Residual Stresses of Small-Bore Butt-Welded Piping Measured by Quantum Beam Hybrid Method

Abstract

1. Introduction

2. Experimental Methods

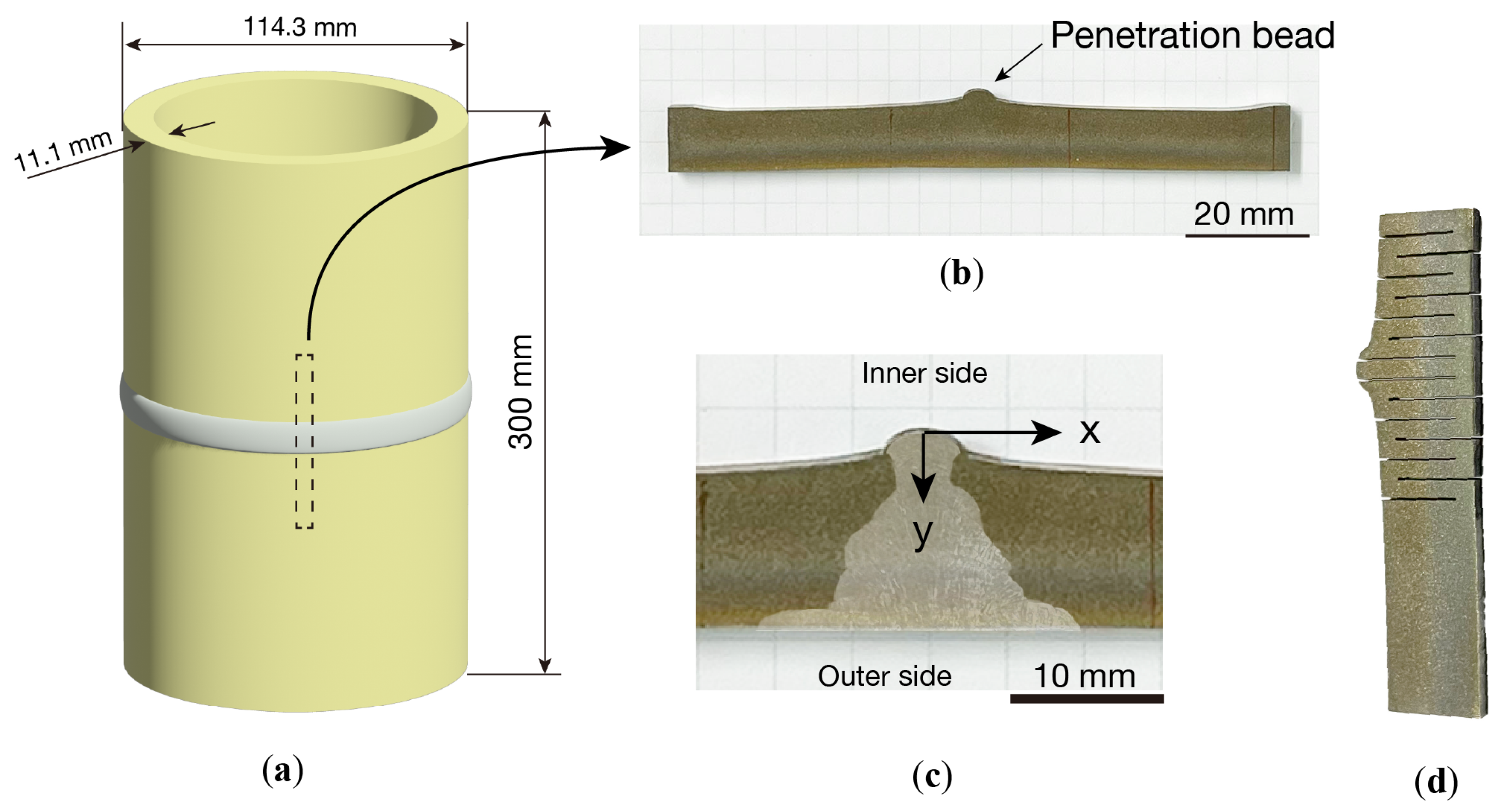

