Abstract

There is an obvious tendency towards increasing the information content of surveys of hard-to-reach objects at high altitudes through the use of remote-controlled robot crawlers. This can be explained by the reasonable desire of industrial objects owners to maintain their property: pipelines, containers, metal structures in operating technical condition, which contributes to reducing accident risks and increasing the economic efficiency of operation (optimization of repair planning, etc.) This paper presents the concept of a robotic device equipped with LIDAR and EMAT which can move over pipes from a diameter of 100 mm by using a special type of magnetic wheel. The robot uses convolutional neural networks to detect structural elements and classify their defects. The article contains information about tests held on a specially developed test rig. The results showed that the device could increase the information level of survey and reduce the labour intensity. In this work, we consider a prototype of the device which has not started mass operation at industrial facilities yet.

1. Introduction

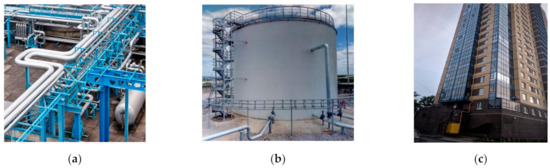

Nowadays, the most common way of condition monitoring of remote pipeline sections and metal structures at altitude is rope access. These objects can be found both on industrial enterprise (for example, pipeline overpass, see Figure 1) and within the city (for example, gas pipeline to roof boiler room, see Figure 2).

Figure 1.

Gas pipeline overpass through an obstacle. Copyrighted by authors.

Figure 2.

(a) Pipeline overpasses and metal structures; (b) Reservoirs; (c) Gas pipeline to roof boiler room. Copyrighted by authors.

Remote-controlled robotic devices are feasible to apply in order to minimize the risks of occupational injuries, reduce the cost of surveys, and increase the quality level of information content.

The authors of the study propose the following steps to reach this goal:

- To analyze spatial configuration of the most common objects and create the informational album of typical obstacles;

- To review the world experience in surveying above-ground pipelines and metal structures at altitude;

- To run an analysis of existing kinematic patterns of movement on vertical metal planes and pipelines of different configurations using magnetic field force for grip;

- To analyze existing magnetic wheel structures;

- To create a device capable of moving over high-situated above-ground gas pipelines and monitoring their technical condition;

- To test the device on a test rig comprising generic obstacles of typical gas pipeline;

- To make recommendations on the organization of work using the developed device.

2. Theoretical Study

2.1. Analysis of Spatial Configurations of the Most Common Objects

Existing options for surface pipelines include vertical, horizontal, and, much less frequently, sloped sections. The most difficult part of a survey is connected with different types of sections in one fragment: for example, the presence of branched horizontal parts makes use of devices with power cable complex.

T-junctions, bends, and concentric reducer fittings are the main shaped elements of overhead pipelines. The maximum height of the weld above the welded pipes depends on the type of connection, but generally is not more than 10 mm. A variety of supports are used for fixing pipelines to walls of buildings and metal structures. The most common of them are supports with U-bolt clamp and rubber inserts.

As the diameter increases, the curvature of the surface decreases, so the pipes with small diameter about 57 mm … 108 mm (2″–4″) due to high curvature significantly complicate the survey process, increase the turning radius of the devices, or make it completely impossible.

The thickness of the metal at the joint has a certain influence on the magnetic adhesion force. Thus, thin-shelled assembly bears the risk of uncontrolled fall [1].

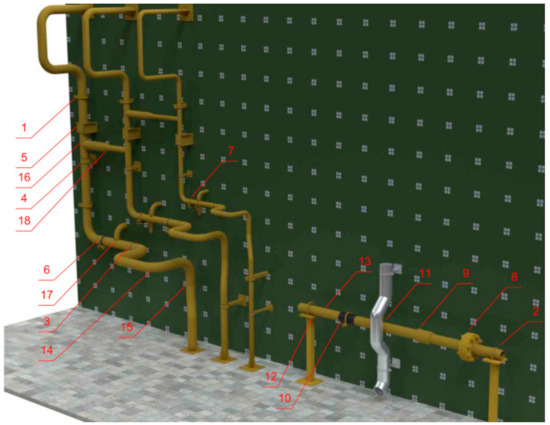

2.2. Development of an Experimental Test Rig

Based on the established information base of typical objects in terms of above-ground pipeline, a list of the main obstacles was drawn up (see Table 1). The test rig comprises pipe supports, fittings, and specific types of obstacles such as an electric insulation joint, test site of bypass with rainwater pipes, not sealed tightly clamp, wide paronite gasket, and consists of three pipe sections: DN50, DN100, and DN200 (2″, 4″, 8″). The general view of the test rig with the main types of obstacles is shown in Figure 3.

Table 1.

Main types of obstacles on the pipeline for robotic examination.

Figure 3.

Construction of the test rig.

