1. Introduction

For a long time, the challenge has been to provide products and services that precisely match the preferences, habits, and needs of users. This is easier to accomplish with custom manufacturing and small batch sizes than in a rigid production environment (mass production) [1,2]. Mass production is a hierarchically organized system in which largely uniform and standardized products are produced in repetitive steps based on the division of labor. Mass production is characterized by low unit costs and high economies of scale. The low prices of mass products encourage the concentration of demand on uniform products—a self-reinforcing effect in favor of the producers of mass products. The diversity of variants is correspondingly low. It is difficult for mass producers to fulfill the individual wishes of individual customers—particularly in the early digital age—at the cost of a mass product. Individualization is more likely to be found where consumers are willing to pay a higher price or to forgo certain functionalities.

When, in an individualized society [3], the demand for higher quality, extended functionalities, and stronger personalization of a product [4,5] increases, classical product development and production processes reach their limits. The way out does not lie in customized products or small series; both the manufacturing process and the product are too customer specific, which means that economies of scale do not apply, and that costs and product prices are higher than those of mass-produced products.

However, when mass production approaches are combined with customized product development and manufacturing, additional value can be created [6]. Mass customization takes advantage of industrial organizational processes and highly automated, flexible production systems, and it combines them with digital innovations in the area of customer co-design and personalized product development. The integration of cognitive technologies and methods, combined with the exponential growth of storage capacity, computing power, and networks, and the simultaneous availability of vast quantities of data, now makes it possible to offer highly personalized product–service systems. Smart products are being refined with digital services (smart services) and connected to industrial metaverses [7]. This has far-reaching consequences for the production and use of devices, as they should be adaptable, reconfigurable, customizable, flexible, and able to interact with their environment at any time via user-friendly interfaces. In addition, products are now highly adaptable to the needs of the user. As a result, mass markets for uniformly equipped products are expected to become less important in the medium term.

This paper presents three empirical case studies for the implementation of smart services in medium-sized manufacturing companies and discusses the progress of the concept of servitization in industry.

2. Methods

This editorial follows a qualitative research design. The chosen method was to conduct explorative, semi-structured interviews that took place in a virtual environment due to the COVID-19 pandemic.

A total of 30 qualitative interviews were conducted between fall 2020 and summer 2021 by members of the “Platform Learning Systems” project, which is part of acatech—the German Academy of Science and Engineering. The “Platform Learning Systems” brings together key players in the field of artificial intelligence from industry, the service sector, trade, science, civil society, and politics, and accompany the introduction and use of AI in Germany and Europe with studies, use cases, conferences, and public information services such as the Map on AI [8,9].

For each company example, at least one appropriate expert was interviewed. The in-depth interviews will be analyzed using qualitative content analysis methods and presented in textual and graphical form. Qualitative content analysis is “a research method for the subjective interpretation of the content of text data through the systematic classification process of coding and identifying themes or patterns” [10,11]. In addition, the relevant literature and statistics were reviewed and processed.

3. Servitization in Industry: From Selling Products to Smart Product–Service Systems

Smart products are intelligent everyday objects, machines, systems, or means of transportation that are equipped with sensors, controlled by embedded software, and connected to the Internet worldwide [12,13]. Smart services are digital services that complement and enhance physical, increasingly intelligent products by enabling flexible and personalized adaptation to specific customer expectations based on processed data. The combination of smart products and services is unique in its disruptive potential. Smart product–service systems enable better user experiences and altered value propositions [14]. In the case of a manufacturing company, this can mean that networking and data-driven intelligence turn the machine tool into a smart product. Add a digital dashboard that provides information about the status of the machine or the value-added step, and the smart machine tool is complemented by a smart service. When smart products and smart services are bundled into a digital business model with a billing model based on usage or machine hours, it is called a smart product–service system [15]. If a digital marketplace with an APP store is created in relation to the machine tool so that additional APPs can be used and booked, this becomes a smart service platform, or an innovation ecosystem related to the tool. This step-by-step model is emblematic of the digital transformation of machine tool manufacturers and users.

