Digital Twins in Manufacturing: A RAMI 4.0 Compliant Concept

Abstract

:1. Introduction

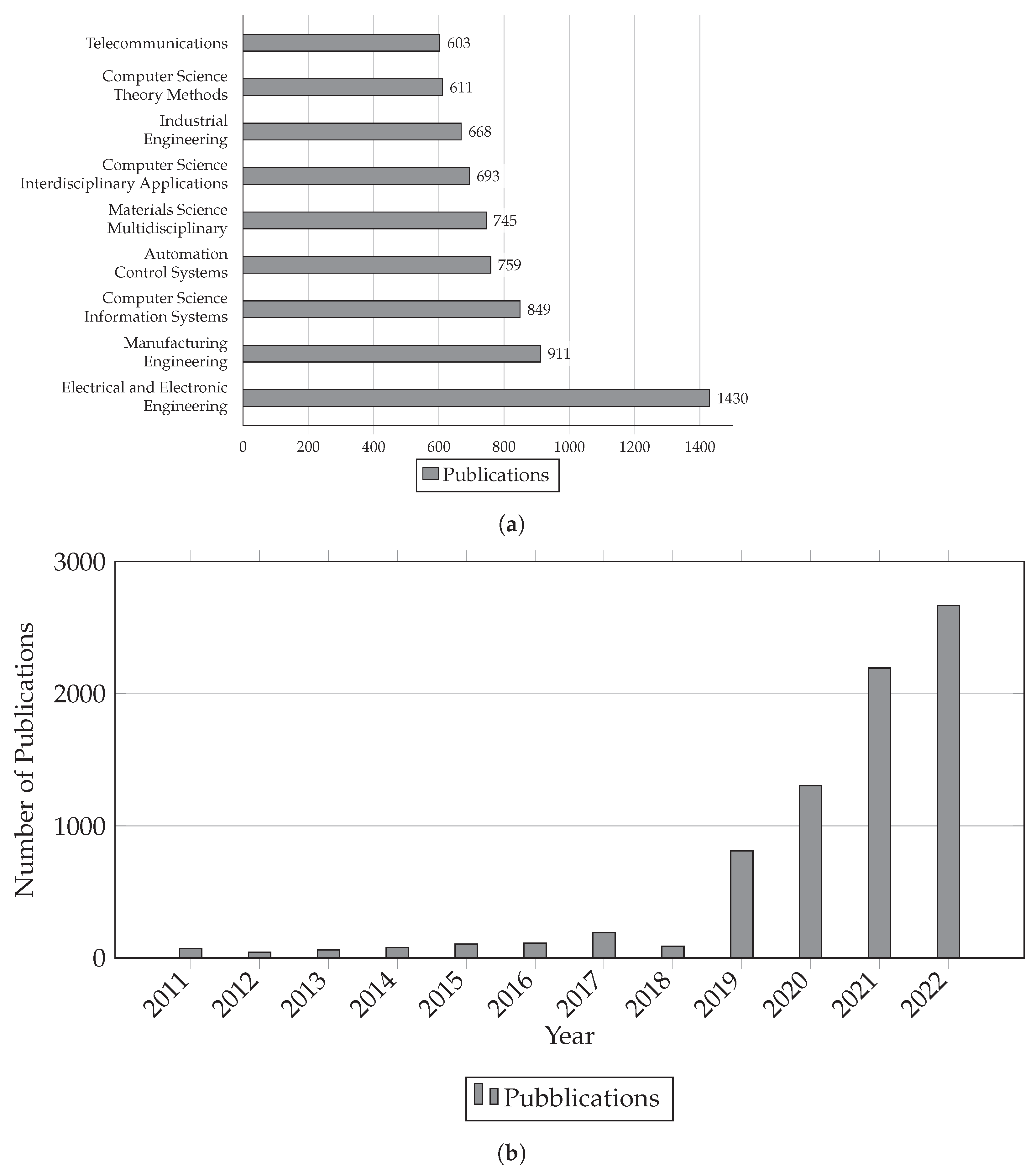

2. State of the Art and Research

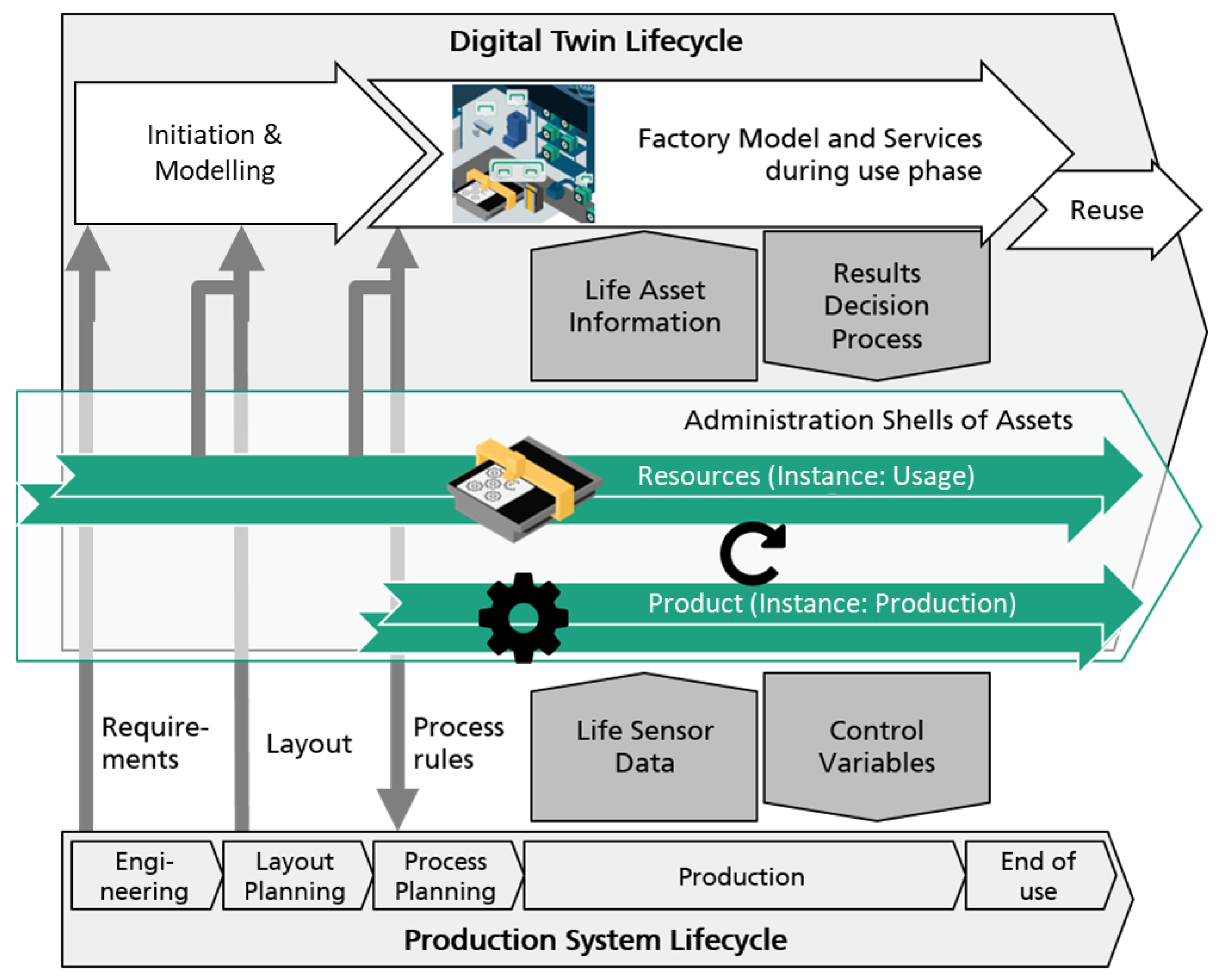

2.1. RAMI 4.0 Architecture

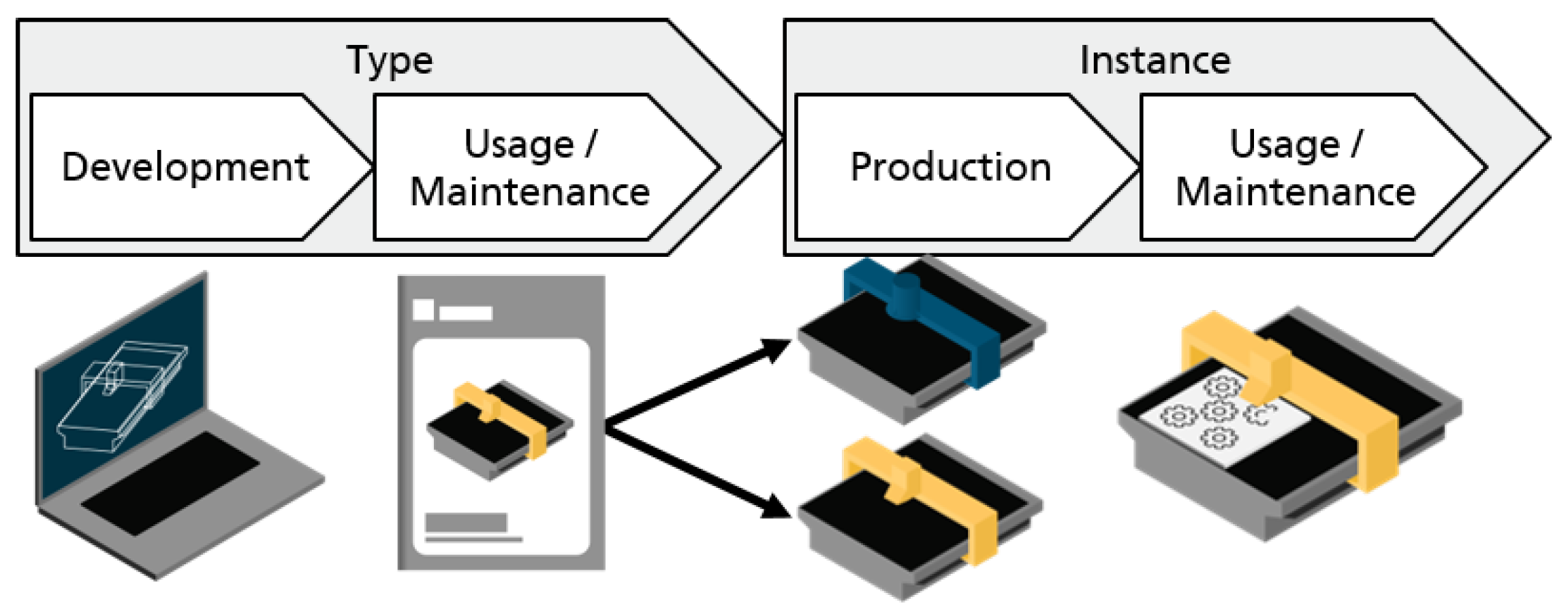

2.2. Asset Administration Shell (AAS)

2.3. Digital Twin

A DM is a digital representation of an existing or planned physical object that does not use any form of automated data exchange between the physical object and the digital object. The digital representation might include a more or less comprehensive description of the physical object. These models might include, but are not limited to simulation models of planned factories, mathematical models, or any other models of a physical object, which do not use any form of automatic data integration. Digital data of existing physical systems might still be in use for the development of such models, but all data exchange is done in a manual way. A change in state of the physical object has no direct effect on the digital object and vice versa.

