Development of an Engineered Slurry-Infiltrated Fibrous Concrete: Experimental and Modelling Approaches

Abstract

:1. Introduction

2. Materials and Methods

2.1. Properties of Materials

2.2. Mix Proportion

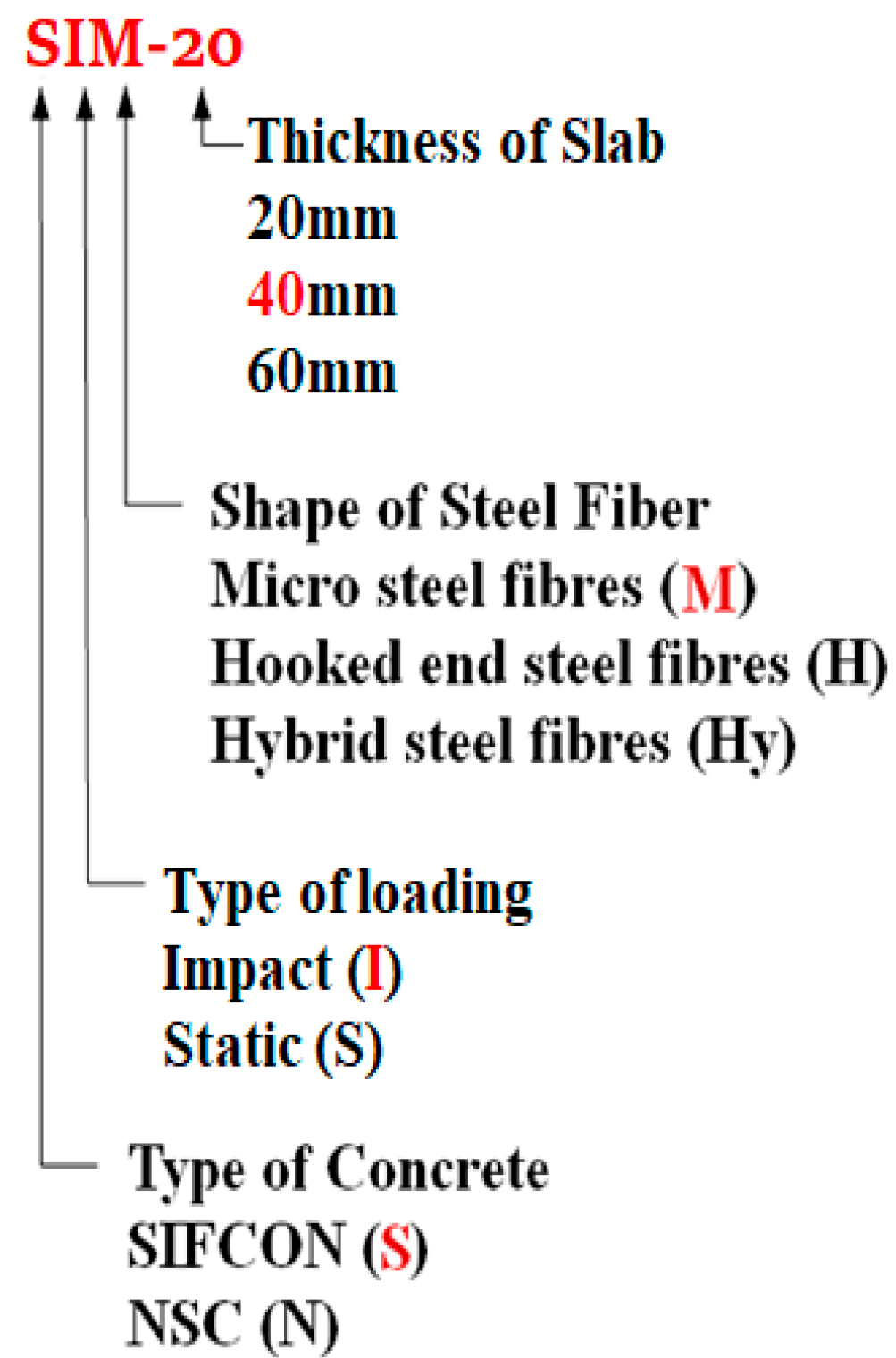

2.3. Samples Description

2.4. Samples Preparation

- The plywood moulds were well cleaned and lubricated with oil on the inner faces to prevent adherence.

- The technique of multi-layer casting is utilised to cast the SIFCON slabs. The mortars must flow properly to guarantee that the fibre is infiltrated. Then, full compaction and vibration were carried out using a vibrating table. For each layer, this process was repeated until the whole mould was filled with the desired thickness. Figure 3 shows the casting process of SIFCON and NSC slabs.

- The moulded samples were covered with a polyethene sheet in a laboratory for 24 h after casting and finishing the top surface of all samples to prevent moisture evaporation from fresh concrete. After that, slab samples were cured for the desired age (between 7 and 56 days). The curing process was carried out by submerging the samples in clean water at room temperature (20 ± 2 °C).