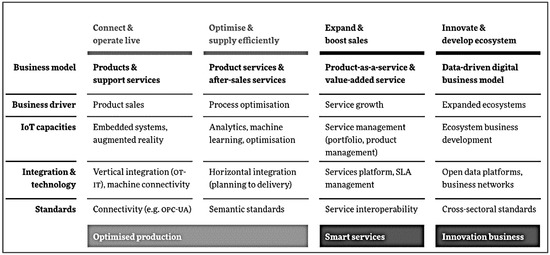

Many companies have already connected their smart products to the Internet; they are in the process of collecting and analyzing relevant data. The speed and radicalness with which current business models need to change is often underestimated. Figure 1 illustrates the process of moving from optimized production to data-driven business model innovation. Connectivity and real-time responses pertaining to the original product or service are followed by optimization and efficiency at the product and process levels, including new after-sales services. Extending the business model to products-as-services and value-added services transforms the company into a service organization. Through the new digital business, the company ultimately becomes a platform company or a participant in a digital ecosystem. While the best networks today have latency periods of ten to fifteen milliseconds, the upcoming 5G/6G mobile communications standard will provide near real-time mobile Internet; data latency, the time between data request and data delivery, will be reduced to just one millisecond; hence, 5G/6G will be ultra-fast, latency-free, energy-efficient, and reliable—a fundamental requirement for the next generation of products and services [16].

Figure 1.

From optimized production to innovation ecosystems (source: own illustration, 2023, based on [6]).

3.1. Usage Models of Smart Offerings

The evolution of physical products and traditional services using data and analytics is still a relatively new trend. Until now, the sale of a product has been at the end of the value chain, even though the pay-per-use models shown in Figure 1, as well as the sharing economy, have been on the rise for about two decades. Traditionally, raw materials and components are purchased, supply chains are orchestrated, and labor and machinery are used in the manufacturing process. The finished product is then sold with a profit margin and delivered to the customer. With the sale of the product, the ownership and availability of the product changes from the manufacturer to the user. This tried-and-true practice is losing its dominance in the digital age, as the change in question impacts both the development and production process of products and services and the way they are marketed.

The business model describes the product or service that a market participant offers and the characteristics of how it interacts with customers and suppliers [17]. At its core are (1) a unique value proposition; (2) a revenue model or revenue mechanism that describes how the value of the offering can be converted into revenue; and (3) the resources and processes used to deliver the value proposition [18,19]. The key resources are brand, people, technology, partnerships, and data. In the digital age, data amount to a key resource for implementing a company’s value proposition in the form of intelligent, networked products and services, as well as digitized organizational, development, production, and logistics processes.

It should be emphasized that a product or service delivered to the customer is no less interesting from the supplier’s point of view. This is because smart products generate operational data throughout their lifecycle, which opens up new opportunities to drive innovation, provide services, and engage with customers on an ongoing basis. An example from the mobility sector illustrates this: small-scale weather events, such as regional precipitation or fog, can be recorded in the intelligent, connected vehicle via the on-board camera, windshield wiper sensors, or other connected objects, and sent via the vehicle backend to the manufacturer, who, in turn, can provide this safety-related data to weather services, traffic radio, or other connected vehicles and fleets. This has the potential to increase road safety, and this vehicle and mobility data can also be monetized [20].

This development is being driven by rapid technological progress and building technologies have reached the level of technological maturity appropriate for use in the field (and at affordable prices).

3.2. Smart Services: New Value Propositions for the Digital Age

Industry 4.0, in the sense of networked, highly automated, and adaptable production, enables the manufacture of smart products at marketable costs. By analogy, smart services are individualized services at the price of standard services [21]. Disruptive business models are based on extending smart products with a bundle of smart services to offer users new user experiences and new value propositions. Such an enhanced user experience might include a recommendation via the multimodal mobility APP to switch to the metro as a mode of transport because the e-scooter booked is less safe on rainy roads or in dense fog. Weather data were collected in real time and used for the APP travel recommendation. A new service promise could be the guaranteed arrival time for a long-distance trip because the weather and traffic data are processed and made available in the navigation APP in real time, making dynamic route guidance much more precise and reliable than we have become used to.

