Sustainability in the Civil Construction Sector Supported by Industry 4.0 Technologies: Challenges and Opportunities †

Abstract

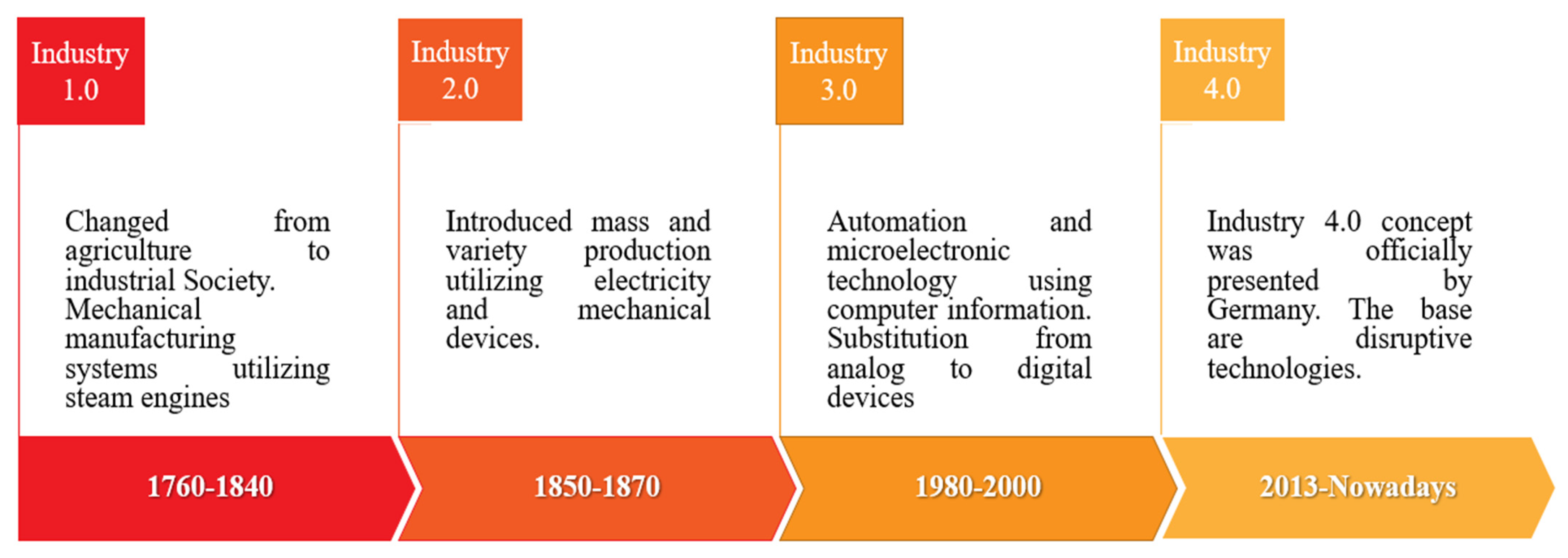

1. Introduction

2. Literature Review

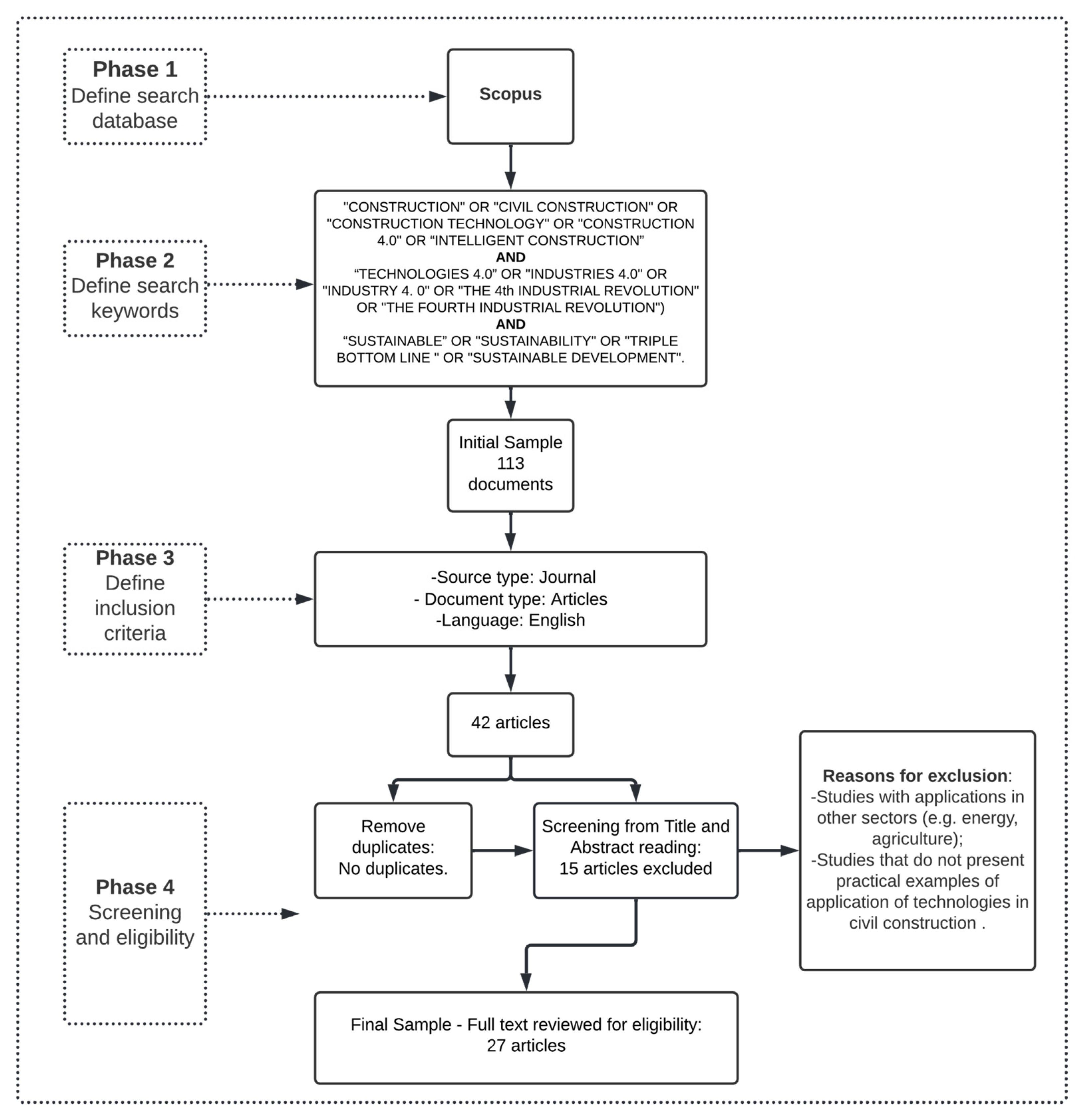

3. Research Methodology

- (1)

- “CONSTRUCTION” OR “CIVIL CONSTRUCTION” OR “CONSTRUCTION TECHNOLOGY” OR “CONSTRUCTION 4.0” OR “INTELLIGENT CONSTRUCTION” AND;

- (2)

- “TECHNOLOGIES 4.0” OR “INDUSTRIES 4.0” OR “INDUSTRY 4. 0” OR “THE 4th INDUSTRIAL REVOLUTION” OR “THE FOURTH INDUSTRIAL REVOLUTION” AND;

- (3)

- “SUSTAINABLE” OR “SUSTAINABILITY” OR “TRIPLE BOTTOM LINE” OR “SUSTAINABLE DEVELOPMENT”.