DS based on the definition of a Digital Model, if there further exists an automated one-way data flow between the state of an existing physical object and a digital object, one might refer to such a combination as Digital Shadow. A change in state of the physical object leads to a change of state in the digital object, but not vice versa.

DS is a data profile that couples with the corresponding entity throughout its life cycle, and carries all the data and knowledge to reflect the individual shape and historical, current, and expected future status.

2.4. Research Methodology

- Preparation

- Planning

- Screening

- Classification

2.4.1. Step 1—Preparation

2.4.2. Step 2—Planning

- Check for the right research field of an article.

- Review the title.

- Verify the abstract.

- Check the full text to find descriptions or definitions of the term “digital twin”.

- Check the references for additional sources.

2.4.3. Step 3—Screening

2.4.4. Step 4—Classification

2.5. Definitions of Digital Twin

3. Research Gap

- Possibility to automatically control the real asset, also with results from the services.

- Possibility for real-time automatic data acquisition and control.

- Data and knowledge-based (compare Table 3): the most up-to-date data and rules available should always be used in the modeling and in the use phase.

| DT Element | Based on Reference |

|---|---|

| real physical asset/entity | [7,14,15,17,18,19,20,22,29,30,31,32,33,34,35,36,37,39,40,42,43,44,45,46,47,49,53] |

| virtual model/entity that describes the real asset (physical, math, 3D models, etc.) and is capable of predicting the behavior of the real asset | all references given in Table 2 |

| data which describe the real physical asset (contains data harvested from the real asset and from services) | [7,15,17,22,23,29,30,31,32,34,45,47,53] |

| services (e.g., monitoring, simulations, prognosis, optimization, and control) | [6,7,17,19,22,29,30,31,32,33,34,41,43,45] |

| full connection between the elements (physical asset, virtual model, data and services) for data exchange | [14,15,17,18,20,22,29,31,33,36,37,42,43,49] |

