Performance of Asphalt Concrete Pavement Reinforced with High-Density Polyethylene Plastic Waste

Abstract

:1. Introduction

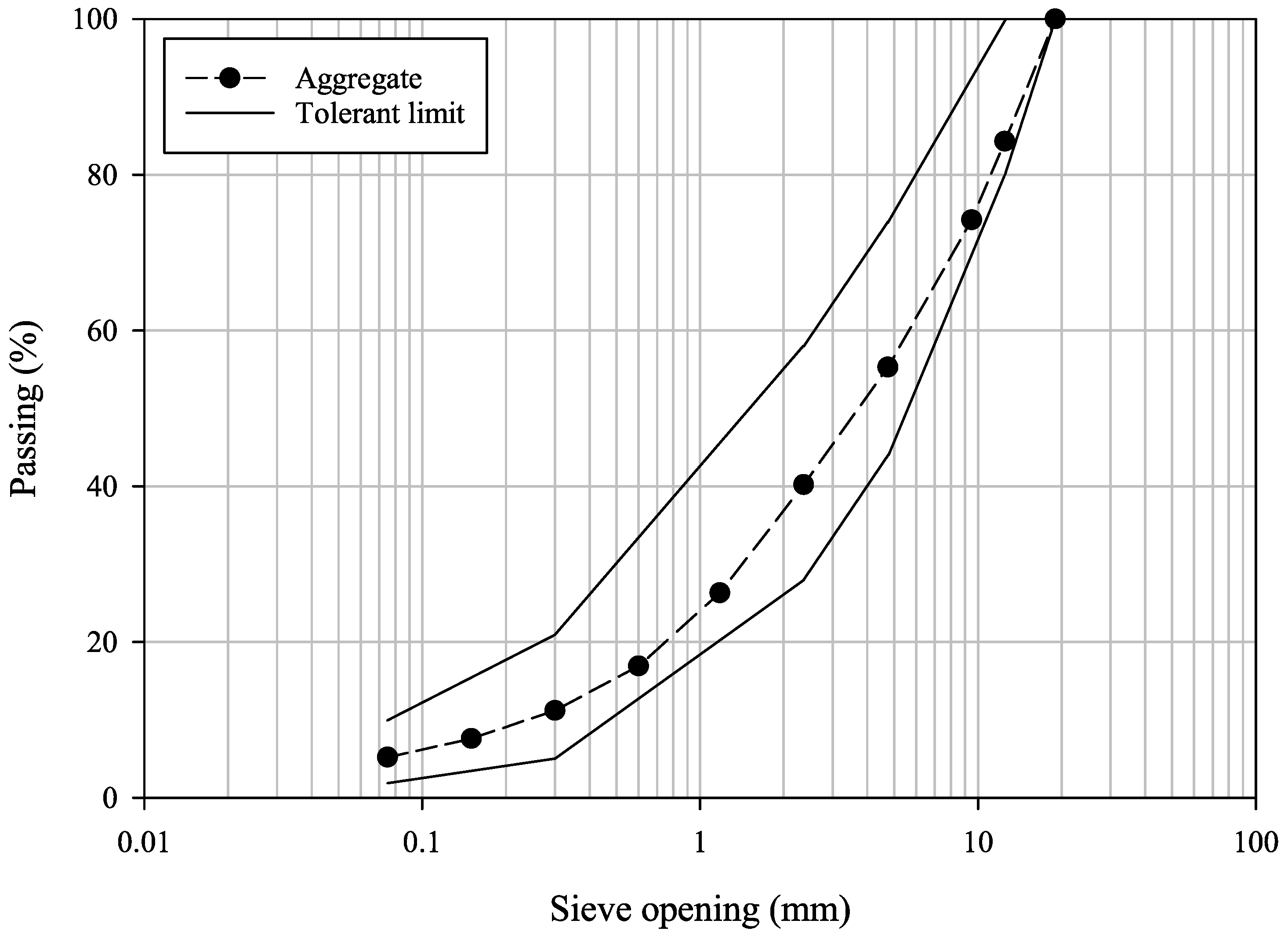

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation and Testing

3. Results and Discussions

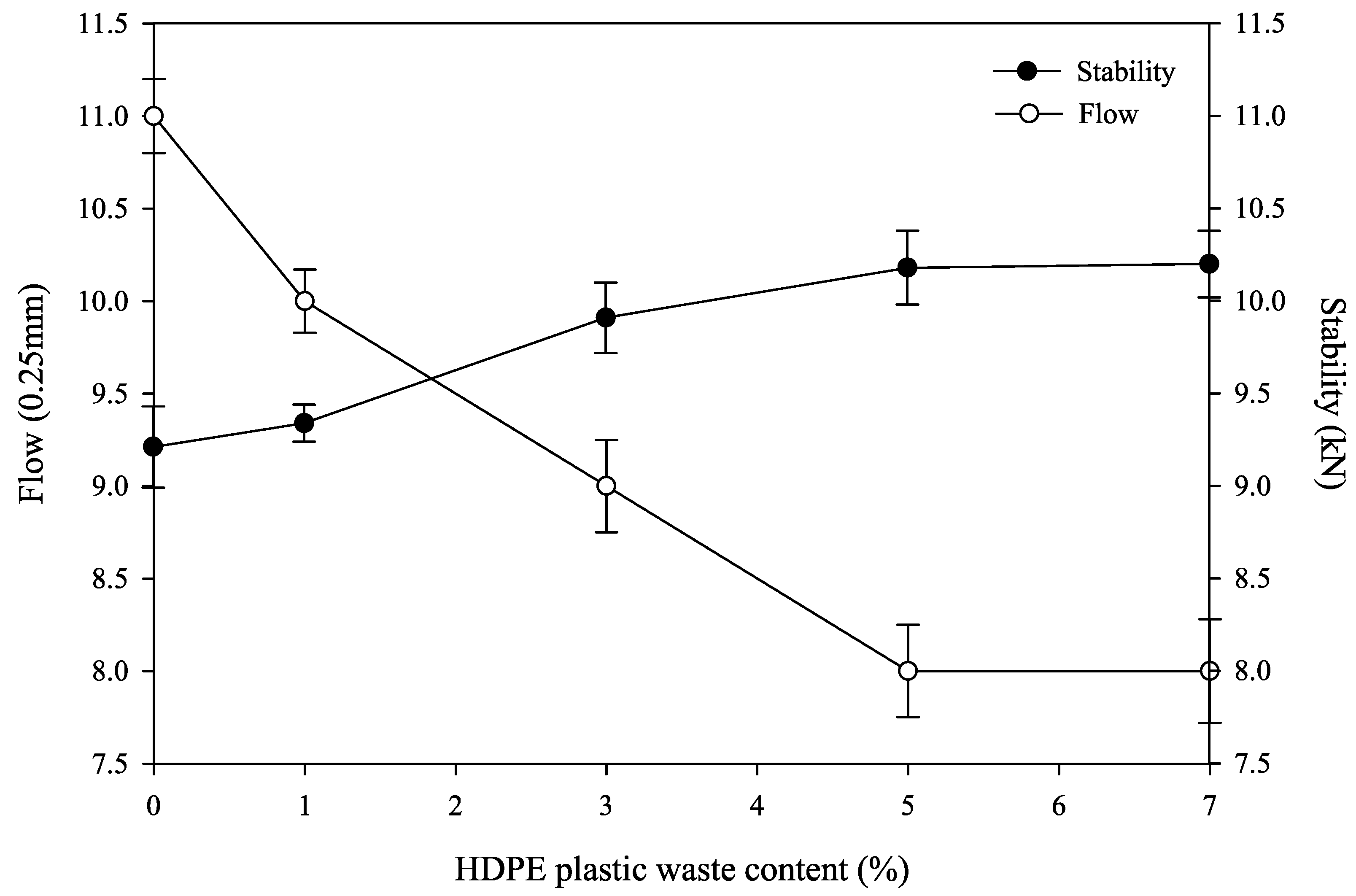

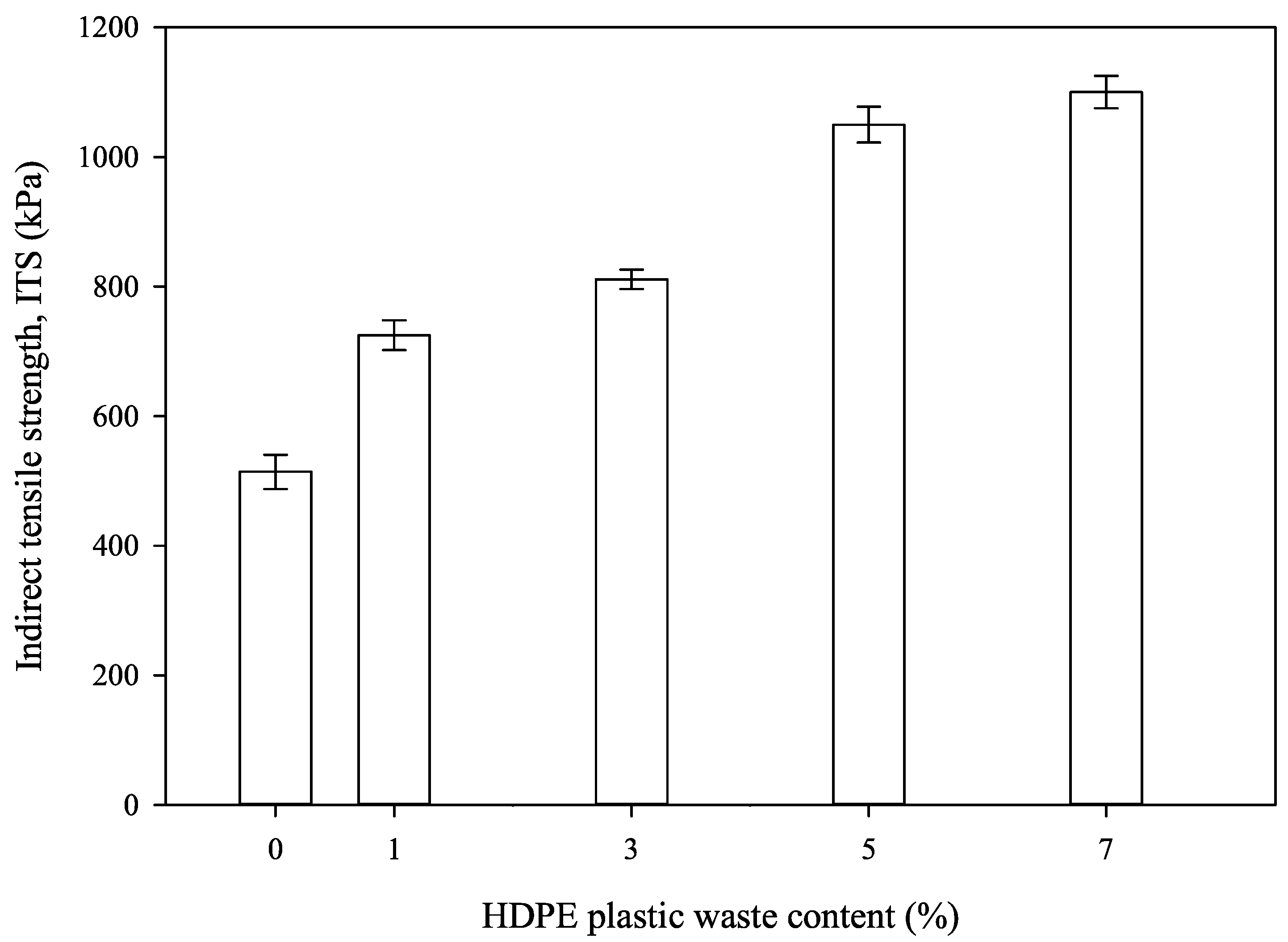

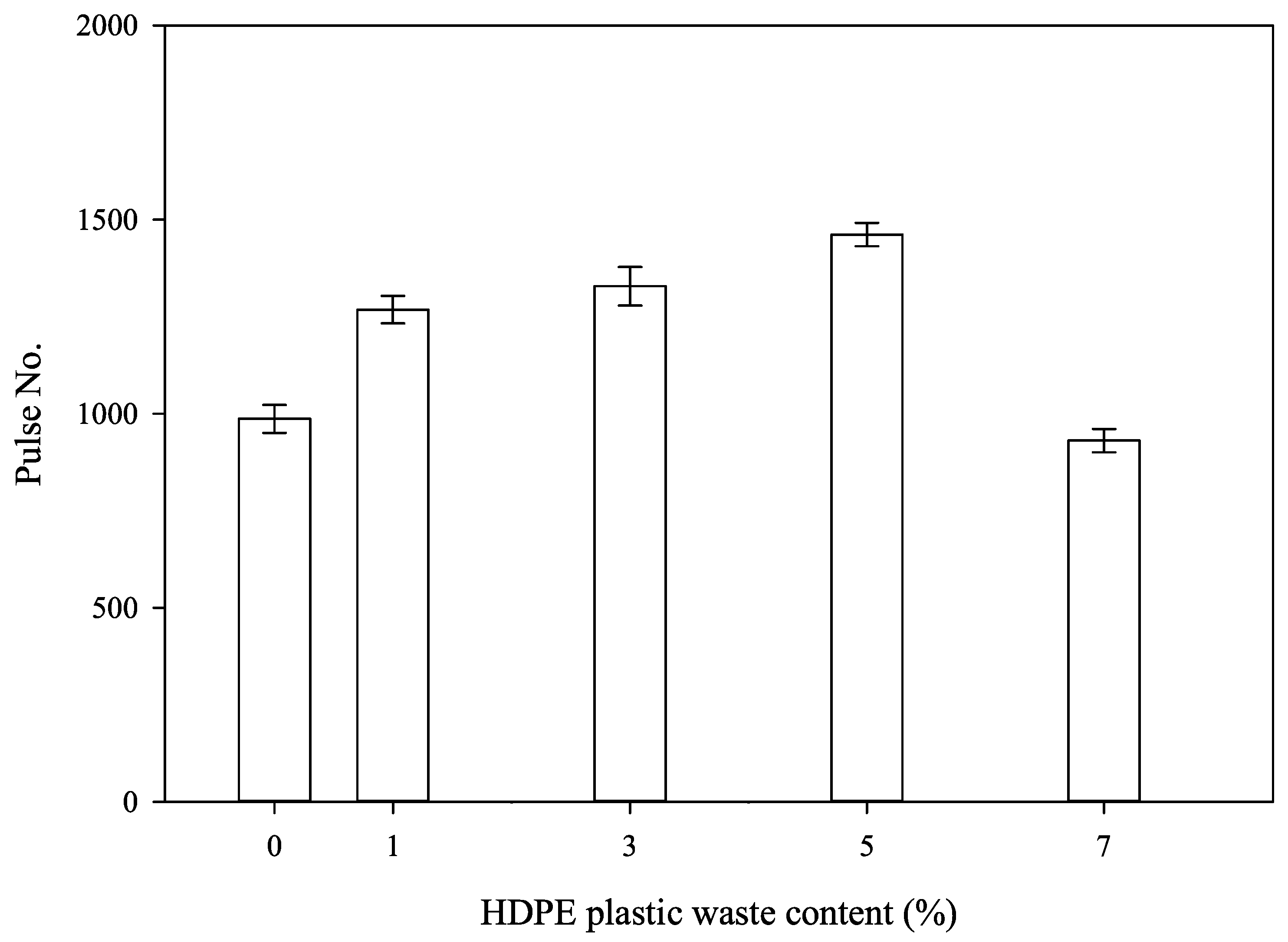

3.1. Performance Test Results

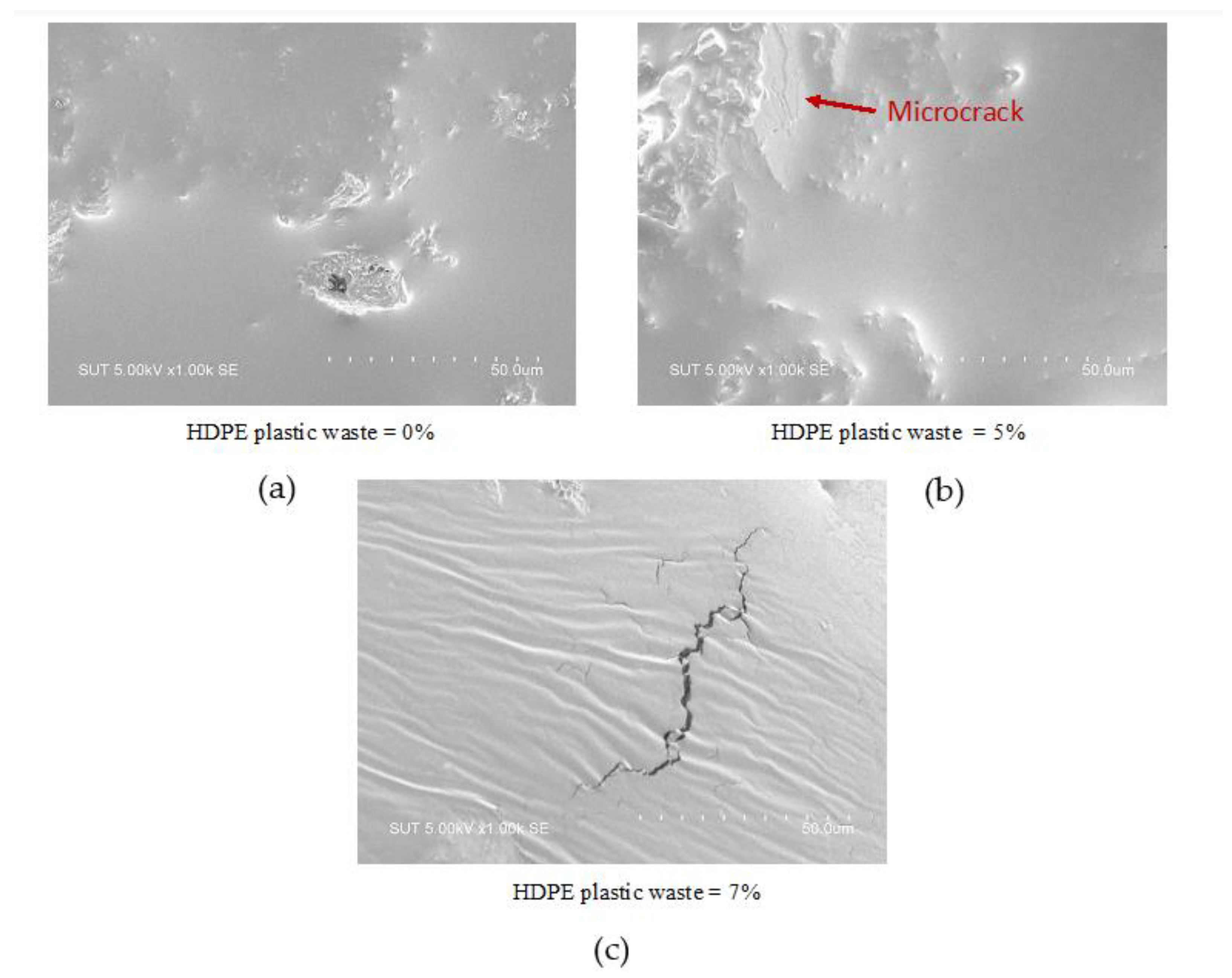

3.2. Microstructure analysis

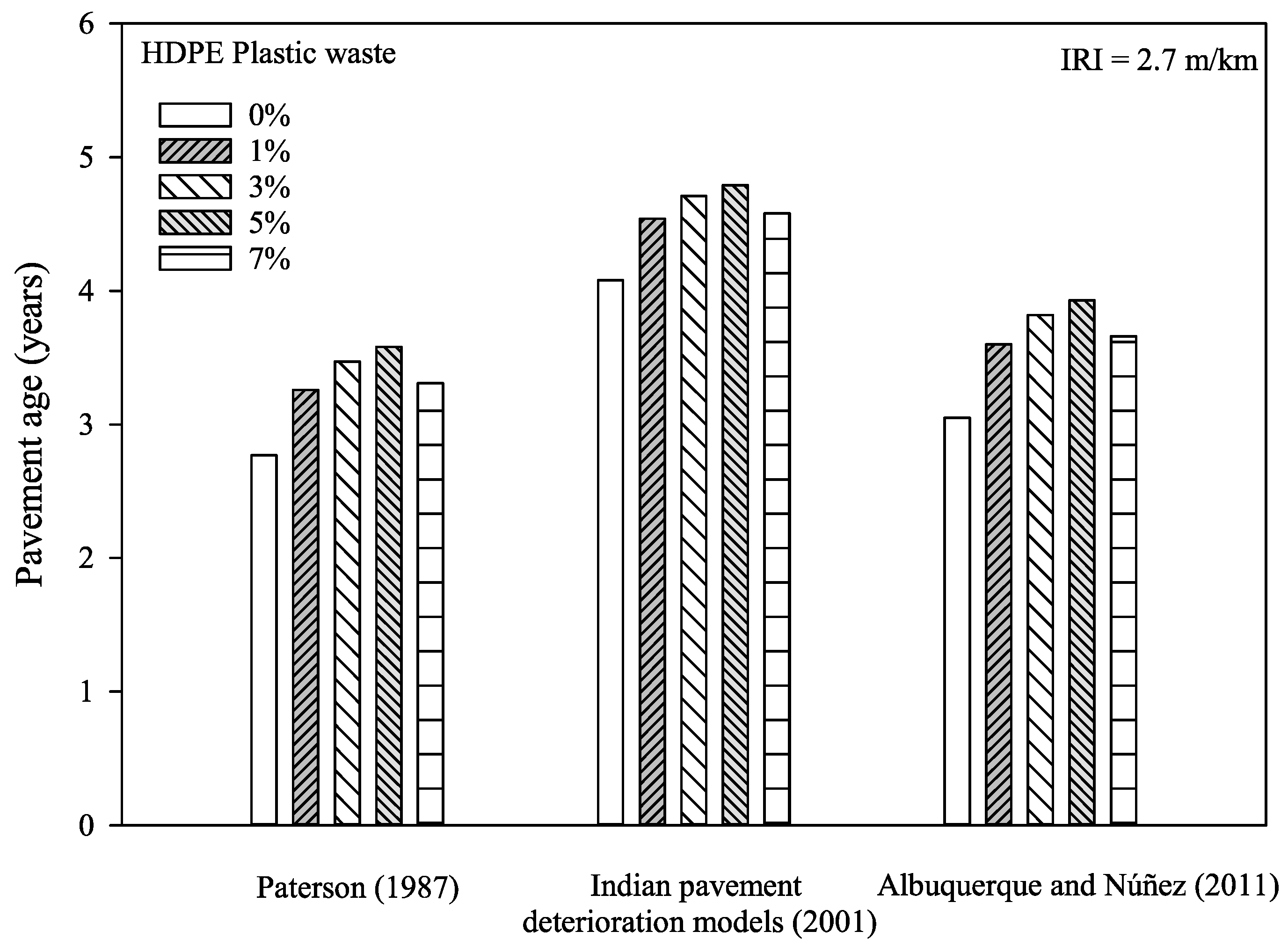

3.3. Pavement Age

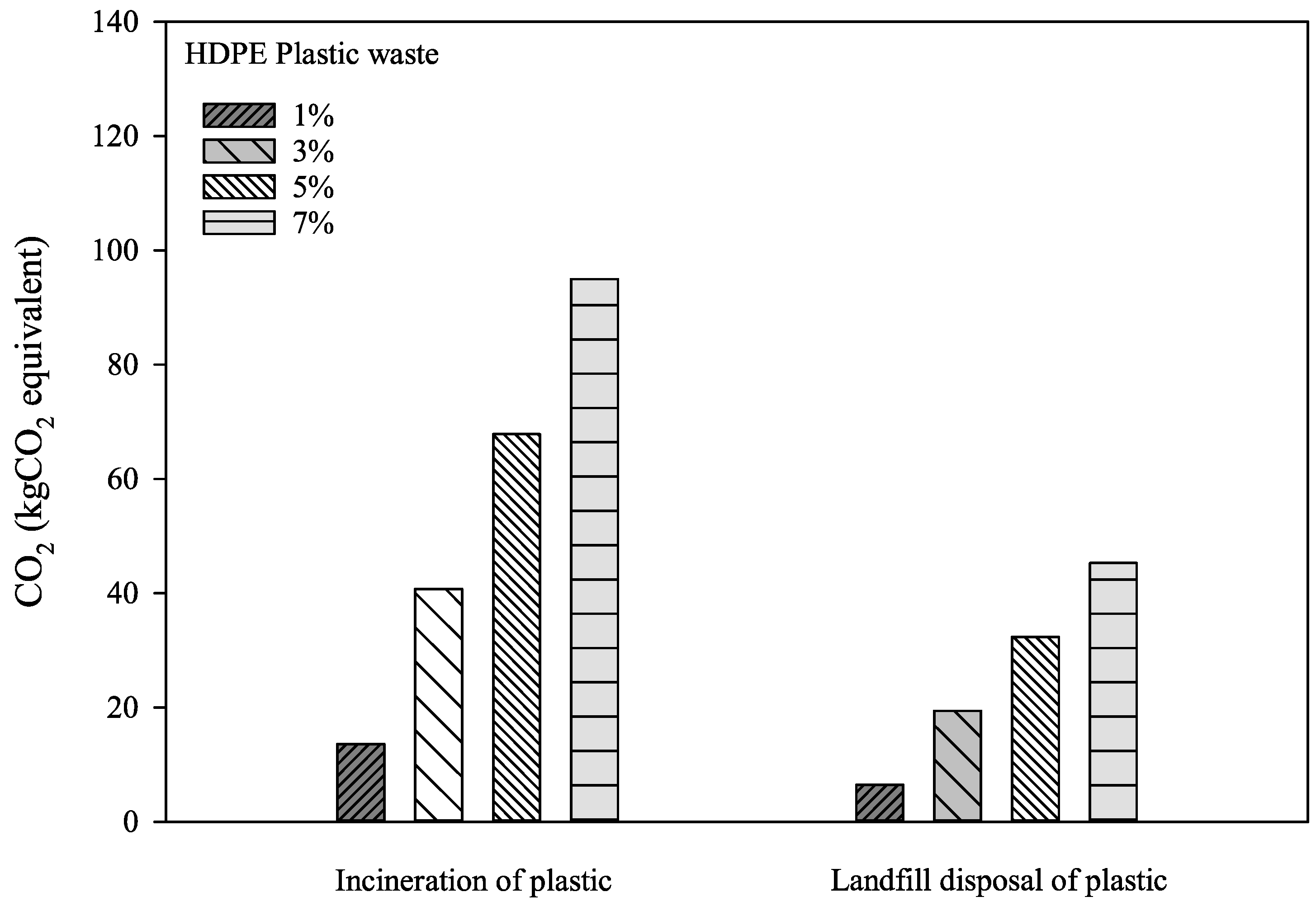

3.4. CO2 Emissions Savings

4. Conclusions

