment with Technological Advancements: The degree to which each topic reflected current trends and advancements in technology.

- Selection Process:Each topic was evaluated against the criteria (see Table 1), and the three topics that stood out as most significant were:

- Interoperability Challenges between Digital Twins and Urban Systems: This topic was frequently mentioned and is crucial for the seamless integration of digital and physical environments.

- The Need for Sustainability-Driven Design Principles in Urban Manufacturing: Sustainability is a core objective of modern urban development, and this topic had strong relevance to our research goals.

- The Emerging Role of BIM in Dynamic Urban Planning: BIM technology is pivotal for the lifecycle management of urban manufacturing assets, aligning closely with technological advancements and our research objectives.

- Justification for Selected Topics:

- Interoperability Challenges: This topic had the highest frequency of mention (79%) and scored the maximum (5) in both relevance to research goals and alignment with technological advancements. This makes it indispensable for the integration of FoF into urban systems.

- Sustainability-Driven Design: With 72% frequency of mention, a relevance score of 5, and an alignment score of 4, this topic is crucial due to the global emphasis on sustainability in urban development.

- Role of BIM: This topic was frequently mentioned (67%), had a high relevance score (4), and the highest alignment score (5), emphasizing its pivotal role in urban planning and lifecycle management of manufacturing assets.

3.1. Conceptual Model of the Infrastructure of Industrial Enterprises Using BIM Technology in Conjunction with MBSE

- (1)

- Integration Framework for BIM and DT Technologies:

- (2)

- Operational Flexibility and Adaptive Infrastructure:

- (3)

- Validation of “Smart” Models:

- (4)

- Practical Implementations and Market Adoption:

- (5)

- Challenges and Opportunities:

3.2. Principles of Operation of the Infrastructure of Industrial Enterprises Using BIM Technology in Conjunction with MBSE

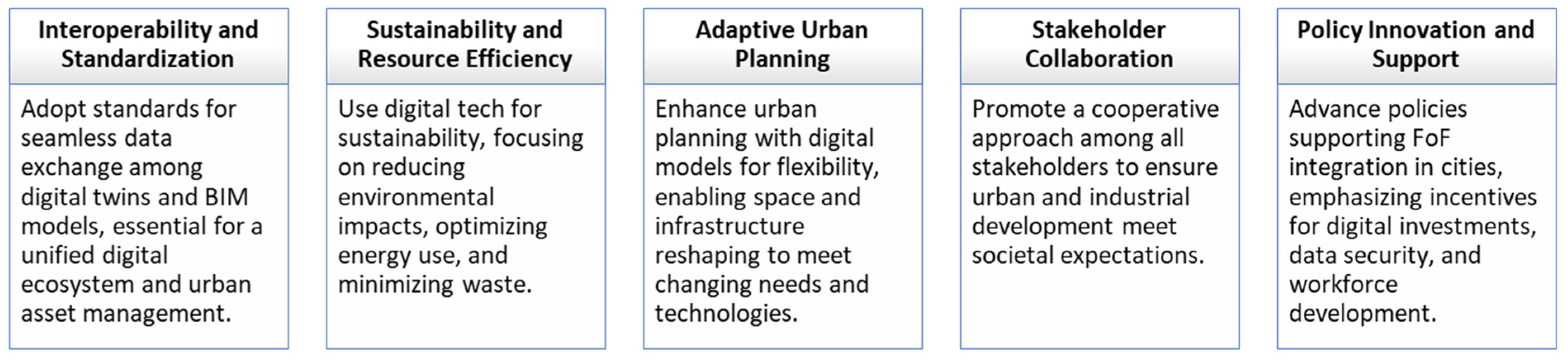

- Interoperability and Standardization: Ensuring seamless data exchange and communication between digital twins, BIM models, and urban digital infrastructures requires the adoption of interoperability standards and protocols. This principle is foundational for creating a cohesive digital ecosystem that supports the lifecycle management of urban assets.

