Abstract

Management of nonurban road network maintenance is a complex management process that requires the inclusion of many technical, economic, and other characteristics of the problem, as well as the continuous application of new knowledge and approaches, to maintenance management. To effectively manage the maintenance of the road network in conditions of limited financial resources, maintenance is examined through three interrelated management functions of planning: implementation, monitoring, and maintenance control. This paper includes an analysis of current and relevant papers on this topic. Based on the conducted analysis, the paper gives a theoretical framework and proposes a management model for road network maintenance between urban areas. This model supports the previously mentioned management functions using Multicriteria Decision-Making Methods. The AHP method and the TOPSIS method are engaged in the process of generating a priority road maintenance plan and Earned Value Analysis in maintenance monitoring and control. The AHP method is used to determine the criteria weight vector as a key role in defining the rank of alternatives and in identifying the optimal maintenance rank of nonurban roads using the TOPSIS method. All of the above aim to ensure the safe flow of traffic and the permanent preservation of the construction, traffic, and economic value of roads between urban areas.

1. Introduction

Management, as a crucial requisite of every organization, is one of the most important human activities. Every organization, every more complex job or activity, such as road network maintenance in urban and nonurban areas, requires management to ensure the undisturbed and safe traffic flow. Road network maintenance management is a complex management process that requires the inclusion of numerous technical, economic, and other characteristics of the problem, as well as the continuous application of new knowledge and approaches to maintenance management. This complexity is one of the reasons that makes road maintenance management a poorly structured problem with a multicriteria nature, and it is effectively solved by using multicriteria methods in conditions of limited budget.

In order to increase the efficiency of maintenance, the aim of this paper is to present new models and procedures that, together, form a unique, new, and original approach to the road infrastructure maintenance management. Such a proposed approach is based on the logical and managerially justified integration of multicriteria methods and Earned Value Analysis (EVA), which form a unique decision support concept applicable to the maintenance management of nonurban road infrastructure.

Accordingly, the original scientific contribution of this paper is reflected in the validation of the proposed model, which indicates an increase in the efficiency of road network maintenance in relation to the previous models presented in the papers of authors who are relevant to the positioning and evaluation of the approach proposed in this research.

In order to bring the problem of this research closer to the reader at the beginning of the paper, the relationship between management and road infrastructure maintenance management, the relationship between decision making road infrastructure maintenance management, and the relationship between multicriteria methods and road infrastructure maintenance management are described, in detail, below.

1.1. Management and Road Infrastructure Maintenance Management

Maintenance management of the road network, in urban and nonurban areas, is a complex process both from the management point of view and from the technical-economic point of view. Thus, management in general, and in this case, road network maintenance management, is said to be a process or series of continuous and related activities aimed at achieving set goals. A closer look at the general concept of managing the maintenance of the road network outside urban areas is possible through the general division of the management process into three main functions: namely, planning, implementation, as well as monitoring and control. The general division of management processes within the business organization into the three mentioned functions is the same as in other management processes. However, its elaboration in this research subject is in line with the needs of management processes aimed at the maintenance of the nonurban road network.

The nonurban road network presents a network of roads outside urban areas that includes roads between urban areas, cities, and settlements. As such, it is intended to connect economically important areas and centers of local communities.

Roads are national assets that support economic activity, as road transport is the basis for economic activity, outdated road infrastructure requires increased maintenance, traffic continues to grow and increases the need for maintenance, etc. [1]. These facts indicate the importance and need for road maintenance management, as well as constant development of urban and nonurban road network maintenance management models. Planning, as the first function of road infrastructure maintenance management, is a complex process in which several authors generally agree. Thus, Marović et al. [1] emphasize that maintenance planning, as part of urban road infrastructure management, is a complex problem from both the managerial and techno-economic aspects, focusing on decision-making processes related to the planning phase during urban road infrastructure project management. Concerning these problems, Jajac et al. [2] emphasize that the prioritization of projects, in terms of particular annual budgets for construction, maintenance, and rehabilitation activities, are the most difficult and important issues in the public decision-making process. The other reasons for this complexity are different participants with different opinions, the multidisciplinary nature of the problem, a large amount of information, as well as conflicting goals and criteria.

1.2. Decision Making and Road Infrastructure Maintenance Management

Management is a complex process that cannot happen without a decision-making process. Decision-making is considered the essence of all the above management functions, while decision support is one of the key factors of successful management.

The decision-making process usually comes after setting goals and objectives that should be achieved, selecting criteria, and preparing to choose the best alternative. Decision-making happens in the management process several times, and in different time intervals, depending on the process that takes place and the resulting need to make appropriate decisions [3]. In this sense, we can say that the management of road network maintenance is achieved only through an effective decision-making process. Therefore, there is a close connection between management and decision-making, as pointed out by numerous authors from the relevant literature within this field. According to Simon [4], decision-making is synonymous with management. Novak [5] defines decision-making as an integral element of managerial activity, while Gorupić [6] considers that managing a business organization means deciding.

Every decision-maker faces more or fewer problems when making decisions. One of the most common problems is the gap between the needs and possibilities. Namely, the needs of every decision-maker are greater than the possibilities or resources available to them. Research, in this paper, is focused on the decision-making process related to the nonurban road network maintenance management, within the limited budget, where it is necessary to create an effective management system, i.e., a road maintenance system, to maximize their use with minimal investment [7].

The complexity of road infrastructure maintenance management stems, mainly, from a large number of different and conflicting criteria, a large number of stakeholders involved in the decision-making process, a limited maintenance budget, and the multidisciplinary nature of the problems, which is why the decision-making process, as an integral part of management, belongs to complex and poorly structured problems [2]. Therefore, successful nonurban road network maintenance management, as a subject of this research, can be achieved through decision support systems and the application of various methods of multicriteria analysis.

1.3. Multicriteria Methods and Road Infrastructure Maintenance Management

When managing the maintenance of a nonurban road network, it is usually poorly structured and unstructured problems that are solved by finding the best option, in relation to defined qualitative and quantitative criteria and their weight, using multicriteria analysis methods. The methods of multi-criteria analysis include the following: Simple Additive Weighting (SAW) [8], Elimination and (Et) Choice Translating Reality (ELECTRE) [9], Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) [10], Multi-Attribute Utility/Value Theory (MAUT/MAVT) [11], Preference Ranking Organization Method for Enrichment Evaluations (PROMETHEE) [12], Analytical Hierarchy Process (AHP) [13], VIKOR [14], etc.

Each method has its advantages and disadvantages depending on the problem. What is common for all of them is that each consists of developing several alternative solutions, defining criteria, evaluating alternative solutions to all criteria, determining the weight of criteria, ranking solutions, conducting sensitivity analysis, and making the final decision [15] Each MCDM method is based on the definition of a decision matrix and a criteria weight vector W, which represents the importance that the decision maker gives to each selected criterion. Therefore, after the definition of the decision matrix and criteria weight vector, the most appropriate MCDM method can be used.

