3.1. Method

The PICO (Population, Intervention, Comparison, Outcome) approach has proven to be an essential tool in scientific research due to its ability to structure and organize complex questions in a clear and systematic manner, as illustrated in

Table 1. When applied rigorously, the PICO methodology enables a detailed and objective analysis of the central elements of a study, minimizing subjective biases that are often present in other approaches, such as narrative reviews [

30]. Although originally developed for healthcare and medical research, the PICO framework has demonstrated value in fields such as production engineering, industrial automation, and digital transformation, as evidenced by recent studies [

31]. It facilitates the formulation of precise research questions and the selection of relevant studies, ensuring that the collected data are analyzed consistently and comparably [

31].

In the present study, the PICO methodology is employed to organize the analysis of the implementation of a low-cost model for digital transformation in industrial organizations within the context of Industry 4.0. Adapting this methodology to the industrial context provides a systematic approach to understanding how the proposed model affects operational efficiency, cost reduction, and the acceleration of digitalization processes within organizations [

32,

33].

The application of the PICO framework in this study is defined as follows:

Population: Industrial organizations that have already implemented or are planning to adopt digital transformation initiatives, with a particular focus on cost-effective strategies. Precisely defining the population is critical to ensuring that the results are relevant and applicable to companies facing similar challenges in integrating digital technologies in an economically efficient manner.

Intervention: The implementation of the low-cost model for digital transformation, incorporating accessible technologies, process automation, and the integration of digital solutions aimed at optimizing internal operations and reducing expenses. This intervention is grounded in growing evidence that cost-efficient digitalization can simultaneously enhance operational performance and organizational competitiveness [

34].

Comparison: A comparison is conducted between traditional processes, executed manually or using pre-existing digital systems, and the application of the low-cost model developed in this study. The analysis evaluates outcomes before and after implementation, emphasizing improvements in efficiency, cost savings, and the speed of digital transformation.

Outcome: The expected outcomes include significant enhancements in operational efficiency, reduction in organizational costs, and acceleration of digital transformation within industrial organizations. Utilizing the PICO methodology allows for the formulation of robust hypotheses and a grounded analysis based on concrete evidence, thereby demonstrating the effectiveness of the proposed model.

The methodology adopted in this study involved a comprehensive review of scientific sources and the application of the PICO framework for article selection, using strict inclusion and exclusion criteria. The selection process relied on detailed bibliographic searches and careful screening of titles and abstracts, prioritizing studies that addressed digital transformation, Industry 4.0, process automation, and cost-effective solutions. Publications that did not meet the relevance criteria were excluded, resulting in a final selection of studies that are directly pertinent to the research objectives. All sources were obtained from reputable scientific databases to ensure reliability and currency [

34].

Although the PICO framework provides a structured and transparent method for organizing the research question and selecting relevant evidence, it also presents inherent limitations. One of the main constraints is its tendency to simplify complex organizational environments into discrete categories (Population, Intervention, Comparison, Outcome). While this enhances clarity, it may also restrict the analysis by overlooking contextual factors, such as organizational culture, management commitment, or market dynamics, which can significantly influence digital transformation processes. Furthermore, PICO was originally designed for clinical and experimental research settings, where variables can be more easily controlled. In industrial and organizational studies, where real environments involve high variability and less experimental control, the rigid structure of PICO may not fully capture the multidimensional nature of digital transformation initiatives.

Another limitation concerns the framework’s dependency on clearly defined comparison conditions. Although PICO encourages the establishment of a Comparison (C) group or baseline, the present study faced practical constraints that hindered the implementation of a formal control group. The case company lacked parallel processes that could serve as a simultaneous comparator, and operational limitations made it unfeasible to maintain two distinct versions of a process in real time. As a result, the comparison relied primarily on pre- and post-intervention performance indicators. While this approach provides valuable insights, it may introduce a degree of bias, as external factors occurring during the implementation period could influence the results. Future studies would benefit from the inclusion of multiple case studies or controlled experimental environments to enhance the robustness of comparative analyses.