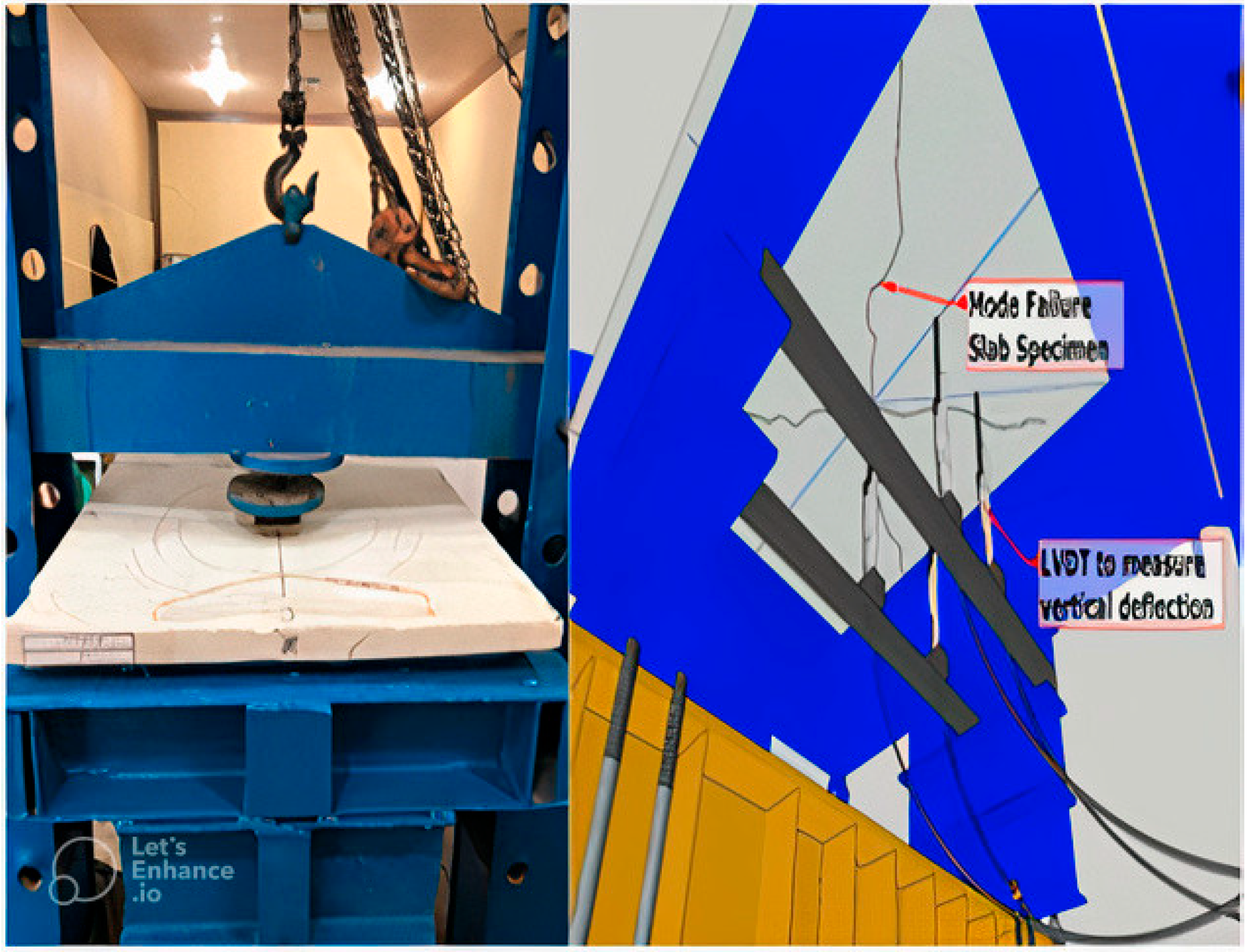

2.5. Test Set-Up and Instrumentation of SIFCON Specimens

2.6. Static Load (Punching Shear) Test of the SIFCON Slabs

2.7. Impact Loading Test of SIFCON Slab

2.8. Numerical Modelling

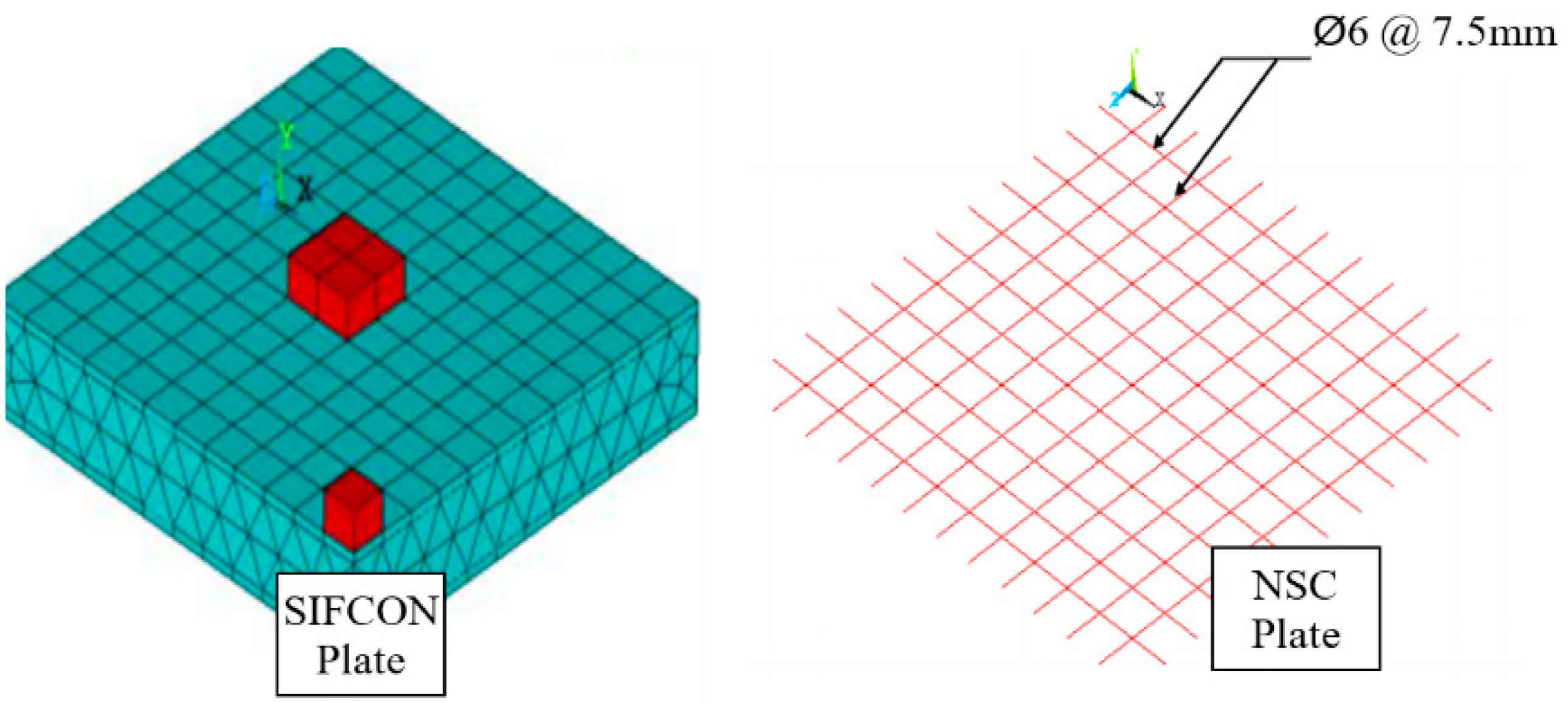

2.8.1. Modelling and Analysis of Slab Specimens

2.8.2. Finite Element Mesh and Boundary Conditions

2.8.3. Static and Impact Analysis Model

3. Results and Discussion

3.1. Experimental Results

3.1.1. Companion Specimen Test Results

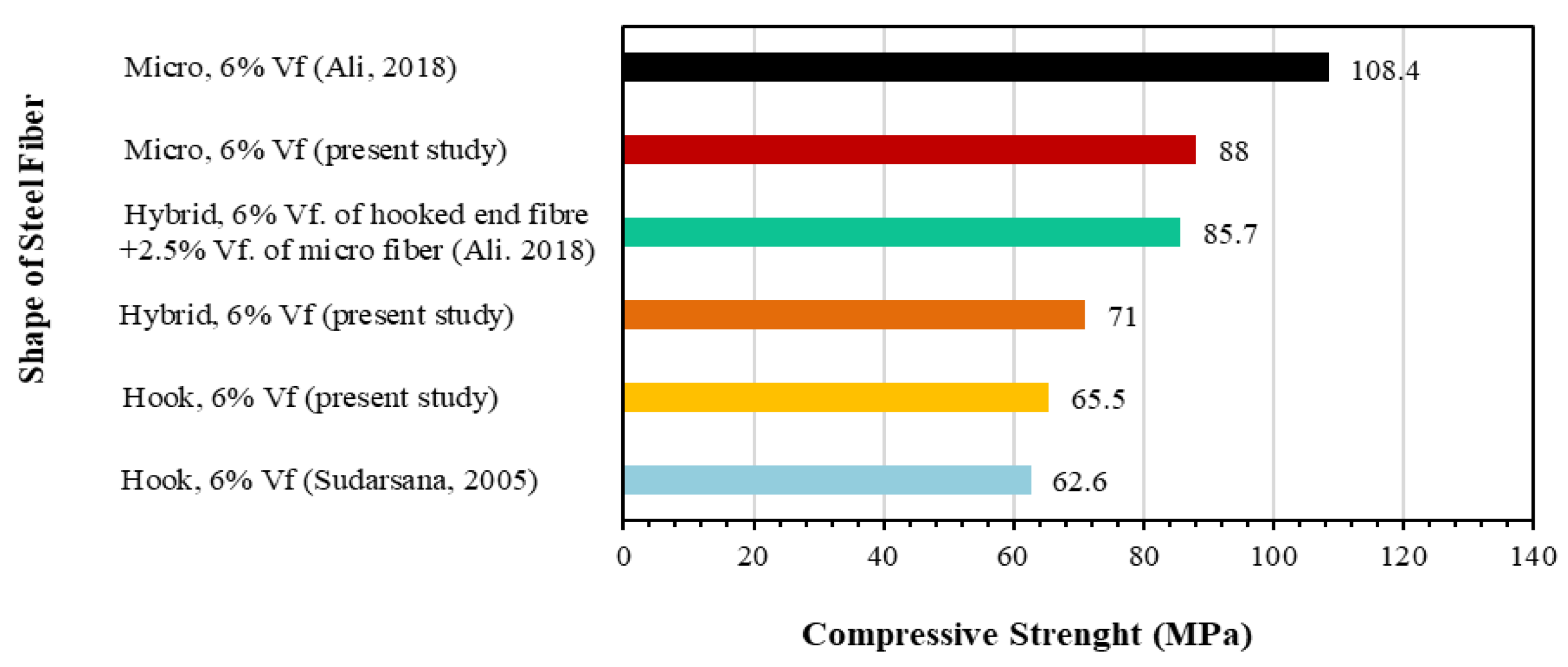

3.1.2. Compressive Strength

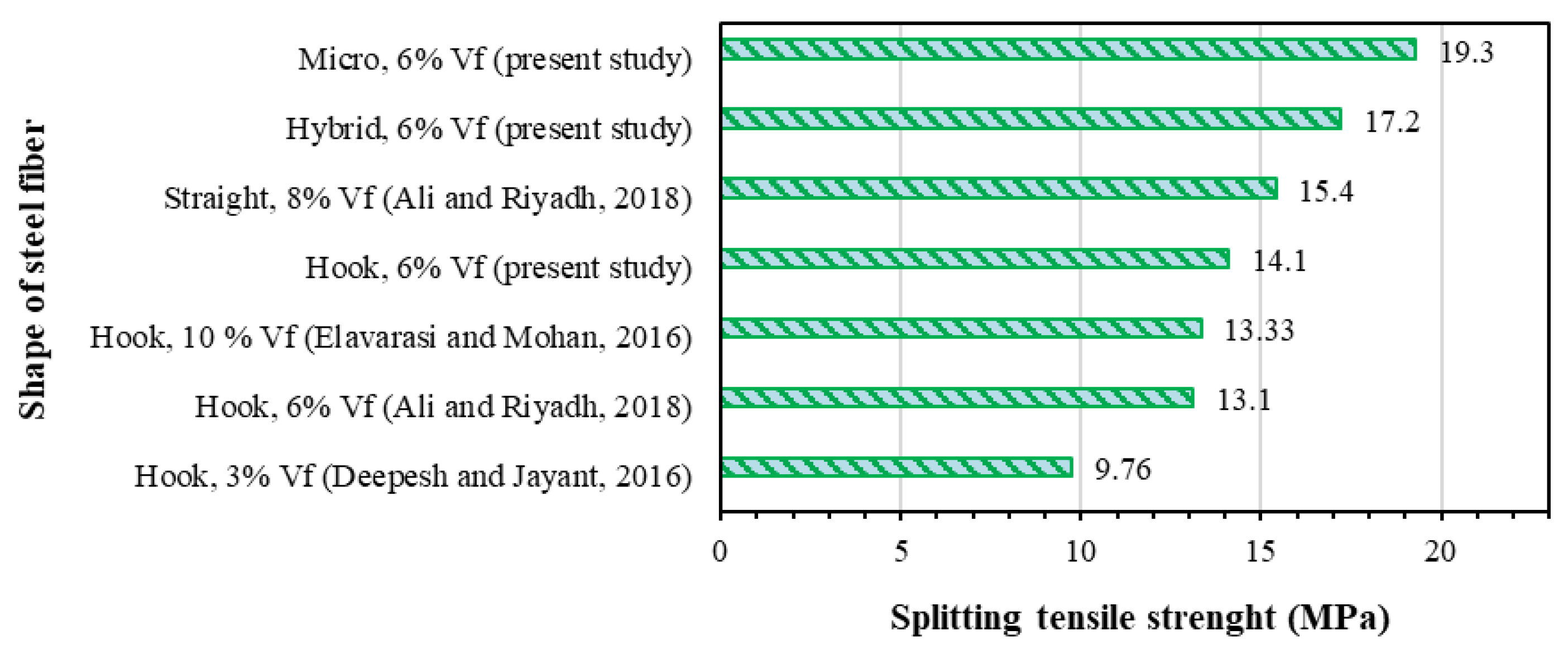

3.1.3. Splitting Tensile Strength

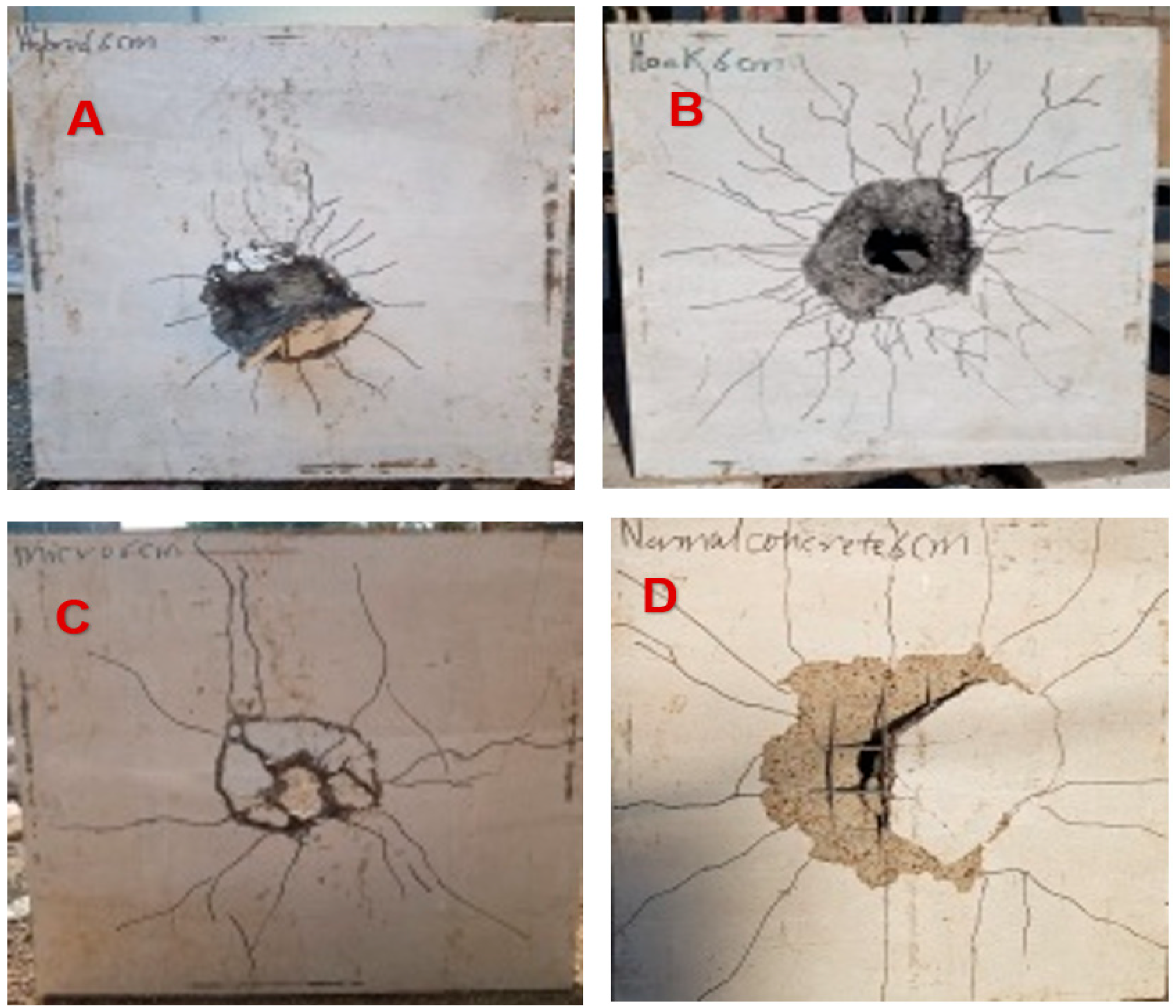