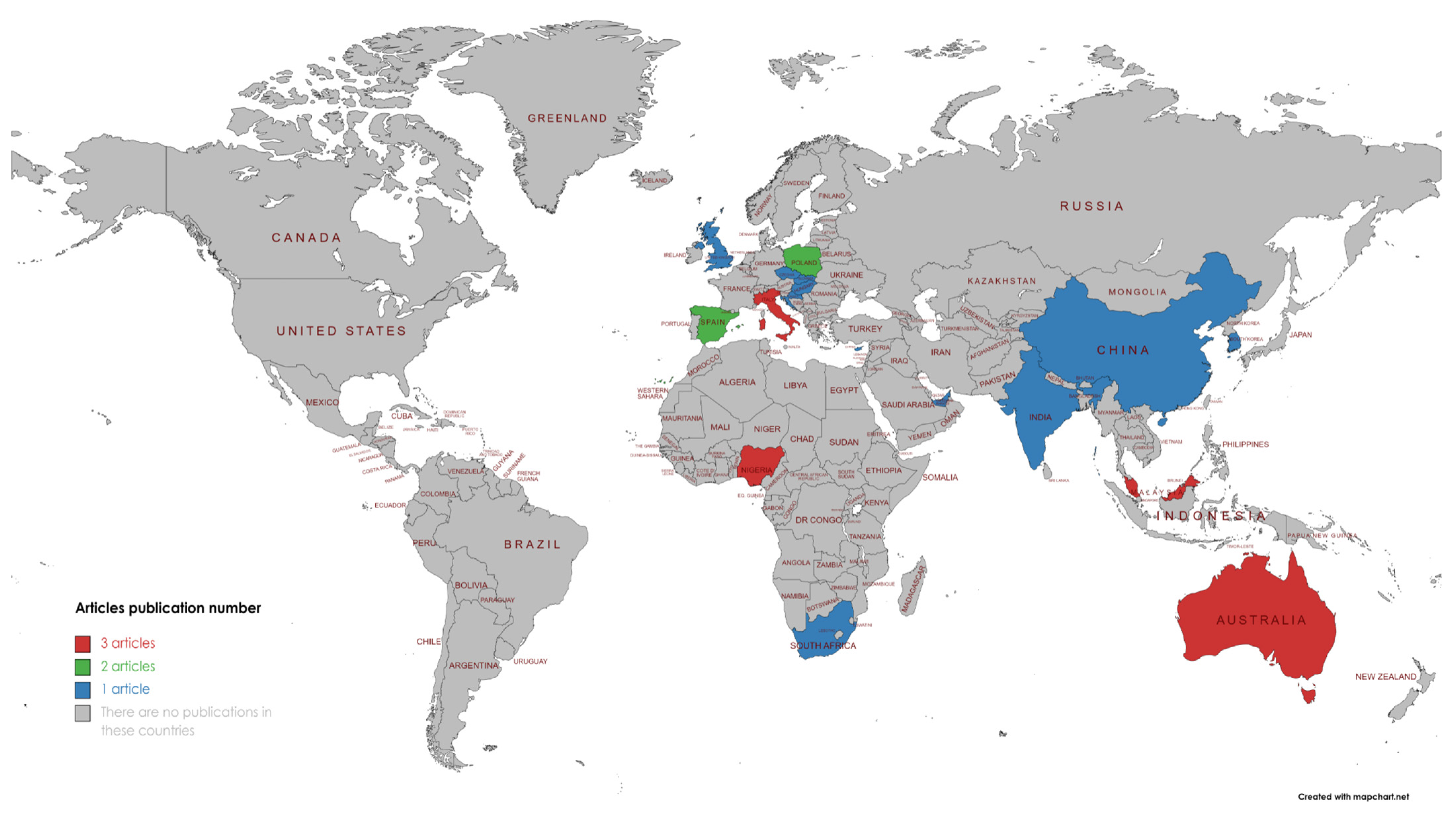

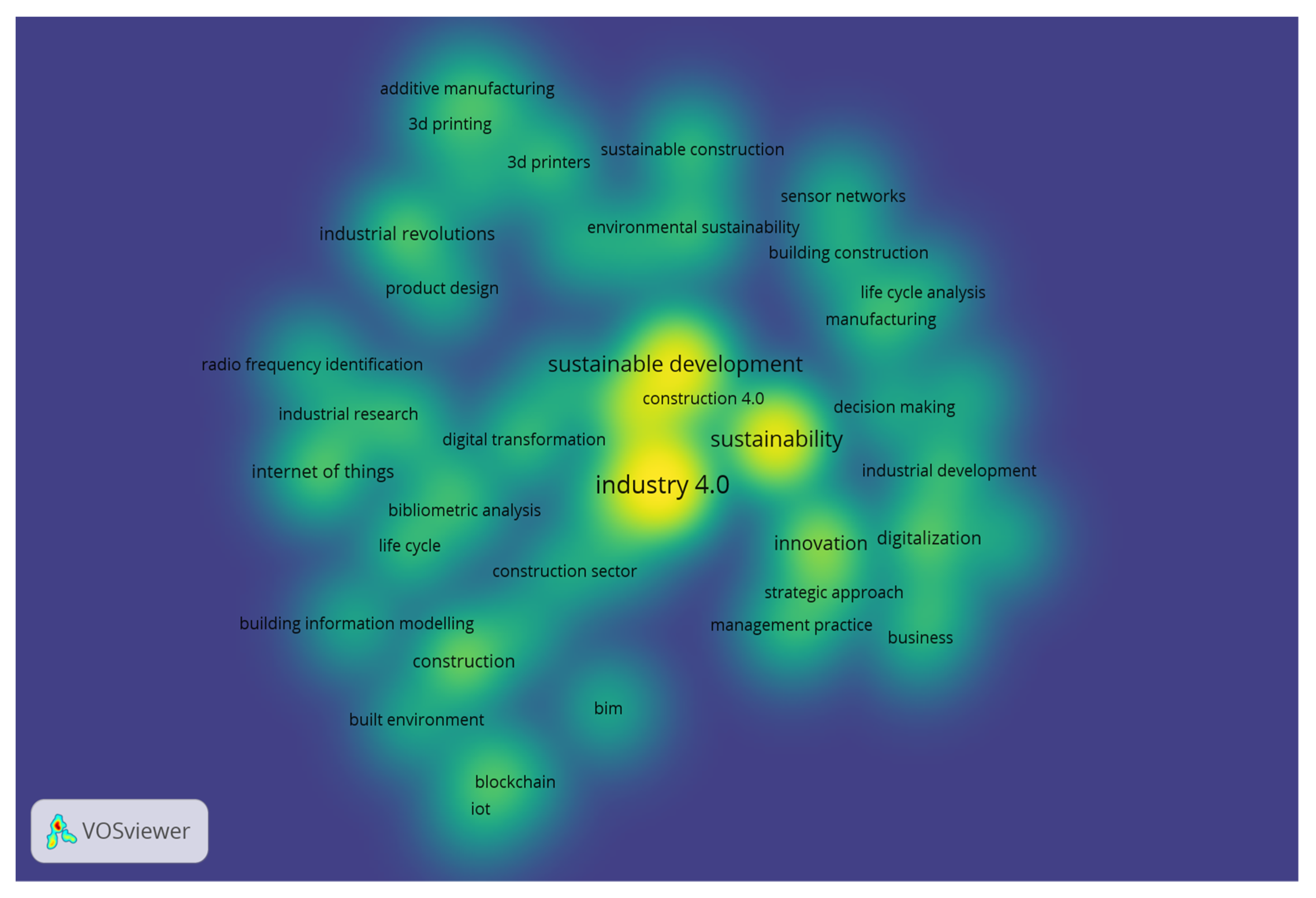

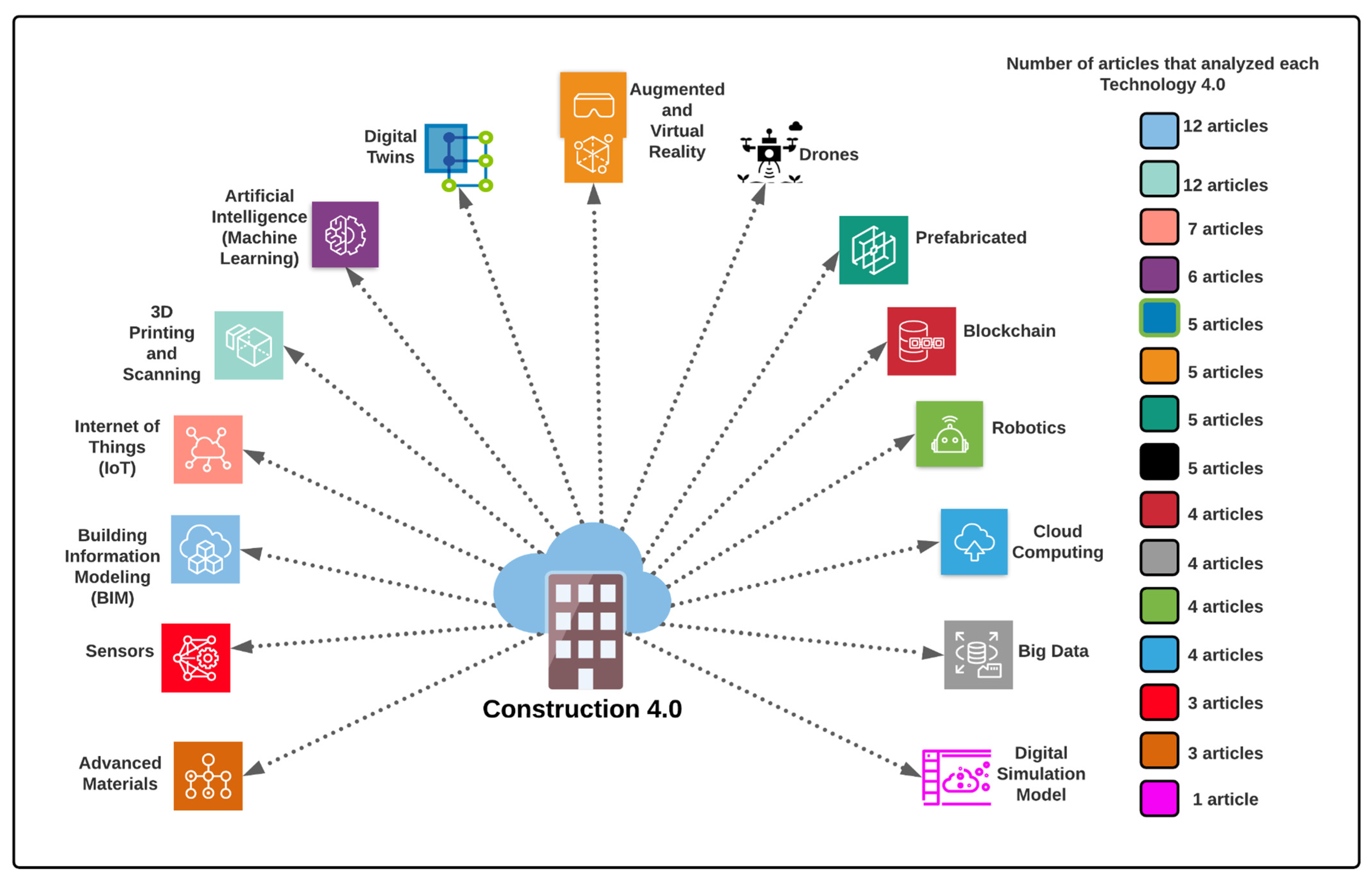

4. Results

5. Discussion

Practical Implications and Future Directions

- The publication’s analysis distribution per year reveals that the interest in adopting Industry 4.0 Technologies in construction has emerged within the last five years, being still a “hot topic”, with few theoretical and empirical investigations;

- Thus far, there are no American publications. Among developing countries, including the BRICS members (Brazil, Russia, India, China and South Africa), only Brazil and Russia have not contributed to the advancement of research in these areas;

- Lack the implementation and impact of many technologies in the context of construction;

- How two or more technologies can be diffused, that is, worked together; or

- There are still technical challenges related to the integration of different technologies. Future research should investigate the challenges encountered in the joint application of different technologies, both in theory and in practice;

- Empirical studies with qualitative and quantitative approaches showing the real advances in the applicability of technological tools in construction;

- The impacts of industry technology 4.0 affect which and how the pillars of sustainability operate;

- Proposals for models that allow replicability within the topic’s construction, technology and sustainability;

- Most articles explore the relationship between industry 4.0 technologies in construction from an economic and some environmental point of view, however, few also address the social pillar.

6. Final Considerations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lezoche, M.; Hernandez, J.E.; Díaz, M.M.E.A.; Panetto, H.; Kacprzyk, J. Agri-food 4.0: A survey of the supply chains and technologies for the future agriculture. In Computers in Industry; Elsevier B.V.: Amsterdam, The Netherlands, 2020; Volume 117, p. 103187. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Yin, Y.; Stecke, K.E.; Li, D. The evolution of production systems from Industry 2.0 through Industry 4.0. Int. J. Prod. Res. 2017, 56, 848–861. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2018, 31, 127–182. [Google Scholar] [CrossRef]

- Candido, D.D.S.; Watts, A.; Abade, L.; Kraemer, M.U.G.; Pybus, O.G.; Croda, J.; de Oliveira, W.; Khan, K.; Sabino, E.C.; Faria, N.R. Routes for COVID-19 importation in Brazil. J. Travel Med. 2020, 27, taaa042. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Su, F.; Pei, T.; Zhang, A.; Du, Y.; Luo, B.; Cao, Z.; Wang, J.; Yuan, W.; Zhu, Y.; et al. COVID-19: Challenges to GIS with Big Data. Geogr. Sustain. 2020, 1, 77–87. [Google Scholar] [CrossRef]