- Sustainability and Resource Efficiency: Integration strategies must prioritize sustainability and resource efficiency, leveraging AI and digital technologies to minimize environmental footprints through optimized energy consumption, waste reduction, and sustainable material usage.

- Adaptive Urban Planning: Urban planning frameworks need to be adaptable, incorporating digital models that can simulate various scenarios and outcomes. This adaptability allows for the dynamic reconfiguration of urban spaces and infrastructure in response to evolving manufacturing technologies and urban needs.

- Stakeholder Collaboration: The integration process must foster collaborative frameworks that engage all relevant stakeholders, including government bodies, industry leaders, academic institutions, and local communities. This collaboration is crucial for aligning urban development and industrial innovation with societal needs and expectations.

- Policy Innovation and Support: Developing and implementing policy innovations that facilitate the integration of FoF into urban settings. This includes providing incentives for digital infrastructure investments, ensuring data privacy and security, and supporting workforce development to meet the demands of the digital age.

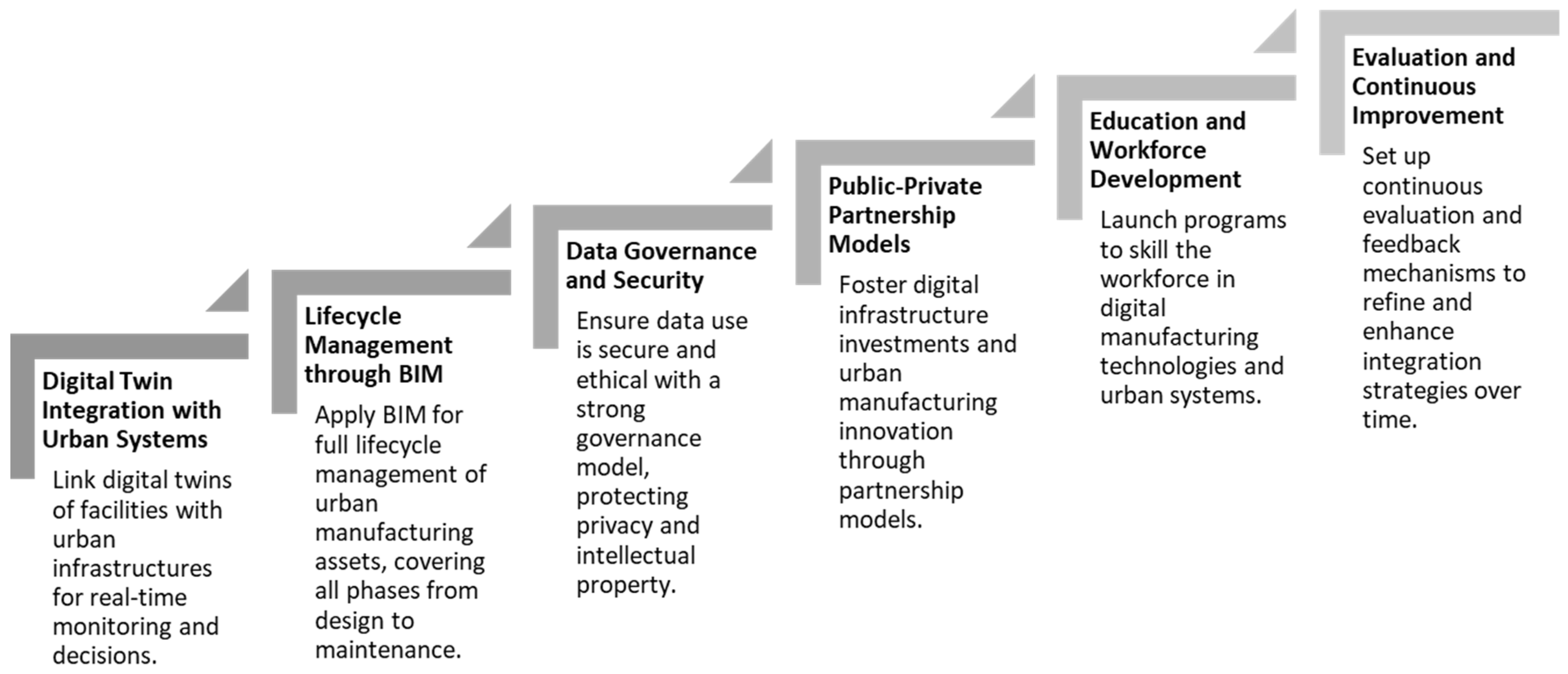

3.3. Framework for the Seamless Integration of Factories of the Future (FoF) into the Digital and Physical Landscape of Smart Cities

- Digital Twin Integration with Urban Systems: A methodology for integrating digital twins of manufacturing facilities with urban digital infrastructures, enabling real-time monitoring and decision-making.

- Lifecycle Management through BIM: Utilizing BIM for comprehensive lifecycle management of urban manufacturing assets, from design and construction to operation and maintenance.

- Data Governance and Security: Establishing a robust data governance model that ensures the secure and ethical use of data, protecting the privacy of individuals and the intellectual property of businesses.

- Public-Private Partnership Models: Developing partnership models that encourage investment in digital infrastructure and foster innovation in urban manufacturing ecosystems.

- Education and Workforce Development: Implementing education and training programs to equip the workforce with the skills necessary for operating and maintaining digital manufacturing technologies and urban systems.

- Evaluation and Continuous Improvement: Creating mechanisms for the continuous evaluation of integration efforts, leveraging feedback loops to refine and improve strategies over time.

4. Discussion

4.1. Implications for Urban Development and Industrial Innovation