In this research, among the mentioned methods, the AHP method was used in determining the importance of criteria, while the TOPSIS method was used in the final ranking of nonurban roads, according to maintenance priorities.

The AHP method, as a multicriteria decision-making method, was developed in 1977 and is used to determine the ranking list of identified alternative solutions that are evaluated according to defined criteria. The method determines the importance factor according to pairwise comparisons of stakeholders involved in the decision-making process. Higher weights define a criterion of greater importance, while lower weights define a less important criterion. The final ranking is obtained by combining the weights of the criteria and the grade of alternative solutions [16].

When it comes to the wider field of construction, there are different examples of its application, such as water supply management system [17], risk management [18], selection of the appropriate material supplier [19], selection of the most suitable concrete mix [20], assessment of dam rehabilitation [21], solving problems in the field of energy efficiency [22], evaluation of solutions in the design of building structures [23], determining the priorities of the restoration of architectural heritage [24], determining the index of the condition of the bridge [25], and choosing the best way to manage demand [26].

The TOPSIS method, developed in 198,1 is based on selecting the optimal alternative according to the shortest distance from the positive ideal solution and the furthest distance from the negative ideal solution, in the geometric sense [10]. Numerous authors have applied the TOPSIS method in poorly structured engineering problems, such as selecting the most suitable contractor [27,28], selecting the appropriate wastewater treatment technology [29], assessing the level of risk safety of bridge construction [30], evaluating bids for highway construction [31], the process of hiring employees according to pre-defined criteria [32], etc.

When it comes to the AHP method application in solving the problem of transport infrastructure, Sirin et al. [33] identify all factors that affect the performance of roads as a fundamental element of road infrastructure during road design, construction, and the maintenance phase.

Khademi and Sheikholeslami [34] combine the AHP method with the Delfi technique, as a hybrid Delfi-AHP model, in prioritizing the maintenance, improvement, and upgrading of lower-class roads. In this research, the Delphi technique was applied in defining the criteria by 76 traffic experts, while the AHP method determines their relative weights, based on which the observed roads are finally ranked according to the priorities of maintenance and reconstruction.

The AHP method can be combined with other methods of multicriteria analysis. Therefore, Sayadinia and Beheshtinia [35] provide a new hybrid approach to multicriteria decision-making by combining AHP, ELECTRE II, ELECTRE III, and ELECTRE IV methods and Copeland techniques in prioritizing road maintenance. Using the AHP method, the weights of individual criteria were also determined, but ELECTRE II, ELECTRE III, and ELECTRE IV methods of multicriteria decision-making were used to rank alternatives. The results obtained with the help of these methods were finally combined with the Copeland technique, thus giving the final list of priorities for the maintenance of the observed roads.

Bhandari and Nalmpantis [36] use the AHP method to rank a total of 13 criteria, divided into three sustainability groups, according to their relative importance. TOPSIS, MOORA, and PROMETHEE methods are used to rank rural roads according to maintenance priorities. Each method gives a similar priority list of observed rural roads.

Jajac et al. [37] propose the concept of decision support on the problem of urban road infrastructure management, based on a combination of AHP, SAW, and PROMETHEE methods and 0–1 programming. The assessment of the importance of the criteria, which includes the opinion of all stakeholders, was performed using the AHP and SAW methods, while the ranking of priorities for the construction of garages, in the urban part of the city of Split, was performed using the PROMETHEE method.

Kilić Pamuković et al. [16] use a combination of the AHP method and PROMETHEE method to rank and determine priorities in the maintenance of asphalt pavement, on the main roads of the city of Split, as part of the road infrastructure. In order to improve the process of planning, the maintenance of asphalt pavements through the applied multicriteria methods—the social, technical, and economic aspects of this problem—have been taken into account.

A similar approach to multicriteria decision-making, based on a combination of AHP and PROMETHEE methods, has been used in other technical and more precise construction issues, such as planning projects for the rehabilitation of historic bridges [38], site selection in the construction project planning phase [39], selection of the best investment project [40], planning the rehabilitation of schools by removing barriers [41], and maintenance of city parking facilities [42]. Regardless of the subject of the research, all authors agree on how complex decision-making processes, such as ranking, cannot take place without the establishment of a decision support system and the application of appropriate multi criteria decision-making methods. Furthermore, Nodrat and Kang [43] developed a tool to prioritize road maintenance and rehabilitation activities. They have taken into account the road condition index, road width, traffic intensity, and maintenance costs. To increase road safety, Francello et al. [44] rank urban road intersections, based on eight safety criteria, by comparing the results obtained using the TOPSIS and VIKOR methods, as well as the Concordance Analysis.

In contrast to decision-making concepts based exclusively on a combination of multi-criteria methods, Jajac et al. [2] presented a multi criteria decision-making approach. It aimed at improving decision-making at the level of urban road infrastructure planning, based on a combination of multi-criteria SAW and AHP methods, with neural networks. Marović et al. [1], to also solve the problem of decision-making in the field of urban infrastructure, developed a model of artificial neural networks to predict road degradation as an auxiliary tool in planning the maintenance of road infrastructure.

Furthermore, Rogulj et al. [41] developed a new expert system for assessing the condition of historic road bridges as part of road infrastructure, using fuzzy logic and alpha cuts in combination with the AHP method used to compare and rank alternative solutions.

According to the defined research problem, and taking into account previously described state of the art methods, the authors proposed a new and unique model for nonurban road infrastructure maintenance management. This model, based on a multicriteria approach and multicriteria methods, is presented within the following chapter.