3.1.4. The Behaviour of SIFCON and NSC Slab under Impact Loads

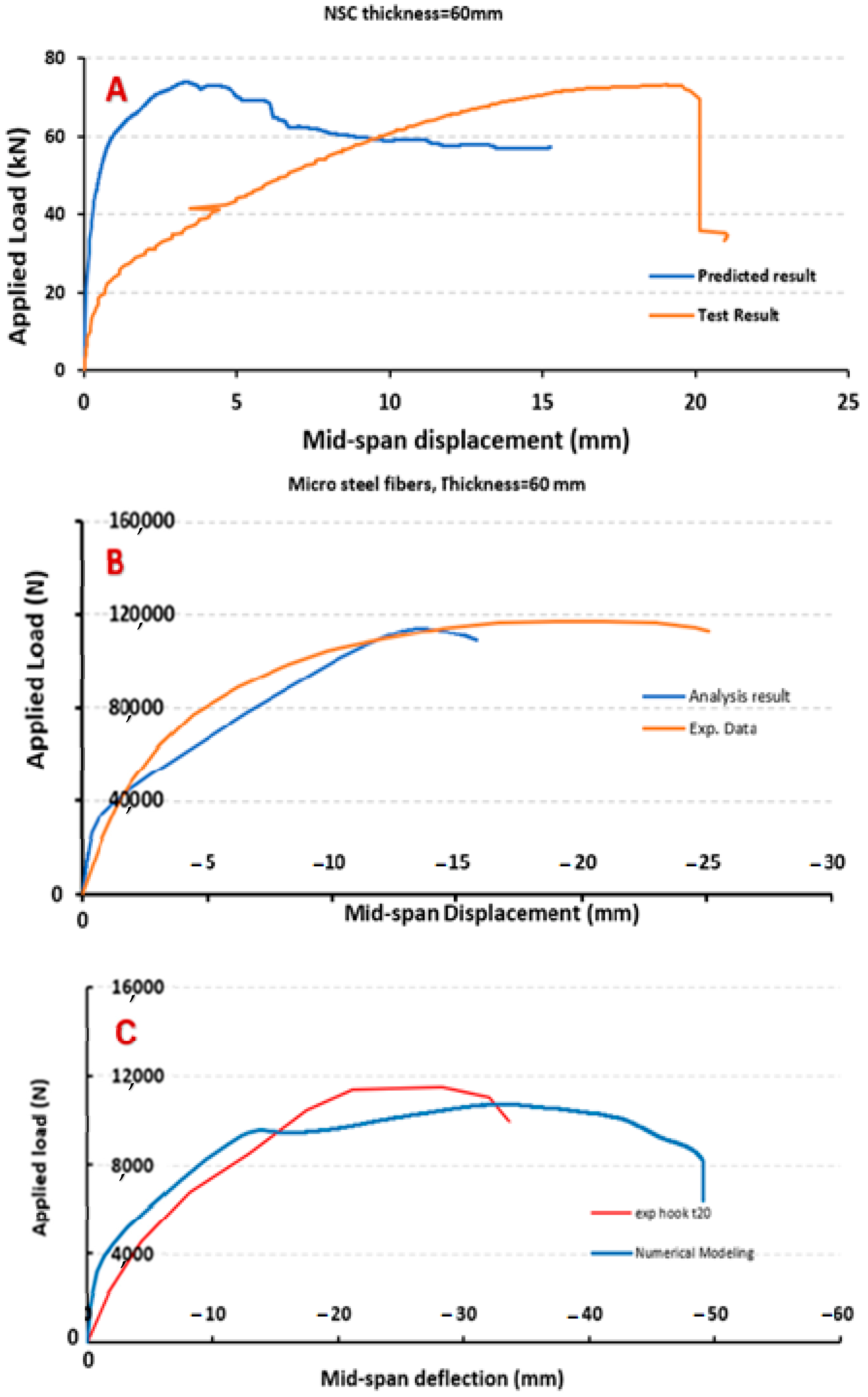

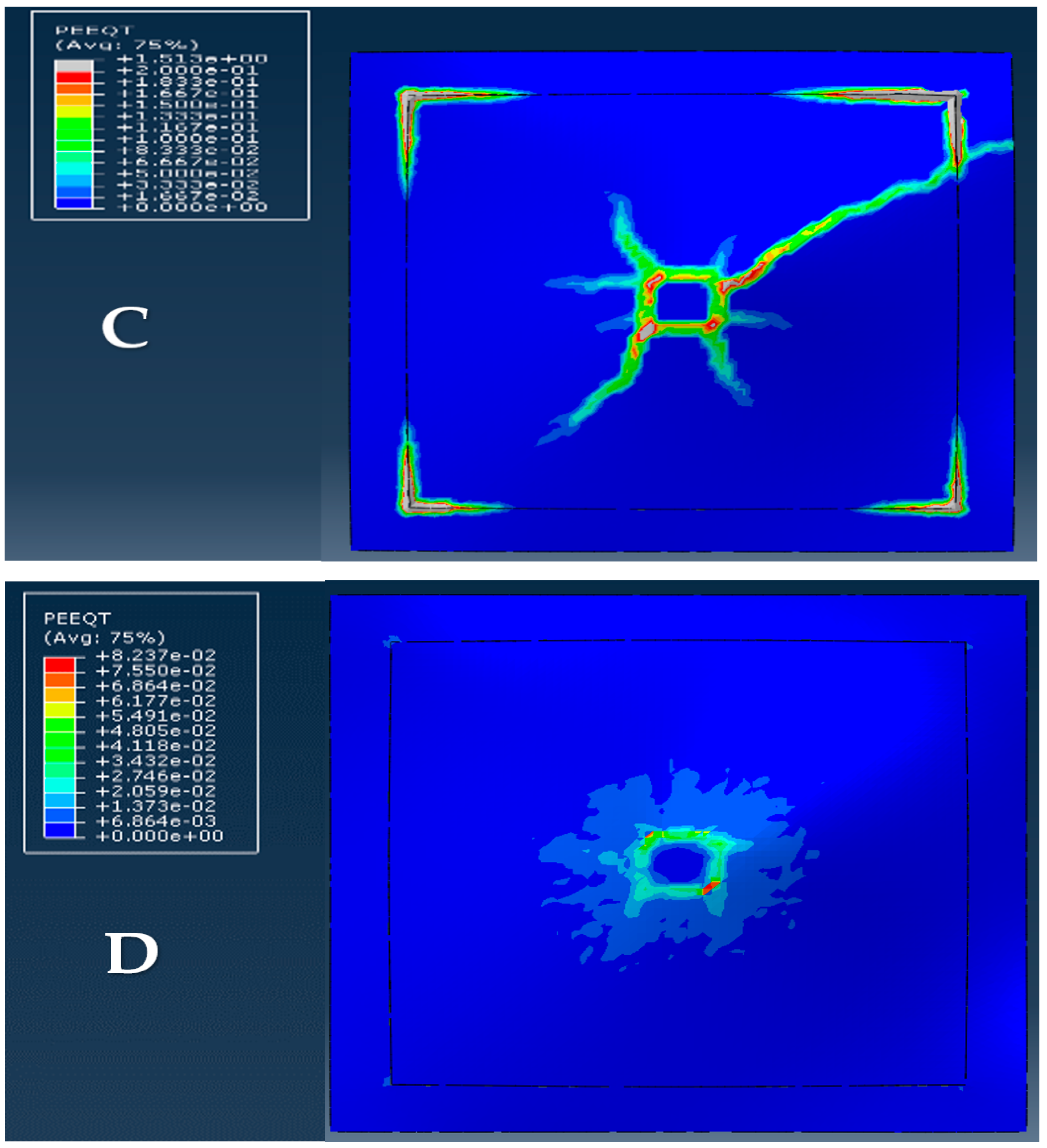

3.2. Finite Element Analysis Results

4. Conclusions

- SIFCON slabs have better mechanical properties than NSC slabs.

- The use of micro- and hybrid steel fibres to reinforce SIFCON slabs gives a higher load-carrying capacity than hook-end steel fibres.

- The slab thickness significantly affects the mechanical properties of the SIFCON mechanical properties, including the load-carrying capacity and impact load resistance.

- The stiffness of SIFCON slabs reinforced with micro-steel fibre is higher than that of hooked-end and hybrid fibre slabs.