The lubricant for smart services is therefore smart data, i.e., large quantities of processed data that provide information about the user’s preferences, the optimal selection decision, or the environmental conditions in which the smart service is used.

Current challenges include the monetization of smart services in addition to the company’s traditional product range, as well as their economical operation. There is potential for revenue generation, for example, in the area of flexible pricing models. In this way, opportunities to generate additional revenue on the basis of data can be exploited throughout the entire product lifecycle. An example of this is services that can be booked “over the air”, such as the above-mentioned activation of a higher performance of the engine or the battery in the vehicle. The machine tool shown in Figure 1 can also be priced according to consumption (pay-per-use), but it can also be priced according to the number of units sold or proportionally to the revenue generated. Payment based on the number of records exchanged is also conceivable for any application domain. Accordingly, metadata hubs and data marketplaces are currently being created, such as the Mobility Data Space, in which leading mobility providers, namely, cities and municipalities, research institutions, the German National Academy of Sciences and Engineering, and the German Federal Ministry of Transport, are participating [22]. The goal is to enable innovative and sustainable mobility services by sharing and using a wide range of data.

3.3. Outcome-Oriented Smart Services

In the digital age, the value of the smart product–service package lies more in the result achieved than in its mere material existence, including specific product characteristics. The product is no longer a means to an end; the smart services developed around the product enhance it, making it unique and valuable. A driverless vehicle can navigate passengers safely and efficiently through traffic, giving them time to spend as they wish instead of sitting behind the wheel in a traffic jam. Measurable results of the intelligent product can also include lower costs, higher revenues, or improved environmental sustainability [23].

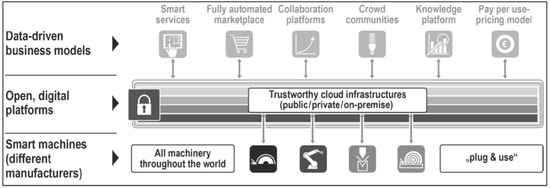

The everything-as-a-service concept (see Figure 2) stands for products and services that focus on their outcomes. In as-a-service or outcome-oriented business models, companies move from selling a product through a single transaction to providing a service with a guaranteed outcome, often offered on a usage basis or via a profit/risk-sharing model. Selling the outcome rather than the product shifts ownership, risk, and responsibility for maintenance back to the provider. This is the example of the machine manufacturer who rents the machine and charges on a usage basis instead of selling the machine. This amortizes over a longer period of time, rather than immediately upon sale.

Figure 2.

Value architecture of data-driven business models (source: [24]).

Another example is the provision of features that can be activated on demand and paid for as they are used. In this way, consumers can rent additional navigation and infotainment services in order to arrive at their destination faster or more relaxed. Such as-a-service models are therefore outcome-based and often combined with flexible pricing. This monetization approach is based on the in-app purchase model of the smartphone industry, and it enables an ongoing customer relationship and continuous upselling potential. Upselling refers to the sales method of offering customers a higher-value—and usually more expensive—product than they originally wanted [18].

The trend towards “everything-as-a-service” (Xaas) is not new; it was already marketed in the dot.com era with performance promises such as “holes instead of drilling” and “temperature instead of air conditioning” [25]. However, the hardware and software performance parameters and data are now much more comprehensive and cheaper to obtain, allowing the more mature technology to break through on a broad scale. Software updates and the intelligent use of data generated during operation will make the product adaptable and intelligent in the future. This requires a high level of competence from the product provider and the partners involved in the innovation ecosystem. After all, the product is not rigid and interchangeable but dynamic and changeable; therefore, it is not completely predictable in its product behavior. This creates significant challenges for customization development, maintenance, and customer service. Finally, software updates must ensure that the product profile and feature set are maintained. To manage this complexity, product manufacturers need to build an entirely new, innovative ecosystem around their products, or to collaborate with leading ecosystems through various platforms.