- Livingston, E.H.; Desai, A.; Berkwits, M. Sourcing Personal Protective Equipment During the COVID-19 Pandemic. JAMA 2020, 323, 1912–1914. [Google Scholar] [CrossRef]

- McCall, B. COVID-19 and artificial intelligence: Protecting health-care workers and curbing the spread. Lancet Digit. Health 2020, 2, e166–e167. [Google Scholar] [CrossRef]

- Tzioutziou, A.; Xenidis, Y. A Study on the Integration of Resilience and Smart City Concepts in Urban Systems. Infrastructures 2021, 6, 24. [Google Scholar] [CrossRef]

- Keogh, M.; Smallwood, J.J. The role of the 4th Industrial Revolution (4IR) in enhancing performance within the construction industry. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 654, p. 012021. [Google Scholar] [CrossRef]

- The World Commission on Environment and Development (WCED). Our Common Future. 1987. Available online: https://sustainabledevelopment.un.org/content/documents/5987our-common-future.pdf (accessed on 14 January 2022).

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of Business of 21st Century, 1st ed.; Capstone Publishing Limited Oxford Centre for Innovation: Oxford, UK, 1994. [Google Scholar]

- UN. Sustainable Development Goals. United Nations. 2015. Available online: https://sustainabledevelopment.un.org/sdgs (accessed on 14 April 2020).

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and trends in Internet of Things (IoT) research: Future applications in the construction industry. Eng. Constr. Arch. Manag. 2020, 28, 457–481. [Google Scholar] [CrossRef]

- Valente, M.; Sibai, A.; Sambucci, M.; Valente, M.; Sibai, A.; Sambucci, M.; Valente, M.; Sibai, A.; Sambucci, M.; Valente, M.; et al. Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry. J. Compos. Sci. 2019, 3, 88. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.; Yang, Y.; Tetteh, M.O. Building information modeling (BIM)-based modular integrated construction risk management—Critical survey and future needs. Comput. Ind. 2020, 123, 103327. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Kang, S.-C.; Al-Hussein, M. Virtual reality applications for the built environment: Research trends and opportunities. Autom. Constr. 2020, 118, 103311. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E.; Linder, C. Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review. Comput. Ind. 2018, 99, 205–225. [Google Scholar] [CrossRef]

- STATISTA. Forecast of the Infrastructure Construction Sector’s Gross Domestic Product (GDP) in Brazil from 2021 to 2025. Statista Research Department. 2022. Available online: https://www.statista.com/statistics/1140201/brazil-infrastructure-construction-gdp/ (accessed on 10 February 2022).

