Abstract

Cement-based materials are the most widely used construction materials in the world for infrastructure works. Unfortunately, they come with a high environmental burden due to carbon dioxide emissions and the need for regular maintenance and repairs. Without these, the service life can decrease. By using a self-healing approach, the service life can be extended, as well as the durability and sustainability of the building material. As the ability to self-heal depends on the age of the material, so will the potential influence of added materials to promote this healing. However, the effects of reduced healing beyond one year are not ubiquitous in the literature. In this study, specimens were studied after a decade of maturation under different storage conditions to conclude on the self-healing capabilities of the old samples. Cracks can still be partially healed after ten years, mainly due to the formation of calcium carbonate crystals, related to the observed regain in mechanical properties measured by repeated four-point bending tests. The initial addition of superabsorbent polymers to the mixture results in greater healing compared to the reference samples, making it a sustainable option for the future of cement-based composites.

1. Introduction

Due to the interest in increasing the durability and sustainability of concrete structures and construction techniques, a wide range of new cementitious materials are being designed and investigated. One of these recent materials is a cementitious material containing Superabsorbent Polymers (SAPs), studied only from 1999 [1], mainly for its internal curing purposes with the mitigation of autogenous shrinkage [2,3,4] and sealing characteristics [1,5,6]. Other positive influences are the modification of rheology, and the increase in freeze–thaw resistance, among others [7,8,9,10,11]. From 2010 [12,13], a combination of the addition of synthetic microfibers and SAPs has been studied for their improved influence on the autogenous healing capacity in cementitious materials. Since they can absorb and retain water, this water can be used to stimulate the precipitation of healing products in the vicinity of SAPs. It was found that optimal conditions for self-healing were present [14,15], as the crack width was limited to 30 µm on average and water was available during dry periods. When exposed to humid conditions, samples with SAPs even show partial healing [15,16,17,18]. These samples were studied in detail, especially at a young age, as they were mostly cracked at 28 days of age. Some of these early samples from the same batch were kept unmodified and reached an age of over 10 years in order to investigate on the influence of maturity.

In the literature, results on visual healing and regain in mechanical properties are mainly found in young samples. When examining the healing of samples older than one month, the following results can be found. Self-healing is possible after being stored in water for three months after being exposed to freeze–thaw and damage [19]. Another study compared the healing of two-month-old and twenty-month-old specimens, which were subsequently healed for a month [20]. Complete healing was still possible, but the rate of healing decreased, as did the healable crack width. They referred to the densification of the cementitious matrix, thus hardening, as reason for the decrease of the healing capacity over time. The main healing products were calcium carbonate derivatives and a small amount of C-S-H, indicating further hydration. At older ages—for example, in high-strength concrete at an age of 60 days—almost no unhydrated cement particles are present to contribute for the strength increase upon healing up to an additional 60 days [21], as C-S-H products are overall stronger than calcium carbonate crystals. The age, related to the amount of further hydration possible, is important [22]. Specimens containing fly ash still show moderate healing at 270 days of age after cracking at 180 days of age [23]. In thin cement-based sheets, healing was observed up to two years of age after being cracked at 28 days [24]. Furthermore, when considering civil constructions, healing products are still noticeably being formed after decades of service life [25,26]. An important factor to consider is the binder content, as it gives the amount of Ca2+ cations needed for calcium carbonate formation, as well as for pozzolanic activity and related calcium hydroxide consumption. A mixture with a low water-to-binder ratio also shows an increased binder content, and a larger portion of unhydrated binder compared to mixtures with a high water-to-binder ratio. Since there are more unhydrated cement grains, a greater amount of C-S-H can be formed due to continued hydration.

As the autogenous healing capacity depends on the age of the material, so will the possible influence of added materials to promote this healing. For example, by using a crystalline admixture, healing can still be achieved after one year [27]. A benchmark reference in the latter research shows a decrease in self-healing ability after one year, due to the consumption of products initially present in the mixture. Even in other systems with self-healing characteristics, a determining factor is the age. This is the case for cementitious systems containing microcapsules [28] or calcium–carbonate-precipitating bacteria [29,30,31,32], for which the healing of aged samples is only poor. Another addition aims to limit the crack widths to the healable range using (micro)fibers [33,34]. In high-performance fiber-reinforced cementitious composites, healing was studied on specimens pre-cracked at 2 months and 11 months of age [35]. Different exposure durations were provided, namely 1, 6 and 24 months for specimens pre-cracked at 2 months of age and 1, 3 and 6 months for specimens pre-cracked after 11 months of age. It was found that healing was still possible, and the longer the curing period, the more healing was observed. Small cracks closed more easily and completely. Effects beyond one year are not ubiquitous in the literature. In the latter study [36], healing was still possible but to a lesser extent, as would be the case for younger specimens.