2.1. Welded Piping and Welded Specimen

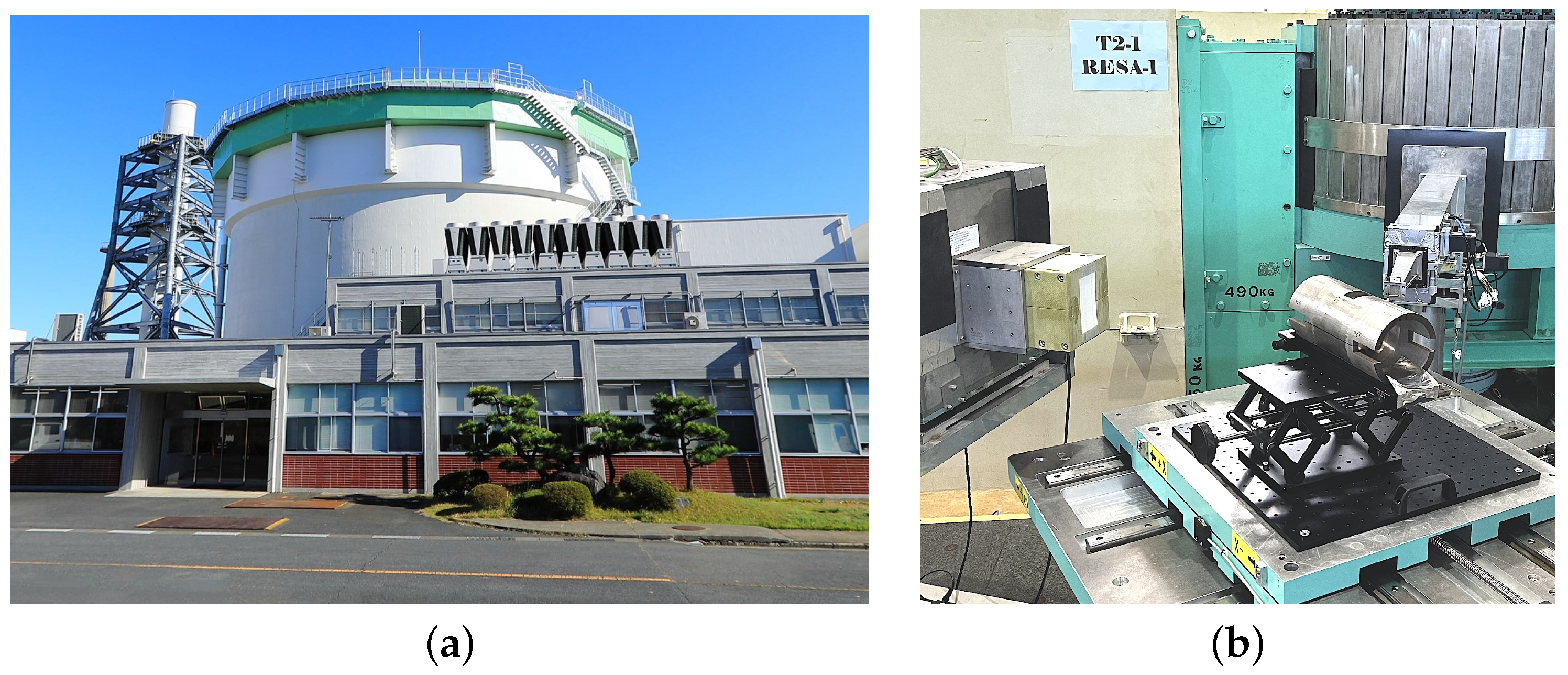

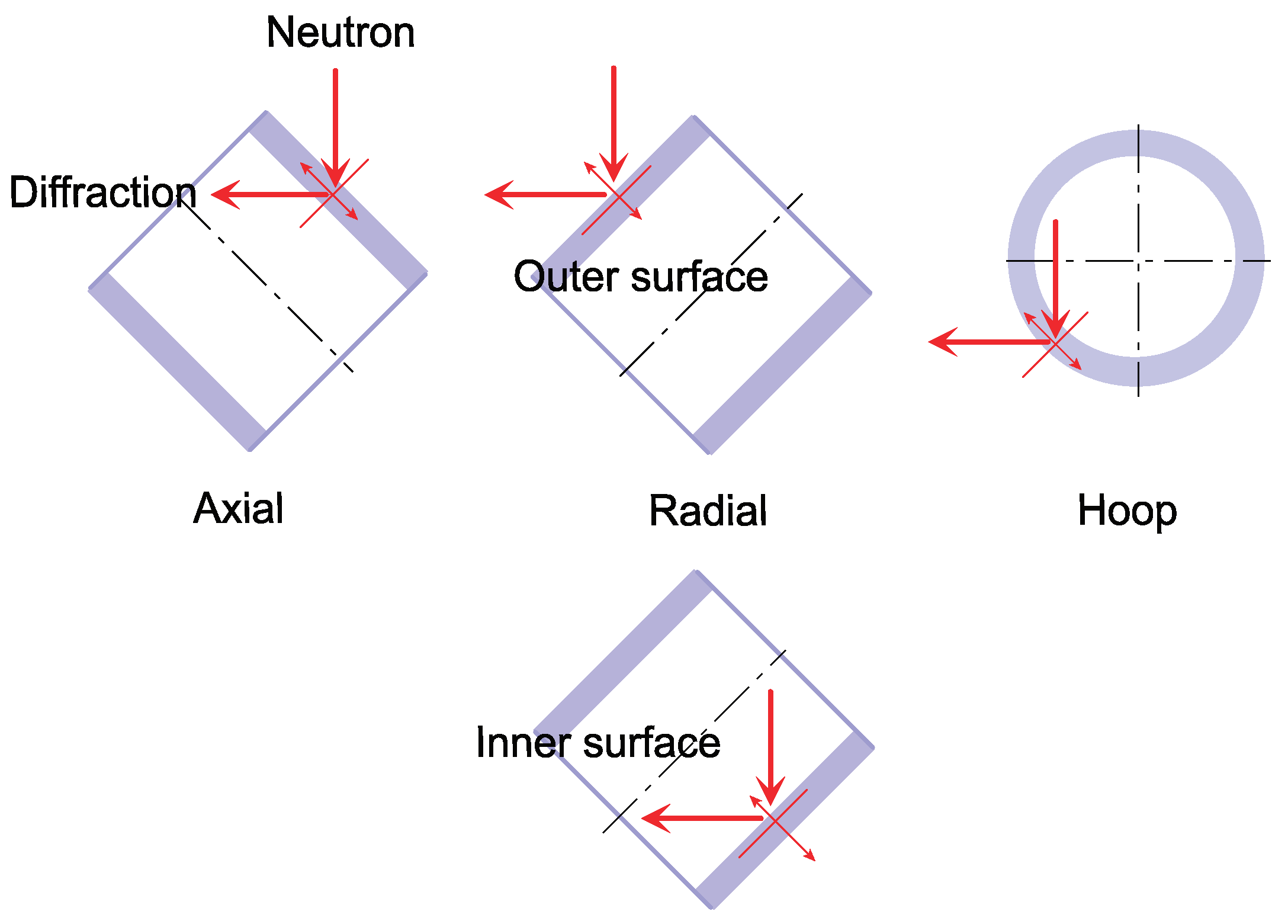

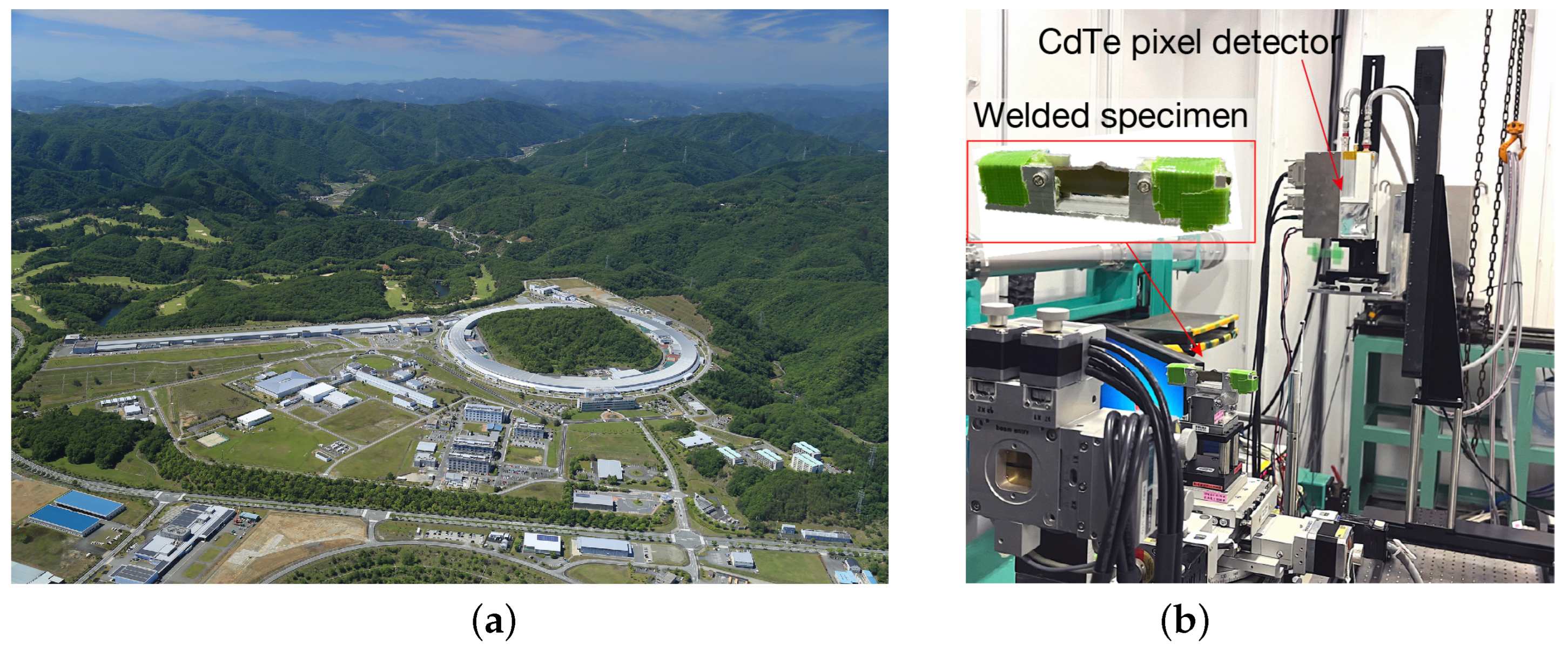

2.2. Stress Measurement Using Neutrons

