Enhancing Moisture Damage Resistance in Asphalt Concrete: The Role of Mix Variables, Hydrated Lime and Nanomaterials

Abstract

1. Introduction

2. Materials

2.1. Asphalt Cement

2.2. Aggregate

2.3. Mineral Filler

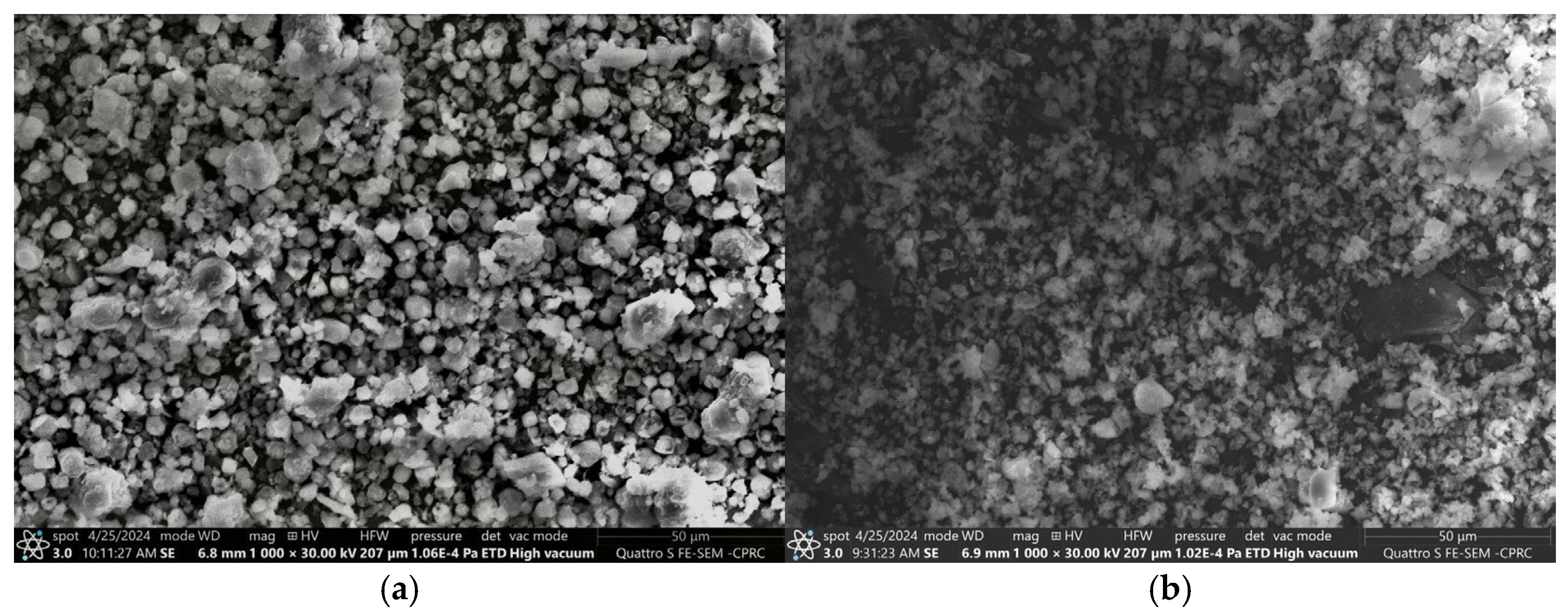

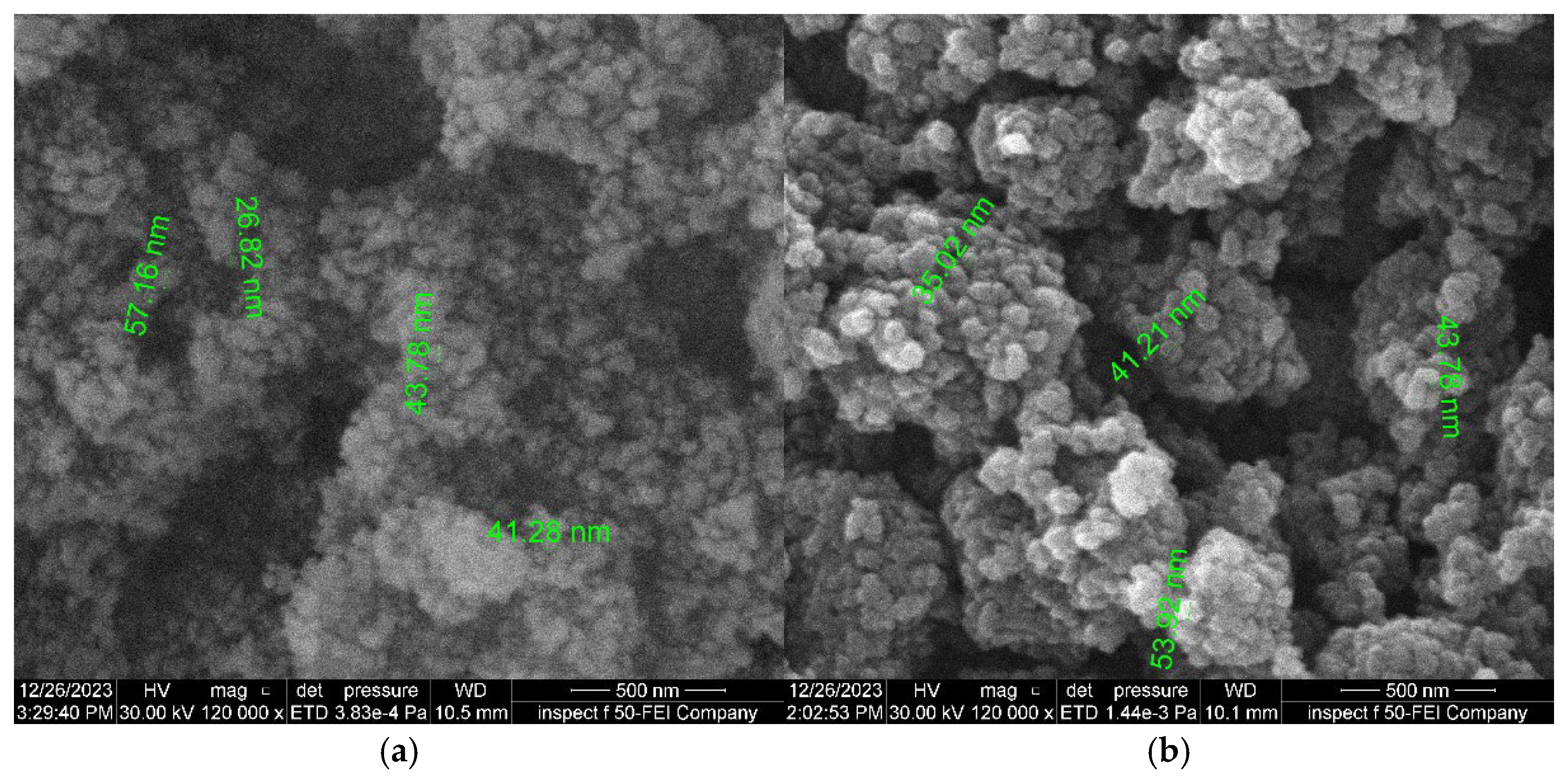

2.4. Nanomaterials Additives

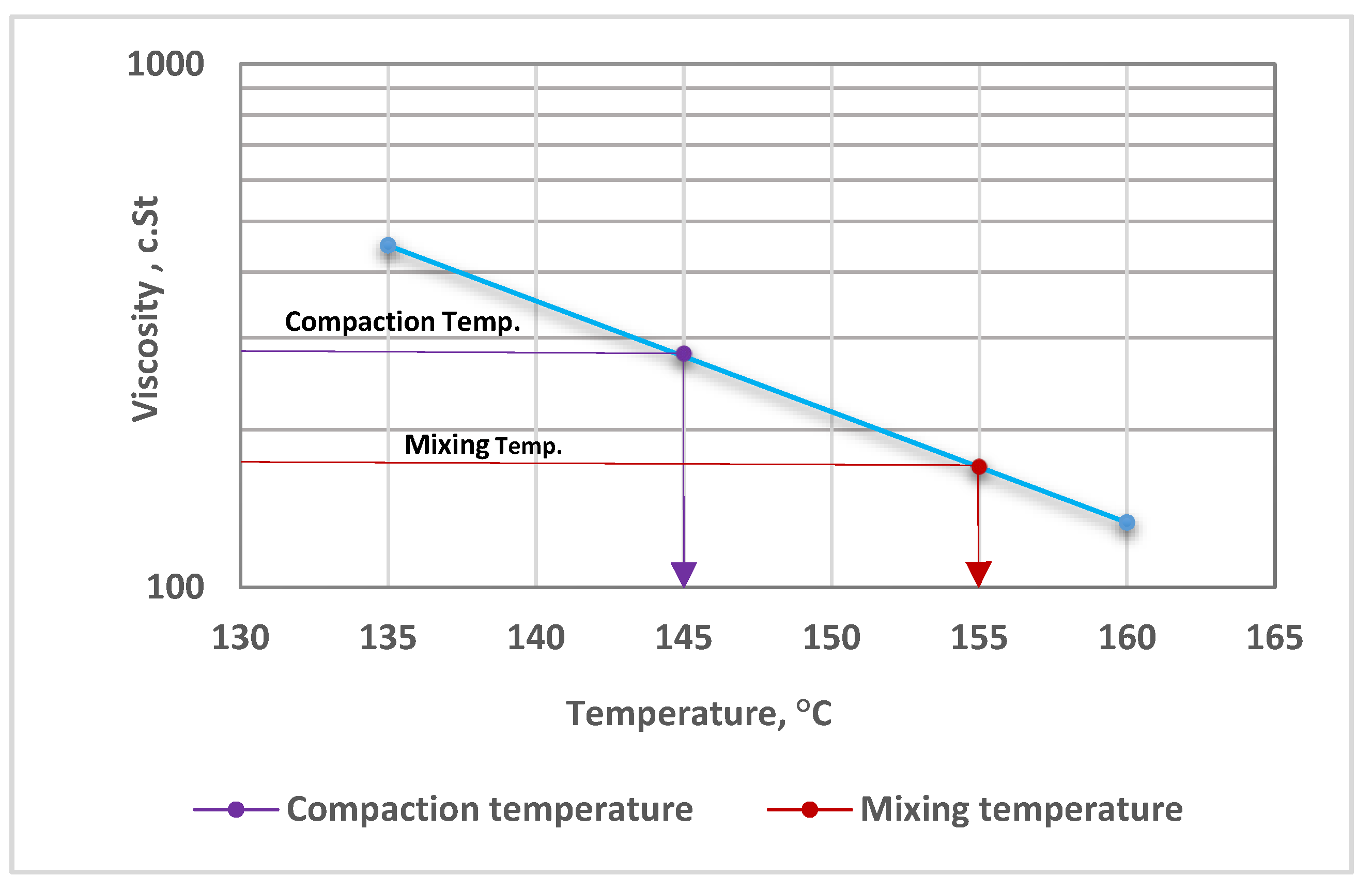

2.5. Nanomaterials Addition Method

