Railway Vehicle Wheel Restoration by Submerged Arc Welding and Its Characterization

Abstract

:1. Introduction

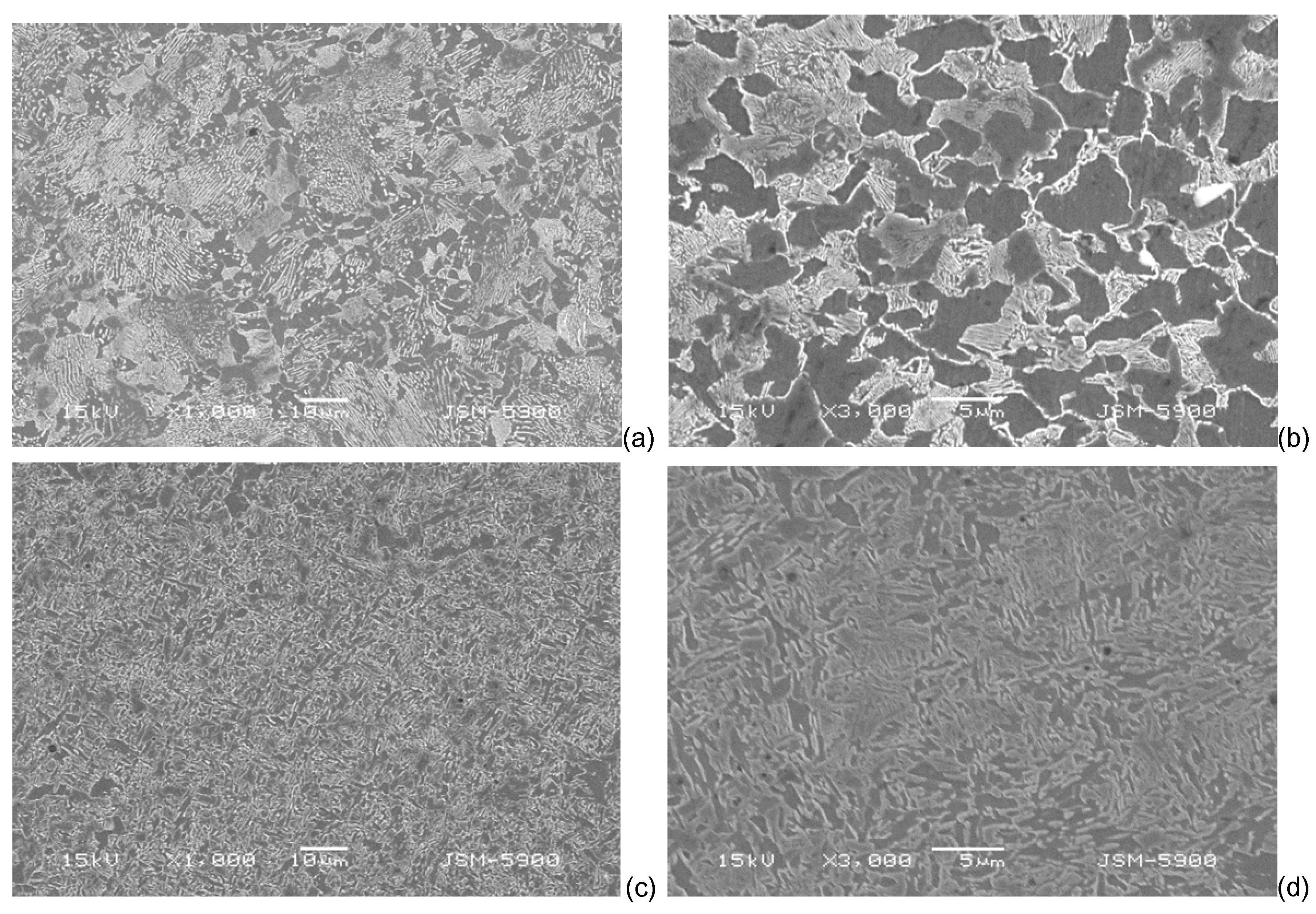

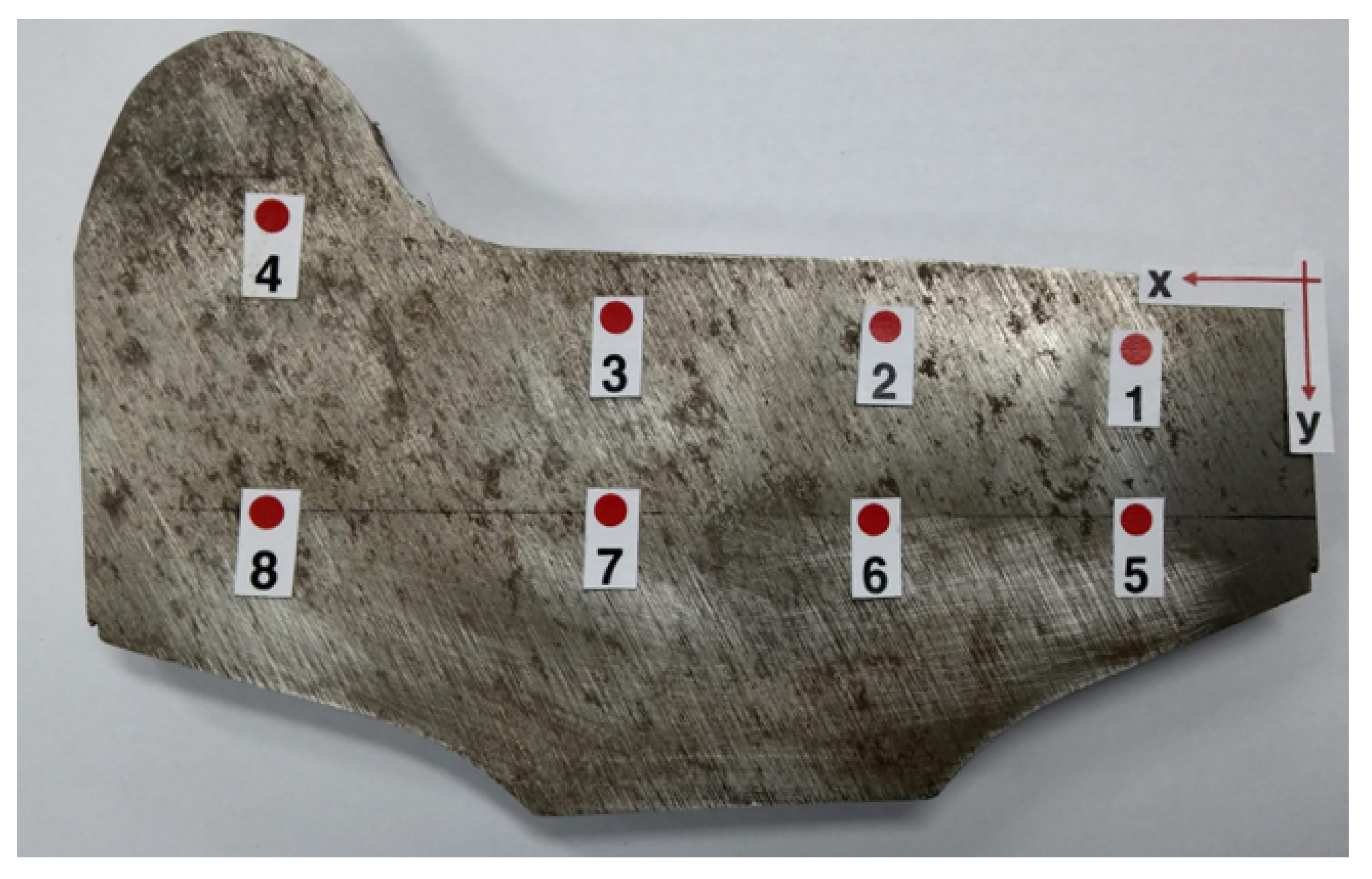

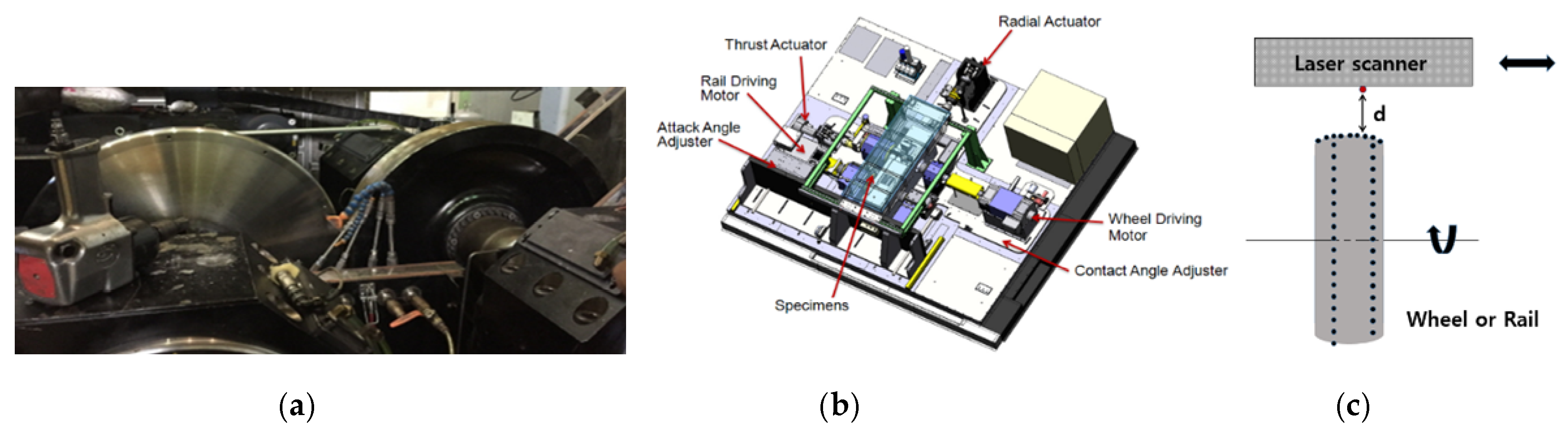

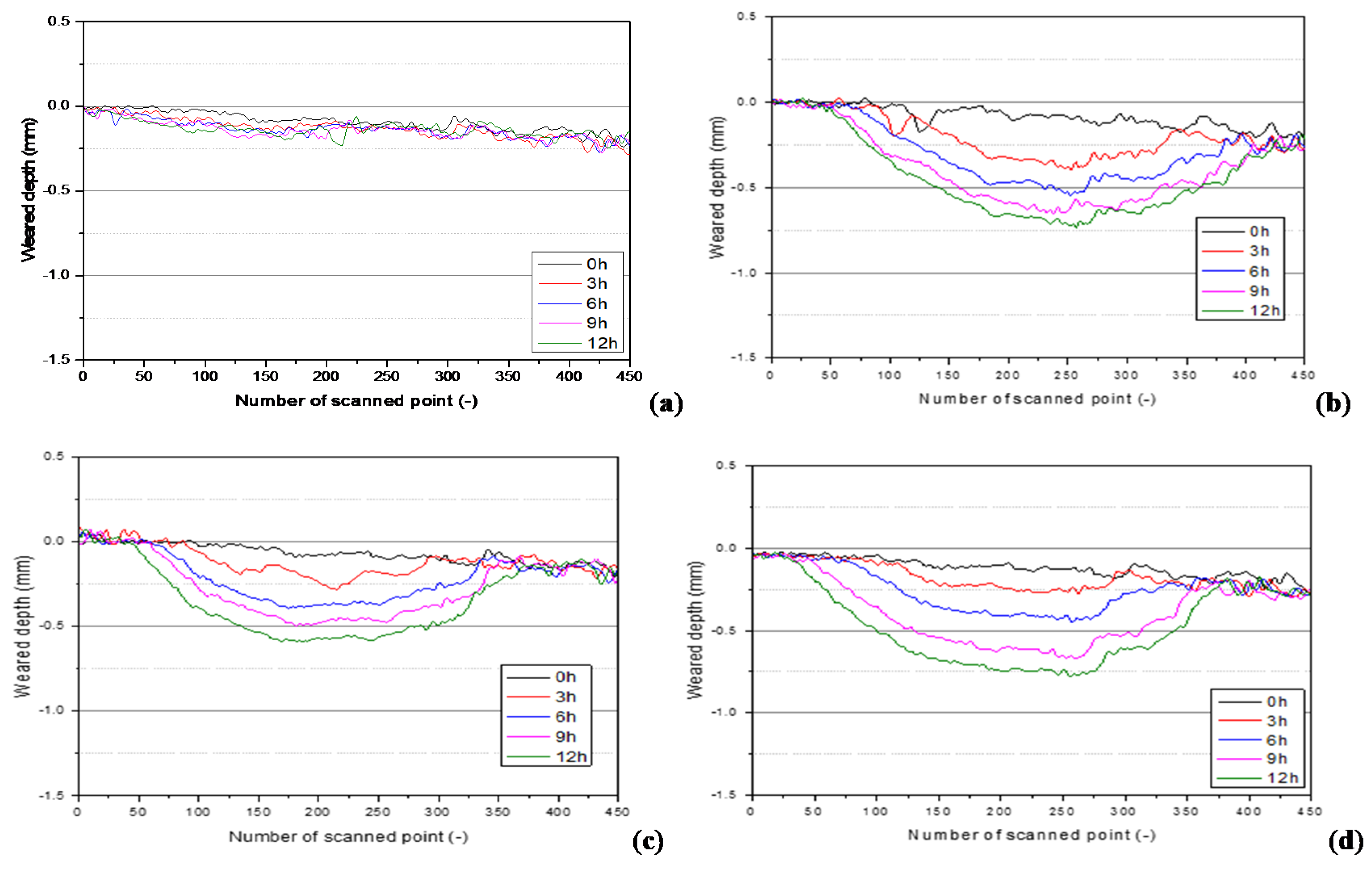

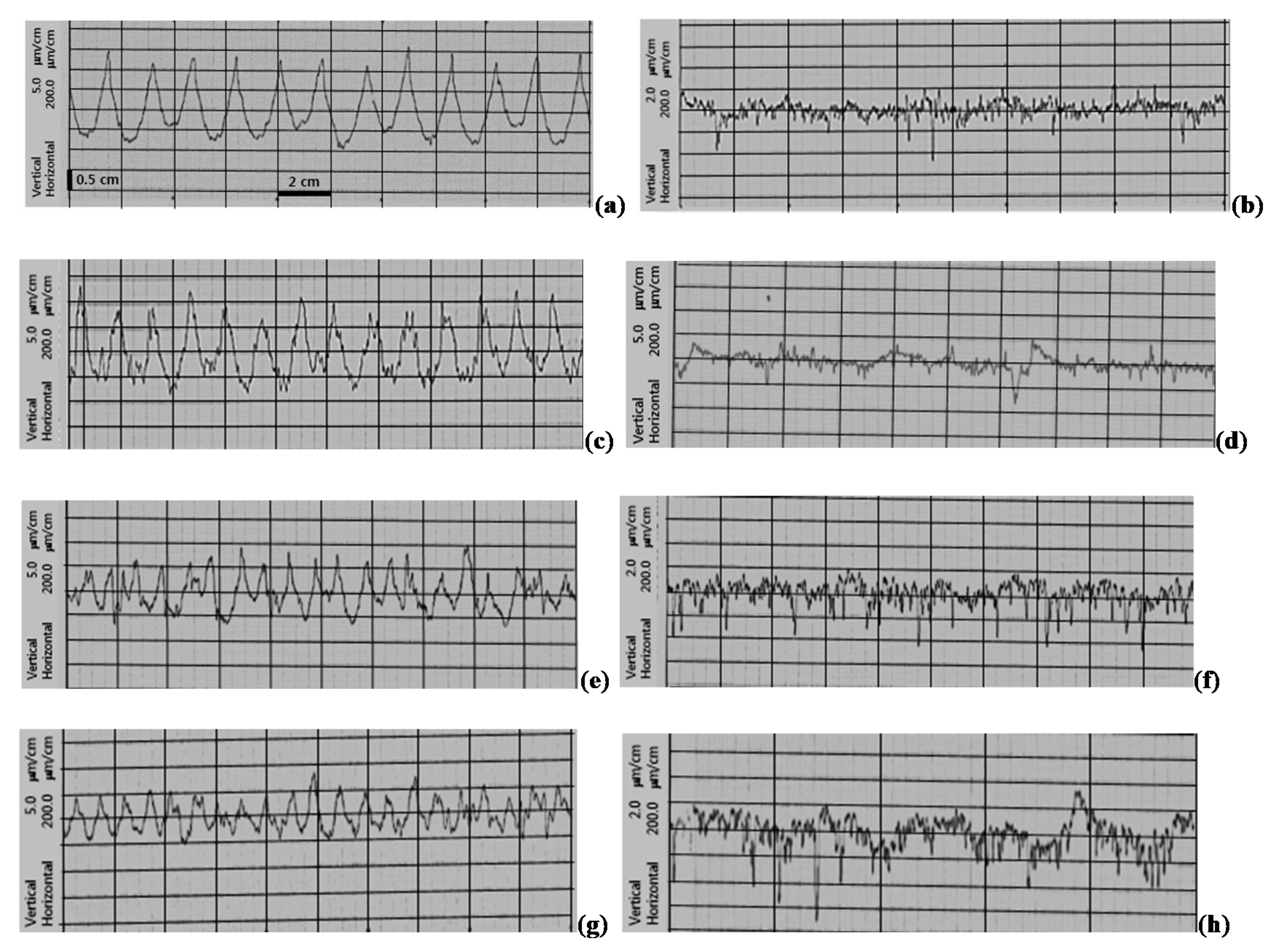

2. Materials and Methods

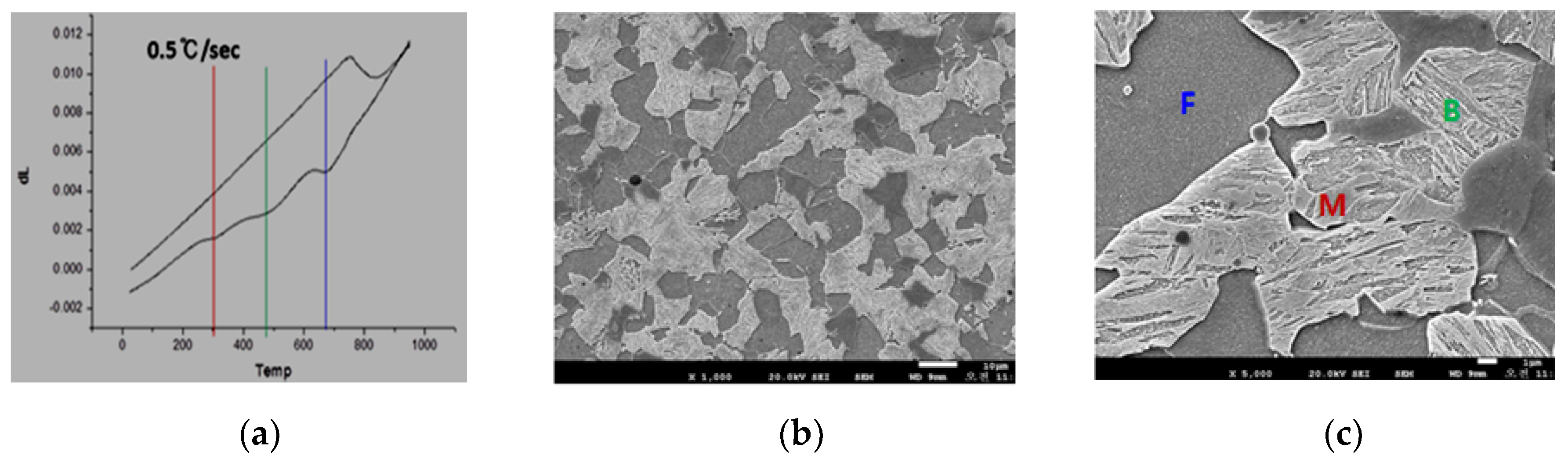

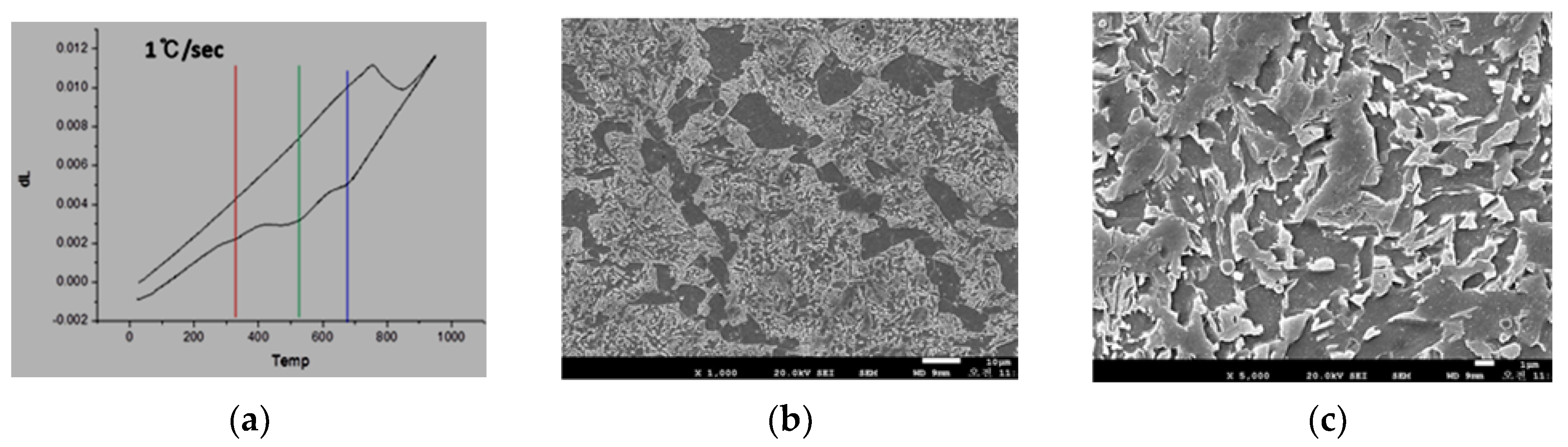

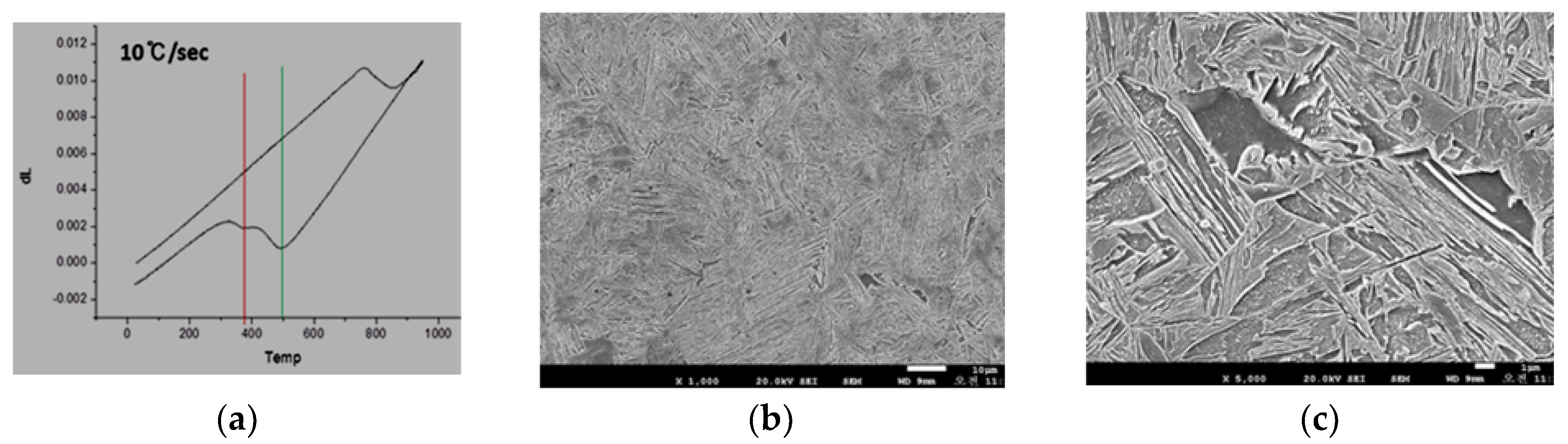