The shelf-life of polymers is a few years, as is the case for superabsorbent polymers. Therefore, it needs to be verified whether the SAPs can still do their job after maturation in the alkaline cementitious matrix. The effect of age cannot be investigated until the actual specimens reach the required maturity. In a previous study, the age was studied up to 8 years [37]. In this study, specimens from the same batch were studied after a decade of maturation, being cracked at the age of 10 years by means of four-point bending tests and retesting after 28 days of curing under different conditions in order to study the visual precipitation of products and the regain in mechanical properties.

2. Materials and Methods

Samples containing CEM I 52.5 N (Holcim, Obourg, Belgium) (mass equivalent over one mass equivalent of cement, 1:1), fly ash (Class F, OBBC, Oosterzele, Belgium) (1:1), fine quartz sand (M34, Silbelco, Antwerp, Belgium) (0.7:1), water (0.6:1), superplasticizer (Glenium 51, conc. 35%, BASF, Ludwigshafen, Germany) (0.01:1), and PVA fibers (15 dtex, 8 mm cutting length, 12 cN/dtex tenacity, Kuraray, Kurashiki, Japan) (0.04:1) were used as the reference mixture composition. The reference samples were called REF. The SAP samples additionally contained SAPs, expressed as the mass percentage of cement weight at 0.5 m% (0.005:1) or 1 m% (0.01:1). Two polyacrylate-type of SAPs were tested. The first one (SAP A, BASF, Ludwigshafen, Germany) is a copolymer of acrylamide and sodium acrylate, having a particle size of 100.0 ± 21.5 μm. The second (SAP B, BASF, Ludwigshafen, Germany) is a cross-linked potassium salt polyacrylate with a particle size of 477 ± 53 μm. Both SAPs are produced by bulk polymerization, have an irregular form shape, and can swell up to 300 times its own weight in a liquid [15]. Additional water was added on top to compensate for the loss of workability while ensuring the same effective water-to-binder ratio [38]. The amounts of additional water were for 0.5 m% SAP A (0.153:1), for 0.5 m% SAP B (0.044:1), and for 1 m% SAP B (0.089:1), respectively. The sample series names were respectively called: 0.5 A, 0.5 B, and 1.0 B. The SAPs were first dry-mixed with the binder material to ensure even distribution. The total amount of water with dissolved superplasticizer was added at one time. The samples were prepared and stored at 20 ± 2 °C and a RH > 95% until they reached the required maturity.

The effect of autogenous healing was investigated by four-point bending loading at 10 years of age. The force–vertical–displacement curves were recalculated to stress–strain curves using goniometry. The strain was calculated at the bottom side of the specimens. Three specimens were loaded to complete failure to determine the first cracking strength σfc defined as the first observed drop in the stress–strain curve. The material ductility MC was determined as the strain in the percentage between the strain at the first cracking strength and the strain after the observed strain-hardening due to flexure at the point where strain-softening started to occur, and no increment in the stress–strain curves could be observed. This moment was defined as a failure, and the samples were unloaded at this stage. The number of cracks # was determined after failure of the specimen.

Next, a self-healing testing sequence was executed. First, three additional specimens were loaded at a strain of 1%. The first cracking strength σfc was determined, next the average observed crack width w and maximal crack width wmax by means of microscopic analysis. The loading was increased by 1.5 µm∙s−1 to achieve a quasistatic loading condition. Second, the samples were stored under specific healing conditions. These were (1) 20 ± 2 °C and a RH > 95%, (2) a standard laboratory condition of 20 ± 2 °C and a RH of 60 ± 5%, and (3) wet–dry cycles with 1-h submersion in water at 20 ± 0.5 °C and 23 h pf storage under standard laboratory conditions of 20 ± 2 °C and a RH of 60 ± 5%. The wet–dry cycling was performed in an automated setup. The crack mouths were always oriented upwards during the curing period. After this curing period, the samples were reloaded to 1% strain to determine the regain in mechanical properties. The regain in first cracking strength, i.e., the healing ratio, HR, was calculated as the division of the first cracking strength during reloading σfc,r and the initial first cracking strength during preloading σfc of the same sample, following Equation (1):