3. Experimental Tests

3.1. Physical Binder Test

3.2. Marshall Test

3.3. Indirect Tensile Strength Test

3.4. Compression Strength Test

4. Results and Discussion

4.1. Impact of Nanomaterials on Asphalt Physical Properties

4.2. Marshall Test

4.3. Indirect Tensile Strength Results

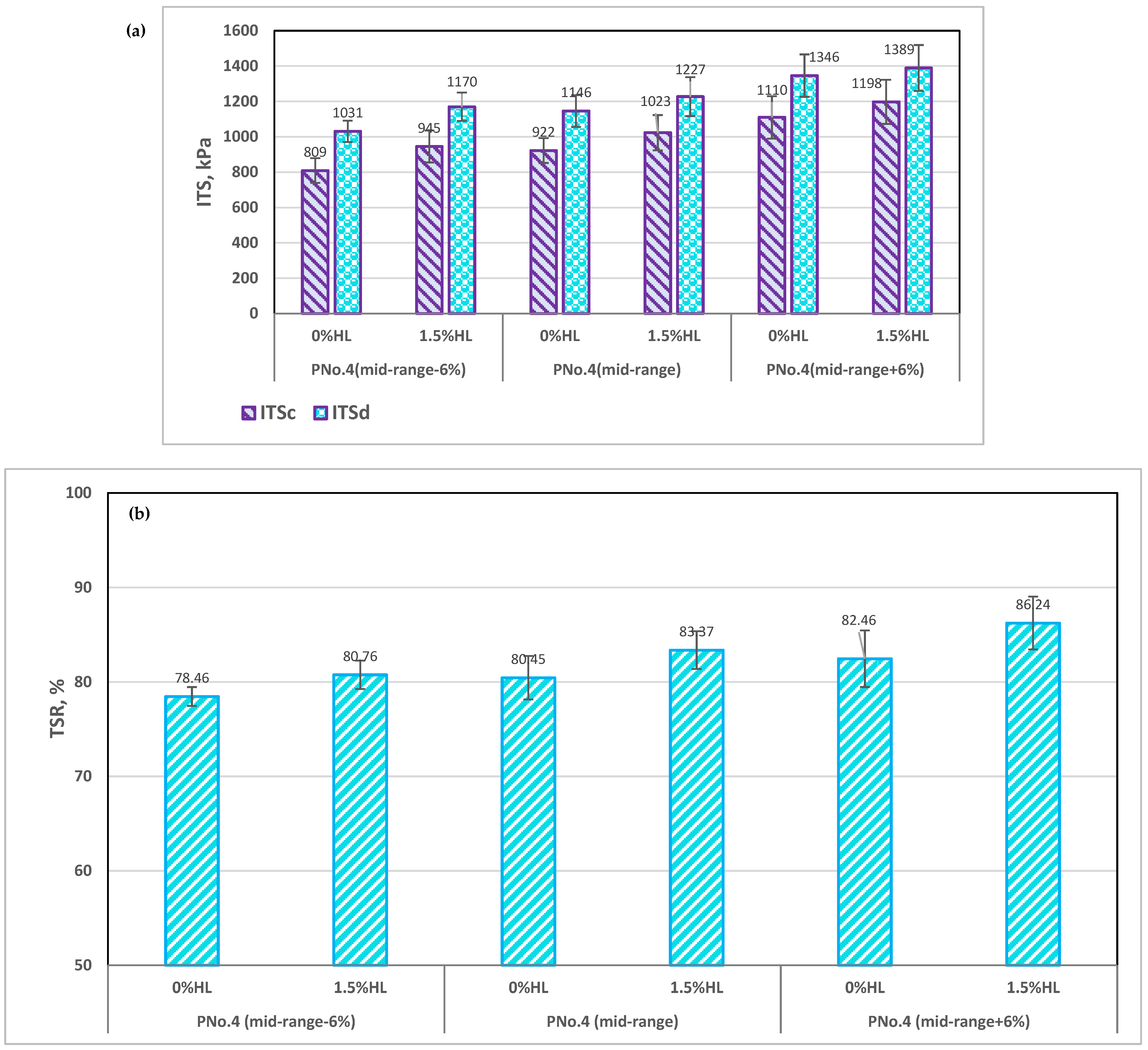

4.3.1. Effect of Mix Variables

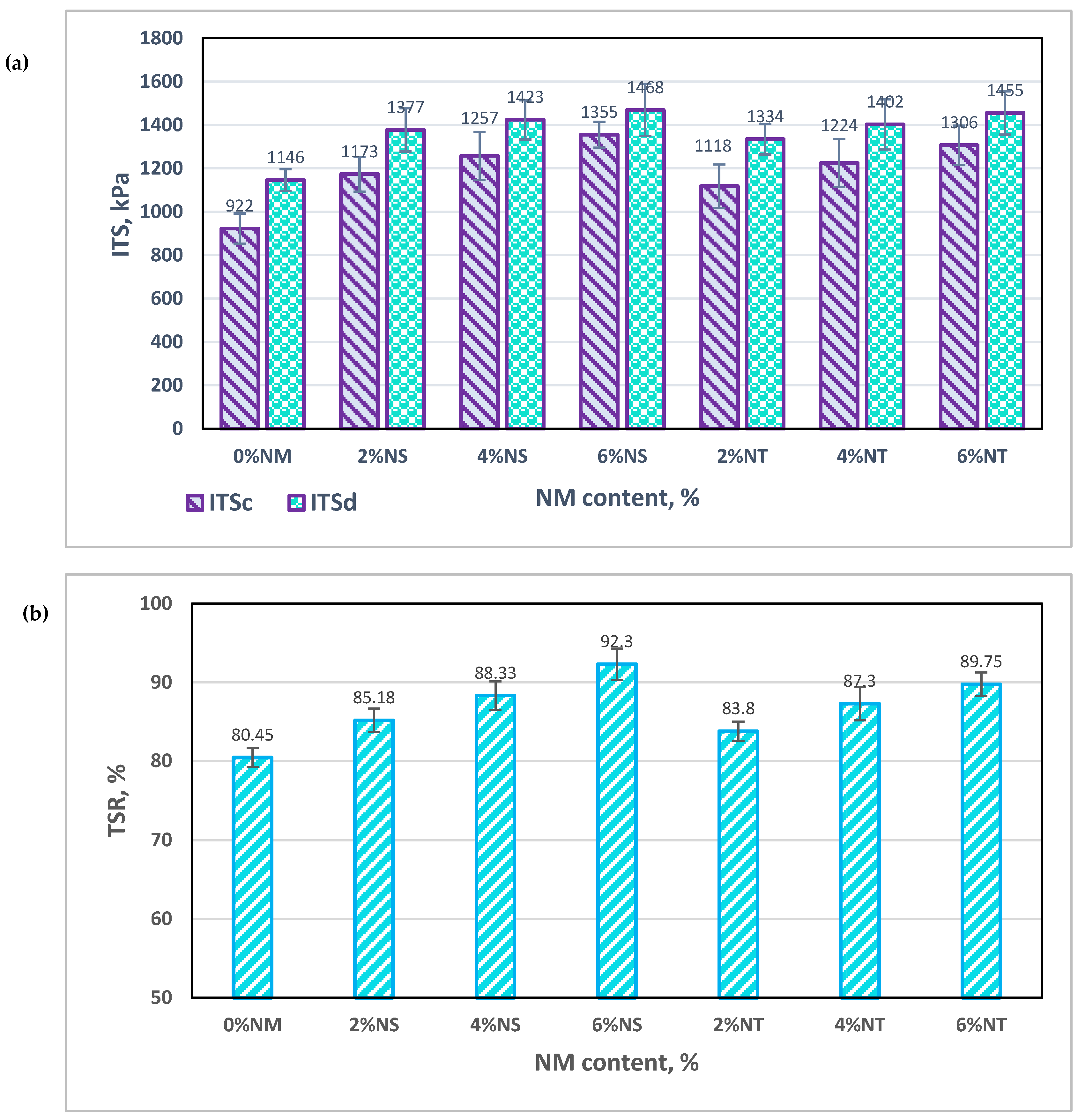

4.3.2. Effect of Modifiers

