Properties of Blast-Furnace Slag Cement Concrete Subjected to Accelerated Curing †

Abstract

:1. Introduction

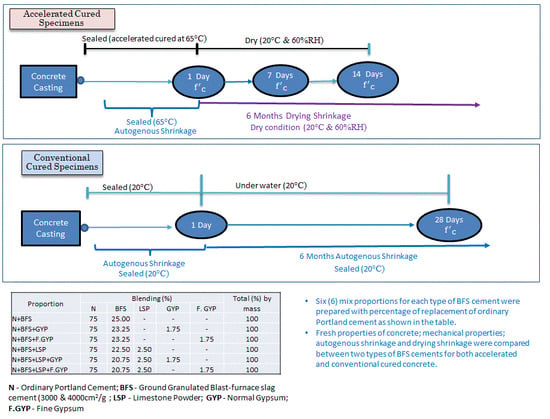

2. Materials and Test Methods

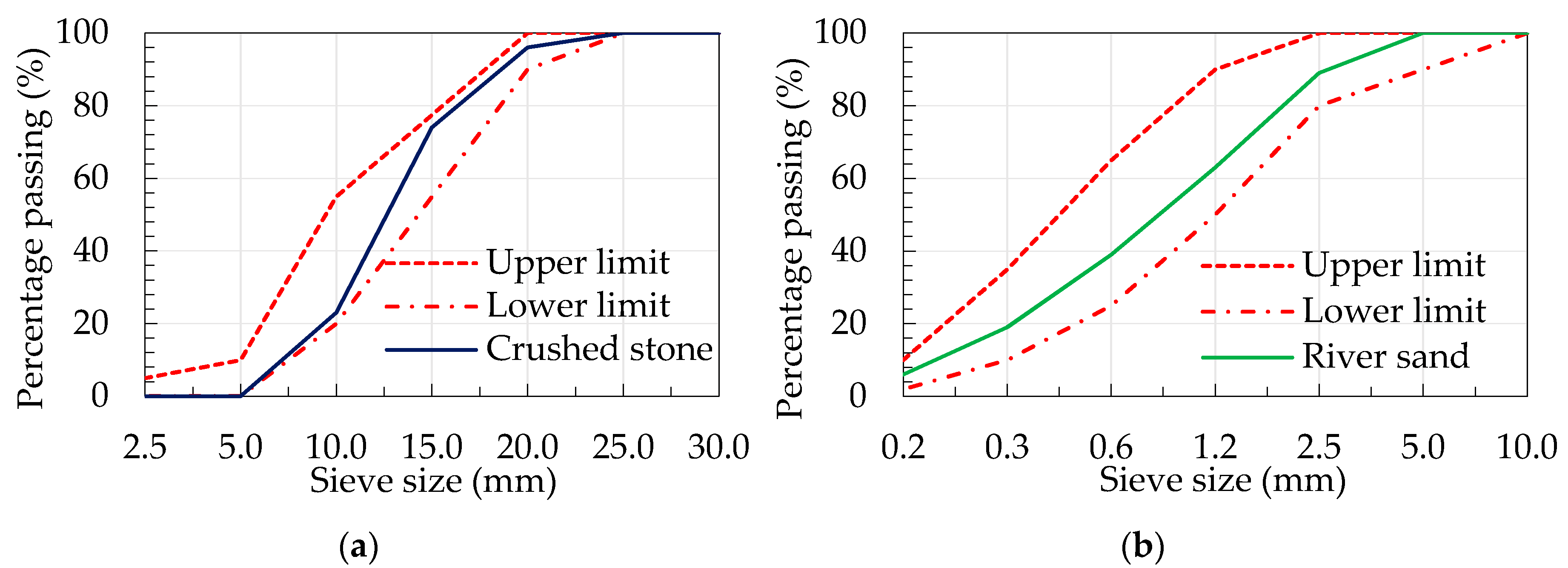

2.1. Concrete Materials

2.2. Mix Proportions of Concrete

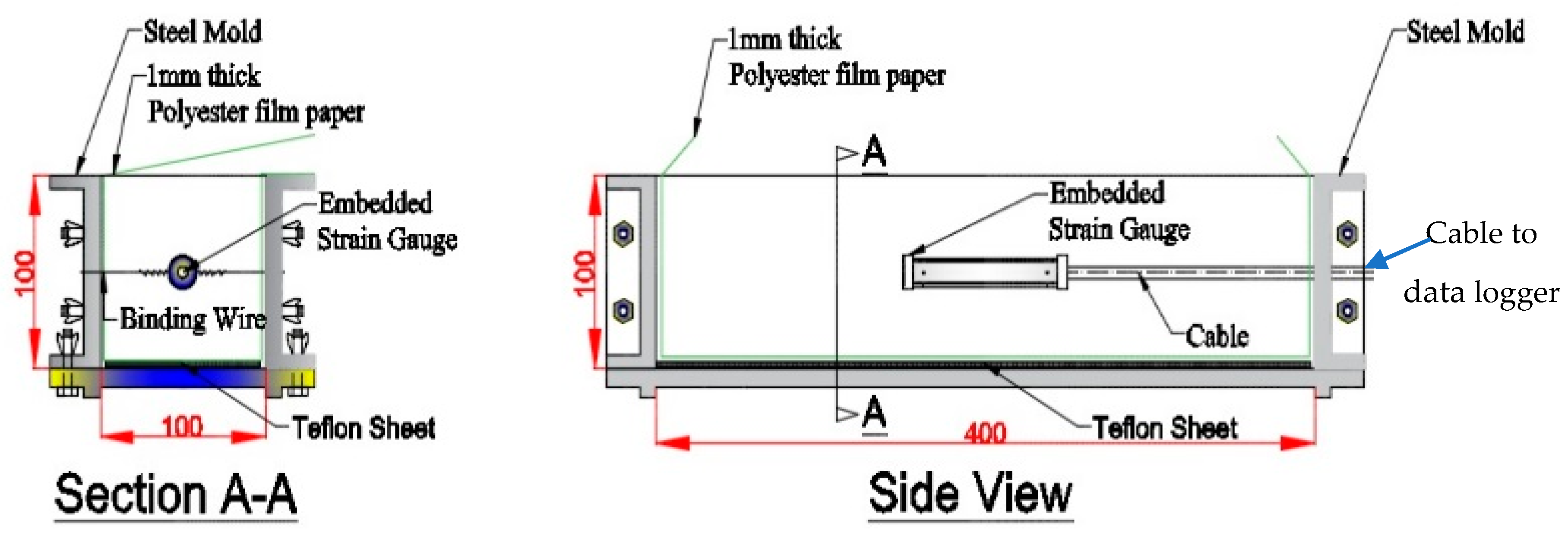

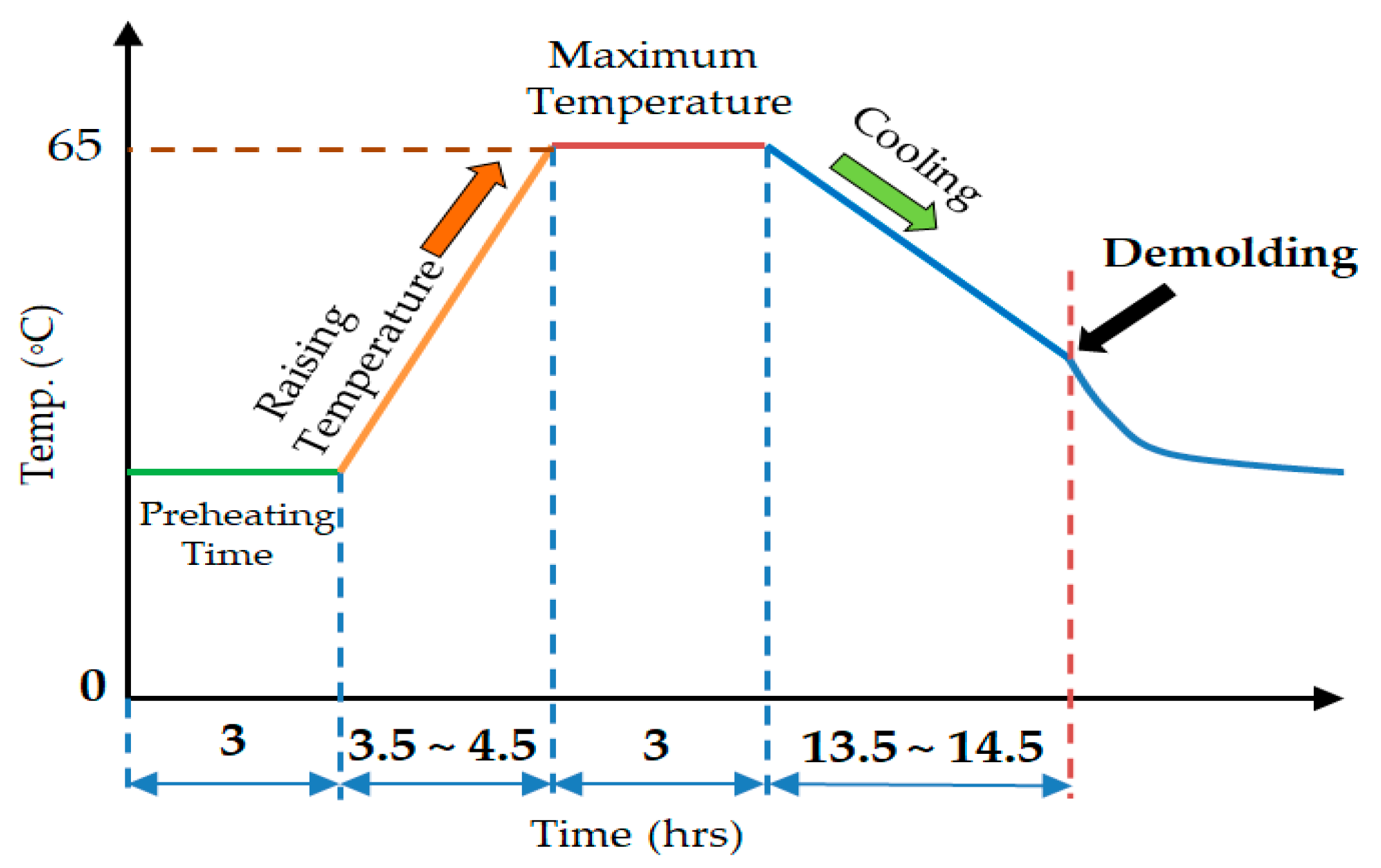

2.3. Test Methods

3. Results

3.1. Fresh Properties

3.2. Setting Time

