Improved Alkali–Silica Reaction Forecast in Concrete Infrastructures through Stochastic Climate Change Impact Analysis

Abstract

1. Introduction

2. Computational Methods

- A stochastic analysis of the weather parameters to account for the extreme events of climate change;

- ASR chemophysics in a partially or variably saturated porous media to account for the uncertain moisture access;

- Thermal equation development to account for the annual seasonal variation and global warming impact;

- Numerical analysis with finite element method (FEM) for long-term-damage assessment of concrete mesostructures under the influence of ASR expansion.

2.1. ASR Chemophysics

2.1.1. Mass and Momentum Balance Equation

2.1.2. Richards’ Equation

2.1.3. Retention Model

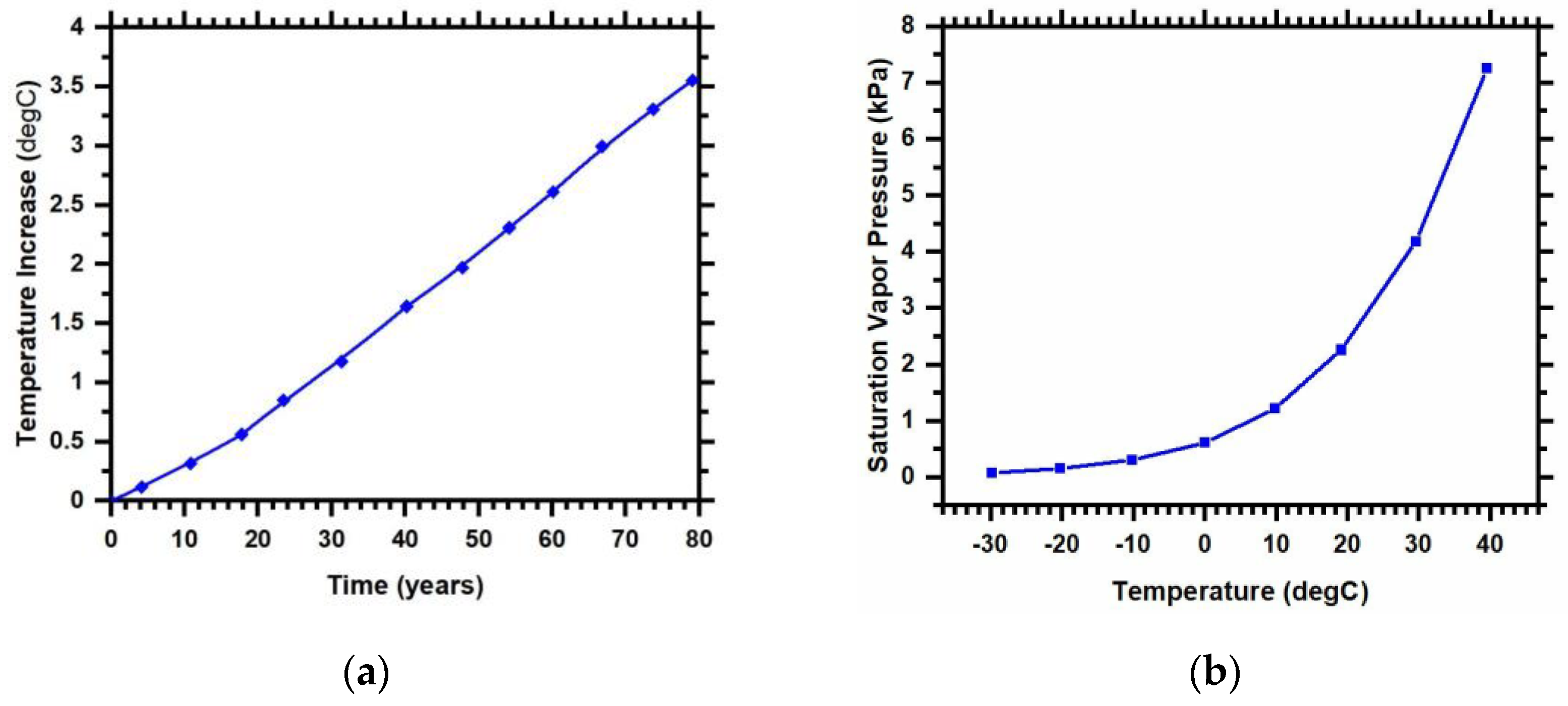