4. On the Progress of Servitization in Industry: Three Empirical Case Studies from Small- and Medium-Sized Manufacturing Companies

Large amounts of data are available virtually free of charge from sensors, the Internet, and other data sources. Collecting, structuring, evaluating, and interpreting these data presents an immense potential that can already be tapped into today via artificial intelligence platforms. These data are used to improve physical products or services. The following examples show how specific added value can be created by intelligent services in different areas. The examples were collected and prepared in the context of a qualitative company survey of the German AI platform [8].

4.1. Case Study #1: The Refined Machine Tool—Smart Services in Plastics Processing

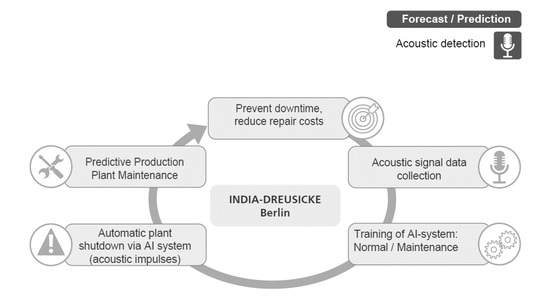

The Berlin-based manufacturing company India-Dreusicke uses about 70 machines for plastics processing. Several times a week, the injection molds must be completely disassembled, and the precision parts relubricated. If maintenance is not carried out as planned, there is a risk of damage to machines, molds, or the product itself, resulting in high costs, waiting times, and production downtime. This makes maintenance essential but also costly and time-consuming. In addition, the exact timing of maintenance is unpredictable, so an intelligent service could add real value.

With the help of predictive maintenance based on artificial intelligence methods, the possible time window for maintenance of the systems should be maximized, and potential faults in the systems should be detected at an early stage. Injection molds are large steel elements into whose cavity the product is injected under very high pressure. Ejectors then push the finished parts out of the mold. The necessary lubricating film in the molds wears off gradually during operation and must therefore be applied permanently.

The smart service is based on data pertaining to acoustic signals that indicate the normal condition of a system or a possible need for maintenance. Together with a start-up company, the company collected the data over several months and then used them to train an AI system. Today, the AI system is able to detect acoustic impulses that are inaudible to employees and to provide information about the optimal maintenance period for the system. This allows for the early detection of damage or restrictions to the machines, preventing unplanned downtime or loss of production. At the same time, necessary maintenance can be scheduled and performed in a timely manner without jeopardizing the production goals. Microphones, software, and hardware products are used around the machine fleet for this digital service.

The added value of this intelligent maintenance approach lies in the more efficient execution of maintenance work, as well as in cost and time savings achieved by minimizing equipment downtime and production losses (see Figure 3). The data-based value proposition can be linked to guaranteed asset availability, which outperforms existing offerings that require machine maintenance at fixed points in time.

Figure 3.

Acoustic analysis of maintenance needs in plastics processing (source: own illustration, 2023, based on based on [8]).

4.2. Case Study #2: Intelligent Planning Assistance—Smart Services in Metal Processing

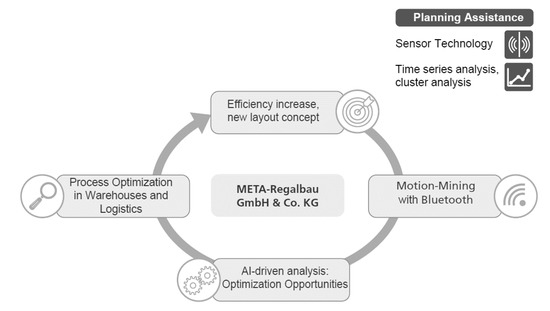

META-Regalbau, a metalworking SME based in Arnsberg, Germany, develops and produces shelving systems for commercial and private use. These include shelving and pallet racking, storage platforms, and multi-level shelving systems for industrial warehouses, workshops, offices, and private rooms. The smart service aims to optimize internal logistics processes via sensor and AI-based data analysis processes.

In the course of incoming shelving orders, logistics employees have to assemble many individual components at different locations in the warehouse then pack them and prepare them for outgoing goods. The picking process had a lot of potential for optimization, as there were long waiting times for tools and the overall layout could be improved.