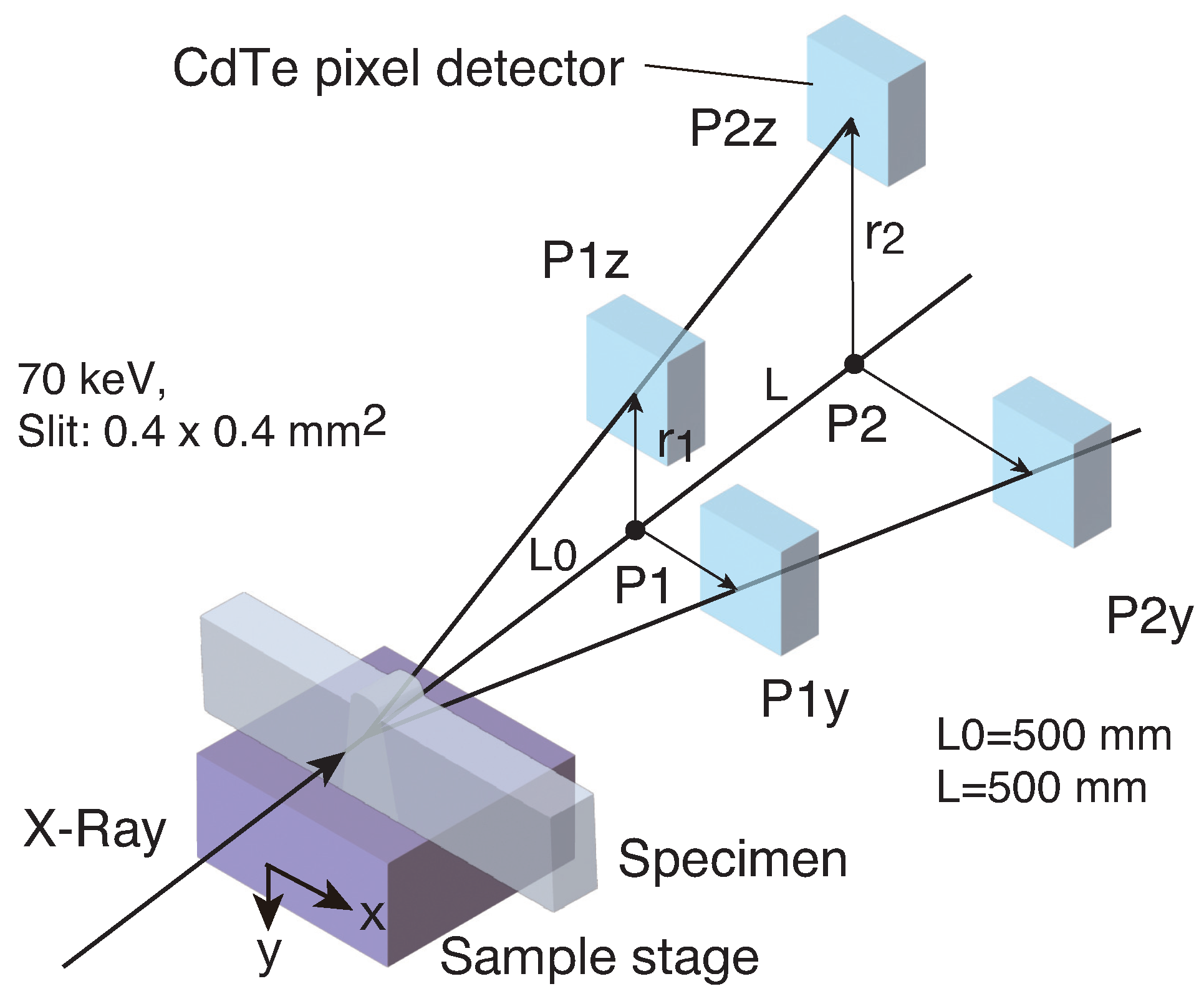

2.3. Double-Exposure Method (DEM)

3. Results and Discussion

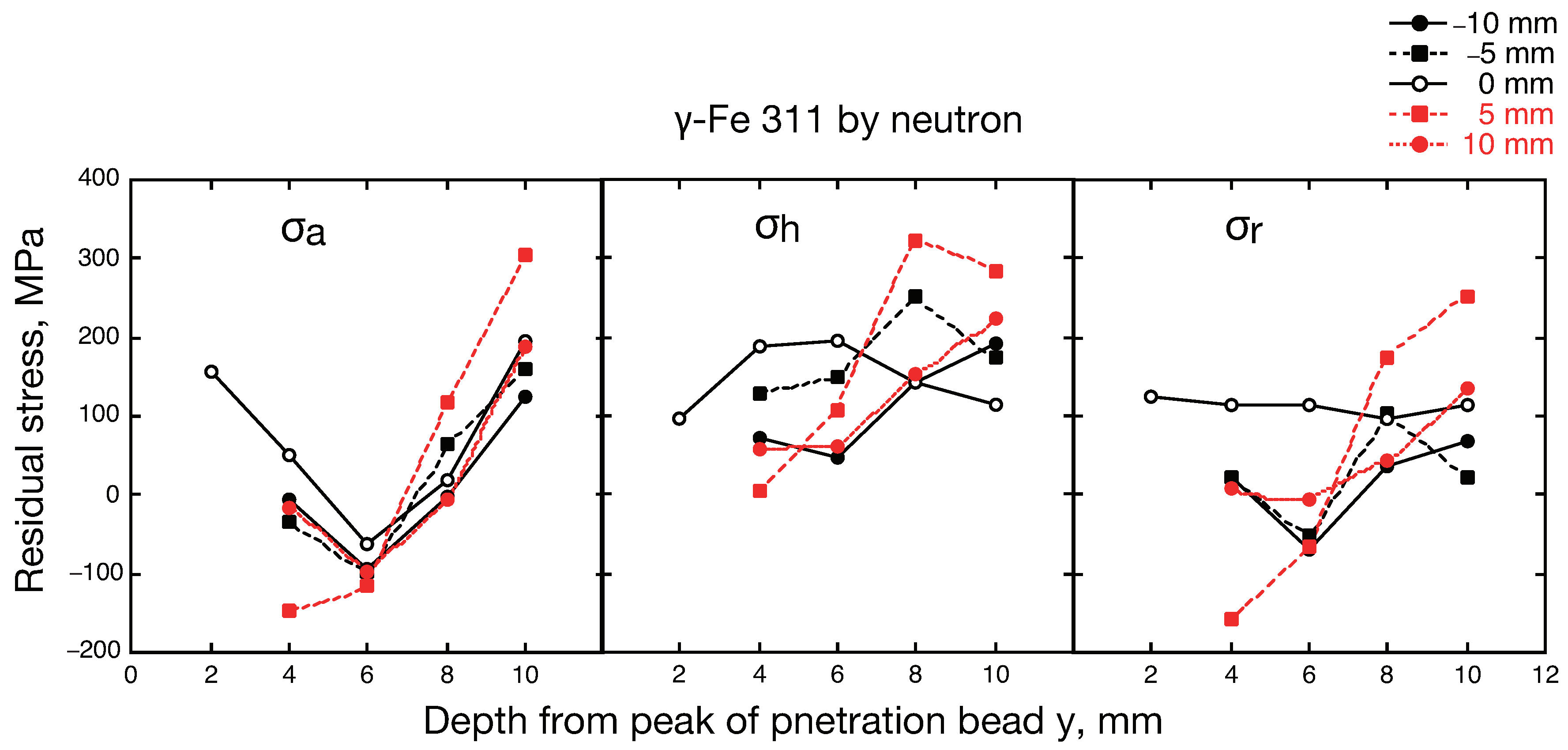

3.1. Residual Stress Measured by Neutron Diffraction