For the first cracking strength σfc, a total of six repetitions (from the samples until failure and the samples loaded to 1% preloading strain) were taken into account, while, for all other parameters, three repetitions were used. A statistical analysis was performed using the standard deviations on the single results.

3. Results and Discussion

The results for the 10-year-old specimens are given in Table 1. This table shows the first cracking strength σfc, the average crack width at 1% preloading strain w, the maximal crack width found at 1% preloading strain wmax, the ductility as flexural strain-hardening at failure MC, the number of cracks observed at failure #, and the healing ratios HR of the specimens reloaded after being stored under the different healing conditions, being at high RH+, standard RH−, and wet/dry cycling wd.

Table 1.

First cracking strength σfc (MPa), average crack width at 1% strain w (µm), maximal crack width at 1% strain wmax (µm), flexural strain-hardening amount as a measure for multiple cracking at full flexural strain-hardening MC (%), number of cracks at full flexural strain-hardening # (-),healing ratio HR at high RH+, standard RH−, and wet/dry cycling wd (%).

Typical strengths and crack widths were obtained. Due to the macropore formation by SAPs, the strength is reduced, and the decrease in strength is still acceptable. This is due to the low initial water-to-binder ratio. Due to the internal curing effect by SAPs, there is denser formation of the cementitious matrix, partly compensating the macropore formation. Due to the stress initiator property of SAPs [39], the number of cracks increases. This also results in a higher ductility, as shown by the increase in the multiple cracking amount.

When performing the wet/dry cycles, SAPs are clearly visible in specimens subjected to wet conditions. SAPs therefore survive storage for up to 10 years in a cementitious composite and are still capable of swelling. The healing ratios are always higher for SAP compared to REF samples, as is also the case for young specimens. This is due to the water action by SAPs during dry periods and the ability of SAPs to extract moisture from the surrounding environment by adsorption. This leads to more favorable conditions for the formation of healing products, since water is available [17]. The main visual appearance of the healing products was the whitish crystallization of calcium carbonate, as was confirmed by means of a microscopic analysis.

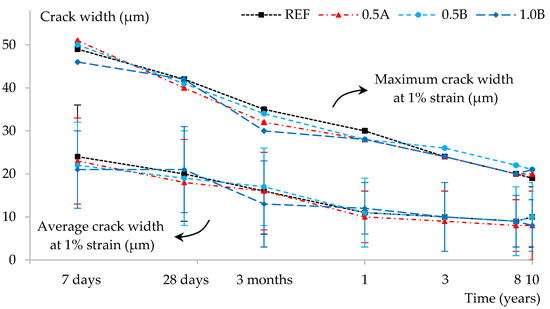

The results obtained were compared to the same batch of specimens tested at 7 days, 28 days, 3 months, 1 year, 3 years, and 8 years of age [37]. The results in terms of average crack widths and maximum crack widths are given in Figure 1.

Figure 1.

The observed mean crack width at 1% strain preloading and the observed maximal crack width at 1% strain (µm).

The average and maximum crack widths are not statistically significantly different for all the studied mixture compositions. In general, it is found that the crack widths decrease with time. This is due to the stronger matrix and further hydration, resulting in a stronger adhesion of the microfibers to the cementitious matrix. This leads to smaller fiber pullout lengths and thus smaller crack widths during strain hardening [40]. This can also have a positive effect. As crack widths decrease with time, healing products will require less bridging of the crack. While the autogenous healing capacity decreases with time, the overall healing may still be sufficient, depending on the remaining availability of the building blocks.