2.3. Review of the World Experience in Surveying Above-Ground Pipelines and Metal Structures of Complex Spatial Configuration

In the oil and gas industry, there is an urgent need to find alternatives to manual inspection in case of reducing risks and costs. The use of drones is one of the recent technologies [2]. This method has a number of advantages, such as access to objects at altitude, technical diagnosis of pipes with nonferromagnetic surfaces, large viewing angle, and high resolution shooting [3].

The usage of drones can solve some problems connected with surveying of hard-to-reach objects, but it has a lot of disadvantages:

- Generally, drones have a low battery charge, therefore due to the presence of special inspection equipment the duration of the examination is about 15–20 min;

- As the battery capacity increases, the size of the drone and the number of screws grow, which negatively affects maneuverability;

- There is a high risk of accident while surveying narrow areas;

- It is not possible to inspect the complex pipe manifold due to advanced maneuvering.

- Limited on-board computer selection caused by weight restriction;

- High control complexity compared to land-based devices.

This way, the use of drones is less informative and does not allow to reach the information content completeness of survey, which makes it suitable only for the initial assessment of large objects.

Let us consider more advanced remote monitoring arrangements for above-ground pipelines and metal structures: Saudi Aramco [4], INTROSCAN [5], ARA Lab [6], Waygate technologies [7], University of Tsukuba [8], University of Coimbra [9], SSC Pacific [10], DEEP TREKKER [11], DFKI [12], and RIT [13]. Table 2 presents the technical characteristics of the proposed device.

Table 2.

Technical characteristics of robotic devices.

An analysis of existing devices revealed the following «weak spots»:

Outer diameter of 125 mm (5″) is the minimum diameter to survey the pipelines, most robot crawlers are not able to move over the pipes of smaller diameter or move erratically due to high surface curvature;

Electrical power cable is most frequently used to power the robots. The use of this cable makes it impossible to survey metal structures of complex spatial configuration;

These devices have no possibility to overcome specific obstacles. This leads to an uncontrolled fall.

Considered robotic devices have the following types of kinematic configurations:

Magnetic crawler. The possibility of a tank steering and solved problem of low surface contact are the pros [14]. Cons: high coefficient of friction and adhesion due to large contact surface resulting in increased energy consumption for moving, bad maneuverability need for caterpillar tension systems, etc. [15].

Magnetic circuits of different configurations [16]. Highly adhesive, simply structured, and cheaply produced [17]. Disadvantages connected with the risks of breaking away from the surface in case of «magnetic chain» disconnection.

Magnetic wheel. Wheeled robots have the highest speed of movement, simple mechanics and control, and besides, the ability of land–wall transition [18]. However, they are not suitable for overcoming specific obstacles and have low surface contact, which can lead to failure.

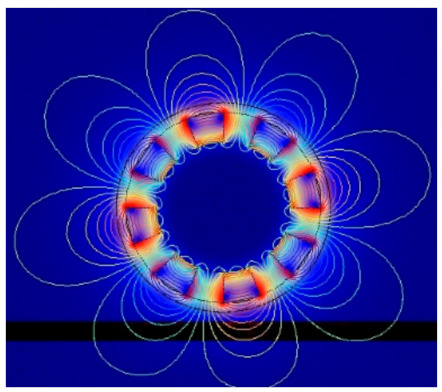

Wheel with magnets, located according to Halbach-Array [19]. While using a special configuration of permanent magnets—Halbach-Array—it is easy to get a significant increase of adhesion force (about two times, see Figure 4). The main purpose of the assembling is that the compensation of lower magnetic flux leads to strengthening of the upper one [20].

Figure 4.

Magnetic wheel with Halbach-Array.

However, Halbach-Array requires a rigid wheel design or presence of a specific mechanism [21], which rotates the shaft with the assembly when crossing certain types of obstacles.

Wheel with swinging inside part [22]. If the inside part is in an incorrect position, there is a risk of losing adhesion and the following uncontrolled fall, see Figure 5.

Figure 5.

Wheel construction with Halbach-Array inside.

2.4. Design of Wireless Mobile Robot Crawler System for Pipe Inspection

During the engineering development, the design of the device presented in Figure 6 was proposed. The robot crawler has a LIDAR system [23] as well as an EMAT on a telescopic retractable rod.

Figure 6.

Design of the proposed robot crawler.

The special flexible shape of the wheel with the magnet inside makes it possible to overcome obstacles (Figure 7).

Figure 7.

Special design of flexible rubber tire allows to overcome obstacles without separation from the ferromagnetic surface. Copyrighted by authors.

The characteristics of the device and its components are presented in Table 3.

Table 3.

Technical characteristics of the developed robot crawler.

Above-ground gas pipelines are subject to vibrations that are potentially hazardous processes. A large number of studies are underway to explore it and minimize its negative impact [24,25,26]. With some modifications, the device will be able to evaluate the vibration parameters along the length of the gas pipeline.