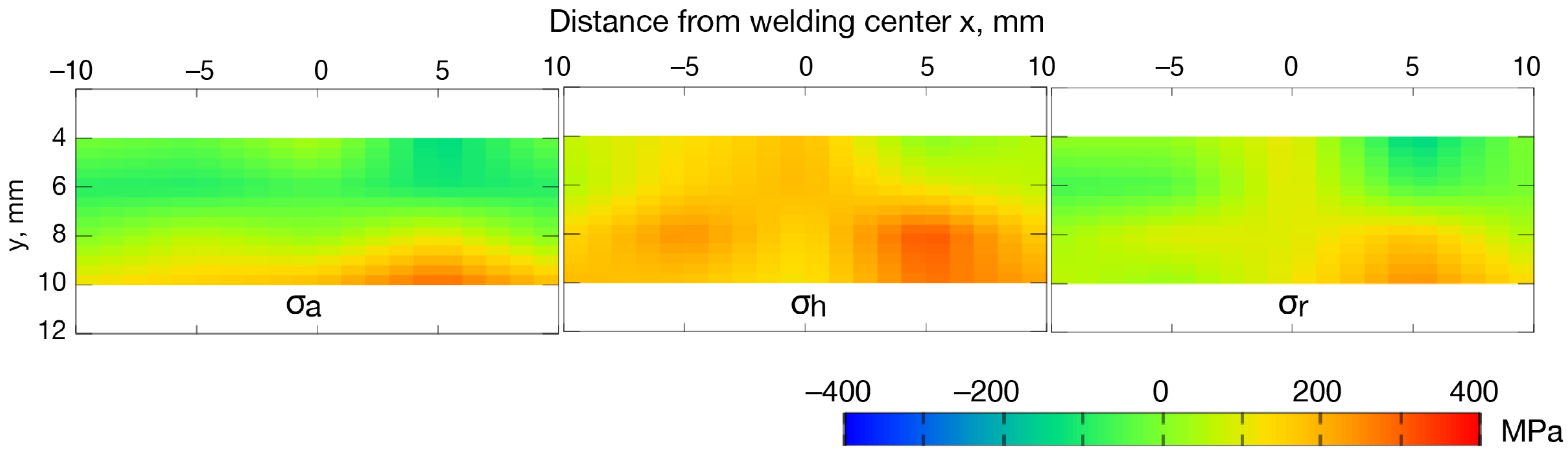

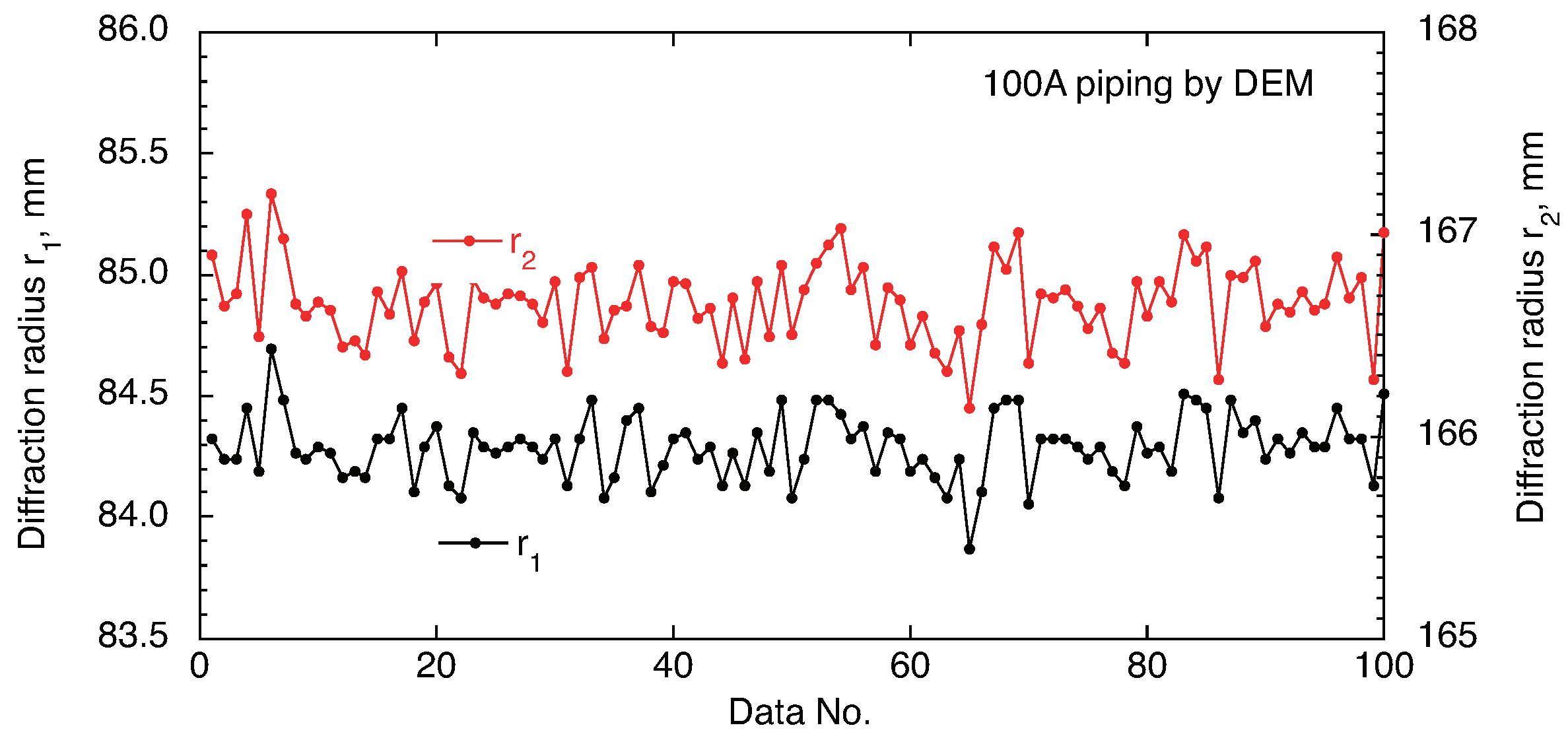

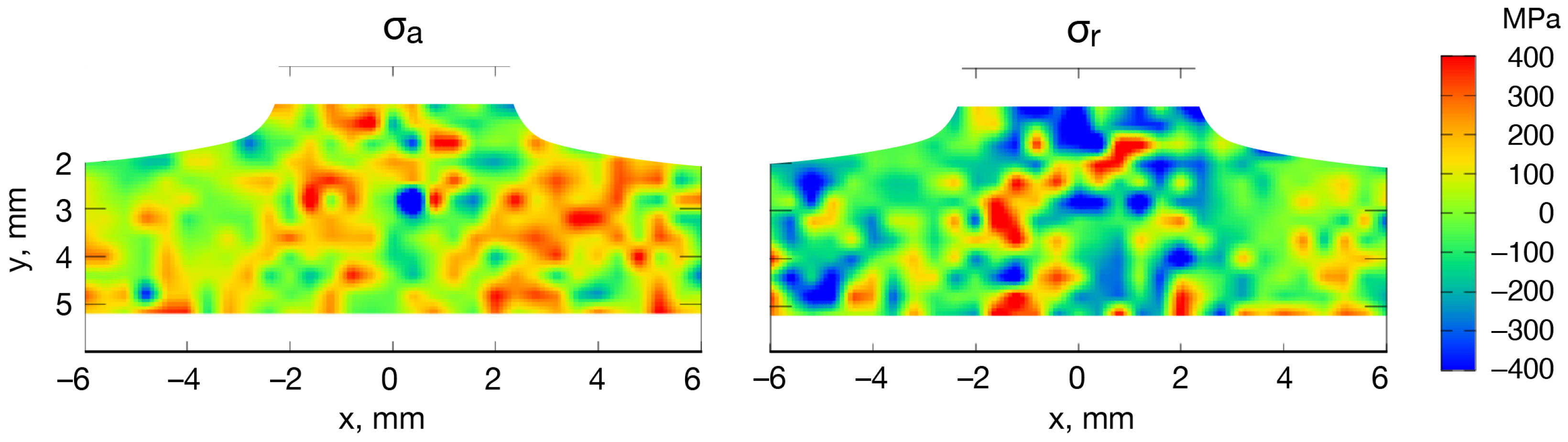

3.2. Residual Stresses Measured by Double-Exposure Method

