Cement-Bonded Particleboards with Banana Pseudostem Waste: Physical Performance and Bio-Susceptibility

Abstract

:1. Introduction

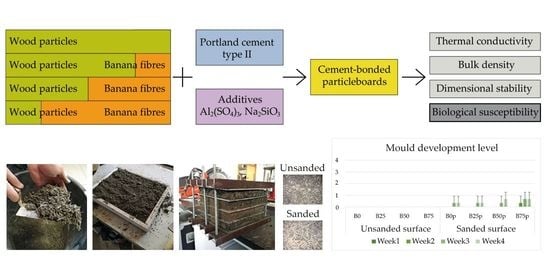

2. Materials and Methods

2.1. Materials

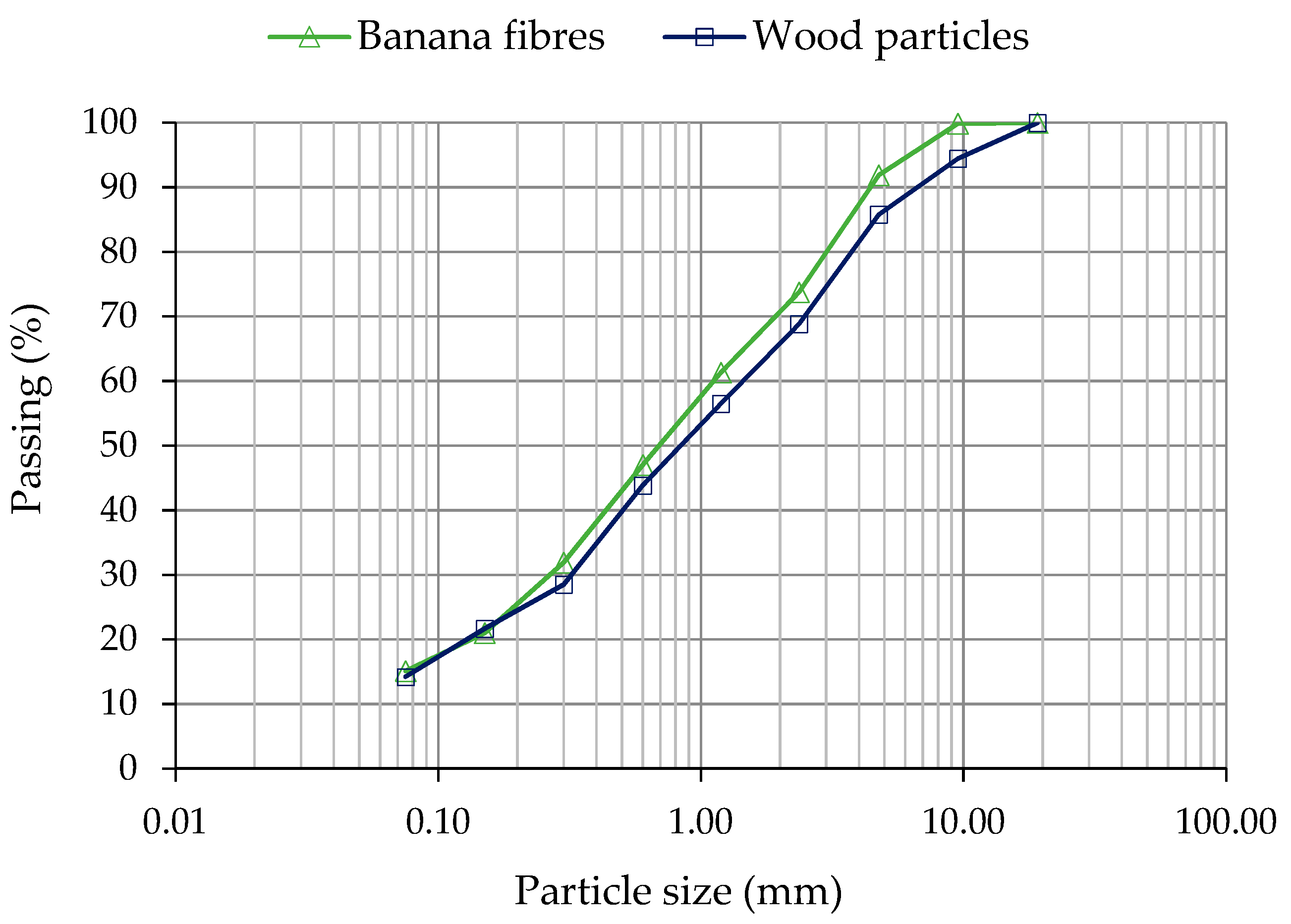

2.1.1. Banana Pseudostem Waste

2.1.2. Maritime Pine Particles

2.1.3. Binder and Additives

2.1.4. Board Manufacturing

2.2. Methods

3. Results and Discussion

3.1. Thermal Conductivity

3.2. Bulk Density

3.3. Dimensional Stability

3.4. Biological Susceptibility to Moulds

4. Conclusions

- The thermal conductivity of the CBPB increased with the replacement of wood by banana fibres and ranged between 0.233 W/(m.K) and 0.279 W/(m.K).

- The bulk density values, ranging between 1754–1995 kg/m3, were generally higher than those reported in the literature for other particleboards. Moreover, the bulk density generally increased with the proportion of banana fibre, being the highest value obtained for CBPB with an equal proportion of wood particles and banana fibres.

- Specimens with a higher percentage of banana fibres presented less thickness swelling and higher dimensional stability.

- Although cement-bonded particleboards with unsanded surfaces showed no signs of biological growth, the boards with sanded surfaces simulating some surface wear over time had increased bio-susceptibility. Under the conditions of the test performed, the biological susceptibility to the moulds A. niger and P. funicullosum of the boards slightly increased with the percentage of banana fibres.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, L.; Wang, L.; Tsang, D.C.W.; Mechtcherine, V.; Poon, C.S. Efficacy of green alternatives and carbon dioxide curing in reactive magnesia cement-bonded particleboards. J. Clean. Prod. 2020, 258, 120997. [Google Scholar] [CrossRef]