- The stability and ITS of the HDPE-ACP samples increased with HDPE plastic waste content because of the increase of the molecular and polymer network in the AC. On the other hand, the flow values of the sample decreased with the increase in HDPE plastic waste content up to 5 wt.% and then leveled. The reduction of flow values resulted from the increasing strength of the samples.

- The maximum MR and fatigue life values of the HDPE-ACP samples were with an HDPE plastic waste content of 5% by aggregate weight because of the higher modulus. However, for the HDPE plastic waste content of 7 wt.%, the MR and fatigue life values of the HDPE-ACP sample decreased because the excessive HDPE plastic waste content increased the polymer network, resulting in less compatibility in the AC.

- SEM images show that the aggregates were filled and covered by the AC and HDPE plastic waste. The excessive HDPE plastic waste content of 7 wt.% cause a surface rupture of the sample. The higher dosages of polymers in the sample led to a less compatible AC matrix.

- Improvements in the pavement age of the HDPE-ACP samples were observed compared with the samples with no HDPE plastic waste. The highest pavement age of the HDPE-ACP sample was found at an HDPE plastic waste content of 5% by aggregate weigh.

- Based on the emission factor of incineration of plastic, the CO2 emissions savings of the HDPE-ACP were 13.57, 40.71, 67.85, and 94.99 kg CO2-e/m3 for HDPE plastic waste contents of 1, 3, 5, and 7% by aggregate