In this work we consider only the prototype device (as in many other robotic works [4,5,6], and therefore the indicator of reliability, durability, and maintainability of the robot cannot be precisely determined. However, the following may be noted:

- We have used the most suitable constructive materials that will ensure sufficient durability (Table 4);

Table 4. Materials used in the design of the device.

Table 4. Materials used in the design of the device. - Maintainability is provided with the possibility of large-unit repair. In addition, the sensors are easily removable, this allows them to be «hot» replaced in the field. Individual elements (fasteners, gears) are made of unified standard sizes—this allows them to achieve good interchangeability;

- Overall metrics of reliability of the device are still difficult to assess, as there is no extensive field experience.

2.5. Neural Network Classification of Objects

While surveying hard-to-reach objects, it is important to identify the obstacle and to estimate its main parameters. The detection of complication signatures (traces of corrosion, cracks, misalignment of supports) is also important [27,28,29,30,31,32]. Damage caused by incorrect identification of an obstacle may entail the risk of uncontrolled fall of the device and occurrence of emergency, untimely complications, and detecting may result in extra material costs for their separate investigation and liquidation. Therefore, the use of machine vision and the prediction of complications in the surveying pipelines and metal structures of complex spatial configuration is a crucial task, which, being realized, will improve quality of the surveying hard-to-reach objects and will help to avoid contingency, resulting in safe operation.

The application of machine vision technology involves the automated objects classification and helps the engineer to take into account the possible risk of emergency.

As the objects classification task is flexible and varies according to the field of application, it was decided to use artificial intelligence technology with the possibility of overfitting to the necessary databases of obstacles and complications.

The input data obtained by the robotic device in the surveying pipelines and metal structures of complex spatial configuration are characterized by the following features:

- Axial displacement, change of the angle, rotations, other distortions;

- Fast staff turnover, the need for high data processing rate;

- A wide variety of different types of objects (elements of pipe manifold, supporting structures, defects, leaks);

- The use of high-resolution cameras results in a large amount of input data;

- Updating the database for the new survey.

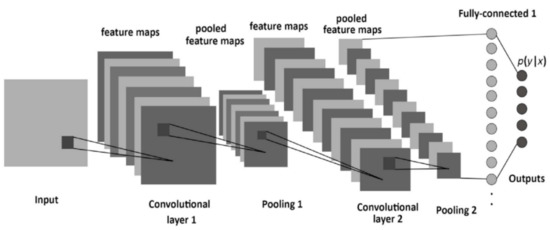

For the project realization, the authors used convolutional neural network with extractor of FPN functions (Feature Pyramid Network) [33], which has the following advantages:

- Decreased amount of learnable parameters and increased speed of learning in comparison with fully connected neural network [34];

- Ability to implement computations and network learning algorithms on graphic processors (GPU) [35];

- Displacement stability of input data [36];

- The use of convolutional kernels helps to avoid generalization of the displayed information. Scanning by parts allows to take into consideration a larger number of properties of the object, which improves the quality of recognition.

The architecture of the neural network consists of:

- Number of layers;

- Number of sites (neurons) in each layer;

- Type of activation function.

Convolutional neural networks are constructed from the following types of layers:

- Convolutional—performs convolution, which is characterized by the following parameters:

- Filters: number of output channels;

- Kernel size: convolutional kernel, is a local receptive field that specifies the width and height of the 2D convolution window;

- Padding: function that allows to create a zero-fill around the perimeter of the input image, so that the output has the same width and height;

- Activation: activation function;

- Input shape: dimension of the input signal.

- Pooling—this layer works in a similar way to the convolutional layer, but it does not have the convolutional kernel, but the pooling layer calculates the maximum or average values of the input data;

- Reshaping layers—change the dimension the input data;

- Dense—fully connected layer;

- Dropout—regularization technique that allows to avoid overfitting by keeping neurons in a state of activity (not zero) with a given probability.

Figure 8 presents a typical topology of a convolutional neural network containing input layer, convolutional layers, pooling layers, and standard fully connected layer.

Figure 8.

Convolutional Neural Network topology.

Since this study addresses two classification challenges, namely, the identification of obstacles on the path of the robotic device and the detection of complication signatures, it was agreed to use two convolutional neural networks with different topologies trained in different databases, the architectures of which are presented in Table 5.

Table 5.

Architectures of applied neural networks.

Input layer receives data in the format of the image with dimension of WxHxCin pixels, where W = 1920—the width of the image, H = 1080—the height of the image, Cin = 3—the number of image channels. In this layer of the neural network there is a compression to dimension of 250 × 250 × 1 in case of identifying the obstacles and 250 × 250 × 3 in case of detection of complication signatures as the number of image channels (color) has no informative value for the first task, but for detection of complication signatures color is an important characteristic, for example for detecting signs of corrosion. Next, the data is normalized to a range (−0.5:1) for further processing by subsequent layers:

where —normalization function; —pixel color value; —pixel maximum value—255; —pixel minimum value—0.