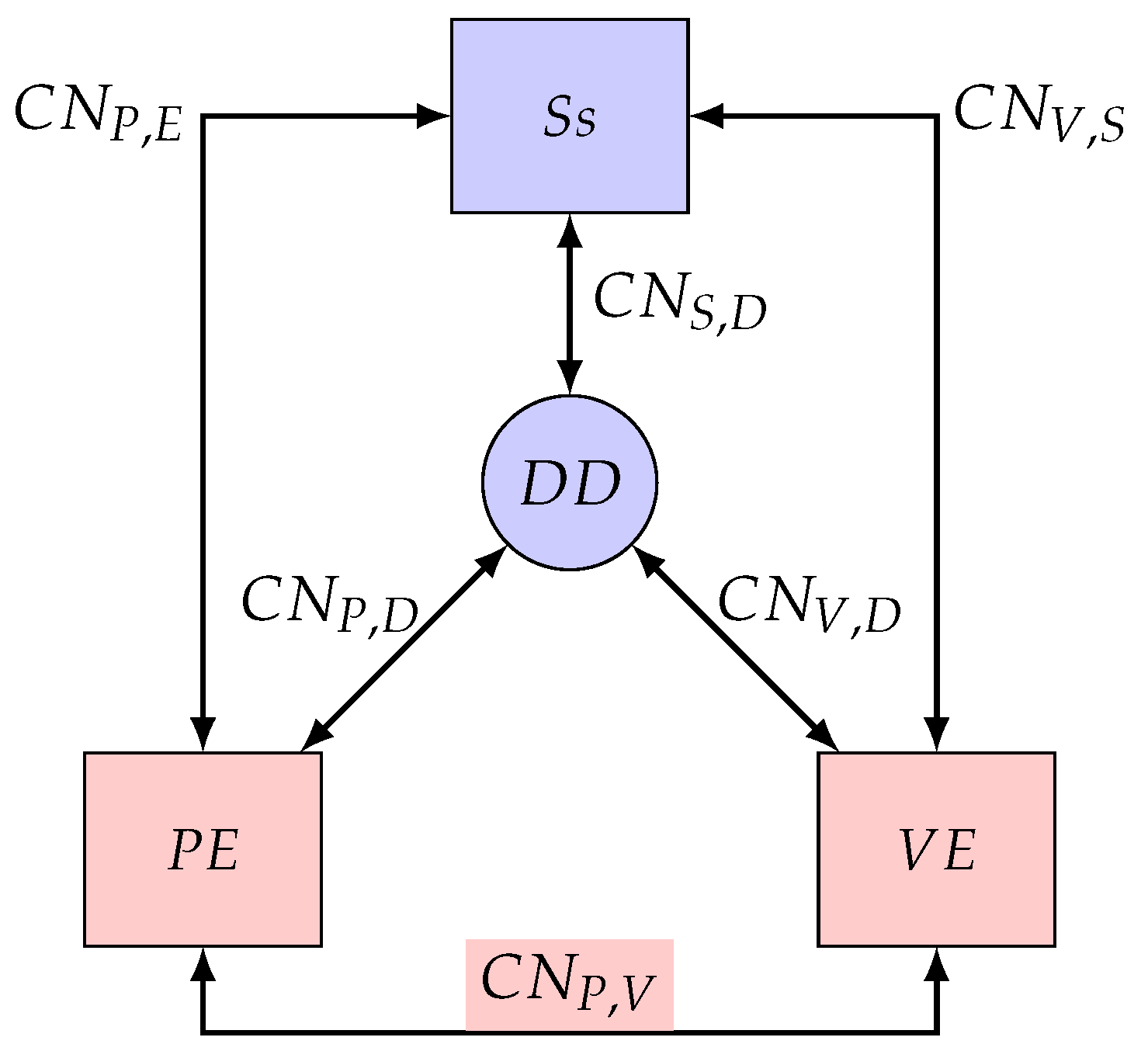

4. Conceptual Approach

- Data and knowledge-based: The AAS provides current information about the resources in each case through an active connection to the physical resource.Due to the system’s modular structure, the individual components can be kept up to date with little effort because the management of the resources lies with the respective experts and does not have to be carried out by a simulation expert.

- Modularization: AAS provides modularization for individual resources. In the case of the replacement of resources, adaptation of the model is easily possible. Only the relationships of the resources to each other must be maintained in a factory model.

- Light weight: The real-time capability depends on the technologies used but is not prevented by the concept.

- Hierarchy: AAS offers the possibility to build a hierarchy. In the present concept, the product, the production facilities, and the factory model can already be called hierarchy levels. However, any units, e.g., production areas, can also be formed.

- Standardization: The concept is based on DIN SPEC 91345 [8], which also includes the AAS. The AAS can be seen as a regulation that can work with standardized information models, etc. In addition, there are currently further standardization efforts in this area. It is crucial that modelers adhere to the existing standards.

- Servitization: The use of standard services is highly dependent on the implementation of the factory model and the technologies used. The AASs on the resource level enable the standard protocols during communication and are therefore an enabler of a service-oriented architecture.

- Openness and scalability: Modularization at the resource level enables easy extensibility of the model. Only the integration into the factory model depends on the concrete implementation and determines the effort required to integrate additional resources. The AAS is operated as an open-source project, so the work can be accessed here.

- Robustness: This aspect must be considered, especially during implementation.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bracht, U.; Geckler, D.; Wenzel, S. Digitale Fabrik: Methoden und Praxisbeispiele, 2nd ed.; Aktualisierte und Erweiterte Auflage VDI-Buch; Springer Vieweg: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Abele, E.; Reinhart, G. Zukunft der Produktion: Herausforderungen, Forschungsfelder, Chancen; Carl Hanser Fachbuchverlag: Munich, Germany, 2011. [Google Scholar] [CrossRef]

- Westkämper, E.; Löffler, C. Strategien der Produktion: Technologien, Konzepte und Wege in die Praxis; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Schuh, G.; Häfner, C.; Hopmann, C.; Rumpe, B.; Brockmann, M.; Wortmann, A.; Maibaum, J.; Dalibor, M.; Bibow, P.; Sapel, P.; et al. Effizientere Produktion mit Digitalen Schatten. Zwf Z. Wirtsch. Fabr. 2020, 115, 105–107. [Google Scholar] [CrossRef]

- Schuh, G.; Gützlaff, A.; Sauermann, F.; Maibaum, J. Digital Shadows as an Enabler for the Internet of Production. In Advances in Production Management Systems. The Path to Digital Transformation and Innovation of Production Management Systems; Lalic, B., Majstorovic, V., Marjanovic, U., von Cieminski, G., Romero, D., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2020; Volume 591, pp. 179–186. [Google Scholar] [CrossRef]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. NASA Technology Roadmap (Draft): Modeling, Simulation, Information Technology & Processing Roadmap Technology Area. Natl. Aeronaut. Space Adm. 2010, 11, 1–38. [Google Scholar]

- Stark, R.; Damerau, T. Digital Twin. In CIRP Encyclopedia of Production Engineering; The International Academy for Production Engineering; Chatti, S., Tolio, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–8. [Google Scholar] [CrossRef]

- DIN Deutsches Institut für Normung e. V. DIN SPEC 91345: Referenzarchitekturmodell Industrie 4.0 (RAMI4.0). 2016. Available online: https://www.din.de/de/forschung-und-innovation/themen/industrie4-0/din-veroeffentlicht-din-spec-zu-rami4-0-158570 (accessed on 24 June 2023).