2. Proposed Nonurban Road Network Maintenance Management Model

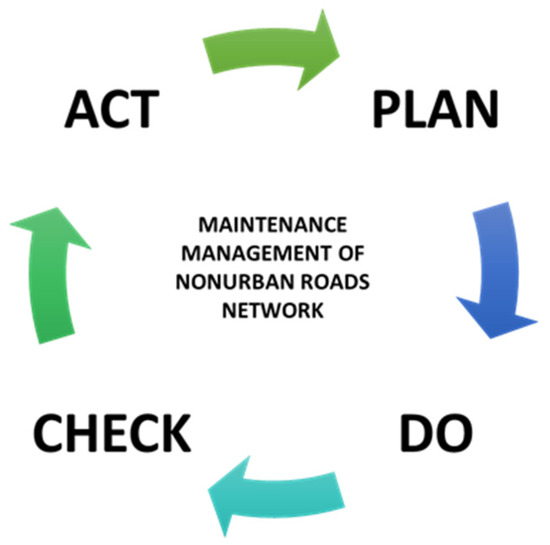

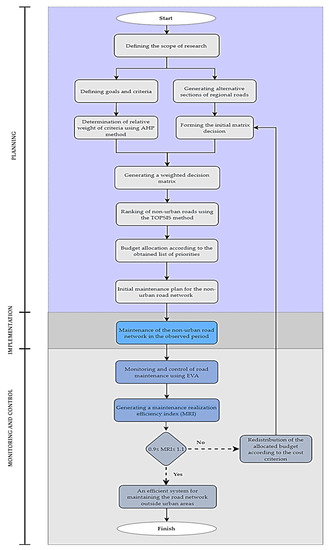

The proposed model represents a multicriteria approach to decision-making, based on the multiple-criteria decision-making methods AHP and TOPSIS and Earned Value Analysis (EVA) to improve the management of road network maintenance in nonurban areas. The model is divided into three phases. The first phase corresponds to the process of road maintenance management planning, which results in the initial maintenance plan observed outside urban roads and the distribution of planned investments according to the identified priority. All this, together, is included in a plan for the maintenance of the nonurban road network, which is followed by the implementation of maintenance, in the observed period of the defined area, as the second phase of the model. Monitoring and control is the third and last phase of the proposed model. In this phase, we compare the planned and actual condition of the observed roads in a particular planning period using the Earned Value Analysis, which results in appropriate indicators of implementation efficiency. The model phases are interdependently connected and operate in a defined sequence. The proposed model is based on the concept of interaction between maintenance management functions that ensure the planned quality of maintained nonurban roads, known as the Plan—Do—Check—Act (PDCA) Cycle (Figure 1).

Figure 1.

Maintenance management model through PDCA cycle.

According to Figure 1, maintenance management of nonurban roads is an iterative process for their continuous improvement through the planning function, presented by the Plan component, followed by the implementation of the plan presented by the Do component, and monitoring of maintenance according to the plan presented by the Check and Act components. Each of the listed components shown in Figure 1 results in an output that is, at the same time, an input variable for the next component. Therefore, the generated maintenance plan for nonurban roads is the input variable for the implementation phase, while maintained nonurban roads are the input variable for the monitoring and control of maintenance in which the planned and performed condition is compared. The Act component implies the implementation of corrective actions, in case of deviation from the plan, in order to obtain an efficient and quality system of nonurban road maintenance as the final product of this cycle. A detailed elaboration of the PDCA cycle is presented through the proposed model of nonurban road network maintenance management (Figure 2).

Figure 2.

Nonurban road network maintenance management model.

2.1. Defining the Scope of Research

According to the Strategy for the Development of Public Roads [45] in the area of the Herzegovina-Neretva Canton, in a spatial and traffic Sense, the scope of this research is very important and unique in the area where significant corridors, Corridor Vc and the Adriatic-Ionian Corridor, are interconnected. The development of traffic infrastructure in this area is an indicator and precondition of the economic development of Bosnia and Herzegovina. Transport Corridor V, with its branch C, from the port of Ploce through Bosnia and Herzegovina and via Osijek in Croatia leads to Budapest in Hungary and connects with Pan-European Corridor V. Further, Corridor Vc, with its passage through Croatia, connects with Corridor X on the Zagreb-Belgrade section. In its southern part, the Adriatic-Ionian Highway passes through Bosnia and Herzegovina, which, on the one hand, connects Bosnia and Herzegovina with Croatia and the Vb Corridor and, on the other hand, towards the southeast with Montenegro, Albania, Greece, and further towards Turkey. Therefore, the development of transport infrastructure in this strategically important area is an indicator and precondition of the economic development of the whole of Bosnia and Herzegovina. The scope of this research is the network of regional roads of the Herzegovina-Neretva Canton that consists of twelve regional road routes in their total length of 392,726 km, as shown in Table 1.

Table 1.

Observed network of regional roads.

The research is focused exclusively on sections of regional roads as part of the road infrastructure that can be improved to achieve the level of development of the road infrastructure of the European Union countries through systematic maintenance management. According to the ordinance on the maintenance of public roads [46]. the basic goals of their maintenance are the following: to prevent the deterioration of roads, enable safe traffic, reduce user costs with good road condition, bring the road into a designed condition, taking into account changing traffic needs, and protect the road from users and third parties, as well as protect the environment from the harmful effects of roads and road traffic, to permanently preserve the construction, traffic, and economic value of the road.

2.2. A Model for Establishing a Hierarchical Structure of Goals

The hierarchical structure of goals generally represents the relationship between the main goal at the highest level and the criteria at the lower level, according to which alternatives located at the lowest level of the hierarchical structure are evaluated to assess the importance of elements at a certain level [47]. For the previously defined scope of this research, to establish a hierarchical structure of goals, the main goal, criteria as measurable quantities, and alternatives at its last level have been defined. An online survey was conducted with representatives of three expert groups to identify the decision-making criteria, based on which a total of eleven criteria were identified and divided by type into technical, social, and economic criteria (Table 2). In addition to the criteria, the main goal of the defined hierarchical structure is the effective management of nonurban road network maintenance. The possible alternatives, previously presented in the previously defined area of this study, are to be ranked according to the maintenance priorities of regional road sections.

Table 2.

Identification of appropriate criteria.

2.3. Determination of Weight Criteria by AHP Method

The AHP method enables the decomposition and solution of the most complex problems, including quantitative and qualitative aspects of the problem that is being decomposed. In this paper, the AHP method is applied to determine the relative weights of criteria that, according to the preferences and opinions of the stakeholders involved, have a significant impact on the management of nonurban road network maintenance. Determining the weight of criteria is a particular issue in the multicriteria analysis, and it depends on the preferences of decision-makers and their way of demonstration.

When it comes to simple decision-making problems, only one person, or a homogeneous interest group, who can accurately determine the weight of the criteria is usually involved.

Managing the maintenance of the nonurban road network involves a large number of participants with, often, conflicting goals and interests that need to be met. Therefore, in order to make effective decisions on maintenance management, stakeholders were divided into three expert groups. The first expert group consists of representatives of the municipality to which the observed roads outside urban areas belong, the second group consists of experts in the field of transport infrastructure, while the last, third group consists of experts from companies in charge of maintenance of observed roads. Determining the relative weight of criteria is determined by comparing criteria as elements of a previously developed hierarchical structure, by using the Saaty’s scale of relative importance, shown in Table 3 [13].

Table 3.

Saaty’s scale of relative importance [13].

