Strain-Induced Martensitic Transformation and Texture Evolution in Cold-Rolled Co–Cr Alloys

Abstract

:1. Introduction

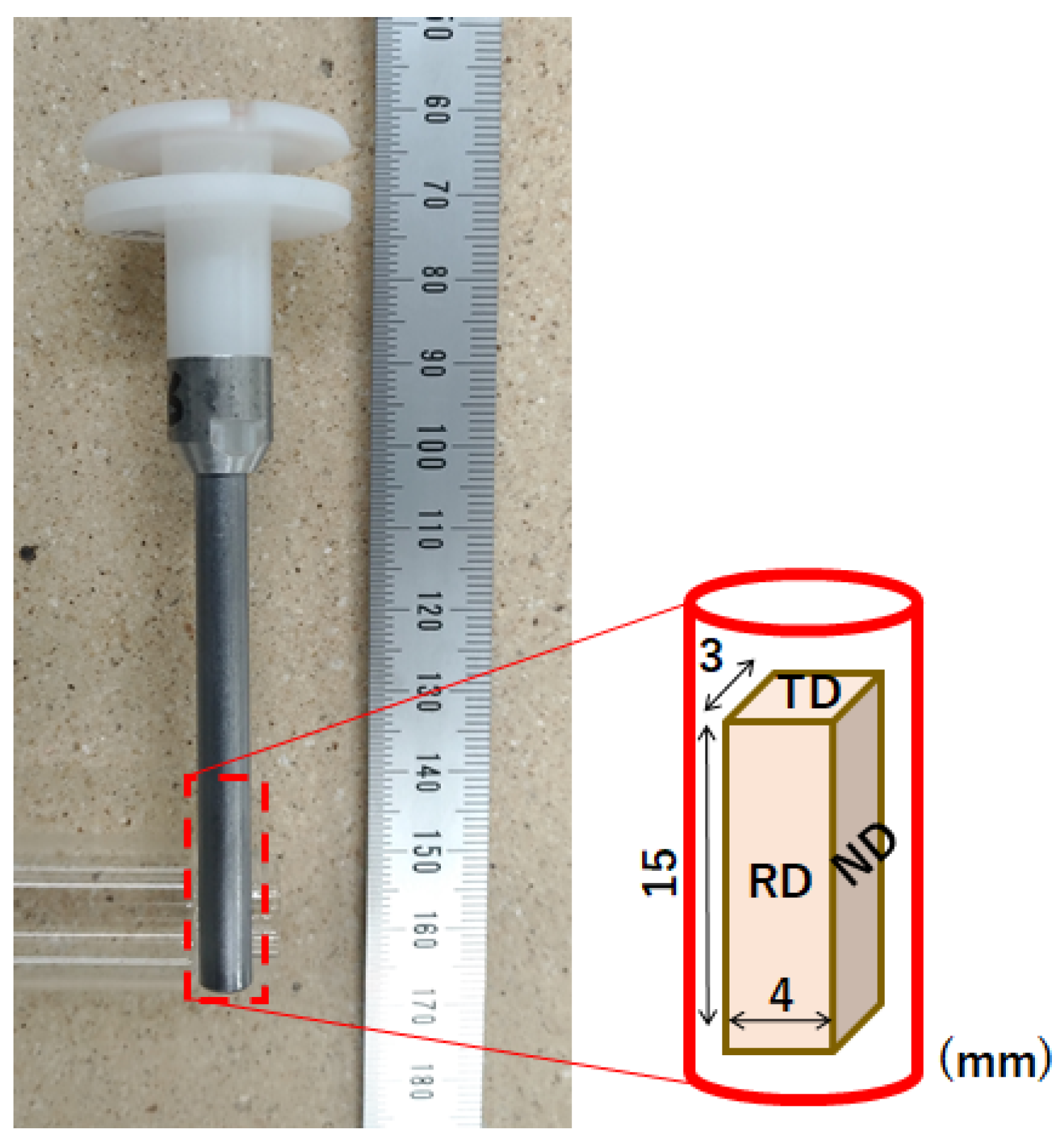