- Fokaides, P.; Apanaviciene, R.; Černeckiene, J.; Jurelionis, A.; Klumbyte, E.; Kriauciunaite-Neklejonoviene, V.; Pupeikis, D.; Rekus, D.; Sadauskiene, J.; Seduikyte, L.; et al. Research Challenges and Advancements in the field of Sustainable Energy Technologies in the Built Environment. Sustainability 2020, 12, 8417. [Google Scholar] [CrossRef]

- Mesa, J.A.; Fúquene-Retamoso, C.; Maury-Ramírez, A. Life Cycle Assessment on Construction and Demolition Waste: A Systematic Literature Review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- Ahmed, H.M.; Abdelhaffez, G.S.; Ahmed, A.A. Potential use of marble and granite solid wastes as environmentally friendly coarse particulate in civil constructions. Int. J. Environ. Sci. Technol. 2020, 19, 889–896. [Google Scholar] [CrossRef]

- Bogue, R. What are the prospects for robots in the construction industry? Ind. Robot. 2018, 45, 1–6. [Google Scholar] [CrossRef]

- Bedarf, P.; Dutto, A.; Zanini, M.; Dillenburger, B. Foam 3D printing for construction: A review of applications, materials, and processes. Autom. Constr. 2021, 130, 103861. [Google Scholar] [CrossRef]

- Jamali, K.; Kaushal, V.; Najafi, M. Evolution of Additive Manufacturing in Civil Infrastructure Systems: A Ten-Year Review. Infrastructures 2021, 6, 108. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Petrella, A.; Coppola, A.; Notarnicola, M.; Fiorito, F. Building Envelope Prefabricated with 3D Printing Technology. Sustainability 2021, 13, 8923. [Google Scholar] [CrossRef]

- Nawari, N.O.; Ravindran, S. Blockchain and Building Information Modeling (BIM): Review and Applications in Post-Disaster Recovery. Buildings 2019, 9, 149. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Newman, C.; Edwards, D.; Martek, I.; Lai, J.; Thwala, W.D.; Rillie, I. Industry 4.0 deployment in the construction industry: A bibliometric literature review and UK-based case study. Smart Sustain. Built Environ. 2020, 10, 557–580. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Xu, M.; Nie, X.; Li, H.; Cheng, J.C.; Mei, Z. Smart construction sites: A promising approach to improving on-site HSE management performance. J. Build. Eng. 2022, 49, 104007. [Google Scholar] [CrossRef]

- Yevu, S.K.; Yu, A.T.; Darko, A. Digitalization of construction supply chain and procurement in the built environment: Emerging technologies and opportunities for sustainable processes. J. Clean. Prod. 2021, 322, 129093. [Google Scholar] [CrossRef]

- Lee, C.-H.; Liu, C.-L.; Trappey, A.J.; Mo, J.P.; Desouza, K.C. Understanding digital transformation in advanced manufacturing and engineering: A bibliometric analysis, topic modeling and research trend discovery. Adv. Eng. Inform. 2021, 50, 101428. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA Statement for Reporting Systematic Reviews and Meta-Analyses of Studies That Evaluate Health Care Interventions: Explanation and Elaboration. PLoS Med. 2009, 6, e1000100. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef]

- Zamani, S.H.; Rahman, R.A.; Fauzi, M.A.; Yusof, L.M. Government pandemic response strategies for AEC enterprises: Lessons from COVID-19. J. Eng. Des. Technol. 2022; in press. [Google Scholar] [CrossRef]

- Orzeł, B.; Wolniak, R. Digitization in the Design and Construction Industry—Remote Work in the Context of Sustainability: A Study from Poland. Sustainability 2022, 14, 1332. [Google Scholar] [CrossRef]

- Teisserenc, B.; Sepasgozar, S. Project Data Categorization, Adoption Factors, and Non-Functional Requirements for Blockchain Based Digital Twins in the Construction Industry 4.0. Buildings 2021, 11, 626. [Google Scholar] [CrossRef]

- Teisserenc, B.; Sepasgozar, S. Adoption of Blockchain Technology through Digital Twins in the Construction Industry 4.0: A PESTELS Approach. Buildings 2021, 11, 670. [Google Scholar] [CrossRef]

- Bisták, A.; Hulínová, Z.; Neštiak, M.; Chamulová, B. Simulation Modeling of Aerial Work Completed by Helicopters in the Construction Industry Focused on Weather Conditions. Sustainability 2021, 13, 13671. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Nagy, O.; Papp, I.; Szabó, R.Z. Construction 4.0 Organisational Level Challenges and Solutions. Sustainability 2021, 13, 12321. [Google Scholar] [CrossRef]

- Choi, S.-W.; Lee, E.-B.; Kim, J.-H. The Engineering Machine-Learning Automation Platform (EMAP): A Big-Data-Driven AI Tool for Contractors’ Sustainable Management Solutions for Plant Projects. Sustainability 2021, 13, 10384. [Google Scholar] [CrossRef]

- Slivkova, S.; Brumarova, L.; Kluckova, B.; Pokorny, J.; Tomanova, K. Safety of Constructions from the Point of View of Population Protection in the Context of Industry 4.0 in the Czech Republic. Sustainability 2021, 13, 9927. [Google Scholar] [CrossRef]

- Czajkowski, A.; Remiorz, L.; Pawlak, S.; Remiorz, E.; Szyguła, J.; Marek, D.; Paszkuta, M.; Drabik, G.; Baron, G.; Paduch, J.; et al. Global Water Crisis: Concept of a New Interactive Shower Panel Based on IoT and Cloud Computing for Rational Water Consumption. Appl. Sci. 2021, 11, 4081. [Google Scholar] [CrossRef]

- Gallo, P.; Romano, R.; Belardi, E. Smart Green Prefabrication: Sustainability Performances of Industrialized Building Technologies. Sustainability 2021, 13, 4701. [Google Scholar] [CrossRef]

- Lekan, A.; Clinton, A.; Owolabi, J. The Disruptive Adaptations of Construction 4.0 and Industry 4.0 as a Pathway to a Sustainable Innovation and Inclusive Industrial Technological Development. Buildings 2021, 11, 79. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J.; Stergioulas, L. Distributed Manufacturing: A New Digital Framework for Sustainable Modular Construction. Sustainability 2021, 13, 1515. [Google Scholar] [CrossRef]

- Sharifah-NurFarhana, S.S.; Rohana, M.; Afzan, A.Z.; Nadia, Z.; Yon Syafni, S. Assessing Predicting Factors: Good Management Practices Towards the Successful Implementation of Green Supply Chain Management (GSCM) in IBS Construction Project; CIDB: Kuala Lumpur, Malaysia, 2021.

- Balasubramanian, S.; Shukla, V.; Islam, N.; Manghat, S. Construction Industry 4.0 and Sustainability: An Enabling Framework. IEEE Trans. Eng. Manag. 2021, 33, 1–19. [Google Scholar] [CrossRef]

- Gambo, N.; Musonda, I. Effect of the Fourth Industrial Revolution on Road Transport Asset Management Practice in Nigeria. J. Constr. Dev. Ctries 2021, 26, 19–43. [Google Scholar] [CrossRef]

- Aghimien, D.; Aigbavboa, C.; Aghimien, L.; Thwala, W.; Ndlovu, L. 3D Printing for sustainable low-income housing in South Africa: A case for the urban poor. J. Green Build. 2021, 16, 129–141. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Momaya, K. Actionable strategy framework for digital transformation in AECO industry. Eng. Constr. Arch. Manag. 2021, 28, 1397–1422. [Google Scholar] [CrossRef]

- Akyazi, T.; Alvarez, I.; Alberdi, E.; Oyarbide-Zubillaga, A.; Goti, A.; Bayon, F. Skills Needs of the Civil Engineering Sector in the European Union Countries: Current Situation and Future Trends. Appl. Sci. 2020, 10, 7226. [Google Scholar] [CrossRef]

- Panteli, C.; Kylili, A.; Fokaides, P.A. Building information modelling applications in smart buildings: From design to commissioning and beyond A critical review. J. Clean. Prod. 2020, 265, 121766. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Sepasgozar, S.M.E.; Shirowzhan, S.; Niemela, M.; Tripp, A.; Nagabhyrava, S.; Mansuri, Z.; Alonso-Marroquin, F. Criteria development for sustainable construction manufacturing in Construction Industry 4.0: Theoretical and laboratory investigations. Constr. Innov. 2020, 20, 379–400. [Google Scholar] [CrossRef]

- Zulkefli, N.S.; Mohd-Rahim, F.A.; Zainon, N. Integrating Building Information Modelling (BIM) and Sustainability to Greening Existing Building: Potentials in Malaysian Construction Industry. Int. J. Sustain. Constr. Eng. Technol. 2020, 11, 76–83. [Google Scholar] [CrossRef]