- Adolphs, P.; Auer, S.; Bedenbender, H.; Billmann, M.; Hankel, M.; Heidel, R.; Hoffmeister, M.; Huhle, H.; Jochem, M.; Kiele-Dunsche, M.; et al. Ergebnispapier Struktur der Verwaltungsschale: Fortentwicklung des Referenzmodells für die Industrie 4.0-Komponente. 2016. Available online: https://www.zvei.org/fileadmin/user_upload/Presse_und_Medien/Publikationen/2016/april/Struktur_der_Verwaltungsschale/Struktur-der-Verwaltungsschale.pdf (accessed on 12 January 2023).

- Beregi, R.; Pedone, G.; Háy, B.; Váncza, J. Manufacturing Execution System Integration through the Standardization of a Common Service Model for Cyber-Physical Production Systems. Appl. Sci. 2021, 11, 7581. [Google Scholar] [CrossRef]

- Steindl, G.; Stagl, M.; Kasper, L.; Kastner, W.; Hofmann, R. Generic Digital Twin Architecture for Industrial Energy Systems. Appl. Sci. 2020, 10, 8903. [Google Scholar] [CrossRef]

- Roscher, M. Energieinformationssystemarchitektur für Produzierende Unternehmen. Ph.D. Thesis, Faculty of Mechanical Engineering, Aachen, Germany, 2018. [Google Scholar]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of Digital Twin Applications in Manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- ISO 23247-1:2021; Automation Systems and Integration—Digital Twin Framework for Manufacturing—Part 1: Overview and General Principles. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 23704-1:2022; General Requirements for Cyber-Physically Controlled Smart Machine Tool Systems (CPSMT)—Part 1: Overview and Fundamental Principles. International Organization for Standardization: Geneva, Switzerland, 2022.

- He, B.; Bai, K.J. Digital Twin-Based Sustainable Intelligent Manufacturing: A Review. Adv. Manuf. 2021, 9, 1–21. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in Manufacturing: A Categorical Literature Review and Classification. IFAC Pap. 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication; Cocoa Beach, FL, USA, 2015; Available online: https://www.3ds.com/fileadmin/PRODUCTS-SERVICES/DELMIA/PDF/Whitepaper/DELMIA-APRISO-Digital-Twin-Whitepaper.pdf (accessed on 18 December 2022).

- Bauernhansl, T.; Krüger, J.; Reinhart, G.; Schuh, G. WGP-Standpunkt Industrie 4.0; Wissenschaftliche Gesellschaft für Produktionstechnik: Darmstadt, Germany, 2016. [Google Scholar]

- Tao, F.; Zhang, M. Digital Twin Driven Smart Manufacturing; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Stark, R.; Kind, S.; Neumeyer, S. Innovations in Digital Modelling for next Generation Manufacturing System Design. CIRP Ann. 2017, 66, 169–172. [Google Scholar] [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital Twin: Values, Challenges and Enablers From a Modeling Perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Zimmermann, T.C.; Masuhr, C.; Stark, R. MBSE-Entwicklungsfähigkeit für Digitale Zwillinge. Z. Wirtsch. Fabr. 2020, 115, 51–54. [Google Scholar] [CrossRef]

- Glock, C.H.; Hochrein, S. Purchasing Organization and Design: A Literature Review. Bus. Res. 2011, 4, 149–191. [Google Scholar] [CrossRef]

- Hersi, M.; Traversy, G.; Thombs, B.D.; Beck, A.; Skidmore, B.; Groulx, S.; Lang, E.; Reynolds, D.L.; Wilson, B.; Bernstein, S.L.; et al. Effectiveness of Stop Smoking Interventions among Adults: Protocol for an Overview of Systematic Reviews and an Updated Systematic Review. Syst. Rev. 2019, 8, 28. [Google Scholar] [CrossRef] [PubMed]

- Tawfik, G.M.; Dila, K.A.S.; Mohamed, M.Y.F.; Tam, D.N.H.; Kien, N.D.; Ahmed, A.M.; Huy, N.T. A Step by Step Guide for Conducting a Systematic Review and Meta-Analysis with Simulation Data. Trop. Med. Health 2019, 47, 46. [Google Scholar] [CrossRef] [PubMed]

- Czwick, C.; Anderl, R. Cyber-Physical Twins - Definition, Conception and Benefit. Procedia CIRP 2020, 90, 584–588. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Abramovici, M.; Göbel, J.C.; Savarino, P. Reconfiguration of Smart Products during Their Use Phase Based on Virtual Product Twins. CIRP Ann. 2017, 66, 165–168. [Google Scholar] [CrossRef]

- Garetti, M.; Rosa, P.; Terzi, S. Life Cycle Simulation for the Design of Product–Service Systems. Comput. Ind. 2012, 63, 361–369. [Google Scholar] [CrossRef]

- Kraft, E.M. The Air Force Digital Thread/Digital Twin—Life Cycle Integration and Use of Computational and Experimental Knowledge. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2016. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the Digital Twin for Design and Production Engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Gartner. Definition of Digital Twin—Gartner Information Technology Glossary. Available online: https://www.gartner.com/en/information-technology/glossary/digital-twin (accessed on 18 December 2022).