2. Materials and Methods

3. Results

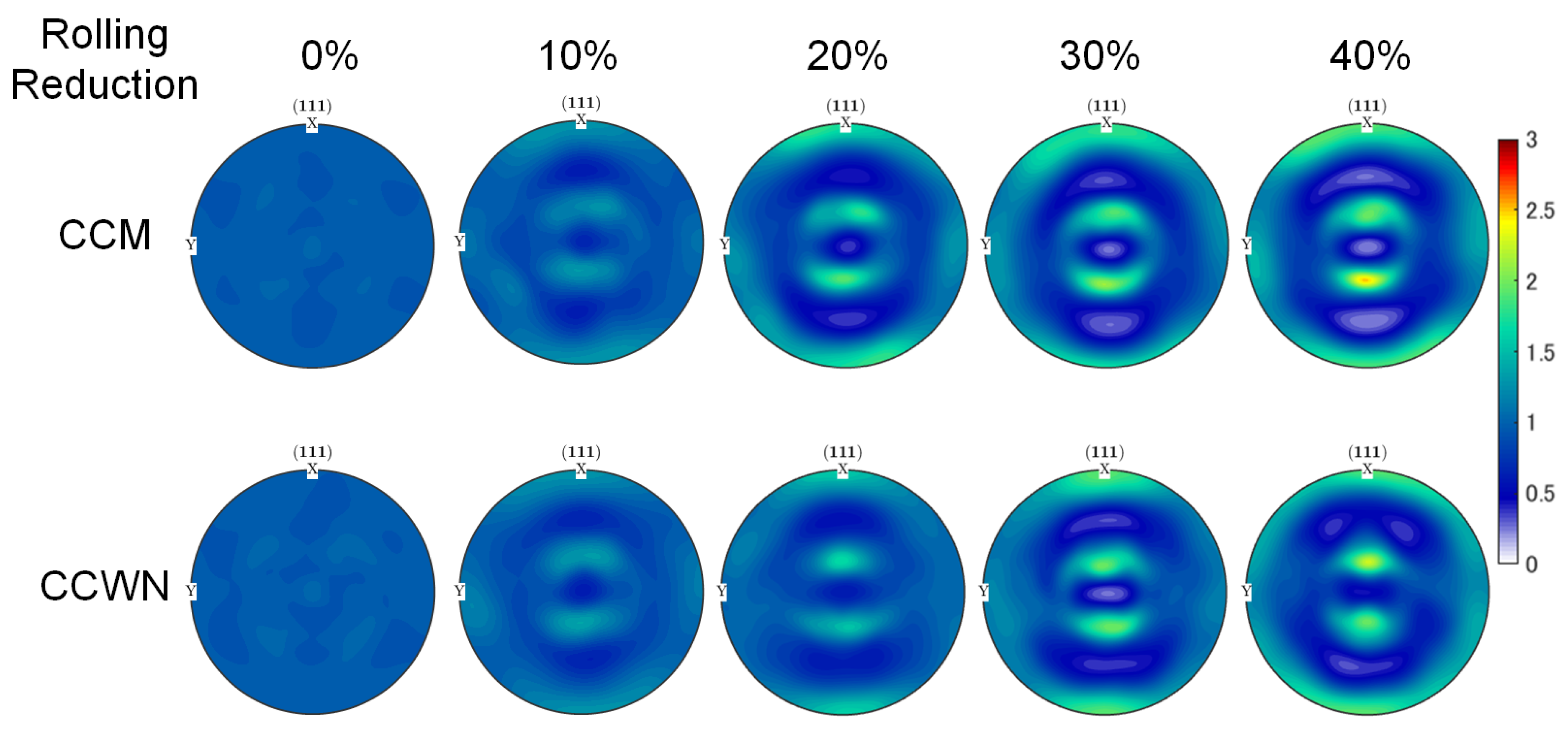

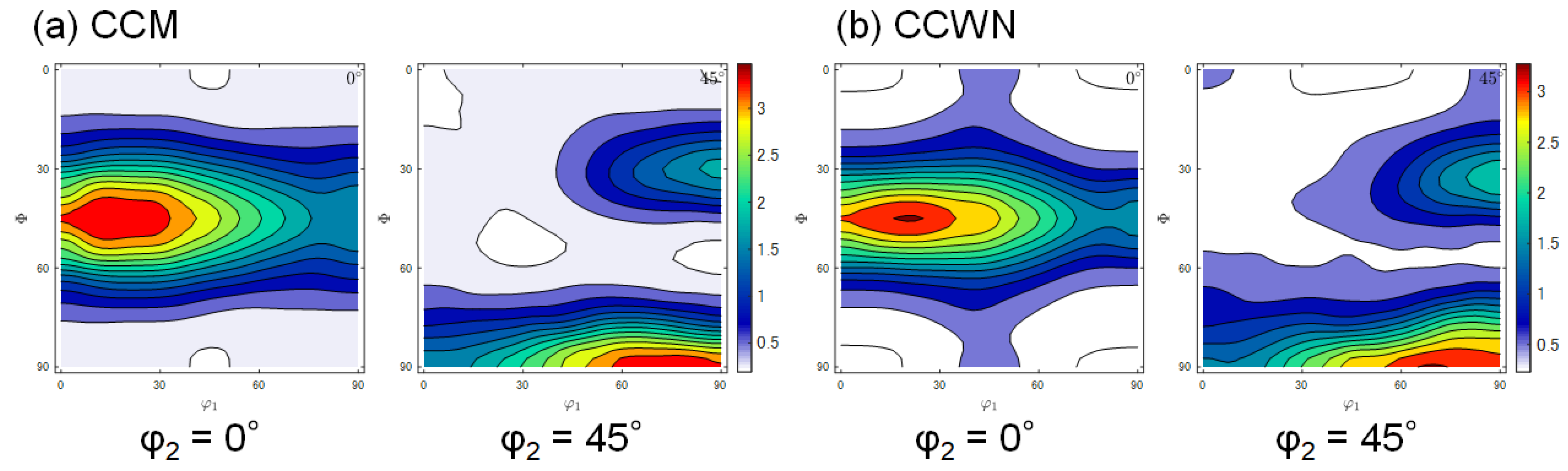

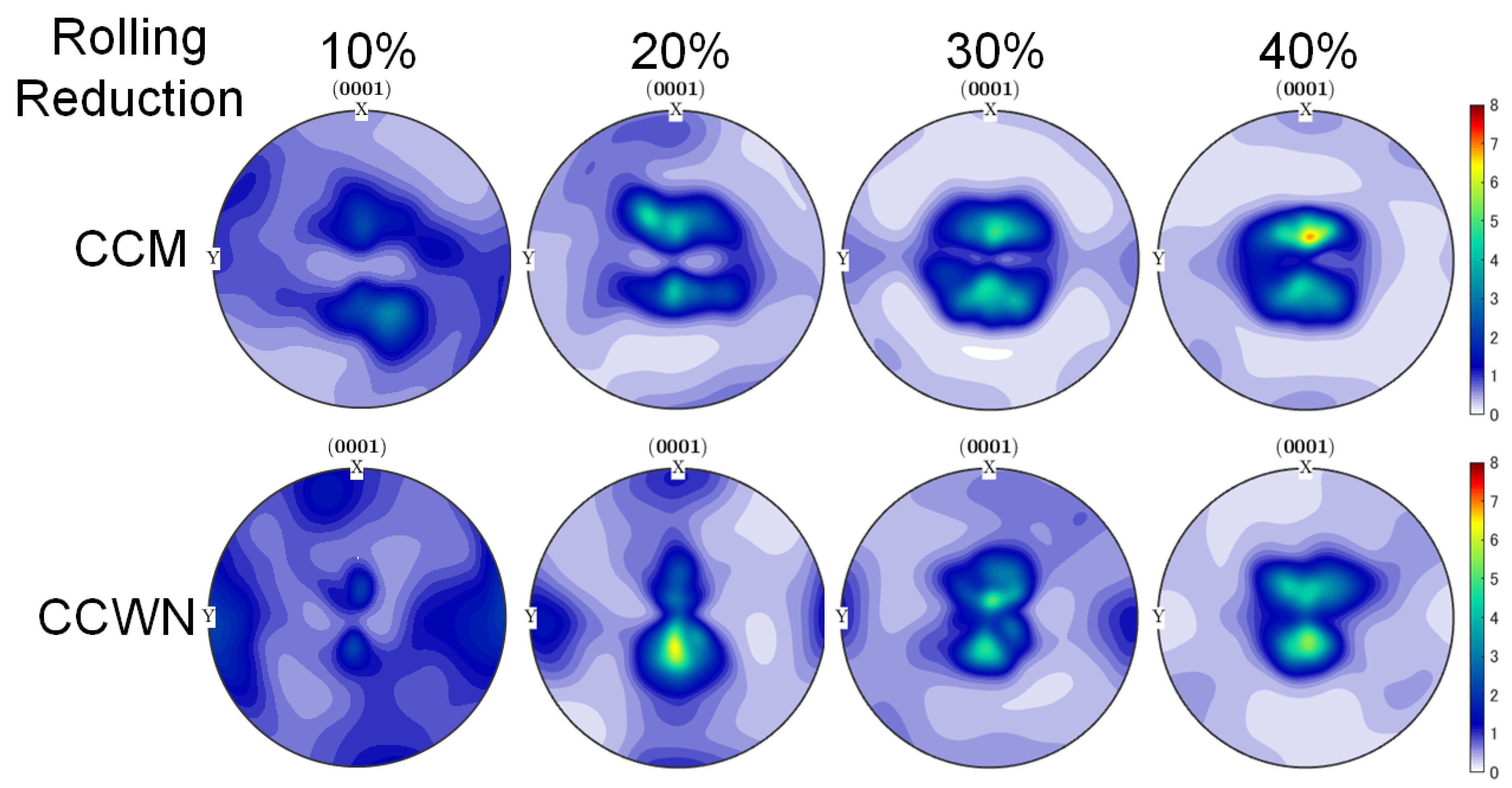