Convolutional layer is a set of feature maps that slide across the entire data region of the previous layer and highlight certain features of objects. The convolutional layer can be considered as a special case of a fully connected layer, provided that weights outside the local receptive field are equal to zero for each neuron, and the parameters of the convolutional kernel are distributed among the neurons.

where –j—feature map (previous input layer output); –k layer shift coefficients for the j—feature map; –j map, k layer convolutional kernel; —activation function, LeakyReLU activation ( is used in both architectures.

The choice of LeakyReLU activation function is explained by the fact that it has a number of advantages:

- Fast in computation

- 1.

- Gradients do not disappear for ;

- 2.

- Provides fast convergence in practice;

- 3.

- Works if x < 0, which ensures continuous computing, as opposed to function ReLU ( [37].

MaxPooling minimizes the size of the previous layer maps by selecting maximum local features:

where —layer k outlet; —k layer shift coefficients; —local maximum feature sampling operation.

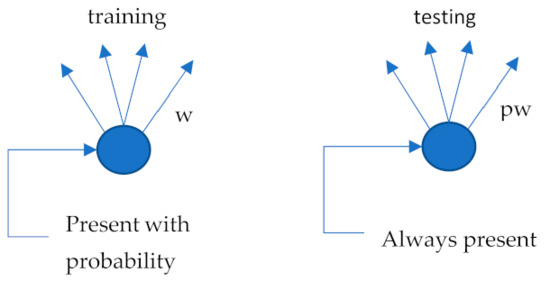

Dropout layer reduces the process of retraining the neural network. In case of using this layer, the learning process affects only part of the parameters on each iteration. All neurons are present during testing, but their outputs are multiplied by a given probability to maintain the scale of input data (Figure 9).

Figure 9.

Dropout technology, where p—given probability value, w—neural network sites weight.

The flatten layer smooths input data without affecting size. When receiving input data in 15 × 15 × 128 dimension, output data dimension after conversion is 28,800 × 1.

Dense layer is a fully connected layer that classifies an object, simulating a non-linear function, whose gradual optimization increases the efficiency of recognition. The neurons of each map of the pooling are interconnected with one neuron of that layer. The value of the neuron can be calculated according to the following formula [38]:

where –j—feature map (previous k layer output); —LeakyReLU activation function;

k−1 layer shift coefficient;

– layer weighting matrix.

The output layer is connected to all the neurons of the previous fully connected layer. The number of neurons in this layer corresponds to the number of identified objects (classes) for a classification task. In each architecture of the used neural networks an additional Dense layer was added, which performed the object detection task, and the number of neurons of this layer matched the bounding box that coordinates to highlight objects.

An error backpropagation algorithm was chosen to teach the neural network—it is the terminology of the neural network to minimize the cost function (a function of calculating the error value or the «cost of a given target function») as well as gradient descent in logistic or linear regression [39]. Teaching by this method involves two passes across all layers of the network: forward pass and backward pass. The purpose of the method is to calculate:

where —cost function.

Thus, it is necessary to minimize the cost function J using the optimal set of parameters in theta.

Let us introduce the following notation: —input vector, —output vector, —i-th weight coefficient of the j-th neuron of the k-th layer, —i-th neuron limit of the k-th layer, —reference output value of the i-th neuron [40].

The output value of the j-th neuron of the k-th layer is calculated by the formula:

The output of the j-th neuron of the output layer is calculated by the formula:

Network error functional is equal:

where —error of the j-th neuron of the output layer.

Error of the j-th element of the k-th hidden layer:

Error gradients are equal:

The weight coefficients and displacement of the neurons are calculated by the following formulae:

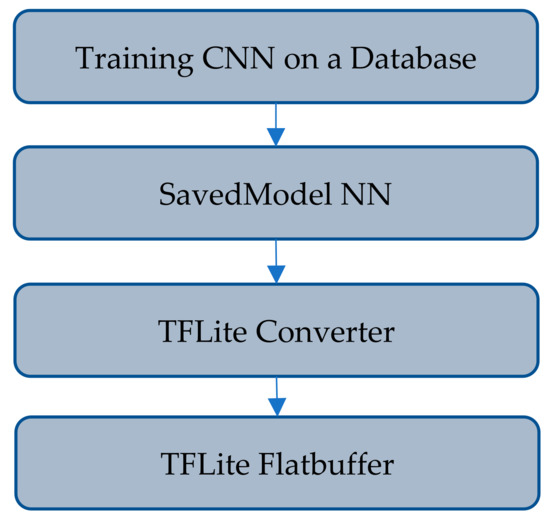

After teaching the neural network model, a decision was accepted to use TensorFlow Lite technology—a tool set that provides machine learning on the device, helping developers run their models on mobile, built-in devices and devices of the Internet of things [41]. The acceleration sequence of the standard neural network model is shown in Figure 10.