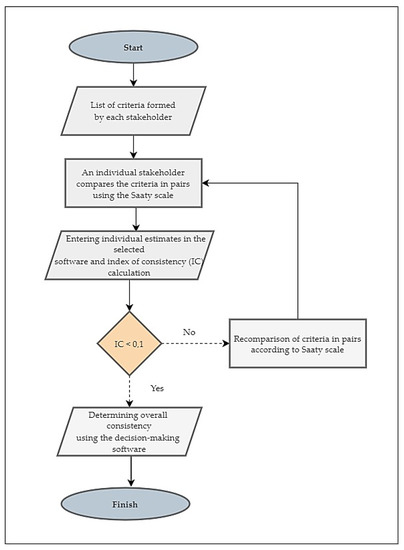

When it comes to defining relative weights of the criteria, the views of all stakeholders involved need to be taken into account. The group decision-making process begins with each stakeholder individually ranking the criteria according to importance in the criteria list, from 1 to n, and comparing the criteria in pairs based on the Saaty’s scale. Then, the assigned grades are entered into a specific software (e.g., Decision Expert) that simply calculates index of consistency (IC) that must be less than 10%. The index of consistency (IC) is a measure of the consistency of decision makers in their judgments. A higher value of IC represents a lower measure of consistency while a lower value of IC represents a higher consistency of the decision maker. The index of consistency limit value is usually 0.1 or 10%. In general, this means that, when the judgment of the decision maker is relatively consistent, the IC will be less than or equal to 0.1, and when the IC is greater than 0.1, inconsistency occurs when it is necessary to repeat the evaluation process in the decision matrix. If the condition of consistency is met, the overall consistency of the assessment is determined, and if this is not the case, the assessment should be repeated, as shown in Figure 3.

Figure 3.

Flow diagram of determining the relative weight of the criteria.

The compromise relative weight of all criteria is obtained by combining individual assessments of all evaluators presented using pairwise comparison matrix A.

where n is the number of considered evaluation criteria, while each element of the matrix aij represents the importance of the i-th criterion in the relation to the j-th criterion.

If aij represents the importance of criterion i over criterion j and ajk represents the importance of criterion j over criterion k then aik, the importance of criterion i over criterion k must equal aijajk for the judgments to be consistent. Problem becomes with w′ = λmaxw′ where λmax is the largest of principal eigenvalue of = (aij′), the perturbed value of = (aij) with a′ji = 1/a′ij forced. To simplify the notation, we shall continue to write w = λmax w, where A is the matrix of pairwise comparisons. The solution is obtained by raising the matrix to a sufficiently large power, then summing over the rows, and normalizing to obtain the priority vector w = (w1, w2, …, wn) [48].

Using the principal eigenvalue of the matrix A, it is possible to perform the consistency check in order to exclude unacceptable conflicts in the expressed pairwise comparisons.

Therefore, to validate comparisons of criteria, it is necessary to calculate the consistency ratio (), which presents a relation between the index of consistency () and the random consistency index () as follows:

represents the random consistency index, which depends on the dimensions of the matrix and, in this case, depends on the number of analyzed criteria. The consistency ratio is obtained by comparing the with the appropriate one of the following set of numbers, each of which is an average random consistency index derived from a sample of randomly generated reciprocal matrices (Table 4).

Table 4.

Average random consistency index [49].

Index of consistency (IC) is possible to calculate according to:

where is the maximum eigenvalue of the matrix and n is the matrix dimension. If value of CR is not less than 0.10, study the problem and revise the judgments.

The relative weights of the criteria, obtained in the previously described manner, represent the input data for the multicriteria decision-making method TOPSIS, which, as an output for the data, gives a list of nonurban roads, according to the priority of the maintenance or maintenance plan.

2.4. Priority Nonurban Road Maintenance Plan Based on the TOPSIS Method

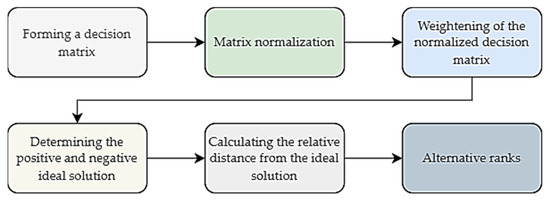

TOPSIS method was developed in 1981 by Hwang and Yoon, and today, it is considered one of the most used methods of multi criteria decision making. It was applied, as such, in the proposed model of nonurban road network maintenance to rank sections of roads outside urban areas, according to maintenance priorities, through the six steps shown in Figure 4.

Figure 4.

TOPSIS Method Procedure.

The process begins with the formation of a decision matrix D:

Previous presented decision matrix D is a rectangular matrix m × n, where m is the number of alternatives, and n is the number of judgment criteria, in which the generic column represents the performance of i-th alternative, with respect to j-th criterion.

For all elements of the decision matrix to be expressed in dimensionless size, it is necessary to normalize the matrix using the following formula:

In the third step, the normalized matrix R = [rij] is multiplied by a unit matrix of weight coefficients, i.e., each element of the normalized matrix rij is multiplied by the weight of each criterion wij t, based on which the following matrix is obtained:

It is followed by determining the positive () and negative ideal solution (). Positive Ideal Solution (PIS) is a value that maximizes the desired function and is calculated as follows [50]:

where belongs to the criteria to be maximized, according to Table 2. The negative ideal solution () represents the value that minimizes the desired function, and it is calculated using the following expression [50]:

where belongs to the criteria that are minimized, according to Table 2.

Thus, it can be concluded that the best are those alternatives that have the highest vij in relation to the criteria that are maximized and the smallest vij in relation to the criteria that need to be minimized.

In the next step of the TOPSIS method, it is necessary to calculate the Euclidean distances of individual alternatives from the ideal positive and ideal negative solution based on the following formulas (9) and (10):

For each alternative, it is necessary to calculate the relative distance from the ideal solution using the formula:

According to the given formula, when the alternative Ai is closer to the ideal solution, the value Ci* is closer to 1. Alternative Ai will take the value 1 if its values are equal to the ideal positive solution and the value 0 if the values if the alternative Ai are equal to a negative ideal solution. In the last step of the TOPSIS method, it is necessary to rank the alternatives, and in this case, the sections of regional roads by values Ci*, where the best alternative is the one to which the value Ci* is the closest to value 1, while other alternatives are ranked according to falling values. The analysis and comparison of alternatives, according to the obtained data, is performed using the TOPSIS method, which results in the initial ranking of regional road sections according to maintenance priorities.

2.5. Results of AHP and TOPSIS Methods in Planning Function

After all the steps of the AHP method, mentioned earlier, have been performed, Table 5 shows the pairwise comparison matrix A with weight vector and index of consistency (IC).

Table 5.

Pairwise comparison matrix with weight vector and consistency.

After multiplying each element in the comparison pairwise matrix by the criteria weight vector, the decision matrix D, shown in Table 6, is obtained. Weighted decision matrix is used as the input for the calculation, according to the TOPSIS method.