- He, P.; Hossain, M.U.; Poon, C.S.; Tsang, D.C.W. Mechanical, durability and environmental aspects of magnesium oxychloride cement boards incorporating waste wood. J. Clean. Prod. 2019, 207, 391–399. [Google Scholar] [CrossRef]

- Ferrandez-Villena, M.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Garcia, M.T. Properties of cement-bonded particleboards made from Canary Islands palm (Phoenix canariensis Ch.) trunks and different amounts of potato starch. Forests 2020, 11, 560. [Google Scholar] [CrossRef]

- Rana, M.N.; Islam, M.N.; Nath, S.K.; Das, A.K.; Ashaduzzaman, M.; Shams, M.I. Influence of chemical additive on the physical and mechanical properties of cement-bonded composite panels made from jute stick. J. Build. Eng. 2020, 31, 101358. [Google Scholar] [CrossRef]

- Farag, E.; Alshebani, M.; Elhrari, W.; Klash, A.; Shebani, A. Production of particleboard using olive stone waste for interior design. J. Build. Eng. 2020, 29, 101119. [Google Scholar] [CrossRef]

- Adelusi, E.A.; Olaoye, K.O.; Adebawo, F.G. Strength and dimensional stability of cement-bonded boards manufactured from mixture of Ceiba pentandra and Gmelina arborea sawdust. J. Eng. Res. Rep. 2019, 8, 1–10. [Google Scholar] [CrossRef]

- Dadile, A.M.; Sotannde, O.A.; Alao, J.S. Physico-mechanical properties of cement-bonded particleboards made from date palm fibres (Phoenix dactylifera) and obeche sawdust (Triplochyton schleroxylon). J. Mater. Sci. Res. Rev. 2019, 4, 1–5. [Google Scholar]