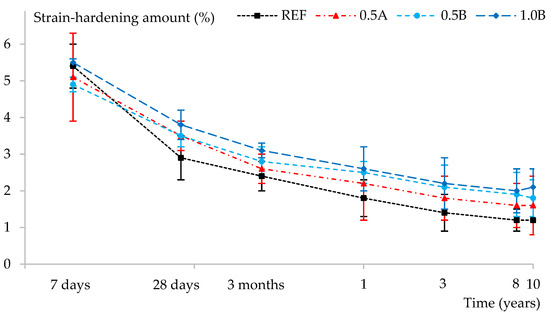

The same conclusions can be drawn by examining the overall ductility, with the results shown in Figure 2.

Figure 2.

The amount of ductility as measured by the amount of flexural strain-hardening in the stress-strain curve (%) as a function of the time.

Again, due to hardening, the fibers are more bound to the cementitious matrix. This will result in less fiber pullout and thus lower ductility. The highest ductility is found in young specimens, while the ductility significantly decreases over time, although the number of cracks tends to increase. Specimens containing SAPs tend to show more ductility. This is mainly due to the stress initiator property mentioned above. Even though the amount of porosity related to the amount of additional water is higher for 0.5 A, both mixtures containing SAP B tend to show more ductility. The main cause is the difference in particle size, since SAP B is about five times larger compared to SAP A.

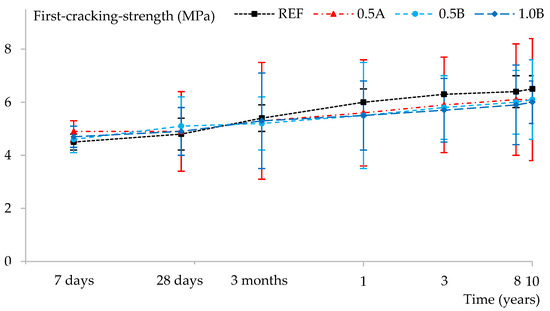

SAPs cause the formation of macropores, influencing the mechanical properties besides the crack initiator property. The first cracking strength, measured as the first drop in the stress/strain curve, is shown in Figure 3 for all mixtures studied.

Figure 3.

The first cracking strength (MPa) of all samples studied, as a function of time, measured as the first drop in the stress–strain curve.

Overall, the first cracking strength increases with time. This is due to further hydration and hardening. The values are typical for a strain-hardening cementitious composite with similar mixture compositions [41,42,43]. A trend can be observed in terms of the influence of SAPs. At an early age, at 7 days and 28 days, the strength of the mixtures containing SAPs is the same or slightly higher than that of the reference specimens. This is mainly due to the internal curing effect of SAPs [44,45], counterbalancing the strength decrease caused by macropore formation. After three months, the strength in the reference samples is higher than that of the SAP samples. In this case, the delayed hardening compared to SAP samples is now taking place. This shows that the macropore formation is again the determining factor, and a decrease in first cracking strength is noticed. The results, however, are not statistically significant, and a large standard deviation was obtained. The older the SAP samples, the larger the influence of the macro porosity on the observed standard deviation. Some macropores are altered due to further hydration, further scattering the obtained strength results. Furthermore, due to the adsorption of moisture during the storage conditions, partial curing may have occurred in the vicinity of the SAP particles.