2.2. Thermal Equation Development

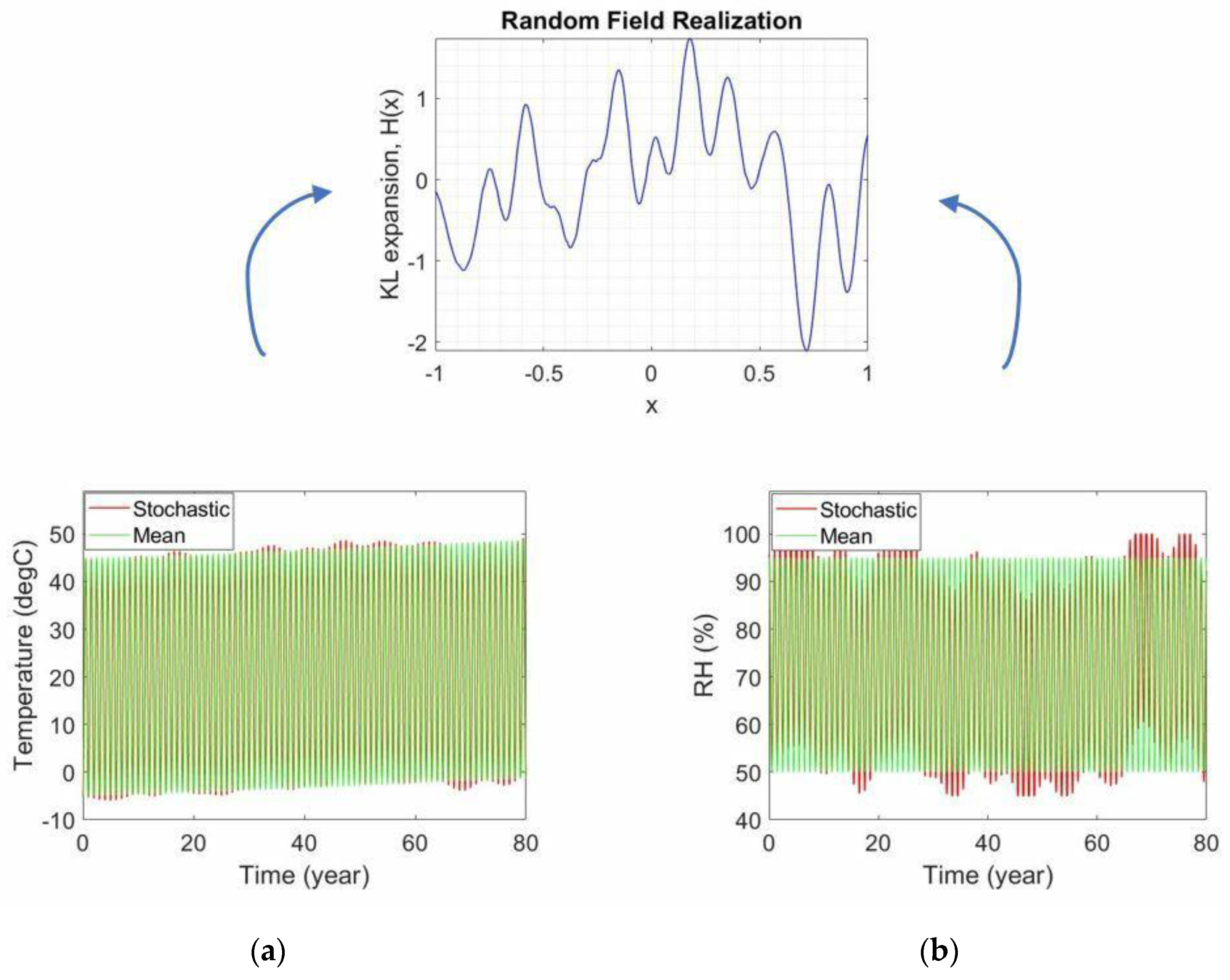

2.3. Stochastic Analysis

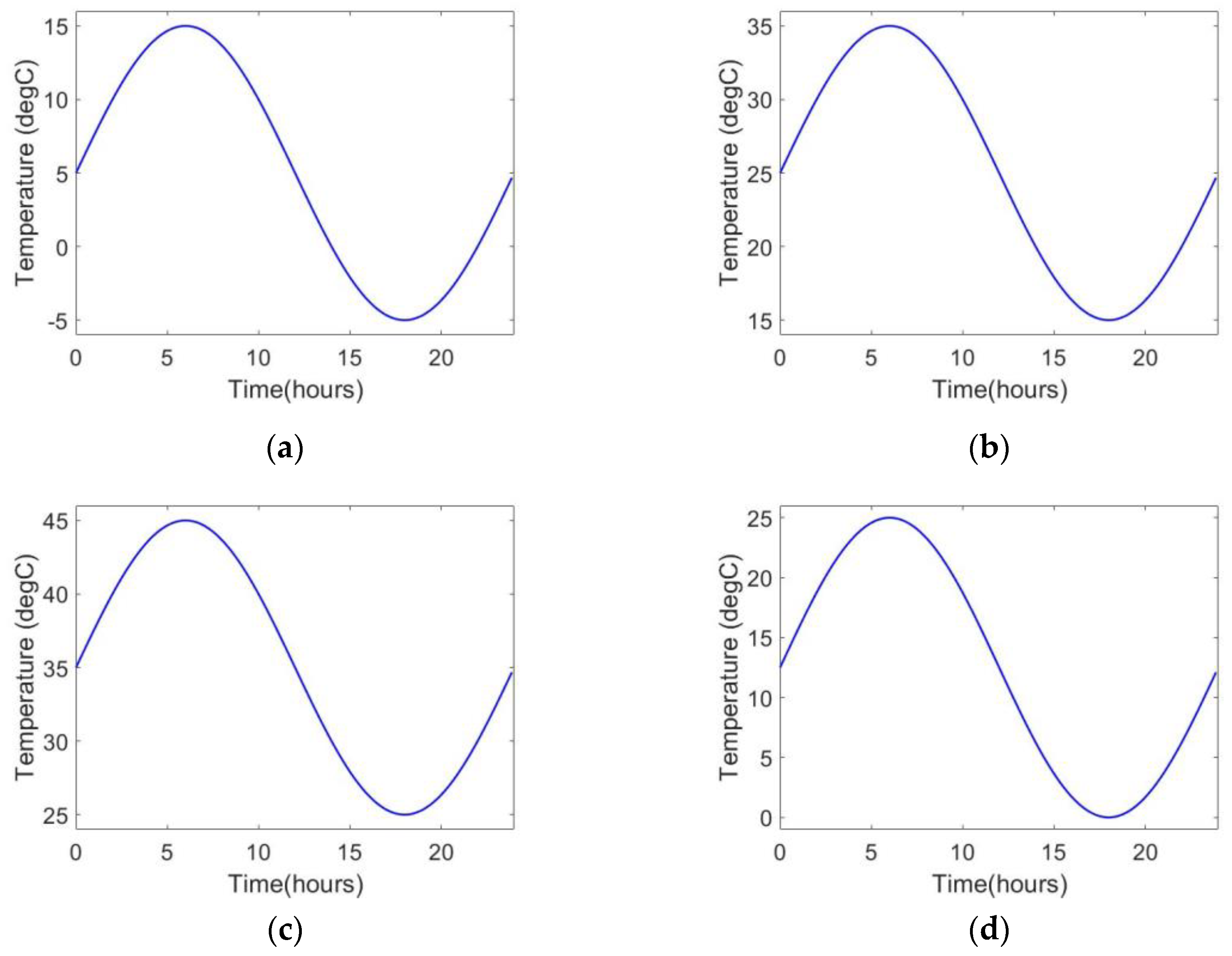

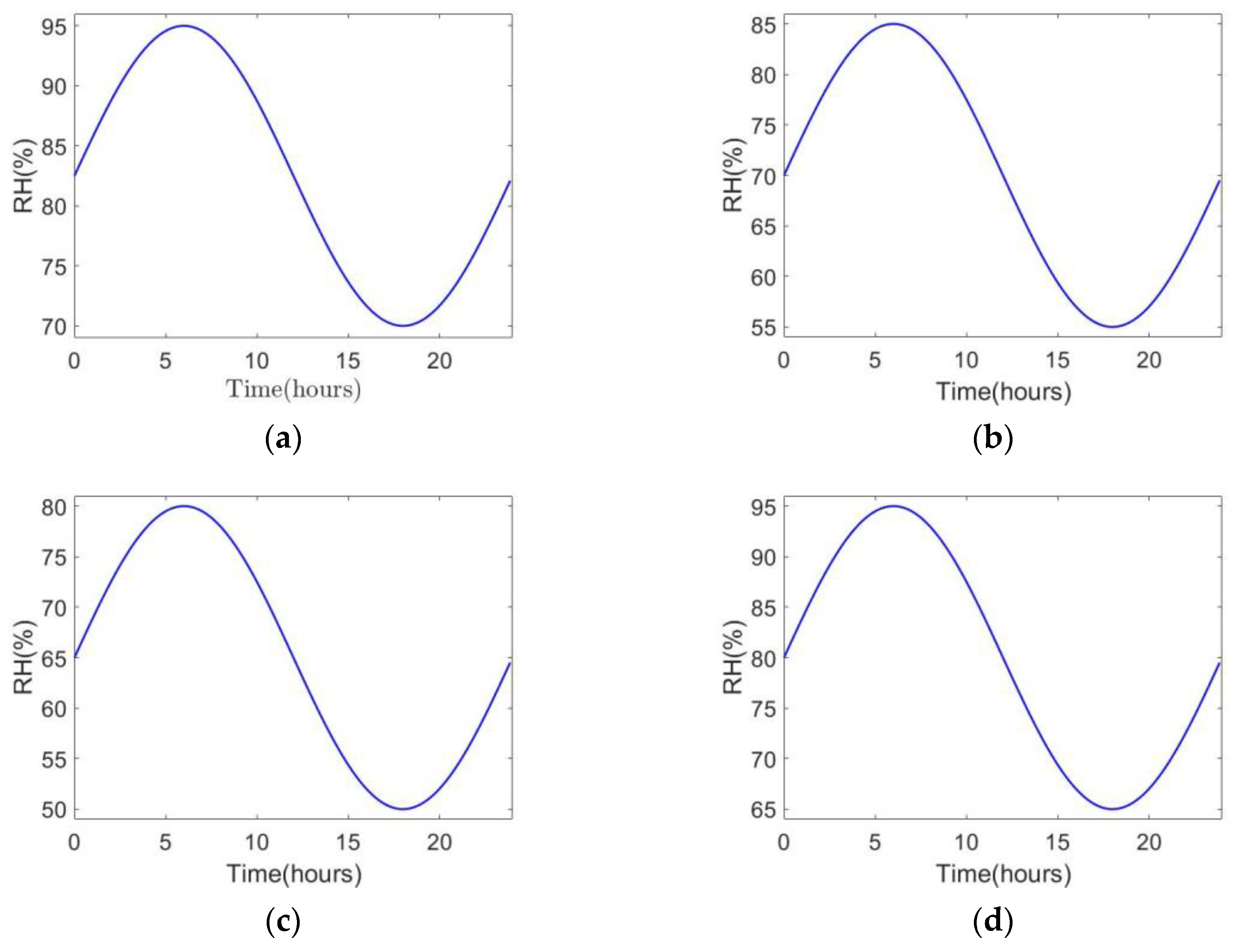

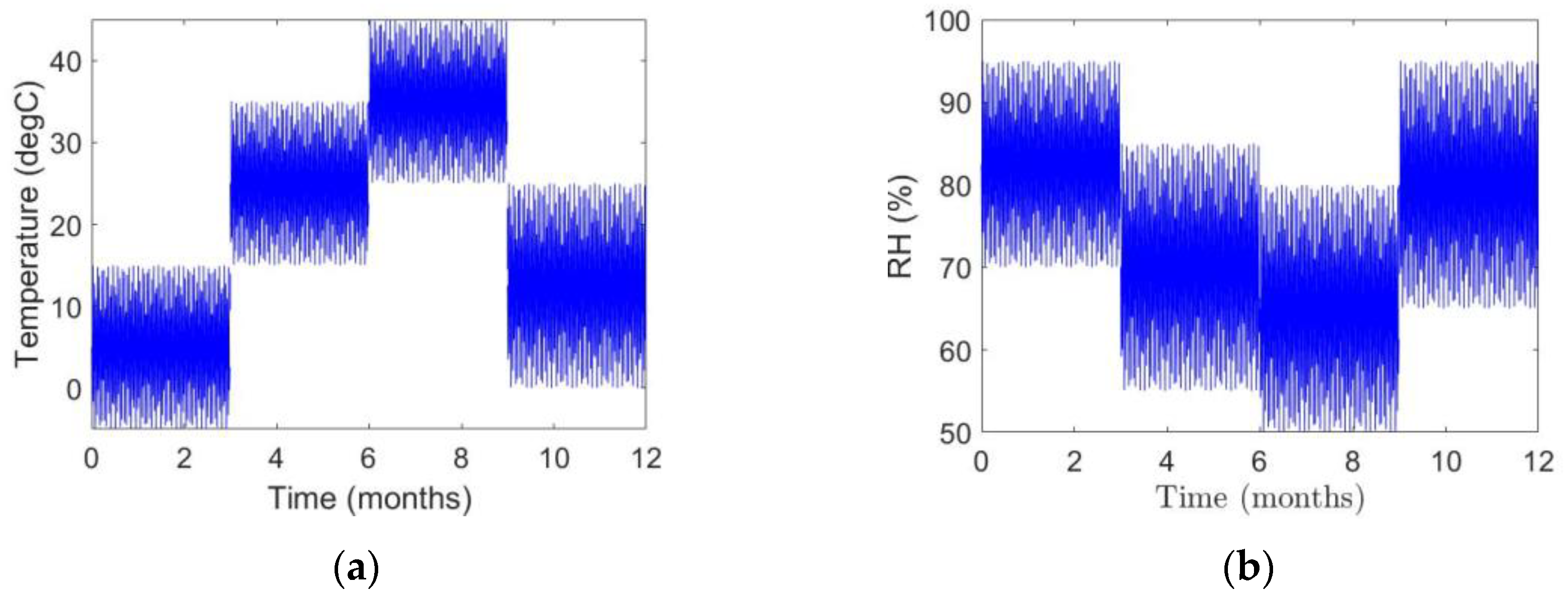

Stochastic Temperature and Humidity

2.4. Numerical Analysis

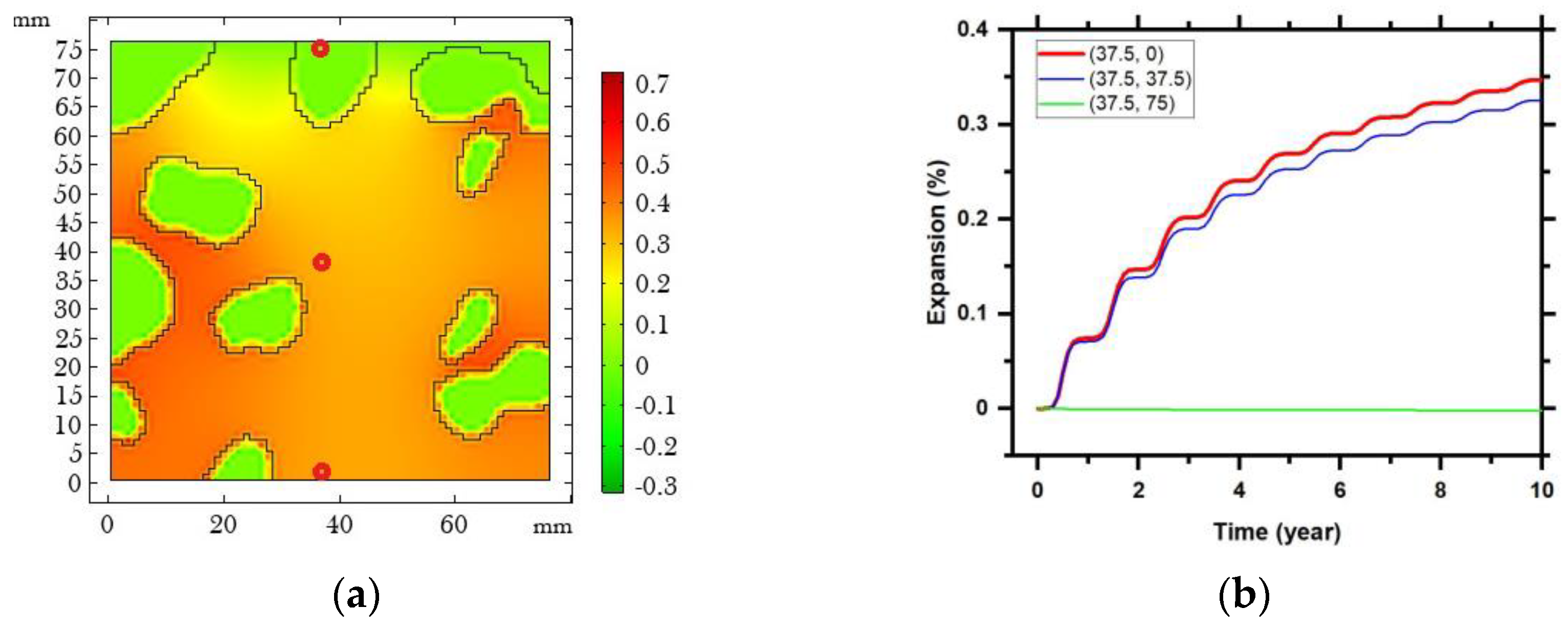

2.4.1. Mesoscopic Geometry

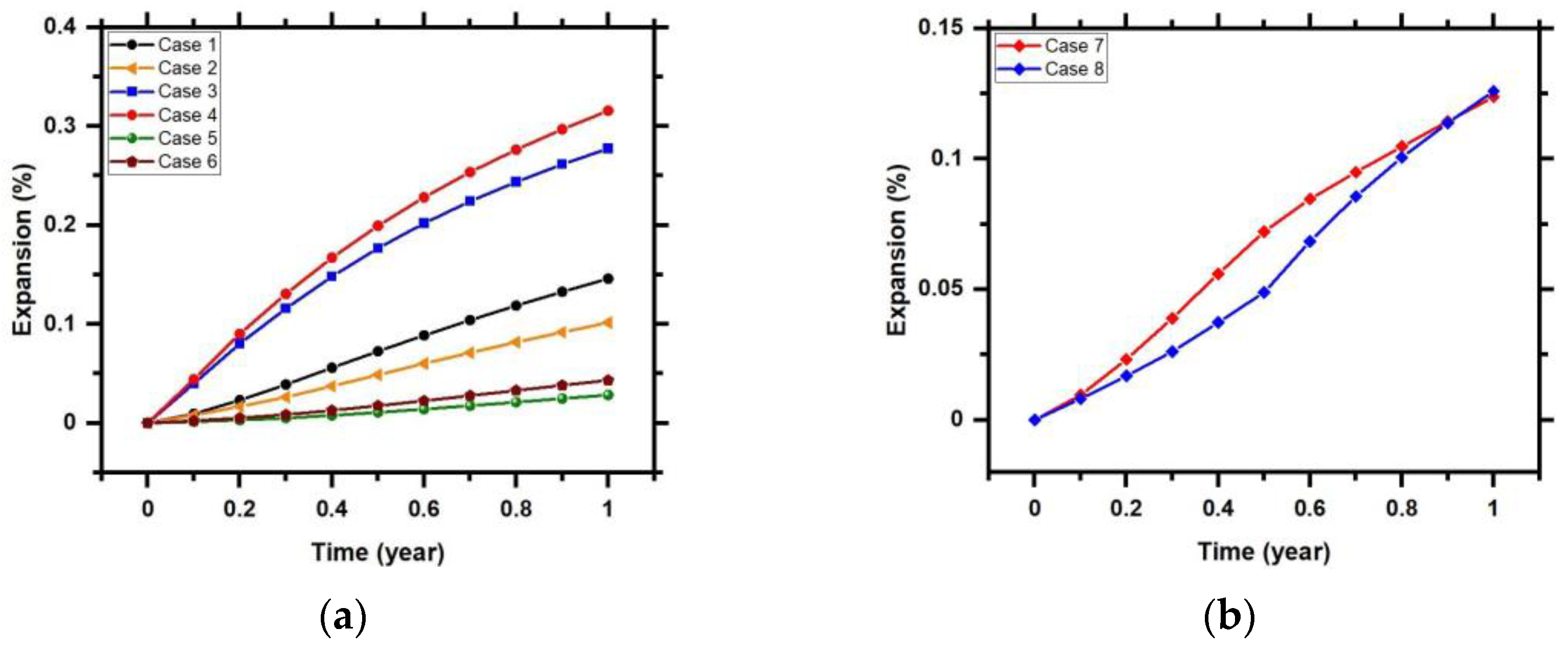

