Enhancement Seismic Response of a Bored Tunnel Using Isolation for the Challenge of a Faulted Rock Crossing

Abstract

1. Introduction

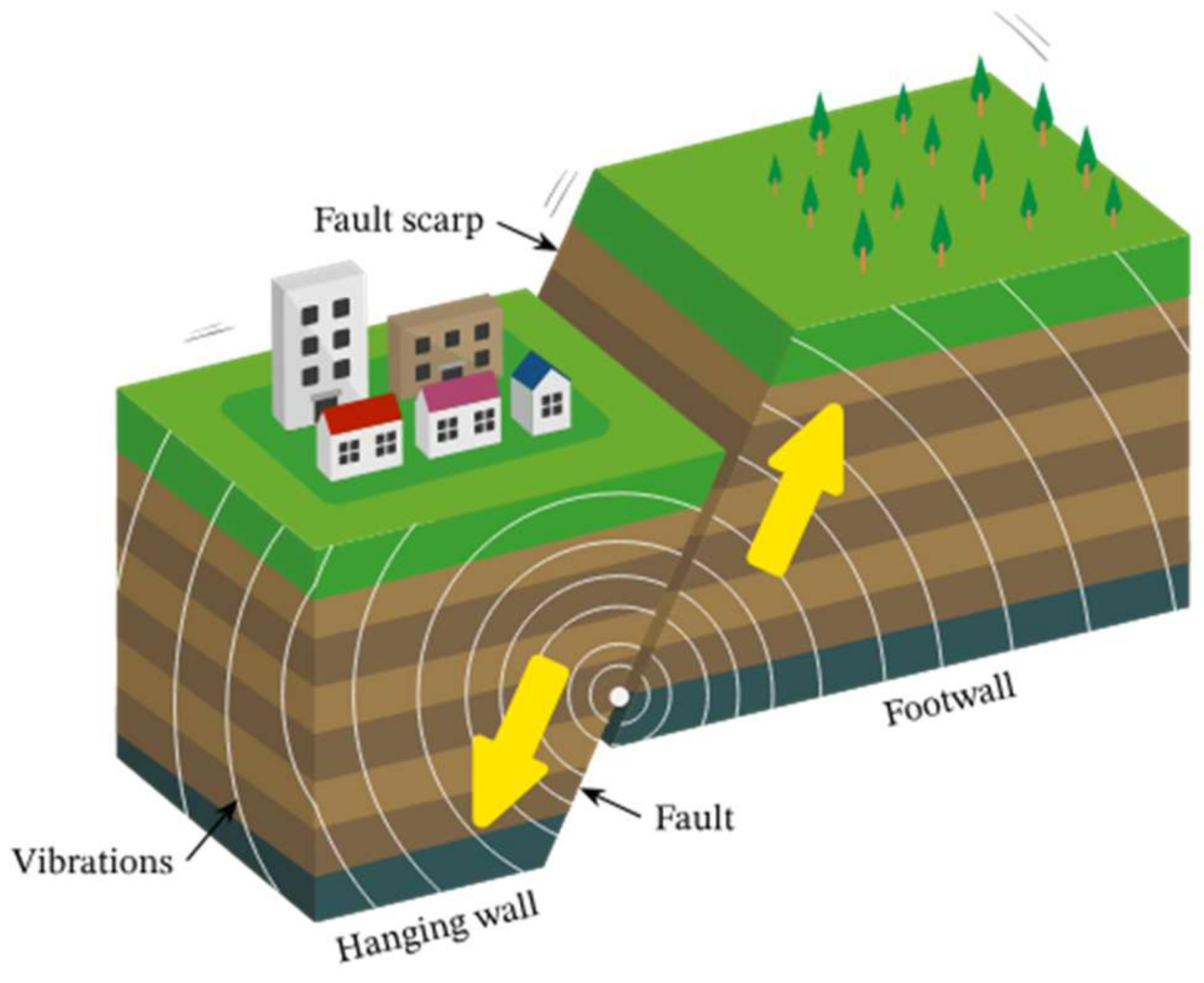

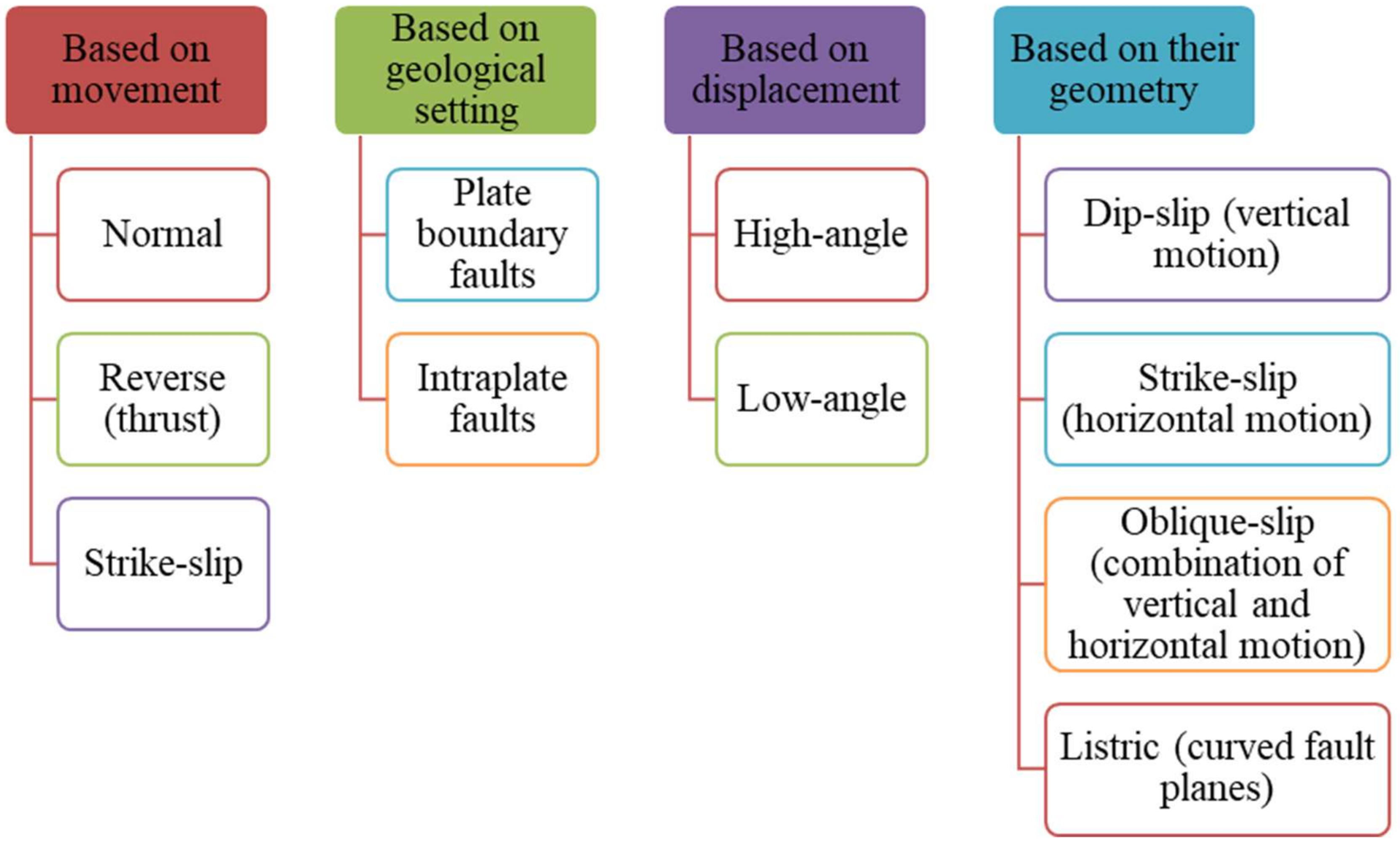

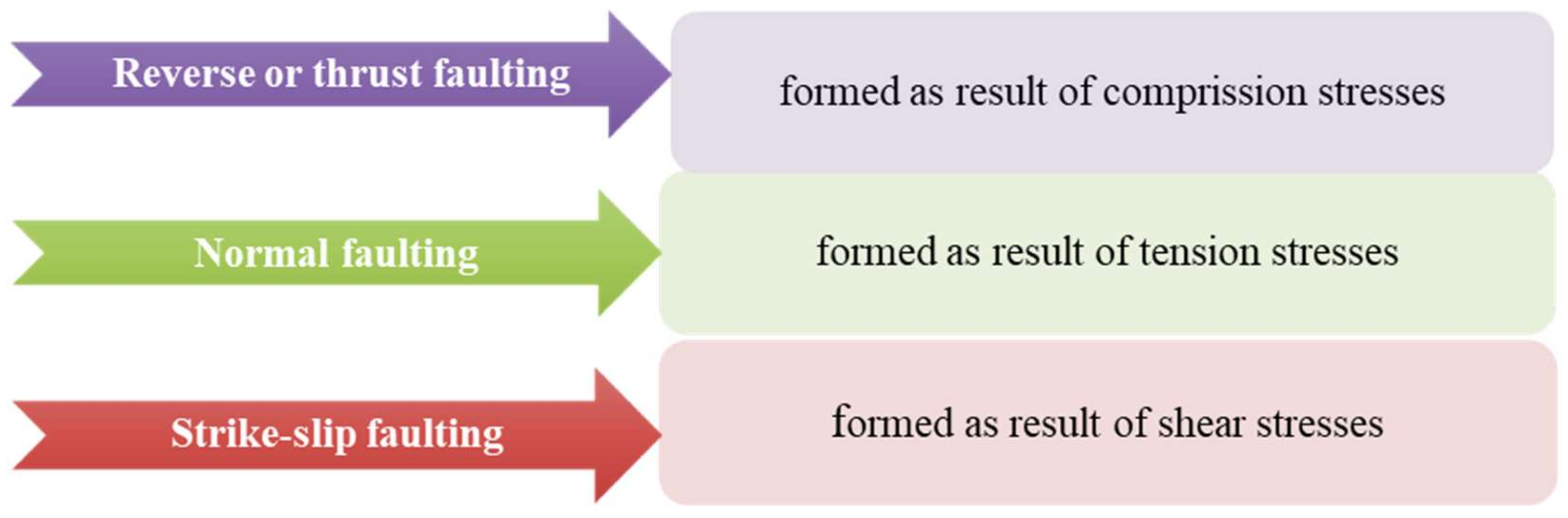

2. Faulted Rock

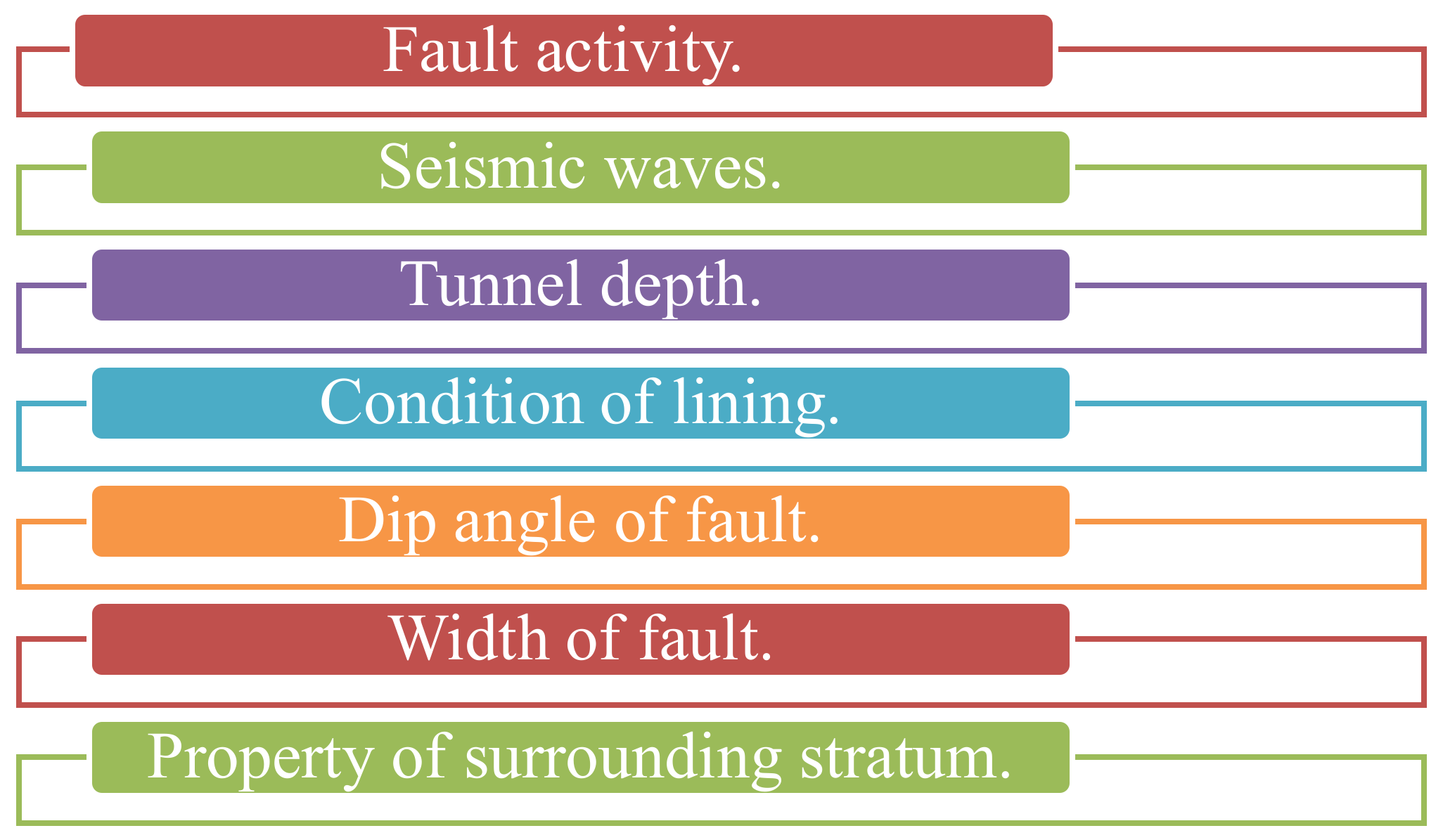

2.1. Seismic Response of a Tunnel in Faulted Rock

2.2. Seismic Protection of Tunnels in Faulted Rock

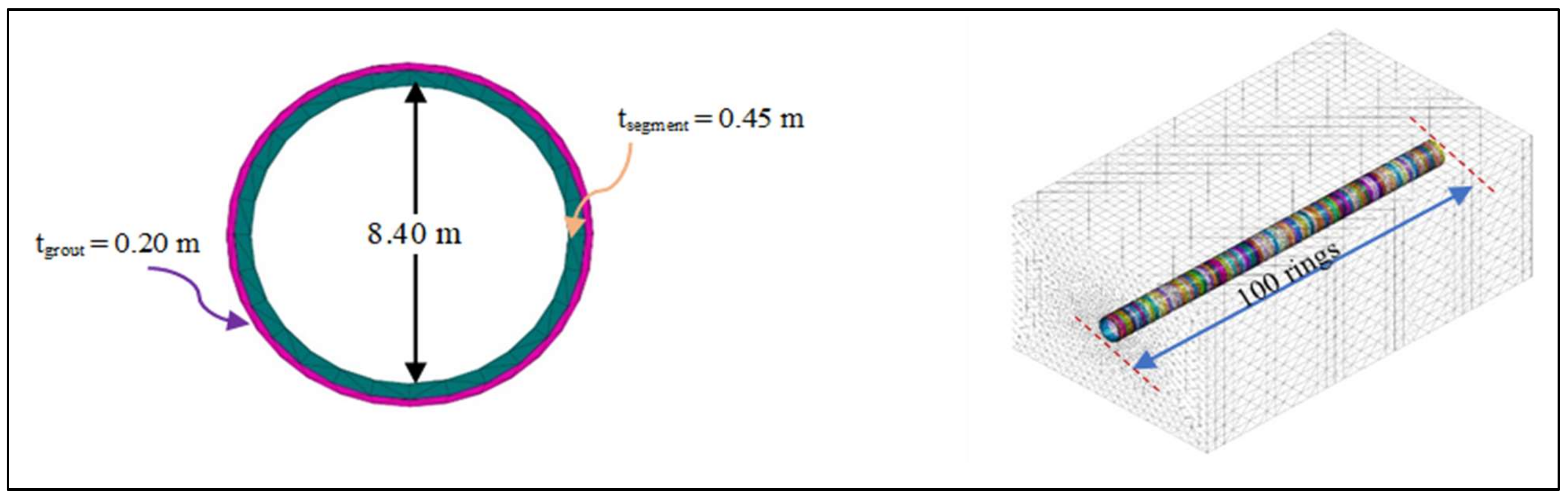

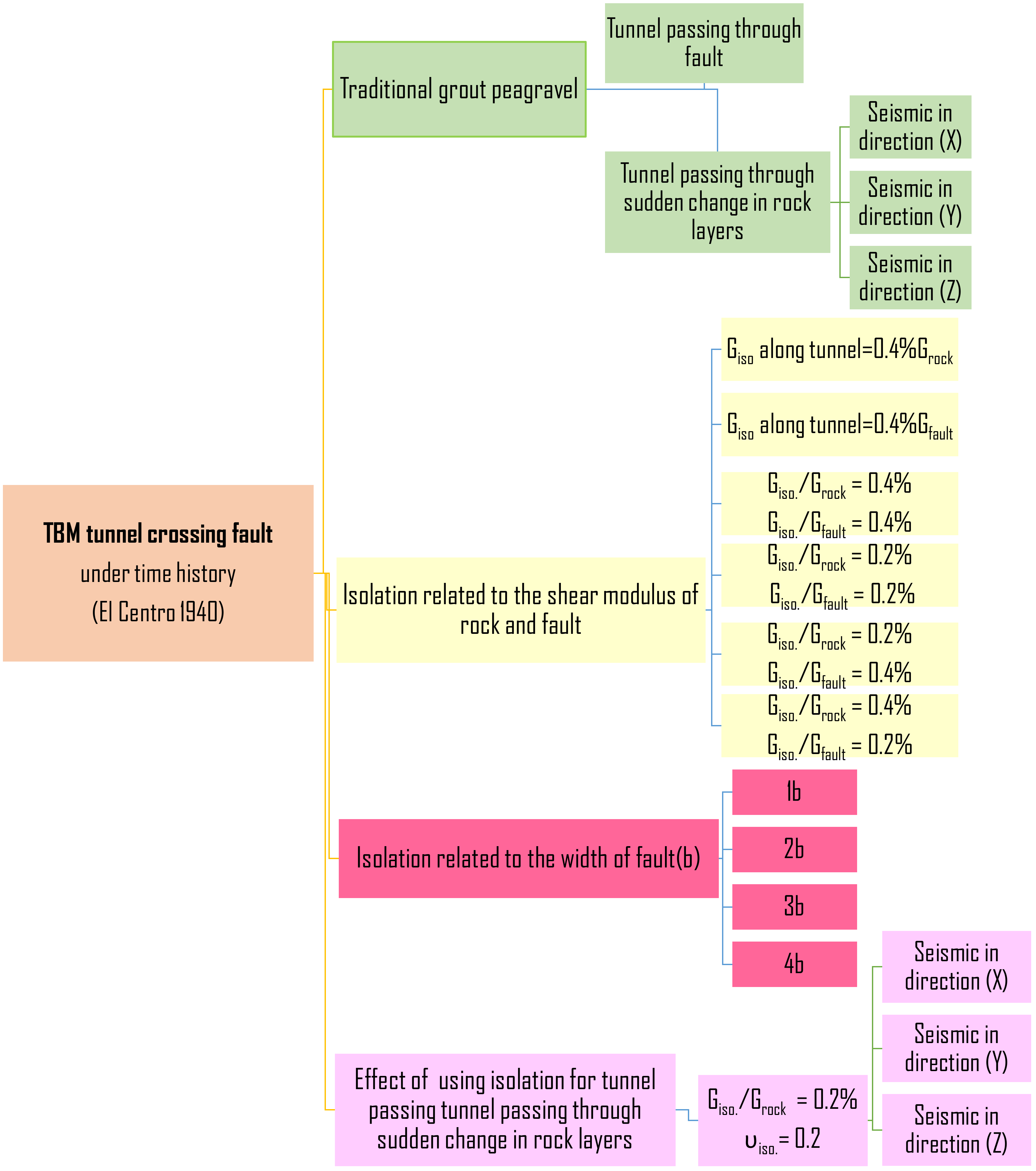

3. Numerical Modeling

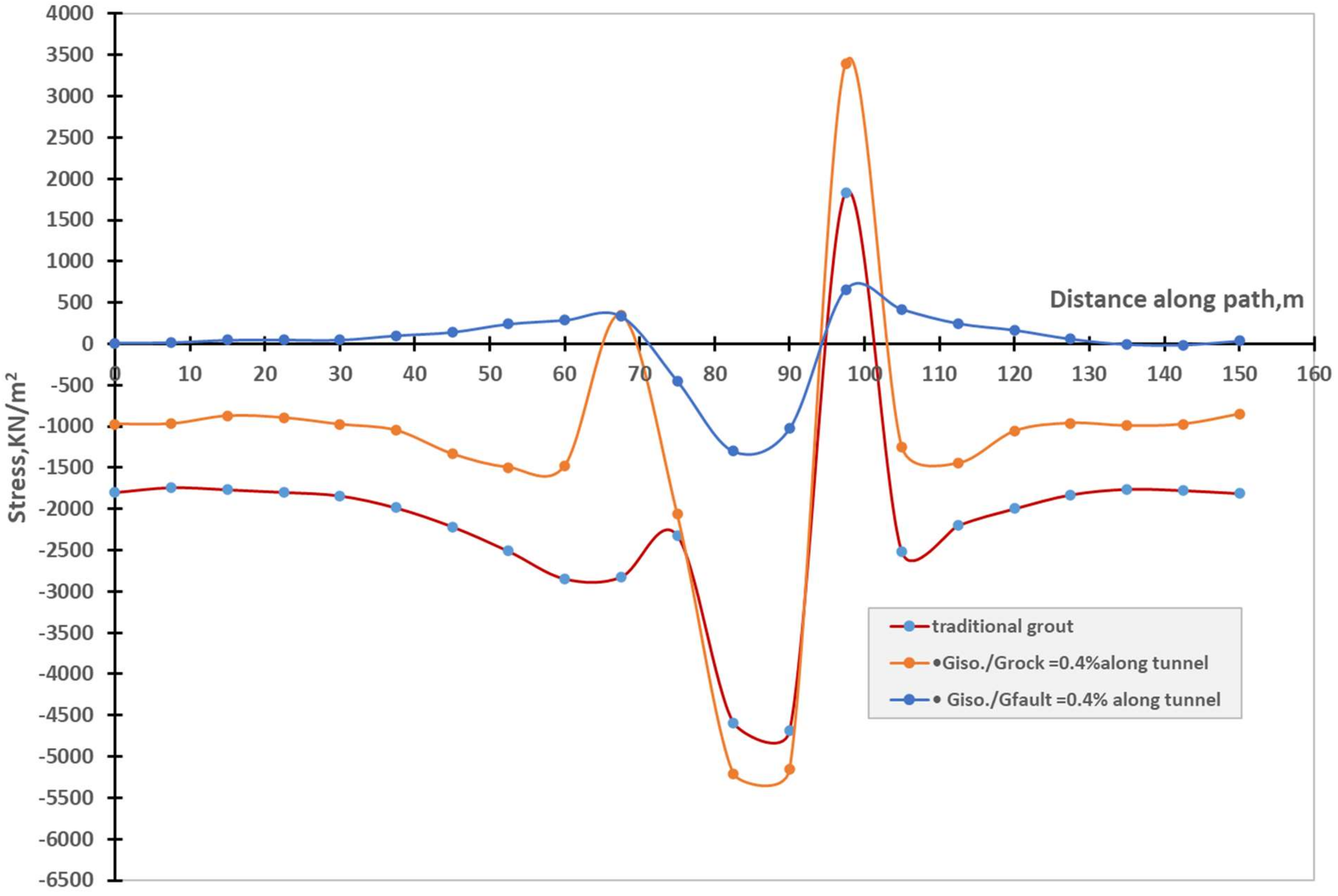

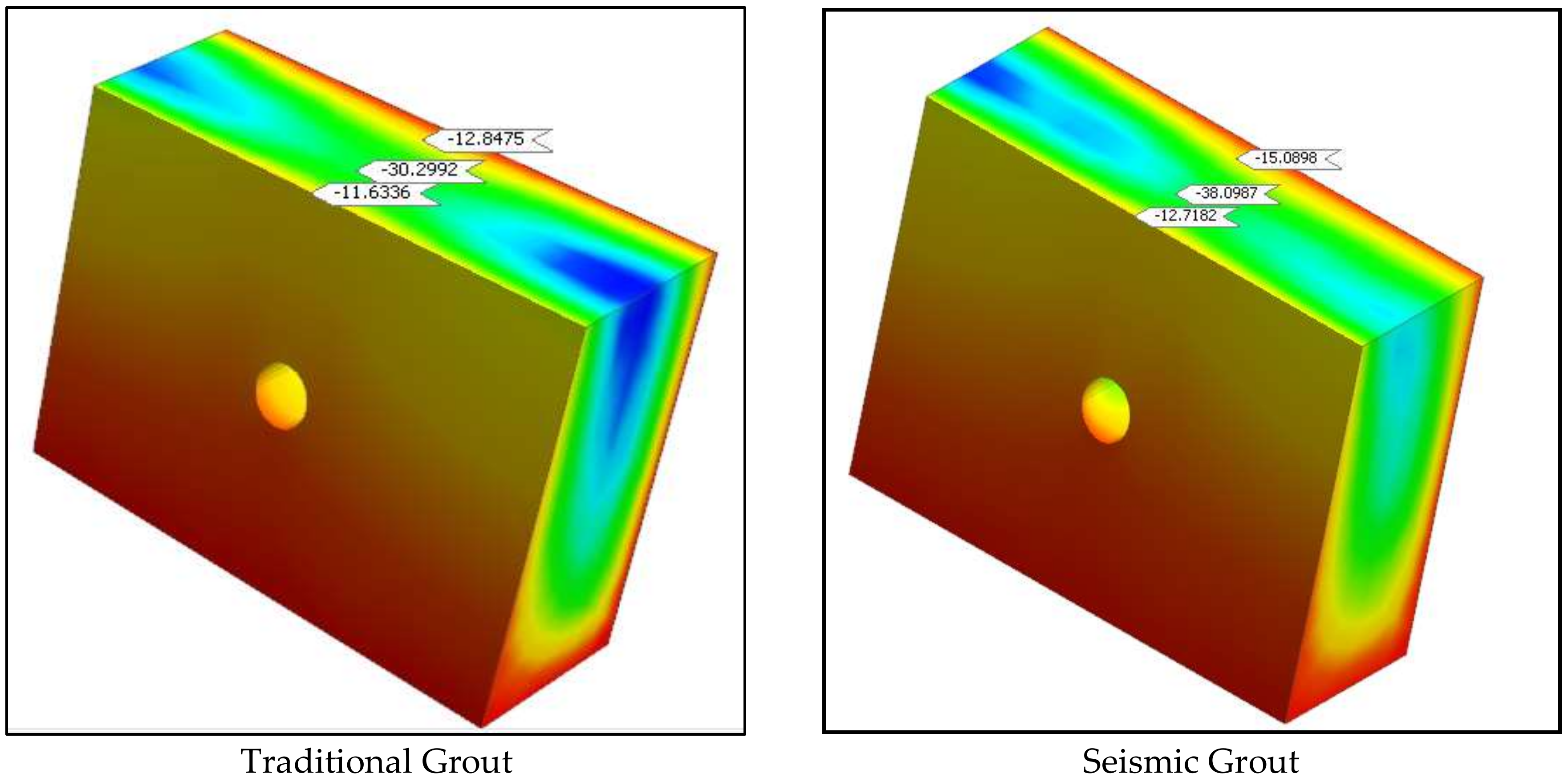

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, X.M.; Liu, M. Numerical simulation of influences of fault angulation on tunnel longitudinal stability. J. Xuzhou Inst. Archit. Technol. 2007, 7, 17–19. [Google Scholar]