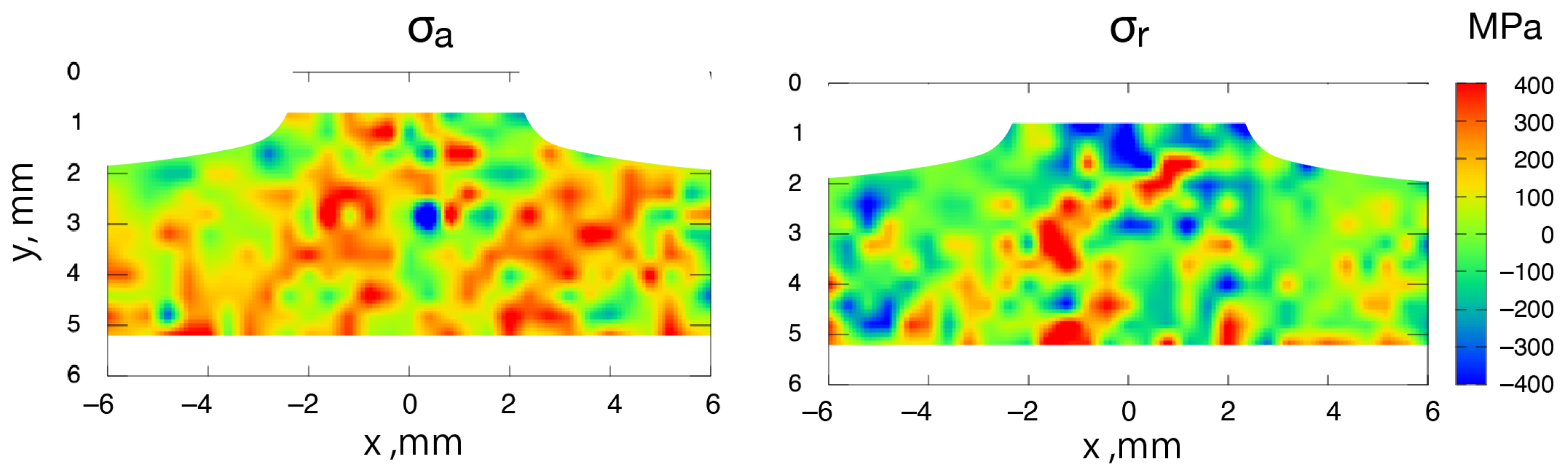

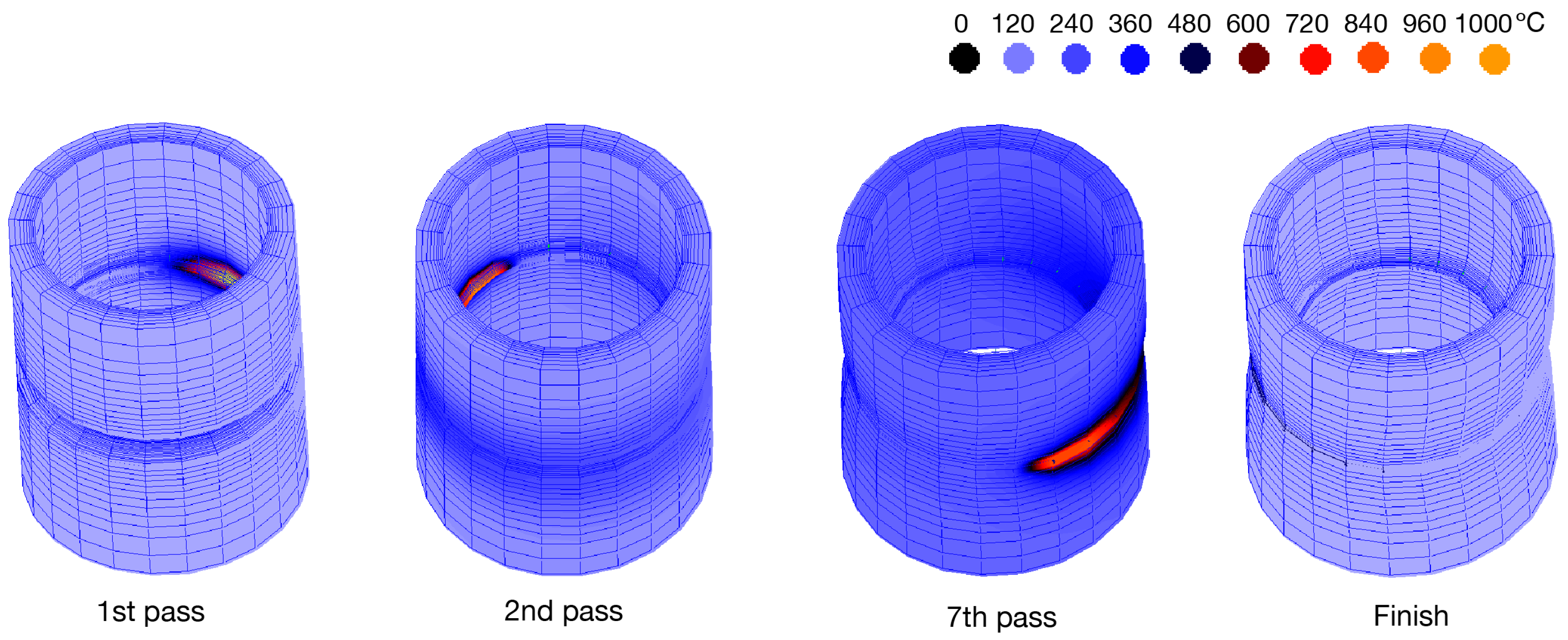

3.3. Comparison of Actual Stress Analysis and Simulation

4. Conclusions

- (1)