- Enhanced Operational Efficiency: By leveraging real-time data and predictive analytics, cities can optimize manufacturing processes, reduce waste, and minimize environmental impacts, contributing to the sustainability goals of urban areas. The integration of intelligent algorithms into systems will be the key to significant improvements and the discovery of new insights.

- Adaptive Urban Infrastructure: The principles of flexibility and adaptability highlighted in our framework underscore the need for urban infrastructure to evolve in tandem with advancements in manufacturing technologies. This adaptability is crucial for maintaining the relevance and competitiveness of urban industrial areas.

- Collaborative Urban Planning: The emphasis on stakeholder collaboration points towards a participatory approach to urban planning, where the needs and insights of various stakeholders, including manufacturers, urban planners, policymakers, and residents, are integrated into the development process.

4.2. Challenges in Integration

- Technological Interoperability: Achieving seamless data exchange between diverse systems and platforms remains a significant challenge, necessitating the development of standardized protocols and interfaces. The open data philosophy will play an important role in fostering further progress within interoperability.

- Data Governance and Privacy: The management of vast amounts of data generated by integrated systems raises concerns about data governance, privacy, and security, requiring robust regulatory frameworks.

- Skill Development and Workforce Training: The successful implementation of integrated technologies demands a skilled workforce capable of navigating the complexities of BIM and DT systems, including IA algorithms, highlighting the need for comprehensive training programs.

- Technological Interoperability:

- Develop and adopt standardized protocols and interfaces to ensure seamless data exchange.

- Foster open-source platforms and collaborative initiatives to promote interoperability.

- Data Governance and Privacy:

- Implement robust data governance frameworks to protect privacy and ensure ethical data use.

- Develop policies and regulations that balance innovation with data security.

- Talent Development:

- Create specialized training programs to equip the workforce with the necessary skills.

- Collaborate with educational institutions to develop curricula that focus on digital manufacturing technologies.

4.3. Future Directions

- Developing Scalable Integration Models: Future studies should aim to develop scalable models of integration that can be adapted to different urban and industrial contexts, considering the diverse needs and capacities of cities worldwide.