- Liu, H.; Song, H.W.; Tang, D.K. Numerical modeling of influence of fault spacengel on longitudinal stability of tunnel. J. Heilongjiang Inst. Sci. Technol. 2008, 18, 447–450. [Google Scholar]

- Jeon, S.; Kim, J.; Seo, Y.; Hong, C. Effect of a fault and weak plane on the stability of a tunnel in rock—A scaled model test and numerical analysis. Int. J. Rock Mech. Min. Sci. 2004, 41, 658–663. [Google Scholar] [CrossRef]

- Lee, F.H.; Hong, S.H.; Gu, Q.; Zhao, P. Application of large three-dimensional finite-element analyses to practical problems. Int. J. Geomech. 2011, 11, 529–539. [Google Scholar] [CrossRef][Green Version]

- Meschke, G.; Nagel, F.; Stascheit, J. Computational simulation of mechanized tunneling as part of an integrated decision support platform. Int. J. Geomech. 2011, 11, 519–528. [Google Scholar] [CrossRef]

- Chen, S.L.; Abousleiman, Y.N.; Muraleetharan, K.K. Closed-form elastoplastic solution for the wellbore problem in strain hardening/softening rock formations. Int. J. Geomech. 2012, 12, 494–507. [Google Scholar] [CrossRef]

- Verma, A.K.; Deb, D. Numerical analysis of an interaction between hydraulic-powered support and surrounding rock strata. Int. J. Geomech. 2013, 13, 181–192. [Google Scholar] [CrossRef]

- Lu, A.; Zhang, N.; Zhang, X.; Lu, D.; Li, W. Analytic method of stress analysis for an orthotropic rock mass with an arbitrary-shaped tunnel. Int. J. Geomech. 2015, 15, 04014068. [Google Scholar] [CrossRef]

- Zareifard, M.R.; Fahimifar, A. Elastic–brittle–plastic analysis of circular deep underwater cavities in a Mohr-Coulomb rock mass considering seepage forces. Int. J. Geomech. 2015, 15, 04014077. [Google Scholar] [CrossRef]

- Yang, F.; Yang, J.S. Stability of shallow tunnel using rigid blocks and finite-element upper bound solutions. Int. J. Geomech. 2010, 10, 242–247. [Google Scholar] [CrossRef]

- Kumar, J.; Bhattacharya, P. Reducing the computational effort for performing linear optimization in the lower-bound finite elements limit analysis. Int. J. Geomech. 2011, 11, 406–412. [Google Scholar] [CrossRef]

- Duenser, C.; Thoeni, K.; Riederer, K.; Lindner, B.; Beer, G. New developments of the boundary element method for underground constructions. Int. J. Geomech. 2012, 12, 665–675. [Google Scholar] [CrossRef]

- Kumar, J.; Sahoo, J.P. Upper bound solution for pullout capacity of vertical anchors in sand using finite elements and limit analysis. Int. J. Geomech. 2012, 12, 333–337. [Google Scholar] [CrossRef]

- Kermani, E.; Qiu, T.; Li, T. Simulation of collapse of granular columns using the discrete element method. Int. J. Geomech. 2015, 15, 04015004. [Google Scholar] [CrossRef]