To realize this potential, the picking process was analyzed together with a software service provider. By automatically analyzing the manual work processes (motion mining), important measurements could be taken in the warehouse. Small transmitters (Bluetooth beacons) were attached to the walls. Employees also wore sensors as they walked around the warehouse to record walking distances and longer waiting times at shelves or machines, as well as to analyze the existing picking process with the help of artificial intelligence. This allowed the company to identify long tool queues and employee coordination needs and to redesign the process accordingly. The AI-based analysis enabled the company to design an intelligent layout with the best possible arrangement for a new warehouse and to make internal logistics processes more efficient. According to the company, the annual savings amount to more than EUR 20,000, which means that the cooperation with the start-up will have already paid for itself in under two years.

The logistics management actively involved the works council and employees in the process optimization (see Figure 4), informing them of the goal of the AI-based optimization and how the technologies worked, which contributed to the success of the project. In this case, the data-based value proposition can refer to an optimal picking process that can deliver faster shipment of goods and higher customer satisfaction.

Figure 4.

Smart optimization of the picking process in metal processing (source: own illustration, 2023, based on based on [8]).

4.3. Case Study #3: Autonomous Palletizing—Smart Services in Wood Processing

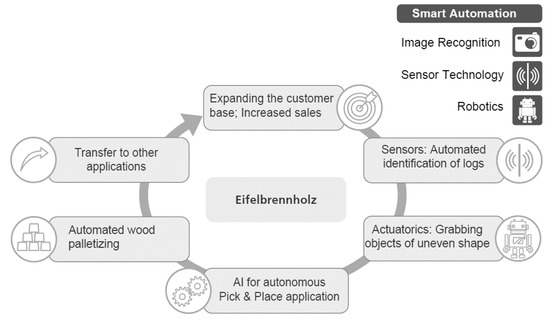

Eifelbrennholz, a small company based in Monschau, North Rhine-Westphalia, Germany, has been a producer and supplier of firewood for 25 years. The company covers all stages of the firewood production process, from harvesting to processing to shipping. So far, only private households are customers.

Business-to-business marketing to DIY stores or retailers has not yet been carried out, as large customers only buy firewood on pallets for efficiency of storage and delivery logistics. Manual palletizing is not economically viable in high-wage Germany. Therefore, the company decided to automate the firewood handling process using a 6-axis kinematic system. On the input side of the system, disordered firewood logs are identified using computer vision technology. The software can recognize and classify objects such as logs in digital still and moving images. The logs are then placed in a fixed arrangement on a pallet by an automated gripping tool. Because each log has a unique, natural surface, traditional bin-picking approaches (automated reaching into the box) cannot be used.

The intelligent service includes a cost-effective, autonomous pick-and-place application for firewood handling which optimizes the overall process and can serve large customers at competitive prices. This AI-based process for automating the palletizing of firewood, developed with RWTH Aachen University and Digital in NRW, is based on appropriate camera technology (sensors) and gripping technology (actuators). A 3D camera captures the disordered logs in lattice boxes. With the help of point clouds, a digital image (digital twin) of each log is created. An algorithmic segmentation can identify the geometry of the nearest trunk. The geometry of the trunks, the attack points, the deposition structures, and the movement paths of the objects must be “learned” from a new database and then algorithmically clustered.

Based on these data, a robot and a custom gripper can reliably pick up the uneven logs. AI supports the robot in the autonomous pick-and-place application (see Figure 5).

Figure 5.

Autonomous stacking of logs in firewood production (source: own illustration, 2023, based on [8]).

The value proposition of this smart service is that autonomous log stacking can guarantee measurable savings (labor costs) and revenue increases by expanding the customer segment (key accounts). In this case, the investment in technology also pays off for firewood producers in high-wage countries. In addition, regional fuel trade eliminates the need for transportation, saving costs and reducing the carbon footprint.