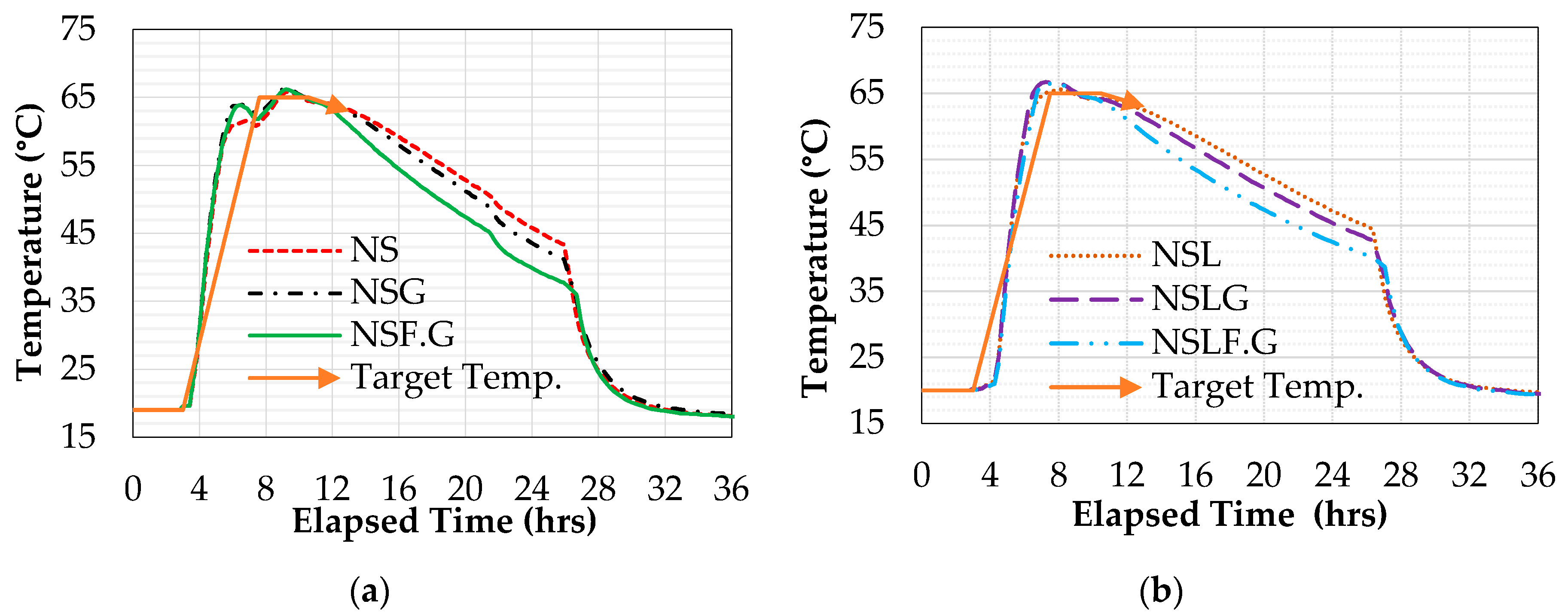

3.3. Accelerated Temperature History

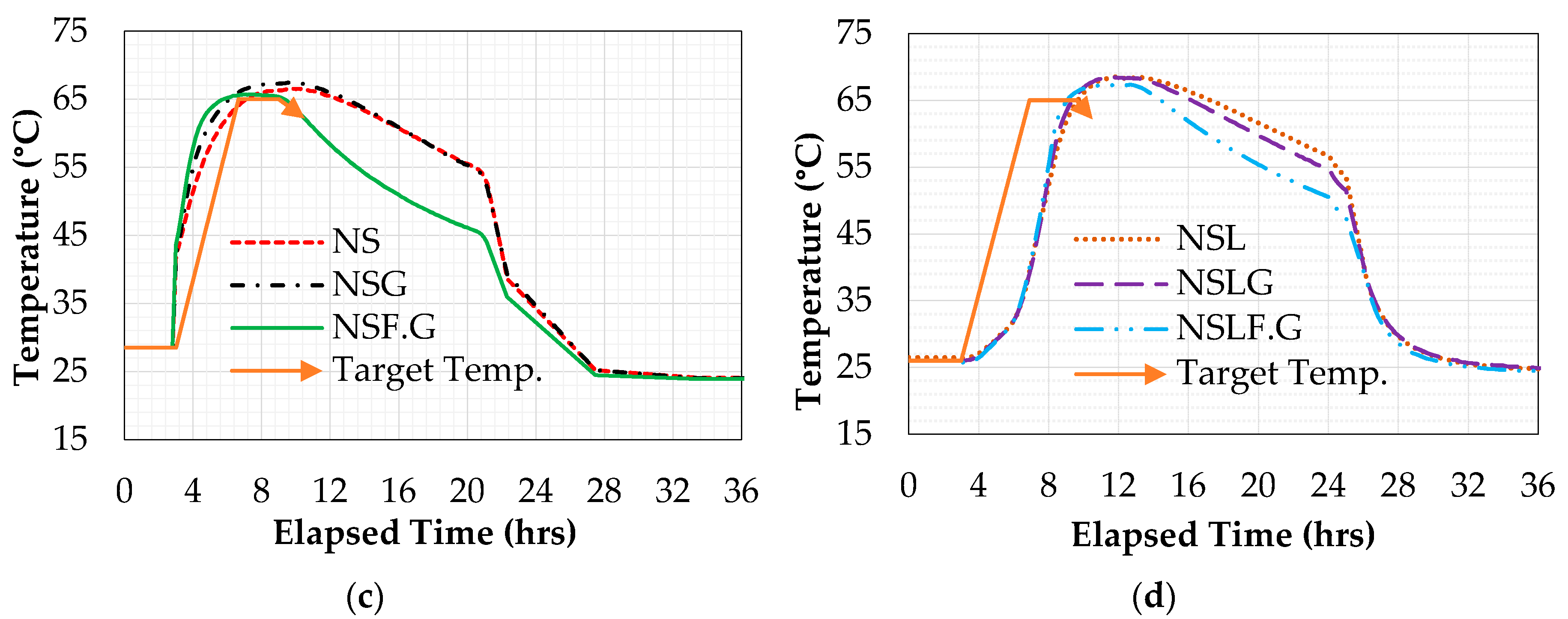

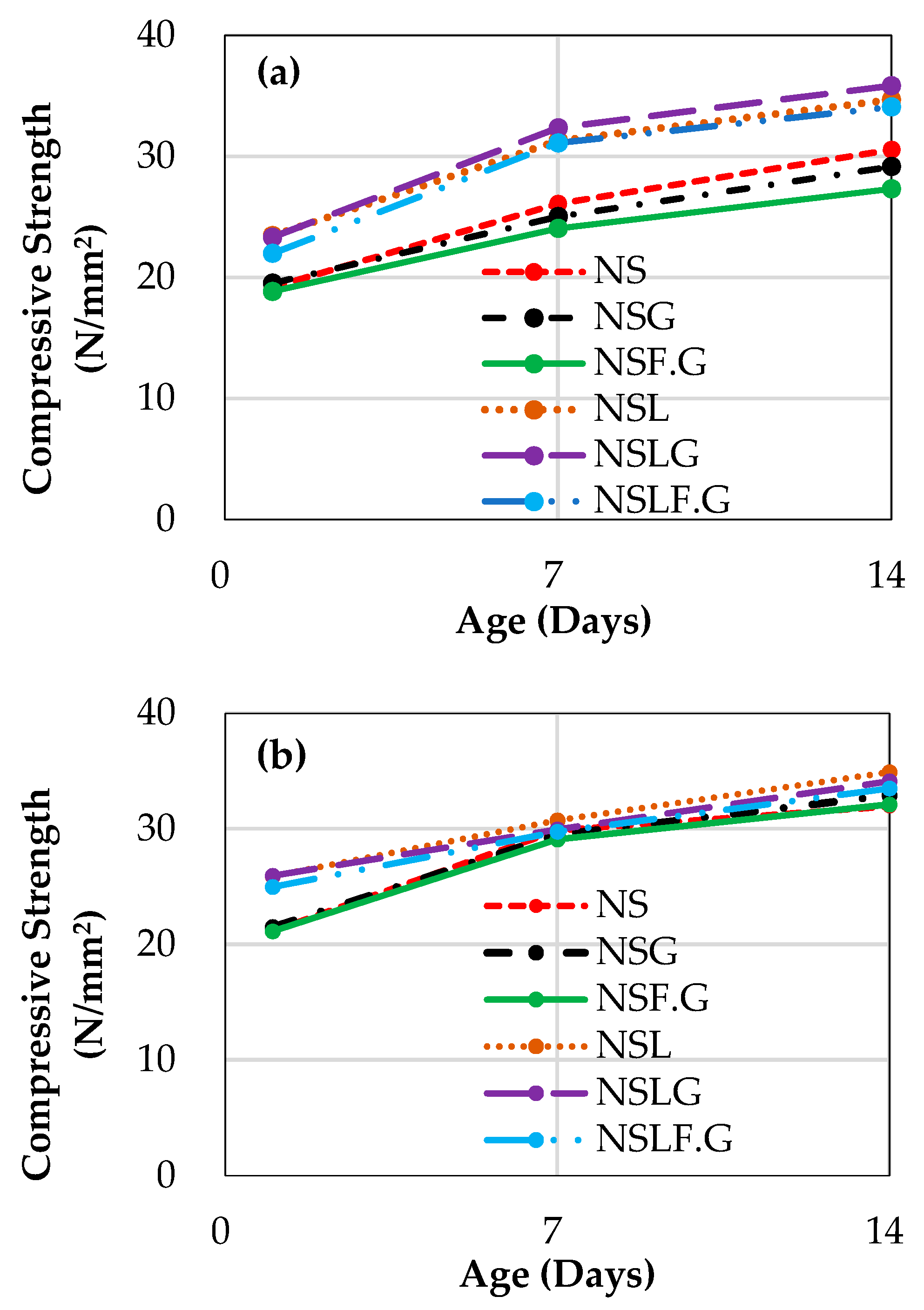

3.4. Compressive Strength

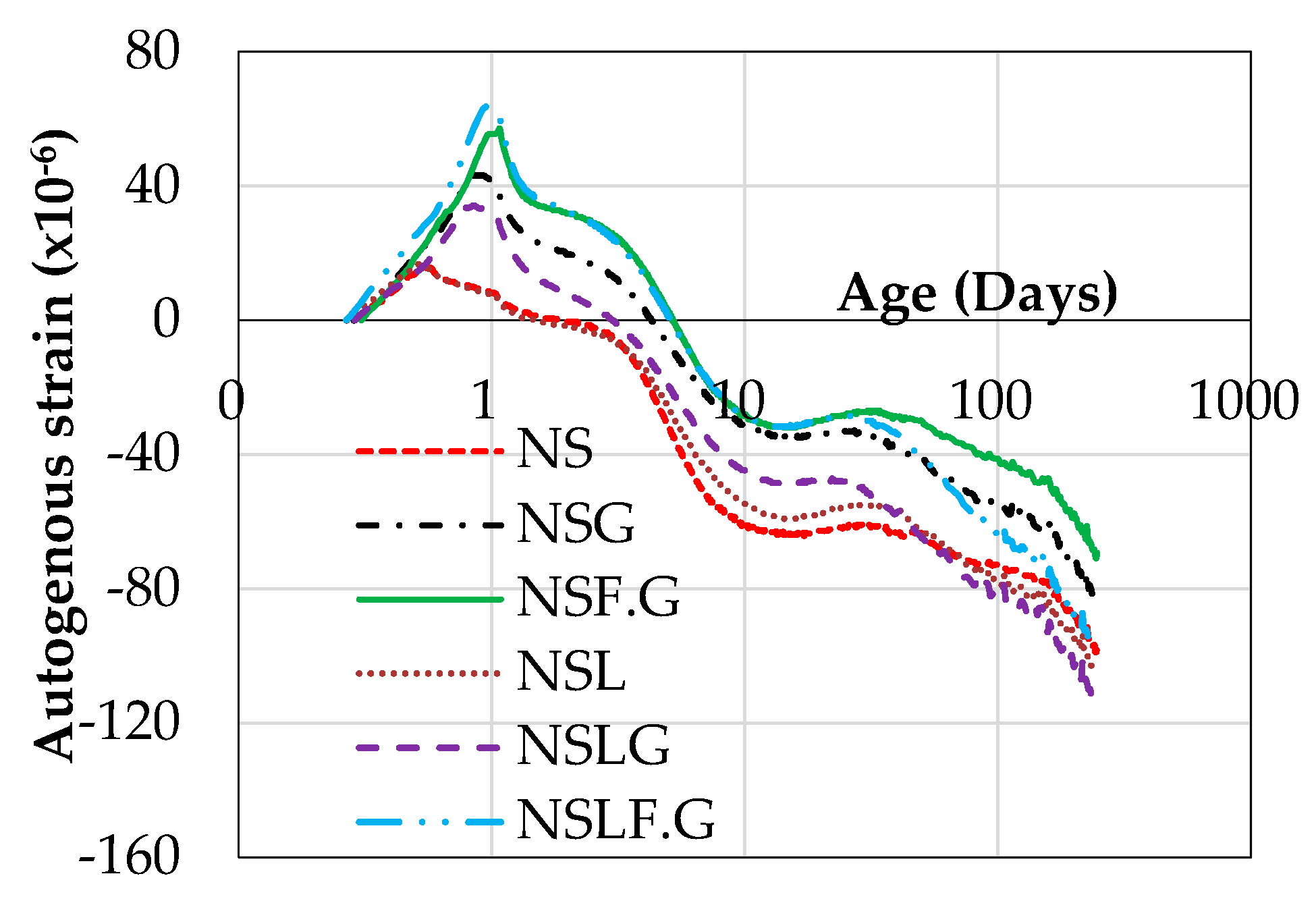

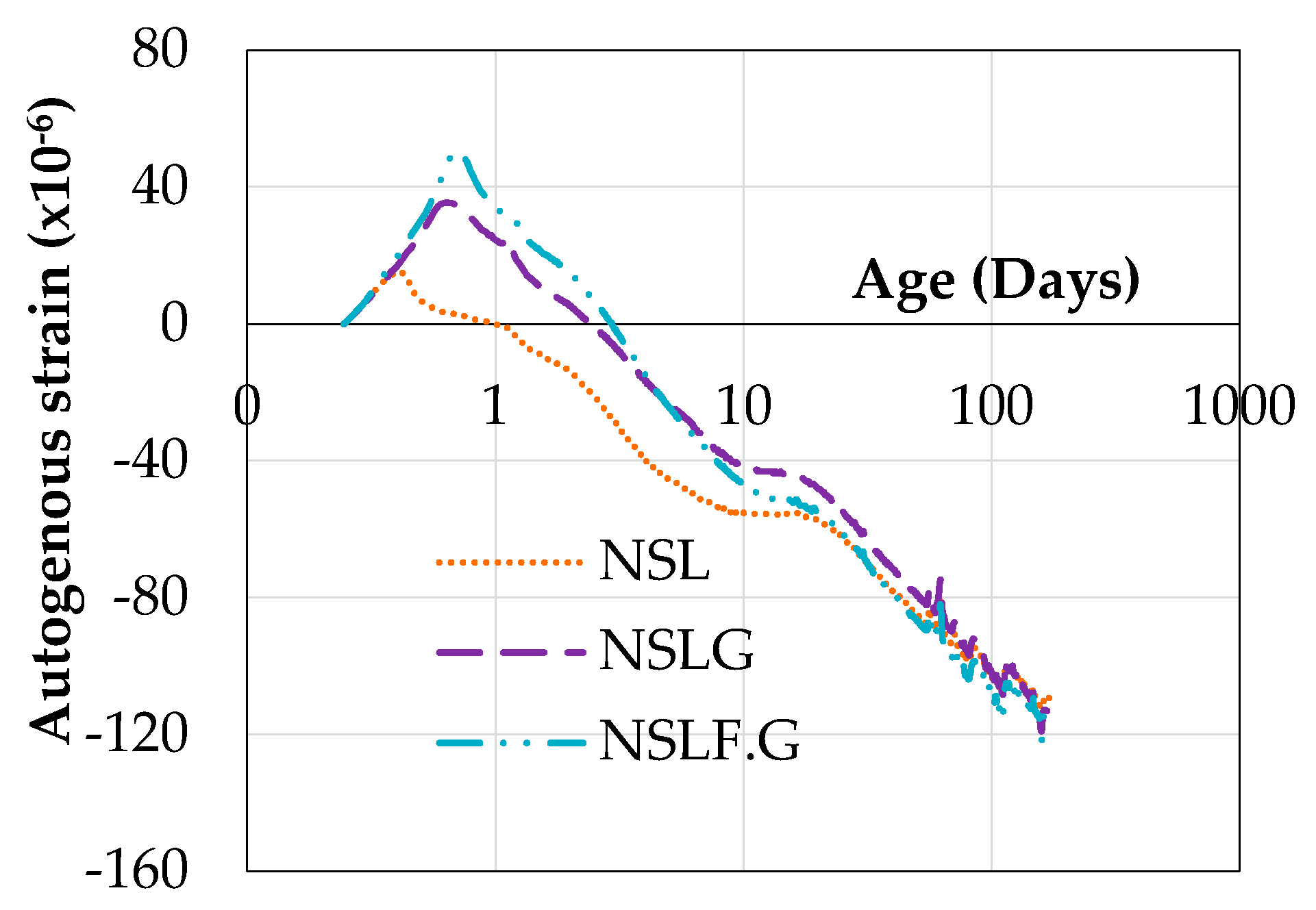

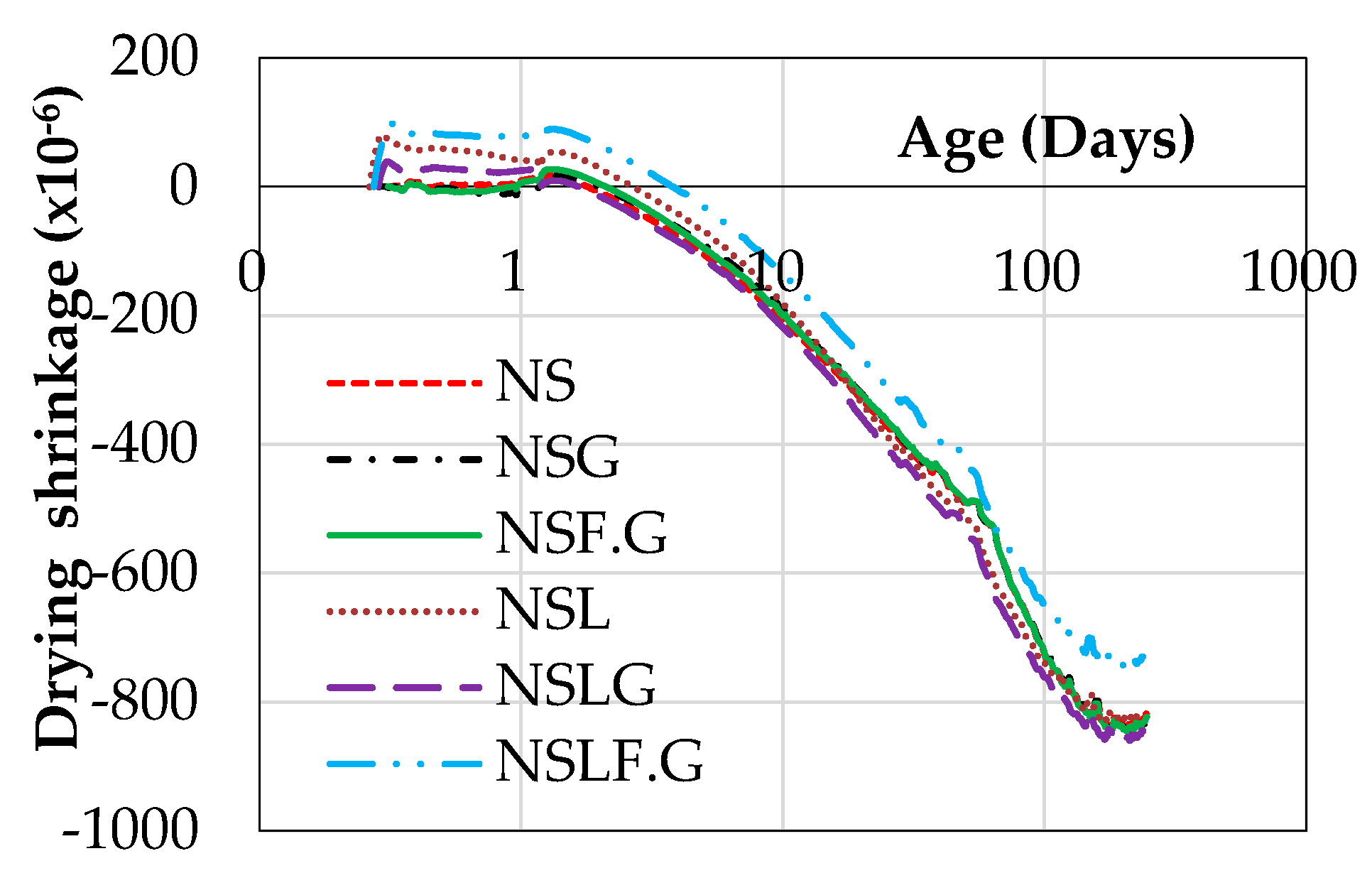

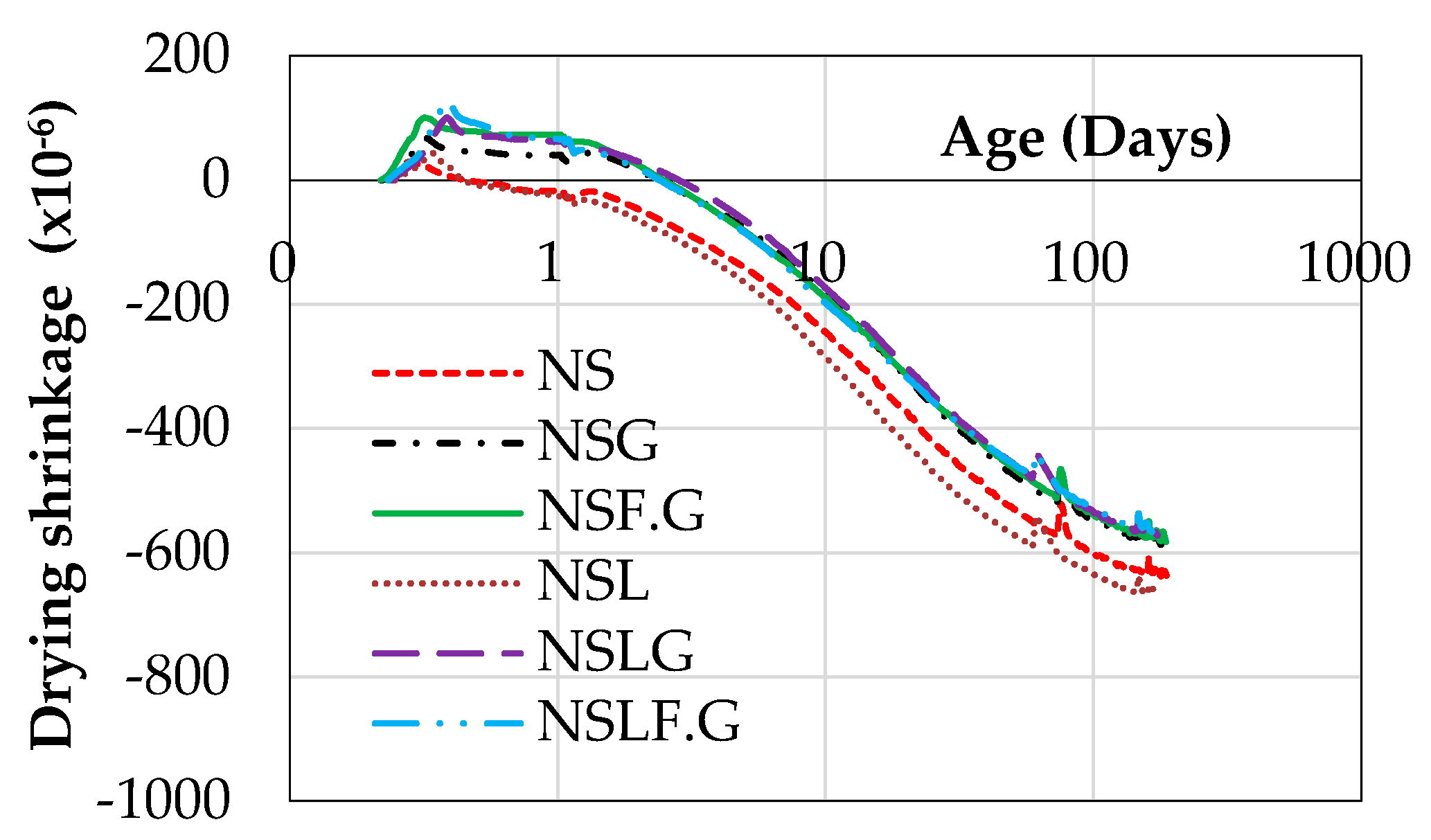

3.5. Autogenous and Drying Shrinkage, Sealed and Accelerated Cured Concrete