- Kim, Y.G.; Han, B.H.; Lee, S.B.; Kim, E.T. A case study of collapse and reinforcement for large span waterway tunnel at thrust fault zone. Tunn. Undergr. Space 2011, 21, 251–263. [Google Scholar]

- Zhao, K.; Janutolo, M.; Barla, G.; Chen, G. 3D simulation of TBM excavation in brittle rock associated with fault zones: The Brenner Exploratory Tunnel case. Eng. Geol. 2014, 181, 93–111. [Google Scholar] [CrossRef]

- Dalgıç, S. Tunneling in fault zones, Tuzla tunnel, Turkey. Tunn. Undergr. Space Technol. 2003, 18, 453–465. [Google Scholar] [CrossRef]

- Shrestha, P.K.; Panthi, K.K. Groundwater effect on faulted rock mass: An evaluation of Modi Khola pressure tunnel in the Nepal Himalaya. Rock Mech. Rock Eng. 2014, 47, 1021–1035. [Google Scholar] [CrossRef]

- Fraldi, M.; Guarracino, F. Limit analysis of collapse mechanisms in cavities and tunnels according to the Hoek–Brown failure criterion. Int. J. Rock Mech. Min. Sci. 2009, 46, 665–673. [Google Scholar] [CrossRef]

- Fraldi, M.; Guarracino, F. Analytical solutions for collapse mechanisms in tunnels with arbitrary cross sections. Int. J. Solids Struct. 2010, 47, 216–223. [Google Scholar] [CrossRef]

- Fraldi, M.; Guarracino, F. Evaluation of impending collapse in circular tunnels by analytical and numerical approaches. Tunn. Undergr. Space Technol. 2011, 26, 507–516. [Google Scholar] [CrossRef]

- Mollon, G.; Dias, D.; Soubra, A.H. Face stability analysis of circular tunnels driven by a pressurized shield. J. Geotech. Geoenvironmental Eng. 2010, 136, 215–229. [Google Scholar] [CrossRef]

- Huang, F.; Qin, C.B.; Li, S.C. Determination of minimum cover depth for shallow tunnel subjected to water pressure. J. Cent. South Univ. 2013, 20, 2307–2313. [Google Scholar] [CrossRef]

- Xiong, W.; Fan, W.; Peng, J.B.; Deng, L.S.; Yan, F.R. Numerical analysis of effect of normal fault activity on road mountain tunnel project. Chin. J. Rock Mech. Eng. 2010, 29, 2845–2852. [Google Scholar]

- Huang, S.; Si, T.; Chen, W. Finite element analyses of influence of fault on large-span tunnel surrounding rock stress. Chin. J. Rock Mech. Eng. 2006, 25, 3788–3793. [Google Scholar]

- Osman, A.S.; Mair, R.J.; Bolton, M.D. On the kinematics of 2D tunnel collapse in undrained clay. Geotechnique 2006, 56, 585–595. [Google Scholar] [CrossRef]

- Wang, Y.; Jing, H.; Su, H.; Xie, J. Effect of a fault fracture zone on the stability of tunnel-surrounding rock. Int. J. Geomech. 2017, 17, 04016135. [Google Scholar] [CrossRef]

- Dowding, C.H.; Rozan, A. Damage to rock tunnels from earthquake shaking. J. Geotech. Eng. Div. 1978, 104, 175–191. [Google Scholar] [CrossRef]

- ITA (International Tunneling and Underground Space Association). Tunnel Market Survey. 2016. Available online: https://www.tunnel-online.info/en/artikel/tunnel_Tunnel_Market_Survey_2016_3051818.html (accessed on 8 December 2019).

- Yu, H.T.; Chen, J.T.; Yuan, Y.; Zhao, X. Seismic damage of mountain tunnels during the 5.12 Wenchuan earthquake. J. Mt. Sci. 2016, 13, 1958–1972. [Google Scholar] [CrossRef]

- He, W.; Wu, Z.; Kojima, Y.; Asakura, T. Failure mechanism of deformed concrete tunnels subject to diagonally concentrated loads. Comput. Aided Civ. Infrastruct. Eng. 2009, 24, 416–431. [Google Scholar] [CrossRef]

- Loukidis, D.; Bouckovalas, G.D.; Papadimitriou, A.G. Analysis of fault rupture propagation through uniform soil cover. Soil Dyn. Earthq. Eng. 2009, 29, 1389–1404. [Google Scholar] [CrossRef]

- Anastasopoulos, I.; Gazetas, G. Foundation–structure systems over a rupturing normal fault: Part I. Observations after the Kocaeli 1999 earthquake. Bull. Earthq. Eng. 2007, 5, 253–275. [Google Scholar] [CrossRef]

- Zhong, Z.; Wang, Z.; Zhao, M.; Du, X. Structural damage assessment of mountain tunnels in fault fracture zone subjected to multiple strike-slip fault movement. Tunn. Undergr. Space Technol. 2020, 104, 103527. [Google Scholar] [CrossRef]

- Jaramillo, C.A. Impact of seismic design on tunnels in rock–Case histories. Undergr. Space 2017, 2, 106–114. [Google Scholar] [CrossRef]

- Yue, L.F.; Suppe, J.; Hung, J.H. Structural geology of a classic thrust belt earthquake: The 1999 Chi-Chi earthquake Taiwan (Mw = 7.6). J. Struct. Geol. 2005, 27, 2058–2083. [Google Scholar] [CrossRef]

- Wang, Z. A preliminary report on the Great Wenchuan Earthquake. Earthq. Eng. Eng. Vib. 2008, 7, 225–234. [Google Scholar] [CrossRef]

- Chen, Z.; Shi, C.; Li, T.; Yuan, Y. Damage characteristics and influence factors of mountain tunnels under strong earthquakes. Nat. Hazards 2012, 61, 387–401. [Google Scholar] [CrossRef]

- Lin, M.L.; Chung, C.F.; Jeng, F.S.; Yao, T.C. The deformation of overburden soil induced by thrust faulting and its impact on underground tunnels. Eng. Geol. 2007, 92, 110–132. [Google Scholar] [CrossRef]

- Durukal, E. Critical evaluation of strong motion in Kocaeli and Düzce (Turkey) earthquakes. Soil Dyn. Earthq. Eng. 2002, 22, 589–609. [Google Scholar] [CrossRef]

- Ma, C.; Lu, D.; Zhao, Y.; Wang, Z.; Du, X. Performance of an underground structure seismic mitigation system improved by frictional deformation absorbing braces. Structures 2022, 37, 1–16. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, B.; Jiang, Y.; Yuan, S. Investigation and assessment on mountain tunnels and geotechnical damage after the Wenchuan earthquake. Sci. China Ser. Technol. Sci. 2009, 52, 546–558. [Google Scholar] [CrossRef]

- Yu, H.; Chen, J.; Bobet, A.; Yuan, Y. Damage observation and assessment of the Longxi tunnel during the Wenchuan earthquake. Tunn. Undergr. Space Technol. 2016, 54, 102–116. [Google Scholar] [CrossRef]

- Wang, W.L.; Wang, T.T.; Su, J.J.; Lin, C.H.; Seng, C.R.; Huang, T.H. Assessment of damage in mountain tunnels due to the Taiwan Chi-Chi Earthquake. Tunn. Undergr. Space Technol. 2001, 16, 133–150. [Google Scholar] [CrossRef]

- Li, T. Damage to mountain tunnels related to the Wenchuan earthquake and some suggestions for aseismic tunnel construction. Bull. Eng. Geol. Environ. 2012, 71, 297–308. [Google Scholar] [CrossRef]

- Kiani, M.; Akhlaghi, T.; Ghalandarzadeh, A. Experimental modeling of segmental shallow tunnels in alluvial affected by normal faults. Tunn. Undergr. Space Technol. 2016, 51, 108–119. [Google Scholar] [CrossRef]

- Moradi, M.; Rojhani, M.; Galandarzadeh, A.; Takada, S. Centrifuge modeling of buried continuous pipelines subjected to normal faulting. Earthq. Eng. Eng. Vib. 2013, 12, 155–164. [Google Scholar] [CrossRef]