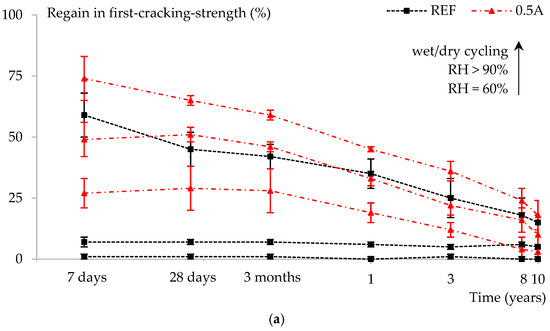

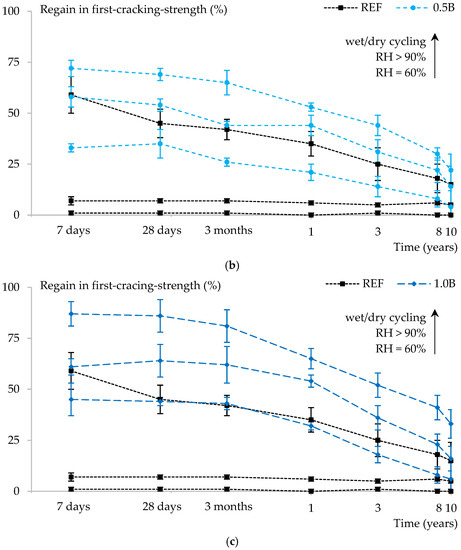

The regain in mechanical properties, measured by dividing the first cracking strength at reloading and the first cracking strength at preloading, is presented in Figure 4 for 0.5 A (a), 0.5 B (b), and 1.0 B (c), respectively, compared to the reference samples. Each subfigure shows the healing (y-axis) of an SAP sample series as compared to the reference after being cracked at a certain age (x-axis) and healing for 28 days at the different curing conditions. These curing conditions are depicted from bottom to top as: RH = 60%, RH > 90%, and wet/dry cycling, providing three datasets per sample series. The more water is available, the more regain in the first cracking strength is observed, hence the logical order of curves from bottom to top.

Figure 4.

The measured regain in first cracking strength after curing in wet/dry cycling; a high relative humidity of more than 90%; and a relative humidity of 60% of: (a) 0.5 m% of SAP A compared to reference samples, (b) 0.5 m% of SAP B compared to reference samples, and (c) 1.0 m% of SAP B compared to the reference samples.

The general trend is that the healing decreases with time. Although the average crack width is smaller (see Figure 1), the building blocks are consumed due to further hydration. Early-age cementitious materials contain more unhydrated binder particles for the formation of C-S-H, continued later on by a combination of further hydration and calcium carbonate precipitation. In these specimens, the pozzolanic activity of fly ash also takes effect. Since this reaction consumes Ca(OH)2, as is also the case in the continuous carbonation of the samples, there may be fewer building blocks, again leading to a lower amount of healing at later ages. However, at later ages, CaCO3 precipitation is the primary healing mechanism for crack closure, and the distinct whitish crystals are clearly found from 3 months of age onwards by visual inspection. Since C-S-H crystals are stronger than CaCO3 precipitation, healing should be more important for younger specimens. Although the cracks may have closed in the older specimens, the weaker CaCO3 crystals result in an observed weaker regain in mechanical properties, i.e., the first cracking strength. The microfibers used also act as a nucleation site for CaCO3 crystal formation [15,46]. The visual healing was dominated by CaCO3 crystallization at later ages. Specimens containing (a higher amount of) SAPs also tend to show more stimulated precipitation of crystals in the crack. However, no information is provided on the crystal formation in the interior of a crack due to the limitations of the microscopic technique. The difference between visual monitoring and calculation of the regain in mechanical properties clearly shows the difference between the definitions of self-sealing and self-healing found in the literature. Sealing refers to the closure of cracks without a regain in mechanical properties, while healing also includes the regain in mechanical properties. This last point must always be verified in addition to the physical sealing and the regain in impermeability related to certain substances.

Considering the results of the reference system in Figure 4, 28 days of healing in wet–dry cycling results in a regain in mechanical properties of about 60% at 7 days of age. This decreases to approximately 45% at 28 days of age and is still 15% at 10 years of age. The inclusion of 0.5 m% SAP A increases these values to 75%, 65%, and 20%, respectively. This is a notable increase, which is even better when 0.5 m% or 1 m% SAP B is added, with a maximum of 85%, 80%, and 30%, respectively. This shows the positive influence of SAPs in terms of promoting autogenous healing.

When storing reference samples at a high relative humidity, no significant healing is observed. When considering SAP samples, this healing is still in the range of 10–50%. The adsorption of moisture from the environment is sufficient to promote partial healing in the vicinity of the SAP particles. Moisture is adsorbed (up to a couple of times the weight of dry SAP [47]) and released for the formation of healing products. Even under standard relative humidity conditions, healing leads to a regain in mechanical properties, albeit to a lesser extent.

4. Conclusions

Small crack widths after 10 years can still be partially healed. The main visual healing product is calcium carbonate. Further hydration was less likely, because most of the binder already hardened during storage conditions. A partial regain in mechanical properties is seen in the reference samples.

In general, the samples containing SAPs show greater healing compared to the reference samples and are still capable of swelling after a decade of storage in an alkaline cementitious environment. This makes them a sustainable option for the future, as less maintenance and repair will be required. It is worth mentioning that the SAP particles were not exposed to UV light, because they were stored inside in the cementitious material. These dark conditions are very beneficial in preventing SAP degradation.