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H.a. Recent Advances and Trends in Predictive Manufacturing Systems in Big Data Environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- El Saddik, A. Digital Twins: The Convergence of Multimedia Technologies. IEEE Multimed. 2018, 25, 87–92. [Google Scholar] [CrossRef]

- Digital Twin Consortium. Definition Digital Twin. 2020. Available online: https://www.digitaltwinconsortium.org/glossary/glossary/ (accessed on 25 November 2022).

- Reifsnider, K.; Majumdar, P. Multiphysics Stimulated Simulation Digital Twin Methods for Fleet Management. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2013. [Google Scholar] [CrossRef]

- Rios, J.; Hernández, J.C.; Oliva, M.; Mas, F. Product Avatar as Digital Counterpart of a Physical Individual Product: Literature Review and Implications in an Aircraft. In Transdisciplinary Lifecycle Analysis of Systems; IOS Press: Clifton, VA, USA, 2015; pp. 657–666. [Google Scholar] [CrossRef]

- Schroeder, G.N.; Steinmetz, C.; Pereira, C.E.; Espindola, D.B. Digital Twin Data Modeling with AutomationML and a Communication Methodology for Data Exchange. IFAC-PapersOnLine 2016, 49, 12–17. [Google Scholar] [CrossRef]

- Bajaj, M.; Cole, B.; Zwemer, D. Architecture To Geometry—Integrating System Models With Mechanical Design. 2016. Available online: https://arc.aiaa.org/doi/10.2514/6.2016-5470 (accessed on 20 November 2022).

- Rosen, R.; von Wichert, G.; Lo, G.; Bettenhausen, K.D. About The Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-PapersOnLine 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Schluse, M.; Rossmann, J. From Simulation to Experimentable Digital Twins: Simulation-based Development and Operation of Complex Technical Systems. In Proceedings of the 2016 IEEE International Symposium on Systems Engineering (ISSE), Edinburgh, UK, 3–5 October 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Canedo, A. Industrial IoT Lifecycle via Digital Twins. In Proceedings of the Eleventh IEEE/ACM/IFIP International Conference on Hardware/Software Codesign and System Synthesis, New York, NY, USA, 2–7 October 2016; p. 1. [Google Scholar] [CrossRef]

- Gabor, T.; Belzner, L.; Kiermeier, M.; Beck, M.T.; Neitz, A. A Simulation-Based Architecture for Smart Cyber-Physical Systems. In Proceedings of the 2016 IEEE International Conference on Autonomic Computing (ICAC), Wuerzburg, Germany, 17–22 July 2016; pp. 374–379. [Google Scholar] [CrossRef]

- Söderberg, R.; Wärmefjord, K.; Carlson, J.S.; Lindkvist, L. Toward a Digital Twin for Real-Time Geometry Assurance in Individualized Production. CIRP Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Bolton, R.N.; McColl-Kennedy, J.R.; Cheung, L.; Gallan, A.; Orsingher, C.; Witell, L.; Zaki, M. Customer Experience Challenges: Bringing Together Digital, Physical and Social Realms. J. Serv. Manag. 2018, 29, 776–808. [Google Scholar] [CrossRef]

- Industrial Digital Twin Association e. V. Digital Twin. 2022. Available online: https://industrialdigitaltwin.org/en/glossary/digital-twin (accessed on 11 November 2022).

- Baudoin, C.; Bournival, E.; Buchheit, M.; Simmon, E.; Zarkout, B. The Industry IoT Vocabulary. 2022. Available online: https://www.iiconsortium.org/wp-content/uploads/sites/2/2022/04/Industry-IoT-Vocabulary.pdf (accessed on 11 November 2022).

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Modeling, Simulation, Information Technology & Processing Roadmap; Technical report; National Aeronautics and Space Administration: Washington, DC, USA, 2010.