- Hossain, M.U.; Wang, L.; Yu, I.K.M.; Tsang, D.C.W.; Poon, C.S. Environmental and technical feasibility study of upcycling wood waste into cement-bonded particleboard. Constr. Build. Mater. 2018, 173, 474–480. [Google Scholar] [CrossRef]

- Atoyebi, O.D.; Awolusi, T.F.; Davies, I.E.E. Artificial neural network evaluation of cement-bonded particle board produced from red iron wood (Lophira alata) sawdust and palm kernel shell residues. Case Stud. Constr. Mater. 2018, 9, e00185. [Google Scholar] [CrossRef]

- Sousa, J.P. Cement Bonded Particle Board VIROC. Technical File. Available online: https://www.investwood.pt/wp-content/uploads/2020/10/VIROC_DTA_2020.1_EN.pdf (accessed on 29 July 2020).

- Okino, E.Y.A.; de Sousa, M.R.; Santana, M.A.E.; da Alves, M.V.S.; de Sousa, M.E.; Teixeira, D.E. Cement-bonded wood particleboard with a mixture of eucalypt and rubberwood. Cem. Concr. Compos. 2004, 26, 729–734. [Google Scholar] [CrossRef]

- Okino, E.Y.A.; de Sousa, M.R.; Santana, M.A.E.; da Alves, M.V.S.; de Sousa, M.E.; Teixeira, D.E. Physico-mechanical properties and decay resistance of Cupressus spp. cement-bonded particleboards. Cem. Concr. Compos. 2005, 27, 333–338. [Google Scholar] [CrossRef]

- Quiroga, A.; Rintoul, I. Mechanical properties of hierarchically structured wood-cement composites. Constr. Build. Mater. 2015, 84, 253–260. [Google Scholar] [CrossRef]

- Wang, L.; Chen, S.S.; Tsang, D.C.W.; Poon, C.-S.; Shih, K. Recycling contaminated wood into eco-friendly particleboard using green cement and carbon dioxide curing. J. Clean. Prod. 2016, 137, 861–870. [Google Scholar] [CrossRef]

- Soroushian, P.; Aouadi, F.; Chowdhury, H.; Nossoni, A.; Sarwar, G. Cement-bonded straw board subjected to accelerated processing. Cem. Concr. Compos. 2004, 26, 797–802. [Google Scholar] [CrossRef]

- Jorge, F.C.; Pereira, C.; Ferreira, J.M.F. Wood-cement composites: A review. Eur. J. Wood Wood Prod. 2004, 62, 370–377. [Google Scholar] [CrossRef]

- Gaspar, F.; Bakatovich, A.; Davydenko, N.; Joshi, A. Building insulation materials based on agricultural wastes. In Bio-Based Materials and Biotechnologies for Eco-Efficient Construction; Elsevier: Amsterdam, The Netherlands, 2020; pp. 149–170. [Google Scholar] [CrossRef]

- Liuzzi, S.; Sanarica, S.; Stefanizzi, P. Use of agro-wastes in building materials in the Mediterranean area: A review. Energy Procedia 2017, 126, 242–249. [Google Scholar] [CrossRef]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Maraveas, C. Production of sustainable construction materials using agro-wastes. Materials 2020, 13, 262. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Viel, M.; Collet, F.; Lanos, C. Chemical and multi-physical characterization of agro-resources’ by-product as a possible raw building material. Ind. Crop. Prod. 2018, 120, 214–237. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Dai, C. Development of banana fibers and wood bottom ash modified cement mortars. Constr. Build. Mater. 2020, 241, 118041. [Google Scholar] [CrossRef]

- Borysiuk, P.; Jenczyk-Tolloczko, I.; Auriga, R.; Kordzikowski, M. Sugar beet pulp as raw material for particleboard production. Ind. Crop. Prod. 2019, 141, 111829. [Google Scholar] [CrossRef]