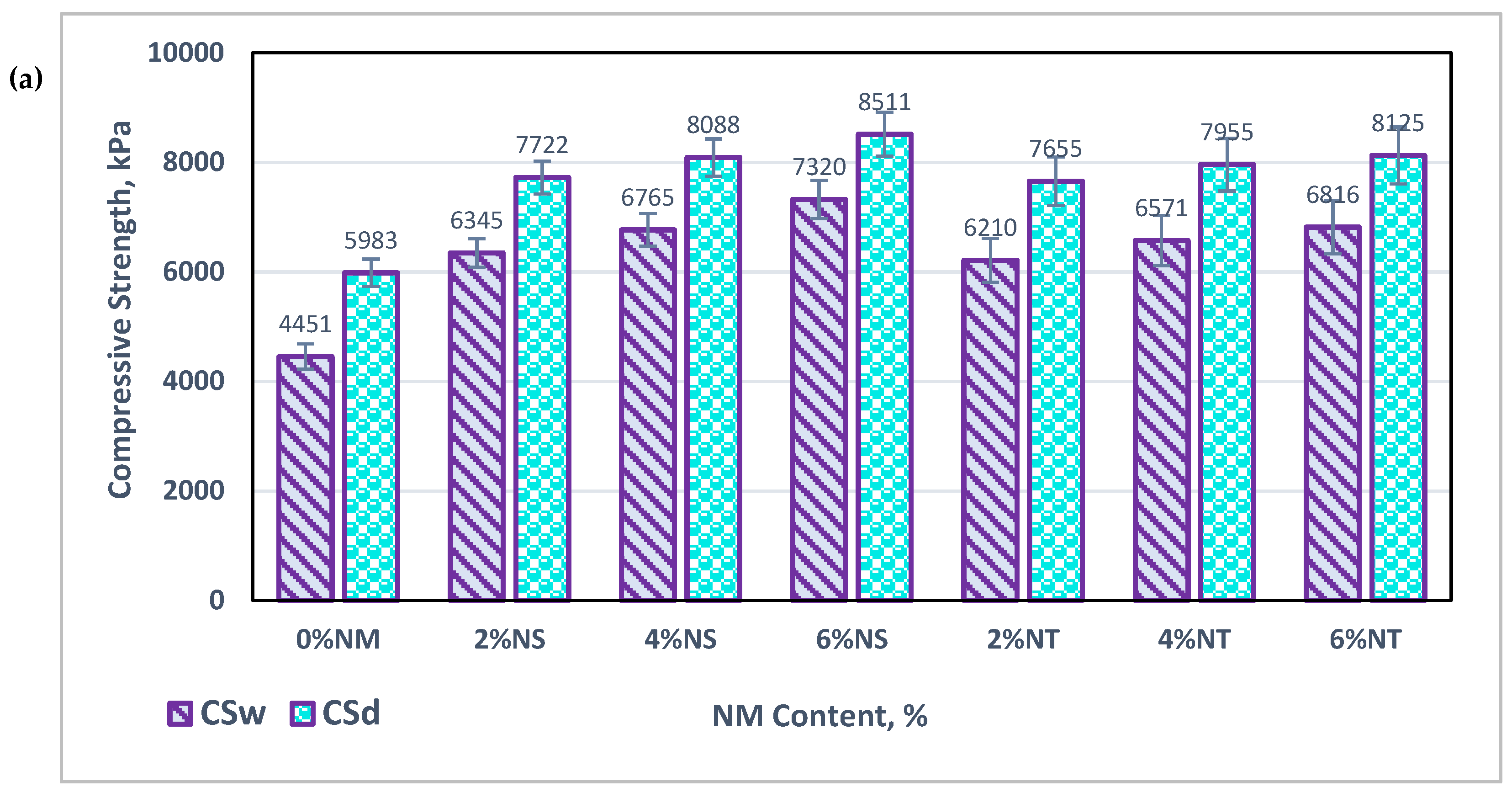

4.3.3. Statistical Analysis

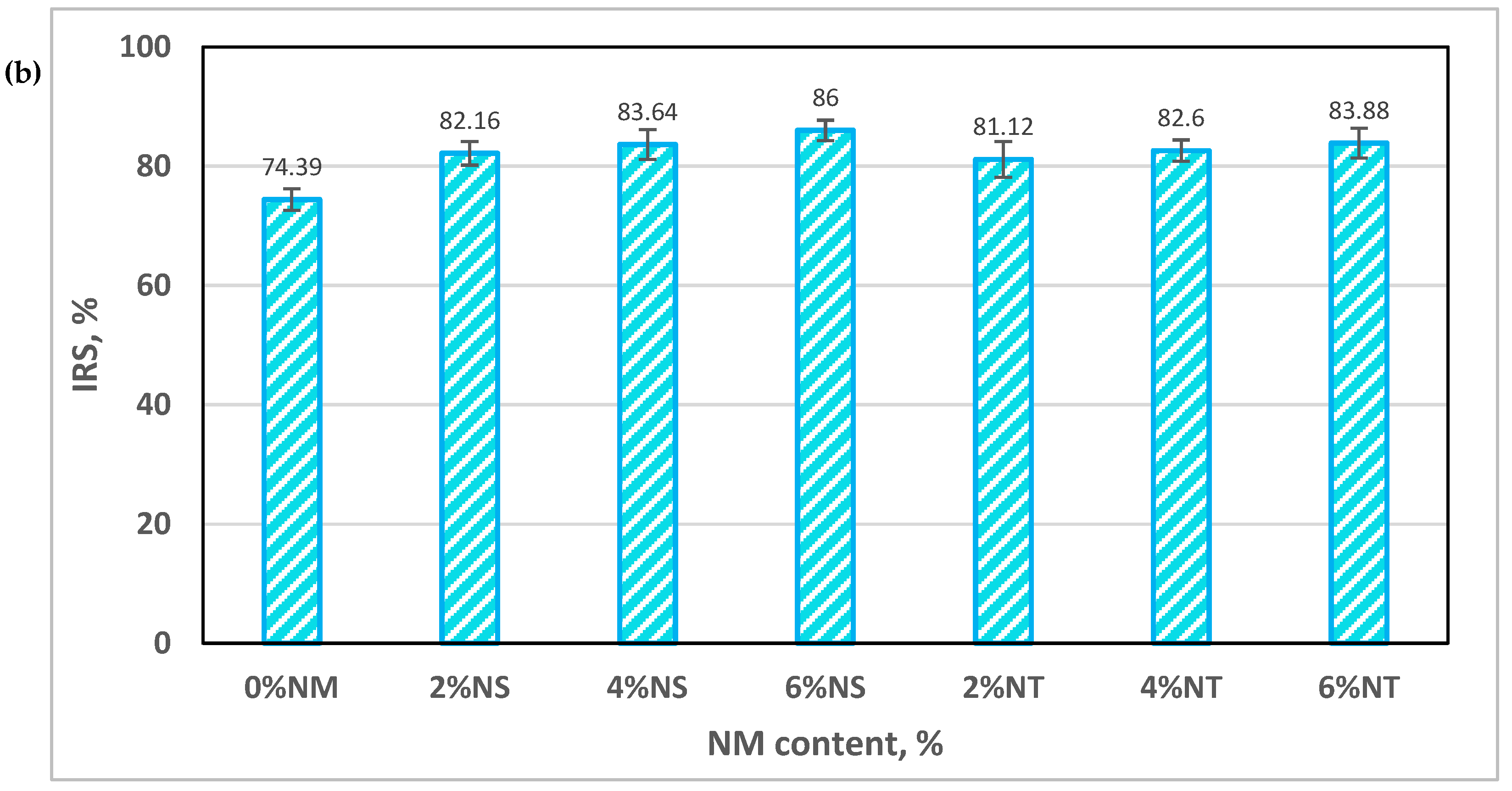

4.4. Index of Retained Strength Test Results

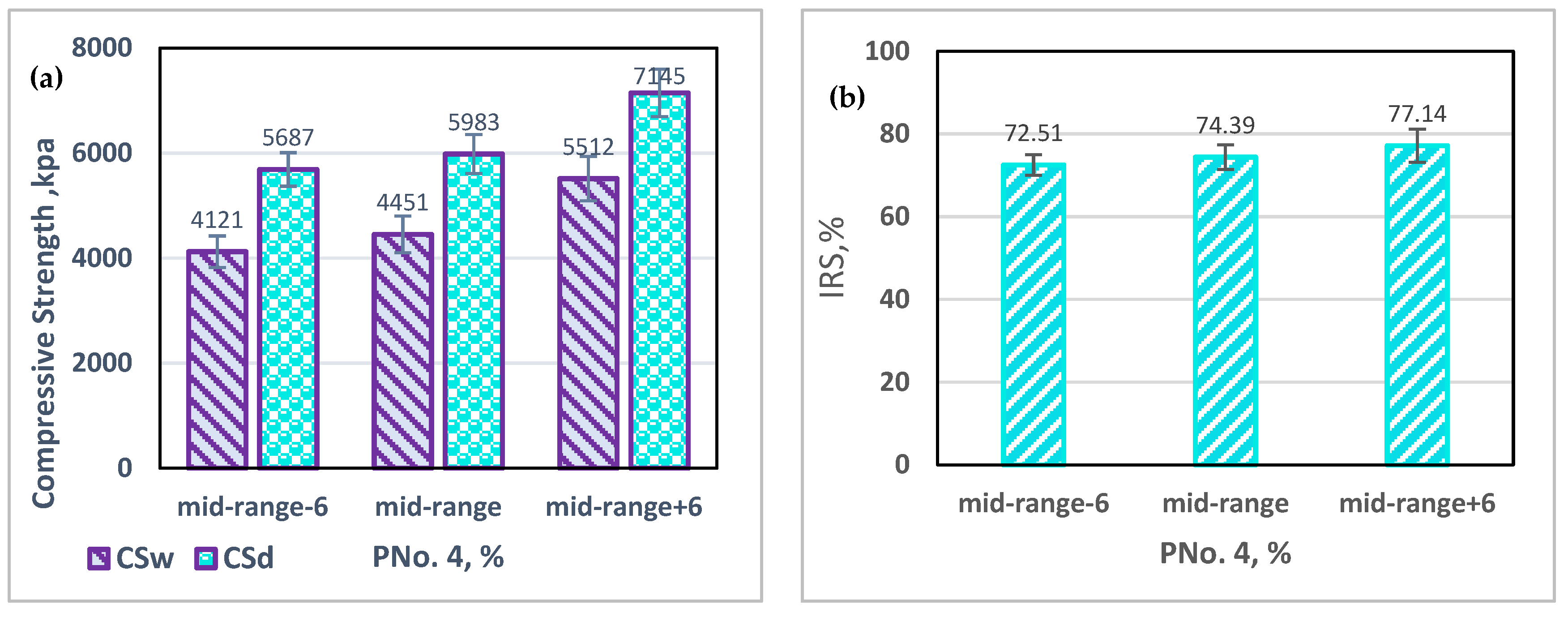

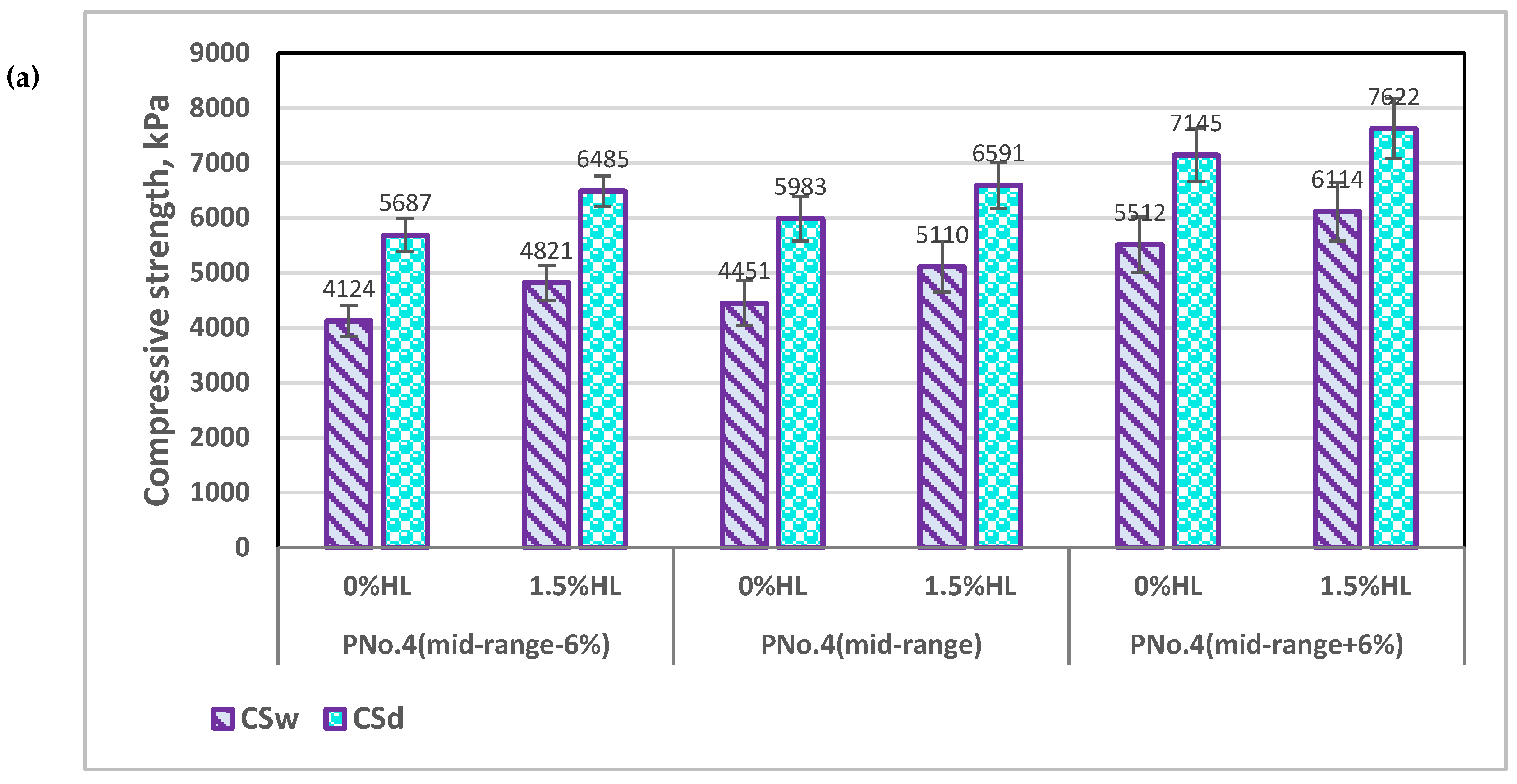

4.4.1. Effect of Mix Variables

4.4.2. Effect of Modifiers

4.4.3. Statistical Analysis

5. Conclusions

- Mix variables, particularly the asphalt content (AC) and aggregate gradation, significantly influenced moisture resistance. The optimal asphalt content (OAC) led to improved performance in TSR and IRS tests, with values of 80.45% and 74.39%, respectively. Fine gradation (mid-range + 6%) provided the best results for the TSR (82.46% at 0% HL and 86.24% at 1.5% HL) and IRS (77.14% at 0% HL and 80.20% at 1.5% HL) due to the dense structure and enhanced particle interlocking.