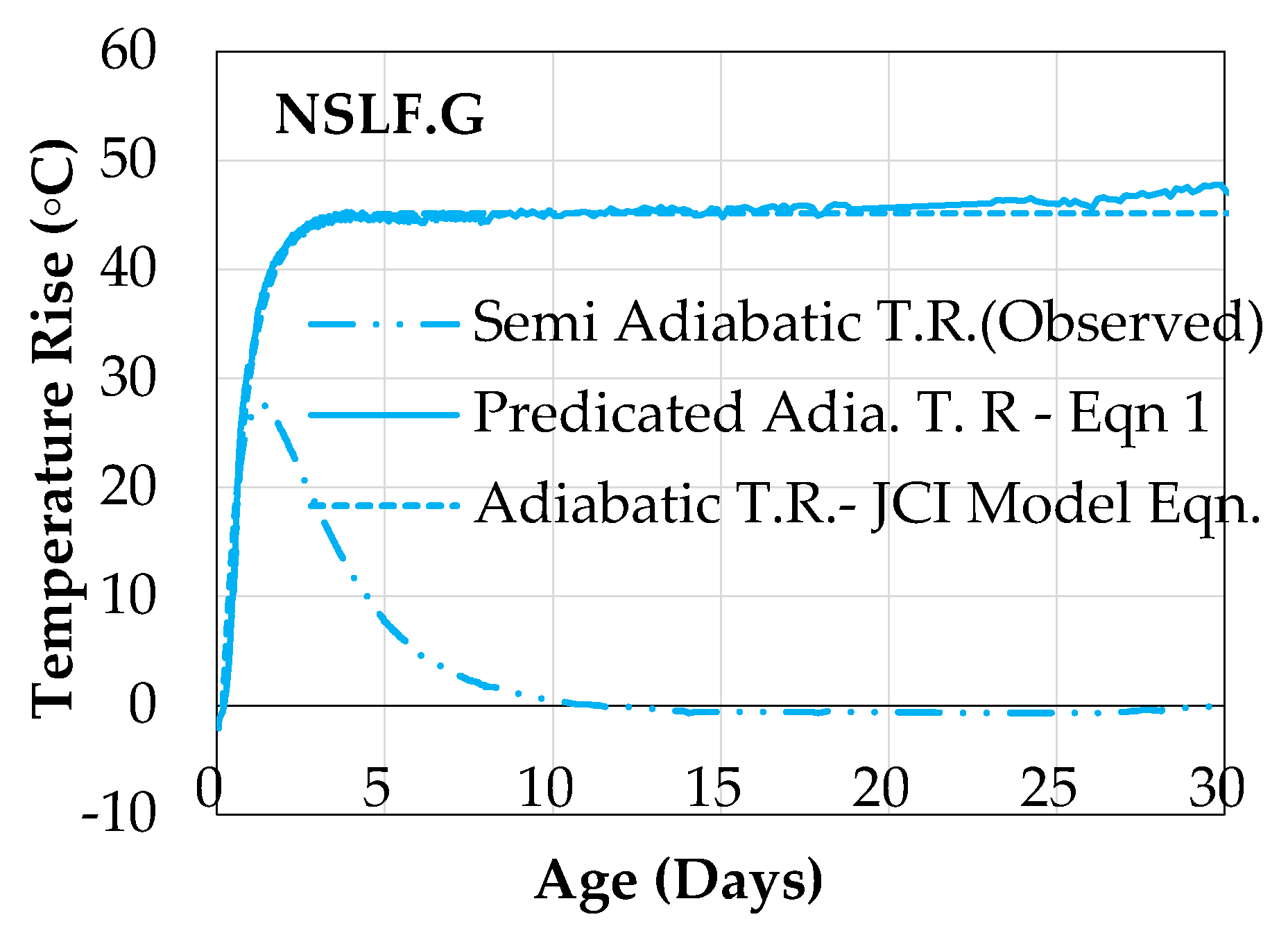

3.6. Heat of Cement Hydration of Concrete, Semi-Adiabatic Condition

4. Discussions

5. Conclusions

- Fine gypsum contributed to higher expansion at early age in sealed and accelerated cured concrete. A combination of limestone powder and fine gypsum had the highest expansion in concrete;

- Limestone powder contributed to compressive strength of concrete at early age whereas gypsum addition showed significant influence on concrete strength at 28 days;