A comparison of the different sample series showed that the healing conditions for 0.5 A and 0.5 B were similar in terms of self-healing ability and regain in mechanical properties for all ages studied. However, more SAP B (0.5 B towards 1.0 B) could be added to the mixture, as less initial mixing water is required as compared to the same amount of SAP A without compromising the initial mechanical properties. This leads to a better overall healing performance, as the healing is further promoted due a larger quantity of SAPs being present in the cementitious matrix, both at an early age, as well as after a decade of maturing.

Since healing is still possible after a decade, the service life of a structure can be extended. However, more data is needed to conclude whether healing with SAPs is still feasible after 10 years of maturing.

Funding

This research received no external funding.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Acknowledgments

The author wants to thank the companies for providing the materials.

Conflicts of Interest

The author declares no conflict of interest.

References

- Tsuji, M.; Shitama, K.; Isobe, D. Basic studies on simplified curing technique, and prevention of initial cracking and leakage of water through cracks of concrete by applying superabsorbent polymers as new concrete admixture. J. Soc. Mater. Sci. 1999, 48, 1308–1315. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials I. Principles and theoretical background. Cem. Concr. Res. 2001, 31, 647–654. [Google Scholar] [CrossRef]

- Hasholt, M.T.; Jensen, O.M.; Kovler, K.; Zhutovsky, S. Can superabsorbent polymers mitigate autogenous shrinkage of internally cured concrete without compromising the strength? Constr. Build. Mater. 2012, 31, 226–230. [Google Scholar] [CrossRef]

- Schröfl, C.; Mechtcherine, V.; Gorges, M. Relation between the molecular structure and the efficiency of superabsorbent polymers (SAP) as concrete admixture to mitigate autogenous shrinkage. Cem. Concr. Res. 2012, 42, 865–873. [Google Scholar] [CrossRef]

- Lee, H.X.D.; Wong, H.S.; Buenfeld, N.R. Potential of superabsorbent polymer for self-sealing cracks in concrete. Adv. Appl. Ceram. 2010, 109, 5. [Google Scholar] [CrossRef]

- Snoeck, D.; Steuperaert, S.; Van Tittelboom, K.; Dubruel, P.; De Belie, N. Visualization of water penetration in cementitious materials with superabsorbent polymers by means of neutron radiography. Cem. Concr. Res. 2012, 42, 1113–1121. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Wyrzykowski, M.; Schröfl, C.; Snoeck, D.; Lura, P.; De Belie, N.; Mignon, A.; Van Vlierberghe, S.; Klemm, A.J.; Almeida, F.C.R.; et al. Application of super absorbent polymers (SAP) in concrete construction-update of RILEM state-of-the-art report. Mater. Struct. 2021, 54, 80. [Google Scholar] [CrossRef]

- Schröfl, C.; Erk, K.A.; Siriwatwechakul, W.; Wyrzykowski, M.; Snoeck, D. Recent progress in superabsorbent polymers for concrete. Cem. Concr. Res. 2022, 151, 106648. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Secrieru, E.; Schröfl, C. Effect of superabsorbent polymers (SAPs) on rheological properties of fresh cement-based mortars—Development of yield stress and plastic viscosity over time. Cem. Concr. Res. 2015, 67, 52–65. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Schröfl, C.; Wyrzykowski, M.; Gorges, M.; Cusson, D.; Margeson, J.; De Belie, N.; Snoeck, D.; Ichimiya, K.; Igarashi, S.-I.; et al. Effect of superabsorbent polymers (SAP) on the freeze-thaw resistance of concrete: Results of a RILEM interlaboratory test. Mater. Struct. 2017, 50, 14. [Google Scholar] [CrossRef]

- Mönnig, S.; Lura, P. Superabsorbent polymers—An additive to increase the freeze-thaw resistance of high strength concrete. In Advances in Construction Materials; Grosse, C.U., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 351–358. [Google Scholar]

- Kim, J.S.; Schlangen, E. Super Absorbent Polymers to Simulate Self Healing in ECC; van Breugel, K., Ye, G., Yuan, Y., Eds.; RILEM Publications SARL: Delft, The Netherlands, 2010; pp. 849–858. [Google Scholar]

