Investigating the Multi-Recyclability of Recycled Plastic-Modified Asphalt Mixtures

Abstract

1. Introduction

1.1. State-of-the-Knowledge

1.2. Objective

2. Materials

3. Methods

3.1. Research Plan

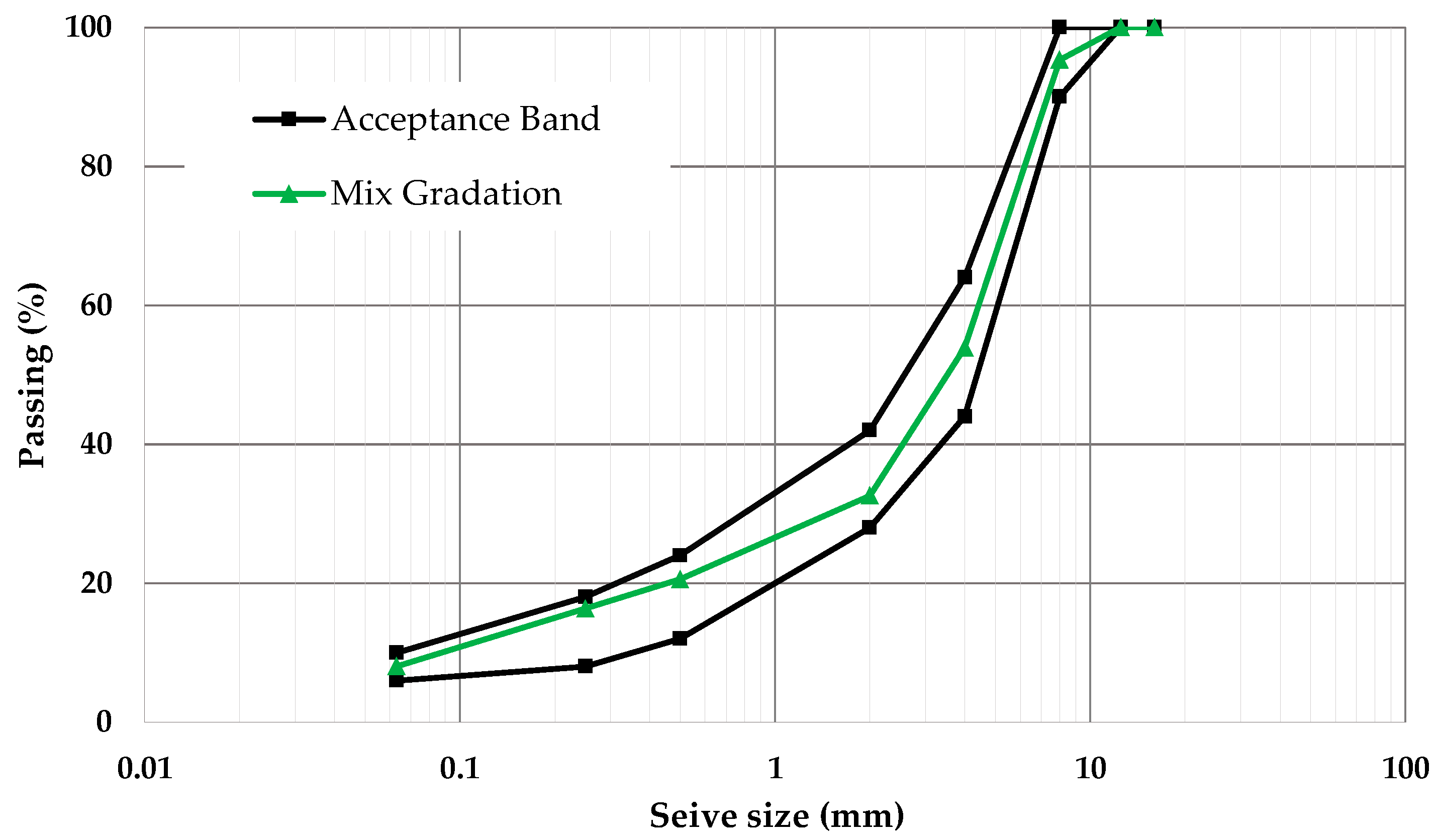

3.2. Mix Design and Sample Preparation

3.3. RAP Manufacturing

3.4. Binder Ageing

3.5. Multiple Recycling

3.6. Testing Methods

4. Results and Discussion

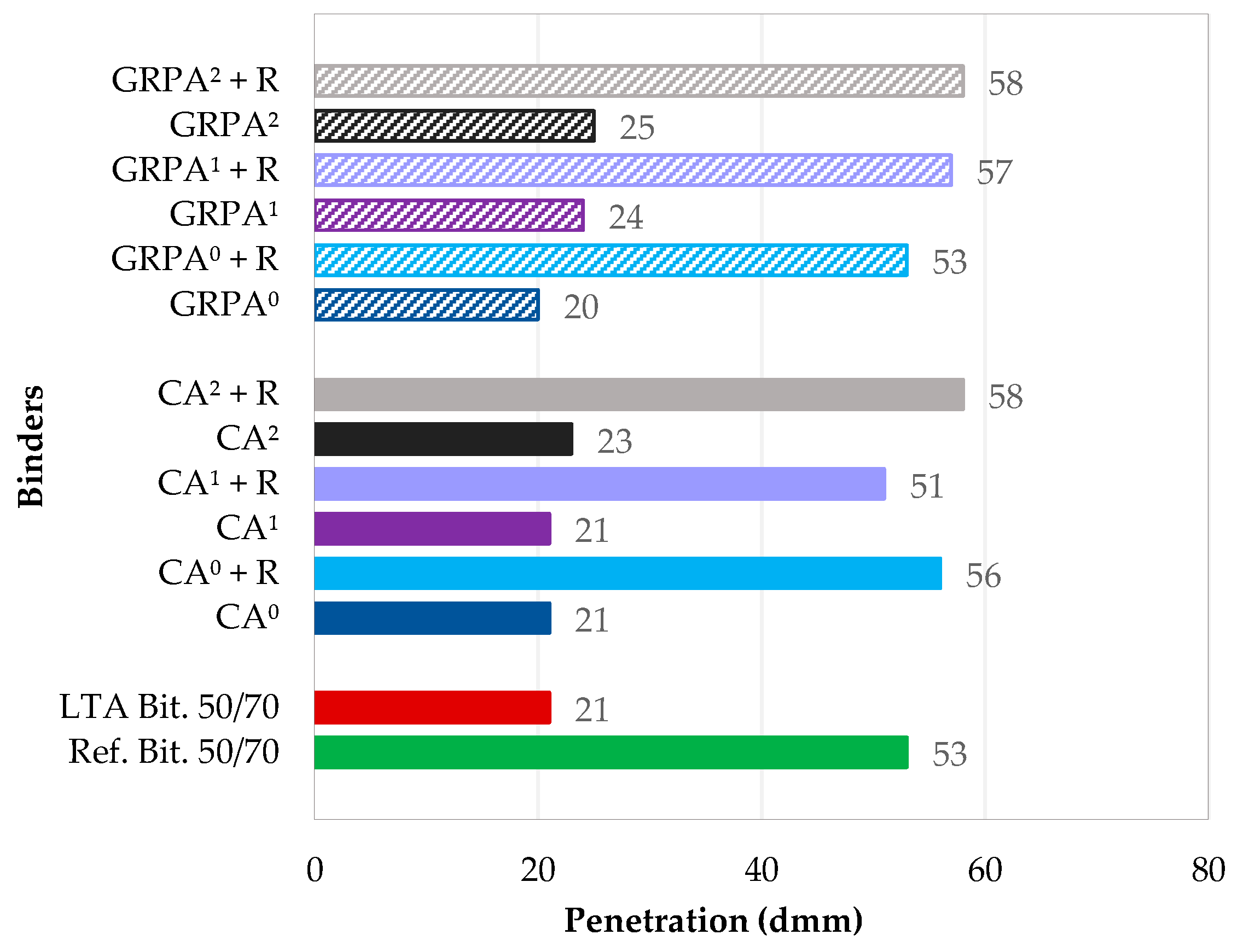

4.1. Penetration Test

4.2. Softening Point Test

4.3. Dynamic Viscosity Test

4.4. Dynamic Shear Rheometer (DSR) Analysis

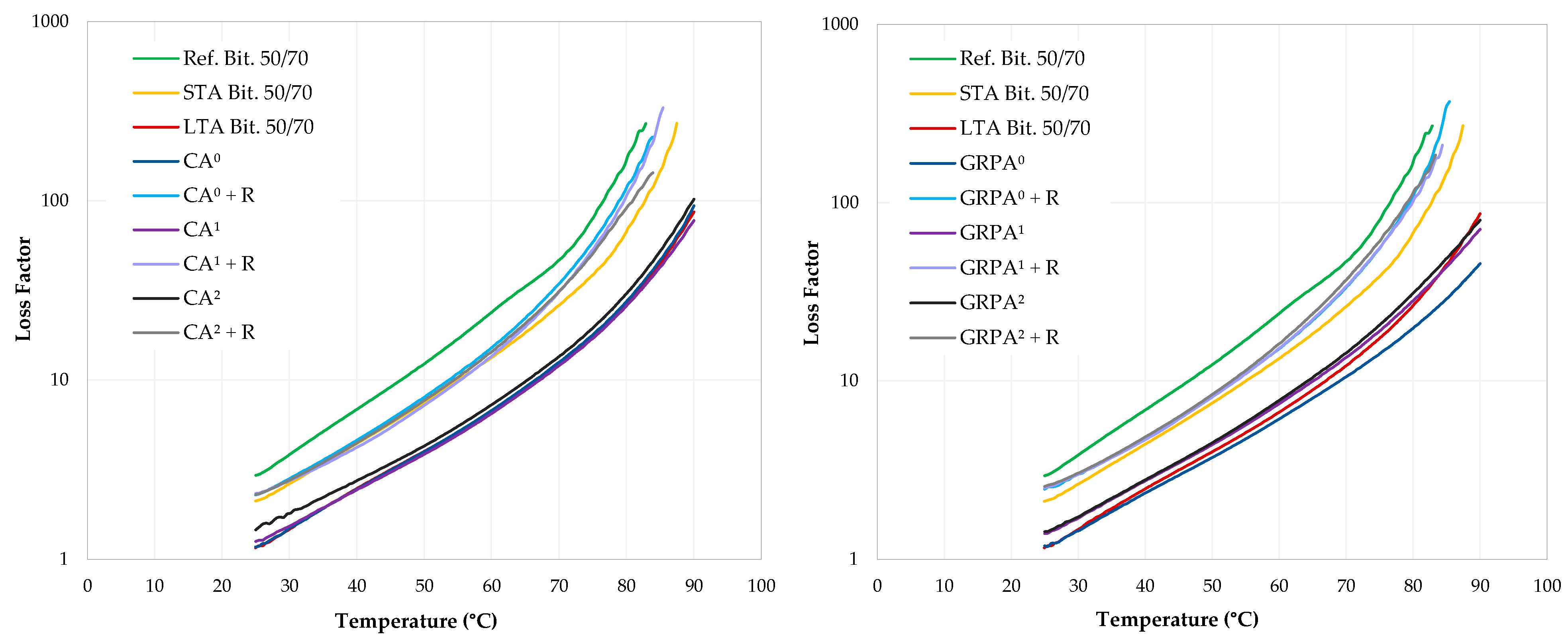