- Lekan, A.; Aigbavboa, C.; Babatunde, O.; Olabosipo, F.; Christiana, A. Disruptive technological innovations in construction field and fourth industrial revolution intervention in the achievement of the sustainable development goal 9. Int. J. Constr. Manag. 2020, 1–12. [Google Scholar] [CrossRef]

- Zainon, N.; Lun, G.W.; Zaid, N.S.M.; Myeda, N.E.; Aziz, N.M. Developing a Framework for Life Cycle Assessment of Construction Materials through Building Information Modelling (BIM). Int. J. Innov. Creat. Chang. 2019, 10, 253–276. [Google Scholar]

- Homadovski, A. Arhitektonski programi kao komunikacijske platforme korporacija. Prost. Znan. Časopis Arhit. Urban. 2018, 26, 82–93. [Google Scholar] [CrossRef]

- Sperimentazione, R.E.; Sferra, A.S. Emergency: Innovative prefabricated construction components for an eco-solidarity architecture. TECHNE-J. Technol. Archit. Environ. 2017, 14, 328–334. [Google Scholar] [CrossRef]

- Doussoulin, J.P.; Bittencourt, M. How effective is the construction sector in promoting the circular economy in Brazil and France? A waste input-output analysis. Struct. Chang. Econ. Dyn. 2021, 60, 47–58. [Google Scholar] [CrossRef]

- Manjia, M.B.; Abanda, H.F.; Pettang, C. A Contribution to the Sustainable Construction Indicators Evaluation in Developing Countries: The Case of Cameroon. Lect. Notes Netw. Syst. 2017, 72, 137–148. [Google Scholar] [CrossRef]

- Nunes, K.; Mahler, C.F. Comparison of construction and demolition waste management between Brazil, European Union and USA. Waste Manag. Res. 2020, 38, 415–422. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the circular economy to the UN sustainable development goals through sustainable construction. Resour. Conserv. Recycl. 2021, 178, 106023. [Google Scholar] [CrossRef]

- Agarwal, R.; Chandrasekaran, S.; Mukund, S. Imagining Construction’s Digital Future; McKinsey & Company: Hong Kong, China, 2016; Available online: https://www.mckinsey.com/business-functions/operations/our-insights/imagining-constructions-digital-future (accessed on 28 April 2020).

- Lu, K.; Jiang, X.; Tam, V.W.Y.; Li, M.; Wang, H.; Xia, B.; Chen, Q. Development of a Carbon Emissions Analysis Framework Using Building Information Modeling and Life Cycle Assessment for the Construction of Hospital Projects. Sustainability 2019, 11, 6274. [Google Scholar] [CrossRef]

- Li, D.; Lu, M. Integrating geometric models, site images and GIS based on Google Earth and Keyhole Markup Language. Autom. Constr. 2018, 89, 317–331. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Zhou, J. Enhancing environmental sustainability over building life cycles through green BIM: A review. Autom. Constr. 2015, 57, 156–165. [Google Scholar] [CrossRef]

- Oreto, C.; Massotti, L.; Biancardo, S.A.; Veropalumbo, R.; Viscione, N.; Russo, F. BIM-Based Pavement Management Tool for Scheduling Urban Road Maintenance. Infrastructures 2021, 6, 148. [Google Scholar] [CrossRef]

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- FIA. Tecnologia na Construção Civil: O que é, Importância e Exemplos. Fundação Instituto de Administração (FIA). 2020. Available online: https://fia.com.br/blog/tecnologia-na-construcao-civil/ (accessed on 3 April 2020).

- Alves, N. Casas Pré-Fabricadas: Tipos, Vantagens e Como Funciona. CONSTRUCT. 2017. Available online: https://constructapp.io/pt/casas-pre-fabricadas/ (accessed on 3 April 2020).

- Bahia, L.D.; Pinheiro, B.R. Evolução dos Indices de Tecnologia dos Complexos Têxtil e Construção Civil no Brasil (1985–2009). 2017. Available online: https://www.econstor.eu/handle/10419/177508 (accessed on 15 May 2020).

- Garcia-Troncoso, N.; Xu, B.; Probst-Pesantez, W. Development of Concrete Incorporating Recycled Aggregates, Hydrated Lime and Natural Volcanic Pozzolan. Infrastructures 2021, 6, 155. [Google Scholar] [CrossRef]

- Gomes, R.I.; Bastos, D.; Farinha, C.B.; Pederneiras, C.M.; Veiga, R.; de Brito, J.; Faria, P.; Silva, A.S. Mortars with CDW Recycled Aggregates Submitted to High Levels of CO2. Infrastructures 2021, 6, 159. [Google Scholar] [CrossRef]

- Zeeberg, A. Bricks Alive! Scientists Create Living Concrete. The New York Times. 2020. Available online: https://www.nytimes.com/2020/01/15/science/construction-concrete-bacteria-photosynthesis.html (accessed on 15 April 2021).

- de Almeida Corrêa e Silva, T.; De Paula, H.M. Gestão da água em usina de concreto: Análise do emprego de Moringa oleifera no tratamento de água residuária e proposta de reuso após tratamento. Matéria 2019, 24. [Google Scholar] [CrossRef]

- Riedl, R.; Benlian, A.; Hess, T.; Stelzer, D.; Sikora, H. On the Relationship Between Information Management and Digitalization. Bus. Inf. Syst. Eng. 2017, 59, 475–482. [Google Scholar] [CrossRef]

- WEF. Winsun: Demonstrating the Viability of 3D Printing at Construction Scale. World Economic Forum. 2016. Available online: https://www.futureofconstruction.org/case/winsun/ (accessed on 24 December 2021).

- UNESP. Unesp/Tupã Iniciará Fabricação de Máscaras de Proteção. Universidade Estadual Paulista Júlio de Mesquita Filho (UNESP). 2020. Available online: https://www.tupa.unesp.br/#!/noticia/614/unesp-tupa-iniciara-fabricacao-de-mascaras-de-protecao (accessed on 22 April 2021).

- UNESP. Unesp Produz Equipamentos para Apoiar Saúde do Vale do Paraíba. Universidade Estadual Paulista Júlio de Mesquita Filho (UNESP). 2020. Available online: https://www2.unesp.br/portal#!/noticia/35698/unesp-produz-equipamentos-para-apoiar-saude-do-vale-do-paraiba/ (accessed on 22 April 2021).

- UNESP. Universidade Pública Unida pelo SUS-Soluções Contra o COVID-19. Universidade Estadual Paulista Júlio de Mesquita Filho (UNESP). 2020. Available online: https://www.feis.unesp.br/index.php/estagios/#!/departamentos/engenharia-mecanica/grupos/gpea/ (accessed on 22 April 2021).

- Salvadore, G.; Rota, E.; Corsi, E.; Colombina, G. Industrial Wearable Robots: A HUMANufacturing Approach. IFMBE Proc. 2019, 76, 1729–1733. [Google Scholar] [CrossRef]

- Baldwin, E. Esqueletos Robóticos Podem Ajudar os Trabalhadores da Construção Civil a Partir de 2020. ArchDaily. 2020. Available online: https://www.archdaily.com.br/br/908668/esqueletos-roboticos-podem-ajudar-os-trabalhadores-da-construcao-civil-a-partir-de (accessed on 22 April 2021).

- Farinaccio, R. Testamos um Exoesqueleto Simples usado na Indústria Automobilística. Techmundo. 2018. Available online: https://www.tecmundo.com.br/produto/128710-testamos-exoesqueleto-simples-usado-industria-automobilistica.htm (accessed on 22 April 2021).

- Kas, K.A.; Johnson, G.K. Using unmanned aerial vehicles and robotics in hazardous locations safely. Process Saf. Prog. 2019, 39, e12066. [Google Scholar] [CrossRef]

- Antunes, J. Should You Choose LiDAR or Photogrammetry for Aerial Drone Surveys? UAV Expo. 2018. Available online: https://www.commercialuavnews.com/construction/choose-lidar-photogrammetry-aerial-drone-surveys (accessed on 22 April 2021).