- Applying AI to urban industrial areas. The recent popularity of AI applied to all areas of life has proven to be a valuable tool that promotes advances in all fields of knowledge. Future developers of models and algorithms in Industrial Urban Areas must incorporate knowledge and experience to maximise the efficiency and effectiveness of the results.

- Evaluating Economic and Social Impacts: There is a need for comprehensive studies to evaluate the economic benefits and social impacts of integrating FoF into urban areas, including job creation, economic diversification, and quality of life improvements.

- Advancing Policy and Regulatory Frameworks: To support the integration of FoF, future research should also explore the development of supportive policy and regulatory frameworks that incentivize innovation while ensuring social equity and environmental sustainability.

- Developing Scalable Integration Models:

- Conduct pilot projects to test integration models in various urban contexts.

- Use the results to refine and scale the models, considering different city sizes and industrial capacities.

- Evaluating Economic and Social Impacts:

- Develop metrics and indicators to assess the economic and social benefits of FoF integration.

- Conduct longitudinal studies to track changes in job creation, economic growth, and quality of life.

- Smart Manufacturing Hubs:

- ○

- Centralized locations where advanced manufacturing processes are integrated with urban infrastructure.

- ○

- These hubs leverage IoT, AI, and digital twins for real-time optimization and monitoring.

- Decentralized Production Units:

- ○

- Smaller, flexible production units distributed across urban areas to meet local demands.

- ○

- These units utilize BIM for efficient space management and resource allocation.

- Collaborative Platforms:

- ○

- Digital platforms that facilitate collaboration between manufacturers, suppliers, and urban planners.

- ○

- They enable data sharing, joint decision-making, and coordinated urban-industrial planning.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burggräf, P.; Bergs, T.; Dannapfel, M.; Korff, A.; Ebade Esfahani, M.; Splettstoesser, A.; Steinlein, J. Achieving Parametric Transparency in Model-Based Factory Planning. Prod. Eng. 2021, 15, 57–67. [Google Scholar] [CrossRef]

- Badenko, V.L.; Bolshakov, N.S.; Tishchenko, E.B.; Fedotov, A.A.; Celani, A.C.; Yadykin, V.K. Integration of Digital Twin and BIM Technologies within Factories of the Future. Mag. Civ. Eng. 2021, 101, 10114. [Google Scholar] [CrossRef]

- Kalsoom, T.; Ahmed, S.; Rafi-ul-Shan, P.M.; Azmat, M.; Akhtar, P.; Pervez, Z.; Imran, M.A.; Ur-Rehman, M. Impact of IoT on Manufacturing Industry 4.0: A New Triangular Systematic Review. Sustainability 2021, 13, 12506. [Google Scholar] [CrossRef]

- Bolshakov, N.; Badenko, V.; Yadykin, V.; Tishchenko, E.; Rakova, X.; Mohireva, A.; Kamsky, V.; Barykin, S. Cross-Industry Principles for Digital Representations of Complex Technical Systems in the Context of the MBSE Approach: A Review. Appl. Sci. 2023, 13, 6225. [Google Scholar] [CrossRef]

- Butt, J. A Conceptual Framework to Support Digital Transformation in Manufacturing Using an Integrated Business Process Management Approach. Designs 2020, 4, 17. [Google Scholar] [CrossRef]

- Rajani, R.L.; Heggde, G.S.; Kumar, R.; Bangwal, D. Demand Management Approaches in Services Sector and Influence on Company Performance. Int. J. Product. Perform. Manag. 2023, 72, 2808–2837. [Google Scholar] [CrossRef]

- Dér, A.; Hingst, L.; Nyhuis, P.; Herrmann, C. A Review of Frameworks, Methods and Models for the Evaluation and Engineering of Factory Life Cycles. Adv. Ind. Manuf. Eng. 2022, 4, 100083. [Google Scholar] [CrossRef]

- Bécue, A.; Maia, E.; Feeken, L.; Borchers, P.; Praça, I. A New Concept of Digital Twin Supporting Optimization and Resilience of Factories of the Future. Appl. Sci. 2020, 10, 4482. [Google Scholar] [CrossRef]