- Cai, Q.P.; Peng, J.M.; Ng, C.W.; Shi, J.W.; Chen, X.X. Centrifuge and numerical modelling of tunnel intersected by normal fault rupture in sand. Comput. Geotech. 2019, 111, 137–146. [Google Scholar] [CrossRef]

- Tsinidis, G.; de Silva, F.; Anastasopoulos, I.; Bilotta, E.; Bobet, A.; Hashash, Y.M.; He, C.; Kampas, G.; Knappett, J.; Madabhushi, G.; et al. Seismic behaviour of tunnels: From experiments to analysis. Tunn. Undergr. Space Technol. 2020, 99, 103334. [Google Scholar] [CrossRef]

- Demirci, H.E.; Bhattacharya, S.; Karamitros, D.; Alexander, N. Experimental and numerical modelling of buried pipelines crossing reverse faults. Soil Dyn. Earthq. Eng. 2018, 114, 198–214. [Google Scholar] [CrossRef]

- Kiyomiya, O.; Nakamichi, M.; Yokota, H.; Shiraishi, S. New type flexible joint for the Osaka Port Yumeshima Tunnel Osamu Kiyomiya. In Proceedings of the Oceans’ 04 MTS/IEEE Techno-Ocean’04 (IEEE Cat. No. 04CH37600), Kobe, Japan, 9–12 November 2004; Volume 4, pp. 2086–2091. [Google Scholar]

- Russo, M.; Germani, G.; Amberg, W. Design and construction of large tunnel through active faults: A recent application. In Proceedings of the International Conference of Tunneling and Underground Space Use, Istanbul, Turkey, 16–18 October 2002; pp. 1–14. [Google Scholar]

- Hashash, Y.M.; Hook, J.J.; Schmidt, B.; John, I.; Yao, C. Seismic design and analysis of underground structures. Tunn. Undergr. Space Technol. 2001, 16, 247–293. [Google Scholar] [CrossRef]

- Douglas, W.S.; Warshaw, R. Design of seismic joint for San Francisco bay tunnel. J. Struct. Div. 1971, 97, 1129–1141. [Google Scholar] [CrossRef]

- Ertuğrul, N. Analysis of Seismic Behavior of Underground Structures: A Case Study on Bolu Tunnels. Master’s Thesis, Middle East Technical University, Ankara, Turkey, 2010. [Google Scholar]

- Kontoe, S.; Zdravkovic, L.; Potts, D.M.; Menkiti, C.O. Case study on seismic tunnel response. Can. Geotech. J. 2008, 45, 1743–1764. [Google Scholar] [CrossRef]

- Wang, T.T.; Kwok, O.L.A.; Jeng, F.S. Seismic response of tunnels revealed in two decades following the 1999 Chi-Chi earthquake (Mw 7.6) in Taiwan: A review. Eng. Geol. 2021, 287, 106090. [Google Scholar] [CrossRef]

- Zhang, P.Z.; Wen, X.Z.; Shen, Z.K.; Chen, J.H. Oblique, high-angle, listric-reverse faulting and associated development of strain: The Wenchuan earthquake of May 12, 2008, Sichuan, China. Annu. Rev. Earth Planet. Sci. 2010, 38, 353–382. [Google Scholar] [CrossRef]

- Zhang, L.F.; Li, R.H.; Liu, H.; Fang, Z.B.; Wang, H.B.; Yuan, Y.; Yu, H.T. A Review on Seismic Response and Aseismic Measures of Fault-crossing Tunnels. IOP Conf. Ser. Earth Environ. Sci. 2020, 570, 052046. [Google Scholar] [CrossRef]

- Ma, S.; Chen, W.; Zhao, W. Mechanical properties and associated seismic isolation effects of foamed concrete layer in rock tunnel. J. Rock Mech. Geotech. Eng. 2019, 11, 159–171. [Google Scholar] [CrossRef]

- Cui, G.; Ma, J.; Wang, D. A large 3D laboratory test on the deformation characteristic of shallow loess tunnel under different plastic states. Bull. Eng. Geol. Environ. 2021, 80, 7577–7590. [Google Scholar] [CrossRef]

- Shahidi, A.R.; Vafaeian, M. Analysis of longitudinal profile of the tunnels in the active faulted zone and designing the flexible lining (for Koohrang-III tunnel). Tunn. Undergr. Space Technol. 2005, 20, 213–221. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, M.; Xi, C. Tunnel collapse mechanism and its control strategy in fault fracture zone. Shock Vib. 2021, 2021, 9988676. [Google Scholar] [CrossRef]

| Material | Modulus of Elasticity (E) (GPa) | Poisson’s Ratio (ν) | Unit Weight (γ) (kN/m3) | Cohesion (cu) (kN/m2) | Friction Angle (φ) |

|---|---|---|---|---|---|

| Rock 1 (medium-strong) | 6.00 | 0.30 | 23.00 | 700.00 | 39° |

| Rock 2 (medium-weak) | 1.00 | 0.30 | 23.00 | 200.00 | 30° |

| Fault | 0.2 | 0.30 | 21.00 | 150.00 | 23° |

| Material | Modulus of Elasticity (E) (GPa) | Poisson’s Ratio (ν) | Unit Weight (γ) (kN/m3) |

|---|---|---|---|

| Concrete for segment | 30.00 | 0.20 | 25.00 |

| Grout for tunnel (pea gravel) | 1.00 | 0.30 | 23.00 |

| Material | Modulus of Elasticity (E) (kN/m2) | Poisson’s Ratio (ν) | Unit Weight (γ) (kN/m3) |

|---|---|---|---|

| Giso./Grock = 0.4% | 24,000 | 0.20 | 10.0 |

| Giso./Grock = 0.2% | 12,000 | 0.20 | 10.0 |

| Giso./Gfault = 0.4% | 800 | 0.20 | 8.0 |

| Giso./Gfault = 0.2% | 400 | 0.20 | 8.0 |

| Material | Modulus of Elasticity (E) (kN/m2) | Poisson’s Ratio (ν) | Unit Weight (γ) (kN/m3) |

