Abstract

Considering the first ten years of Industrie 4.0 in Germany—the digital transformation of industry towards the goal of increased manufacturing productivity and mass customization—significant progress has been achieved. However, future efforts are required. This review first evaluates the status quo of implementation and research in Germany and finds that large-scale companies have proceeded faster than small- and middle-sized enterprises. Currently, regardless of their size, companies have in common a shortage of qualified specialists, coupled with a lack of adequate base technologies for Industrie 4.0 and an insufficient digital mindset. The creation of platform-based digital business models is particularly lagging behind, despite high research interest. This review subsequently identifies three research-driven fields of action that are particularly important for the future of Industrie 4.0: (1) resilience of value networks in the strategic area of sovereignty, (2) Open-Source as a driver for the strategic area of interoperability, and (3) the strategic combination of digitalization and sustainability as a basis for sustainable business models in the strategic area of sustainability.

1. Introduction

Companies have always been interested in meeting customer needs, increasing customer loyalty, improving manufacturing efficiency and flexibility, and increasing sales through improved and novel products and services [1,2]. Ten years ago, researchers from computer science, engineering, economics, and related scientific disciplines, as well as representatives from industry and the service sector, presented a concept for the future of industrial value creation and customer-specific mass production that resonated globally. Under the leadership of Prof. Henning Kagermann, Prof. Wolfgang Wahlster, and Prof. Wolf-Dieter Lukas, a conceptual framework for the fourth industrial revolution was presented at the Hannover Fair 2011 [3], which has had a lasting impact on research in the areas of product development and systems engineering, production technology, and production systems, as well as in business process management and business model innovation [4]. Companies stepped up their efforts to automate and network production systems and value chains to advance the goal of higher productivity through a smart factory approach and to progress toward mass customization through digitally enhanced, tailor-made products and services at the price of a mass-produced product [5].

From a strategic and global perspective, significant progress has been achieved in this regard [6]. However, to date, it largely remains unclear how far research and adoption has proceeded country-wise and which focus points are set in the second decade of Industrie 4.0. This also holds for Germany, where the industrial sector plays a pivotal role, and where Industrie 4.0 had been developed as a concept. This review fills this research gap by following this guiding question: What is the status quo of adoption and research in Industrie 4.0 in Germany, and which fields of action require future attention?

We find that German industry has proceeded significantly in adapting to Industrie 4.0 whereby large-scale enterprises are more mature than small- and medium-scale enterprises. Regarding research and Research and Development (R&D) across the four key themes Value Creation Scenarios for Industrie 4.0, Prospective Technological Trends, New Methods and Tools for Industrie 4.0, and Work and Society, significant insights have been gained. However, in the face of increasing volatility and rapid changes in the development of Industrie 4.0, more interdisciplinary research is required across all research fields. Regarding the three strategic areas defined by German government for the next decade of Industrie 4.0 in Germany, we find that (1) resilience of value networks in the strategic area of sovereignty, (2) Open-Source as a driver for the strategic area of interoperability, and (3) the strategic combinations of digitalization and sustainability as a basis for sustainable business models in the strategic area of sustainability deserve attention in the fields of industry and research to deepen the industrial transformation and to stay competitive from the perspective of German researchers and company representatives.

These descriptive findings add to country-specific research on Industrie 4.0 in Germany and are a valuable source for cross-country comparisons of the status quo of adoption and research. For practitioners, the findings help to identify future fields of actions and to deepen adoption of Industrie 4.0. Thereby, the review contributes to the academic and practical discussion of Industrie 4.0 not only in Germany, but also globally.

2. Methodology

By analyzing what is needed for the further dissemination and implementation of Industrie 4.0, this review firstly details the current status quo in implementation, scientific research, and R&D across the four key themes of Industrie 4.0 in German research: Value Creation Scenarios for Industrie 4.0, Prospective Technological Trends, New Methods and Tools for Industrie 4.0, and Work and Society [7].

Therefore, we rely on an efficient literature review of sources distributed across different academic disciplines and popular literature [8,9]. To cover relevant publications across engineering, production, and management, we relied on three publication databases (EBSCOhost, Emerald Insight and Google Scholar). We were searching for the terms “Industrie 4.0” and “Industry 4.0” in combination with “Germany” and “Deutschland”. The title, abstracts, and keywords of the first 50 results for each search term were analyzed by two researchers independently to ensure reliability. Only those search results with a clear reference to “Industrie 4.0” were considered as relevant. For these, a forward and backward search was conducted, focusing on whether new research items tackled the implementation status of Industrie 4.0 in Germany and/or one or some of the four key themes of research, and excluding those research items that did not deliver knowledge to this research interest.

In addition, we applied a qualitative discourse analysis [10] of primary and secondary data from expert interviews originating from research projects conducted with the participation of the authors on Industrie 4.0 and in adjacent topic areas, such as Artificial Intelligence, Smart Services, or Advanced Systems Engineering, among others, to identify current and future research issues and to derive evidence from these expert interviews regarding adoption and the four aforementioned key themes of research on Industrie 4.0.

Secondly, building on the matrix method of literature review [11], we discussed one field of action each in the three strategic areas that will drive the next decade of Industrie 4.0: sustainability (“digitainabilized” platform-based business models), sovereignty (resilient value networks) and interoperability (Open-Source) [12].

Here, given the three strategic areas of the vision 2030 of the German Plattform Industrie 4.0, building on the efficient literature review from the first step, we searched for the terms “sustainability”, “sovereignty”, and “interoperability”, with two researchers working independently in three publication databases (EBSCOhost, Emerald Insight, and Google Scholar) to identify fields of action requiring specific attention to drive Industrie 4.0 to success. Therefore, implications for research and practice raised in the research items received keywords and a prioritization. The two researchers then aggregated the assigned keywords and prioritization and discussed those cases with discrepancies. The three aforementioned fields of action with the highest prioritization were identified, and evidence acquired in the literature review was matched on these fields of action to round off this review on the status and outlook for Industrie 4.0 adoption and research in Germany.

However, the focused scope of the review should be taken into account when reading the review. The key themes of the research on Industrie 4.0 [7] and the strategic areas in the vision 2030 [12] were applied to structure the review. On the one hand, this approach may lead to (international) developments outside these guidelines being disregarded. On the other hand, this review gives evidence for researchers and practitioners to develop measures to strengthen Industrie 4.0 in accordance with the politically set strategy in Germany.

3. Status Quo: 10 Years of Industrie 4.0 in Practice and Research in Germany

The industry sector—predominantly comprising the automotive industry, the electrical and chemical industry, mechanical and plant engineering, and metal production—plays a pivotal role for the German economy. With a contribution to German gross value added (GVA) of 20.2% in 2021 [13], its contribution is almost twice as high as that of competitors on the world market, such as France, the United Kingdom, or the United States and is only matched among the biggest economies of the world, such as Japan, China, and South Korea [14,15]. Industry is a significant driver of innovation, with almost 60% of total German Research & Development (R&D) spending invested in this sector [16,17]. This indicates the relevance of the industrial sector for the German economy.

3.1. Development of German Industry since 2011 and Outlook on Industry Strategy until 2030

Since Industrie 4.0 was propagated as the vision for the digital transformation of German industry in 2011—aiming at connecting resources, services, and humans in real time throughout production on the basis of Cyber Physical Systems (CPS) and the Internet of Things (IoT) [3]—the gross value added of German industry increased in absolute terms, while its proportion relative to the GVA of German economy remained stable, in comparison to a decline in other countries [15,18]. German industry even experienced an internationally unmatched phase of “reindustrialization” until 2016, with increasing employee numbers, an increasing proportion of GVA, and higher productivity gains compared to other sectors, before the COVID-19 crisis and interrelated supply chain problems initiated a phase of deterioration in German industry, which was also due to its high dependency from world markets originating in its export orientation [19].