Figure 10.

Sequencer for converting the neural network model to an accelerated TFLite model.

Thus, the pre-trained convolutional neural network was converted to an accelerated model using Flatbuffer—an effective cross-platform library for serialization (the process of converting the data structure into a sequence of bytes) [42], which helped to achieve the following benefits:

- Optimization for machine learning on the device, excluding 5 key constraints: delay (no return to server), confidentiality (no personal data leaving the device), connectivity (no Internet connection required), size (reduced model and binary size), and energy consumption (efficient output and lack of network connections, possibility to reduce the weight of the used computer in the robotic device) [43];

- Support for multiple platforms including Linux devices, microcontrollers, and microcomputers (if there is a need to overfit to a new data set, the process can be performed directly on a robotic device);

- High performance with hardware acceleration and model optimization.

2.6. Modelling of Wheel Magnetic Fields

The modelling of the magnetic field of wheels was implemented in the Comsol Multiphysics software based on Maxwell’s equation:

where D—dielectric density; J—current density; H—magnetic field strength; B—magnetic induction; E—electric field strength; —electric foreign charge volume density. Since the magnetostatics problem was solved in the absence of electrical currents, it is permissible to use one equation ∇ × H = 0, which is equal to putting in a magnetic scalar potential Vm, which is determined from H = −∇Vm. The design of the wheel has neodymium magnets of N38 class, and their calculation was carried out in an improved way with the properties’ assignment by the remanence method.

3. Experimental Apparatus and Procedure

Description of Experimental Device Survey

The experimental program evaluated the device’s ability to pass over pipelines, as well as to perform its functions of LIDAR scanning and measuring metal thickness using EMAT (see Figure 11).

Figure 11.

Test rig shot with LIDAR. Copyrighted by authors.

In addition to the EMAT and LIDAR studies, there were tests conducted on the detachable forces and moments that occur on the device drives using the PCE-FM200 dynamometer (the characteristics are shown in the Table 6).

Table 6.

Technical characteristics of the dynamometer.

4. Results and Discussion

The developed device demonstrated the successful passing over the surveyed above-ground pipelines, including overcoming obstacles.

During the testing of the robotic device and its embedded neural networks a pilot database was established, containing 937 elements of above-ground pipelines, a fragment of which is presented in Table 7.

Table 7.

Database fragment.

Table 8 details the process of input processing, classification, and detection of pipeline constructive elements, which is a visualization of row 2 in Table 7.

Table 8.

Step-by-step visualization of the obstacle classification process. Copyrighted by authors.

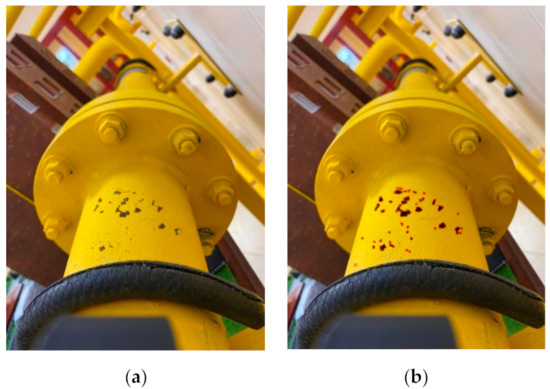

Figure 12a,b illustrates the results of data processing by the neural network for detection of complication signatures on elements of above-ground pipelines affected by coating destruction and/or corrosion. On the left, there are original data before processing by the neural network, on the right there are data after processing in the mode of applying the red contour with shading of the silhouette of discovered objects.

Figure 12.

The result of data processing by the neural network on detection of complication signatures on the example of corrosion identification. (a) Original data before processing by the neural network; (b) data after processing in the mode of applying the red contour with shading of the silhouette of discovered objects. Copyrighted by authors.

To obtain experimental data representing the result of a robotic device working in a mode of classification of obstacles and complications after learning the neural network, based on the NVIDIA Jetson AGX Xavier processor, 36 successful runs were performed on the test bench shown in Figure 3. The work collected statistical data on the classification of obstacles. The robotic device proposed by the authors correctly identified each obstacle presented on the test bench.

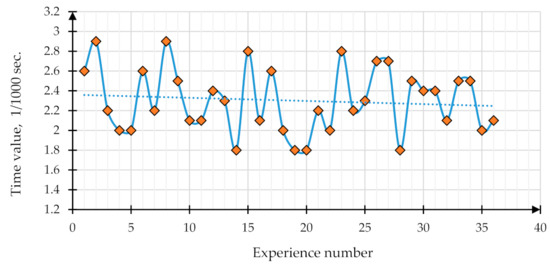

Due to input data convolutional technique and the use of an accelerated neural network model, an effective object classification speed on the average of 0.0025 s. was achieved. Figure 13 presents statistics on the data processing speed of the neural network, the results of each test, reduced to the average for each of the 36 iterations. The use of the additional component FPN (Feature Pyramid Network) by the neural network, which improves the method of target detection, allowed us to achieve maximum efficiency of object classification (see Figure 14).