weight, respectively. Future research should focus on the impact of potential drainage and discharge of microplastics on the built environment of asphalt concrete reinforced with HDPE plastic waste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lenz, N.V.; Skender, H.P.; Mirković, P.A. The macroeconomic effects of transport infrastructure on economic growth: The case of Central and Eastern E.U. member states. Econ. Res.-Ekon. Istraž. 2018, 31, 1953–1964. [Google Scholar]

- Jain, S.S.; Aggarwal, S.; Parida, M. HDM-4 Pavement Deterioration Models for Indian National Highway Network. J. Transp. Eng. 2005, 131, 623–631. [Google Scholar] [CrossRef]

- Albuquerque, F.S.; Núñez, W.P. Development of Roughness Prediction Models for Low-Volume Road Networks in Northeast Brazil. Transp. Res. Rec. J. Transp. Res. Board 2011, 2205, 198–205. [Google Scholar] [CrossRef]

- Paterson, W.D.O. Road Deterioration and Maintenance Effects: Models for Planning and Management; World Bank Publications: Washington, DC, USA, 1987. [Google Scholar]

- Casey, D.; McNally, C.; Gibney, A.; Gilchrist, M.D. Development of a recycled polymer modified binder for use in stone mastic asphalt. Resour. Conserv. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Takaikaew, T.; Tepsriha, P.; Horpibulsuk, S.; Hoy, M.; Kaloush, K.E.; Arulrajah, A. Performance of Fiber-Reinforced Asphalt Concretes with Various Asphalt Binders in Thailand. J. Mater. Civ. Eng. 2018, 30, 04018193. [Google Scholar] [CrossRef]

- Jafar, J.J. Utilisation of Waste Plastic in Bituminous Mix for Improved Performance of Roads. KSCE J. Civ. Eng. 2016, 20, 243–249. [Google Scholar] [CrossRef]

- Mazumder, M.; Ahmed, R.; Ali, A.W.; Lee, S.J. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build. Mater. 2018, 186, 313–329. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef] [Green Version]

- Yousefi, A.A.; Kadi, A.A.I.T. Composite asphalt binders: Effects of modified RPE on asphalt. J. Mater. Civ. Eng. 2000, 12, 113–123. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Yi-Qiu, T. Effect of polyethylene on life of flexible pavements. Constr. Build. Mater. 2009, 23, 1456–1464. [Google Scholar] [CrossRef]