The deepening adaption towards Industrie 4.0 correlated with the continuing strength of industry as a value driver of the German economy, but could not prevent the phase of downturn during the pandemic. This phase is deemed to be temporary, due to two factors: First, extensive investments made by companies in the development of digital technologies and competencies in the first ten years of Industrie 4.0 have not amortized yet, because they are not easily quantifiable in terms of return on investment, as it is mostly intangible assets and human capital that have been targets of investment so far [19] (pp. 195–197). Second, after these significant digitalization steps in the first phase of Industrie 4.0, industry has appeared to “take a breath” regarding innovative value-driving projects in the run-up to the next wave of industrial digitalization [20], which will likely focus on industrial artificial intelligence (AI) and the creation of digital platform-based business models [6,21,22].

Put together, in the first ten years, German industry invested in shaping the breeding ground of Industrie 4.0, the base layer of digital infrastructure, architecture, products, and competences. To exploit this breeding ground—the cumulated value creation potential of Industrie 4.0 for German industry is estimated at 425 billion Euros until 2025 [23]—the German government set the ambitious goal in its Industrial Strategy 2030 of increasing the contribution of industry to GVA to 25% in 2030 (an increase of roughly five percentage points compared to 2021) [16]. After ten years of Industrie 4.0, the German government’s goals thus incentivize an acceleration of research and adoption of the changes to strengthen value creation, scalation, and sustainable long-term orientation of German industry.

3.2. Status Quo: Adoption of Industrie 4.0 in German Industry

To assess whether German industry is in a position to achieve these strategic goals by deepening its digital transformation, this section provides a status quo overview on the adoption of Industrie 4.0.

In practice, Industrie 4.0 is increasingly perceived as a competitive advantage by companies in the industrial sector [7]. The call for the digital transformation of industry towards the paradigm of smart factory has received significant attention in economic circles and has also holistically incentivized research [6,7]. Capitalizing on the global market leadership of German industry, its good network with customers, high competencies in creating individual solutions, and the strength and flexibility of small and medium-scale enterprises, many companies have made significant progress regarding digitalization in the last ten years [6,24]. However, there are industry-wide internal and external barriers to the implementation of Industrie 4.0. These barriers contribute to a slanted picture regarding the current adoption of Industrie 4.0 by German industry enterprises [24,25].

One dividing line occurs between large-scale enterprises and small and medium-scale enterprises (SMEs), whose digital transformation has proceeded at a slower rate. A recent study found that some SMEs in a sound financial position are not incentivized by competitive pressure to initiate digitalization (laziness–success paradox). Correspondingly, they operate with a lack of strategic expertise and a lack of digital enterprise culture, which preempts the drive toward digitalization of core processes [24]. Cost pressure is also higher for smaller companies. It nudges them to reject digital solutions if they are not perceived as cost-effective improvements over the analogous status quo. Digital projects are among those abandoned first if SMEs face financial problems; those projects do not contribute immediately to value creation, and when they are implemented, they often serve an immediate goal in the production chain rather than strengthening basic industrial infrastructure.

As a consequence, compared with large-scale enterprises, SMEs are worse off regarding data management, which is a prerequisite for the next decade of Industrie 4.0. If SMEs apply AI solutions, they do so primarily for their products and services, and only very seldomly for improving internal processes [26]. This is due to a lack of know-how and an insufficient data base regarding internal processes, resulting from rudimental data management. Thus, in the current adoption rates, SMEs are lagging behind large-scale enterprises as industry proceeds into the second decade of Industrie 4.0.

In general, large-scale enterprises are significantly more mature regarding their progress in digitalization [25]. Only a few have not yet started digitalization, often due to a lack of enthusiasm of top management in initiating the transformation, as qualitative focus interviews indicate [24]. However, these companies are endangering their competitiveness and are exceptions. Large-scale enterprises rather face other barriers occurring in later stages in the process of digitalization; legal restrictions, data security and privacy concerns, and uncertainty regarding the expansion of digitalization activities hinder a deepening of digitalization [24].

These factors are likely to also affect SMEs in the later stages of digitalization and complement other general factors inhibiting digitalization, irrespective of company size. The insufficient digital infrastructure in Germany—Germany has the fourth-lowest IT-investment to GDP ratio within the EU [27]—and structural disadvantages in Northern and Eastern Germany are major barriers already hindering the initiation of digital projects [19].

If these internal and external barriers do not hinder digitalization ambitions, the disproportionate shortage of qualified employees in German industry does [15,28]. Without the required knowledge, successful digitalization projects that create network effects and attract follow-up investments are less likely [29,30]. Additionally, asymmetry in industrial value chains—especially in the automotive industry—hinders proactive and targeted digitalization. Companies that are highly dependent on bigger suppliers or customers in the value chain have little control over measures implemented and need to react to the digitalization requirements of those partners. This aggravates digitalization barriers, especially for SMEs who have fewer resources to facilitate such responses.

Brought together, just as industry is proceeding into the second decade of Industrie 4.0, SMEs are lagging behind large-scale enterprises (see reasons in Table 1). In general, digitalization expertise that does not meet the standards of domain expertise in German industry, insufficient external digital infrastructure, lacking creativity and courage for thinking in new business models and problems in becoming agile [24,31] (p. 22) often inhibit the adoption of Industrie 4.0 in Germany.

Table 1.

Hindering factors of Industrie 4.0 in Germany per company type (Own Illustration).

3.3. Status Quo: Industrie 4.0 in Germany from a Research Perspective

Hence, evidence-based targeted improvements in the four key themes of Industrie 4.0 [7] are required. Therefore, a more detailed assessment of the status quo setting a focus on the need for research and development in Germany is required.

3.3.1. Research Theme: Value Creation Scenarios

Regarding Value Creation Scenarios for Industrie 4.0, platform-based business models for industry are considered as among the most promising fields of action for Industrie 4.0 [32]. Until now, especially in the B2C sector, they have not been widely adapted [33]. Especially for SMEs, market penetration seems to be inhibited by high investment costs, challenges in determining concrete benefits, and insufficient data quality originating from the aforementioned rudimentary data management [25]. Thus, only the first steps towards digital business models have been made in many domains so far [25,32].

Correspondingly, industry-wide innovation environments that build the base layer for platform-based business models are correspondingly under-researched [24]. Developing global digital ecosystems compliant with European data protection standards that could be based on Open-Source architecture promise to drive research and implementation in this area of action [34,35]. However, to develop and further analyze value creation scenarios for Industrie 4.0, the basic technologies and infrastructure need to be put into practice.

3.3.2. Research Theme: Prospective Technological Trends

Considering Prospective Technological Trends, blind spots in implementation und domestic production can be identified relating to technologies with the potential to strengthen the sovereignty of German industry [24,36,37]. Considering the volatile geo-economic and geopolitical status quo, resilient ecosystems ensuring safe, secure control and self-determination for companies with regard to their data require more attention. This includes trialing certification, norming, and standardization, with the aim of creating a resilient basic infrastructure. In addition, it is important to ensure the availability of key technologies for Industrie 4.0 (e.g., 5G) to safeguard and stabilize value chains [38]. Such a resilient infrastructure is required for the next evolutive step of Industrie 4.0 towards the smart factory, where machines, components, materials, and people exchange information seamlessly, in an automated fashion, and in real time in order to adapt production optimally to changing conditions in a self-learning manner [39,40].