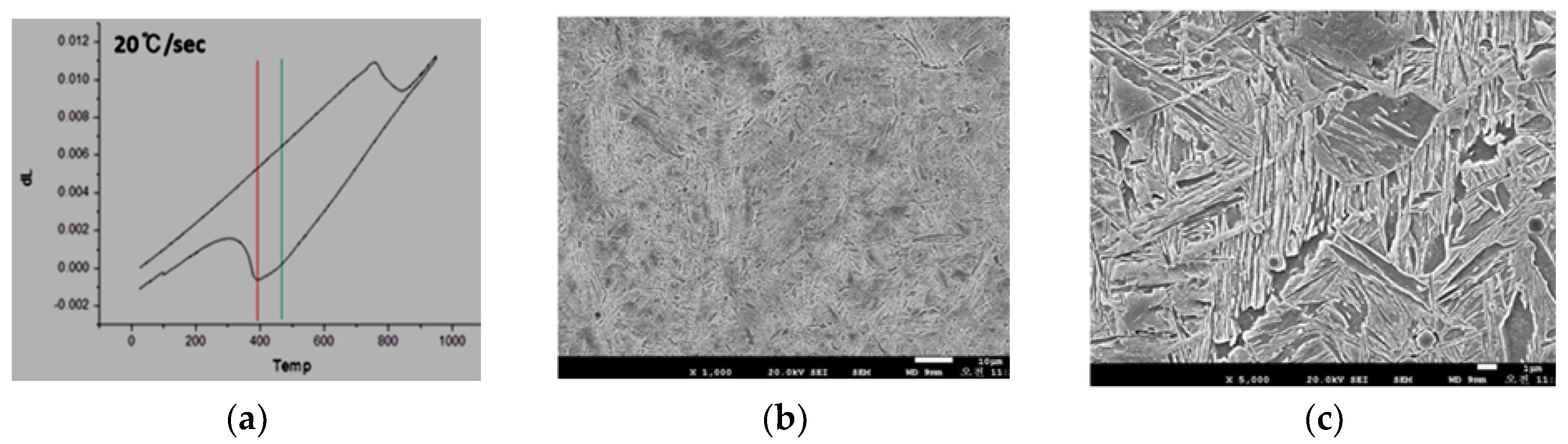

2.1. Welding Wire and Dilatometric Analysis of Phase Transformation

2.2. Restoration Process of Full-Size Worn Wheels

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Selvi, S.; Sankaran, S.; Srivatsavan, P.R. Comparative study of hardfacing of valve seat ring using MMAW process. J. Mater. Process. Technol. 2008, 207, 356–362. [Google Scholar] [CrossRef]

- Bayhan, Y. Reduction of wear via hardfacing of chisel ploughshare. Tribol. Int. 2006, 39, 570–574. [Google Scholar] [CrossRef]