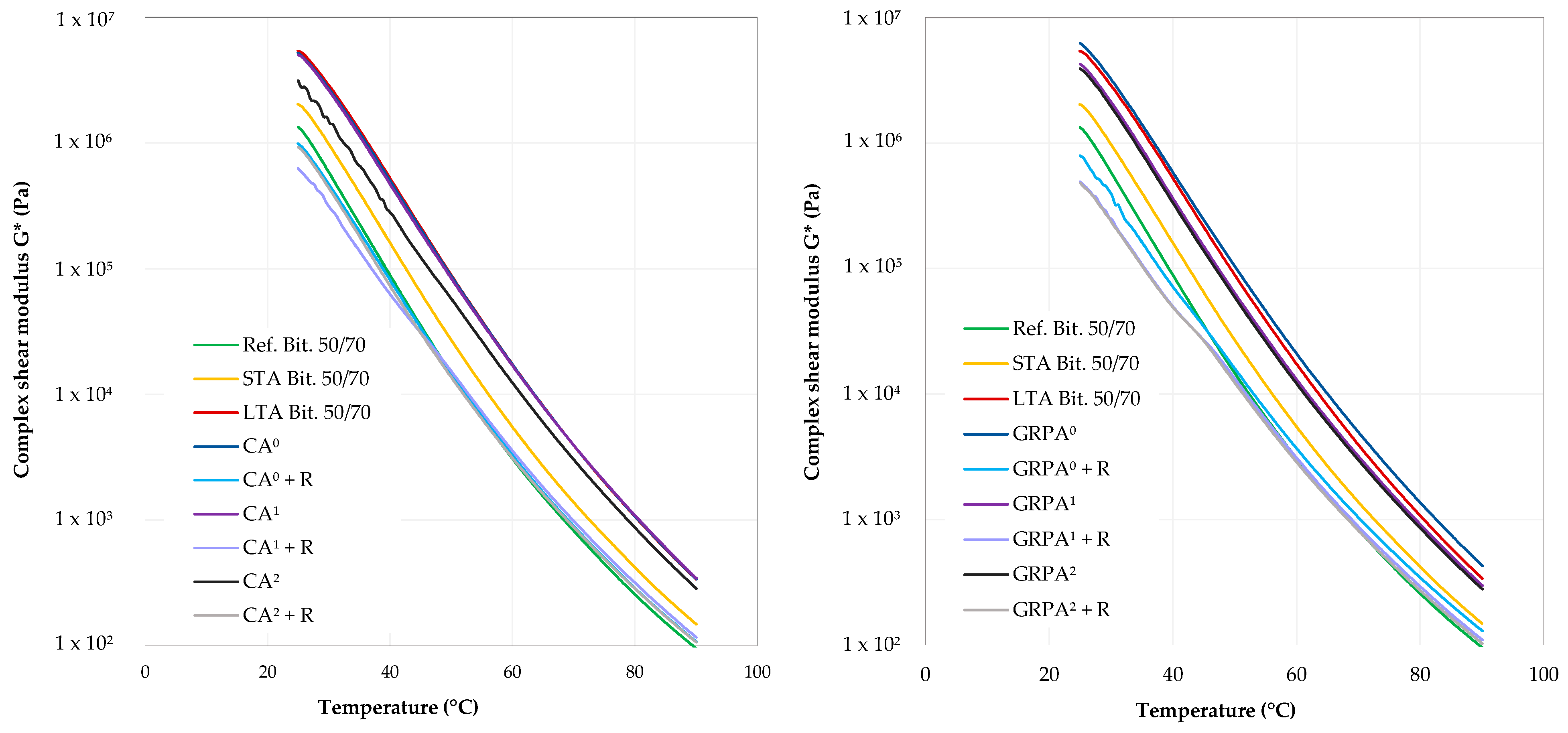

4.4.1. Temperature Sweep Test

- Plate geometry: 25 mm with a 1 mm gap;

- Test temperature range: 25 °C to 90 °C;

- Temperature increment rate: 1 °C/min;

- Constant shear stress: 500 ± 5 Pa;

- Test frequency: 1.59 Hz (10 rad/s).

- As expected, both short-term and long-term ageing increased the stiffness of the reference Bit. 50/70, however, within the loss factor figure, the significance of short-term ageing is more visible compared to other testing methods.

- None of the recycled binders, neither the control mix binders nor the GRP mix binders, were shown the same loss factor plots compared to the Ref. Bit. 50/70 virgin bitumen. It is worth mentioning that if a higher dosage of rejuvenator had been added during the recycling cycles, the binders would become excessively soft, and the corresponding mixtures would be susceptible to rutting. This fact is also attested by the loss factors at high temperatures, where the recycled binders showed similar loss factors at these temperatures.

- It is noteworthy that despite the difference between the recycled binders’ loss factor curves and Ref. Bit. 50/70 at unaged (virgin) state, the aged binders showed very similar curves after long-term ageing with the PAV aged bitumen 50/70 (LTA Bit. 50/70).

- Regardless of the Ref. Bit. 50/70, as it was observed via other testing methods, the extracted binders from the control and the GRP-modified asphalt mixtures after the first cycle of recycling showed comparative performance.

- Not similar to the loss factor plots, the G* isochronal plots of the extracted binders from the aged/recycled control and testing asphalt mixtures were comparable to the reference bitumen 50/70 in its un-aged state. This could assure the accuracy of the optimized rejuvenator dosage.