5. Discussion: Data-Driven Product and Service Revolution

Smart data, smart products, and smart services are on the agenda of many innovative companies. Driven by real-time 5G networks, exponential growth in compute and storage performance metrics, the near-infinite availability of sensor and Internet data, and advances in machine and deep learning, business strategies are increasingly based on data-driven value propositions and enhanced user experiences around products and services. Data are being used not only to optimize processes and functions but also to create entirely new business models. Data enables disruption, and data-driven innovation is revolutionizing the one-sided-markets for products and services [26].

Data can contribute to a new kind of value proposition in a variety of ways, as examples from manufacturing, online retail, and automotive industries have shown. At its core, there are two thrusts: data can add value to a company’s most important resource, or it can become the company’s most important resource. Companies that focus on the latter—that is, using data as their primary key resource—are often startups; that is, they are without extensive product and service offerings, traditional processes and organizational structures, and a large number of demanding existing customers. Startups start “from scratch” and can radically put data at the center of their strategy. This is easier for startups because they are not burdened by the structural inertia or legacy of an established large company—an influencing factor often referred to as “the innovator’s dilemma” [27,28].

6. Conclusions

As large companies move toward data-driven value propositions and the delivery of intelligent products and services, such as self-learning, predictive, personalized, and speech processing, they will need to break down existing silos in order to fully leverage data for the customer. Some companies are already doing this and experimenting with data as a key resource; they are harnessing the power of innovation ecosystems, wherein they form new value-creating partnerships with young and established players [29]. This is a promising path, as the practical examples in this article and other practical studies from industry and services have shown.

This requires a clear digital strategy within the company. After all, data are only valuable if they are used to reorganize business processes or create new revenue models. The memorable application examples from industry, services, and retail are intended to inspire market participants with concrete learning paths and best-practice views to resolutely implement their previously defined digital strategy and seize the opportunities of the data and platform economy. The product of the future is intelligent and enhanced by digital services. The benchmark has been set by digital pioneers; now, it is time to implement it across the economy. This is important in order to remain globally competitive with China, the U.S., and other leading innovation regions, and at the same time to enable users to enjoy convincing performance promises and new experiences arising from the digital product–service system.

Funding

This research was funded by the Federal Ministry of Research and Education, project title: Plattform Lernende Systeme (2017–2022; funding number: 01IS17097).

Acknowledgments

The author wishes to thank Ursula Ohliger and the other project members of the Learning Systems Platform for their support in data collection and data preparation.

Conflicts of Interest

The author declares no conflict of interest.

References

- Gu, X.; Koren, Y. Mass-individualisation: The twenty first century manufacturing paradigm. Int. J. Prod. Res. 2022, 60, 7572–7587. [Google Scholar] [CrossRef]

- Hu, S.J. Evolving paradigms of manufacturing: From mass production to mass customization and personalization. Procedia Cirp. 2013, 7, 3–8. [Google Scholar] [CrossRef]

- Reckwitz, A. The Society of Singularities: Reply to Four Critics. Anal. Krit. 2023, 45, 177–187. [Google Scholar] [CrossRef]

- Wan, J.; Li, X.; Dai, H.N.; Kusiak, A.; Martinez-Garcia, M.; Li, D. Artificial-intelligence-driven customized manufacturing factory: Key technologies, applications, and challenges. Proc. IEEE 2020, 109, 377–398. [Google Scholar] [CrossRef]

- Korneeva, E.; Hönigsberg, S.; Piller, F.T. Mass customization capabilities in practice–introducing the mass into customized tech-textiles in an SME network. Int. J. Ind. Eng. Manag. 2021, 12, 115. [Google Scholar] [CrossRef]

- Kagermann, H.; Winter, J. The second wave of digitalization. In Germany and the World 2030: What Will Change. How We Must Act; Mayr, S., Messner, D., Meyer, L., Eds.; Econ Verlag: Berlin, Germany, 2018. [Google Scholar]

- Mourtzis, D.; Panopoulos, N.; Angelopoulos, J.; Wang, B.; Wang, L. Human centric platforms for personalized value creation in metaverse. J. Manuf. Syst. 2022, 65, 653–659. [Google Scholar] [CrossRef]

- Platform Learning Systems. AI for SME (KI im Mittelstand); Federal Ministry of Education and Research/Acatech—National Academy of Science and Engineering: Munich, Germany, 2021. [Google Scholar]

- Platform Learning Systems. Map on AI. 2021. Available online: www.ki-landkarte.de (accessed on 9 July 2023).