- The non-linear finite element analysis is suitable for modelling of behaviours of SIFCON slabs under the studied loading systems (static and dynamic loads).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kadhim, A.; Sadique, M.; Al-Mufti, R.; Hashim, K. Long-term performance of novel high-calcium one-part alkali-activated cement developed from thermally activated lime kiln dust. J. Build. Eng. 2020, 32, 101766. [Google Scholar] [CrossRef]

- Shubbar, A.A.; Sadique, M.; Nasr, M.S.; Al-Khafaji, Z.S.; Hashim, K.S. The impact of grinding time on properties of cement mortar incorporated high volume waste paper sludge ash. Karbala Int. J. Mod. Sci. 2020, 6, 7. [Google Scholar] [CrossRef]

- Khamees, S.S.; Kadhum, M.M.; Alwash, N.A. Experimental and numerical investigation on the axial behavior of solid and hollow SIFCON columns. SN Appl. Sci. 2020, 2, 1094. [Google Scholar] [CrossRef]

- Abbas, A.S.; Kadhum, M.M. Impact of fire on mechanical properties of slurry infiltrated fiber concrete (SIFCON). Civ. Eng. J. 2020, 6, 12–23. [Google Scholar] [CrossRef]

- Saatci, S.; Vecchio, F.J. Effects of shear mechanisms on impact behavior of reinforced concrete beams. ACI Struct. J. 2009, 106, 78–86. [Google Scholar]

- Majdi, H.S.; Shubbar, A.; Nasr, M.S.; Al-Khafaji, Z.S.; Jafer, H.; Abdulredha, M.; Masoodi, Z.A.; Sadique, M.; Hashim, K. Experimental data on compressive strength and ultrasonic pulse velocity properties of sustainable mortar made with high content of GGBFS and CKD combinations. Data Brief 2020, 31, 105961–105972. [Google Scholar] [CrossRef] [PubMed]

- Kadhim, A.; Sadique, M.; Al-Mufti, R.; Hashim, K. Developing one-part alkali-activated metakaolin/natural pozzolan binders using lime waste. Adv. Cem. Res. 2021, 33, 342–356. [Google Scholar] [CrossRef]

- Shubbar, A.A.; Sadique, M.; Shanbara, H.K.; Hashim, K. The Development of a New Low Carbon Binder for Construction as an Alternative to Cement. In Advances in Sustainable Construction Materials and Geotechnical Engineering, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 205–213. [Google Scholar] [CrossRef]