Figure 13.

Neural network object classification speed diagram.

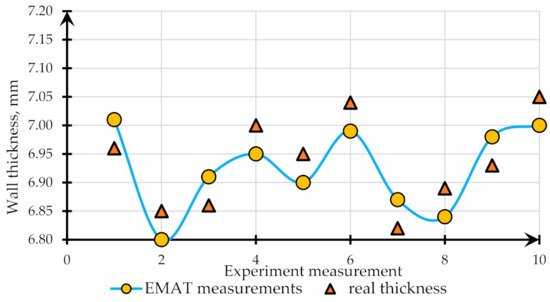

Figure 14.

Results of the comparison of EMAT thickness measurements with their real values.

The comparison of the 219 × 7 mm wall thickness measurement data obtained by EMAT with their real values measured by a wet contact high-precision thickness gauge showed convincing convergence. Thus, it is shown that in an existing configuration the device is able to accurately measure the thickness of the elements, while magnetic wheels with their existing configuration have little effect on the accuracy of measurement.

The results of the tests showed, in the simulation of magnetic force in the software complex Comsol Multiphysics (9.8 kg on one wheel), that the forces values obtained using the dynamometer (9.6 kg) and the calculated values differ no more than 5%, which is a very good approximation.

5. Conclusions

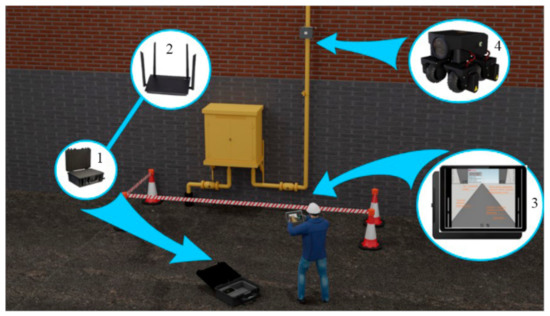

The result of the work was the development of a robot crawler prototype capable of moving on complex curvilinear surfaces and evaluating the thickness of pipe metal. The device has successfully passed preliminary bench tests, which, however, have revealed some problems with small diameter pipe overpassing and neural networks operation. In the future, it is planned to further develop the device operating with an improved model of neural networking input data processing and algorithms of its presentation to the user. Moreover, the following scheme of robot crawler working, which is shown in Figure 15, is supposed to be used.

Figure 15.

Organization plan for robotic survey. 1—transport case, 2—industrial Wi-Fi router, 3—operator’s tablet, 4—robotic device for pipeline inspection.

As the robot has not started mass operation on industrial sites yet, it is impossible to give exact figures, but in spite of this it is estimated that the cost per 100 km of pipeline survey with the use of this robotic device is $25,000/year (operator’s work and depreciation charges) compared to the same 100 km survey by a group of two industrial climbers—94,000 $/year. Inspection with the help of the device does not require paperwork on admission to work at heights.

At present, the tablet application and the quality improvement of the product are underway in development. The work in these areas will be continued and the authors hope to see a positive outcome in one year.

Author Contributions

Conceptualization, V.P.; methodology, V.P.; software, A.R.; validation, A.L., A.S. and M.K.; formal analysis, V.P.; investigation, A.L.; resources, V.P.; data curation, A.S.; writing—original draft preparation, M.K.; writing—review and editing, M.K.; visualization, A.R.; supervision, A.L.; project administration, V.P. and A.L.; funding acquisition, V.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Saint Petersburg Mining University, grant number FSRW-2020-0014.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors gratefully acknowledge the support of the Department of Transport and Storage of Oil and Gas, Saint Petersburg Mining University.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Jose, J.; Devaraj, D.; Mathanagopal, R.M.; Ramanathan, K.C.; Tokhi, M.O.; Sattar, T.P. INVESTIGATIONS ON THE EFFECT OF WALL THICKNESS ON MAGNETIC ADHESION FOR WALL CLIMBING ROBOTS. Int. J. Robot. Autom. 2021, 36. [Google Scholar] [CrossRef]

- Trujillo, M.Á.; Martínez-de Dios, J.R.; Martín, C.; Viguria, A.; Ollero, A. Novel Aerial Manipulator for Accurate and Robust Industrial NDT Contact Inspection: A New Tool for the Oil and Gas Inspection Industry. Sensors 2019, 19, 1305. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jimenez-Cano, A.E.; Braga, J.; Heredia, G.; Ollero, A. Aerial Manipulator for Structure Inspection by Contact from the Underside. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 1879–1884. [Google Scholar]

- SAIR–Arabian Robotics Company. Available online: http://arabianbots.com/sair/ (accessed on 13 April 2022).