- Mayring, P. Qualitative content analysis: A step-by-step guide. Qual. Content Anal. 2021, 1, 1–100. [Google Scholar]

- Hsieh, H.-F.; Shannon, S.E. Three approaches to qualitative content analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef]

- Khan, S.; Tomar, S.; Fatima, M.; Khan, M.Z. Impact of artificial intelligent and industry 4.0 based products on consumer behaviour characteristics: A meta-analysis-based review. Sustain. Oper. Comput. 2022, 3, 218–225. [Google Scholar] [CrossRef]

- Zheng, P.; Wang, Z.; Chen, C.H.; Khoo, L.P. A survey of smart product-service systems: Key aspects, challenges, and future perspectives. Adv. Eng. Inform. 2019, 42, 100973. [Google Scholar] [CrossRef]

- Koldewey, C.; Hemminger, A.; Reinhold, J.; Gausemeier, J.; Dumitrescu, R.; Chohan, N.; Frank, M. Aligning strategic position, behavior, and structure for smart service businesses in manufacturing. Technol. Forecast. Soc. Chang. 2022, 175, 121329. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, Z.; Cao, Y.; Miao, R.; Ming, X. An integrated framework of user experience-oriented smart service requirement analysis for smart product service system development. Adv. Eng. Inform. 2022, 51, 101458. [Google Scholar] [CrossRef]

- Firyaguna, F.; John, J.; Khyam, M.O.; Pesch, D.; Armstrong, E.; Claussen, H.; Poor, H.V. Towards industry 5.0: Intelligent reflecting surface (irs) in smart manufacturing. arXiv 2022, arXiv:2201.02214. [Google Scholar]

- Seiberth, G.; Gründinger, W. Data-driven business models in connected cars, mobility services and beyond. BVDW Res. 2018, 1, 18. [Google Scholar]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through Industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Johnson, M.W.; Christensen, C.M.; Kagermann, H. Reinventing your Business Model. Harv. Bus. Rev. 2008, 86, 50–59. [Google Scholar]

- Werne, J.; Winter, J. Point of no return: Turning data into value. J. AI Robot. Workplace Autom. 2021, 1, 43–57. [Google Scholar]

- Winter, J. Business Model Innovation in the German Industry: Case Studies from the Railway, Manufacturing and Construction Sectors. J. Innov. Manag. 2023, 11, 1–17. [Google Scholar] [CrossRef]

- Mobility Data Space. Available online: www.mobility-dataspace.eu (accessed on 9 July 2023).

- Aas, T.H.; Breunig, K.J.; Hellström, M.M.; Hydle, K.M. Service-oriented Business Models in Manufacturing in the Digital Era. Towards a new Taxonomy. Int. J. Innov. Manag. 2020, 24, 1–15. [Google Scholar] [CrossRef]

- Acatech—National Academy of Science and Engineering. Digital Service Platforms (Digitale Serviceplattformen); Acatech: Munich, Germany, 2016. [Google Scholar]

- Winter, J. Digital Business Model Innovation: Empirical insights into the drivers and value of Artificial Intelligence. Int. J. Comput. Technol. 2021, 21, 63–75. [Google Scholar] [CrossRef]

- Kagermann, H.; Oesterle, H.; Jordan, J.M. IT-Driven Business Models: Global Case Studies; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- O’Reilly, C.A., III; Tushman, M.L. Lead and Disrupt: How to Solve the Innovator’s Dilemma; Stanford University Press: Redwood City, CA, USA, 2021. [Google Scholar]

- Christensen, C.M.; Raynor, M.; McDonald, R. What is disruptive innovation? Harv. Bus. Rev. 2015, 93, 44–53. [Google Scholar]

- Cusumano, M.; Gawer, A.; Yoffie, D.B. The Business of Platforms: Strategy in the Age of Digital Competition, Innovation, and Power; Harper Business: New York, NY, USA, 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).