- Snoeck, D.; Van Tittelboom, K.; De Belie, N.; Steuperaert, S.; Dubruel, P. The Use of Superabsorbent Polymers as a Crack Sealing and Crack Healing Mechanism in Cementitious Materials; Alexander, M.G., Beushausen, H.-D., Dehn, F., Moyo, P., Eds.; Taylor & Francis Group: London, UK; CRC Press: Cape Town, South Africa, 2012; pp. 152–157. [Google Scholar]

- Snoeck, D. Superabsorbent polymers to seal and heal cracks in cementitious materials. RILEM Tech. Lett. 2018, 3, 32–38. [Google Scholar] [CrossRef]

- Snoeck, D.; Van Tittelboom, K.; Steuperaert, S.; Dubruel, P.; De Belie, N. Self-healing cementitious materials by the combination of microfibres and superabsorbent polymers. J. Intell. Mater. Syst. Struct. 2014, 25, 13–24. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. Repeated autogenous healing in strain-hardening cementitious composites by using superabsorbent polymers. J. Mater. Civ. Eng. 2015, 28, 04015086-1. [Google Scholar] [CrossRef]

- Snoeck, D.; Pel, L.; De Belie, N. Autogenous Healing in Cementitious Materials with Superabsorbent Polymers Quantified by Means of NMR. Sci. Rep. 2020, 10, 642. [Google Scholar] [CrossRef] [PubMed]

- Snoeck, D.; Dewanckele, J.; Cnudde, V.; De Belie, N. X-ray computed microtomography to study autogenous healing of cementitious materials promoted by superabsorbent polymers. Cem. Concr. Compos. 2016, 65, 83–93. [Google Scholar] [CrossRef]

- Jacobsen, S.; Sellevold, E.J. Self-healing of high-strength concrete after deterioration by freeze/thaw. Cem. Concr. Res. 1996, 26, 55–62. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J. The effects of age, cement content, and healing time on the self-healing ability of high-strength concrete. Constr. Build. Mater. 2018, 187, 149–159. [Google Scholar] [CrossRef]

- Zhong, W.; Yao, W. Influence of damage degree on self-healing of concrete. Constr. Build. Mater. 2008, 22, 1137–1142. [Google Scholar] [CrossRef]

- Hilloulin, B.; Hilloulin, D.; Grondin, F.; Loukili, A.; De Belie, N. Mechanical regains due to self-healing in cementitious materials: Experimental measurements and micro-mechanical model. Cem. Concr. Res. 2016, 80, 21–32. [Google Scholar] [CrossRef]

- Hung, C.-C.; Su, Y.-F. Medium-term self-healing evaluation of Engineered Cementitious Composites with varying amounts of fly ash and exposure durations. Constr. Build. Mater. 2016, 118, 194–203. [Google Scholar] [CrossRef]

- Hannant, D.J.; Keer, J.G. Autogenous healing of thin cement-based sheets. Cem. Concr. Res. 1983, 13, 357–365. [Google Scholar] [CrossRef]

- Abrams, D.A. Test of a 40 ft Reinforced Concrete Highway Bridge; American Society for Testing Materials: Philadelphia, PA, USA, 1913; Volume 13. [Google Scholar]

- Hearn, N. Self-sealing, autogenous healing and continued hydration: What is the difference? Mater. Struct. 1998, 31, 563–567. [Google Scholar] [CrossRef]

- Cuenca, E.; Tejedor, A.; Ferrara, L. A methodology to assess crack-sealing effectiveness of crystalline admixtures under repeated cracking-healing cycles. Constr. Build. Mater. 2018, 179, 619–632. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Wang, Y.; Liu, Y.; Hong, S.; Zhang, J.; Lin, S.; Xing, F. Performance recovery concerning the permeability of concrete by means of a microcapsule based self-healing system. Cem. Concr. Compos. 2017, 78, 84–96. [Google Scholar] [CrossRef]

- Qian, C.; Chen, H.; Ren, L.; Luo, M. Self-healing of early age cracks in cement-based materials by mineralization of carbonic anhydrase microorganism. Front. Microbiol. 2015, 6, 1225. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zheng, Q.; Ashour, A.; Han, B. Self-healing cement concrete composites for resilient infrastructures: A review. Compos. Part B Eng. 2020, 189, 107892. [Google Scholar] [CrossRef]