Table 6.

The weighted decision matrix.

When calculating in the TOPSIS method, it is important to choose values that represent a positive and a negative ideal solution. Based on these data, the n-dimensional Euclidean deviation, from the positive and negative ideal points, is calculated. The relative distance from the ideal solution gives a ranking list of sections of the nonurban road network according to maintenance priorities. The best alternative is the one whose value of the relative distance of the alternative is closest to 1, while the other alternatives are ranked in descending order. Euclidean deviation, relative distance of alternatives from ideal solutions, and final rank of maintenance priorities in the first iteration are shown in Table 7.

Table 7.

Ranking of nonurban roads according to maintenance priorities.

A share of the planned maintenance budget is distributed on the observed roads on the basis of the order obtained by the TOPSIS method. In this way, the initial plan for nonurban road maintenance is generated as input for the implementation and planning and control model phase.

2.6. Monitoring and Control of the Plan for Priority Maintenance of the Road Network in Nonurban Areas

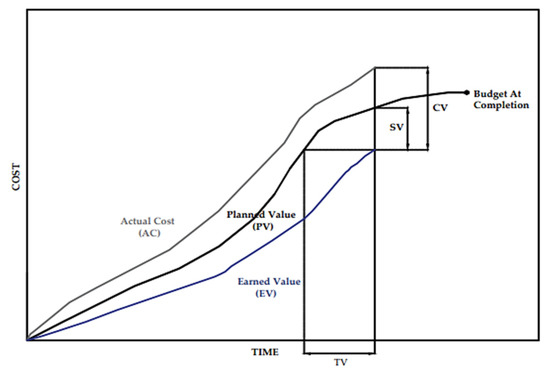

Since each local government unit has a limited budget for road network maintenance in the third phase of the proposed model, emphasis is placed on financial constraints in regional road maintenance. The aim is to invest in maintenance according to the plan obtained through the AHP and TOPSIS methods. The allocated annual budget, intended for the maintenance of regional roads is distributed according to the obtained list of priorities. In the phase of realization, through summer and winter, regular maintenance in the middle of the current year, a comparison of planned, realized, and achieved maintenance is made by using the Earned Value Analysis, determining the actual efficiency index of maintenance realization. The obtained index values give a real picture of how the improved system of maintenance of the observed roads outside urban areas are functioning. In case of poor functioning of the maintenance system in the final phase of the model, it is necessary to revise the cost criterion based on which the compromise solution was selected. Then, the quality of maintenance of the observed roads should be significantly improved by investing funds for maintenance, from the highest-ranked section to the lower-ranked, based on the application of selected multi criteria decision-making methods. The necessary data will be obtained on the basis of the collected documents on the annual investment in the maintenance of regional roads of the observed county. Compared to the traditional monitoring method, based on the comparison of planned and actual project costs, EVA integrates and compares planned costs, the value of execution, and actual costs, giving a much more authoritative picture for assessing the execution of the monitored and controlled project. The Earned Value Analysis is especially suitable for projects in which there is a risk of rising costs, such as projects for the maintenance of the nonurban road network Figure 5. Graphically shows EVA indicators and among them:

Figure 5.

Graphic representation of EVA indicators.

- PV shows the budget cost of work performed, and it is calculated as the value of money that is planned to be spent in order to complete a task in its entirety.

- AC curve shows actual cost of work performance, and that value is calculated as financial resources spent on the percentage of work actually performed.

- EV shows budgeted cost of work performed and it is calculated as the planned cost for the percentage of work performed

- Schedule Variance—SV shows the time deviation from the plan and is calculated as the difference between EV and PV

- Cost Variance—CV shows the cost deviation from the budget and is calculated as the difference between EV and AC

- Time Variance—TV) defines the amount of time the project is ahead or behind by translating SV to time units.

After comparing the plan, obtained through the AHP and TOPSIS method, and the actual situation on the roads, whose maintenance is carried out by monitoring and control, earlier presented EVA indicators are determined. According to the settings of the EVA method road maintenance index (MRI) is calculated as follows:

As this research is about the problem of nonurban road maintenance in conditions of limited budget, the maintenance road index (MRI) is based on the budgeted cost of work performed (EV) and actual cost of work performance for the percentage of work performed (AC) at the time of monitoring and plan control. Since road maintenance is performed on an annual basis in this study, the control date is set at half execution, i.e., 50% of the current year in which the observed roads are maintained. On a certain date, the percentage of work performed is determined (in Table 8. labeled with E). Based on the obtained percentage of execution, the budgeted cost of work performed or earned value (EV) is calculated (in Table 8. labeled with F). Finally, based on the actual financial resources spent for each road section in the observed period, the actual cost of work performed or actual cost (AC) is determined (in Table 8. marked labeled with G). After that, comparison of the planned and executed situation is made and according to equation 14 MRI is calculated. MRI is calculated for each section separately as a local indicator of performance according to the EVA method. The ideal value of the MRI index is 1, where the realized value is equal to the actual cost and the realized profitability is 100%. In this example, we will take a tolerance limit of 10%, which is why the adopted MRI control value is between 0.9 and 1.1, as a value indicating the efficient investment and allocation of limited financial resources. Roads within these maintenance index values form an efficient road network maintenance system and the budget for these roads is well allocated in the planning phase of the proposed model (Table 8).

Table 8.

Results of the planning and control process.

Roads whose index value is not within this range enter the next iteration and are ranked, again, according to the TOPSIS method. In this case, because of changed conditions, it is necessary to correct the cost criterion (C7 in Table 2) by using the new maintenance cost (J), obtained by the following expression, as input to the decision matrix D:

Since the cost criterion has been changed by introducing this maintenance cost (in Table 8, labeled with J), it is necessary to repeat the TOPSIS method and obtain a new road ranking according to maintenance priority only for those roads whose MRI previously did not meet ideal values. The procedure is repeated until the entire road network meets the requirements of an efficient nonurban road network maintenance system, as previously shown in Figure 2. In this way, the redistribution of the remaining financial resources will be made depending on the amount of work performed up to the date of control and the percentage of remaining work that needs to be done in the second half of the year. The presented results of the validation of the proposed model indicate its functionality in creating an effective system for maintaining the nonurban road network. In the next chapter, this will be compared with state-of-the-art methods, which will show the advantages of the proposed model.

3. Discussion

Nonurban roads are an economically significant public good that should be carefully managed throughout the life cycle of the maintenance project, and as such, they are a prerequisite for the development of urban road infrastructure. Previous research in the field of this topic is mainly focused on the decision-making process related exclusively to the planning function in the management of urban road infrastructure projects. The three basic management functions, i.e., the activities that make up the maintenance management process, are planning, implementation, and monitoring and control.