- The residual stresses in welded piping were measured using the neutron diffraction method. Because of the large gauge volume and low spatial resolution, it was difficult to obtain detailed residual stress near the weld root, which is the most critical area.

- (2)

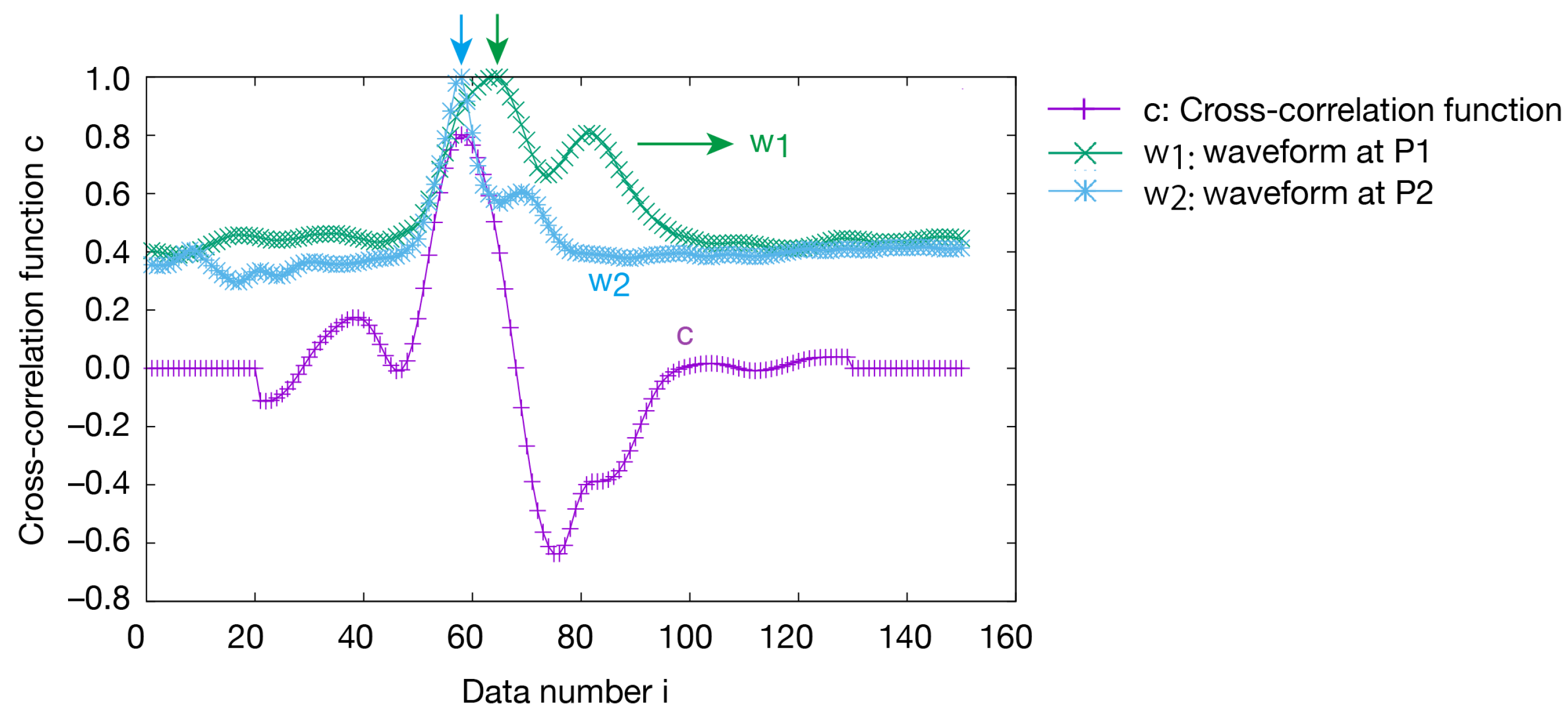

- The welded piping showed complicated diffraction patterns that were a mixture of diffraction spots and continuous rings. Therefore, the diffraction waveforms were obtained by circumferentially integrating the diffraction images measured at the front and rear positions using the double-exposure method. Using the cross-correlation between the two waveforms to determine the diffraction angle, it was possible to measure the residual stress with high accuracy.

- (3)

- In the measurement by a single detector, the error of more than MPa due to the diffraction crystal grain position. The double-exposure method can cancel out the error, and has the advantage of being able to determine the diffraction angle with high accuracy. The double-exposure method has made it to measure residual stresses in coarse-grained materials and welded components.

- (4)