2.4.2. Parametric Study

Seasonal Variations

Stochastic Distributions

2.4.3. ASR Damage

3. Results and Discussion

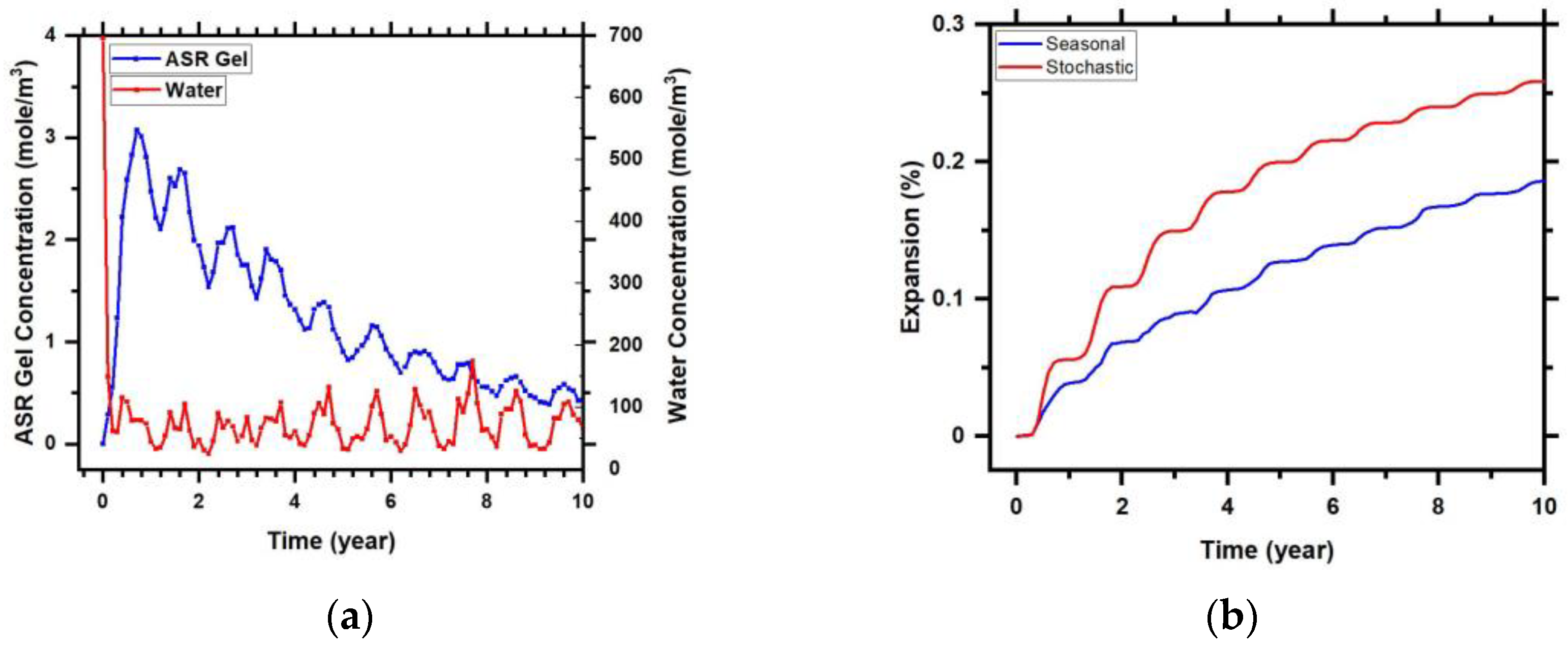

3.1. Validation of the Developed Model

- NaOH and KOH are interchangeable in the model.

- This work focuses on ASR gel production and its evolution over time. Thus, the production of non-expansive calcium silicate gel (CSH), which limits ASR expansion through a reaction between the available calcium and ASR gel, is kept out of the consideration.

- ASR-induced volumetric expansion is not unidirectional, i.e., values may change depending on the boundary conditions applied to the concrete domain.

- This model represents the stationary boundaries, i.e., the geometry is not changing with time or expansion.