- Grznár, P.; Gregor, M.; Krajčovič, M.; Mozol, Š.; Schickerle, M.; Vavrík, V.; Ďurica, L.; Marschall, M.; Bielik, T. Modeling and Simulation of Processes in a Factory of the Future. Appl. Sci. 2020, 10, 4503. [Google Scholar] [CrossRef]

- Dér, A.; Hingst, L.; Karl, A.; Nyhuis, P.; Herrmann, C. Factory Life Cycle Evaluation through Integrated Analysis of Factory Elements. Procedia CIRP 2021, 98, 418–423. [Google Scholar] [CrossRef]

- Yildiz, E.; Møller, C.; Bilberg, A. Demonstration and Evaluation of a Digital Twin-Based Virtual Factory. Int. J. Adv. Manuf. Technol. 2021, 114, 185–203. [Google Scholar] [CrossRef]

- Delbrugger, T.; Lenz, L.T.; Losch, D.; Rosmann, J. A Navigation Framework for Digital Twins of Factories Based on Building Information Modeling. In Proceedings of the 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017; IEEE: New York, NY, USA, 2017; pp. 1–4. [Google Scholar]

- Bolshakov, N.; Badenko, V.; Yadykin, V.; Celani, A.; Fedotov, A. Digital Twins of Complex Technical Systems for Management of Built Environment. IOP Conf. Ser. Mater. Sci. Eng. 2020, 869, 062045. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Salehi, V. Development of an Agile Concept for Mbse for Future Digital Products through the Entire Life Cycle Management Called Munich Agile MBSE Concept (MAGIC). Comput. Aided. Des. Appl. 2020, 17, 147–166. [Google Scholar] [CrossRef]

- Reisinger, J.; Knoll, M.; Kovacic, I. Design Space Exploration for Flexibility Assessment and Decision Making Support in Integrated Industrial Building Design. Optim. Eng. 2021, 22, 1693–1725. [Google Scholar] [CrossRef]

- Suntsova, O. The Definition of Smart Economy and Digital Transformation of Business in the Concepts Industry 4.0 and 5.0. Technol. Audit Prod. Reserv. 2022, 4, 18–23. [Google Scholar] [CrossRef]

- Bolshakov, N.; Rakova, X.; Celani, A.; Badenko, V. Operation Principles of the Industrial Facility Infrastructures Using Building Information Modeling (BIM) Technology in Conjunction with Model-Based System Engineering (MBSE). Appl. Sci. 2023, 13, 11804. [Google Scholar] [CrossRef]

- Salierno, G.; Cabri, G.; Leonardi, L. Different Perspectives of a Factory of the Future: An Overview. In Proceedings of the Advanced Information Systems Engineering Workshops: CAiSE 2019 International Workshops, Rome, Italy, 3–7 June 2019; Proceedings 31. pp. 107–119. [Google Scholar]

- Reisinger, J.; Kugler, S.; Kovacic, I.; Knoll, M. Parametric Optimization and Decision Support Model Framework for Life Cycle Cost Analysis and Life Cycle Assessment of Flexible Industrial Building Structures Integrating Production Planning. Buildings 2022, 12, 162. [Google Scholar] [CrossRef]

- Adanič, L.; de Oliveira, S.G.; Tibaut, A. BIM and Mechanical Engineering—A Cross-Disciplinary Analysis. Sustainability 2021, 13, 4108. [Google Scholar] [CrossRef]

- Szeligova, N.; Faltejsek, M.; Teichmann, M.; Kuda, F.; Endel, S. Potential of Computed Aided Facility Management for Urban Water Infrastructure with the Focus on Rainwater Management. Water 2023, 15, 104. [Google Scholar] [CrossRef]

- Bangwal, D.; Tiwari, P.; Chamola, P. Green HRM, Work-Life and Environment Performance. Int. J. Environ. Work. Employ. 2017, 4, 244–268. [Google Scholar] [CrossRef]