- Aкycтичecкиe Koнтpoльныe Cиcтeмы-Cкaнep-Дeφeктocкoп A2072 IntroScan. Available online: https://acsys.ru/skaner-defektoskop-a2072-introscan/ (accessed on 13 April 2022).

- Nguyen, S.; La, H. Development of a Steel Bridge Climbing Robot. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019. [Google Scholar] [CrossRef] [Green Version]

- Viktor BIKE–Inspection Robotics. Available online: https://inspection-robotics.com/bike/ (accessed on 13 April 2022).

- Wang, R.; Kawamura, Y. An Automated Sensing System for Steel Bridge Inspection Using GMR Sensor Array and Magnetic Wheels of Climbing Robot. J. Sens. 2016, 2016, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Past Projects. Available online: https://www.isr.uc.pt/index.php/projects/past-projects?task=showprojects.show%28%29&idProject=13 (accessed on 13 April 2022).

- Burmeister, A.; Pezeshkian, N.; Talke, K.; Ostovari, S.; Everett, H.; Hart, A.; Gilbreath, G.; Nguyen, H. Design of a Multi-Segmented Magnetic Robot for Hull Inspection. In Proceedings of the ASNE Mega Rust 2014: Naval Corrosion Conference, San Diego, CA, USA, 24 June 2014. [Google Scholar]

- Trekker, D. DT340L Pipe Crawler Package. Available online: https://www.deeptrekker.com/shop/products/dt340l-pipe-crawler-package (accessed on 13 April 2022).

- Robot System: Magnet Crawler-Marine Inspection Robotic Assistant System. Available online: https://robotik.dfki-bremen.de/en/research/robot-systems/magnet-crawler/ (accessed on 13 April 2022).

- EMAT Thickness Measurement RobotRover Inspectioning Technology Co., Ltd. Available online: http://www.ritinspection.com/products/287.html (accessed on 13 April 2022).

- Tang, Y.; Song, H.; Yu, Y.; Zhang, J.; Hu, W.; Guo, X. Dynamic Simulation Analysis and Experiment of Large-Caliber Self-Propelled Pipeline Crawler Based on ADAMS. J. Phys. Conf. Ser. 2021, 2095, 012049. [Google Scholar] [CrossRef]

- Khan, M.; Chuthong, T.; Do, C.; Thor, M.; Billeschou, P.; Larsen, J.; Manoonpong, P. ICrawl: An Inchworm-Inspired Crawling Robot. IEEE Access 2020, 8, 1. [Google Scholar] [CrossRef]

- Magnetic Drive Wheel for Wall Climbing Robot-Faizeal. Available online: https://www.fzmag.com/magnetic-drive-wheel-for-wall-climbing-robot/ (accessed on 13 April 2022).

- Zhang, Y.; Dai, Z.; Xu, Y.; Qian, R. Design and Adsorption Force Optimization Analysis of TOFD-Based Weld Inspection Robot. J. Phys. Conf. Ser. 2019, 1303, 012022. [Google Scholar] [CrossRef]

- Mahmood, S.; Bakhy, S.; Tawfik, M. Magnetic–Type Climbing Wheeled Mobile Robot for Engineering Education. IOP Conf. Ser. Mater. Sci. Eng. 2020, 928, 022145. [Google Scholar] [CrossRef]

- Lawrence, K.H. Design of Permanent Multipole Magnets with Oriented Rare Earth Cobalt Materials. Nucl. Instrum. Methods 1980, 169, 1–10. [Google Scholar]

- Bjørk, R.; Bahl, C.; Smith, A.; Pryds, N. Optimization and Improvement of Halbach Cylinder Design. J. Appl. Phys. 2008, 104, 013910. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Zhang, X.; Li, M.; Cao, J.; Huang, Z. Optimization Design and Flexible Detection Method of a Surface Adaptation Wall-Climbing Robot with Multisensor Integration for Petrochemical Tanks. Sensors 2020, 20, 6651. [Google Scholar] [CrossRef] [PubMed]

- Eto, H.; Asada, H. Development of a Wheeled Wall-Climbing Robot with a Shape-Adaptive Magnetic Adhesion Mechanism. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020. [Google Scholar] [CrossRef]

- Intel® RealSenseTM LiDAR Camera L515. Available online: https://www.intelrealsense.com/lidar-camera-l515/ (accessed on 13 April 2022).