According to Certo and Certo [51], the mentioned functions are integrated in such a way that the result of one management function depends on the results of other functions, and as such cannot be separated in practice. Planning is the primary function of the management process, which includes defining goals and strategies and determining the ways and means to achieve the set goals. With its plan as output feedback, planning is related to implementation, as well as monitoring and control, as the next management functions. Realization includes performing maintenance activities on the selected alternative, while monitoring and control is a function of the maintenance management process in which a comparison is made between planned and achieved, based on which possible changes to existing plans are made. Therefore, to cover all these functions and create an efficient road network maintenance management system, this paper proposes a model that, in addition to planning road network maintenance in nonurban areas, includes other management functions, e.g., implementation and performance, as well as monitoring and maintenance control.

Decision-making is seen as a function of managing the maintenance of the road network outside urban areas and is an integral part of all management functions that are realized precisely by decision-making. The presented results of this research confirm that by ranking maintenance priorities based on multicriteria decision-making methods, a limited budget for road infrastructure can be distributed much better, and more efficiently, compared to traditional allocations that include only economic and financial criteria. To generate a priority maintenance plan through the proposed model, we used a combination of the AHP method and applied the TOPSIS multicriteria method. The AHP method was used to determine the relative weights of the criteria that, based on expert opinion, have the greatest impact on the maintenance of the observed roads. The obtained criterion weights, together with the elements from the normalized decision matrix, gave a weighted decision matrix. It was used as input for the TOPSIS method used to rank roads according to maintenance priorities.

As can be seen from the review of previous research, the AHP method, in combination with other methods of multicriteria decision-making, is most often used to determine the relative importance of criteria. A group of authors [26,32] combine the AHP method with the TOPSIS and PROMETHEE methods in the problems of hiring employees and choosing the best way to manage demand. According to the results of the comparison, the TOPSIS method proved to be the solution with highest percentage of accuracy and reliability. Compared to the PROMETHEE method, it proved to be a much better option to combine with the AHP method. The reason of this is that the TOPSIS method, because of its integrity, allows full ranking of alternatives and does not require additional comparison in pairs to obtain the final ranking of priorities, as is the case with the PROMETHEE method.

According to Panda and Jagadev [50] some of the advantages of the TOPSIS method are: preference orientation and decision-maker selection, simple numerical representation indicating the ideal set of attribute values, simple calculation method, a clear difference between all alternatives, applicability to qualitative and quantitative data, etc.

The TOPSIS method, in combination with the AHP method, has not been applied in previous research in the field of nonurban road network maintenance management, and the model presented in this paper aims to improve current models and increase the efficiency of nonurban road network maintenance systems. The proposed model was tested on the nonurban road network of Herzegovina-Neretva Canton. The observed nonurban road network consists of a total of 12 observed sections, which are ranked based on 11 qualitative and quantitative criteria. Based on data on traffic intensity, length and width of roads, level of road development, economic importance of the road, annual maintenance cost, time of last reconstruction, etc., as well as the basic weight of criteria obtained by AHP method, a ranking list of sections according to maintenance priorities was generated. The highest value of the relative distance of alternatives (Qi*) in the amount of 0.742 determined the R-418 road as the road with the highest maintenance priority, while the other roads were ranked in descending values. By normalizing the value of the relative distance of alternatives, the distribution of the annual maintenance budget, according to the observed shares, was determined. Thus, the initial plan for nonurban road maintenance was obtained as an output variable of the planning function. Compared to previous research based only on the planning function, giving a ranking list of alternatives according to priorities, the proposed maintenance management model, in addition to planning, includes other management functions: namely, the implementation and monitoring and control of maintenance.

According to Radujković et al. [52], monitoring and control of the plan are often neglected in practice, whereby planning as the primary management function loses its original meaning because it lacks knowledge about the progress of work execution and performance achieved by the monitoring and control function. So far, the most commonly used traditional monitoring and control methods are based only on a comparison of planned and actual costs, as well as time, without taking into account the achieved value, thus providing insufficient information for optimal decision making [53].

According to Radujković [52], the Earned Value Analysis is especially suitable for projects in which there is a risk of increasing costs, which corresponds to the nature of projects for the maintenance of road infrastructure elements. Therefore, in this paper, the monitoring and control of the plan obtained using of the multi-criteria methods is controlled and monitored using the Earned Value Analysis (EVA) which mainly reflects the scientific contribution of this paper. According to the above, in this paper, monitoring and control of the plan, generated using the methods of the multicriteria analysis, is performed using the EVA method, which mainly reflects his scientific contribution and improvement of existing maintenance management models.

The maintenance road index (MRI), which is derived from budget cost of work performed or earned value (EV) and actual cost of work performed (AC) indicates a cost deviation from the plan. For those roads where the MRI value ranges between 0.9 and 1.1 it can be said that they form an efficient maintenance system and that the budget for them is well distributed. For roads that do not meet the ideal MRI values, the cost criterion values are corrected, and the TOPSIS method is repeated to better reallocate the limited budget, according to the new priority list of maintenance, but only of those sections that did not meet the mentioned condition in the first iteration. According to the presented model, the presented procedure is repeated until the moment when the maintenance road index (MRI), for all observed sections, is within acceptable values.

The proposed model can be applied to the urban road network or any other road infrastructure element in order to achieve an effective road maintenance management system.

4. Conclusions

Planning, implementation and monitoring and control are three basic, interconnected, and inseparable management functions that jointly form a complete and efficient management system. The general division of management functions in this paper is applied in the maintenance management of nonurban road network. While previous research in this area mainly covers only the planning function, the proposed model of nonurban road network maintenance management, in addition to planning, includes the implementation, as well as monitoring and control, of maintenance, while decision-making is seen as a management function and is an integral part of any management function.

The management of road network maintenance belongs to poorly structured problems and includes a large number of stakeholders and different qualitative and quantitative criteria. Therefore, its management functions require the application of multi criteria decision-making methods. Thus, in the proposed model, the AHP method is used in the planning function to obtain the relative weights of the defined criteria. At the same time, the obtained values are used as input for the TOPSIS method of multicriteria decision-making, resulting in an initial priority maintenance plan. The planning function without the monitoring and control function loses its original meaning in the proposed model for monitoring and controlling the implementation of the maintenance plan. Therefore, the Earned Value Analysis is used, thus giving a more objective picture of the progress of maintenance activities in the observed period compared to traditional monitoring and control methods.

The Earned Value Analysis (EVA) is relatively unused in the construction field despite its many advantages. Therefore, this paper shows how it can be applied not only in construction projects but also in road network maintenance projects that include a high risk of increasing costs during implementation.