- Bosch, A.; Volker, L.; Koutamanis, A. BIM in the Operations Stage: Bottlenecks and Implications for Owners. Built Environ. Proj. Asset Manag. 2015, 5, 331–343. [Google Scholar] [CrossRef]

- Coupry, C.; Noblecourt, S.; Richard, P.; Baudry, D.; Bigaud, D. BIM-Based Digital Twin and XR Devices to Improve Maintenance Procedures in Smart Buildings: A Literature Review. Appl. Sci. 2021, 11, 6810. [Google Scholar] [CrossRef]

- Bolshakov, N.; Badenko, V.; Yadykin, V.; Celani, A. As-Built BIM in Real Estate Management: The Change of Paradigm in Digital Transformation of Economy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 940, 012017. [Google Scholar] [CrossRef]

- Godager, B.; Mohn, K.; Merschbrock, C.; Klakegg, O.J.; Huang, L. Towards an improved framework for enterprise BIM: The role of ISO 19650. J. Inf. Technol. Constr. 2022, 27, 1075–1103. [Google Scholar] [CrossRef]

- Arisekola, K.; Madson, K. Digital Twins for Asset Management: Social Network Analysis-Based Review. Autom. Constr. 2023, 150, 104833. [Google Scholar] [CrossRef]

- Chen, Z.S.; Zhou, M.D.; Chin, K.S.; Darko, A.; Wang, X.J.; Pedrycz, W. Optimized Decision Support for BIM Maturity Assessment. Autom. Constr. 2023, 149, 104808. [Google Scholar] [CrossRef]

- Pidgeon, A.; Dawood, N. Bridging the Gap between Theory and Practice for Adopting Meaningful Collaborative BIM Processes in Infrastructure Projects, Utilising Multi-Criteria Decision Making (MCDM). J. Inf. Technol. Constr. 2021, 26, 783–811. [Google Scholar] [CrossRef]

- Kukkonen, V.; Kücükavci, A.; Seidenschnur, M.; Rasmussen, M.H.; Smith, K.M.; Hviid, C.A. An Ontology to Support Flow System Descriptions from Design to Operation of Buildings. Autom. Constr. 2022, 134, 104067. [Google Scholar] [CrossRef]

- Liu, Z.; Chi, Z.; Osmani, M.; Demian, P. Blockchain and Building Information Management (Bim) for Sustainable Building Development within the Context of Smart Cities. Sustainability 2021, 13, 2090. [Google Scholar] [CrossRef]

- Petri, I.; Rezgui, Y.; Ghoroghi, A.; Alzahrani, A. Digital Twins for Performance Management in the Built Environment. J. Ind. Inf. Integr. 2023, 33, 100445. [Google Scholar] [CrossRef]

- Figueiredo, K.; Pierott, R.; Hammad, A.W.A.; Haddad, A. Sustainable Material Choice for Construction Projects: A Life Cycle Sustainability Assessment Framework Based on BIM and Fuzzy-AHP. Build. Environ. 2021, 196, 107805. [Google Scholar] [CrossRef]

- Sikelis, K.; Tsekouras, G.E.; Kotis, K. Ontology-Based Feature Selection: A Survey. Future Internet 2021, 13, 158. [Google Scholar] [CrossRef]

- Wang, H.; Pan, Y.; Luo, X. Integration of BIM and GIS in Sustainable Built Environment: A Review and Bibliometric Analysis. Autom. Constr. 2019, 103, 41–52. [Google Scholar] [CrossRef]

- Fernández-Alvarado, J.F.; Fernández-Rodríguez, S. 3D Environmental Urban BIM Using LiDAR Data for Visualisation on Google Earth. Autom. Constr. 2022, 138, 104251. [Google Scholar] [CrossRef]