- Zheng, T.; Su, Y.; Zhang, X.; Zhou, H.; Qian, C. Effect and Mechanism of Encapsulation-Based Spores on Self-Healing Concrete at Different Curing Ages. ACS Appl. Mater. Interfaces 2020, 12, 52415–52432. [Google Scholar] [CrossRef] [PubMed]

- Skevi, L.; Reeksting, B.; Gebhard, S.; Paine, K. Bacteria Based Self-healing of Later-Age Cracks in Concrete. In International RILEM Conference on Early-age and Long-term Cracking in RC Structures; Springer: Cham, Switzerland, 2021; Volume 31, pp. 367–376. [Google Scholar]

- Snoeck, D.; De Belie, N. From straw in bricks to modern use of microfibres in cementitious composites for improved autogenous healing—A review. Constr. Build. Mater. 2015, 95, 774–787. [Google Scholar] [CrossRef]

- Yang, E.-H. Designing added functions in Engineered Cementitious Composites. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2008. [Google Scholar]

- Ferrara, L.; Krelani, V.; Moretti, F.; Roig-Flores, M.; Serna Ros, P. Effects of autogenous healing on the recovery of mechanical performance of High Performance Fibre Reinforced Cementitious Composites (HPFRCCs): Part 1. Cem. Concr. Compos. 2017, 83, 76–100. [Google Scholar] [CrossRef]

- Yıldırım, G.; Khiavi, A.H.; Yeşilmen, S.; Şahmaran, M. Self-healing performance of aged cementitious composites. Cem. Concr. Compos. 2018, 87, 172–186. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. Autogenous healing in strain-hardening cementitious materials with and without superabsorbent polymers: An 8-year study. Front. Mater. 2019, 6, 48. [Google Scholar] [CrossRef]

- Snoeck, D.; Pel, L.; De Belie, N. The water kinetics of superabsorbent polymers during cement hydration and internal curing visualized and studied by NMR. Sci. Rep. 2017, 7, 9514. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Zhu, Y.; Yang, Y. Incorporation of SAP particles as controlling pre-existing flaws to improve the performance of ECC. Constr. Build. Mater. 2011, 28, 139–145. [Google Scholar] [CrossRef]

- Kan, L.; Shi, H. Investigation of self-healing behavior of Engineered Cementitious Composites (ECC) materials. Constr. Build. Mater. 2012, 29, 348–356. [Google Scholar] [CrossRef]

- Yang, E.-H.; Yang, Y.; Li, V.C. Use of High Volumes of Fly Ash to Improve ECC Mechanical Properties and Material Greenness. ACI Mater. J. 2007, 104, 303–311. [Google Scholar]

- Yang, Y.; Lepech, M.D.; Yang, E.-H.; Li, V.C. Autogenous Healing of Engineered Cementitious Composites under Wet-dry Cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composites (PVA-ECC). ACI Mater. J. 1997, 98, 483–492. [Google Scholar]

- Snoeck, D.; Goethals, W.; Hovind, J.; Trtik, P.; Van Mullem, T.; Van den Heede, P.; De Belie, N. Internal curing of cement pastes by means of superabsorbent polymers visualized by neutron tomography. Cem. Concr. Res. 2021, 147, 106528. [Google Scholar] [CrossRef]

- Zhong, P.; Hu, Z.; Griffa, M.; Wyrzykowski, M.; Liu, J.; Lura, P. Mechanisms of internal curing water release from retentive and non-retentive superabsorbent polymers in cement paste. Cem. Concr. Res. 2021, 147, 106494. [Google Scholar] [CrossRef]

- Homma, D.; Mihashi, H.; Nishiwaki, T. Self-Healing Capability of Fibre Reinforced Cementitious Composites. Adv. Concr. Technol. 2009, 7, 217–228. [Google Scholar] [CrossRef]

- Snoeck, D.; Velasco, L.F.; Mignon, A.; Van Vlierberghe, S.; Dubruel, P.; Lodewyckx, P.; De Belie, N. The effects of superabsorbent polymers on the microstructure of cementitious materials studied by means of sorption experiments. Cem. Concr. Res. 2015, 77, 26–35. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).