- Rocha Almeida, R.; Del Menezzi, C.H.S.; Teixeira, D.E. Utilization of the coconut shell of babaçu (Ornignya sp.) to produce cement-bonded particleboard. Bioresour. Technol. 2002, 85, 159–163. [Google Scholar] [CrossRef]

- Cabral, M.R.; Nakanishi, E.Y.; Mármol, G.; Palacios, J.; Godbout, S.; Lagacé, R.; Junior, H.S.; Fiorelli, J. Potential of Jerusalem Artichoke (Helianthus tuberosus L.) stalks to produce cement-bonded particleboards. Ind. Crop. Prod. 2018, 122, 214–222. [Google Scholar] [CrossRef]

- Cavdar, A.D.; Yel, H.; Boran, S.; Pesman, E. Cement type composite panels manufactured using paper mill sludge as filler. Constr. Build. Mater. 2017, 142, 410–416. [Google Scholar] [CrossRef]

- Nazerian, M.; Sadeghiipanah, V. Cement-bonded particleboard with a mixture of wheat straw and poplar wood. J. For. Res. 2013, 24, 381–390. [Google Scholar] [CrossRef]

- Omoniyi, T.E.; Olorunnisola, A.O. Effects of manufacturing techniques on the physico-mechanical properties of cement-bonded bagasse fiber composite. J. Nat. Fibers 2020, 1–12. [Google Scholar] [CrossRef]

- Ogunsile, B.O.; Adepegba, J.A. Cement bonded particle board from Musa paradisiaca stalk. Pac. J. Sci. Technol. 2015, 16, 12–20. [Google Scholar]

- Nadhari, W.N.A.W.; Danish, M.; Nasir, M.S.R.M.N.; Geng, B.J. Mechanical properties and dimensional stability of particleboard fabricated from steam pre-treated banana trunk waste particles. J. Build Eng. 2019, 26, 100848. [Google Scholar] [CrossRef]

- Israeli, Y.; Lahav, E. Banana. Encycl. Appl. Plant Sci. 2017, pp. 363–381. [CrossRef]

- FAO. Medium-Term Outlook: Prospects for Global Production and Trade in Bananas and Tropical Fruits; FAO: Rome, Italy, 2020; Available online: http://www.fao.org/3/ca7568en/ca7568en.pdf (accessed on 5 August 2020).

- FAO (Food and Agriculture Organization of the United Nation). Banana Market Review: Preliminary Results 2019; FAO: Rome, Italy, 2020; Available online: http://www.fao.org/3/ca9212en/ca9212en.pdf (accessed on 5 August 2020).

- Cordeiro, N.; Belgacem, M.N.; Torres, I.C.; Moura, J.C.V.P. Chemical composition and pulping of banana pseudo-stems. Ind. Crop. Prod. 2004, 19, 147–154. [Google Scholar] [CrossRef]

- Sing Nee Nigam, P.; Pandey, A. Biotechnology for Agro-Industrial Residues Utilization. 2009. Available online: http://link.springer.com/10.1007/978-1-4020-9942-7 (accessed on 5 August 2020).

- Fernandes, B.; Silva, V.; Faria, P. Cement-wood boards with banana tree waste for buildings rehabilitation. In Proceedings ENCORE2020—4º Encontro de Conservação e Reabilitação de Edifícios, 3–6 Novembro 2020; Menezes, M., Veiga, M.R., Silva, A.S., Nunes, L., Machado, J.S., Eds.; LNEC: Lisboa, Portugal, 2020; pp. 663–672. (In Portuguese) [Google Scholar]

- EN 1097-3. Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids; CEN: Brussels, Belgium, 1998. [Google Scholar]

- Wang, L.; Chen, S.S.; Tsang, D.C.W.; Poon, C.S.; Shih, K. Value-added recycling of construction waste wood into noise and thermal insulating cement-bonded particleboards. Constr. Build. Mater. 2016, 125, 316–325. [Google Scholar] [CrossRef]