- Substituting 1.5% HL for LS filler improved moisture resistance compared with mixtures without HL (0% HL), at each PNo. 4 level. The TSR increased by 2.93% at PNo. 4 (mid-range -6%), 3.62% at PNo. 4 (mid-range), and 4.58% at PNo. 4 (mid-range + 6%), while the IRS increased by 2.52%, 4.20%, and 3.96%, respectively.

- The inclusion of nanomaterials (NS and NT) improved the physical properties of the asphalt binder by reducing penetration, raising the softening point, and decreasing ductility. SEM analysis showed that NS particles have a densely packed structure with a large surface area, which contributes to significant improvements in stiffness and resistance to moisture damage. NT particles, on the other hand, displayed spherical cluster shapes that facilitated homogeneous dispersion in the mixture.

- NM additives significantly enhanced the mixture’s performance against moisture susceptibility, as revealed by the TSR and IRS test results. A 6% dosage of NS and NT showed the best performance, with NS performing slightly better than NT. Optimal TSR values of 92.30 and 89.75 and IRS values of 86 and 83.88 were obtained with 6% NS and NT, respectively.

- The ANOVA results provided valuable insights into the variables that had a significant impact on resisting moisture damage. In this study, both mix variables and modifiers were statistically significant with respect to the tensile strength and compression strength tests. It was observed that NS had the highest level of significance, while AC had the lowest significance compared with other variables.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Styer, J.; Tunstall, L.; Landis, A.; Grenfell, J. Innovations in Pavement Design and Engineering: A 2023 Sustainability Review. Heliyon 2024, 10, e33602. [Google Scholar] [CrossRef] [PubMed]

- Omar, H.A.; Yusoff, N.I.M.; Mubaraki, M.; Ceylan, H. Effects of Moisture Damage on Asphalt Mixtures. J. Traffic Transp. Eng. 2020, 7, 600–628. [Google Scholar] [CrossRef]

- Kringos, N.; Scarpas, A. Physical and Mechanical Moisture Susceptibility of Asphaltic Mixtures. Int. J. Solids Struct. 2008, 45, 2671–2685. [Google Scholar] [CrossRef]

- Raza, A.; Khan, I.; Tufail, R.F.; Frankovska, J.; Mushtaq, M.U.; Salmi, A.; Awad, Y.A.; Javed, M.F. Evaluation of Moisture Damage Potential in Hot Mix Asphalt Using Polymeric Aggregate Treatment. Materials 2022, 15, 5437. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zhou, S.; Peng, A. Analysis of Moisture Susceptibility of Foamed Warm Mix Asphalt Based on Cohesion, Adhesion, Bond Strength, and Morphology. J. Clean. Prod. 2020, 277, 123334. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, K.; Liu, K.; Shi, X. Adhesion Characteristics of Graphene Oxide Modified Asphalt Unveiled by Surface Free Energy and AFM-Scanned Micro-Morphology. Constr. Build. Mater. 2020, 244, 118404. [Google Scholar] [CrossRef]

- Liu, X.; Sha, A.; Li, C.; Zhang, Z.; Li, H. Influence of Water on Warm-Modified Asphalt: Views from Adhesion, Morphology and Chemical Characteristics. Constr. Build. Mater. 2020, 264, 120159. [Google Scholar] [CrossRef]

- Notani, M.A.; Hajikarimi, P.; Moghadas Nejad, F.; Khodaii, A. Performance Evaluation of Using Waste Toner in Bituminous Material by Focusing on Aging and Moisture Susceptibility. J. Mater. Civ. Eng. 2021, 33, 04020405. [Google Scholar] [CrossRef]

- Zhou, L.; Huang, W.; Zhang, Y.; Lv, Q.; Yan, C.; Jiao, Y. Evaluation of the Adhesion and Healing Properties of Modified Asphalt Binders. Constr. Build. Mater. 2020, 251, 119026. [Google Scholar] [CrossRef]

- Sengoz, B.; Agar, E. Effect of Asphalt Film Thickness on the Moisture Sensitivity Characteristics of Hot-Mix Asphalt. Build. Environ. 2007, 42, 3621–3628. [Google Scholar] [CrossRef]

- Hasan, E.A.; Abed, Y.H.; Abedali Al-Haddad, A.H. Improved Adhesion Bond between Asphalt Binder-Aggregate as Indicator to Reduced Moisture Damage. J. Phys. Conf. Ser. 2021, 1973, 012059. [Google Scholar] [CrossRef]

- XIONG Rui GUAN Bowen, C.S. Application of Grey Entropy Method to Analyze Influencing Factors of Durability of Asphalt Mixture under Freeze-Thaw and Corrosion. J. Highw. Transp. Res. Dev. 2013, 30, 28–32. [Google Scholar]

- Xiong, R.; Chu, C.; Qiao, N.; Wang, L.; Yang, F.; Sheng, Y.; Guan, B.; Niu, D.; Geng, J.; Chen, H. Performance Evaluation of Asphalt Mixture Exposed to Dynamic Water and Chlorine Salt Erosion. Constr. Build. Mater. 2019, 201, 121–126. [Google Scholar] [CrossRef]

- Ma, Y.; Elseifi, M.A.; Dhakal, N.; Bashar, M.Z.; Zhang, Z. Non-Destructive Detection of Asphalt Concrete Stripping Damage Using Ground Penetrating Radar. Transp. Res. Rec. 2021, 2675, 938–947. [Google Scholar] [CrossRef]

- Lucas Júnior, J.L.O.; Babadopulos, L.F.A.L.; Soares, J.B.; Souza, L.T. Evaluating the Effect of Amine-Based Anti-Stripping Agent on the Fatigue Life of Asphalt Pavements. Int. J. Pavement Eng. 2022, 23, 2785–2795. [Google Scholar] [CrossRef]

- Xiao, R.; Ding, Y.; Polaczyk, P.; Ma, Y.; Jiang, X.; Huang, B. Moisture Damage Mechanism and Material Selection of HMA with Amine Antistripping Agent. Mater. Des. 2022, 220, 110797. [Google Scholar] [CrossRef]

- Yang, S.L.; Baek, C.; Park, H.B. Effect of Aging and Moisture Damage on Fatigue Cracking Properties in Asphalt Mixtures. Appl. Sci. 2021, 11, 10543. [Google Scholar] [CrossRef]

- Ali, Y.; Irfan, M.; Buller, A.S.; Khan, H.A.; Gul, H.M.F. A Binary Logistic Model for Predicting the Tertiary Stage of Permanent Deformation of Conventional Asphalt Concrete Mixtures. Constr. Build. Mater. 2019, 227, 116608. [Google Scholar] [CrossRef]

- Anastasio, S.; Perez Fortes, A.P.; Hoff, I. Effect of Aggregate Petrology on the Durability of Asphalt Pavements. Constr. Build. Mater. 2017, 146, 652–657. [Google Scholar] [CrossRef]

- Othman, M.; Rafiq, M.; Rosli, M. Jurnal Teknologi An Overview of Moisture Damage in Asphalt Mixtures. J. Teknol.-UTM 2015, 4, 125–131. [Google Scholar]

- Sarsam, S.I.; Alwan, A.H. Impact of Moisture Damage on Rutting Resistance, Shear and Tensile Properties of Asphalt Pavement. Int. J. Sci. Res. Knowl. 2014, 2, 453–462. [Google Scholar] [CrossRef]

- Abu Abdo, A.M.; Jung, S.J. Effects of Asphalt Mix Design Properties on Pavement Performance: A Mechanistic Approach. Adv. Civ. Eng. 2016, 2016, 04020405. [Google Scholar] [CrossRef]

- Zeiada, W.; Abu Dabous, S.; Al-Ruzouq, R.; Hamad, K.; Souliman, M.; Mirou, S. Effect of Air Voids and Asphalt Content Changes on Laboratory and Simulated Long-Term Fatigue Performance of Asphalt Concrete Pavements. Innov. Infrastruct. Solut. 2022, 8, 48. [Google Scholar] [CrossRef]

- Ziari, H.; Hajiloo, M. The Effect of Mix Design Method on Performance of Asphalt Mixtures Containing Reclaimed Asphalt Pavement and Recycling Agents: Superpave versus Balanced Mix Design. Case Stud. Constr. Mater. 2023, 18, e01931. [Google Scholar] [CrossRef]

- Kanitpong, K.; Charoentham, N.; Likitlersuang, S. Investigation on the Effects of Gradation and Aggregate Type to Moisture Damage of Warm Mix Asphalt Modified with Sasobit. Int. J. Pavement Eng. 2012, 13, 451–458. [Google Scholar] [CrossRef]