In addition to the roll-out of digital twins, this requires, above all, the integration of artificial intelligence (AI) in the processes, products, and services of industry [41]. This would allow for the automation of production, the control of industrial drives (motion control), demand-driven maintenance of machinery, process optimization, and quality assurance through non-destructive testing, among other advances [42]. To implement AI industry-wide in factories, groundwork by research and in practice in the other key themes of Industrie 4.0 is required.

3.3.3. Research Theme: New Methods and Tools for Industrie 4.0

Regarding New Methods and Tools for Industrie 4.0, models and simulations for the AI-driven smart factory are required. Although models and simulations meeting the needs of the cyber-physical matrix systems already exist (e.g., digital twins) [36], research has not made sufficient advancements regarding these for the highest expansion stage of the AI-driven smart factory [25,39]. Here, a lack of connection of different business models with data and data analytics hinders advancements. Consequently, on a higher complexity level, coupled, hybrid, and holistic models are required [43].

Regarding implementation, even digital twins require industry-wide roll-out [44]. The lack of clarity among companies regarding the quantification of the benefits of digital projects for business operations could explain why they have not been rolled out so far [24]. KPI-driven assessments measuring indirect and direct effects of digital projects on value creation that go beyond traditional cost-benefit analysis need to be developed by academic and practice-oriented research [24].

3.3.4. Research Theme: Work and Society

Considering the fact that Industrie 4.0 is significantly interrelated with transformations in the workforce, Work and Society as the fourth key theme of Industrie 4.0 deserves attention as well. In the existing workforce—17% of German employees worked in the industrial sector in 2018 [19] (p. 193)—most of the employees are in wait-and-see mode and are cautious regarding Industrie 4.0. They are mostly indifferent, do not drive its implementation proactively, and are expected to react negatively toward the digital transformation of industry if its value added does not become visible, if employers do not communicate transparently about transformation steps, and if employees have the feeling that technology is being applied to control their work [29,30].

Digital transformation is accompanied by increased demand for qualified specialists with domain knowledge and information and communications technology (ICT) expertise. However, employees with the required skills to manage the transformation towards the smart factory are scarce. In 2021, more than every second company in industry sector is lacking qualified specialists in the long run [28]. Required soft skills include an interdisciplinary mindset, process know-how, leadership skills, a change and problem-solving mentality, and an orientation towards self-management. Hard skills are required in data analytics, processes, and customer-relationship-management, as well as abilities regarding IT security and IT business analytics and specific know-how about IT systems [29]. Additionally, AI-related competences are required (e.g., regarding human–machine interaction, basic knowledge about machine learning, and awareness regarding AI) [41,45].

In sum, our literature review indicates that the four key themes of Industrie 4.0 receive high attention in scientific research and in practice-oriented research, although more focus is required for interdisciplinary research in the face of accelerating technological progress [6]. The Research Council of the Plattform Industrie 4.0 (Forschungsbeirat der Plattform Industrie 4.0: advisory body of high-level experts from science and industry advising the Plattform Industrie 4.0) is continuously monitoring research progress and potentials, and defines potentials for research projects in those areas deserving more attention. This promises an evidence-driven advancement of Industrie 4.0. Complemented with academic research on Industrie 4.0, the research community leverages innovation by creating incentives for companies to fund collaborative research and by providing guidance for (public) funding programs. However, there remains future research potential across all key themes, especially in the face of the next decade of Industrie 4.0 facing a future full of ambiguities, potentials, and threats in implementing Industrie 4.0 [46].

4. Fields of Action for the Next Decade of Industrie 4.0 from a German Perspective

Against this background, German government, informed by the Research Council of the Plattform Industrie 4.0 and the Plattform Industrie 4.0 itself, has recognized the need for a strategic development of Industrie 4.0 for the next decade. It set the ambitious goal in its Industrial Strategy 2030 of increasing the share of German industry in gross value added in the economy to 25% by 2030—an increase of five percentage points [16]. Industrie 4.0 promises to be an important driver in this regard, with its target vision of the AI-driven smart factory and digital, platform-based business models. To leverage the potential of Industrie 4.0 in view of the economic, ecological, and geopolitical challenges of our time, and to follow a holistic approach for creating open digital ecosystems, strategic focus in Germany is set on three areas: sovereignty, interoperability, and sustainability [12].

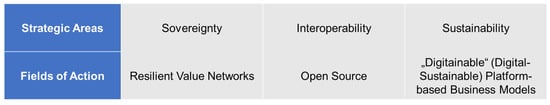

Despite having been central to Industrie 4.0 already in the first ten years, German policy makers have recognized the need to intensify efforts in these areas in order to position German industry competitively in the market in the face of increasing political, ecological, and economic ambiguities [12]. Based on the matrix review assessment, one promising field of action was identified for each strategic area of the vision 2030 of the Plattform Industrie 4.0 (see descriptive Figure 1), as discussed in the following. For each field of action, an exemplary best case is presented that shows possible implementation paths.

Figure 1.

Strategic Areas [8] and Promising Fields of Action for Industrie 4.0 (Own Illustration).

4.1. Sovereignty

Globalization has caused high interdependencies in global value chains. German industry is highly dependent on raw materials, predominantly from the Far East (e.g., China). The digitalization of industry creates new dependencies, predominantly from the US, where most of the technology companies delivering services for German industry (e.g., Microsoft with Azure, Amazon with AWS, or Salesforce and Oracle with its services) are located. Under the presidency of Donald J. Trump, the U.S. gradually turned away from Europe as its primary geostrategic and economic partner [47]. Even though it might have been a temporary phenomenon, it highlighted—together with the “trade war” between China and the US—the importance of technological sovereignty for the EU and Germany in terms of economic policy [48]. This has been recognized by policymakers, e.g., in the EU White Paper on Artificial Intelligence [49], which emphasizes the importance of economic sovereignty in general and in particular for Industrie 4.0 with the vision 2030 of the German Plattform Industrie 4.0 [12]. Whereas technological sovereignty demands government action to ensure independence on a macroeconomic level, on a microeconomic level, individual companies need to operationalize this strategic directive by increasing their ability “to cope with shocks of different sorts” [50] (p. 5) by becoming resilient.

The resilience of value networks requires specific attention as the COVID-19 pandemic has unveiled the dependency of German industry on global value chains [51]. Supply chain problems have led to a widespread production standstill causing a phase of deterioration in German industry. The shortages of semiconductor electronics and cable harnesses, as well as the Russian invasion in Ukraine causing oil and electricity price explosions, are affecting companies significantly. With these factors put together, German industry companies are not resilient in facing crises and volatility on the world market [52]. To increase the resilience of its value networks, German industry requires a strategy coupling robustness, to reduce the effects of volatility on company performance, with agility, in order to respond quickly to unpredictable disruptive events. Three measures to increase resilience can be identified in this regard: (1) the adoption of value creation networks, (2) safe and secure data integration, and (3) reliance on Industrie 4.0 technologies [53].

The paradigm of single sourcing coupled with just-in-time delivery has caused a production standstill during the COVID-19 pandemic due to the strict lockdowns in divergent parts of the world over time. German industry is still dependent on global value chains, as 43% of Germany’s net exports are only generated due to its embedding in global value chains [54]. This dependency needs to be reduced.