- Fernandez, J.E.; Vijande, R.; Tucho, R.; Rodriguez, J.; Martin, A. Materials selection to excavator teeth in mining industry. Wear 2001, 250, 11–18. [Google Scholar] [CrossRef]

- Singla, S.; Kang, A.S.; Grewal, J.S.; Cheema, G.S. Wear behavior of weld overlay on excavator bucket teeth. Procedia Mater. Sci. 2014, 5, 256–266. [Google Scholar] [CrossRef] [Green Version]

- Eremin, E.N.; Losev, A.S. Wear resistance increase of pipeline valves by overlaying welding flux-cored wire. Procedia Eng. 2015, 113, 435–440. [Google Scholar] [CrossRef] [Green Version]

- Malinov, V.L.; Malonov, L.S.; Golyakevich, A.A.; Orlov, L.N. Improving the endurance of crane wheels using new flux-cored wire Veltek-N285C. J. Weld. Int. 2016, 30, 880–883. [Google Scholar] [CrossRef]

- Anan’ev, S.P.; Korotkov, V.A.; Goloviznin, B.L.; Kozlov, V.V. Improving the technology for hardfacing crane wheels. J. Weld. Int. 2007, 21, 534–537. [Google Scholar] [CrossRef]

- Gorunov, A.I. Complex refurbishment of titanium turbine blades by applying heat-resistant coatings by direct metal deposition. Eng. Fail. Anal. 2018, 86, 115–130. [Google Scholar] [CrossRef]

- Gajvoronsky, A.A.; Poznyakov, V.D.; Sarzhevsky, V.A.; Vasiliev, V.G.; Orlovsky, V.Y. Influence of thermo-deformational cycle of hardfacing on the structure and properties of railway wheels at their reconditioning. Paton Weld Sci. Tech. 2010, 5, 15–18. [Google Scholar]

- Markisha, L.I.; Poznyakov, V.D.; Gajvoronsky, A.A.; Berdinkova, E.N.; Alekseenko, T.A. Structure and properties of railway wheel surface after restoration surfacing and service loadin. Paton Weld. J. 2015, 5–6, 96–100. [Google Scholar] [CrossRef] [Green Version]

- Mendez, P.F.; Barnes, N.; Bell, K.; Borlea, S.D.; Gajapathi, S.S.; Guest, S.D.; Izadi, H.A.; Gol, K.; Wood, G. Welding processes for wear resistant overlays. J. Manuf. Process 2014, 16, 4–25. [Google Scholar] [CrossRef]

- Gianni, A.; Ghidini, A.; Karlsson, T.; Ekberg, A. Bainitic steel grade for solid wheels: Metallurgical, mechanical, and in-service testing. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2009, 163–171. [Google Scholar] [CrossRef]

- KS R 9221:2008. Wheels for Railway Rolling Stock; Korean Industrial Standards: Seoul, Korea, 2008. [Google Scholar]

- Lee, K.M.; Polycarpou, A.A. Wear of conventional pearlitic and improved bainitic rail steels. Wear 2005, 259, 391–399. [Google Scholar] [CrossRef]