- Aodah, H.; Chandra, S.; Kareem, Y.A. Estimation of Moisture Damage and Permanent Deformation in Asphalt Mixture from Aggregate Gradation. KSCE J. Civ. Eng. 2014, 18, 1655–1663. [Google Scholar]

- Sangsefidi, E.; Ziari, H.; Sangsefidi, M. The Effect of Aggregate Gradation Limits Consideration on Performance Properties and Mixture Design Parameters of Hot Mix Asphalt. KSCE J. Civ. Eng. 2015, 20, 385–392. [Google Scholar] [CrossRef]

- Ezzat, E.N.; Abed, A.H. The Influence of Using Hybrid Polymers, Aggregate Gradation and Fillers on Moisture Sensitivity of Asphaltic Mixtures. Mater. Today Proc. 2020, 20, 493–498. [Google Scholar] [CrossRef]

- Lesueur, D.; Petit, J.; Ritter, H.J. The Mechanisms of Hydrated Lime Modification of Asphalt Mixtures: A State-of-the-Art Review. Road Mater. Pavement Des. 2013, 14, 1–16. [Google Scholar] [CrossRef]

- Preti, F.; Accardo, C.; Gouveia, B.C.S.; Romeo, E.; Tebaldi, G. Influence of High-Surface-Area Hydrated Lime on Cracking Performance of Open-Graded Asphalt Mixtures. Road Mater. Pavement Des. 2021, 22, 2654–2660. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Oyeyi, A.G.; Tighe, S.L. Experimental Assessment of Mineral Filler on the Volumetric Properties and Mechanical Performance of Hma Mixtures. Civ. Eng. J. 2020, 6, 2312–2331. [Google Scholar] [CrossRef]

- Grajales, J.A.; Pérez, L.M.; Schwab, A.P.; Little, D.N. Quantum Chemical Modeling of the Effects of Hydrated Lime (Calcium Hydroxide) as a Filler in Bituminous Materials. ACS Omega 2021, 6, 3130–3139. [Google Scholar] [CrossRef] [PubMed]

- Albayati, A.; Wang, Y.; Haynes, J. Size Effect of Hydrated Lime on the Mechanical Performance of Asphalt Concrete. Materials 2022, 15, 3715. [Google Scholar] [CrossRef] [PubMed]

- Alabady, H.; Abed, A. Effect of Quality and Quantity of Locally Produced Filler on Moisture Damage Hot Asphaltic Mixtures. E3S Web Conf. 2023, 427, 3039. [Google Scholar] [CrossRef]

- Liang, Y.; Bai, T.; Zhou, X.; Wu, F.; Chenxin, C.; Peng, C.; Fuentes, L.; Walubita, L.F.; Li, W.; Wang, X. Assessing the Effects of Different Fillers and Moisture on Asphalt Mixtures’ Mechanical Properties and Performance. Coatings 2023, 13, 288. [Google Scholar] [CrossRef]

- Behiry, A.E.A.E.M. Laboratory Evaluation of Resistance to Moisture Damage in Asphalt Mixtures. Ain Shams Eng. J. 2013, 4, 351–363. [Google Scholar] [CrossRef]

- Zghair, H.; Joni, H.; Hassan, M. Influence of Micro- Size Silica Powder on Physical and Rheological Characteristics of Asphalt Binder. Int. J. Eng. Technol. 2018, 7, 180. [Google Scholar] [CrossRef]

- Tanzadeh, R.; Shafabakhsh, G. Surface Free Energy and Adhesion Energy Evaluation of Modified Bitumen with Recycled Carbon Black (Micro-Nano) from Gases and Petrochemical Waste. Constr. Build. Mater. 2020, 245, 118361. [Google Scholar] [CrossRef]

- Aljbouri, H.J.; Albayati, A.H. Effect of Nanomaterials on the Durability of Hot Mix Asphalt. Transp. Eng. 2023, 11, 100165. [Google Scholar] [CrossRef]

- Diab, A.; You, Z.; Hossain, Z.; Zaman, M. Moisture Susceptibility Evaluation of Nanosize Hydrated Lime-Modified Asphalt-Aggregate Systems Based on Surface Free Energy Concept. Transp. Res. Rec. 2024, 2446, 52–59. [Google Scholar] [CrossRef]

- Wang, Y.; Latief, R.H.; Al-mosawe, H.; Mohammad, H.K.; Albayati, A.; Haynes, J. Influence of Iron Filing Waste on the Performance of Warm Mix Asphalt. Sustainability 2021, 13, 13828. [Google Scholar] [CrossRef]

- Lima, O.; Afonso, C.; Segundo, I.R.; Landi, S.; Homem, N.C.; Freitas, E.; Alcantara, A.; Branco, V.C.; Soares, S.; Soares, J.; et al. Asphalt Binder “Skincare”? Aging Evaluation of an Asphalt Binder Modified by Nano-TiO2. Nanomaterials 2022, 12, 1678. [Google Scholar] [CrossRef] [PubMed]

- Aljbouri, R.Q.; Albayati, A.H. Investigating the Effect of Nanomaterials on the Marshall Properties and Durability of Warm Mix Asphalt. Cogent Eng. 2023, 10, 2269640. [Google Scholar] [CrossRef]

- Li, J.; Tang, F. Effects of Two Metal Nanoparticles on Performance Properties of Asphalt Binder and Stone Matrix Asphalt Mixtures Containing Waste High Density Polyethelene. Constr. Build. Mater. 2023, 401, 132787. [Google Scholar] [CrossRef]

- Yusoff, N.I.M.; Breem, A.A.S.; Alattug, H.N.M.; Hamim, A.; Ahmad, J. The Effects of Moisture Susceptibility and Ageing Conditions on Nano-Silica/Polymer-Modified Asphalt Mixtures. Constr. Build. Mater. 2014, 72, 139–147. [Google Scholar] [CrossRef]

- Fusco, R.; Moretti, L.; Fiore, N.; D’andrea, A. Behavior Evaluation of Bituminous Mixtures Reinforced with Nano-Sized Additives: A Review. Sustainability 2020, 12, 8044. [Google Scholar] [CrossRef]

- Bala, N.; Napiah, M.; Kamaruddin, I. Nanosilica Composite Asphalt Mixtures Performance-Based Design and Optimisation Using Response Surface Methodology. Int. J. Pavement Eng. 2018, 8436, 29–40. [Google Scholar] [CrossRef]

- Yang, S.; Yan, K.; Liu, W. The Effect of Ultraviolet Aging Duration on the Rheological Properties of Sasobit/SBS/Nano-TiO2-Modified Asphalt Binder. Appl. Sci. 2022, 12, 10600. [Google Scholar] [CrossRef]

- Alhamali, D.; Wu, J.; Liu, Q.; Hassan, N.; Md Yusoff, N.I.; Ali, S. Physical and Rheological Characteristics of Polymer Modified Bitumen with Nanosilica Particles. Arab. J. Sci. Eng. 2015, 41, 946–961. [Google Scholar] [CrossRef]

- Azarhoosh, A.; Moghaddas Nejad, F.; Khodaii, A. Evaluation of the Effect of Nano-TiO2 on the Adhesion between Aggregate and Asphalt Binder in Hot Mix Asphalt. Eur. J. Environ. Civ. Eng. 2018, 22, 946–961. [Google Scholar] [CrossRef]

- Saltan, M.; Terzi, S.; Karahancer, S. Examination of Hot Mix Asphalt and Binder Performance Modified with Nano Silica. Constr. Build. Mater. 2017, 156, 976–984. [Google Scholar] [CrossRef]

- Buhari, R.; Abdullah, M.E.; Ahmad, M.K.; Zabidi, N.; Bakar, S.K.A. Moisture Susceptibility of Modified Asphalt Concrete Containing Titanium Dioxide. Int. J. Adv. Trends Comput. Sci. Eng. 2019, 8, 140–143. [Google Scholar] [CrossRef]

- Sezavar, R.; Shafabakhsh, G.; Mirabdolazimi, S.M. New Model of Moisture Susceptibility of Nano Silica-Modified Asphalt Concrete Using GMDH Algorithm. Constr. Build. Mater. 2019, 211, 528–538. [Google Scholar] [CrossRef]

- Mirabdolazimi, S.M.; Kargari, A.H.; Pakenari, M.M. New Achievement in Moisture Sensitivity of Nano-Silica Modified Asphalt Mixture with a Combined Effect of Bitumen Type and Traffic Condition. Int. J. Pavement Res. Technol. 2021, 14, 105–115. [Google Scholar] [CrossRef]

- Dell’Antonio Cadorin, N.; Victor Staub de Melo, J.; Borba Broering, W.; Luiz Manfro, A.; Salgado Barra, B. Asphalt Nanocomposite with Titanium Dioxide: Mechanical, Rheological and Photoactivity Performance. Constr. Build. Mater. 2021, 289, 18–25. [Google Scholar] [CrossRef]

- Masri, K.; Zali, N.; Putra Jaya, R.; Abu Seman, M.; Mohd Hasan, M.R. The Influence of Nano Titanium as Bitumen Modifier in Stone Mastic Asphalt. Adv. Mater. Sci. Eng. 2022, 2022, 4021618. [Google Scholar] [CrossRef]

- Mohammed, A.M.; Abed, A.H. Effect of Nano-TiO2 on Physical and Rheological Properties of Asphalt Cement. Open Eng. 2024, 14, 20220520. [Google Scholar] [CrossRef]

- SCRB/R9; Standard Specifications for Roads and Bridges, Section R/9, Hot-Mix Asphaltic Concrete Pavement. Revised Edition. State Corporation of Roads and Bridges, Ministry of Housing and Construction: Baghdad, Iraq, 2003.