A short-term measure in this regard is a mitigation of the just-in-time paradigm by maintaining larger inventories. In the event of a catastrophe—for example, in the event of economic lockdown measures in one production country—it would be possible to quickly switch to capacities in other production countries. This mitigates the supply-side risk by diversifying production capacities, but leads to higher costs.

A medium-term approach is a local-for-local strategy, i.e., locating production and the upstream value chain in the sales market. By synchronizing supply- and demand-oriented risks in sales markets, only the respective regional clusters are affected in the event of a disaster. This concentration effect mitigates the risk of supply chain disruptions. At the same time, resources are duplicated to a much greater extent, causing efficiency losses. These solution approaches provide more resilience, but are not able to counter the increasing uncertainty and pressure for change in the market environment.

Thus, in the long run, the monolithic and highly optimized value chains of the present could be gradually replaced by resilient and adaptive value creation networks [53]: multiple sourcing based on regional local for local strategies, the creation of redundancies to allow for flexible reaction on crises, and a diversification and continuous evaluation of the supplier base as part of risk and sustainability management.

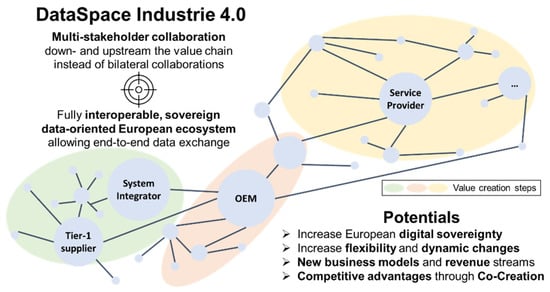

Based on the paradigm of co-creation, value creation networks require data infrastructure that allows companies to collaborate seamlessly in order to develop and strengthen resilient business models that, on a macroeconomic level, promise to increase digital sovereignty [21,55]. The German Plattform Industrie 4.0 drives such an attempt with its European Data Space Industrie 4.0, building a data infrastructure for companies from German industry and the ICT sector (see Figure 2).

Figure 2.

DataSpace Industrie 4.0—Initiative for a sovereign European industrial data ecosystem (own illustration based on Plattform Industrie 4.0 [56]).

These data spaces aim at not only increasing digital sovereignty, but also data sovereignty, enabling the secure, decentralized, and self-determined exchange, collection, analysis, and sharing of data. Thereby, they form the basis for new, highly scalable, data-driven, and platform-based business models—one of the focus points in the next decade of Industrie 4.0 [1,2,3,22].

Next to the establishment of value creation networks, data integration is a prerequisite for a resilient Industrie 4.0. Our analysis indicates that this is currently not achieved in practice, as SMEs especially face problems regarding data management [24,25,43]. They require support and innovative data ecosystem. Data integration comprises, in this regard, the use of platforms where standardized data exchange is enabled. Real-time monitoring of procurement, logistics, production, and sales processes allows for optimization of processes, and the created data could also be integrated into data exchange platforms and could train self-learning AI models for an industry-wide optimization of production.

Therefore, the industry-wide implementation of Industrie 4.0 technologies is key. Software-based risk management is required for resilient and adaptive value creation. Big data analytics and artificial intelligence are the basic technologies for reaching the paradigm of the Smart Factory [26]. Digital twins or digital shadows require industry-wide penetration [39,44]. Only if industry applies those technologies can it future-proof for the next decade of Industrie 4.0.

4.2. Interoperability

Industrie 4.0, postulating the AI-driven smart factory and platform-based business models, requires the establishment of an innovative ecosystem where companies and customers interact seamlessly. To reduce transaction costs, interoperability is key. In the first ten years of Industrie 4.0, significant initiatives were started. The GAIA-X project aims at developing a safe and interconnected data infrastructure for a European digital ecosystem with industry sitting at its heart setting policy rules, guidelines, and a standard architecture framework contributing to cross-sector interoperability. The launch of RAMI 4.0 as an international industry-specific standardization and reference architecture for Industrie 4.0, the coordination of the standardization of Industrie 4.0 by the Standardization Council Industrie 4.0, the establishment of OPC UA as a standard for interoperable interfaces for AI-driven production, and the launch of the administration asset shell have improved industry-specific interoperability predominantly by means of standardization [57,58].

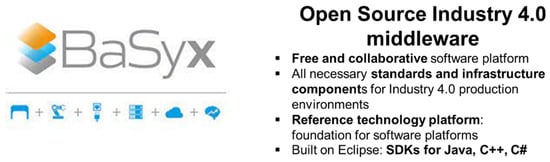

For the next decade of Industrie 4.0, Open-Source will play a pivotal role in implementing and exploiting interoperability for the creation of new platform-based business models [34,35]. Already at the beginning of the 2020s, Open-Source Software (OSS) contributes between €65 billion to €95 billion to the EU’s GDP (equaling EU-GDP of air and water transport combined) and promises significant growth opportunities in the future, especially for Industrie 4.0 [59]. OSS could even be applied to enhance interoperability, as demonstrated by BaSyx-middleware (see Figure 3).

Figure 3.

BaSyx–Open-Source Middleware (Own Illustration).

Currently, economy-wide motivations for participating in OSS mainly lie in the need to find technical solutions, avoid vendor lock-in—a factor that is also relevant for technological sovereignty—and build knowledge in high-quality coding. At the same time, as OSS builds on voluntary contributors, its cost–benefitratio is a highly promising driver for value creation: for every Euro invested, a €12 value creation is achieved [59]. This is a significant lever, especially for SMEs in the industry, given the cost pressures they are facing.

However, to exploit this lever across the breadth of the manufacturing sector, further advancements for OSS from a technological, regulatory, and innovative perspective are required. Within companies, Open-Source needs to be integrated as an elementary step in value creation [34]. This begins with the development and the communication of an Open-Source strategy developed by an interdisciplinary team creating acceptance and support in the workforce from scratch onward. It should be embedded in a top-level vision and strategy, which could imply the application of OS to create standards, to boost business model strategies, or to gain competencies in core technologies.

Once initiated, an Open-Source Program Office (OSPO) should boost implementation. As the central business unit responsible for Open Source (OS) processes, the OSPO is responsible for quality management, checking license compatibilities and Open Source Sofware (OSS) integrity with Intellectual Property, and importantly, also for the qualification of employees regarding OSS [17]. Senior management in this phase needs to ensure the establishment of an OS mindset in the workforce alongside the selection of communities and ecosystems fitting to OS properties.

Additionally, the concrete areas of action of OS need to be crosschecked continuously. It is recommended to only develop OS for non-IP-relevant products, processes, or code, which should not be attached to the primary value proposition of a company. If the latter did occur, a company would cannibalize its market position. This indicates the need for continuous adaptation of and reflection on business models.

In industrial policy, Open-Source has played an important role. However, European governments have taken a more laissez-faire approach, and today, the EU is on the back foot when it comes to capabilities in this area. Hence, it is recommended also for the public sector to establish OSPOs, to publicly fund R&D projects related to Open-Source more intensively, to support entrepreneurial activities around OSS, and to build a European ecosystem around OSS, among other recommendations [59].

4.3. Sustainability

The need for sustainable economizing is more important than ever in view of aggravating global socioeconomic inequality and many tipping points that will be reached in the context of the climate crisis. German industry is the second biggest polluter of greenhouse gas (GHG) emissions beyond the energy sector [60]. Thus, German government has set ambitious goals to reduce the ecological footprint of the industrial sector. Greenhouse gas neutrality should be achieved by 2045 [61].