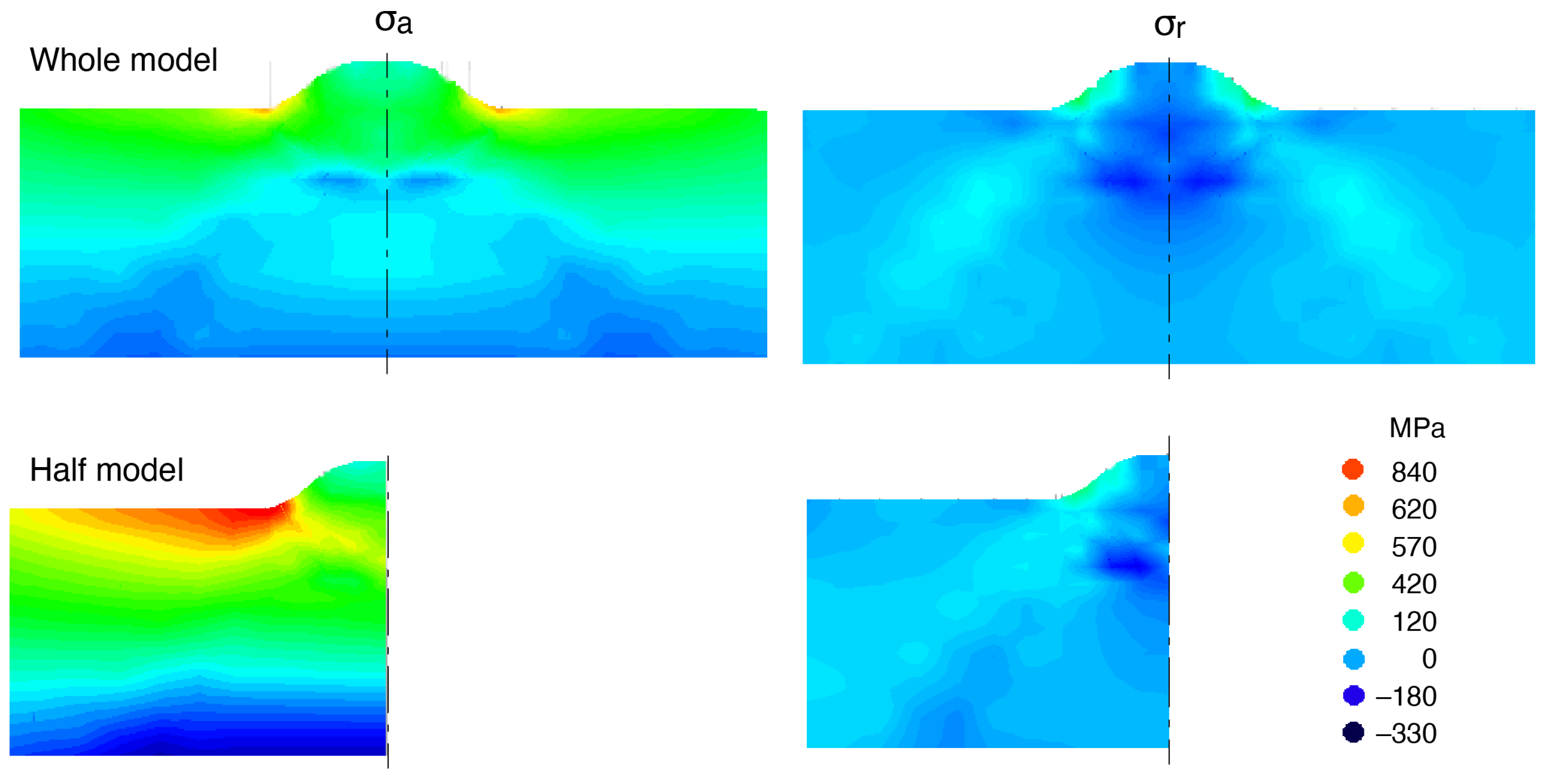

- The welding residual stress measured by the quantum beam hybrid method is asymmetrical with respect to the welding line and has unevenness due to the crystal grains. Large axial residual stress occurs from the HAZ near the penetration bead toward the weld part.

- (5)

- A simulation of a butt-welded pipe was performed using the finite element method. In the half model of the welded pipe, the butt-plane was assumed to keep a plane. The simulated residual stress by the half model was larger than that by the whole model. To perform an accurate simulation, the whole butt-welded piping must be modeled. The real tensile stress area from the HAZ near the penetration bead toward the weld was not obtained by the simulation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Enomoto, K.; Hirano, K.; Mochizuki, M.; Kurosawa, K.; Saito, H.; Hayashi, E. Improvement of residual stress on material surface by water jet peening. J. Soc. Mater. Sci. Jpn. 1996, 45, 734–739. [Google Scholar] [CrossRef]

- Hirano, K.; Enomoto, K.; Hayashi, E.; Kurosawa, K. Effect of water jet peening on corrosion resistance and fatigue strength of type 304 stainless steel. J. Soc. Mater. Sci. Jpn. 1996, 45, 740–745. [Google Scholar] [CrossRef]

- Sano, Y.; Kimura, M.; Sato, K.; Obata, M.; Sudo, A.; Hamamoto, Y.; Shima, S.; Ichikawa, Y.; Yamazaki, H.; Naruse, M.; et al. Development and application of laser peening system to prevent stress corrosion cracking of reactor core shroud. In Proceedings of the 8th International Conference on Nuclear Engineering (ICONE-8), Baltimore, MD, USA, 2–6 April 2000. [Google Scholar]

- Sano, Y. Quarter century development of laser peening without coating. Metals 2020, 10, 152. [Google Scholar] [CrossRef]

- Ando, Y.; Yagawa, G.; Hayase, Y. Evaluation of induction heating stress improvement (IHSI) treatment applied to nuclear primary piping. Int. J. Press. Vessel. Pip. 1982, 10, 399–406. [Google Scholar] [CrossRef]

- Umemoto, T.; Matsushita, A.; Tanaka, A. Application of Induction Heating Stress Improvement to the Joint Between the Recirculation Inlet Nozzle and the Safe-End Weld; IAEA-SM-278/5; International Atomic Energy Agency: Vienna, Austria, 1985; pp. 117–126. [Google Scholar]

- Abdulla, A.; Malaki, M.; Eskandari, A. Strength enhancement of the welded structures by ultrasonic peening. Mater. Des. 2012, 38, 7–18. [Google Scholar] [CrossRef]

- Malaki, M.; Ding, H. A review of ultrasonic peening treatment. Mater. Des. 2015, 87, 1072–1086. [Google Scholar] [CrossRef]

- Aoike, S.; Tsuruki, M.; Okido, S.; Fukuda, Y.; Oritani, N. Analytical study of residual stress improvement method, delta-T process for small-diameter pipe. Trans. Jpn. Soc. Mech. Eng. Ser. A 2012, 78, 481–491. [Google Scholar] [CrossRef][Green Version]

- Maekawa, A.; Serizawa, H.; Nakacho, K.; Murakawa, H. Fast finite element analysis of weld residual stress in large-diameter thick-walled stainless pipe joints and its experimental validation. Q. J. Jpn. Weld. Soc. 2013, 31–34, 129–133. [Google Scholar] [CrossRef][Green Version]

- Haigh, R.D.; Hutchings, M.T.; James, J.A.; Ganguly, S.; Mizuno, R.; Ogawa, K.; Okido, S.; Paradowska, A.M.; Fitzpatrick, M.E. Neutron diffraction residual stress measurements on girth-welded 304 stainless steel pipes with weld metal deposited up to half and full pipe wall thickness. Int. J. Press. Vessel. Pip. 2013, 101, 1–11. [Google Scholar] [CrossRef][Green Version]

- Terachi, T. SCC in Japan. In Proceedings of the International Workshop on Aging Management Considerations in Mechanical Codes Standards, Tokyo, Japan, 28–29 June 2023; Available online: https://www.oecd-nea.org/upload/docs/application/pdf/2023-07/presentations_-_session_3.pdf (accessed on 29 March 2025).

- Materias Committee PA-MSC-1950. Safety Assessment of Recent Atypical Stress Corrosion Cracking Operating Experience in Non-Isolable Stainless Branch Piping. Framatome Doc. No. 51–9357850-000. 2023; pp. 2–8. Available online: https://www.nrc.gov/docs/ML2324/ML23243A870.pdf (accessed on 29 March 2025).