The proposed model seeks to show how the proper layout of the nonurban road network, according to maintenance priorities and the monitoring and control of implementation, even with limited dedicated maintenance funds, can improve the current maintenance management system of the observed road network.

Author Contributions

Conceptualization, A.M. and N.J.; Data curation, A.M. and N.J.; Formal analysis, A.M. and N.J.; Funding acquisition, A.M. and N.J; Investigation, A.M. and N.J.; Methodology, A.M. and N.J.; Project administration, A.M. and N.J.; Resources, A.M. and N.J.; Software, A.M. and N.J.; Supervision, A.M. and N.J.; Validation, A.M. and N.J.; Visualization, A.M. and N.J.; Writing—original draft, A.M. and N.J.; Writing—review & editing, A.M. and N.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research is partially supported through project KK.01.1.1.02.0027, a project co-financed by the Croatian Government and the European Union through the European Regional Development Fund—the Competitiveness and Cohesion Operational Programme.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request due to restrictions e.g., privacy or ethical. The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Marović, I.; Androjić, I.; Jajac, N.; Hanak, T. Urban Road Infrastructure Maintenance Planning with Application of Neural Networks. Complexity 2018, 2018, 5160417. [Google Scholar] [CrossRef]

- Jajac, N.; Marović, I.; Hanak, T. Decision support for management of urban transport projects. Građevinar 2015, 67, 131–141. [Google Scholar]

- Jovanović, P. Project Management, 5th ed.; Grafoslog: Beograd, Serbia, 2002. [Google Scholar]

- Simon, H.A. The New Sciences of Management Decisions; Harper and Row: New York, NY, USA, 1960. [Google Scholar]

- Novak, M. Problems of decision making in organizations of associated labor. In Problems of Economic Development and the Economic System of Yugoslavia; Faculty of Economics: Zagreb, Croatia, 1977. [Google Scholar]

- Gorupić, D. Business Policy of the Company; Ekonomski Institut: Zagreb, Croatia, 1963. [Google Scholar]

- Deluka-Tibljaš, A.; Karleuša, B.; Dragičević, N. Review of multicriteria-analysis methods application in decision making about transport infrastructure. Građevinar 2013, 65, 619–631. [Google Scholar]

- Kalibatas, D.; Kovaitis, V. Selecting the most effective alternative of waterproof membranes for multifunctional inverted flat roofs. J. Civ. Eng. Manag. 2017, 23, 650–660. [Google Scholar] [CrossRef] [Green Version]

- Govindan, K.; Jepsen, M.B. ELECTRE: A comprehensive literature review on methodologies and applications. Eur. J. Oper. Res. 2016, 250, 1–29. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making. Methods and Applications. A State-of-the-Art-Survey; Lecture Notes in Economics and Mathematical Systems; Springer: Berlin, Germany, 1981; Volume 186. [Google Scholar]

- Keeney, R.L.; Raiffa, H. Decision with Multiple Objectives; Willey: New York, NY, USA, 1976. [Google Scholar]

- Bezhadian, M.; Kazemzadeh, R.B.; Albadvi, A.; Aghdasi, M. PROMETHEE: A comprehensive literature review on methodologies and application. Eur. J. Oper. Res. 2010, 200, 198–215. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the Analytic Hierarchy Process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef] [Green Version]

- Opricovic, S. Multicriteria Optimization in Civil Engineering; Faculty of Civil Engineering: Belgrade, Serbia, 1998. [Google Scholar]

- Hajkowicz, S. A comparision of multiple criteria analysis and unaided approaches to environmental decision making. Environ. Sci. Policy 2007, 10, 177–184. [Google Scholar] [CrossRef]

- Kilić Pamuković, J.; Rogulj, K.; Dumanić, D.; Jajac, N. A Sustainable Approach for the Maintenance of Asphalt Pavement Construction. Sustainability 2021, 13, 109. [Google Scholar] [CrossRef]

- Zyound, S.H.; Fuchs-Hanusch, D. Comparision of Several Decision-Making Techniques: A Case of Water Losses Management in Developing Countries. Int. J. Inf. Technol. Decis. Mak. 2019, 18, 1551–1578. [Google Scholar]

- Razi, P.Z.; Ali, M.I.; Ramli, N.I. Overview of analytical hierarchy process decision making method for construction risk management. In Proceedings of the IOP Conference Series-Earth and Environmental Science, Kuantan, Malaysia, 17–18 August 2018. [Google Scholar]

- Eshtehardian, F.; Ghodousi, P.; Bejanpour, A. Using ANP and AHP for the supplier selection in the construction and civil engineering companies; Case study of Iranian company. KSCE J. Civ. Eng. 2013, 17, 262–270. [Google Scholar] [CrossRef]

- Khan, U.; Verma, R.; Kumar Singh, B.; Yadav, V. Application of Multi Criteria Decision Making tools in Selection of Concrete Mix. J. Sci. Ind. Res. 2021, 80, 304–309. [Google Scholar]

- Choi, J.H.; Yoon, T.H.; Kim, J.S.; Moon, Y.I. Rehabilitation Assessment Using the Delphi-AHP Method for Adapting to Climate Change. J. Water Resour. Plan. Manag. 2018, 144, 06017007. [Google Scholar] [CrossRef]

- Stanojević, A.D.; Milošević, M.R.; Milošević, D.M.; Turnšek, B.; Jevremović, L.J. Developing multi-criteria model for the protection of built heritage from the aspect of energy retrofitting. Energy Build. 2021, 250, 111285. [Google Scholar] [CrossRef]

- Szafranko, E. Possibilities of application of multi-criteria analysis methods to evaluate material and technological solutions in the design of building structures. In Proceedings of the International Conference on Modern Trends in Manufacturing Technologies and Equipment (ICMTMTE), Sevastopol, Russia, 7–11 September 2020. [Google Scholar]

- Vodopivec, B.; Selih, J.; Zarnic, R. Interdisciplinary determination of architectural heritage restoration priorities on the case of castles, Annales—Anali za Istrske in Mediteranske Studije. Ser. Hist. Sociol. 2015, 25, 1–18. [Google Scholar]

- Darban, S.; Tehrani, H.G.; Karballaeezadeh, N.; Mosavi, A. Appliction of Analytical Hierarchy Process for Structural Health Monitoring and Prioritizing Concrete Bridges in Iran. Appl. Sci. 2021, 11, 8060. [Google Scholar] [CrossRef]

- Mokhatar, M.R.; Abdullah, M.P.; Massan, M.Y.; Hussin, F. Combination of AHP-PROMETHEE and TOPSIS for Selecting the Best Demand Side Management (DSM) Options. In Proceedings of the IEEE Student Conference on Research and Development, Kuala Lumpur, Malaysia, 13–14 December 2015. [Google Scholar]