- Rossini, N.S.; Dassisti, M.; Olabi, A.G. Methods of measuring residual stresses in components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef] [Green Version]

- Delbergue, D.; Texier, D.; Lévesque, M.; Bocher, P. Comparison of two X-ray residual Stress measurement methods: Sin2 ψ and cos α, through the determination of a martensitic steel X-ray elastic constant. Mater. Res. Proc. 2016, 2, 55–60. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.Y.; Ling, J.; Wang, S.; Ramirez-Rico, J. Precision and accuracy of stress measurement with a portable X-ray machine using an area detector. J. Appl. Crystallogr. 2017, 50, 131–144. [Google Scholar] [CrossRef] [Green Version]

- Neslušan, M.; Minárik, P.; Grenčík, J.; Trojan, K.; Zgútová, K. Non-destructive evaluation of the railway wheel surface damage after longterm operation via Barkhausen noise technique. Wear 2019, 420–421, 195–206. [Google Scholar] [CrossRef]

- Nejad, R.M. Using three-dimensional finite element analysis for simulation of residual stresses in railway wheels. Eng. Fail. Anal. 2014, 45, 449–455. [Google Scholar] [CrossRef]

- UIC 860 Technical Specification for the Supply of Rails, 9th ed.; International Union of Railways: Paris, France, 2008.

- Goo, B.C.; Hwang, S.H.; Choi, S.Y.; Lee, Y.J. Worn-wheel restoration by welding and evaluation of mechanical properties. J. Korean Soc. Railw. 2018, 21, 241–248. [Google Scholar] [CrossRef]

| Type | C | Si | Mn | P | S | Cr | Ni | Al | Ti | N | V | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wheel | 0.67 | 0.15 | 0.7–0.9 | 0.045 | 0.045 | - | - | - | - | - | - | 0.35 |

| Welding wire | 0.06 | 1.38 | 2.37 | - | - | 0.90 | 0.53 | - | 0.026 | - | 0.06 | - |

| Weld metal | 0.185 | 1.05 | 1.88 | 0.016 | 0.011 | 0.706 | 0.442 | 0.018 | 0.036 | 0.0091 | 0.042 | 0.05 |

| YS0.2% (MPa) | UTS (MPa) | (%) | R.A. (%) | E (MPa) | Tem (°C) |

|---|---|---|---|---|---|

| 821 | 1074 | 23 | 49 | 201542 | 20 |

| Specimen | Group A | Group B | Group C | Group D | Group DS | ||||

|---|---|---|---|---|---|---|---|---|---|

| Sulfide Type | Aluminate Type | Silicate Type | Globular Oxide Type | Single Globular Type | |||||

| Thin | Thick | Thin | Thick | Thin | Thick | Thin | Thick | - | |

| No. 1 | 0.5 | 0.0 | 0.0 | 0.0 | 0.5 | 0.0 | 1.5 | 0.5 | 1.5 |

| No. 2 | 0.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 1.5 | 0.5 | 1.5 |

| Point | #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 |

|---|---|---|---|---|---|---|---|---|

| (x, y) | (20, 8) | (50, 8) | 80, 8) | (120, −3) | (20, 30) | (50, 30) | (80, 30) | (120, 30) |

| σx (MPa) | −176 | −209 | −41 | −21 | −256 | −183 | −237 | −107 |

| σy (MPa) | −187 | −225 | +36 | +86 | −256 | −132 | −196 | −35 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coo, B.-C.; Lee, Y.-J. Railway Vehicle Wheel Restoration by Submerged Arc Welding and Its Characterization. Sci 2020, 2, 33. https://doi.org/10.3390/sci2020033

Coo B-C, Lee Y-J. Railway Vehicle Wheel Restoration by Submerged Arc Welding and Its Characterization. Sci. 2020; 2(2):33. https://doi.org/10.3390/sci2020033

Chicago/Turabian StyleCoo, Byeong-Choo, and Young-Jin Lee. 2020. "Railway Vehicle Wheel Restoration by Submerged Arc Welding and Its Characterization" Sci 2, no. 2: 33. https://doi.org/10.3390/sci2020033

APA StyleCoo, B.-C., & Lee, Y.-J. (2020). Railway Vehicle Wheel Restoration by Submerged Arc Welding and Its Characterization. Sci, 2(2), 33. https://doi.org/10.3390/sci2020033