- Wong, M.C.; Hendrikse, S.I.S.; Sherrell, P.C.; Ellis, A.V. Grapevine waste in sustainable hybrid particleboard production. Waste Manag. 2020, 118, 501–509. [Google Scholar] [CrossRef] [PubMed]

- Nemli, G.; Demirel, S. Relationship Between the Density Profile and the Technological Properties of the Particleboard Composite. J. Compos. Mater. 2007, 41, 1793–1802. [Google Scholar] [CrossRef]

- EN 323. Wood-based panels. In Determination of Density; CEN: Brussels, Belgium, 1993. [Google Scholar]

- EN 12664. Thermal performance of building materials and products. Determination of thermal resistance by means of guarded hot plate and heat flow meter methods. In Dry and Moist Products of Medium and Low Thermal Resistance; CEN: Brussels, Belgium, 2001. [Google Scholar]

- EN 317. Particleboards and fibreboards. In Determination of Swelling in Thickness after Immersion in Water; CEN: Brussels, Belgium, 1993. [Google Scholar]

- ASTM D5590-17. Determining the Resistance of Paint Films and Related Coatings to Fungal Defacement by Accelerated Four-Week Agar Plate Assay; ASTM International: Pennsylvania, PA, USA, 2017. [Google Scholar]

- ASTM C1338-19. Standard Test Method for Determining Fungi Resistance of Insulation Materials and Facings; ASTM International: Pennsylvania, PA, USA, 2019. [Google Scholar]

- Parracha, J.L.; Borsoi, G.; Flores-Colen, I.; Veiga, R.; Nunes, L.; Dionísio, A.; Gomes, M.G.; Faria, P. Performance parameters of ETICS: Correlating water resistance, bio-susceptibility and surface properties. Constr. Build. Mater. 2021, 272, 121956. [Google Scholar] [CrossRef]

- Davies, I.O.E.; Davies, O.O.A. Agro-waste-cement particleboards: A review. MAYFEB J. Environ. Sci. 2017, 2, 10–26. [Google Scholar]

- Park, J.H.; Kang, Y.; Lee, J.; Chang, S.J.; Wi, S.; Kim, S. Development of wood-lime boards as building materials improving thermal and moisture performance based on hygrothermal behavior evaluation. Constr. Build. Mater. 2019, 204, 576–585. [Google Scholar] [CrossRef]

- Wang, C.G.; Zhang, S.G.; Wu, H. Performance of Cement Bonded Particleboards Made from Grapevine. Adv. Mater. Res. 2013, 631–632, 765–770. [Google Scholar] [CrossRef]

- LNEC. Maritime pine for structures. In Madeira para Construção nº M2, 2nd ed.; LNEC: Lisboa, Portugal, 2014; p. 12. (In Portuguese) [Google Scholar]

- Idicula, M.; Boudenne, A.; Umadevi, L.; Ibos, L.; Candau, Y.; Thomas, S. Thermophysical properties of natural fibre reinforced polyester composite. Compos. Sci. Technol. 2006, 66, 2719–2725. [Google Scholar] [CrossRef]

- Macêdo, A.N.; Costa e Souza, A.A.; Neto, B.B.P. Cement-wood particleboards made with waste from the Amazon timber industry. Ambiente Construído 2012, 12, 131–150. (In Portuguese) [Google Scholar] [CrossRef]

- Chikhi, M.; Agoudjil, B.; Boudenne, A.; Gherabli, A. Experimental investigation of new biocomposite with low cost for thermal insulation. Energy Build 2013, 66, 267–273. [Google Scholar] [CrossRef]