- Alptekin, O.; Alptekin, N. Analysis of Criteria Influencing Contractior Selection using TOPSIS Method. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 6. [Google Scholar] [CrossRef] [Green Version]

- Erdogan, S.A.; Šaparauskas, J.; Turskis, Z. A Multi-Criteria Decision-Making Model to choose the best option for sustainable construction management. Sustainability 2019, 11, 2239. [Google Scholar] [CrossRef] [Green Version]

- Yahya, M.N.; Gokcekus, H.; Ozsahin, D.U.; Uzun, B. Evaluation of wastewater treatment technologies using TOPSIS. In Proceedings of the 2nd International Conference on Water Problems in the Mediterranean Countries (WPMC), Lefkosa, Cyprus, 6–10 May 2019. [Google Scholar]

- Wu, H.; Liu, S.; Wang, J.W.; Yang, T.Y. Construction Safety Risk Assessment of Bridges in the Marine Environment Based on CRITIC and TOPSIS Models. J. Coast. Res. 2020, 108, 206–210. [Google Scholar] [CrossRef]

- Meng, Q.Y.; Thang, C.L.; Song, T.; Li, N.L. The Application of the Improved TOPSIS Method in Bid Evaluation of Highway Construction. In Proceedings of the 2nd International Conference on Civil Engineering, Architecture and Building Materials (CEABM), Yantai, China, 25 May 2012. [Google Scholar]

- Widiantha, M.M.d.; Rizaldi, T.; Setyohadi, D.P.S.; Riskiawan, H.Y. Comparision of Multi-Criteria Decision Support Methods (AHP, TOPSIS, SAW & PROMETHEE) for Employee Placement. In Proceedings of the 2nd International Joint Conference on Science and Technology (IJCST), Bali, Indonesia, 27–28 September 2017. [Google Scholar]

- Sirin, O.; Gunduz, M.; Shamiyeh, M.E. Application of Analytic Hierarchy Process (AHP) for sustainable pavement performance management in Qatar. Eng. Constr. Archit. Manag. 2020, 28, 3106–3122. [Google Scholar] [CrossRef]

- Khademi, N.; Sheikholeslami, A. Multicriteria Group Decision-Making Technique for a Low-Class Road Maintenance Program. J. Infrastruct. Syst. 2010, 16, 188–198. [Google Scholar] [CrossRef]

- Sayadinia, S.; Beheshtinia, M.A. Proposing a new hybrid multi-criteria decision-making approach for road maintenance prioritization. Int. J. Qual. Reliab. Manag. 2021, 38, 1661–1679. [Google Scholar] [CrossRef]

- Bhandari, B.; Nalmpantis, D. Application of Various Multiple Criteria Analysis Methods for the Evaluation of Rural Road Projects. Open Transp. J. 2018, 12, 57–76. [Google Scholar] [CrossRef]

- Jajac, N.; Knezić, S.; Babić, Z. Integration of Multicriteria Analysis into Decision Support Concept for Urban Road Infrastructure Management. Croat. Oper. Res. Rev. (CRORR) 2010, 1, 74–92. [Google Scholar]

- Jajac, N.; Rogulj, K.; Radnić, J. Selection of the Method fo Rehabilitation of Historic Bridges—A Decision Support Concept for the Planning of Rehabilitation Projects. Int. J. Archit. Herit. 2017, 11, 261–277. [Google Scholar] [CrossRef]

- Jajac, N.; Bilić, I.; Ajduk, A. Decision Support Concept to Management of Construction Projects—Problem of Construction Site Selection. Croat. Oper. Res. Rev. CRORR 2013, 1, 74–92. [Google Scholar]

- Jajac, N.; Bilić, I.; Mladineo, M. Application of Multicriteria Methods to Planning of Investment Project in Field of Civil Engineering. Croat. Oper. Res. Rev. CRORR 2012, 3, 113–124. [Google Scholar]

- Rogulj, K.; Kilić–Pamuković, J.; Jajac, N. Knowledge-Based Fuzzy Expert System to the Condition Assessment of Historic Road Bridges. Appl. Sci. 2021, 11, 1021. [Google Scholar] [CrossRef]

- Jajac, N.; Marović, I.; Baučić, M. Decision Support Concept for Managing the Maintenance of City Parking Facilities. E-GFOS 2014, 9, 60–69. [Google Scholar] [CrossRef]

- Nodrat, F.; Kang, D. Developing a Simplified Maintenance & Rehabilitation Activity Prioritization Tool for Afghanistan Roads. In Proceedings of the International Conference on Intelligent Informatics and Biomedical Sciences (ICIIBMS), Okinawa, Japan, 24–26 November 2017; pp. 154–158. [Google Scholar]

- Francello, G.; Carta, M.; Fadda, P. Road intersections ranking for road safety improvement: Comparative analysis of multi-criteria decision making methods. Transp. Policy 2018, 80, 188–196. [Google Scholar] [CrossRef]

- Ministry of Transport and Communications. Development Strategy of Public Roads in the Herzegovina-Neretva Canton for Period 2020–2030; Ministry of Transport and Communications: Mostar, Bosnia and Herzegovina, 2020.

- Šećkanović, N. Ordinance on the Maintenance of Public Roads. Official Newspaper of the Bosnia and Herzegovina, 13 October 2010. [Google Scholar]

- Saaty, T.L.; Vargas, L.G. Models, Methods, Concepts & Applications of the Analytic Hierarchy Process, 2nd ed.; Springer Science & Business Media: London, UK, 2012. [Google Scholar]

- Saaty, R.W. The Analytical Hierarchy Process—What it is and how it is used. Math. Model 1987, 9, 161–176. [Google Scholar] [CrossRef] [Green Version]

- Saaty, T.L. The Analytical Hierarchy Process: Planning, Priority Setting, Resource Allocation; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Panda, M.; Jagadev, A.K. TOPSIS in Multi-Criteria Decision Making: A Survey. In Proceedings of the 2nd International Conference on Data Science and Business Analytics (ICDSBA), Changsa, China, 21–23 September 2018. [Google Scholar]

- Certo, S.C.; Certo, S.T. Modern Management: Concept and Skills, 14th ed.; Pearson: London, UK, 2016. [Google Scholar]

- Radujković, M.; Car-Pušić, D.; Škomrlj Ostojić, N.; Vukomanović, M.; Burcar Dunović, I.; Delić, D.; Meštrović, H. Project Monitoring and Control; University of Zagreb: Zagreb, Croatia, 2012. [Google Scholar]

- Araszkiewicz, K.; Bochenek, M. Control of Construction Projects using the Earned Value Method-Case Study. Open Eng. 2019, 9, 186–195. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).