- Luo, S.; Yao, J.; Wang, S.; Wang, Y.; Lu, G. A Sustainable BIM-Based Multidisciplinary Framework for Underground Pipeline Clash Detection and Analysis. J. Clean. Prod. 2022, 374, 133900. [Google Scholar] [CrossRef]

- Azzam, A.; El Zayat, M.; Marzouk, M. Integrated Approach for Sustainability Assessment in Power Plant Projects Using Building Information Modeling. Energy Sustain. Dev. 2022, 66, 222–237. [Google Scholar] [CrossRef]

- Keskin, B.; Salman, B. Building Information Modeling Implementation Framework for Smart Airport Life Cycle Management. Transp. Res. Rec. 2020, 2674, 98–112. [Google Scholar] [CrossRef]

- Tarek, H.; Marzouk, M. Integrated Augmented Reality and Cloud Computing Approach for Infrastructure Utilities Maintenance. J. Pipeline Syst. Eng. Pract. 2022, 13, 04021064. [Google Scholar] [CrossRef]

- Tolmer, C.E.; Castaing, C.; Diab, Y.; Morand, D. Adapting LOD Definition to Meet BIM Uses Requirements and Data Modeling for Linear Infrastructures Projects: Using System and Requirement Engineering. Vis. Eng. 2017, 5, 21. [Google Scholar] [CrossRef]

- Pennekamp, J.; Glebke, R.; Henze, M.; Meisen, T.; Quix, C.; Hai, R.; Gleim, L.; Niemietz, P.; Rudack, M.; Knape, S.; et al. Towards an Infrastructure Enabling the Internet of Production. In Proceedings of the 2019 IEEE International Conference on Industrial Cyber Physical Systems (ICPS), Taipei, Taiwan, 6–9 May 2019; IEEE: New York, NY, USA; pp. 31–37. [Google Scholar]

- Zhang, L.; Yan, Y.; Hu, Y.; Ren, W. Reinforcement Learning and Digital Twin-Based Real-Time Scheduling Method in Intelligent Manufacturing Systems. IFAC-PapersOnLine 2022, 55, 359–364. [Google Scholar] [CrossRef]

| Topic | Frequency of Mention (%) | Relevance to Research Goals (1–5) | Alignment with Technological Advancements (1–5) |

|---|---|---|---|

| Interoperability Challenges between Digital Twins and Urban Systems | 79% | 5 | 5 |

| Sustainability-Driven Design Principles in Urban Manufacturing | 72% | 5 | 4 |

| Emerging Role of BIM in Dynamic Urban Planning | 67% | 4 | 5 |

| Economic Impacts of Digital Transformation | 60% | 3 | 4 |

| Social Implications of Technological Integration | 64% | 3 | 3 |

| Policy and Regulatory Challenges | 50% | 4 | 3 |

| Technological Advancements in AI and IoT | 44% | 3 | 4 |

| Workforce Development and Training Needs | 42% | 3 | 3 |

| Data Privacy and Security Concerns | 38% | 4 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolshakov, N.; Celani, A.; Badenko, V.; Benedicto, R.M. Factories of the Future in Digitization of Industrial Urban Areas. Urban Sci. 2024, 8, 66. https://doi.org/10.3390/urbansci8020066

Bolshakov N, Celani A, Badenko V, Benedicto RM. Factories of the Future in Digitization of Industrial Urban Areas. Urban Science. 2024; 8(2):66. https://doi.org/10.3390/urbansci8020066

Chicago/Turabian StyleBolshakov, Nikolai, Alberto Celani, Vladimir Badenko, and Rafael Magdalena Benedicto. 2024. "Factories of the Future in Digitization of Industrial Urban Areas" Urban Science 8, no. 2: 66. https://doi.org/10.3390/urbansci8020066

APA StyleBolshakov, N., Celani, A., Badenko, V., & Benedicto, R. M. (2024). Factories of the Future in Digitization of Industrial Urban Areas. Urban Science, 8(2), 66. https://doi.org/10.3390/urbansci8020066