- Attaelmanan, M.; Cheng, P.F.; Al-Hadidy, A.I. Laboratory evaluation of HMA with high density polyethylene as a modifier. Constr. Build. Mater. 2011, 25, 2764–2770. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U.; Ekblad, J. Phase separation of SBS polymer modified bitumens. J. Mater. Civ. Eng. 1999, 1, 51–57. [Google Scholar] [CrossRef]

- Yeh, P.-H.; Nien, Y.-H.; Chen, W.-C.; Liu, W.-T. Evaluation of Thermal and Viscoelastic Properties of Asphalt Binders by Compounding with Polymer Modifiers. Polym. Compos. 2010, 31, 1738–1744. [Google Scholar] [CrossRef]

- Karmakar, S.; Roy, T.K. Effect of waste plastic and waste tires ash on mechanical behavior of bitumen. J. Mater. Civ. Eng. 2016, 28, 04016006. [Google Scholar] [CrossRef]

- Karakurt, C. Microstructure properties of waste tire rubber composites: An overview. J. Mater. Cycles Waste Manag. 2015, 17, 422–433. [Google Scholar] [CrossRef]

- Cardone, F.; Spadoni, S.; Ferrotti, G.; Canestrari, F. Asphalt mixture modification with a plastomeric compound containing recycled plastic: Laboratory and field investigation. Mater. Struct. 2020, 55, 109. [Google Scholar] [CrossRef]

- Diab, A.; Enieb, M.; Singh, D. Influence of aging on properties of polymer-modified asphalt. Constr. Build. Mater. 2019, 196, 54–65. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, S.; Upadhyay, N. Composition based physicochemical analysis of modified bitumen by high-density polyethylene (HDPE) and low-density polyethylene (LDPE). Orient. J. Chem. 2019, 35, 1167–1173. [Google Scholar] [CrossRef]

- Marks, D.; Miller, M.A.; Vassanadumrongdee, S. The geopolitical economy of Thailand’s marine plastic pollution crisis. Asia Pac. Viewp. 2020, 61, 266–282. [Google Scholar] [CrossRef]

- Radusin, T.; Nilsen, J.; Larsen, S.; Annfinsen, S.; Waag, C.; Eikeland, M.S.; Pettersen, M.K.; Fredriksen, S.B. Use of recycled materials as mid layer in three layered structures-new possibility in design for recycling. J. Clean. Prod. 2020, 259, 120876. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Gravina, R.; Giustozzi, F. Recycled plastic as bitumen modifier: The role of recycled linear low- density polyethylene in the modification of physical, chemical and rheological properties of bitumen. J. Clean. Prod. 2020, 266, 121988. [Google Scholar] [CrossRef]

- Mohammadinia, A.; Naeini, M.; Arulrajah, A.; Horpibulsuk, S.; Leong, M. Shakedown analysis of recycled materials as railway capping layer under cyclic loading. Soil Dyn. Earthq. Eng. 2020, 139, 106423. [Google Scholar] [CrossRef]

- Naeini, M.; Mohammadinia, A.; Arulrajah, A.; Horpibulsuk, S.; Leong, M. Stiffness and strength characteristics of demolition waste, glass and plastics in railway capping layers. Soils Found. 2019, 59, 2238–2253. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Kumar, L.; Gupta, M.; Chauhan, G.S. Polymer-Modified Bitumen of Recycled LDPE and Maleated Bitumen. J. Appl. Polym. 2013, 127, 67–78. [Google Scholar] [CrossRef]

- Almeida, A.; Capitão, S.; Bandeira, R.; Fonseca, M.; Picado-Santos, L. Performance of AC mixtures containing flakes of LDPE plastic film collected from urban waste considering ageing. Constr. Build. Mater. 2020, 232, 117253. [Google Scholar] [CrossRef]

- Karmakar, S.; Roy, T.K. Influence of plastic waste on chemical and mechanical properties of modified bitumen used in the bituminous mix for flexible pavement. J. Mater. Civ. Eng. 2021, 33, 04020440. [Google Scholar] [CrossRef]

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7. [Google Scholar] [CrossRef] [Green Version]

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- DH-S408/2532; Standard of Asphalt Concrete or Hot-Mix Asphalt. DOH (Department of Highways): Bangkok, Thailand, 1989.

- ASTM D1559-89; Test Method for Resistance of Plastic Flow of Bituminous Mixtures Using Marshall Apparatus. American Society of Testing and Materials: West Conshohocken, PA, USA, 1989.

- ASTM D6931-17; Standard Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures. American Society of Testing and Materials: West Conshohocken, PA, USA, 2007.

- ASTM D4123-82; Standard Test Method for Indirect Tensile Test for Resilient Modulus of Bituminous Mixtures. American Society of Testing and Materials: West Conshohocken, PA, USA, 2007.

- AASHTO TP31; Standard Test Method for Determining the Resilient Modulus of Bituminous Mixtures by Indirect Tension. American Association of State Highway and Transportation Officials: Washington, DC, USA, 1994.

- BS-EN-12697-24; Bituminous Mixtures. Test Methods for Hot Mix Asphalt Part 24: Resistance to Fatigue. BSI (British Standards Institution): London, UK, 2004.