3.2. ASR Expansion Analysis

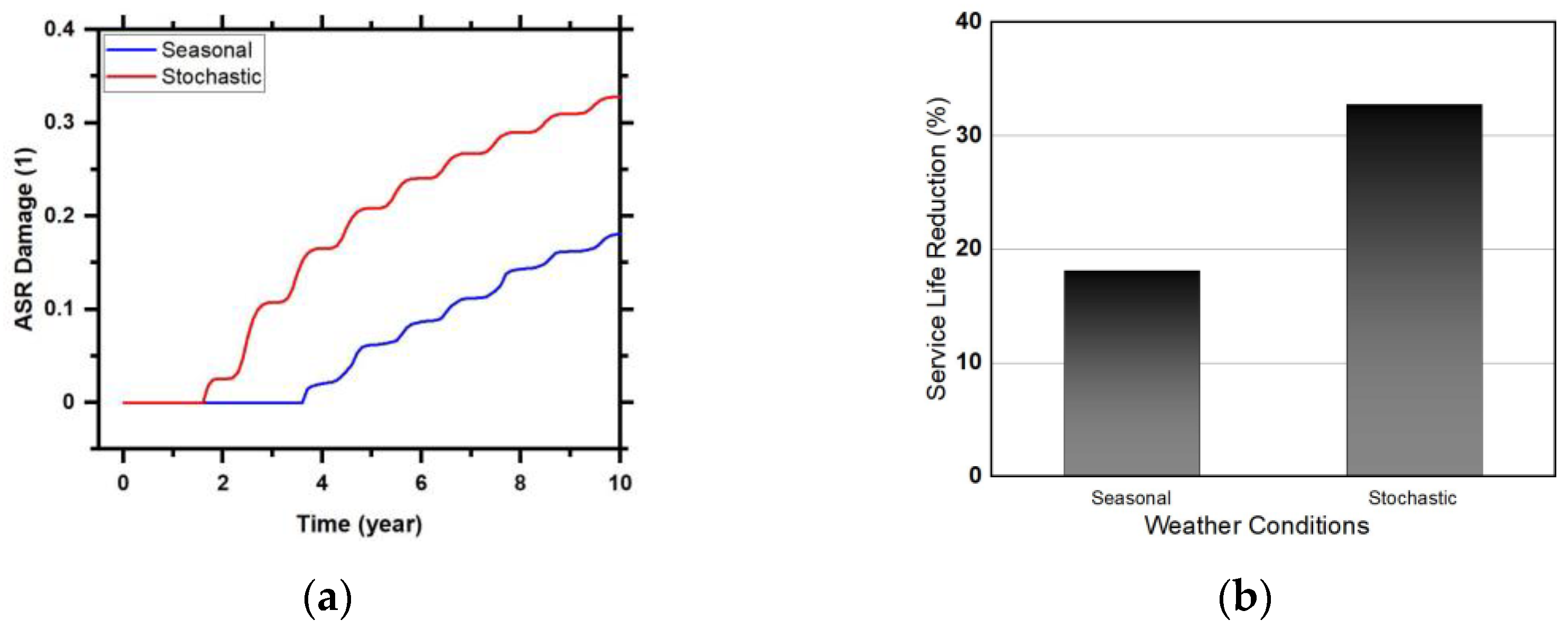

3.3. Long-Term ASR Forecasts

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stanton, T.E. Expansion of concrete through reaction between cement and aggregate. Proc. Am. Soc. Civil Eng. 1940, 66, 1781–1811. [Google Scholar] [CrossRef]

- Poole, A.B. Proceedings of the Third International Symposium on the Effect of Alkalis on the Properties of Concrete. Cement and Concrete Association; Wexham Springs: Slough, UK, 1976. [Google Scholar]

- Hobbs, D.W. Alkali-Silica Reaction in Concrete; Thomas Telford: London, UK, 1988. [Google Scholar]

- Poole, A.B. Introduction to alkali-aggregate reaction in concrete. In The Alkali-Silica Reaction in Concrete; Swamy, R.N., Ed.; Van Nostrand Reinhold: New York, NY, USA, 1992. [Google Scholar]

- Diamond, S. Alkali Silica Reactions–Some Paradoxes. Cem. Concr. Compos. 1997, 19, 391–401. [Google Scholar] [CrossRef]

- Léger, P.; Côté, P.; Tinawi, R. Finite element analysis of concrete swelling due to alkali-aggregate reactions in dams. Comput. Struct. 1996, 60, 601–611. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Fournier, B.; Folliard, K.J. Alkali-Aggregate Reactivity (AAR) Facts Book; Publication FHWA-HIF-13-019; FHWA, U.S. Department of Transportation: Washington, DC, USA, 2013. [Google Scholar]

- Hobbs, D.W. The Alkali-Silica Reaction-A Model for Predicting Expansion in Mortar. Mag. Concr. Res. 1981, 33, 208–220. [Google Scholar] [CrossRef]

- Capra, B.; Bournazel, J.-P. Modeling of Induced Mechanical Effects of Alkali-Aggregate Reactions. Cem. Concr. Res. 1998, 28, 251–260. [Google Scholar] [CrossRef]

- Ulm, F.-J.; Coussy, O.; Kefei, L.; Larive, C. Thermo-Chemo-Mechanics of ASR Expansion in Concrete Structures. J. Eng. Mech. 2000, 126, 233–242. [Google Scholar] [CrossRef]

- Steffens, A.; Bazant, P.Z. Mathematical model for kinetics of alkali–silica reaction in concrete. Cem. Concr. Res. 2000, 30, 419–428. [Google Scholar] [CrossRef]

- Saouma, V.E.; Martin, R.A.; Hariri-Ardebili, M.A.; Katayama, T. A mathematical model for the kinetics of the alkali–silica chemical reaction. Cem. Concr. Res. 2015, 68, 184–195. [Google Scholar] [CrossRef]

- Balbo, F.A.N.; Pianezzer, G.A.; Gramani, L.M.; Kaviski, E.; Teixeira, M.R. An application to the diffusion equation in a model for the damage in concrete due to alkali-silica reaction. Appl. Math. Sci. 2015, 9, 4135–4147. [Google Scholar] [CrossRef]

- Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Intergovernmental Panel on Climate CHANGE: Cambridge, UK, 2013; p. 1535.

- Christidis, N.; Stott, P.A.; Brown, S.J. The Role of Human Activity in the Recent Warming of Extremely Warm Daytime Temperatures. J. Clim. 2011, 24, 1922–1930. [Google Scholar] [CrossRef]

- Duffy, P.B.; Tebaldi, C. Increasing prevalence of extreme summer temperatures in the U.S. Clim. Chang. 2012, 111, 487–495. [Google Scholar] [CrossRef]

- Diffenbaugh, N.S. Verification of extreme event attribution: Using out-of-sample observations to assess changes in probabilities of unprecedented events. Sci. Adv. 2020, 6, eaay2368. [Google Scholar] [CrossRef] [PubMed]

- NOAA (National Oceanic and Atmospheric Administration). National Centers for Environmental Information. 2016. Available online: www.ncei.noaa.gov (accessed on 6 November 2020).

- Dai, A. Recent Climatology, Variability, and Trends in Global Surface Humidity. J. Clim. 2006, 19, 3589–3606. [Google Scholar] [CrossRef]

- Willett, K.M.; Jones, P.D.; Gillett, N.P.; Thorne, P.W. Recent Changes in Surface Humidity: Development of the HadCRUH Dataset. J. Clim. 2008, 21, 5364–5383. [Google Scholar] [CrossRef]

- Vose, R.S.; Applequist, S.; Bourassa, M.A.; Pryor, S.C.; Barthelmie, R.J.; Blanton, B.; Bromirski, P.D.; Brooks, H.E.; DeGaetano, A.T.; Dole, R.M.; et al. Monitoring and Understanding Changes in Extremes: Extratropical Storms, Winds, and Waves. Bull. Am. Meteorol. Soc. 2014, 95, 377–386. [Google Scholar] [CrossRef]

- Wang, X.L.; Feng, Y.; Compo, G.P.; Swail, V.R.; Zwiers, F.W.; Allan, R.J.; Sardeshmukh, P.D. Trends and low frequency variability of extra-tropical cyclone activity in the ensemble of twentieth century reanalysis. Clim. Dyn. 2012, 40, 2775–2800. [Google Scholar] [CrossRef]

- Wang, X.L.; Swail, V.R.; Zwiers, F.W. Climatology and Changes of Extratropical Cyclone Activity: Comparison of ERA-40 with NCEP–NCAR Reanalysis for 1958–2001. J. Clim. 2006, 19, 3145–3166. [Google Scholar] [CrossRef]