- Tuegel, E. The Airframe Digital Twin: Some Challenges to Realization. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar] [CrossRef]

- Gockel, B.; Tudor, A.; Brandyberry, M.; Penmetsa, R.; Tuegel, E. Challenges with Structural Life Forecasting Using Realistic Mission Profiles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2012. [Google Scholar] [CrossRef]

- Bielefeldt, B.; Hochhalter, J.; Hartl, D. Computationally Efficient Analysis of SMA Sensory Particles Embedded in Complex Aerostructures Using a Substructure Approach. In Proceedings of the ASME 2015 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Colorado Springs, CO, USA, 21–23 September 2015; American Society of Mechanical Engineers Digital Collection: Little Falls, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Deng, X.; Korobenko, A.; Lanza di Scalea, F.; Todd, M.D.; Taylor, S.G. Isogeometric Fatigue Damage Prediction in Large-Scale Composite Structures Driven by Dynamic Sensor Data. J. Appl. Mech. 2015, 82, 091008. [Google Scholar] [CrossRef]

| Concept | Case-Study | Review | Definition | |

|---|---|---|---|---|

| undefined | 1.90% | 4.76% | 2.38% | 0.00% |

| DM | 14.29% | 11.90% | 0.00% | 0.00% |

| DS | 26.19% | 7.14% | 2.38% | 0.00% |

| DT | 2.38% | 2.38% | 9.52% | 4.76% |

| Topic | Reference | Definition | Year | Key Element |

|---|---|---|---|---|

| Product related definitions | Reifsnider and Majumdar [38] * | Ultra-high fidelity physical models of the materials and structures that control the life of a vehicle. | 2013 | virtual model |

| Rios et al. [39] | Product digital counterpart of a physical product. | 2015 | virtual model, real asset | |

| Schroeder et al. [40] | Virtual representation of a real product in the context of cyber-physical systems. | 2016 | virtual model, real asset | |

| Manas Bajaj et al. [41] * | A unified system model that can coordinate architecture, mechanical, electrical, software, verification, and other discipline-specific models across the system life cycle, federating models in multiple vendor tools and configuration-controlled repositories. | 2016 | services, hierarchical, virtual models | |

| Abramovici et al. [30] | A virtual twin is a model that integrates interdisciplinary (mechanics, electronics, software, and services) virtual product models and related real-time data of a product instance (physical twin). A virtual twin can be dynamically generated from a model and data space to fulfill a specific task (e.g., dynamic reconfiguration of a smart product during its use phase). | 2017 | real asset, virtual models, data, services, hierarchical, real time | |

| Schleich et al. [33] | In synthesis, the vision of the digital twin describes the vision of a bi-directional relation between a physical artifact and the set of its virtual models. In this context, the virtual “twinning”, i.e., the establishment of such relations between physical parts and their virtual models, enables the efficient execution of product design, manufacturing, servicing, and various other activities throughout the product life cycle. | 2017 | real asset, connection, virtual models, services | |

| Grieves [18] | A digital twin is a distributed and decentralized approach to manage product information at product item level along its life cycle. | 2015 | real asset, virtual model, connection, modularization | |

| Process-related definition | Lee et al. [35] | Coupled model of the real machine that operates in the cloud platform and simulates the health condition with an integrated knowledge from both data-driven analytical algorithms and other available physical knowledge. | 2013 | hierarchical, real-time, real asset, virtual model |

| Rosen et al. [42] | Very realistic models of the process current state and its behavior in interaction with the environment in the real world. | 2015 | connection, real asset, virtual models, | |

| Bauernhansl et al. [19] | The digital shadow first transfers the real production process into the virtual world. Based on this, the Digital Twin can deliver an image of reality that is as identical as possible through a process model and simulation. | 2016 | real asset, virtual model, services | |

| Garetti et al. [31] | The DT consists of a virtual representation of a production system that is able to run on different simulation disciplines that is characterized by the synchronization between the virtual and real system, thanks to sensed data and connected smart devices, mathematical models and real time data elaboration. The topical role within Industry 4.0 manufacturing systems is to exploit these features to forecast and optimize the behavior of the production system at each lifecycle phase in real time. | 2012 | virtual model, real asset, services, real time, connection, data, hierarchical, scalability | |

| General definitions | Schluse and Rossmann [43] | Virtual substitutes of real-world objects consisting of virtual representations and communication capabilities making up smart objects acting as intelligent nodes inside the Internet of Things and services. | 2016 | virtual model, real asset, connection, services |

| Canedo [44] * | Digital representation of a real-world object with focus on the object itself. | 2016 | virtual model, real asset | |

| Gabor et al. [45] | The simulation of the physical object itself to predict future states of the system. | 2016 | data, services, real asset, virtual model | |

| Gartner [34] | A digital twin is a digital representation of a real-world entity or system. The implementation of a digital twin is an encapsulated software object or model that mirrors a unique physical object, process, organization, person or other abstraction. Data from multiple digital twins can be aggregated for a composite view across a number of real-world entities, such as a power plant or a city, and their related processes. | 2022 | real asset, virtual model, modularization, hierarchical, services, data, scalability | |

| Kraft [32] | An integrated multi-physics, multi-scale, probabilistic simulation of an as-built system, enabled by digital thread, which uses the best available models, sensor information, and input data to mirror and predict activities/performance over the life of its corresponding physical twin. | 2016 | services, data, robustness, virtual model, hierarchical, real asset | |

| Söderberg et al. [46] | Real-time optimization using digital copies of physical systems. | 2017 | real-time, real asset, virtual model | |

| Bolton et al. [47] | The dynamic virtual representation of a physical object or system throughout its life cycle, using real-time data to achieve understanding, learning, and reasoning. | 2018 | virtual model, real asset, real time, data | |