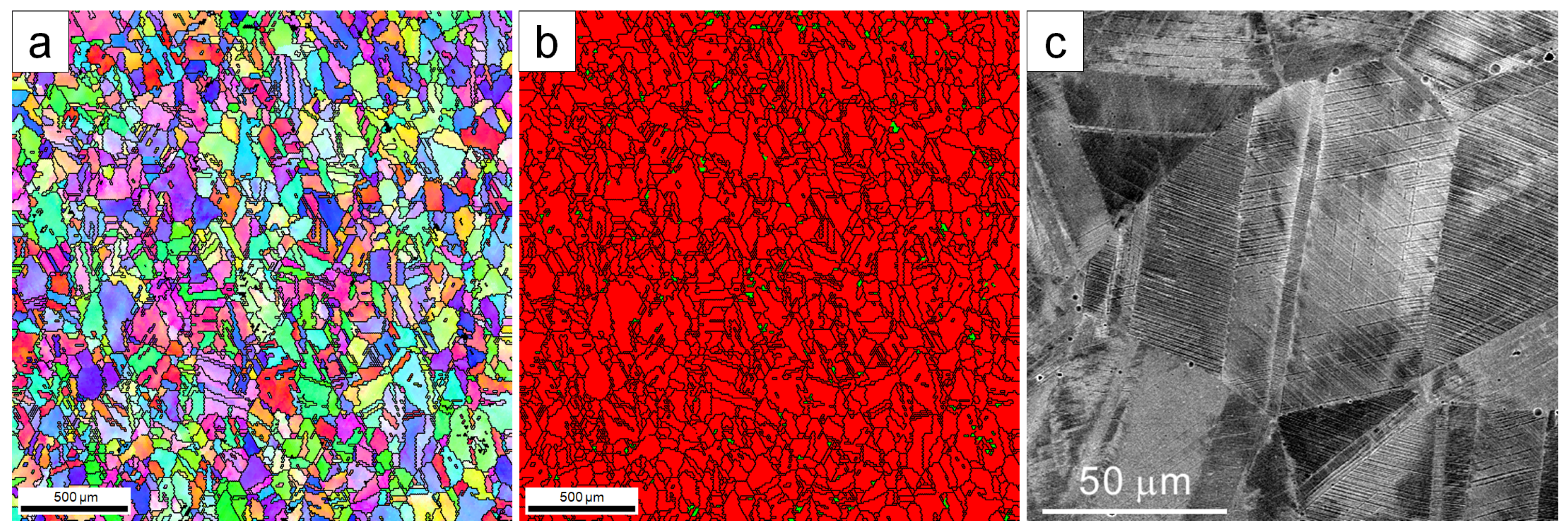

3.1. Texture

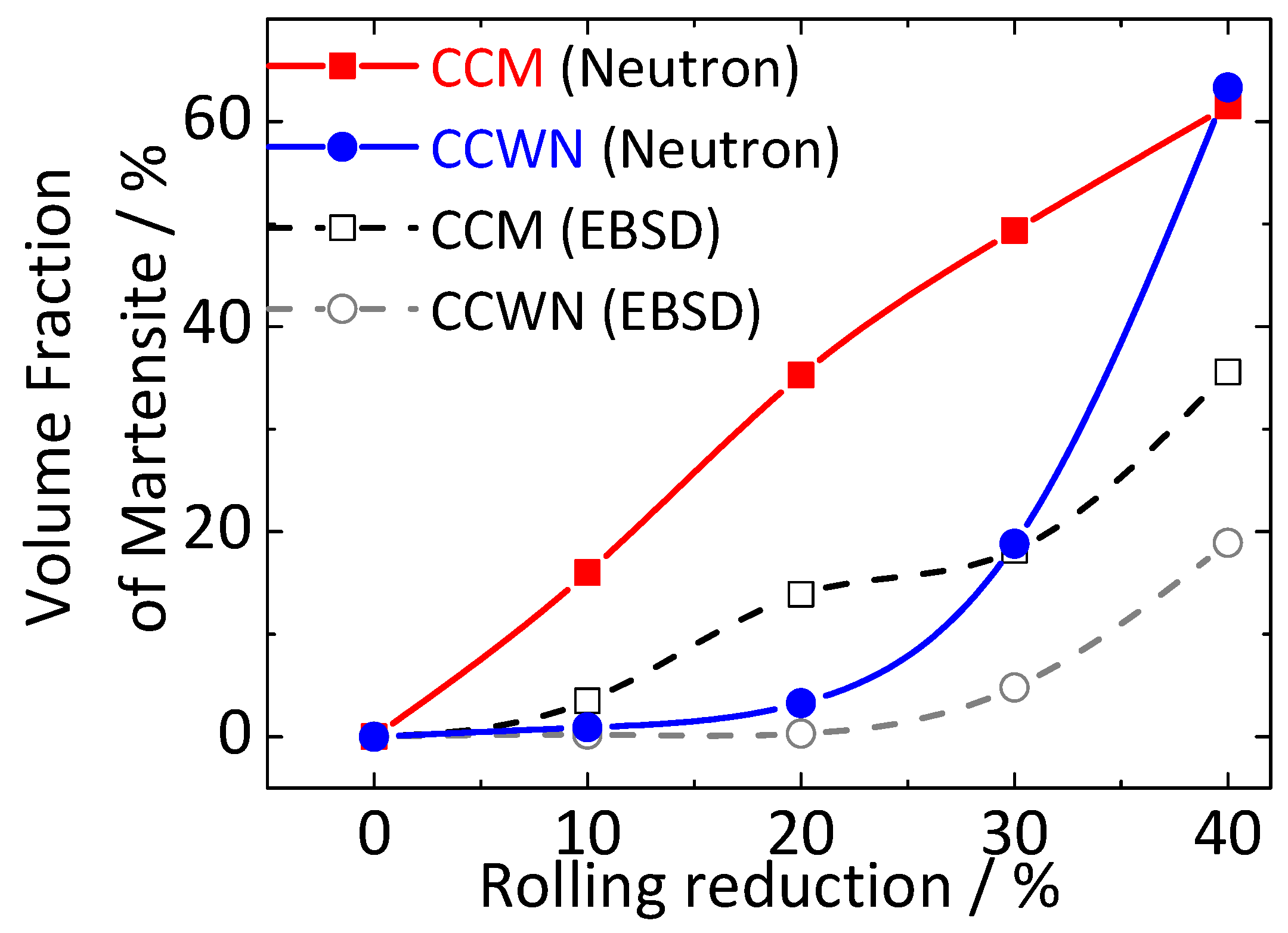

3.2. Phase Fraction

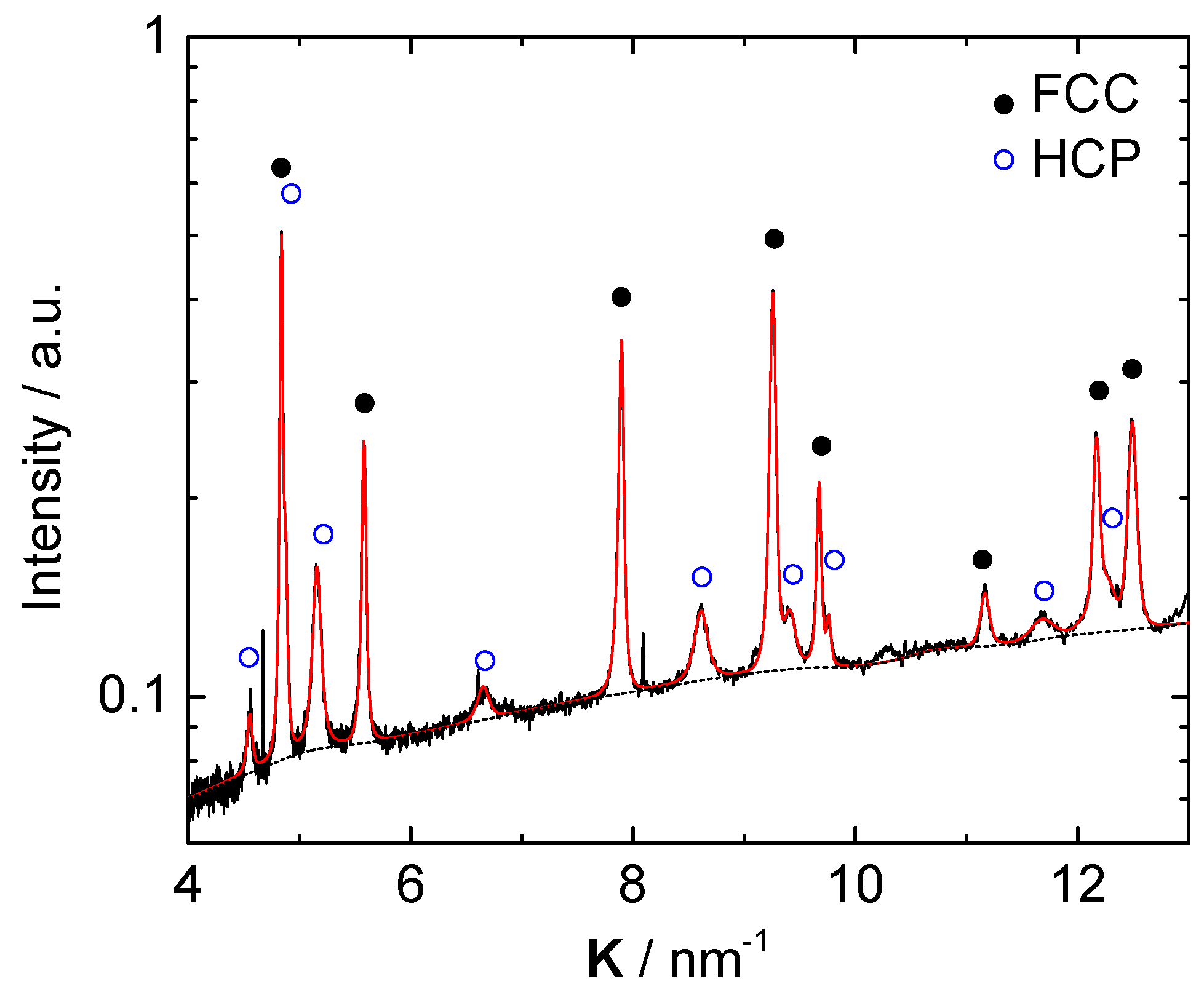

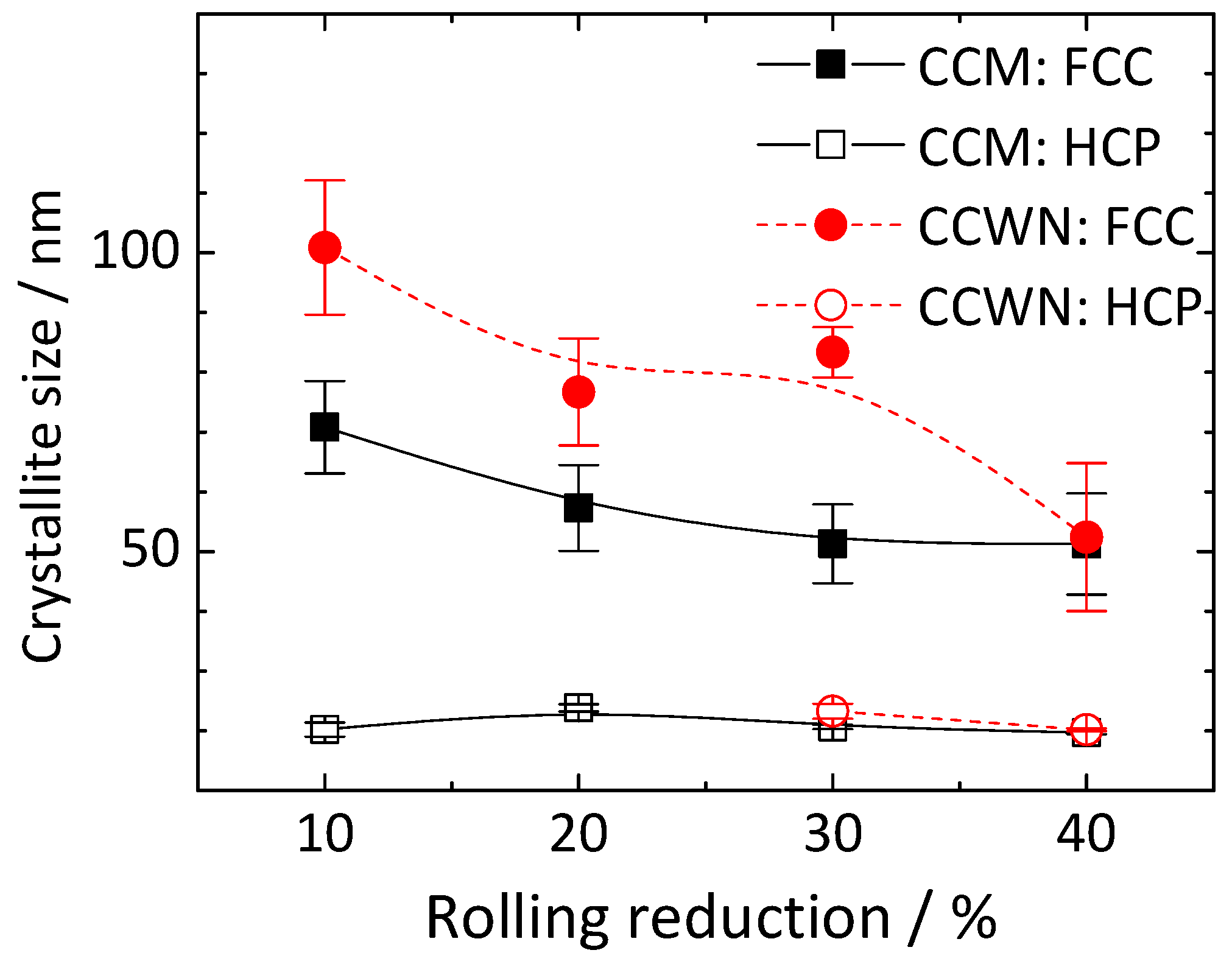

3.3. Characteristics of Dislocations and Crystallite

4. Discussion

5. Conclusions

- Both CCM and CCW alloys developed typical alloy-type textures at medium degree of rolling reduction, mainly consisted of the Brass and Goss components. The (0001) pole figures for the HCP martensite phases in both alloys had pole concentrations at ±15~20° away from the ND toward the RD. The pole densities were increased with increasing strain while the positions of the maximum densities were almost unchanged.