4.4.2. Performance Grading

4.4.3. BTSV Test

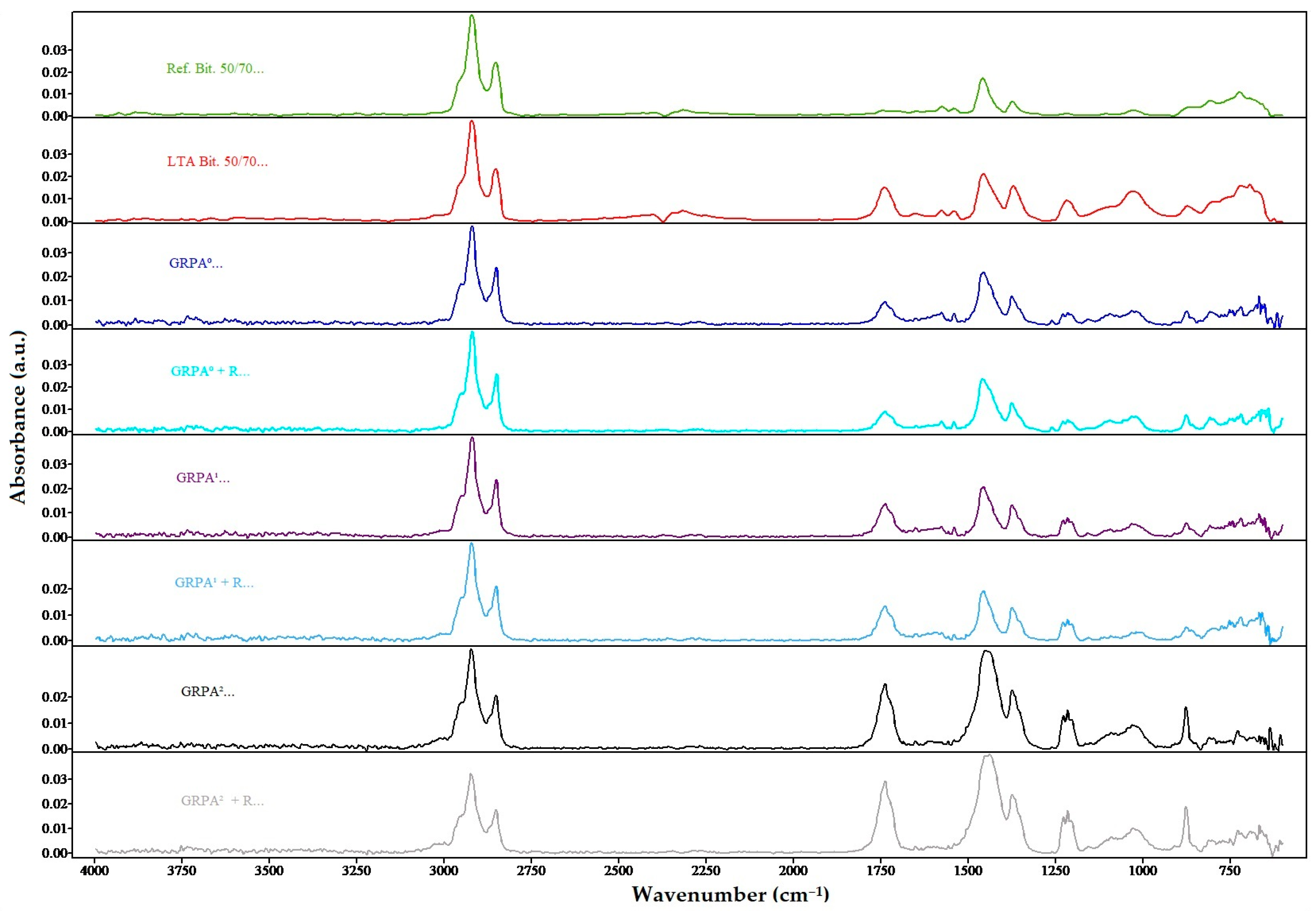

4.5. Fourier Transform Infrared (FTIR) Spectroscopy

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Asphalt Pavement Association. Asphalt the 100% Recyclable Construction Product, EAPA Position Paper; European Asphalt Pavement Association: Brussels, Belgium, 2014; pp. 1–21. [Google Scholar]

- Mantalovas, K.; Di Mino, G. The sustainability of reclaimed asphalt as a resource for road pavement management through a circular economic model. Sustainability 2019, 11, 2234. [Google Scholar] [CrossRef]

- Mantalovas, K.; Di Mino, G. Integrating circularity in the sustainability assessment of asphalt mixtures. Sustainability 2020, 12, 594. [Google Scholar] [CrossRef]

- Manosalvas-Paredes, M.; Roberts, R.; Barriera, M.; Mantalovas, K. Towards more sustainable pavement management practices using embedded sensor technologies. Infrastructures 2020, 5, 4. [Google Scholar] [CrossRef]

- Lachat, A.; Mantalovas, K.; Desbois, T.; Yazoghli-Marzouk, O.; Colas, A.-S.; Di Mino, G.; Feraille, A. From buildings’ end of life to aggregate recycling under a circular economic perspective: A comparative life cycle assessment case study. Sustainability 2021, 13, 9625. [Google Scholar] [CrossRef]

- Bonicelli, A.; Calvi, P.; Martinez-Arguelles, G.; Fuentes, L.; Giustozzi, F. Experimental study on the use of rejuvenators and plastomeric polymers for improving durability of high RAP content asphalt mixtures. Constr. Build. Mater. 2017, 155, 37–44. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C.; Cochran, E. Investigation of fatigue and thermal cracking behavior of rejuvenated reclaimed asphalt pavement binders and mixtures. Int. J. Fatigue 2018, 108, 90–95. [Google Scholar] [CrossRef]

- Mantalovas, K.; Di Mino, G.; Inzerillo, L.; Roberts, R. Exploiting 3D Modelling and Life Cycle Assessment to Improve the Sustainability of Pavement Management; Springer International Publishing: Cham, Switzerland, 2021; Volume 178. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Camargo, I.; Hofko, B.; Graziani, A.; Grilli, V. Dilauryl thiodipropionate as a regeneration agent for reclaimed asphalts. Constr. Build. Mater. 2023, 365, 130049. [Google Scholar] [CrossRef]

- Orešković, M.; Bressi, S.; Di Mino, G.; Presti, D.L. Influence of bio-based additives on RAP clustering and asphalt binder rheology. Bear. Capacit. Roads Railw. Airfields 2017, 1301–1306. [Google Scholar] [CrossRef]