| Tao et al. [23] | Digital twin uses physical data, virtual data and interactive data between them to map all components in the product life cycle. | 2019 | real asset, virtual model, data, connection | |

| Stark and Damerau [7] | A digital twin is a digital representation of an active unique product (real device, object, machine, service, or intangible asset) or unique product-service system (a system consisting of a product and a related service) that comprises its selected characteristics, properties, conditions, and behaviors by means of models, information, and data within a single or even across multiple life cycle phases. | 2019 | real asset, virtual model, services, data, hierarchical, modularization | |

| Rasheed et al. [22] | A digital twin is defined as a virtual representation of a physical asset enabled through data and simulators for real-time prediction, optimization, monitoring, controlling, and improved decision making. | 2020 | virtual model, real asset, services, real-time, hierarchical, data, connection | |

| Industrial Digital Association e. V. [48] | Digital representation, sufficient to meet the requirements of a set of use cases. | 2022 | virtual model, hierarchical, | |

| Claude Baudoin et al. [49] | Digital model of one or more real-world entities, digital twin entities can be objects or processes, that is synchronized with those entities at a specified frequency and fidelity. | 2022 | virtual model, modularization, connection, robustness, real asset, | |

| Digital Twin Consortium [37] | A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity. | 2022 | real asset, virtual model, connection, robustness | |

| Kritzinger et al. [17] | If the data flows between an existing physical object and a digital object are further fully integrated in both directions, one might refer to it as a digital twin. In such a combination, the digital object might also act as controlling instance of the physical object. There might also be other objects, physical or digital, which induce changes of state in the digital object. A change in state of the physical object directly leads to a change in state of the digital object and vice versa. | 2018 | data, real asset, virtual model, connection, hierarchical, modularization, real time, services | |

| Industry-Sector definitions | Shafto et al. [50] | An integrated multi-physics, multi-scale, probabilistic simulation of a vehicle or system that uses the best available physical models, sensor updates, fleet history, etc., to mirror the life of its flying twin. The digital twin is ultra-realistic and may consider one or more important and interdependent vehicle systems. | 2010 | hierarchical, services, virtual model, modularization, scalability, |

| Tuegel [51] * | A cradle-to-grave model of an aircraft structure’s ability to meet mission requirements, including submodels of the electronics, the flight controls, the propulsion system, and other subsystems. | 2012 | modularization, hierarchical, virtual model | |

| Gockel et al. [52] | Ultra-realistic, cradle-to-grave computer model of an aircraft structure that is used to assess the aircraft’s ability to meet mission requirements. | 2012 | virtual model, hierarchical, scalability | |

| Bielefeldt et al. [53] | Ultra-realistic multi-physical computational models associated with each unique aircraft and combined with known flight histories. | 2016 | virtual model, real asset, data, | |

| Bazilevs et al. [54] | High-fidelity structural model that incorporates fatigue damage and presents a fairly complete digital counterpart of the actual structural system of interest. | 2015 | real time, virtual model, robustness | |

| El Saddik [36] | Digital twin is digital copies of biological or non-biological physical entities. By bridging the physical and virtual worlds, data are seamlessly transferred, allowing virtual entities to exist simultaneously with physical entities. | 2018 | virtual model, real asset, connection real time | |

| Negri et al. [29] | Digital twins are digital representations based on semantic data models that allow running simulations in different disciplines, that support not only a prognostic assessment at the design stage (static perspective) but also a continuous update of the virtual representation of the object by a real-time synchronization with sensed data. This allows the representation to reflect the current status of the system and to perform real-time optimizations, decision making and predictive maintenance according to the sensed conditions. | 2017 | virtual model, standardization, data, services, hierarchical, real time, services, connection, real asset | |

| ISO 23704-1:2022 [15] | Digital replica of physical assets (physical twin), processes and systems that can be used for various purposes or a fit-for-purpose digital representation of something outside its own context with data connections that enable convergence between the physical and virtual states at an appropriate rate of synchronization. | 2022 | virtual model, real asset, connection, data, standardization | |

| ISO 23247-1:2021 [14] | Fit for purpose digital representation of an observable manufacturing element with synchronization between the element and its digital representation. | 2021 | virtual model, real asset, connection, standardization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindner, M.; Bank, L.; Schilp, J.; Weigold, M. Digital Twins in Manufacturing: A RAMI 4.0 Compliant Concept. Sci 2023, 5, 40. https://doi.org/10.3390/sci5040040

Lindner M, Bank L, Schilp J, Weigold M. Digital Twins in Manufacturing: A RAMI 4.0 Compliant Concept. Sci. 2023; 5(4):40. https://doi.org/10.3390/sci5040040

Chicago/Turabian StyleLindner, Martin, Lukas Bank, Johannes Schilp, and Matthias Weigold. 2023. "Digital Twins in Manufacturing: A RAMI 4.0 Compliant Concept" Sci 5, no. 4: 40. https://doi.org/10.3390/sci5040040

APA StyleLindner, M., Bank, L., Schilp, J., & Weigold, M. (2023). Digital Twins in Manufacturing: A RAMI 4.0 Compliant Concept. Sci, 5(4), 40. https://doi.org/10.3390/sci5040040