Additionally, the PICO approach may not fully accommodate iterative and emergent aspects of digital transformation, which often involve continuous adaptation rather than discrete interventions. Industrial digitalization typically unfolds incrementally and is influenced by employee adoption, technological maturity, and evolving business needs—factors that extend beyond the linear logic of PICO. For this reason, the methodology should be complemented by qualitative assessments and longitudinal monitoring to ensure a comprehensive understanding of the model’s effectiveness and its broader organizational impact.

Despite these limitations, the adoption of PICO in this study remains justified due to its ability to provide methodological rigor, transparency, and replicability, particularly in structuring the research question and selecting supporting literature. However, recognizing its constraints is essential to guiding future research toward more holistic methodological combinations, such as mixed-methods approaches or multi-case comparative studies.

Data collection was carried out using renowned scientific databases, namely through the B-on platform (Online Knowledge Library), a search engine and aggregator of scientific content provided by the FCT (Foundation for Science and Technology) in Portugal. B-on allows integrated access to a wide range of international scientific information resources, bringing together publications from various repositories, publishers, and databases at a single research point. These include platforms such as Scopus, Web of Science, ScienceDirect (Elsevier), SpringerLink (Springer Nature), Wiley Online Library, Taylor & Francis Online, SAGE Journals, IEEE Xplore, ACM Digital Library, Emerald Insight, Oxford University Press, Cambridge University Press, Nature Publishing Group, and ProQuest, among others. Thus, the use of B-on guarantees access to reliable, up-to-date, and highly rigorous scientific sources, essential for the quality and validity of the research process.

The application of the PICO methodology provides a robust framework for organizing the analysis of the collected data, highlighting the clear connection between the formulated hypotheses and the evidence identified in the literature [

34]. Consequently, this approach facilitates result interpretation and the development of an effective low-cost digital transformation model, emphasizing operational efficiency and cost optimization.

The inclusion criteria adopted in this study were as follows:

Articles that directly address the implementation or evaluation of low-cost models for digital transformation in industrial organizations and Industry 4.0 contexts.

Studies conducted between 2010 and 2025 to ensure the timeliness and relevance of the technologies and practices discussed.

Peer-reviewed publications with full-text availability.

The exclusion criteria were as follows:

Articles that do not focus on cost-effective digital solutions or that address contexts unrelated to Industry 4.0.

Studies lacking clear evidence regarding operational efficiency or cost reduction.

Publications inaccessible in full or with restricted access.

Works not based on empirical methodologies or presenting inconsistent data.

This rigorous selection process ensured that the analysis was based on high-quality, relevant sources and directly applicable to the study of implementing a low-cost digital transformation model in industrial organizations, with a focus on operational efficiency and cost reduction.

The central research question and hypotheses guiding this study were formulated as follows:

Central Research Question (CRQ)

CRQ. Can the adoption of a low-cost model accelerate digital transformation in industrial organizations while enhancing operational efficiency and reducing costs?

Hypotheses (H)

H1. The implementation of a low-cost model leads to significant gains in operational efficiency, optimizing internal processes and reducing organizational waste.

H2. The adoption of a low-cost model accelerates digital transformation, achieving a balance between technological advancement and economic efficiency without compromising organizational performance.

To address these research questions, a comprehensive literature search was conducted in recognized scientific databases using groups of keywords structured by thematic concepts and synonyms, as detailed in

Table 2.

Boolean operators were employed to combine search terms across titles, abstract and keywords, ensuring that only articles addressing all fundamental concepts were retrieved. This strategy significantly improved the relevance and accuracy of the results (

Table 3).