- The volume fraction of the strain-induced martensite increased with increasing rolling reduction in the CCM alloy. On the other hand, the CCW alloy showed only a few percent or martensite up to the rolling reduction of 20%. The martensite fraction rapidly increased after that and reached at the nearly same amount (~60 vol %) at the rolling reduction of 40%.

- Dislocation densities in the FCC phases increased with increasing rolling reduction. The CCM and CCW alloys showed mostly the same values at any strain level. On one hand, the crystallite sizes in the CCM alloys were always smaller than in the CCW alloys. This is probably because the CCM alloy experienced more frequent grain subdivision by the formation of plate-shape martensite. The dislocation densities and crystallite sizes in the HCP phases were insensitive to the strain level in both alloys. Any distinct difference was not confirmed between the two alloys as for the HCP martensite.

- The above analyses of texture and dislocation structure indicated that the plastic deformation of the tested alloys was achieved mainly by the dislocation slip in the FCC phase. The strain induced martensite phase seemed to behave as rigid particles, which merely experienced the dislocation slip. The VPSC texture calculation considering twin as the imaginary martensite was carried out to confirm this conclusion. The texture of the untwinned matrix grains well corresponded to the experimental FCC texture. The copper-oriented grains preferentially experienced twinning in the simulation, i.e., SIMT in reality. In fact, the peak positions on the measured (0001) pole figures corresponded to the positions of (111) pole of the copper orientation in FCC. Hence, we conclude that the observed textures of the martensite phases were resulted from the transformation with the Shoji–Nihshiyama relationship but not from the crystal rotation by the dislocation slip.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chiba, A.; Kumagai, K.; Nomura, N.; Miyakawa, S. Pin-on-disk wear behavior in a like-on-like configuration in a biological environment of high carbon cast and low carbon forged Co–29Cr–6Mo alloys. Acta Mater. 2007, 55, 1309–1318. [Google Scholar] [CrossRef]

- Mani, G.; Feldman, M.D.; Patel, D.; Agrawal, C.M. Coronary Stents: A materials perspective. Biomaterials 2007, 28, 1689–1710. [Google Scholar] [CrossRef] [PubMed]

- Onuki, Y.; Hoshikawa, A.; Sato, S.; Xu, P.G.; Ishigaki, T.; Saito, Y.; Todoroki, H.; Hayashi, M. Rapid measurement scheme for texture in cubic metallic materials using time-of-flight neutron diffraction at iMATERIA. J. Appl. Cryst. 2016, 49, 1579–1584. [Google Scholar] [CrossRef]

- Onuki, Y.; Hoshikawa, A.; Sato, S.; Ishigaki, T.; Tomida, T. Rapid Measurement of Texture of Metals by Time-of-Flight Neutron Diffraction At iMATERIA And Its Applications. J. Mater. Sci. 2017, 52, 11643–11658. [Google Scholar] [CrossRef]

- Ishigaki, T.; Hoshikawa, A.; Yonemura, M.; Morishima, T.; Kamiyama, T.; Oishi, R.; Aizawa, K.; Sakuma, T.; Tomota, Y.; Arai, M. IBARAKI materials design diffractometer (iMATERIA)—Versatile neutron diffractometer at J-PARC. Nucl. Instrum. Methods Phys. Res. Sect. A 2009, 600, 189–191. [Google Scholar] [CrossRef]

- Nakajima, K.; Kawakita, Y.; Itoh, S.; Abe, J.; Aizawa, K.; Aoki, H.; Endo, H.; Masaki, F.; Kenichi, F.; Wu, G.; et al. Materials and Life Science Experimental Facility (MLF) at the Japan Proton Accelerator Research Complex II: Neutron Scattering Instruments. Quantum Beam Sci. 2017, 1, 9. [Google Scholar] [CrossRef]

- Favre, J. Recrystallization of L-605 Cobalt Superalloy during Hot-Working Process. Ph.D. Thesis, INSA de Lyon, Villeurbanne, France, 2012. [Google Scholar]

- Lutterotti, L.; Matthies, S.; Wenk, H.-R.; Schultz, A.J.; Richardson, J.W. Combined texture and structure analysis of deformed limestone from time-of-flight neutron diffraction spectra. J. Appl. Phys. 1997, 81, 594–600. [Google Scholar] [CrossRef]

- Ribárik, G.; Gubicza, J.; Ungár, T. Correlation between strength and microstructure of ball-milled Al–Mg alloys determined by X-ray diffraction. Mater. Sci. Eng. A 2004, 387, 343–347. [Google Scholar] [CrossRef]