|---|---|---|---|

| Isolation for Rock 1 | 12,000 | 0.20 | 11.50 |

| Isolation for Rock 2 | 2000 | 0.20 | 11.50 |

| Model No. | Grout/Isolation Description | Absolute Stresses | |

|---|---|---|---|

| At Rock | At Fault | ||

| Model 1 | Giso./Gfault = 0.4% along tunnel | (52:66)% | (89:185)% |

| Model 2 | Giso./Gfault = 0.4% along tunnel | (−1: −17)% | (19:36)% |

| Model 3 | Giso./Grock = 0.2% and Giso./Gfault = 0.4% | (19:33)% | (28:34)% |

| Model 4 | Giso./Grock = 0.2% and Giso./Gfault = 0.2% | (22:33)% | (18:25)% |

| Model 5 | Giso./Grock = 0.4% and Giso./Gfault = 0.4% | (39:52)% | (30:43)% |

| Model 6 | Giso./Grock = 0.4% and Giso./Gfault = 0.2% | (41:53)% | (19:24)% |

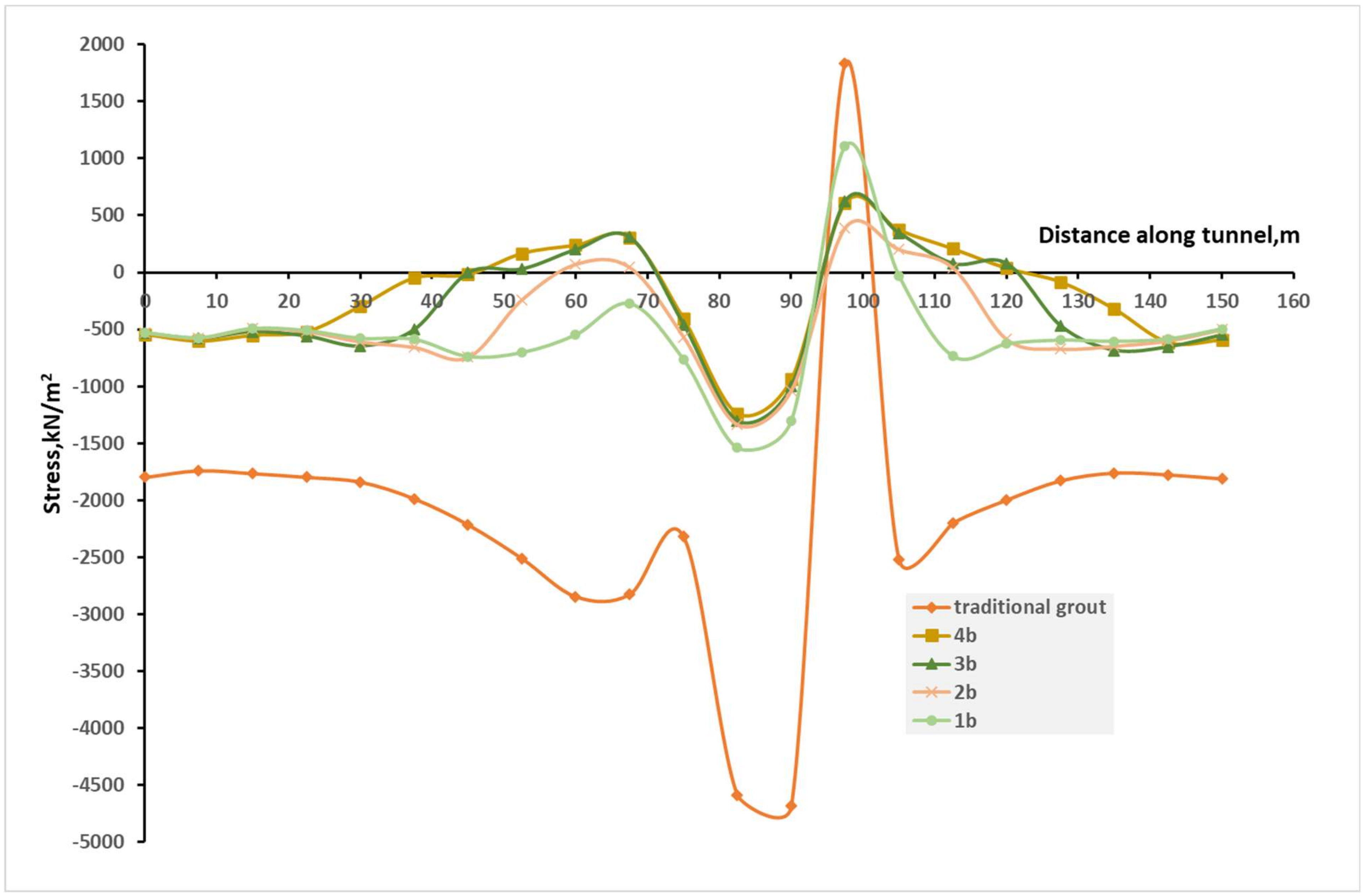

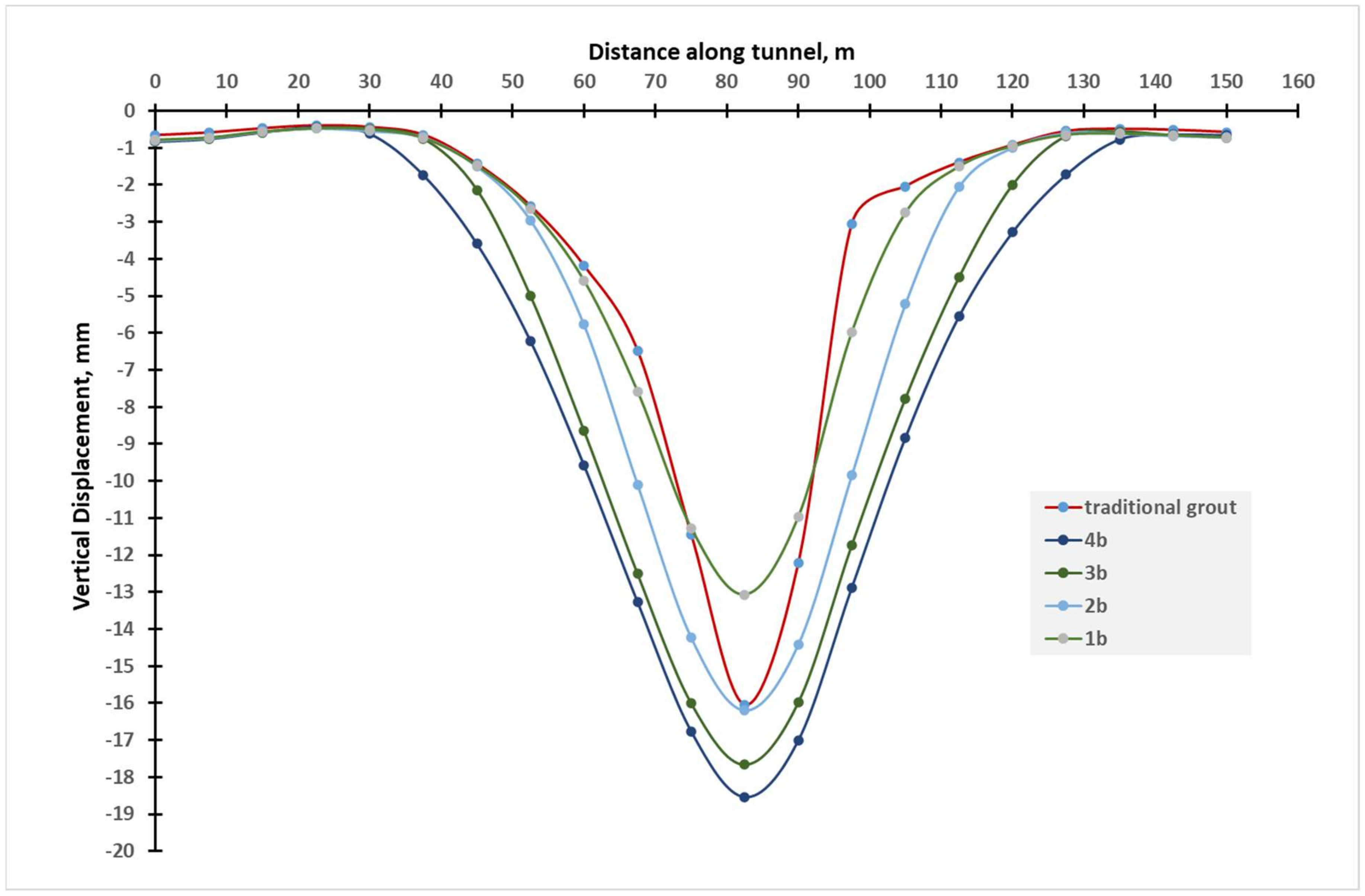

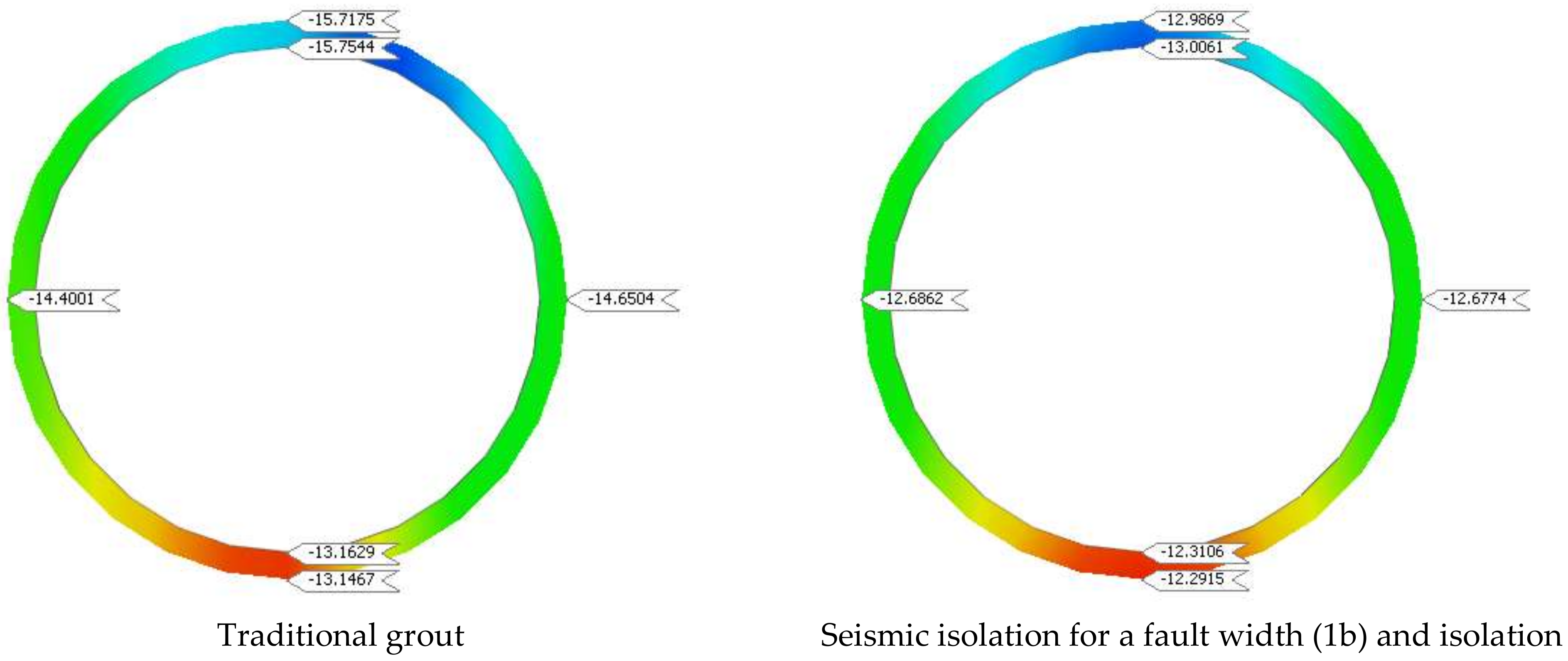

| Model No. | Isolation Width Related to Fault Width (b) | Absolute Stresses | ||

|---|---|---|---|---|

| At Rock | At Fault Hanging from the Wall to the Footwall | |||

| Giso./Grock = 0.2% | Giso./Gfault = 0.4% | Giso./Gfault = 0.4% | ||

| Model 7 | 1b | (19:34)% | ----- | (10:60)% |

| Model 8 | 2b | (28:34)% | (−2:9)% | (−2:21)% |

| Model 9 | 3b | (25:39)% | (−1:−7)% | (−11:34)% |