Industrie 4.0 is pivotal in this regard [62]. The smart factory standalone promises to reduce emissions and increase energy efficiency by optimizing resource need and consumption of production [63]. However, rebound effects, such as overproduction and overconsumption caused by a more efficient smart factory, could even increase the ecological footprint of German industry. The same holds for artificial intelligence as a driver for the smart factory and platform-based business models. According to a recent analysis [64], AI contributes positively to 139 of 169 indicators of the 19 UN Sustainable Development Goals (UN SDGs)–the central reference point of a holistic comprehension of sustainability–whereas it affects 59 of those 169 indicators negatively at the same time.

Thus, to exploit the positive effects of ICT while mitigating its negative externalities on sustainability, a strategic combination of digitalization and sustainability is required to create win–win–win scenarios for economy, ecology, and society [65] (pp. 64–70); ‘Digitainability: [65,66], as a strategic perspective on Industrie 4.0 based on circular economizing and sustainable business models, is the vision in this regard [67].

Building on the approach of an integrated sustainability strategy for AI [65,68], an integrated strategy framework of Industrie 4.0 and sustainability could support companies in becoming future proof for the next decade of Industrie 4.0. Similarly to the integrated sustainability strategy for AI [68] and the adoption guide for SMEs to AI [69], an integrated sustainability strategy for Industrie 4.0 could comprise the five stages of Status & Stakeholder Assessment, Sustainability Target Setting, Impact Check, Adaption of Technological strategy (AI and other ICTs), and Implementation and Continuation [68].

The Status & Stakeholder Assessment, as the first step in entrepreneurial transformation towards future-proofing and sustainable economization demands, the evaluation of the current value chain [70], stakeholder analyses, and assessments of the impact of ICTs on a company’s sustainability, identifies those critical aspects that require attention in sustainability management.

Derived from this, Sustainability Target Setting includes operationalizing a company’s sustainability vision in measurable dimensions. These dimensions include the three aspects of economic, ecological, and social sustainability in addition to ESG criteria [68].

This is followed by a concrete Impact Check to assess where action is needed in the creation and design of products, services, or processes in the company, and how measures need to be designed so that they contribute to these sustainability targets. The UN SDGs are a productive reference point in this regard.

What follows is the merging of the sustainability strategy with the digitalization strategy of a company in the stage of Adaption. Here, companies need to apply ICTs only in those areas where they are really creating benefits based on the current adaption status of ICTs. They need to assess how their products, processes or services can be optimized, or (and) how ne sustainable business models based on AI and other ICTs could be developed.

In the stage of Implementation and Continuation, it is important to create a ‘digitainabilized’ mindset within an industrial company. This includes employee-related measures regarding the use of digital technologies in the company and the permanent integration of the company’s individual sustainability goals into the company organization, as well as the propagation of a change-oriented and agile orientation in implementation [68].

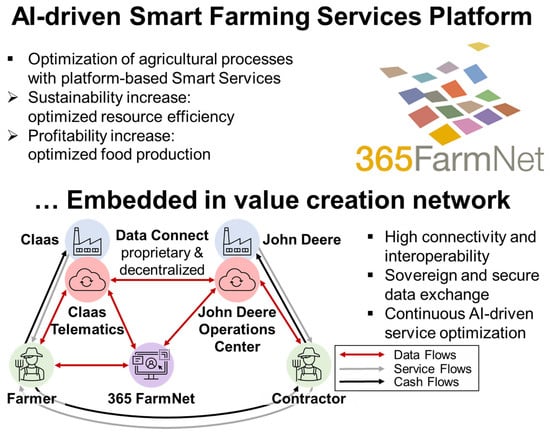

Strategically merging sustainability and AI-driven Industrie 4.0 offers potential for companies to create new and resilient value creation networks or to even design sustainable platform-based business models that promise to increase and solidify revenue streams for industrial companies and in affiliated sectors (e.g., agricultural machinery technology; see Figure 4) [62]. Smart Services are important drivers in this regard [71].

Figure 4.

Smart farming services as an example of ‘digitainabilized’ platform-based business models (Own Illustration based on Plattform Lernende Systeme [58] (p. 16)).

If companies become that innovative, this creates market opportunities for German and European industry to position itself as a market leader regarding sustainable services, products, and service-product system offerings on B2B platforms. Such an ecosystem—given a sufficient level of interoperability—would promise to strengthen the sovereignty of German and European industry. This indicates that the focus areas discussed in this paper are mutually dependent and offer symbiotic potential. Therefore, they deserve future attention in economic implementation and research.

5. Conclusions

Based on an efficient literature review, this review details the status quo regarding the digital transformation of German industry towards Industrie 4.0 ten years after it had been postulated as the new paradigm. On the path towards higher productivity and mass customization, large-scale enterprises proceed faster than small- and middle-sized enterprises, which face competitive pressure and internal barriers towards digitalization to a greater degree. Lack of know-how and strategic courage is problematic in this regard. Industry-wide, the shortage of qualified specialists with both high domain expertise and ICT know-how significantly inhibits the adoption of Industrie 4.0. Coupled with a lack of adequate base technologies for Industrie 4.0 and the lack of data exchange platforms, the creation of platform-based digital business models in industry is especially lagging. In general, it has become evident that academic and practice-oriented research drives and supports the implementation of Industrie 4.0 across all relevant key themes. Its insights require accelerated application into practice.

Furthermore, relying on the matrix method of literature review, this contribution identifies three fields of action in the three strategic areas of the next stage of Industrie 4.0. To strengthen sovereignty of the industrial sector, resilience needs to be increased by complementing efficient but failure-prone value chains with flexible and robust value creation networks based on a high level of data integration built on Industrie 4.0 technologies. Interoperability is key in this regard, as it allows seamless cooperation within value creation networks. Open-Source Software promises to strengthen technical interoperability and is a significant lever for value creation and particularly attractive for SME facing cost and time pressure to adapt faster towards Industrie 4.0. Interoperable value creation networks also allow for the creation of sustainable platform-based business models as a core element for the next stage of Industrie 4.0. Sustainability—given rising socioeconomic inequalities and the climate crisis, and the corresponding policy incentives for sustainability—already impacts industrial economizing in the 21st century [72]. If it is strategically coupled with digitalization it promises to become a success factor, shaping new business opportunities for German industry; ‘Digitainability made in Germany’ could couple industrial excellence with digital skills on platforms for the good of the economy, environment, and society [65,66]. An intertwinement of these strategic areas and fields of action leveraging synergetic potentials promises to cure current weaknesses in industry regarding adoption of Industrie 4.0, to overcome the obstacles in the industry sector, and to exploit the potentials of Industrie 4.0 technologies in a productive manner in the next decade of Industrie 4.0.

For the practice-oriented research community, this review details the status quo of adoption and research on R&D from a German perspective based in the strategic objectives set by the federal government. This creates an evidence base for future cross-country comparisons of the status quo of Industrie 4.0. The identified differences between SMEs and large-scale enterprises regarding its adoption are of significance for interdisciplinary research to identify their causes and interrelations. Intensified research efforts are required in this regard. The identified future fields of action in the strategic areas of Industrie 4.0 necessitate further research attention, as they might allow acceleration of the digital transformation of the industrial sector. Here, a holistic perspective comprising the four key themes applied on these development paths is of importance.