- Suksiripattanapong, C.; Horpibulsuk, S.; Chanprasert, P.; Sukmak, P.; Arulrajah, A. Compressive strength development in fly ash geopolymer masonry units manufactured from water treatment sludge. Constr. Build Mater 2015, 82, 20–30. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Horpibulsuk, S.; Yeanyong, C.; Arulrajah, A. Evaluation of polyvinyl alcohol and high calcium fly ash based geopolymer for the improvement of soft Bangkok clay. Transp. Geotech. 2021, 27, 100476. [Google Scholar] [CrossRef]

- Tabyang, W.; Suksiripattanapong, C.; Phetchuay, C.; Laksanakit, C.; Chusilp, N. Evaluation of municipal solid waste incineration fly ash based geopolymer for stabilised recycled concrete aggregate as road material. Road Mater. Pavement Des. 2021, 1–12. [Google Scholar] [CrossRef]

- Köfteci, S.; Ahmedzade, P.; Kultayev, B. Performance evaluation of bitumen modified by various types of waste plastics. Constr. Build Mater 2014, 73, 592–602. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, S. Gray System Model for Estimating the Pavement International Roughness Index. J. Perform. Constr. Facil. 2005, 19, 62–68. [Google Scholar] [CrossRef]

- FHWA (Federal Highway Administration). National Performance Management Measures: Assessing Pavement Condition for the National Highway Performance Program and Bridge Condition for the National Highway Performance Program [Proposed Rule] (Document No. 2014-30085). Fed. Regist. 2015, 80, 325–393. [Google Scholar]

- Múcka, P. International Roughness Index specifications around the world. Road Mater. Pavement Des. 2017, 18, 929–965. [Google Scholar] [CrossRef]

- Eriksson, O.; Finnveden, G. Plastic waste as a fuel—CO2-neutral or not? Energy Environ. Sci. 2009, 2, 907–914. [Google Scholar] [CrossRef]

- Turner, D.A.; Williams, I.D. Greenhouse gas emission factors for recycling of source-segregated waste materials. Resour. Conserv. Recycl. 2015, 105, 186–197. [Google Scholar] [CrossRef] [Green Version]

| Properties | Aggregate |

|---|---|

| Bulk specific gravity | 2.661 |

| Apparent specific gravity | 2.707 |

| Effective specific gravity | 2.643 |

| Flakiness index (%) | 42 |

| Elongation index (%) | 28 |

| Asphalt Absorption (%) | 0.26 |

| Los Angeles Abrasion (%) Aggregate ¾” | 23.4 |

| Soundness (% WT loss) Aggregate ¾” | 1.1 |

| Soundness (% WT loss) Fine Aggregate | 3.2 |

| Properties | Result | TIS 851/2561 |

|---|---|---|

| Penetration at 25 °C | 67 | 60–70 |

| Softening point (°C) | 48 | 45–55 |

| Ductility | 110 | >100 |

| Properties | Mixture | DH-S408/2532 |

|---|---|---|

| Asphaltic content (%) | 5.0 | 3–7 |

| Marshall air void (%) | 4.1 | 3–5 |

| Marshall density (gm/mL) | 2.385 | - |

| Void in mineral aggregate (VMA) (%) | 14.6 | >14 |

| Void filled with asphalt cement (%) | 71.9 | - |

| Marshall stability (kN) | 9.21 | 8 |

| Marshall flow (0.25 mm) | 11 | 8–16 |

| Stability/Flow ratio (kN/0.25 mm) | 189 | >160 |

| Strength Index (%) | 89.8 | >75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suksiripattanapong, C.; Uraikhot, K.; Tiyasangthong, S.; Wonglakorn, N.; Tabyang, W.; Jomnonkwao, S.; Phetchuay, C. Performance of Asphalt Concrete Pavement Reinforced with High-Density Polyethylene Plastic Waste. Infrastructures 2022, 7, 72. https://doi.org/10.3390/infrastructures7050072

Suksiripattanapong C, Uraikhot K, Tiyasangthong S, Wonglakorn N, Tabyang W, Jomnonkwao S, Phetchuay C. Performance of Asphalt Concrete Pavement Reinforced with High-Density Polyethylene Plastic Waste. Infrastructures. 2022; 7(5):72. https://doi.org/10.3390/infrastructures7050072

Chicago/Turabian StyleSuksiripattanapong, Cherdsak, Khanet Uraikhot, Sermsak Tiyasangthong, Nattiya Wonglakorn, Wisitsak Tabyang, Sajjakaj Jomnonkwao, and Chayakrit Phetchuay. 2022. "Performance of Asphalt Concrete Pavement Reinforced with High-Density Polyethylene Plastic Waste" Infrastructures 7, no. 5: 72. https://doi.org/10.3390/infrastructures7050072

APA StyleSuksiripattanapong, C., Uraikhot, K., Tiyasangthong, S., Wonglakorn, N., Tabyang, W., Jomnonkwao, S., & Phetchuay, C. (2022). Performance of Asphalt Concrete Pavement Reinforced with High-Density Polyethylene Plastic Waste. Infrastructures, 7(5), 72. https://doi.org/10.3390/infrastructures7050072