- Shafabakhsh, G.; Mirabdolazimi, S.M.; Sadeghnejad, M. Evaluation the Effect of Nano-TiO2 on the Rutting and Fatigue Behavior of Asphalt Mixtures. Constr. Build. Mater. 2014, 54, 566–571. [Google Scholar] [CrossRef]

- Enieb, M.; Diab, A. Characteristics of Asphalt Binder and Mixture Containing Nanosilica. Int. J. Pavement Res. Technol. 2017, 10, 148–157. [Google Scholar] [CrossRef]

- Taherkhani, H.; Tajdini, M. Comparing the Effects of Nano-Silica and Hydrated Lime on the Properties of Asphalt Concrete. Constr. Build. Mater. 2019, 218, 308–315. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Napiah, M.B.; Sutanto, M.H.; Alaloul, W.S.; Zoorob, S.E.; Usman, A. Influence of Nanosilica Particles on the High-Temperature Performance of Waste Denim Fibre-Modified Bitumen. Int. J. Pavement Eng. 2022, 23, 207–220. [Google Scholar] [CrossRef]

- Mohammed, A.M.; Abed, A.H. Enhancing Asphalt Binder Performance through Nano-SiO2 and Nano-CaCO3 Additives: Rheological and Physical Insights. Case Stud. Constr. Mater. 2023, 19, e02492. [Google Scholar] [CrossRef]

- Albayati, A.H.; Latief, R.H.; Al-Mosawe, H.; Wang, Y. Nano-Additives in Asphalt Binder: Bridging the Gap between Traditional Materials and Modern Requirements. Appl. Sci. 2024, 14, 3998. [Google Scholar] [CrossRef]

- Abo-Qudais, S.; Al-Shweily, H. Effect of Aggregate Properties on Asphalt Mixtures Stripping and Creep Behavior. Constr. Build. Mater. 2007, 21, 1886–1898. [Google Scholar] [CrossRef]

- Ali, S.; Ismael, M. Improving the Moisture Damage Resistance of HMA by Using Ceramic Fiber and Hydrated Lime. Al-Qadisiyah J. Eng. Sci. 2020, 13, 274–283. [Google Scholar]

- Rasheed, S.S.; Joni, H.H.; Al-Rubaee, R.H. Using Nano Silica to Improve Asphalt Mixture Performance. AIP Conf. Proc. 2023, 2775, 060005. [Google Scholar]

- Razavi, S.H.; Kavussi, A. The Role of Nanomaterials in Reducing Moisture Damage of Asphalt Mixes. Constr. Build. Mater. 2020, 239, 117827. [Google Scholar] [CrossRef]

- Taher, Z.K.; Ismael, M.Q. Moisture Susceptibility of Hot Mix Asphalt Mixtures Modified by Nano Silica and Subjected to Aging Process. J. Eng. 2023, 29, 128–143. [Google Scholar] [CrossRef]

- Ahmed, A.H.; Ismael, M.Q. Effect of Hydrated Lime on Moisture Susceptibility of Asphalt Mixtures. J. Eng. 2019, 25, 89–101. [Google Scholar]

- Abd Al Kareem, H.M.; Albayati, A.H. The possibility of minimizing rutting distress in asphalt concrete wearing course. Eng. Technol. Appl. Sci. Res. 2022, 12, 8063–8074. [Google Scholar] [CrossRef]

- Albayati, A.H.; Al-Mosawe, H.M.; Allawi, A.A.; Oukaili, N. Moisture susceptibility of sustainable warm mix asphalt. Adv. Civ. Eng. 2018, 2018, 3109435. [Google Scholar] [CrossRef]

- Albayati, A.; Al-Mosawe, H.; Sukhija, M.; Naidu, A.N. Appraising the synergistic use of recycled asphalt pavement and recycled concrete aggregate for the production of sustainable asphalt concrete. Case Stud. Constr. Mater. 2023, 19, e02237. [Google Scholar] [CrossRef]

| Variables | Description | Results | References |

|---|---|---|---|

| Asphalt content | AC: 4.3%, 4.8%, and 5.3% | The mixes with OAC performed better at withstanding moisture damage under the compressive strength test and double-punch shear test. | [21] |

| OAC and OAC ± 0.5% | Increased AC above the optimum level reduced the friction (interlocking) between aggregate particles, resulting in a drawback in asphalt concrete mixture performance. | [22] | |

| Two-level content (4.2% and 5.2%) | A lower AC proved to be more effective in withstanding asphalt mixture distress. | [23] | |

| OAC and OAC ± 0.6% | The findings indicated that the mixes formed with OAC and OAC + 0.6% meet the required moisture damage resistance (TSR ≥ 80%). | [24] | |

| Aggregate gradation | Two aggregate types (slag and granite) with fine and coarse gradations | Mixtures with a finer gradation tended to be less susceptible to moisture damage than mixes with a coarser gradation. | [25] |

| Dense bituminous macadam and bituminous concrete were utilized with three different gradations (finer, coarser, and normal) for each mix. | The mixes with fine gradations (upper limit) were better than the mixes with medium or lower gradations regarding Marshall properties, tensile strength ratio, and permanent deformation for both types of mixes. | [26] | |

| Lower limit, mid-range, and upper limit gradations were attempted. | Lower gradations demonstrated better performance in terms of moisture damage and permanent deformation. | [27] | |

| A coarse mix and a fine mix of aggregates were chosen to create the overall structure. | This study inferred that finer-gradation blends exhibit greater resistance to moisture damage in comparison with coarser-gradation combinations. | [28] | |

| HL addition by weight of the filler | HL | The results indicated significant improvements in aggregate bonding and mixture strength. | [29,30] |

| HL | The addition of 2.5% HL can significantly improve asphalt mixtures’ resistance to water, freezing, and thawing cracks. | [31] | |

| HL | HL can interact with asphalt functional groups to create a waterproofing compound that effectively reduces moisture in mixtures. | [32] | |

| HL | Three different sizes of HL were used: micro-, sub-nano-, and nanoscale. This investigation showed a significant correlation between the size of the HL particles and the asphalt mixtures’ ability to mitigate distress. | [33] | |

| HL and cement kiln dust | The mixes containing HL and cement kiln dust had a higher tensile strength ratio than those with no additions. | [34] | |

| Cement, brake pad powder, LS, and HL | HL performed better on pavements in terms of withstanding moisture damage. | [35] |

| NM | NM Percent (% by Weight of Asphalt) | Results | References |

|---|---|---|---|

| NS | 0, 2, 4, 6 | The optimal dosage for enhancing the mixture’s performance was 4% NS, and the results indicated that NS considerably reduces sensitivity to oxidative aging. | [45] |

| NS | 0, 2, 4, 6 | The viscosity of the modified bitumen with 6% NS was significantly increased compared with that of the neat asphalt. Additionally, storage stability improved at the same percent, which preserved the binder stability at high temperatures. | [49] |

| NT | 0, 3, 6 | NT strengthened the adhesion between the aggregate and asphalt. Moreover, the asphalt pavement distress was reduced. | [50] |

| NS | 0, 0.1, 0.3, 0.5 | SEM images revealed a uniform distribution of the NS throughout the asphalt matrix. The 0.3% NS dosage had better moisture damage resistance, with an increment of 26.25% compared with the non-NS asphalt mixture. | [51] |

| NT | 0, 2, 4, 6, 8, 10 | The bitumen’s consistency properties (penetration and softening point) were greatly enhanced. NT increased the modified asphalt binder stiffness. Samples including NT increased the mixture’s resistance to water. | [52] |

| NS | 0, 0.2, 0.4, 0.7, 0.9 | Indirect tensile strength and compressive strength were greatly improved when employing NS as an anti-stripping agent. | [53] |