- Seneviratne, S.I.; Nicholls, N.; Easterling, D.; Goodess, C.M.; Kanae, S.; Kossin, J.; Zwiers, F.W. Changes in Climate Extremes and Their Impacts on the Natural Physical Environment; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2012. [Google Scholar]

- White, P.; Golden, J.S.; Biligiri, K.P.; Kaloush, K. Modeling climate change impacts of pavement production and construction. Resour. Conserv. Recycl. 2010, 54, 776–782. [Google Scholar] [CrossRef]

- Stewart, M.G.; Wang, X.; Nguyen, M.N. Climate change impact and risks of concrete infrastructure deterio-ration. Eng. Struct. 2011, 33, 1326–1337. [Google Scholar]

- Kim, T.-K.; Choi, S.-J.; Kim, J.-H.J.; Chu, Y.-S.; Yu, E. Performance Based Evaluation of Carbonation Resistance of Concrete According to Various Curing Conditions from Climate Change Effect. Int. J. Concr. Struct. Mater. 2017, 11, 687–700. [Google Scholar] [CrossRef]

- Nasr, A.; Honfi, D.; Ivanov, O.L. Probabilistic analysis of climate change impact on chloride-induced deterioration of reinforced concrete considering Nordic climate. J. Infrastruct. Preserv. Resil. 2022, 3, 8. [Google Scholar] [CrossRef]

- Touma, W.E.; Fowler, D.F.; Carrasquillo, R.L. Alkali-Silica Reaction in Portland Cement Concrete: Testing Methods and Mitigation Alternatives. Research Report ICAR 301-1F; International Center for Aggregates Research (ICAR), The University of Texas at Austin: Austin, TX, USA, 2001. [Google Scholar]

- Bentz, D.P.; Garboczi, E.J.; Quenard, D.A. Modelling drying shrinkage in reconstructed porous materials: Application to porous Vycor glass. Model. Simul. Mater. Sci. Eng. 1999, 6, 211. [Google Scholar] [CrossRef]

- Grimal, E.; Sellier, A.; Le Pape, Y.; Bourdarot, E. Creep, shrinkage, and anisotropic damage in alkali-aggregate reaction swelling Mechanism-Part I: A constitutive model. ACI Mater. J. 2008, 105, 227–235. [Google Scholar]

- Vlahinić, I.; Hamlin, M.; Jennings, J.; Thomas, J. A constitutive model for drying of a partially saturated porous material. Mech. Mater. 2009, 41, 319–328. [Google Scholar] [CrossRef]

- Fournier, B.; Ideker, J.H.; Folliard, K.J.; Thomas, M.D.; Nkinamubanzi, P.C.; Chevrier, R. Effect of environ-mental conditions on expansion in concrete due to alkali–silica reaction (ASR). Mater. Charact. 2009, 60, 669–679. [Google Scholar] [CrossRef]

- Multon, S.; Toutlemonde, F. Effect of moisture conditions and transfers on alkali silica reaction damaged structures. Cem. Concr. Res. 2010, 40, 924–934. [Google Scholar] [CrossRef]

- Alnaggar, M.; Di Luzio, G.; Cusatis, G. Modeling Time-Dependent Behavior of Concrete Affected by Alkali Silica Reaction in Variable Environmental Conditions. Materials 2017, 10, 471. [Google Scholar] [CrossRef]

- Buhl, M.; Markolf, S. A review of emerging strategies for incorporating climate change considerations into in-frastructure planning, design, and decision making. Sustain. Resil. Infrastruct. 2023, 8, 157–169. [Google Scholar] [CrossRef]

- Stewart, M.G.; Deng, X. Climate impact risks and climate adaptation engineering for built infrastructure. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civil Eng. 2015, 1, 04014001. [Google Scholar] [CrossRef]

- ASTM C1293; Standard Test Method for Concrete Aggregates by Determination of Length Change of Concrete Due to Alkali-Silica Reaction. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2006.

- Ichikawa, T.; Miura, M. Modified model of alkali-silica reaction. Cem. Concr. Res. 2007, 37, 1291–1297. [Google Scholar] [CrossRef]

- Rahman, M.A. Understanding Mesoscopic Chemo-Mechanical Distress and Mitigation Mechanisms of Concrete Subject to ASR. Master’s Thesis, Boise State University, Boise, ID, USA, 2020. [Google Scholar]

- Richardson, L.F. Weather Prediction by Numerical Process; University Press: Cambridge, UK, 1922; p. 262. [Google Scholar]

- Richards, L.A. Capillary conduction of liquids through porous mediums. Physics 1931, 1, 318–333. [Google Scholar] [CrossRef]

- Bear, J. Dynamics of Fluids in Porous Media; Elsevier: Amsterdam, The Netherlands, 1972. [Google Scholar] [CrossRef]

- Bear, J. Hydraulics of Groundwater; McGraw-Hill: New York, NY, USA, 1979. [Google Scholar]

- van Genuchten, M.T. A Closed-form Equation for Predicting the Hydraulic Conductivity of Unsaturated Soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Schneider, S.; Mallants, D.; Jacques, D. Determining hydraulic properties of concrete and mortar by inverse modelling. Mater. Res. 2012, 1475, imrc11-1475. [Google Scholar] [CrossRef]

- Ruiz, L.; Molénat, J.; Hamon, Y.; Chirié, G.; Michot, D. Experimental Determination of Hydrodynamic Properties of Weathered Granite. Soil Sci. Soc. Am. 2012, 11, vzj2011.0076. [Google Scholar] [CrossRef]

- Bastidas-Arteaga, E.; Chateauneuf, A.; Sánchez-Silva, M.; Bressolette, P.; Schoefs, F. Influence of weather and global warming in chloride ingress into concrete: A stochastic approach. Struct. Saf. 2010, 32, 238–249. [Google Scholar] [CrossRef]

- Riahi, K.; Rao, S.; Krey, V.; Cho, C.; Chirkov, V.; Fischer, G.; Rafaj, P. RCP 8.5—A scenario of comparatively high greenhouse gas emissions. Clim. Change 2011, 109, 33–57. [Google Scholar] [CrossRef]

- Park, A.; Puettmann, K.; Wilson, E.; Messier, C.; Kames, S.; Dhar, A. Can Boreal and Temperate Forest Management be Adapted to the Uncertainties of 21st Century Climate Change? Crit. Rev. Plant Sci. 2014, 33, 251–285. [Google Scholar] [CrossRef]