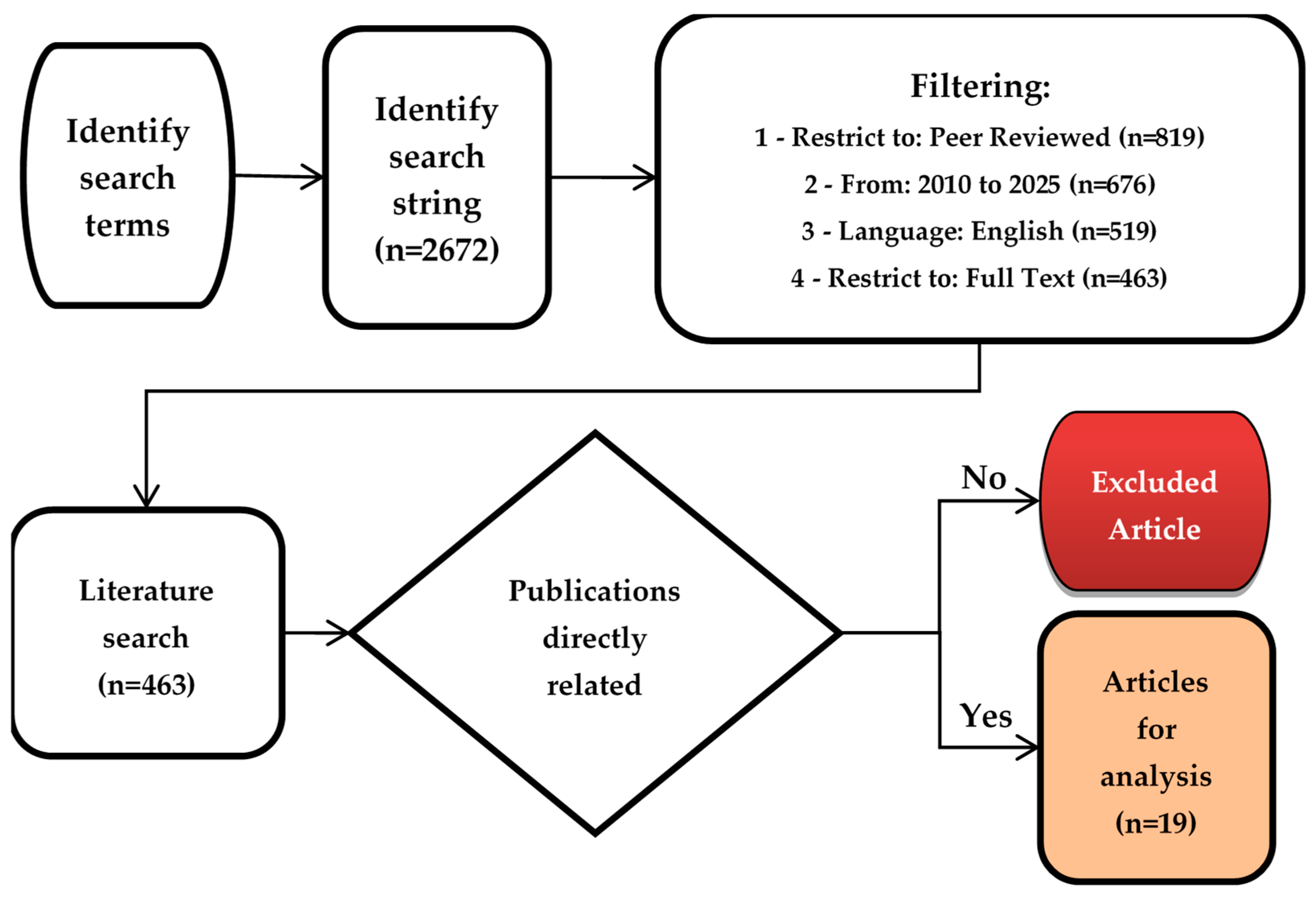

Following the application of additional filters, including publication period, language, full-text availability, and peer-review status, the dataset was refined from an initial 2672 articles to 463, of which, 19 were directly relevant to the study objectives.