| Model 10 | 4b | (29:35)% | (−2:18)% | (−11:33)% |

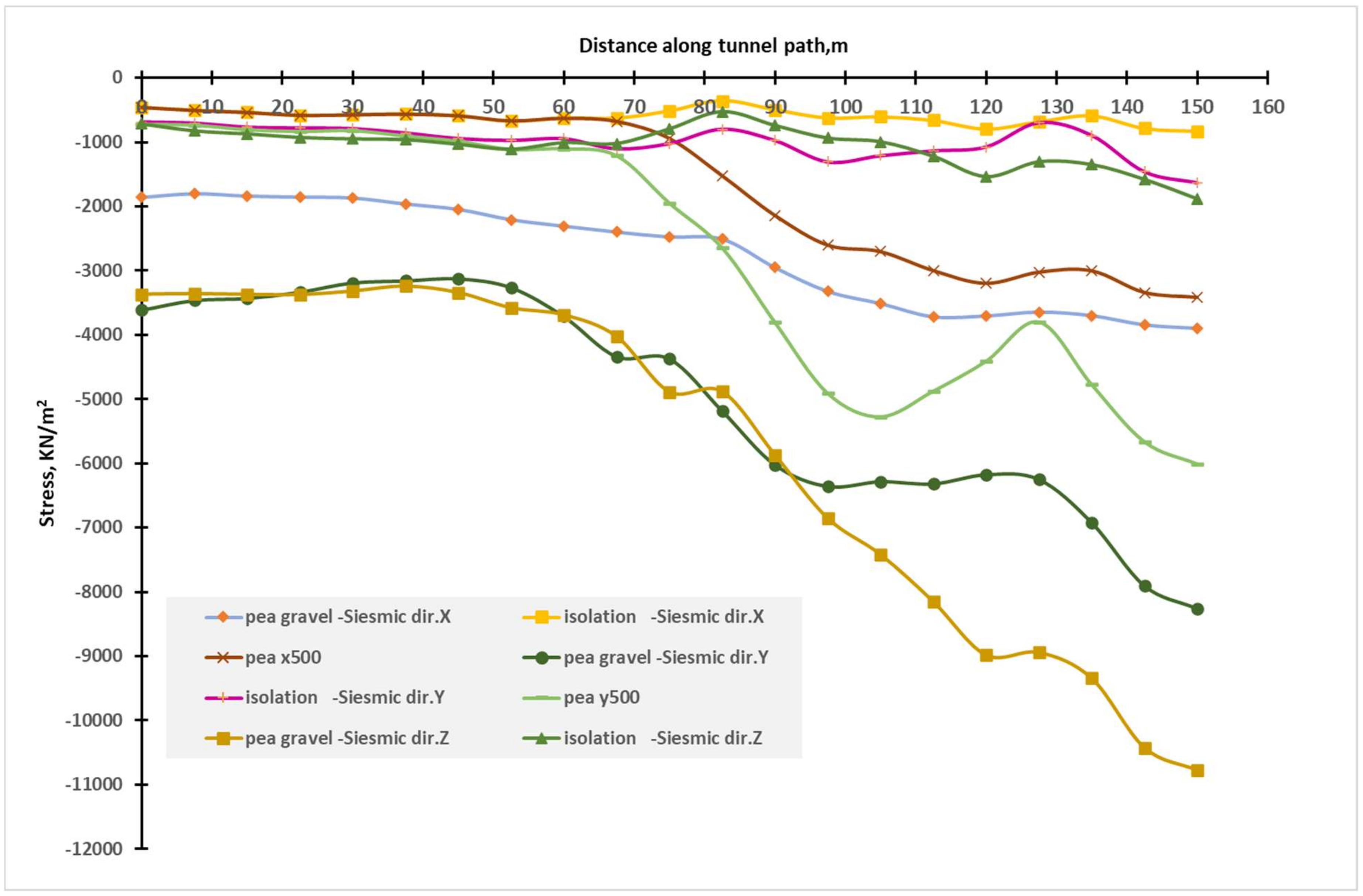

| Seismic Direction | Percentage of Absolute Stresses Using Isolation Compared to Pea Gravel |

|---|---|

| X | 14% to 31% |

| Y | 15% to 30% |

| Z | 11% to 31% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elgamal, A.; Elfaris, N. Enhancement Seismic Response of a Bored Tunnel Using Isolation for the Challenge of a Faulted Rock Crossing. Infrastructures 2024, 9, 66. https://doi.org/10.3390/infrastructures9040066

Elgamal A, Elfaris N. Enhancement Seismic Response of a Bored Tunnel Using Isolation for the Challenge of a Faulted Rock Crossing. Infrastructures. 2024; 9(4):66. https://doi.org/10.3390/infrastructures9040066

Chicago/Turabian StyleElgamal, Ahmed, and Nissreen Elfaris. 2024. "Enhancement Seismic Response of a Bored Tunnel Using Isolation for the Challenge of a Faulted Rock Crossing" Infrastructures 9, no. 4: 66. https://doi.org/10.3390/infrastructures9040066

APA StyleElgamal, A., & Elfaris, N. (2024). Enhancement Seismic Response of a Bored Tunnel Using Isolation for the Challenge of a Faulted Rock Crossing. Infrastructures, 9(4), 66. https://doi.org/10.3390/infrastructures9040066