- Collet, F.; Pretot, S. Thermal conductivity of hemp concretes: Variation with formulation, density and water content. Constr. Build. Mater 2014, 65, 612–619. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, D.M.; Grillet, A.-C.; Diep, T.M.H.; Bui, Q.B.; Woloszyn, M. Influence of thermo-pressing conditions on insulation materials from bamboo fibers and proteins based bone glue. Ind. Crop. Prod. 2018, 111, 834–845. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Thermoplastics reinforced with wood fillers: A literature review. Polym. Plast. Technol. Eng. 1998, 37, 451–468. [Google Scholar] [CrossRef]

| Samples | Banana Fibres [%] | Wood Particles [%] |

|---|---|---|

| B0 | 0 | 100 |

| B25 | 25 | 75 |

| B50 | 50 | 50 |

| B75 | 75 | 25 |

| Properties | Specimens | Area of the Specimen [mm2] | Standards | |

|---|---|---|---|---|

| Physical properties | Thermal conductivity | 3 specimens (1 measurements per specimen) × 4 compositions (B0, B25, B50, B75) | 50 × 50 | EN 12664 (2001) [42] |

| Bulk density | 4 specimens × 4 compositions | 50 × 50 | EN 323 (1993) [41] | |

| Dimensional stability (water immersion) | 4 specimens × 4 compositions | 50 × 50 | EN 317 (1993) [43] | |

| Biological susceptibility to moulds | 3 specimens × 4 compositions × 2 conditions (sanded (p); unsanded (u)) | 45 × 45 | ASTM D5590-17 (2017) [44] and ASTM C1338-19 (2019) [45] | |

| Rating | Description | Contaminated Surface [%] |

|---|---|---|

| 0 | None | 0 |

| 1 | Traces of growth | <10 |

| 2 | Light growth | 10 to 30 |

| 3 | Moderate growth | 30 to 60 |

| 4 | Heavy growth | >60 |

| Specimens | Mould Development | ||||

|---|---|---|---|---|---|

| Week 1 | Week 2 | Week 3 | Week 4 | ||

| Unsanded surface | B0u | 0 | 0 | 0 | 0 |

| B25u | 0 | 0 | 0 | 0 | |

| B50u | 0 | 0 | 0 | 0 | |

| B75u | 0 | 0 | 0 | 0 | |

| Sanded surface | B0p | 0 | 0 | 0.33 ± 0.58 | 0.33 ± 0.58 |

| B25p | 0 | 0 | 0.33 ± 0.58 | 0.33 ± 0.58 | |

| B50p | 0 | 0 | 0.33 ± 0.58 | 0.67 ± 0.58 | |

| B75p | 0 | 0.33 ± 0.58 | 0.67 ± 0.58 | 0.67 ± 0.58 | |

| Viability control (maritime pine) | C (pw) | 3.33 ± 0.58 | 4 | 4 | 4 |

| Scale: 0—no growth; 1—traces of growth; 2—light growth; 3—moderate growth; 4—heavy growth. | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nunes, L.; Cintura, E.; Parracha, J.L.; Fernandes, B.; Silva, V.; Faria, P. Cement-Bonded Particleboards with Banana Pseudostem Waste: Physical Performance and Bio-Susceptibility. Infrastructures 2021, 6, 86. https://doi.org/10.3390/infrastructures6060086

Nunes L, Cintura E, Parracha JL, Fernandes B, Silva V, Faria P. Cement-Bonded Particleboards with Banana Pseudostem Waste: Physical Performance and Bio-Susceptibility. Infrastructures. 2021; 6(6):86. https://doi.org/10.3390/infrastructures6060086

Chicago/Turabian StyleNunes, Lina, Eleonora Cintura, João L. Parracha, Bruno Fernandes, Vitor Silva, and Paulina Faria. 2021. "Cement-Bonded Particleboards with Banana Pseudostem Waste: Physical Performance and Bio-Susceptibility" Infrastructures 6, no. 6: 86. https://doi.org/10.3390/infrastructures6060086

APA StyleNunes, L., Cintura, E., Parracha, J. L., Fernandes, B., Silva, V., & Faria, P. (2021). Cement-Bonded Particleboards with Banana Pseudostem Waste: Physical Performance and Bio-Susceptibility. Infrastructures, 6(6), 86. https://doi.org/10.3390/infrastructures6060086