- Vijayakumar, M.; Kumar, P.D. Study on strength properties of sifcon. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 235–238. [Google Scholar]

- Yazıcı, H.; Aydın, S.; Yiğiter, H.; Yardımcı, M.Y.; Alptuna, G. Improvement on SIFCON performance by fiber orientation and high-volume mineral admixtures. J. Mater. Civ. Eng. 2010, 22, 1093–1101. [Google Scholar] [CrossRef]

- Mohan, A.; Karthika, S.; Ajith, J.; Tholkapiyan, M. Investigation on ultra high strength slurry infiltrated multiscale fibre reinforced concrete. Mater. Today Proc. 2020, 22, 904–911. [Google Scholar] [CrossRef]

- Ali, M.H.; Atiş, C.D.; Al-Kamaki, Y.S.S. Mechanical properties and efficiency of SIFCON samples at elevated temperature cured with standard and accelerated method. Case Stud. Constr. Mater. 2022, 17, e01281. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Al-Lami, K.; Vatin, N.I.; Dixit, S.; Fediuk, R. Pure and mixed-mode (I/III) fracture toughness of preplaced aggregate fibrous concrete and slurry infiltrated fibre concrete and hybrid combination comprising nano carbon tubes. Constr. Build. Mater. 2023, 362, 129696. [Google Scholar] [CrossRef]

- Soylu, N.; Bingöl, A.F. Research on effect of the quantity and aspect ratio of steel fibers on compressive and flexural strength of SIFCON. Chall. J. Struct. Mech. 2019, 5, 29. [Google Scholar]

- Aygörmez, Y.; Al-mashhadani, M.M.; Canpolat, O. High-temperature effects on white cement-based slurry infiltrated fiber concrete with metakaolin and fly ash additive. Rev. Construcción 2020, 19, 324–333. [Google Scholar] [CrossRef]

- Kanagavel, R.; Kalidass, A. Mechanical properties of hybrid fibre reinforced quaternary concrete. Građevinar 2017, 69, 175530. [Google Scholar]

- Pradeep, T.; Sharmila, S. Cyclic behavior of RC beams using SIFCON sections. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 1–10. [Google Scholar]

- Ali, A.S.; Riyadh, Z. Experimental and Numerical Study on the Effects of Size and type of Steel Fibers on the (SIFCON) Concrete Specimens. Int. J. Appl. Eng. Res. 2018, 13, 1344–1353. [Google Scholar]

- Khamees, S.S.; Kadhum, M.M.; Alwash, N.A. Effect of hollow ratio and cross-section shape on the behavior of hollow SIFCON columns. J. King Saud Univ.-Eng. Sci. 2021, 33, 166–175. [Google Scholar] [CrossRef]

- Jerry, A.H.; Fawzi, N.M. The effect of using different fibres on the impact-resistance of slurry infiltrated fibrous concrete (SIFCON). J. Mech. Behav. Mater. 2022, 31, 135–142. [Google Scholar] [CrossRef]

- Akçaözoğlu, K.; Kıllı, A. The effect of curing conditions on the mechanical properties of SIFCON. Rev. Constr. 2021, 20, 37–51. [Google Scholar]

- Rao, H.S.; Ghorpade, V.G.; Ramana, N.; Gnaneswar, K. Response of SIFCON two-way slabs under impact loading. Int. J. Impact Eng. 2010, 37, 452–458. [Google Scholar] [CrossRef]

- Al-Obaidi, Z.A.-J.A. The Effect of Using Recycled Aggregates on Some Mechanical and Impact Properties of Concrete Slabs Reinforced with Plastic Waste Fibers; EasyChair: Manchester, UK, 2020; pp. 2314–2516. [Google Scholar]

- Drdlová, M.; Sviták, O.; Prachař, V. Slurry infiltrated fibre concrete with waste steel fibres from tires-the behaviour under static and dynamic load. In Proceedings of the Materials Science Forum, Tokyo, Japan, 9–11 June 2017; pp. 76–82. [Google Scholar]

- Azoom, K.; Pannem, R.M.R. Punching strength and impact resistance study of sifcon with different fibres. Int. J. Civ. Eng. Technol. 2017, 8, 1123–1131. [Google Scholar]

- Rao, H.S.; Ramana, N.; Gnaneswar, K. Behaviour of steel reinforced slurry infiltrated fibrous concrete (SIFCON) two way slabs in punching shear. Indian J. Eng. Mater. Sci. 2008, 15, 334–342. [Google Scholar]

- Rao, H.S.; Ramana, N. Behaviour of slurry infiltrated fibrous concrete (SIFCON) simply supported two-way slabs in flexure. Indian J. Eng. Mater. Sci. 2005, 12, 427–433. [Google Scholar]

- Yılmaz, T.; Kıraç, N.; Anil, Ö.; Erdem, R.T.; Sezer, C. Low-velocity impact behaviour of two way RC slab strengthening with CFRP strips. Constr. Build. Mater. 2018, 186, 1046–1063. [Google Scholar] [CrossRef]

- Vu, C.-C.; Ho, N.-K.; Pham, T.-A. Weibull statistical analysis and experimental investigation of size effects on the compressive strength of concrete-building materials. Case Stud. Constr. Mater. 2022, 17, e01231. [Google Scholar] [CrossRef]

- Naser, F.H.; Abeer, S. Flexural behaviour of modified weight SIFCON using combination of different types of fibres. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chennai, India, 5–6 October 2020; p. 012178. [Google Scholar]

- Khamees, S.S.; Kadhum, M.M.; Nameer, A.A. Effects of steel fibers geometry on the mechanical properties of SIFCON concrete. Civ. Eng. J. 2020, 6, 21–33. [Google Scholar] [CrossRef]