The implications of this review are not restricted to research, but are also directed to industrial companies and political stakeholders. The review on the status quo of Industrie 4.0 adoption focusing on the causes of different degrees of maturity serves to inform corporate management about current weaknesses and opportunities to increase competitiveness. All industrial companies must anchor digitalization within core company strategy, comprising the strengthening of the digitalization culture, introducing clear accountability among top-level management, establishing a program for lifelong learning, and taking a long-term perspective in assessing the added value of digitalization measures to company revenues. The German government needs to upgrade the basic infrastructure for Industrie 4.0, especially for Industrial AI; must develop an ICT skills strategy for the industrial sector; and is advised to emphasize the strategic areas of Industrie 4.0 to maintain and increase the competitiveness of German industries. Concurrently, the future fields of action raised by this review could inspire strategic middle-term orientation of industrial companies, as well as providing evidence for political stakeholders for the orientation of future Industrie 4.0 funding programs. In this way, this review extensively supports the accumulation of knowledge for science, application, and politics with regard to the current and future orientation of Industrie 4.0 in Germany.

Author Contributions

J.W., A.F. and J.B. have developed all sections of the paper jointly. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are delighted to thank Joachim Sedlmeir and an anonymous referee for many helpful suggestions on a draft of this entry, and to Victoria Neubert for valuable proof-reading.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Autio, E.; Thomas, L.D.W. Value co-creation in ecosystems: Insights and research promise from three disciplinary perspectives. In Handbook of Digital Innovation; Nambisan, S., Lyytinen, K., Yoo, Y., Eds.; Edward Elgar Publishing: Cheltenham, UK, 2020; pp. 107–132. [Google Scholar] [CrossRef]

- Lingens, B.; Miehé, L.; Gassmann, O. The ecosystem blueprint: How firms shape the design of an ecosystem according to the surrounding conditions. Long Range Plan. 2021, 54, 102043. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative Industrie 4.0: Final Report of the Industrie 4.0 Working Group; Research Union of the German Government: Berlin, Germany, 2012. [Google Scholar]

- Spath, D.; Gausemeier, J.; Dumitrescu, R.; Winter, J.; Steglich, S.; Drewel, M. Digitalisation of Society. In Handbook of Engineering Systems Design; Maier, A., Oehmen, J., Vermaas, P.E., Eds.; Springer: Cham, Germany, 2021; pp. 1–27. [Google Scholar] [CrossRef]

- Salvador, F.; Piller, F.; Aggarwal, S. Surviving on the long tail: An empirical investigation of business model elements for mass customization. Long Range Plan. 2020, 53, 101886. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W. Ten Years of Industrie 4.0. Sci 2022, 4, 26. [Google Scholar] [CrossRef]

- Forschungsbeirat der Plattform Industrie 4.0 (Ed.) Key Themes of Industrie 4.0. Research and Development Needs for Successful Implementation of Industrie 4.0. 2019. Available online: https://en.acatech.de/publication/key-themes-of-industrie-4-0/download-pdf/?lang=en (accessed on 19 April 2022).

- vom Brocke, J.; Simons, A.; Niehaves, B.; Riemer, K.; Plattfaut, R.; Cleven, A. Reconstructing the Giant: On the Importance of Rigour in Documenting the Literature Search Process. In Proceedings of the 17th European Conference on Information Systems, Verona, Italy, 26 June 2009; pp. 2206–2217. [Google Scholar]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D.A., Bryman, A., Eds.; Sage Publications Ltd.: Thousand Oaks, CA, USA, 2009; pp. 671–689. ISBN 978-144-620-064-3. [Google Scholar]

- Mayring, P. Qualitative Inhaltsanalyse. In Handbuch Qualitative Forschung: Grundlagen, Konzepte, Methoden und Anwendungen; Flick, U., von Kardoff, E., Keupp, H., Rosenstiel, L.V., Wolff, S., Eds.; Beltz: München, Germany, 1991; pp. 209–213. ISBN 362-127-229-1. [Google Scholar]

- Klopper, R.; Sam, L.; Hemduth, R. The matrix method of literature review. Alternation 2007, 14, 262–279. [Google Scholar] [CrossRef]

- Plattform Industrie 4.0 (Ed.) 2030 Vision for Industrie 4.0. Shaping Digital Ecosystems Globally. 2019. Available online: https://www.plattform-i40.de/IP/Redaktion/EN/Downloads/Publikation/Vision-2030-for-Industrie-4.0.pdf?__blob=publicationFile&v=9 (accessed on 21 April 2022).

- Statistisches Bundesamt (Ed.) Volkswirtschaftliche Gesamtrechnungen. Inlandsproduktberechung 2021. Fachserie 18 Reihe 1.1. 2022. Available online: https://www.destatis.de/DE/Themen/Wirtschaft/Volkswirtschaftliche-Gesamtrechnungen-Inlandsprodukt/Publikationen/Downloads-Inlandsprodukt/inlandsprodukt-erste-ergebnisse-pdf-2180110.pdf?__blob=publicationFile (accessed on 15 April 2022).

- WTO. World Trade Report 2021. Economic Resilience and Trade. 2021. Available online: https://www.wto.org/english/res_e/booksp_e/wtr21_e/00_wtr21_e.pdf (accessed on 13 May 2022).

- OECD. Main Economic Indicators. Volume 2022 Issue 5. 2022. Available online: https://www.oecd-ilibrary.org/deliver/bb256505-en.pdf?itemId=%2Fcontent%2Fpublication%2Fbb256505-en&mimeType=pdf (accessed on 13 May 2022).

- Bundesministerium für Wirtschaft und Energie. Industrial Strategy 2030. Guidelines for a German and European Industrial Policy. 2019. Available online: https://www.bmwi.de/Redaktion/EN/Publikationen/Industry/industrial-strategy-2030.pdf?__blob=publicationFile&v=7 (accessed on 9 May 2022).

- Destatis. Germany. Statistical Country Profile, Edition 02/2022. 2022. Available online: https://www.destatis.de/EN/Themes/Countries-Regions/International-Statistics/Country-Profiles/germany.pdf?__blob=publicationFile (accessed on 13 May 2022).

- Kinkel, S. Industrie in Deutschland: Kern Wirtschaftlichen Wachstums und inländischer Wertschöpfung. In Die Modernität der Industrie; Priddat, B.P., West, K.-W., Eds.; Metropolis-Verlag: Marburg, Germany, 2012; pp. 193–214. ISBN 978-3-89518-936-4. [Google Scholar]

- Institut für Weltwirtschaft. Analyse der industrierelevanten wirtschaftlichen Rahmenbedingungen in Deutschland im Internationalen Vergleich. Endbericht and das Bundesministerium für Wirtschaft und Energie, Referat I C 4. 2020. Available online: https://www.bmwi.de/Redaktion/DE/Publikationen/Studien/industriestudie.pdf?__blob=publicationFile&v=4 (accessed on 13 May 2022).

- Kagermann, H.; Winter, J. The second wave of digitalization. In Germany and the World 2030: What Will Change. How we Must Act; Mair, S., Messner, D., Meyer, L., Eds.; Econ: Berlin, Germany, 2018; pp. 216–227. ISBN 343-021-010-0. [Google Scholar]

- Kagermann, H. Change Through Digitization—Value Creation in the Age of Industry 4.0. In Management of Permanent Change; Albach, H., Meffert, H., Pinkwart, A., Reichwald, R., Eds.; Springer: Wiesbaden, Germany, 2015; pp. 23–45. ISBN 978-3-658-05014-6. [Google Scholar]

- Kagermann, H.; Nonaka, Y. Revitalizing Human-Machine Interaction for the Advancement of Society—Perspectives from Germany and Japan. Acatech DISKUSSION. 2019. Available online: https://en.acatech.de/publication/revitalizing-human-machine-interaction-for-the-advancement-of-society-perspectives-from-germany-and-japan/ (accessed on 3 May 2022).