- Castronovo, F.; Awad, B.; Akhavian, R. Implementation of Virtual Design Reviews in the Generation of As-Built Information. In Construction Research Congress (CRC); American Society of Civil Engineers (ASCE): Reston, VA, USA, 2018. [Google Scholar]

- Legner, C.; Eymann, T.; Hess, T.; Matt, C.; Böhmann, T.; Drews, P.; Mädche, A.; Urbach, N.; Ahlemann, F. Digitalization: Opportunity and Challenge for the Business and Information Systems Engineering Community. Bus. Inf. Syst. Eng. 2017, 59, 301–308. [Google Scholar] [CrossRef]

- Covington, M.J.; Carskadden, R. Threat implications of the Internet of Things. In Proceedings of the 2013 5th International Conference on Cyber Conflict (CYCON 2013), Tallinn, Estonia, 4–7 June 2013; Available online: https://ieeexplore.ieee.org/abstract/document/6568380 (accessed on 22 April 2021).

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef]

- Nakamura, J. 5 Inovações na Construção Civil que Estão Agitando o Mercado. BUILDIN Construção e Informação. 2019. Available online: https://www.sienge.com.br/blog/inovacoes-na-construcao-civil/ (accessed on 10 April 2021).

- de Matos Nogueira, R.; Santos, J.S.; dos Santos, R.P.; Galvão, B.B.; Swartele, J.C.; Santos, R.C.; De, R.D.; Nogueira, M.; De Andrade, W.V.; Júlio, S.; et al. Importância Da Sondagem Spt Na Construção Civil. Rev. Pesqui. Ação 2019, 5, 171–178. Available online: https://revistas.brazcubas.br/index.php/pesquisa/article/view/683 (accessed on 10 April 2021).

- CELERE. Um dos Prédios Mais Sustentáveis do Mundo e o Impacto da Internet das Coisas na Construção. Equipe CELERE. 2018. Available online: https://celere-ce.com.br/construcao-civil/predios-mais-sustentaveis-do-mundo-internet-das-coisas/ (accessed on 6 January 2022).

- Cho, Y.S.; Lim, N.Y.; Joung, W.S.; Jung, S.H.; Choi, S.K. Management of Construction Fields Information Using Low Altitude Close-range Aerial Images. Korean J. Geomat. 2014, 32, 551–560. [Google Scholar] [CrossRef][Green Version]

- Lee, M.L.; Lee, Y.L.; Goh, S.L.; Koo, C.H.; Lau, S.H.; Chong, S.Y. Case Studies and Challenges of Implementing Geotechnical Building Information Modelling in Malaysia. Infrastructures 2021, 6, 145. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive manufacturing as an enabling technology for digital construction: A perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Franco, J.T. Assim é Construída uma Parede de Tijolos Utilizando Realidade Aumentada. ArchDaily. 2019. Available online: https://www.archdaily.com.br/br/908796/assim-e-construida-uma-parede-de-tijolos-utilizando-realidade-aumentada (accessed on 6 January 2022).

- Brum, E.M.; Pandolfo, A.; Berticelli, R.; Kalil, R.M.L.; Pasquali, P.B. Economic, social and environmental aspects of the sustainability of a construction waste recycling plant. Gestão Produção 2021, 28, e5120. [Google Scholar] [CrossRef]

- Bellini, O.E. Adaptive Exoskeleton Systems: Remodelage for Social Housing on Piazzale Visconti (BG). In Regeneration of the Built Environment from a Circular Economy Perspective; Springer: Cham, Switzerland, 2019; pp. 363–374. [Google Scholar] [CrossRef]

- Jeelani, I.; Gheisari, M. Safety challenges of UAV integration in construction: Conceptual analysis and future research roadmap. Saf. Sci. 2021, 144, 105473. [Google Scholar] [CrossRef]

- de Lima, R.L.P.; Boogaard, F.C.; Sazonov, V. Assessing the Influence of Floating Constructions on Water Quality and Ecology. In WCFS2020; Springer: Singapore, 2022; pp. 397–406. [Google Scholar] [CrossRef]

- Rodrigues, M. Civil Construction Planning Using Augmented Reality. In Sustainability and Automation in Smart Constructions; Springer: Cham, Switzerland, 2021; pp. 211–217. [Google Scholar] [CrossRef]

- Ahmed, S. A Review on Using Opportunities of Augmented Reality and Virtual Reality in Construction Project Management. Organ. Technol. Manag. Constr. Int. J. 2019, 11, 1839–1852. [Google Scholar] [CrossRef]

- Delgado, J.M.D.; Oyedele, L.; Demian, P.; Beach, T. A research agenda for augmented and virtual reality in architecture, engineering and construction. Adv. Eng. Inform. 2020, 45, 101122. [Google Scholar] [CrossRef]

- Kanan, R.; Elhassan, O.; Bensalem, R. An IoT-based autonomous system for workers’ safety in construction sites with real-time alarming, monitoring, and positioning strategies. Autom. Constr. 2018, 88, 73–86. [Google Scholar] [CrossRef]

- Gamil, Y.; Abdullah, M.A.; Abd Rahman, I.; Asad, M.M. Internet of things in construction industry revolution 4.0: Recent trends and challenges in the Malaysian context. J. Eng. Des. Technol. 2020, 18, 1091–1102. [Google Scholar] [CrossRef]

| Search Criteria | Inclusion Criteria | Exclusion Criteria |

|---|---|---|

| Database | SCOPUS | Other databases |

| Topic | Title, abstract and keywords | Words that were not present in the title, abstract and keywords |

| Publication Period | Without restriction | Without restriction |

| Document Type | Articles | Other documents |

| Publication Stage | Without restriction | Without restriction |

| Source | Journals | Books and Conferences |

| Language | English | Other languages |

| Number of Articles | Authorship | Year | Country | Title | Technologies 4.0 Applied in Civil Construction |

|---|---|---|---|---|---|

| 1 | [39] | 2022 | Poland | Digitization in the Design and Construction Industry-Remote Work in the Context of Sustainability: A Study from Poland | Digitalization of services (remote work) |

| 2 | [40] | 2021 | Australia | Adoption of blockchain technology through digital twins in the construction industry 4.0: A PESTELS approach | Blockchain/Digital Twins |

| 3 | [41] | 2021 | Australia | Project data categorization, adoption factors, and non-functional requirements for blockchain based digital twins in the construction industry 4.0 | Blockchain/Digital Twins |

| 4 | [42] | 2021 | Slovakia | Simulation modeling of aerial work completed by helicopters in the construction industry focused on weather conditions | Digital Simulation Model |

| 5 | [43] | 2021 | Spain | Circular economy in the building and construction sector: A scientific evolution analysis | Building Information Modeling (BIM) |

| 6 | [44] | 2021 | Hungary | Construction 4.0 organizational level challenges and solutions | Augmented and Virtual Reality |

| 7 | [35] | 2021 | China | Understanding digital transformation in advanced manufacturing and engineering: A bibliometric analysis, topic modeling and research trend discovery | BIM/Digital Twins/Additive Manufacturing (3D) |

| 8 | [45] | 2021 | South Korea | The engineering machine-learning automation platform (Emap): A big-data-driven AI tool for contractors’ sustainable management solutions for plant projects | Artificial Intelligence (Machine Learning)/Big Data |

| 9 | [46] | 2021 | Czech Republic | Safety of construction from the point of view of population protection in the context of industry 4.0 in the Czech Republic | BIM |

| 10 | [28] | 2021 | Italy | Building envelope prefabricated with 3D printing technology | 3D printing for prefabricated components to building |

| 11 | [47] | 2021 | Poland | Global water crisis: Concept of a new interactive shower panel based on IoT and cloud computing for rational water consumption | IoT and cloud computing |

| 12 | [48] | 2021 | Italy | Smart green prefabrication: Sustainability performances of industrialized building technologies | Premanufactured Building Technologies |

| 13 | [49] | 2021 | Nigeria | The disruptive adaptations of construction 4.0 and industry 4.0 as a pathway to a sustainable innovation and inclusive industrial technological development | All 4.0 Technologies |

| 14 | [50] | 2021 | United Kingdom | Distributed manufacturing: A new digital framework for sustainable modular construction | Modular building construction (Premanufactured); IoT; BIM; Advances in Materials |

| 15 | [51] | 2021 | Malaysia | Assessing predicting factors: Good management practices towards the successful implementation of green supply chain management (gscm) in IBS construction project | Industrialized Building System (IBS) and Digitalization |