Figure 1 presents a flowchart illustrating the systematic article selection and screening process, demonstrating the methodological rigor applied in the literature review and ensuring the selection of high-quality sources to support the research.

3.2. Articles Synthesis and Analysis

The following table provides a comprehensive overview of the key aspects covered in the literature (

Table 4).

The systematic synthesis of the identified literature, summarized in

Table 4, reveals a clear predominance of studies centered on automation and artificial intelligence (AI) as the driving forces behind industrial digital transformation. Indeed, all reviewed works (100%) emphasize the technological dimension, confirming its consolidated theoretical and practical relevance within the context of Industry 4.0. However, only 37% of the analyzed articles incorporate aspects related to low-cost adoption, signaling an underexplored research domain with significant practical implications, particularly for small- and medium-sized enterprises (SMEs) facing resource constraints.

In terms of the type of contribution, a marked prevalence of literature reviews (approximately 60%) is observed, followed by conceptual models and a smaller number of case studies. This distribution suggests that the academic debate remains largely conceptual, oriented toward theoretical consolidation rather than empirical application. The scarcity of validated case studies underscores a lack of practical testing of proposed frameworks or models, limiting the transferability of knowledge to real industrial environments.

Moreover, the intersection of “low-cost adoption” and “automation/AI integration” appears in only a minority of the works. This indicates that, although the technological core of Industry 4.0 is well established, its translation into accessible, incremental, and financially viable implementation paths remains insufficiently developed. The few articles that address both aspects tend to focus on general guidelines rather than detailed, cost-structured methodologies or replicable models.

Therefore, the literature portrays a mature theoretical ecosystem regarding automation and AI, but one that is fragmented in terms of accessibility, affordability, and operational scalability. These gaps highlight the necessity for research that bridges theory and practice through structured, validated, and economically feasible frameworks adaptable to different organizational contexts.

3.3. Discussion of Article Analysis Results

The analysis of the reviewed literature reveals strong theoretical maturity around automation and AI, confirming their central role in industrial digital transformation. Nevertheless, significant gaps persist regarding low-cost and incremental implementation approaches. While all studies emphasize the technological component, only about one-third address financially accessible strategies, and just a small portion incorporate sustainability as a structured objective. Most works are conceptual or review-based, with limited empirical validation and scarce practical guidance for SMEs.

These findings reveal a disconnect between the academic discourse and industrial reality, where organizations—especially SMEs—require concrete, validated, and cost-effective methodologies to adopt Industry 4.0 technologies. The lack of structured implementation frameworks limits the diffusion of digital transformation beyond large corporations with substantial investment capacities. Consequently, the literature demonstrates a pressing need for pragmatic, modular, and financially viable models capable of guiding stepwise technological adoption with measurable outcomes.

In particular, the limited number of case studies highlights the absence of empirical validation, an essential element for assessing feasibility, replicability, and scalability. Moreover, the weak connection between technical, organizational, and managerial dimensions restricts the holistic understanding necessary for sustainable and resilient transformation processes. Governance aspects, risk management, and workforce adaptation are often treated superficially or independently, rather than as integral components of implementation.

Hence, the results justify the development of a low-cost implementation framework designed to operationalize digital transformation in a structured, evidence-based, and accessible manner. This framework should integrate technical, economic, and governance dimensions, supported by modular maturity levels that allow incremental progress according to organizational capacity and digital readiness. Additionally, standardized validation mechanisms—including ROI estimation, payback analysis, and pilot testing protocols—are essential to ensure empirical robustness and industrial relevance.

Overall, the synthesis confirms that although automation and AI are extensively addressed, guidance for accessible, practical, and empirically verifiable adoption remains limited. This knowledge gap creates a solid foundation for advancing research toward the Implementation of a Low-Cost Model for Digital Transformation of Industrial Organizations in Industry 4.0, enabling the development of a replicable, scalable, and governance-oriented model that supports organizations—especially SMEs—in their journey toward efficient and responsible digital transformation.