- Bundesministerium für Wirtschaft und Energie. Digitale Strategie 2025. 2016. Available online: https://www.bmwi.de/Redaktion/DE/Publikationen/Digitale-Welt/digitale-strategie-2025.pdf?__blob=publicationFile&v=8 (accessed on 3 May 2022).

- Forschungsbeirat der Plattform Industrie 4.0 (Ed.) Blinde Flecken in der Umsetzung von Industrie 4.0—Identifizieren und Verstehen. 2022. Available online: https://www.acatech.de/publikation/blinde-flecken-i40/download-pdf/?lang=wildcard (accessed on 3 May 2022).

- Schuh, G.; Anderl, R.; Dumitrescu, R.; Krüger, A.; Ten Hompel, M. (Eds.) Using the Industrie 4.0 Maturity Index in Industry. Current Challenges, Case Studies and Trends. Acatech COOPERATION. 2020. Available online: https://www.acatech.de/publikation/der-industrie-4-0-maturity-index-in-der-betrieblichen-anwendung/download-pdf/?lang=en (accessed on 9 May 2022).

- Forschungsbeirat der Plattform Industrie 4.0 (Ed.) Künstliche Intelligenz zur Umsetzung von Industrie 4.0 im Mittelstand. Expertise des Forschungsbeirats der Plattform Industrie 4.0. 2020. Available online: https://www.acatech.de/publikation/fb4-0-ki-in-kmu/download-pdf/?lang=de (accessed on 3 May 2022).

- European Commission. The Digital Economy and Society Index (DESI) 2020. 2020. Available online: https://ec.europa.eu/newsroom/dae/document.cfm?doc_id=67086 (accessed on 3 May 2022).

- Deutscher Industrie- und Handelskammertag. Fachkräfteengpässe schon über Vorkrisenniveau. DIHK-Report Fachkräfte 2021. Available online: https://www.dihk.de/resource/blob/61638/9bde58258a88d4fce8cda7e2ef300b9c/dihk-report-fachkraeftesicherung-2021-data.pdf (accessed on 5 May 2022).

- Acatech (Ed.) Kompetenzentwicklungsstudie Industrie 4.0. Erste Ergebnisse und Schlussfolgerungen. 2016. Available online: https://www.acatech.de/publikation/kompetenzentwicklungsstudie-industrie-4-0-erste-ergebnisse-und-schlussfolgerungen/download-pdf/?lang=de (accessed on 5 May 2022).

- Acatech (Ed.) Kompetenzen für Industrie 4.0. Qualifizierungsbedarfe und Lösungsansätze. Acatech POSITION. 2016. Available online: https://www.acatech.de/publikation/kompetenzen-fuer-industrie-4-0-qualifizierungsbedarfe-und-loesungsansaetze/download-pdf/?lang=de (accessed on 5 May 2022).

- Mrugalska, B.; Ahmed, J. Organizational Agility in Industry 4.0: A Systematic Literature Review. Sustainability 2021, 13, 8272. [Google Scholar] [CrossRef]

- Gausemeier, J.; Dumitrescu, R.; Echterfeld, J.; Pfänder, T.; Steffen, D.; Thielemann, F. Innovationen für die Märkte von Morgen: Strategische Planung von Produkten, Dienstleistungen und Geschäftsmodellen; Carl Hanser Verlag: München, Germany, 2019; ISBN 978-3-446-42824-9. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 49th Hawaii International Conference on System Sciences (HICSS), Honolulu, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar] [CrossRef] [Green Version]

- Forschungsbeirat der Plattform Industrie 4.0 (Ed.) Open Source als Innovationstreiber für Industrie 4.0. Expertise des Forschungsbeirats der Plattform Industrie 4.0. 2022. Available online: https://www.acatech.de/publikation/open-source-i40-innovationstreiber/download-pdf/?lang=de (accessed on 5 May 2022).

- Zeid, A.; Sundaram, S.; Moghaddam, M.; Kamarthi, S.; Marion, T. Interoperability in Smart Manufacturing: Research Challenges. Machines 2019, 7, 21. [Google Scholar] [CrossRef] [Green Version]

- Thoben, K.-D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and Smart Manufacturing—A Review of Research Issues and Application Examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef] [Green Version]

- Glass, R.; Meissner, A.; Gebauer, C.; Stürmer, S.; Metternich, J. Identifying the barriers to Industrie 4.0. Procedia CIRP 2018, 72, 985–988. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Trappey, C.V.; Govindarajan, U.H.; Sun, J.J.; Chuang, A.C. A Review of Technology Standards and Patent Portfolios for Enabling Cyber-Physical Systems in Advanced Manufacturing. IEEE Access 2016, 4, 7356–7382. [Google Scholar] [CrossRef]

- Forschungsbeirat der Plattform Industrie 4.0 (Ed.) Modellierungs- und Simulationsbedarfe der Intelligenten Fabrik. Expertise des Forschungsbeirats der Plattform Industrie 4.0. 2021. Available online: https://www.acatech.de/publikation/modellierungs-und-simulationsbedarfe-der-intelligenten-fabrik-expertise/download-pdf/?lang=de (accessed on 3 May 2022).

- Drossel, W.-G.; Ihlenfeldt, S.; Langer, T.; Dumitrescu, R. Cyber-Physische Systeme. Forschen für die digitale Fabrik. In Digitalisierung; Neugebauer, R., Ed.; Springer Vieweg: Berlin, Germany, 2018; pp. 197–222. ISBN 978-3-662-55889-8. [Google Scholar]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Sansana, J.; Joswiak, M.N.; Castillo, I.; Wang, Z.; Rendall, R.; Chiang, L.H.; Reis, M.S. Recent trends on hybrid modelling for Industry 4.0. Comput. Chem. Eng. 2021, 151, 107365. [Google Scholar] [CrossRef]

- Kennet, R.S.; Bortman, J. The digital twin in Industry 4.0: A wide-angle perspective. Qual. Reliab. Eng. Int. 2021, 38, 1357–1366. [Google Scholar] [CrossRef]

- André, E.; Bauer, W.; Aurich, J.C.; Bullinger-Hoffmann, A.; Heister, M.; Huchler, N.; Neuburger, R.; Peissner, M.; Stich, A.; Suchy, O. Kompetenzentwicklung für KI. Veränderungen, Bedarfe und Handlungsoptionen. Plattform Lernende Systeme, Ed.; 2022. Available online: https://www.plattform-lernende-systeme.de/files/Downloads/Publikationen/AG2_WP_Kompetenzentwicklung_KI.pdf (accessed on 21 April 2022).

- Forschungsbeirat der Plattform Industrie 4.0 (Ed.) Forschungs- und Entwicklungsbedarfe zur Erfolgreichen Umsetzung von Industrie 4.0. 2. Überarbeite Fassung. Available online: https://www.acatech.de/publikation/themenfelder-i40-akt/download-pdf?lang=de (accessed on 7 August 2022).

- Nielsen, K.L.; Dimitrova, A. Trump, trust and the transatlantic relationship. Policy Stud. 2021, 42, 699–719. [Google Scholar] [CrossRef]

- Leonard, M.; Pisani-Ferry, J.; Ribakova, E.; Shapiro, J. Redefining Europe’s Economic Sovereignty. 2019. Available online: https://www.jstor.org/stable/pdf/resrep28498.pdf (accessed on 21 April 2022).