| 16 | [52] | 2021 | United Arab Emirates | Construction Industry 4.0 and Sustainability: An Enabling Framework | Building information modeling and automation vis-à-vis others such as cyber–physical systems and smart materials, with significant growth expected in the future for blockchain- and three-dimensional-printing-related technologies. |

| 17 | [53] | 2021 | Nigeria/South Africa | Effect of the Fourth Industrial Revolution on Road Transport Asset Management Practice in Nigeria | robotics, mobility, virtual and augmented reality, Internet of things and cloud computing, machine learning, artificial intelligence, blockchain, three-dimensional (3D) printing drones and digital engineering. |

| 18 | [54] | 2021 | South Africa | 3D printing for sustainable low-income housing in South Africa: A case for the urban poor | three-dimensional (3D) printing), factor analysis aided by 3D printing technology, accessibility of technology |

| 19 | [55] | 2021 | India | Actionable strategy framework for digital transformation in AECO industry | Three-dimensional (3D) scanning, BIM, Drones/Augmented Reality/IOT/Machine Learning/Cloud Computing/Big Data/Sensors |

| 20 | [56] | 2020 | Spain | Skill needs of the civil engineering sector in the European Union countries: Current situation and future trends | (BIM), the Internet of Things (IoT), 3D laser scanning and component printing, big data analytics, augmented reality (AR), robotic construction, artificial intelligence (AI), sensor systems, intelligent materials, drones |

| 21 | [57] | 2020 | Cyprus (First author) | Building information modeling applications in smart buildings: From design to commissioning and beyond A critical review | BIM/ IOT (and digital design techniques, research in building design and optimization, BIM and LCA monitoring and tools) |

| 22 | [58] | 2020 | Australia | Criteria development for sustainable construction manufacturing in Construction Industry 4.0: Theoretical and laboratory investigations | Three-dimensional (3D) printing construction, software Strand7 Finite Element Analysis, Physical and mechanical properties of samples |

| 23 | [59] | 2020 | Malaysia | Integrating building information modeling (BIM) and sustainability to greening existing building: Potentials in Malaysian construction industry | Building Information Modeling (BIM), building lifecycles and technology and digitization in the construction industry. |

| 24 | [60] | 2020 | Nigeria | Disruptive technological innovations in construction field and fourth industrial revolution intervention in the achievement of the sustainable development goal 9 | BIM/Drones/Robots/Artificial Intelligence |

| 25 | [61] | 2019 | Malaysia | Developing a framework for life cycle assessment of construction materials through building information modeling (BIM)] | BIM |

| 26 | [62] | 2018 | Croatia | Architectural programs as corporate communications platforms | IoT |

| 27 | [63] | 2017 | Italy | Emergency: innovative prefabricated construction components for an eco-solidarity architecture | Printing machine to produce panels prefabricated |

| Technology | Challenges | Opportunities Construction Industry 4.0 |

|---|---|---|

| 1. Pre-manufacture Items produced outside the construction site | The use of conventional construction methods is associated with increased costs, incompatibility of skills, loss of productivity, quality, safety and sustainability and an aging workforce that has reached its limits [73] | Prefabricated items generate savings of financial resources and time as they are installed with more agility [74]. Example: Prefabricated houses, where the structures of the houses are built industrially and only assembled on the construction site [75]. In the context of pre-molded materials, the use of Drywall stands out, which are light and versatile plaster partitions with the function of prevention of superstructures in constructions, used in larger scale in Europe and the U.S.A. [74] |

| 2. Advances in Materials Green materials, nanomaterials, self-cure materials and reuse and recycled materials | Emphasis of the production function in civil construction, mainly concentrated in the use of such products as metallurgical, ferrous, and non-ferrous [76]. Construction and demolition wastes (C.D.W.) are generated at a large scale in the construction sector [77,78] | The changes in materials seek greater strength, greater durability, better appearance, better workability, and molding. Example: Live concrete or self-repairing, a mixture of ingredients that grows and regenerates itself, used to assemble structures in remote areas to fill cracks [79]. Another example is the use of moringa oleifera in wastewater treatment, which allows the kneading of concrete [80]. The replacement of natural aggregates with C.D.W. recycled aggregates in construction materials, such as mortars, has environmental benefits [77,78] |

| 3. 3D Printing Additive manufacturing technique, where the printer adds layer by layer to print walls and other components | Partially digitalized business and company models [81] | Faster construction and assembly with less waste, where the printing is performed on the construction site itself and pre-made parts made of concrete or metals [82]. Examples: The construction of a 1100 m2 two-story house with one day of printing, two days of assembly and requirement of only three workers [82]. Another example is the manufacture of masks and protective equipment by students from Universidade Estadual Paulista de Guaratinguetá, Ilha Solteira and Tupã during the COVID-19 pandemic [83,84,85] |

| 4. Exoskeletons Wearable robotic device, which amplifies human strength up to 20 times | The execution of repetitive operations or actions that require excessive effort have always been the main causes of musculoskeletal injuries in people working on production or construction lines [86] | Used to help workers carry heavy materials on the construction site, avoiding physical stress and injuries [87]. Example: The Industry 4.0 Technologies program leads companies to rethink processes and consider human factors, ergonomics, and sustainability. This leads to a new trend, which places workers in a modern intelligent factory, allowing them to take advantage of interconnected tools [88] |

| 5. Drones/UAVs Unmanned, remotely controlled aircraft | Work performed manually and the need to enter confined spaces and high works, two of the most dangerous practices in civil construction [89] | Used for structure construction, mapping, and monitoring. Example: On the construction site, it performs the mapping and topography of areas and soil, together with 3D scanning and photogrammetry, monitors the progress and quality of structures [90] |

| 6. Augmented Reality Virtualization and interaction with the environment | Creating the model of a building has always been a complex task, especially for existing structures, as it has always included the adoption of traditional methods and physical tools for collecting information [91] | Devices allow interaction with the project in an immersive digital structure. Example: Visualization and interaction with the architectural projects before the realization, which allows the correction of errors. Use of augmented reality glasses to detect defects in constructions [73] |

| 7. Big Data Collection and storage of large amount of construction data | The use of Big Data, marked the dematerialization of information and separates it from its physical carriers, storage, transmission, and processing equipment [92] | Collection of data from works to retain knowledge and assist in future works. Example: Access to Google and NASA Earth Exchange Climate Data Centers, Satellite Images and Weather Information, Ground, Water and Geospatial Data from the Resource Conservation Service for planning and control during the project creation phase [1] |

| 8. Internet of Things (IoT) Connects all objects present in the environment and transmits data in real time through wireless sensors | Previous global technologies are marked by the widespread adoption of mobile devices connected to the “common Internet” without interconnectivity between devices [93] | It allows the connection and collection of information of the machines, materials, vehicles, and people present on the construction site, in real time. Example: Monitoring of delivery trucks in real time, so that the site is properly and promptly prepared to receive the resources, without harming the flow [94]. IoT can also guarantee the quality of the concrete, where sensors connected to smartphones are linked to the reinforcement and warn when the material has reached a reliable resistance level [95] |

| 9. Sensors Installed in numerous objects to allow the capture of information and the implementation of corrective actions | The analysis was based on the tactile–visual contact, that is, the method of execution through simple probing [96] | Traceability of materials since each tool present in the work has an identity. Together with the Internet of things, they can collect information and make corrective actions in real time. Example: Using digital maps to obtain general information about the terrain through high-definition cameras with sensors mounted on drones to explore specific areas [68]. The Edge, one of the most sustainable buildings in the world, uses sensors to manage the lighting system, which allows it to manage the energy generated and adapt the lighting and air ventilation according to the internal use [97] |

| 10. Artificial Intelligence (AI) Computers learn and recognize events, capture, and share information in real time | It is difficult to control the processes on the construction site efficiently because there was no integrated way to verify information about people, materials and equipment in real time to perform corrective actions [82] | A.I. can monitor hundreds of activities simultaneously on the construction site by monitoring and detecting irregularities. Example: Monitoring schedules, costs, safety risks, warning about deviations in schedules, or failure to meet safety standards, which allows quick action to correct the problem [82] |