- Deng, D.; Murakawa, H. Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements. Comput. Mater. Sci. 2006, 37, 269–277. [Google Scholar] [CrossRef]

- Webster, P.J. Neutron strain scanning. Neutron News 1991, 2, 19–22. [Google Scholar] [CrossRef]

- Webster, P.J.; Mills, G.; Wang, X.D.; Kang, W.P.; Holden, T.M. Impediments to efficient through-surface strain scanning. Neutron Res. 1996, 3, 223–240. [Google Scholar] [CrossRef]

- Poulsen, H.F.; Nielsen, S.F.; Lauridsen, E.M.; Schmidt, S.; Suter, R.M.; Lienert, U.; Margulies, L.; Lorentzen, T.; Juul Jensen, D. Three-dimensional maps of grain boundaries and the stress state of individual grains in polycrystals and powders. J. Appl. Crystallogr. 2001, 34, 751–756. [Google Scholar] [CrossRef]

- Kutsal, M.; Poulsen, H.F.; Winther, G.; Sørensen, H.O.; Detlefs, C. High-resolution 3D X-ray diffraction microscopy: 3D mapping of deformed metal microstructures. J. Appl. Crystallogr. 2022, 55, 1125–1138. [Google Scholar] [CrossRef] [PubMed]

- Hayashi, Y.; Setoyama, D.; Fukuda, K.; Okuda, K.; Katayama, N.; Kimura, H. Scanning three-dimensional X-ray diffraction microscopy with a spiral slit. Quantum Beam Sci. 2023, 7, 16. [Google Scholar] [CrossRef]

- Suzuki, K.; Shobu, T.; Shiro, A.; Zhang, S. Evaluation welding residual stress using diffraction spot tracing method. Adv. Mater. Res. 2014, 996, 76–81. [Google Scholar] [CrossRef]

- Suzuki, K.; Shobu, T.; Shiro, A. Stress measurements of coarse grain materials using double exposure method with hard synchrotron X-rays. Mater. Res. Proc. 2018, 6, 69–74. [Google Scholar]

- JRR-3 Instrument. Available online: https://jrr3uo.jaea.go.jp/jrr3uoe/instruments/index.htm (accessed on 29 March 2025).

- He, B.B. Two-Dimensional X-Ray Diffraction; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; p. 260. [Google Scholar]

- Toyokawa, H.; Saji, C.; Kawase, M.; Wu, S.; Furukawa, Y.; Kajiwara, K.; Sata, M.; Hirono, T.; Shiro, A.; Shobu, T.; et al. Development of CdTe pixel detectors combined with an aluminum Schottky diode sensor and photon-counting ASICs. J. Instr. 2017, 12, C01044. [Google Scholar] [CrossRef]

- BL14B1 Outline. Available online: http://www.spring8.or.jp/wkg/BL14B1/instrument/lang-en/INS-0000000309 (accessed on 29 March 2025).

- SPring-8. Available online: http://www.spring8.or.jp/ja/about_us/access/img/img02l.jpg (accessed on 29 March 2025).

- Hutchings, M.T.; Withers, P.J.; Holden, T.M.; Lorentzen, T. Introduction to the Characterization of Residual Stress by Neutron Diffraction; Taylor & Francis: Boca Raton, FL, USA, 2005; p. 203. [Google Scholar]

- Kröner, E. Berechnung der elastischen Konstanten des Vielkristalls aus den Konstanten des Einkristalls. Z. Phys. 1958, 151, 504–518. [Google Scholar] [CrossRef]

- Ledbetter, H.M. Predicted single-crystal elastic constants of stainless-steel 316. Br. J.-Non-Destr. Test. 1981, 23, 286–287. [Google Scholar]

- X-Ray and Mechanical Elastic Constants by Kröner Model. Available online: https://x-ray.jsms.jp/kroner/index.html (accessed on 29 March 2025).

- Kohari, A. Introduction to Probability and Statistics; Iwanami Syoten: Tokyo, Japan, 1973; pp. 91–100. [Google Scholar]

- Suzuki, K.; Kura, K.; Miura, Y.; Shiro, A.; Toyokawa, H.; Saji, C.; Kajiwara, K.; Shobu, T. A study on stress measurement of welded part using double exposure method. J. Soc. Mater. Sci. Jpn. 2022, 71, 1005–1012. [Google Scholar] [CrossRef]

- Suzuki, K.; Miura, Y.; Shiro, A.; Toyokawa, H.; Saji, C.; Shobu, T.; Morooka, S. Actual stress analysis of small-bore butt-welded pipe by complementary use of synchrotron X-rays and neutrons. J. Soc. Mater. Sci. Jpn. 2023, 72, 316–323. [Google Scholar] [CrossRef]

- Okamura, Y.; Yamashita, H.; Fukuda, T.; Futami, T. Structual integrity evaluation for core shroud and PLR piping with SCC. J. High Press. Inst. Jpn. 2005, 43, 4–14. [Google Scholar]

- Suzuki, K.; Yamagishi, A.; Nishikawa, S.; Shobu, T. Residual stresses in dissimilar metal Joint by multi-pass Welds. Maintenology 2012, 11, 91–98. [Google Scholar]

- Deng, D.; Kiyoshima, S. FEM prediction of welding residual stresses in a SUS304 girth-welded pipe with emphasis on stress distribution near weld start/end location. Comput. Mater. Sci. 2010, 50, 612–621. [Google Scholar] [CrossRef]

- Deng, D. Influence of deposition sequence on welding residual stress and deformation in an austenitic stainless steel J-groove welded joint. Mater. Des. 2013, 43, 1022–1033. [Google Scholar] [CrossRef]

- Nye, J.F. Physical Properties of Crystals; Oxford University Press: Oxford, UK, 2000; pp. 123–130. [Google Scholar]

- Holden, T.M. Intergranular stresses. J. Neutron Res. 1999, 7, 291–317. [Google Scholar] [CrossRef]

- Suzuki, K.; Shobu, T. Residual microstress of austenitic stainless steel due to tensile deformation. Mater. Sci. Forum 2010, 652, 7–12. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suzuki, K.; Miura, Y.; Toyokawa, H.; Shiro, A.; Shobu, T.; Morooka, S.; Shibayama, Y. Residual Stresses of Small-Bore Butt-Welded Piping Measured by Quantum Beam Hybrid Method. Quantum Beam Sci. 2025, 9, 15. https://doi.org/10.3390/qubs9020015

Suzuki K, Miura Y, Toyokawa H, Shiro A, Shobu T, Morooka S, Shibayama Y. Residual Stresses of Small-Bore Butt-Welded Piping Measured by Quantum Beam Hybrid Method. Quantum Beam Science. 2025; 9(2):15. https://doi.org/10.3390/qubs9020015

Chicago/Turabian StyleSuzuki, Kenji, Yasufumi Miura, Hidenori Toyokawa, Ayumi Shiro, Takahisa Shobu, Satoshi Morooka, and Yuki Shibayama. 2025. "Residual Stresses of Small-Bore Butt-Welded Piping Measured by Quantum Beam Hybrid Method" Quantum Beam Science 9, no. 2: 15. https://doi.org/10.3390/qubs9020015

APA StyleSuzuki, K., Miura, Y., Toyokawa, H., Shiro, A., Shobu, T., Morooka, S., & Shibayama, Y. (2025). Residual Stresses of Small-Bore Butt-Welded Piping Measured by Quantum Beam Hybrid Method. Quantum Beam Science, 9(2), 15. https://doi.org/10.3390/qubs9020015