- Ahrens, C.D. Meteorology Today: An Introduction to Weather, Climate, and the Environment; Cengage Learning Canada Inc.: Toronto, ON, Canada, 2015. [Google Scholar]

- Papadopoulos, V.; Giovanis, D.G. Stochastic Finite Element Methods: An Introduction; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Lawrence, M.G. The Relationship between Relative Humidity and the Dewpoint Temperature in Moist Air. Am. Meteorol. Soc. 2005, 86, 225–234. [Google Scholar] [CrossRef]

- Takiya, H.; Watanabe, N.; Kozaki, T.; Sato, S. Effects of water-to-cement ratio and temperature on diffusion of water in hardened cement pastes. J. Nucl. Sci. Technol. 2014, 52, 728–738. [Google Scholar] [CrossRef]

- Folliard, K.J.; Ryan, B.; Thano, D.; Lianxiang, D.; Sabrina, G.; Jason, I.; Tyler, L.; Stephanie, W.; Maria, J.; Benoit, F.; et al. Preventing ASR/DEF in New Concrete: Final Report; Publication FHWA/TX-06/0-4085-5; FHWA, U.S. Department of Transportation: Washington, DC, USA, 2006. [Google Scholar]

- German, R.M.; Park, S.J. Handbook of Mathematical Relations in Particulate Materials Processing: Ceramics, Powder Metals, Cermets, Carbides, Hard Materials, and Mineral; John Wiley & Sons: Hoboken, NJ, USA, 2009; Volume 3. [Google Scholar]

- Neville, A.M. Properties of Concrete; Pearson Education Limited: London, UK, 2011. [Google Scholar]

- Rahman, A.; Lu, Y. A time-dependent chemo-mechanical analysis of alkali-silica reaction for the disparate geometry of concrete meso-structure. Constr. Build. Mater. 2019, 211, 847–857. [Google Scholar] [CrossRef]

- Ben Haha, M. Mechanical Effects of Alkali Silica Reaction in Concrete Studied by SEM-Image Analysis. Ph.D. Thesis, École Polytechnique Fédérale de Lausanne, À la Faculté Sciences et Techniques de L’ingénieur, Paris, France, 2006. [Google Scholar]

- Pan, T.; Chen, C.; Yu, Q. Three-dimensional micromechanical modeling of concrete degradation under multiphysics fields. Compos. Struct. 2017, 175, 7–18. [Google Scholar] [CrossRef]

- National Oceanic and Atmospheric Administration. Comparative Climatic Data for the United States through 2018; National Oceanic and Atmospheric Administration, US Department of Commerce: Washington, DC, USA, 2018. [Google Scholar]

| Mortar | Aggregate | Source | |

|---|---|---|---|

| Diffusion coefficient of ASR gel (m2/s) | 1 × 10−10 | 1 × 10−12 | [13] |

| Diffusion coefficient of (m2/s) | 5 × 10−10 | 0 | [54] |

| Initial concentration of H2O (mole/m3) | 1000 | 0 | Calibrated |

| Initial concentration of Silanol (mole/m3) | 0 | 0 | [58] |

| Initial concentration of ASR gel (mole/m3) | 0 | 0 | |

| Initial concentration of expanded ASR gel (mole/m3) | 0 | 0 | |

| Activation energy, (J/mole) | 43,000 | 43,000 | [59] |

| Universal gas constant, (J/(mole. K)) | 8.3144598 | 8.3144598 | Constant |

| Initial pressure (atm) | 1 | 1 | Calibrated |

| Reference pressure (atm) | 1 | 1 | Calibrated |

| Residual water content, | 0 | 0.08 | [46,47] |

| Saturated water content, | 0.185 | 0.308 | |

| van Genuchten coefficient, α (1/m) | 3.23 × 10−4 | 15.3 | |

| van Genuchten coefficient, n | 1.217 | 1.406 | |

| Hydraulic conductivity, (m/s) | 6 × 10−13 | 5.35 × 10−11 | [60] |

| Heat capacity (J/(kg K)) | 1548 | 850 | |

| Thermal conductivity (W/(m-K)) | 1.73 | 2.9 | |

| Initial temperature (K) | 293.15 | 293.15 | Calibrated |

| Reference temperature (K) | 293.15 | 293.15 | Calibrated |

| Young’s modulus (Pa) | 5 × 106 | 60 × 106 | [60] |

| Poisson’s ratio | 0.2 | 0.25 | |

| Density (kg/m3) | 3150 | 2600 |

| Case ID | Ambient Temperature (°C) | Ambient Humidity (%) | Representing Conditions |

|---|---|---|---|

| Case 1 | 38 | 100 | Used in the model validation [55]. |

| Case 2 | 38 | 30 | Fully insulated. |

| Case 3 | 60 | 30 | High temperature, Fully insulated. |

| Case 4 | 60 | 100 | High temperature, Maximum saturation. |

| Case 5 | 20 | 100 | Low temperature,Maximum saturation. |

| Case 6 | 25 | 70 | Room temperature and humidity. |

| Case 7 | 38 | 100, 30 | 100% humidity for the first half of the year and then late drying to 30% over the last half of the year. |

| Case 8 | 38 | 30, 100 | Drying at 30% humidity for the first half of the year and then late water supply to 100% over the last half of the year. |

| Case 9 | RH1 | T1 | Seasonal variation. |

| Case 10 | RH2 | T2 | Stochastic distribution. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.A.; Lu, Y. Improved Alkali–Silica Reaction Forecast in Concrete Infrastructures through Stochastic Climate Change Impact Analysis. Infrastructures 2023, 8, 120. https://doi.org/10.3390/infrastructures8080120

Rahman MA, Lu Y. Improved Alkali–Silica Reaction Forecast in Concrete Infrastructures through Stochastic Climate Change Impact Analysis. Infrastructures. 2023; 8(8):120. https://doi.org/10.3390/infrastructures8080120

Chicago/Turabian StyleRahman, Md Asif, and Yang Lu. 2023. "Improved Alkali–Silica Reaction Forecast in Concrete Infrastructures through Stochastic Climate Change Impact Analysis" Infrastructures 8, no. 8: 120. https://doi.org/10.3390/infrastructures8080120

APA StyleRahman, M. A., & Lu, Y. (2023). Improved Alkali–Silica Reaction Forecast in Concrete Infrastructures through Stochastic Climate Change Impact Analysis. Infrastructures, 8(8), 120. https://doi.org/10.3390/infrastructures8080120