- Russo, F.; Eskandarsefat, S.; Venturini, L.; Viscione, N. A complete study on an asphalt concrete modified with graphene and recycled hard-plastics: A case study. Case Stud. Constr. Mater. 2022, 17, e01437. [Google Scholar] [CrossRef]

- Joohari, I.B.; Giustozzi, F. Chemical and high-temperature rheological properties of recycled plastics-polymer modified hybrid bitumen. J. Clean. Prod. 2020, 276, 123064. [Google Scholar] [CrossRef]

- D’angelo, S.; Ferrotti, G.; Cardone, F.; Canestrari, F. Asphalt Binder Modification with Plastomeric Compounds Containing Recycled Plastics and Graphene. Materials 2022, 15, 516. [Google Scholar] [CrossRef]

- Viscione, N.; Presti, D.L.; Veropalumbo, R.; Oreto, C.; Biancardo, S.A.; Russo, F. Performance-based characterization of recycled polymer modified asphalt mixture. Constr. Build. Mater. 2021, 310, 125243. [Google Scholar] [CrossRef]

- Duarte, G.M.; Faxina, A.L. Asphalt concrete mixtures modified with polymeric waste by the wet and dry processes: A literature review. Constr. Build. Mater. 2021, 312, 125408. [Google Scholar] [CrossRef]

- Diab, A.; Enieb, M.; Singh, D. Influence of aging on properties of polymer-modified asphalt. Constr. Build. Mater. 2019, 196, 54–65. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Pasquini, E.; Tusar, M.; Hernando, D.; Wang, D.; Mikhailenko, P.; Pasetto, M.; Baliello, A.; Falchetto, A.C.; Miljković, M.; et al. RILEM interlaboratory study on the mechanical properties of asphalt mixtures modified with polyethylene waste. J. Clean. Prod. 2022, 375, 134124. [Google Scholar] [CrossRef]

- White, G. Evaluating recycled waste plastic modification and extension of bituminous binder for asphalt. In Proceedings of the Eighteenth Annual International Conference on Pavement Engineering, Asphalt Technology and Infrastructure, Liverpool, UK, 27–28 February 2019; Volume 1, pp. 1–14. [Google Scholar]

- Lu, D.X.; Enfrin, M.; Boom, Y.J.; Giustozzi, F. Future recyclability of hot mix asphalt containing recycled plastics. Constr. Build. Mater. 2023, 368, 130396. [Google Scholar] [CrossRef]

- ANAS Gruppo FS Italiane. Capitolato Speciale di Appalto, Norme Tecniche per l’esecuzione del contratto Parte 2. Paviment. Str.; ANAS S.p.A.; Gruppo Ferrovie dello Stato Italiane: Rome, Italy, 2021. [Google Scholar]

- Schwettmann, K.; Nytus, N.; Radenberg, M.; Stephan, D. Bitumen reuse: Physical and chemical approach to investigate the effectiveness of rejuvenators. Road Mater. Pavement Des. 2022, 24, 1130–1157. [Google Scholar] [CrossRef]

- Caputo, P.; Eskandarsefat, S.; Porto, M.; Loise, V.; Oliviero Rossi, C.; Scarpelli, F.; Penelope Di Santo, M.; Venturini, L. Towards advances in differentiating recycling agents: Softening agents vs. rejuvenating agents. In Proceedings of the 7th EE CONGRESS Eurasphalt Eurobitume, Virtual, 15–17 June 2021. [Google Scholar]

- CEN. EN 12697-52:2017; Bituminous Mixtures—Test Methods—Part 52: Conditioning to Address Oxidative Ageing. European Committee for Standardization: Brussels, Belgium, 2017.

- Kim, Y.R.; Castorena, C.; Saleh, N.F.; Braswell, E.; Elwardany, M.; Rad, F.Y. Long-Term Aging of Asphalt Mixtures for Performance Testing and Prediction; National Academies Press: Washington, DC, USA, 2017. [Google Scholar]

- CEN. EN 12607-1:2014; Bitumen and Bituminous Binders—Determination of the Resistance to Hardening under Influence of Heat and Air—Part 1: RTFOT Method. European Committee for Standardization: Brussels, Belgium, 2014.

- CEN. EN 14769:2012; Bitumen and Bituminous Binders—Accelerated Long-Term Ageing Conditioning by a Pressure Ageing Vessel (PAV). European Committee for Standardization: Brussels, Belgium, 2012.