| NS | 0, 0.2, 0.4, 0.7, 0.9 | Incorporating NS increased the asphalt mixture’s resistance to moisture sensitivity at various air void contents (4%, 5%, and 6%). | [54] |

| NT | 3, 6, 9, 12, 15 | The asphalt binder’s mechanical and rheological characteristics were improved by adding the photocatalytic semiconductor nano-TiO2. | [55] |

| NT | 0, 1, 2, 3, 4, 5 | The stone–mastic asphalt’s mechanical characteristics were improved by incorporating 3% NT. There was a 3% to 5% NT optimum value in enhancing the consistency properties of bitumen (penetration and softening point). | [56] |

| NT | 0, 1, 3, 5, 7 | Viscosity was increased and bituminous sensitivity was decreased with the inclusion of NT. Adding 5% NT improved the physical characteristics of the asphalt and its resistance to fatigue cracking and rutting. | [57] |

| Test | Units | ASTM Designation | Result | SCRB Specification |

|---|---|---|---|---|

| Penetration | 1⁄10 mm | D5 | 44 | 40–50 |

| Ductility | cm | D113 | 138 | ≥100 |

| Softening point (ring and ball) | °C | D36 | 52 | ----- |

| Kinematics viscosity, at 135 °C | Pa.s | D2170 | 450 | ≥400 |

| Flash point (Cleveland open cup) | °C | D92 | 249 | ≥232 |

| Specific gravity | ----- | D70 | 1.03 | ----- |

| Residue from thin-film oven test. | ||||

| Retained penetration of original (%) | 1⁄10 mm | D5 | 63 | >55 |

| Ductility | cm | D113 | 76 | >25 |

| Test | ASTM Specification | Result | SCRB Specification |

|---|---|---|---|

| Coarse aggregate | |||

| Bulk specific gravity | C127 | 2.610 | ----- |

| Apparent specific gravity | C127 | 2.642 | ----- |

| Water absorption | C127 | 0.54 | ----- |

| Los Angeles abrasion % | C131 | 16. 6 | 30 max |

| Fine aggregate | |||

| Bulk specific gravity | C128 | 2.651 | ------ |

| Apparent specific gravity | C128 | 2.684 | ------ |

| Water absorption | C128 | 0.723 | ------- |

| Material Property | Limestone Dust | Hydrated Lime |

|---|---|---|

| Specific gravity | 2.72 | 2.42 |

| Passing No.200 (%) | 93 | 98 |

| Surface area (m2/gm) | 244 | 398 |

| Properties | Nanomaterials | |

|---|---|---|

| NS | NT | |

| Chemical formula | SiO2 | TiO2 |

| Appearance | White powder | White powder |

| Average particle size, nm | 25~60 | 20~55 |

| Specific surface area, m2/gm | 190~250 | 120~160 |

| Purity, % | 99.8 | 99.9 |

| Meting point, °C | 2030 | 1730 |

| Bulk density, g/mL | 0.08 | 0.51 |

| Molecule wt., g/mol | 60.08 | 85.42 |

| Element | Atomic % | Atomic % Error | Weight % | Weight % Error |

|---|---|---|---|---|

| Si | 29.9 | 0.1 | 42.7 | 0.1 |

| O | 69.7 | 0.4 | 56.6 | 0.3 |

| Ca | 0.0 | 0.0 | 0.7 | 0.0 |

| Ci | 0.3 | 0.0 | 0.1 | 0.0 |

| Element | Atomic % | Atomic % Error | Weight % | Weight % Error |

|---|---|---|---|---|

| Ti | 18.2 | 0.1 | 39.4 | 0.2 |

| O | 79.2 | 1.3 | 57.1 | 0.9 |

| Mg | 1.2 | 0.1 | 1.3 | 0.1 |

| Si | 0.5 | 0.0 | 0.6 | 0.0 |

| S | 0.4 | 0.0 | 0.5 | 0.0 |

| Ca | 0.4 | 0.0 | 0.6 | 0.0 |

| V | 0.2 | 0.0 | 0.5 | 0.1 |

| Nanoparticles | Temperature, °C | Time, min | Speed, rpm | Percent |

|---|---|---|---|---|

| NS | 150 ± 5 | 60 | 3000 | (2%, 4%, and 6%) |

| NT | 155 ± 5 | 30 | 3500 | (2%, 4%, and 6%) |

| Variables | Mixtures | Tests |

|---|---|---|

| Asphalt content | OAC − 0.5% | Modified binder tests: Penetration test (ASTM D5) Softening point test (ASTM D36) Ductility test (ASTM D113) Asphalt concrete tests: Tensile strength ratio test (ASTM D4867) Index of retained strength test (ASTM D1075) |

| OAC | ||

| OAC + 0.5% | ||

| Aggregate gradation (PNo. 4) | Mid-range -6% | |

| Mid-range | ||

| Mid-range + 6% | ||

| Hydrated lime at PNo. 4 levels | 0%HL + PNo. 4 (mid-range -6%) | |

| 0%HL + PNo. 4 (mid-range) | ||

| 0%HL + PNo. 4 (mid-range + 6%) | ||

| 1.5%HL + PNo. 4 (mid-range -6%) | ||

| 1.5%HL + PNo. 4 (mid-range) | ||

| 1.5%HL + PNo. 4 (mid-range + 6%) | ||

| Nano-silica | 0%NS | |

| 2%NS | ||

| 4%NS | ||

| 6%NS | ||

| Nano-titanium | 0%NT | |

| 2%NT | ||

| 4%NT | ||

| 6%NT |

| Source | DF | Adj SS | Adj MS | f-Value | p-Value | f Critical |

|---|---|---|---|---|---|---|

| PNo. 4 | 2 | 22.473 | 11.237 | 60.92 | 0.004 | 9.27 |

| AC | 2 | 12.544 | 6.272 | 34.00 | 0.009 | |

| HL | 1 | 14.920 | 14.920 | 80.89 | 0.003 | |

| NS | 3 | 116.644 | 38.881 | 210.79 | 0.001 | |

| NT | 3 | 75.925 | 25.308 | 137.21 | 0.001 | |

| Error | 3 | 0.553 | 0.184 | |||

| Lack-of-fit | 2 | 0.553 | 0.276 | * | * | |

| Pure error | 1 | 0.000 | 0.0000 | |||

| Total | 14 | 291.679 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value | F-Critical |

|---|---|---|---|---|---|---|

| PNo. 4 | 2 | 27.553 | 13.777 | 73.03 | 0.003 | 9.27 |

| AC | 2 | 7.226 | 3.613 | 19.15 | 0.02 | |

| HL | 1 | 12.322 | 12.322 | 65.32 | 0.004 | |

| NS | 3 | 128.155 | 42.718 | 226.46 | 0.000 | |

| NT | 3 | 91.226 | 30.408 | 161.20 | 0.001 | |

| Error | 3 | 0.566 | 0.188 | |||

| Lack-of-fit | 2 | 0.566 | 0.283 | * | * | |

| Pure error | 1 | 0.000 | 0.000 | |||

| Total | 14 | 320.873 |

| Mixture Type | TSR | IRS |

|---|---|---|

| Mix variables | ||

| Mixture at OAC | 80.45 | 74.39 |

| PNo. 4 (mid-range + 6%) | 82.46 | 77.14 |

| Modifiers | ||

| PNo. 4 (mid-range + 6%) + 1.5%HL | 86.24 | 80.20 |

| 6% NS | 92.30 | 86 |

| 6% NT | 89.75 | 83.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adwar, N.N.; Albayati, A.H. Enhancing Moisture Damage Resistance in Asphalt Concrete: The Role of Mix Variables, Hydrated Lime and Nanomaterials. Infrastructures 2024, 9, 173. https://doi.org/10.3390/infrastructures9100173

Adwar NN, Albayati AH. Enhancing Moisture Damage Resistance in Asphalt Concrete: The Role of Mix Variables, Hydrated Lime and Nanomaterials. Infrastructures. 2024; 9(10):173. https://doi.org/10.3390/infrastructures9100173

Chicago/Turabian StyleAdwar, Noor N., and Amjad H. Albayati. 2024. "Enhancing Moisture Damage Resistance in Asphalt Concrete: The Role of Mix Variables, Hydrated Lime and Nanomaterials" Infrastructures 9, no. 10: 173. https://doi.org/10.3390/infrastructures9100173

APA StyleAdwar, N. N., & Albayati, A. H. (2024). Enhancing Moisture Damage Resistance in Asphalt Concrete: The Role of Mix Variables, Hydrated Lime and Nanomaterials. Infrastructures, 9(10), 173. https://doi.org/10.3390/infrastructures9100173