- Yang, P.; Bai, H.; Xue, X.; Xiao, K.; Zhao, X. Vibration Reliability Characterization and Damping Capability of Annular Periodic Metal Rubber in the Non-Molding Direction. Mech. Syst. Signal Process. 2019, 132, 622–639. [Google Scholar] [CrossRef]

- Shen, G.; Li, M.; Xue, X. Damping Energy Dissipation and Parameter Identification of the Bellows Structure Covered with Elastic-Porous Metal Rubber. Shock Vib. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Xue, X.; Ruan, S.; Li, A.; Bai, H.; Xiao, K. Nonlinear Dynamic Modelling of Two-Point and Symmetrically Supported Pipeline Brackets with Elastic-Porous Metal Rubber Damper. Symmetry 2019, 11, 1479. [Google Scholar] [CrossRef] [Green Version]

- Mumtaz, M.; Mansoor, A.; Masood, H. A New Approach to Aircraft Surface Inspection Based on Directional Energies of Texture. In Proceedings of the 2010 20th International Conference on Pattern Recognition, Istanbul, Turkey, 23–26 August 2010; pp. 4404–4407. [Google Scholar]

- Jahanshahi, M.; Masri, S. Effect of Color Space, Color Channels, and Sub-Image Block Size on the Performance of Wavelet-Based Texture Analysis Algorithms: An Application to Corrosion Detection on Steel Structures. In Proceedings of the Computing in Civil Engineering (2013), Los Angeles, CA, USA, 24 June 2013; pp. 685–692. [Google Scholar]

- Ji, G.; Zhu, Y.; Zhang, Y. The Corroded Defect Rating System of Coating Material Based on Computer Vision. In Transactions on Edutainment VIII; Springer: Berlin/Heidelberg, Germany, 2012; Volume 7220, pp. 210–220. [Google Scholar]

- Siegel, M.; Gunatilake, P.; Podnar, G. Robotic Assistants for Aircraft Inspectors. Instrum. Meas. Mag. IEEE 1998, 1, 16–30. [Google Scholar] [CrossRef]

- Bahaa, B.; Zaidan, A.; Alanazi, H.; Rami, A. Towards Corrosion Detection System. Int. J. Comput. Sci. Issues 2010, 7. [Google Scholar]

- Ortiz, A.; Bonnin-Pascual, F.; Garcia-Fidalgo, E.; Company-Corcoles, J. Vision-Based Corrosion Detection Assisted by a Micro-Aerial Vehicle in a Vessel Inspection Application. Sensors 2016, 16, 2118. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.-Y.; Dollár, P.; Girshick, R.B.; He, K.; Hariharan, B.; Belongie, S.J. Feature Pyramid Networks for Object Detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017. [Google Scholar] [CrossRef] [Green Version]

- Albawi, S.; Abed Mohammed, T.; ALZAWI, S. Understanding of a Convolutional Neural Network. In Proceedings of the 2017 International Conference on Engineering and Technology (ICET), Antalya, Turkey, 21–23 August 2017. [Google Scholar]

- Luo, Z.; Liu, H.; Wu, X. Artificial Neural Network Computation on Graphic Process Unit. In Proceedings of the 2005 IEEE International Joint Conference on Neural Networks, Montreal, QC, Canada, 31 July–4 August 2005; Volume 1, pp. 622–626. [Google Scholar]

- Sultana, F.; Sufian, A.; Dutta, P. Advancements in Image Classification Using Convolutional Neural Network|Request PDF. In Proceedings of the 2018 Fourth International Conference on Research in Computational Intelligence and Communication Networks (ICRCICN), Kolkata, India, 22–23 November 2018. [Google Scholar]

- Nwankpa, C.; Ijomah, W.; Gachagan, A.; Marshall, S. Activation Functions: Comparison of Trends in Practice and Research for Deep Learning. arXiv 2018, arXiv:1811.03378. [Google Scholar]

- Ghosh, A.; Sufian, A.; Sultana, F.; Chakrabarti, A.; De, D. Fundamental Concepts of Convolutional Neural Network. In Recent Trends and Advances in Artificial Intelligence and Internet of Things; Springer: Cham, Switzerland, 2020; pp. 519–567. ISBN 978-3-030-32643-2. [Google Scholar]

- Шaклa, Hишaнт-Maшиннoe Oбyчeниe & TensorFlow [Teкcт]: [16+]-Search RSL. Available online: https://search.rsl.ru/ru/record/01009872794? (accessed on 13 April 2022).

- Gafarov, F.; Galimyanov, A. Artificial Neural Networks and Their Applications, 1st ed.; Kazan University: Kazan, Russia, 2018; pp. 25–28. [Google Scholar]

- TeнзopΦлoy Лaйт|TensorFlow Lite. Available online: https://www.tensorflow.org/lite/guide?hl=ru (accessed on 13 April 2022).

- FlatBuffers: FlatBuffers. Available online: https://google.github.io/flatbuffers/ (accessed on 13 April 2022).

- Cпpaвoчник пo API TensorFlow Lite. Available online: https://www.tensorflow.org/lite/api_docs?hl=ru (accessed on 13 April 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).