- European Asphalt Pavement Association. Recommendations for the Use of Rejuvenators in Hot and Warm Asphalt Production. European Asphalt Pavement Association: Brussels, Belgium, 2018; pp. 1–24. [Google Scholar]

- CEN. EN 1426:2015; Bitumen and Bituminous Binders—Determination of Needle Penetration. European Committee for Standardization: Brussels, Belgium, 2015.

- CEN. EN 1427:2015; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. European Committee for Standardization: Brussels, Belgium, 2015.

- CEN. EN 13302:2018; Bitumen and bituminous Binders—Determination of Dynamic Viscosity of Bituminous Binder Using a Rotating Spindle Apparatus. European Committee for Standardization: Brussels, Belgium, 2018; p. 16.

- Cavalli, M.; Zaumanis, M.; Mazza, E.; Partl, M.; Poulikakos, L. Effect of ageing on the mechanical and chemical properties of binder from RAP treated with bio-based rejuvenators. Compos. Part B Eng. 2018, 141, 174–181. [Google Scholar] [CrossRef]

- CEN. EN 14770:2012; Bitumen and Bituminous Binders—Determination of Complex Shear Modulus and Phase Angle—Dynamic Shear Rheometer (DSR). European Committee for Standardization: Brussels, Belgium, 2012.

- Loise, V.; Oliviero Rossi, C.; Venturini, L.; Eskandarsefat, S.; Sangalli, L. Rejuvenating vs. softening agents: A rheological and microscopic study. In Proceedings of the 1st Macedonian Road Congress, Skopje, North Macedonia, 8 November 2019; pp. 411–419. [Google Scholar]

- CEN. EN 17643:2022; Bitumen and Bituminous Binders—Determination of Equishear Modulus Temperature and Phase Angle Using a Dynamic Shear Rheometer (DSR)—BTSV Test. European Committee for Standardization: Brussels, Belgium, 2022.

- Pipintakos, G.; Soenen, H.; Ching, H.V.; Velde, C.V.; Van Doorslaer, S.; Lemière, F.; Varveri, A.; Bergh, W.V.D. Exploring the oxidative mechanisms of bitumen after laboratory short- and long-term ageing. Constr. Build. Mater. 2021, 289, 123182. [Google Scholar] [CrossRef]

- Marsac, P.; Piérard, N.; Porot, L.; Van den Bergh, W.; Grenfell, J.; Mouillet, V.; Pouget, S.; Besamusca, J.; Farcas, F.; Gabet, T.; et al. Potential and limits of FTIR methods for reclaimed asphalt characterisation. Mater. Struct. 2014, 47, 1273–1286. [Google Scholar] [CrossRef]

- Celauro, C.; Teresi, R.; Dintcheva, N.T. Effect of Short-Term and UV Irradiation Aging on the Behaviour of SBS-Modified Bitumen. Sustainability 2022, 14, 6915. [Google Scholar] [CrossRef]

| Properties | Unit | Value/Aspect |

|---|---|---|

| Material State | - | Granules |

| Colour | - | Black |

| Apparent density at 25 °C | g/cm3 | 0.4–0.6 |

| Softening Point | °C | 160–180 |

| Properties | Unit | Value/Aspect |

|---|---|---|

| Material State | - | Liquid |

| Colour | - | Dark brown-purple |

| Density at 25 °C | g/cm3 | 0.85–0.95 |

| Viscosity at 25 °C | cP | 50–150 |

| Flash point | °C | ≥200 |

| Binders from the Control Mix | Cycle of Rejuvenation | Optimum Dosage * (%) | Binders from the Testing Mix | Cycle of Rejuvenation | Optimum Dosage * (%) |

|---|---|---|---|---|---|

| CA⁰ + R | 1 | 4.5 | GRPA⁰ + R | 1 | 5.5 |

| CA1 + R | 2 | 4.5 | GRPA1 + R | 2 | 4.5 |

| CA2 + R | 3 | 4.4 | GRPA2 + R | 3 | 4.4 |

| Reference Binders | Softening Point (°C) | Binders from the Control Mix | Softening Point (°C) | Binders from the Testing Mix | Softening Point (°C) |

|---|---|---|---|---|---|

| LTA Bit. 50/70 | 60.8 | CA⁰ | 60.8 | GRPA⁰ | 62.5 |

| Ref. Bit. 50/70 | 49.6 | CA⁰ + R | 49.7 | GRPA⁰ + R | 50.2 |

| LTA Bit. 50/70 | 60.8 | CA1 | 60.6 | GRPA1 | 59.4 |

| Ref. Bit. 50/70 | 49.6 | CA1 + R | 50.3 | GRPA1 + R | 49.3 |

| LTA Bit. 50/70 | 60.8 | CA2 | 58.6 | GRPA2 | 58.5 |

| Ref. Bit. 50/70 | 49.6 | CA2 + R | 49.2 | GRPA2 + R | 48.8 |

| Reference Binder | Upper PG (°C) | Upper Critical Temp. (°C) | Binders from the Control Mix | Upper PG (°C) | Upper Critical Temp. (°C) | Binders from the Testing Mix | Upper PG (°C) | Upper Critical Temp. (°C) |