| 11. Building Information Modeling (BIM) Digital platform that integrates all construction information throughout the life cycle, using various virtualization and simulation technologies | The construction work, besides taking more time, involved complicated processes, such as management, process control and quality control to completion, which generated numerous problems [98]. Besides that, the unforeseen ground conditions are some of the main contributors to construction cost overruns and late completion [99] | It integrates all the projects and all those involved in construction. Example: BIM contains information on geometry, materials, structure, thermal efficiency and energy performance, installations, production costs [100]. Augmented reality can give digital instructions that virtually overlap the workspace, directing the masons, step by step, during the construction process [101] |

| 12. Blockchain A digital ledger system that creates a distributed, immutable storage of data and information on a network | Data and information shared by value chain members across the project lifecycle are fragmented and vulnerable to manipulation, causing inefficiencies and unreliability [41] | Blockchain is a reliable system for information security of shared data with BIM and IoT. Example: Blockchain implementation reduces data fragmentation and increases trust and transparency of contracts and project processes, allowing secure and assertive management of information, which results in increased collaboration and efficiency [41] |

| 13. Digital Twin An exact virtual replica of the environment or a physical object that provides real-time performance data | The lack of structure and poor digitalization in the construction industry makes it difficult to implement technologies that have the power to improve processes throughout the project lifecycle, such as the Digital Twin [41] | Digital Twin benefits the entire project lifecycle by providing real-time monitoring of data. Example: Automated and simultaneous monitoring of progress and compliance with safety and quality specifications, logistics, resource planning and predictive maintenance [41,102] |

| Industry 4.0 Technologies | Triple Bottom Line | ||

|---|---|---|---|

| Social | Economic | Environmental | |

| 1. Pre-manufacture | Improve health and safety of workers and local community; Access to habitation with low cost [48] | Improve quality, time, and cost, because construction activities are led within controlled environment [48,63] | Prefabricated reduce natural resources use and increase the effectiveness of waste management at the end-of-life, as the disassembly and recovery materials is facilitated; Reducing of local CO2 emissions, particulate matter and noise [48] |

| 2. Advances in Materials | Income generation for civil construction waste recycling plants and employees so that the material becomes a problem and a sustainable output [102] | The positive uses of solid waste technological treatment are considered beneficial from the economic and environmental point of view and saving the natural resources [24] | |

| 3. 3D Printing | Low-income housing [54] | 3D printing allows for mass customization and fast implementation, which can reduce costs [28,58] 3D printing reduces the cost of construction due to zero waste; it uses recycled materials and it decreases the use of transport [56] | Optimization of resources (energy and materials) use and waste management due to the high precision in the use of materials, which does not generate waste, and the incorporation of recycled materials for the deposition in 3D [58] |

| 4. Exoskeletons | Reduction in work accidents and preservation of health and safety [102] | Costs with trained workers and investment in training [102] | Exoskeleton system it is possible to innovate the architectural image, to support an equitable and sustainable development based on the prevention and risk management and extend the useful life cycle of the built environment [103] |

| 5. Drones/UAVs | Lack of regulatory and administrative interventions to guide the UAVs’ safe operation on construction sites [104] | Low-cost unmanned aerial system [70] | To obtain data and images from underneath floating buildings, drones can be equipped with cameras and sensors to collect characteristic construction information [105] |

| 6. Augmented Reality | Training of workers and prevention of occupational risks [56] | Planning of works in the virtual environment, with a preview of the necessary operations and processes, making it possible to correctly dimension and optimize financial resources [106] | Optimizes the use of resources in all phases of the project, from design to use, identifying potential areas for improvement in energy and water consumption, preventing errors and defects through early visualization of events in the virtual environment [107,108] |

| Augmented reality or virtual reality can increase customers’ understanding the final product early in the design phase, avoiding changes during the project execution and consequently avoiding redesign costs [55] | |||

| 7. Big Data | Using big data, information on work progress and suppliers and employees payments are distributed through blockchain-based smart contracts for appropriate project managerial [34] Big Data-generated data in the stages of a project is collected and formalized into a repository to be used as a knowledge base [45] | The use of cloud-based big data enables building sustainability management as a means of predicting, managing, and monitoring the impacts of a building project on the environment [71] | |

| 8. Internet of Things (IoT) | IoT maintain safety and health of workers through real-time alerting of potential falls and collisions [109] IoT can monitoring urban places exposed to extreme environmental conditions, as areas subject to flooding and landslides, minimizing or preventing deaths in natural disasters [62] | Automated real-time data collection saves resources as it streamlines the planning, communication, control and optimization of processes, inventories, preventive maintenance, time and budgets [15,110] | Real-time monitoring of parameters on emissions and consumption of resources, such as water and energy, to reducing resource scarcity [47] |

| 9. Sensors | Sensors monitoring health parameters of workers and the environment avoiding ergonomic injuries and release of harmful substances [33]. | Due to the wide variety of pollutants in the civil construction, pollutant monitoring technologies should play a significant role in the very near future as the technologies of low cost sensors evolve fast [22] | |

| 10. Artificial Intelligence (AI) | A challenge for the current management model, such as the replacement of manual activities with digital activities, also continuous workers and knowledge transfer from other sectors [44] | Artificial Intelligence can predict and respond to potential risks in a construction project cycle, reducing design changes and rework predicts, design cost estimating, design error check, change in order forecast, and predictive maintenance, bringing potential environmental benefits by optimizing the use of resources [45] | |

| 11. Building Information Modeling (BIM) | Monitoring health and safety issues—reduction of work accidents. The BIM are able automatically detect safety hazards and suggest preventive actions to workers [57] Population protection requirements can be incorporated in the information modeling system, helping to choose places safe and sustainable to build [46] | BIM increasing productivity and efficiency of operations and process; Decrease of time execution and improve quality of the projects [60] BIM can provide accurate statistics, facilitating cost estimation, construction schedule control and provide spatial and time information [15]. | The use of BIM models contributes to assess and improve: energy performance; CO2 emissions; resource efficiency and waste management; air quality [57] Use BIM to improve design from the projects conception, for example, design for disassembly and deconstruction, contributes to reduce the use of resources and improve waste management in construction [43] |

| 12. Blockchain | Increased collaboration and transparency among stakeholders. Data security [41] | Cost reduction by eliminating indirect costs and inefficiencies [41] | Improves waste management through the traceability material in the entire project lifecycle [41] |

| 13. Digital Twin | Facilities management, by employing state of the art technologies such as digital twins and digital asset management to improve the environmental issues resulting from the careless consumption of energy related to the greenhouse effect and that can interfere in the societal quality of life [22]. | A DT can be used to learn and suggest new scenarios before building a product, manufacturing tools and equipment, because developing a construction process, and planning for developing, avoiding loose time, natural resources and money [17,40]. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Almeida Barbosa Franco, J.; Domingues, A.M.; de Almeida Africano, N.; Deus, R.M.; Battistelle, R.A.G. Sustainability in the Civil Construction Sector Supported by Industry 4.0 Technologies: Challenges and Opportunities. Infrastructures 2022, 7, 43. https://doi.org/10.3390/infrastructures7030043

de Almeida Barbosa Franco J, Domingues AM, de Almeida Africano N, Deus RM, Battistelle RAG. Sustainability in the Civil Construction Sector Supported by Industry 4.0 Technologies: Challenges and Opportunities. Infrastructures. 2022; 7(3):43. https://doi.org/10.3390/infrastructures7030043

Chicago/Turabian Stylede Almeida Barbosa Franco, Jacqueline, Ana Mariele Domingues, Nelson de Almeida Africano, Rafael Mattos Deus, and Rosane Aparecida Gomes Battistelle. 2022. "Sustainability in the Civil Construction Sector Supported by Industry 4.0 Technologies: Challenges and Opportunities" Infrastructures 7, no. 3: 43. https://doi.org/10.3390/infrastructures7030043

APA Stylede Almeida Barbosa Franco, J., Domingues, A. M., de Almeida Africano, N., Deus, R. M., & Battistelle, R. A. G. (2022). Sustainability in the Civil Construction Sector Supported by Industry 4.0 Technologies: Challenges and Opportunities. Infrastructures, 7(3), 43. https://doi.org/10.3390/infrastructures7030043