- Hanawa, K.; Onuki, Y.; Todoroki, H.; Saito, Y.; Suzuki, S.; Sato, S. Effect of Scattering Vector of Neutron Diffraction for Rolled Steel Sheets on Neutron Diffraction Line-Profile Analysis. Adv. X-ray Chem. Anal. Jpn. 2017, 48, 338–345. [Google Scholar]

- Lebensohn, R.A.; Tomé, C.N. A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: Application to zirconium alloys. Acta Metall. Mater. 1993, 41, 2611–2624. [Google Scholar] [CrossRef]

- Tomé, C.N.; Lebensohn, R.A.; Kocks, U.F. A model for texture development dominated by deformation twinning: Application to zirconium alloys. Acta Metall. Mater. 1991, 39, 2667–2680. [Google Scholar] [CrossRef]

- Leffers, T.; Ray, R.K. The brass-type texture and its deviation from the copper-type texture. Prog. Mater. Sci. 2009, 54, 351–396. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX–Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- Dillamore, I.L.; Roberts, W.T. Preferred orientation in wrought and annealed metals. Metall. Rev. 1965, 10, 271–380. [Google Scholar]

- Koizumi, Y.; Suzuki, S.; Yamanaka, K.; Lee, B.-S.; Sato, K.; Li, Y.; Kurosu, S.; Matsumoto, H.; Chiba, A. Strain-induced martensitic transformation near twin boundaries in a biomedical Co–Cr–Mo alloy with negative stacking fault energy. Acta Mater. 2013, 61, 1648–1661. [Google Scholar] [CrossRef]

- Jacques, P.J.; Allain, S.; Bouaziz, O.; De, A.; Gourgues, A.F.; Hance, B.M.; Houbaert, Y.; Huang, J.; Iza-Mendia, A.; Kruger, S.E.; et al. On measurement of retained austenite in multiphase TRIP steels—Results of blind round robin test involving six different techniques. Mater. Sci. Technol. 2009, 25, 567–574. [Google Scholar] [CrossRef]

- Sato, S.; Kuroda, A.; Satoh, K.; Kumagai, M.; Harjo, S.; Tomota, Y.; Siato, Y.; Todoroki, H.; Onuki, Y.; Suzuki, S. In-situ observation of dislocation evolution in ferritic and austenitic stainless steels under tensile deformation by using neutron diffraction. Tetsu-to-Hagané 2018, 104, 201–207. [Google Scholar] [CrossRef]

- Nishiyama, Z. Martensitic Transformation; Academic Press: New York, NY, USA, 1978; pp. 48–52. [Google Scholar]

- Sato, A.; Chishima, E.; Yamaji, Y.; Mori, T. Orientation and composition dependencies of shape memory effect IN Fe-Mn-Si alloys. Acta Metall. 1984, 32, 539–547. [Google Scholar] [CrossRef]

- Kwon, E.P.; Fujieda, S.; Shinoda, K.; Suzuki, S. Texture evolution and fcc/hcp transformation in Fe–Mn–Si–Cr alloys by tensile deformation. Mater. Sci. Eng. A 2010, 527, 6524–6532. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onuki, Y.; Sato, S.; Nakagawa, M.; Yamanaka, K.; Mori, M.; Hoshikawa, A.; Ishigaki, T.; Chiba, A. Strain-Induced Martensitic Transformation and Texture Evolution in Cold-Rolled Co–Cr Alloys. Quantum Beam Sci. 2018, 2, 11. https://doi.org/10.3390/qubs2020011

Onuki Y, Sato S, Nakagawa M, Yamanaka K, Mori M, Hoshikawa A, Ishigaki T, Chiba A. Strain-Induced Martensitic Transformation and Texture Evolution in Cold-Rolled Co–Cr Alloys. Quantum Beam Science. 2018; 2(2):11. https://doi.org/10.3390/qubs2020011

Chicago/Turabian StyleOnuki, Yusuke, Shigeo Sato, Maiko Nakagawa, Kenta Yamanaka, Manami Mori, Akinori Hoshikawa, Toru Ishigaki, and Akihiko Chiba. 2018. "Strain-Induced Martensitic Transformation and Texture Evolution in Cold-Rolled Co–Cr Alloys" Quantum Beam Science 2, no. 2: 11. https://doi.org/10.3390/qubs2020011

APA StyleOnuki, Y., Sato, S., Nakagawa, M., Yamanaka, K., Mori, M., Hoshikawa, A., Ishigaki, T., & Chiba, A. (2018). Strain-Induced Martensitic Transformation and Texture Evolution in Cold-Rolled Co–Cr Alloys. Quantum Beam Science, 2(2), 11. https://doi.org/10.3390/qubs2020011