|---|---|---|---|---|---|---|---|---|

| LTA Bit. 50/70 | 76 | 80 | CA⁰ | 76 | 80 | GRPA⁰ | 82 | 82.2 |

| Ref. Bit. 50/70 | 64 | 67.5 | CA⁰ + R | 64 | 68.5 | GRPA⁰ + R | 70 | 70.6 |

| LTA Bit. 50/70 | 76 | 80 | CA1 | 76 | 80.1 | GRPA1 | 76 | 78.4 |

| Ref. Bit. 50/70 | 64 | 67.5 | CA1 + R | 64 | 69.4 | GRPA1 + R | 64 | 68.0 |

| LTA Bit. 50/70 | 76 | 80 | CA2 | 76 | 78.2 | GRPA2 | 76 | 78.4 |

| Ref. Bit. 50/70 | 64 | 67.5 | CA2 + R | 64 | 68.3 | GRPA2 + R | 48.8 | 68.2 |

| Reference Binder | TBTSV (°C) | δBTSV (°) | Binders from the Control Mix | TBTSV (°C) | δBTSV (°) | Binders from the Testing Mix | TBTSV (°C) | δBTSV (°) |

|---|---|---|---|---|---|---|---|---|

| LTA Bit. 50/70 | 61.0 | 81.9 | CA⁰ | 60.9 | 82 | GRPA⁰ | 62.2 | 81.7 |

| Ref. Bit. 50/70 | 49.9 | 85.3 | CA⁰ + R | 49.9 | 82.8 | GRPA⁰ + R | 50.4 | 83.2 |

| LTA Bit. 50/70 | 61.0 | 81.9 | CA1 | 60.8 | 81.7 | GRPA1 | 59.1 | 81.9 |

| Ref. Bit. 50/70 | 49.9 | 85.3 | CA1 + R | 50.1 | 82.2 | GRPA1 + R | 49.2 | 82.7 |

| LTA Bit. 50/70 | 61.0 | 81.9 | CA2 | 58.7 | 81.6 | GRPA2 | 58.6 | 82 |

| Ref. Bit. 50/70 | 49.9 | 85.3 | CA2 + R | 49.4 | 82.3 | GRPA2 + R | 48.7 | 82.7 |

| Binders | Sulfoxide Index (SI) | Carbonyl Index (CI) |

|---|---|---|

| Ref. Bit. 50/70 | 0.58 | 0.36 |

| LTA Bit. 50/70 | 0.16 | 0.08 |

| CA⁰ | 0.60 | 1.13 |

| CA⁰ + R | 0.15 | 0.08 |

| CA1 | 0.36 | 0.19 |

| CA1 + R | 0.31 | 0.26 |

| CA2 | 0.29 | 0.59 |

| CA2 + R | 0.25 | 0.62 |

| GRPA⁰ | 0.36 | 0.26 |

| GRPA⁰ + R | 0.33 | 0.21 |

| GRPA1 | 0.31 | 0.37 |

| GRPA1 + R | 0.19 | 0.41 |

| GRPA2 | 0.23 | 0.32 |

| GRPA2 + R | 0.23 | 0.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Mino, G.; Vijayan, V.; Eskandarsefat, S.; Venturini, L.; Mantalovas, K. Investigating the Multi-Recyclability of Recycled Plastic-Modified Asphalt Mixtures. Infrastructures 2023, 8, 84. https://doi.org/10.3390/infrastructures8050084

Di Mino G, Vijayan V, Eskandarsefat S, Venturini L, Mantalovas K. Investigating the Multi-Recyclability of Recycled Plastic-Modified Asphalt Mixtures. Infrastructures. 2023; 8(5):84. https://doi.org/10.3390/infrastructures8050084

Chicago/Turabian StyleDi Mino, Gaetano, Vineesh Vijayan, Shahin Eskandarsefat, Loretta Venturini, and Konstantinos Mantalovas. 2023. "Investigating the Multi-Recyclability of Recycled Plastic-Modified Asphalt Mixtures" Infrastructures 8, no. 5: 84. https://doi.org/10.3390/infrastructures8050084

APA StyleDi Mino, G., Vijayan, V., Eskandarsefat, S., Venturini, L., & Mantalovas, K. (2023). Investigating the Multi-Recyclability of Recycled Plastic-Modified Asphalt Mixtures. Infrastructures, 8(5), 84. https://doi.org/10.3390/infrastructures8050084