- Qian, C.; Stroeven, P. Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Sudarsana, R.H.; Ramana, N.; Gnaneswar, K. Behaviour of restrained SIFCON two way slabs part 1: Flexure. Asian J. Civ. Eng. (Build. Hous.) 2005, 10, 427–449. [Google Scholar]

- Labib, M.; Moslehy, Y.; Ayoub, A. Softening coefficient of reinforced concrete elements subjected to three-dimensional loads. Mag. Concr. Res. 2018, 70, 11–27. [Google Scholar] [CrossRef]

- Ipek, M.; Aksu, M. The effect of different types of fiber on flexure strength and fracture toughness in SIFCON. Constr. Build. Mater. 2019, 214, 207–218. [Google Scholar] [CrossRef]

- Tuyan, M.; Yazıcı, H. Pull-out behavior of single steel fiber from SIFCON matrix. Constr. Build. Mater. 2012, 35, 571–577. [Google Scholar] [CrossRef]

- Agha, A.A.; Kadhum, M.M. Behavior of Reactive Powder Concrete Columns under Axial Compression. Master’s Thesis, Babylon University, Babylon, Irak, 2015; pp. 571–577. [Google Scholar]

- Deepesh, P.; Jayant, K. Study of mechanical and durability properties of SIFCON by partial replacement of cement with fly ash as defined by an experimental based approach. Int. J. Innov. Res. Sci. Technol. 2016, 5, 8568–8574. [Google Scholar]

- Elavarasi, M.; Saravana Raja Mohan, K. Performance of Slurry Infiltrated Fibrous Concrete (Sifcon) with Silica Fume. Int. J. Chem. Sci. 2016, 14, 2710–2722. [Google Scholar]

- Ožbolt, J.; Riedel, W. Modelling the response of concrete structures from strain rate effects to shock induced loading. In Understanding the Tensile Properties of Concrete; Elsevier: Amsterdam, The Netherlands, 2013; pp. 295–340e. [Google Scholar]

| Mix Type | Mix Proportion | ||||||

|---|---|---|---|---|---|---|---|

| Cement (Kg/m3) | Sand (Kg/m3) | SF Kg/m3 10% rep. | Gravel (Kg/m3) | Fibres% | w/b Ratio | SP% (wt. of Binder) | |

| SIFCON | 872.1 | 969 | 96.9 | - | 6 | 0.33 | 3.7 |

| NSC | 518 | 763 | - | 768 | - | 0.44 | - |

| Type of Slab | Type of Loading | Type of Fibre | Slab Symbol | Slab Thickness (mm) |

|---|---|---|---|---|

| SIFCON Slab | Static | Micro-steel fibre | SSM-20 | 20 |

| SSM-40 | 40 | |||

| SSM-60 | 60 | |||

| Hybrid fibre | SSH-20 | 20 | ||

| SSH-40 | 40 | |||

| SSH-60 | 60 | |||

| Hook-end steel fibre | SSH-20 | 20 | ||

| SSH-40 | 40 | |||

| SSH-60 | 60 | |||

| Impact | Micro-steel fibre | SIM-20 | 20 | |

| SIM-40 | 40 | |||

| SIM-60 | 60 | |||

| Hybrid fibre | SIHy-20 | 20 | ||

| SIHy-40 | 40 | |||

| SIHy-60 | 60 | |||

| Hook-end steel fibre | SIH-20 | 20 | ||

| SIH-40 | 40 | |||

| SIH-60 | 60 | |||

| Normal Concrete Slabs | Static | - | NS-60 | 60 |

| Impact | NS-60 | 60 |

| The Shape of Steel Fibre (6% Vf) | Compressive Strength (MPa) | Elastic Modulus (GPa) | Splitting Tensile Strength (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 7 Days | 28 Days | 56 Days | 7 Days | 28 Days | 56 Days | 7 Days | 28 Days | 56 Days | |

| Micro steel | 68.2 | 88 | 117 | 23.3 | 28.6 | 31.6 | 17.1 | 19.3 | 20.2 |

| Hybrid fibre | 61.6 | 71 | 109.6 | 21.7 | 26.8 | 30 | 15.3 | 17.2 | 18 |

| Hook-end fibre | 45.7 | 65.5 | 95.2 | 19.6 | 25.4 | 27 | 12.6 | 14.1 | 14.6 |

| Sample Type | No. of Blows at Failure |

|---|---|

| SIFCON with hybrid steel fibres | 1324 |

| SIFCON with micro-steel fibres | 1075 |

| SIFCON with hook-end steel fibres | 1086 |

| NSC | 580 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yas, M.H.; Kadhum, M.M.; Al-Dhufairi, W.G.B. Development of an Engineered Slurry-Infiltrated Fibrous Concrete: Experimental and Modelling Approaches. Infrastructures 2023, 8, 19. https://doi.org/10.3390/infrastructures8020019

Yas MH, Kadhum MM, Al-Dhufairi WGB. Development of an Engineered Slurry-Infiltrated Fibrous Concrete: Experimental and Modelling Approaches. Infrastructures. 2023; 8(2):19. https://doi.org/10.3390/infrastructures8020019

Chicago/Turabian StyleYas, Mohammed H., Mohammed M. Kadhum, and Watheq G. B. Al-Dhufairi. 2023. "Development of an Engineered Slurry-Infiltrated Fibrous Concrete: Experimental and Modelling Approaches" Infrastructures 8, no. 2: 19. https://doi.org/10.3390/infrastructures8020019

APA StyleYas, M. H., Kadhum, M. M., & Al-Dhufairi, W. G. B. (2023). Development of an Engineered Slurry-Infiltrated Fibrous Concrete: Experimental and Modelling Approaches. Infrastructures, 8(2), 19. https://doi.org/10.3390/infrastructures8020019