- European Commission. On Artificial Intelligence—A European Approach to Excellence and Trust. White Paper. 2020. Available online: https://ec.europa.eu/info/sites/default/files/commission-white-paper-artificial-intelligence-feb2020_en.pdf (accessed on 21 April 2022).

- Neumann, K.; van Erp, T.; Steinhöfel, E.; Sieckmann, F.; Kohl, H. Patterns for Resilient Value Creation: Perspective of the German Electrical Industry during the COVID-19 Pandemic. Sustainability 2021, 13, 6090. [Google Scholar] [CrossRef]

- Cai, M.; Luo, J. Influence of COVID-19 on Manufacturing Industry and Corresponding Countermeasures from Supply Chain Perspective. J. Shanghai Jiaotong Univ. (Sci.) 2020, 25, 409–416. [Google Scholar] [CrossRef]

- Guan, D.; Wang, D.; Hallegatte, S.; Davis, S.J.; Huo, J.; Li, S.; Bai, Y.; Lei, T.; Xue, Q.; Coffman, D. Global supply-chain effects of COVID-19 control measures. Nat. Hum. Behav. 2020, 4, 577–587. [Google Scholar] [CrossRef]

- Forschungsbeirat der Plattform Industrie 4.0 (Ed.) Wertschöpfungsnetzwerke in Zeiten von Infektionskrisen. Expertise des Forschungsbeirats der Plattform Industrie 4.0. 2021. Available online: https://www.acatech.de/publikation/wertschoepfungsnetzwerke-in-zeiten-von-infektionskrisen-expertise/download-pdf/?lang=de (accessed on 21 April 2022).

- World Trade Organization. Beyond Production. Global Value Chain Development Report 2021. 2021. Available online: https://www.wto.org/english/res_e/booksp_e/00_gvc_dev_report_2021_e.pdf (accessed on 21 April 2022).

- Kagermann, H.; Streibich, K.-H.; Suder, K. (Eds.) Digital Sovereignty. Status Quo and Perspectives. Acatech IMPULSE. Available online: https://www.acatech.de/publikation/digitale-souveraenitaet-status-quo-und-handlungsfelder/download-pdf/?lang=en (accessed on 10 July 2022).

- Plattform Industrie 4.0 (Ed.) Creating the DataSpace Industrie 4.0. Position Paper. 2021. Available online: https://www.plattform-i40.de/IP/Redaktion/EN/Downloads/Publikation/PositionPaper-DataSpace.html (accessed on 21 April 2022).

- Tantik, E.; Anderl, R. Integrated Data Model and Structure for the Asset Administration Shell in Industrie 4.0. Procedia CIRP 2017, 60, 86–91. [Google Scholar] [CrossRef]

- Bundesministerium für Wirtschaft und Energie. Von der Vision in Die Praxis. Industrie 4.0-Umsetzungsprojekte. 2020. Available online: https://www.plattform-i40.de/IP/Redaktion/DE/Downloads/Publikation/Umsetzungsprojekte.pdf?__blob=publicationFile&v=10 (accessed on 21 April 2022).

- Blind, K.; Böhm, M.; Grzegorzewska, P.; Katz, A.; Muto, S.; Pätsch, S.; Schubert, T. The Impact of Open Source Software and Hardware on Technological Independence, Competitiveness and Innovation in the EU Economy. European Commission, Ed.; 2021. Available online: https://digital-strategy.ec.europa.eu/en/library/study-about-impact-open-source-software-and-hardware-technological-independence-competitiveness-and (accessed on 19 April 2022).

- Bundesministerium für Umwelt, Naturschutz und Nukleare Sicherheit. Klimaschutzplan 2050. Klimaschutzpolitische Grundsätze und Ziele der Bundesregierung. 2019. Available online: https://www.bmuv.de/fileadmin/Daten_BMU/Download_PDF/Klimaschutz/klimaschutzplan_2050_bf.pdf (accessed on 19 April 2022).

- Bundesregierung. Klimaschutzgesetz 2021. Generationenvertrag für das Klima. 2021. Available online: https://www.bundesregierung.de/breg-de/themen/klimaschutz/klimaschutzgesetz-2021-1913672 (accessed on 19 April 2022).

- Sautter, B. Shaping Digital Ecosystems for Sustainable Production: Assessing the Policy Impact of the 2030 Vision for Industrie 4.0. Sustainability 2021, 13, 12596. [Google Scholar] [CrossRef]

- Chen, M.; Sinha, A.; Hu, K.; Shah, M.I. Impact of technological innovation on energy efficiency in industry 4.0 era: Moderation of shadow economy in sustainable development. Technol. Forecast. Soc. Change 2021, 164, 120521. [Google Scholar] [CrossRef]

- Vinuesa, R.; Azizpour, H.; Leite, I.; Balaam, M.; Dignum, V.; Domisch, S.; Felländer, A.; Langhans, S.D.; Tegmark, M.; Nerini, F.F. The role of Artificial Intelligence in achieving the Sustainable Development Goals. Nat. Commun. 2020, 11, 233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lichtenthaler, U.C. Digitainability: The Combined Effects of the Megatrends Digitalization and Sustainability. J. Innov. Manag. 2021, 9, 64–80. [Google Scholar] [CrossRef]

- Gupta, S.; Motlagh, M.; Rhyner, J. The Digitalization Sustainability Matrix: A Participatory Research Tool for Investigating Digitainability. Sustainability 2020, 12, 9283. [Google Scholar] [CrossRef]

- Plattform Industrie 4.0 (Ed.) Zehn Thesen, Wie Digitale Geschäftsmodelle Nachhaltigkeit in der Industrie 4.0 fördern. 2019. Available online: https://www.plattform-i40.de/IP/Redaktion/DE/Downloads/Publikation/Thesen-Nachhaltigkeit-Geschaeftsmodelle.pdf?__blob=publicationFile&v=6 (accessed on 19 April 2022).

- Plattform Lernende Systeme (Ed.) Mit KI den Nachhaltigen Wandel gestalten. Zur Strategischen Verknüpfung von KI und Nachhaltigkeitsmanagement in Wirtschaft, Wissenschaft und Gesellschaft. 2022. Available online: https://www.plattform-lernende-systeme.de/files/Downloads/Publikationen/PLS_Booklet_Mit_KI_den_nachhaltigen_Wandel_gestalten.pdf (accessed on 7 August 2022).

- Plattform Lernende Systeme (Ed.) KI im Mittelstand. Potenziale Erkennen, Voraussetzungen Schaffen, Transformation Meistern. 2022. Available online: https://www.plattform-lernende-systeme.de/files/Downloads/Publikationen/PLS_Booklet_KMU.pdf (accessed on 10 July 2022).

- Gawellek, M. Digitale Vernetzung für nachhaltige Geschäftsmodelle. In Klimawandel in der Wirtschaft. Warum Wir ein Bewusstsein für Dringlichkeit Brauchen; Hildebrandt, A., Ed.; Springer Gabler: Wiesbaden, Germany, 2020; pp. 189–208. [Google Scholar] [CrossRef]

- Frank, M.; Koldewey, C.; Rabe, M.; Dumitrescu, R.; Gausemeier, J.; Kühn, A. Smart Services—Concept of a New Market Offering. Z. Wirtschatftlichen Fabr. 2018, 113, 306–312. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).