- There was an insignificant difference in compressive strength, especially at 28 days, between two types of slag cements even when additives such as limestone powder and gypsum were used;

- Similar drying shrinkage was observed at later age. Concrete containing fine gypsum showed slightly lower shrinkage which may help in cracking resistance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sheikibrahim, K.; Sathish, S.; Mohammed Fahad, A.S.; Sathish Sharma, A.; Karthika, H.; Shanmuganathan, N. Ground Granulated Blast Furnace Slag (GGBS or GGBFS) and Flyash in Concrete. Int. Res. J. Eng. Technol. 2018, 5, 266–270. [Google Scholar]

- Ashish, D.K.; Singh, B.; Verma, S.K. The effect of attack of chloride and sulphate on ground granulated blast furnace slag concrete. Adv. Concr. Constr. 2016, 4, 107–121. [Google Scholar] [CrossRef]

- Suresh, D.; Nagaraju, K. Ground Granulated Blast Slag (GGBS) in Concrete—A review. IOSR J. Mech. Civ. Eng. 2015, 12, 76–82. [Google Scholar]

- Nagao, Y.; Suzuki, K. Basic properties and utilization of steam-cured concrete using Ground Granulated Blast-Furnace Slag. Nippon Steel Sumitomo Met. Tech. Rep. 2015. [Google Scholar]

- Bhanumathidas, N.; Kalidas, N. Dual role of gypsum: Set retarder and strength accelerator. Indian Concr. J. 2004, 78, 1–4. [Google Scholar]

- Esping, O. Effect of limestone filler BET (H2O)-area on the fresh and hardened properties of self-compacting concrete. Cem. Concr. Res. 2008, 38, 938–944. [Google Scholar] [CrossRef]

- Saito, S.; Ozawa, M.; Sakaguchi, Y.; Morimoto, H. Study on initial stress of precast concrete members using steam curing. In Proceedings of the Japan Concrete Institute, Osaka, Japan, 12–14 July 2011; Volume 33. [Google Scholar]

- Japan’s Concrete Technology; Japan Society of Civil Engineers: Tokyo, Japan, January 2014; Volume 131.

- Japanese Standards Association. JIS R 5210: Portland Cement; Japanese Standards Association: Tokyo, Japan, 2009. [Google Scholar]

- ASTM C150/C150M-18: Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A6206: Ground Granulated Blast-Furnace Slag for Concrete; Japanese Standards Association: Tokyo, Japan, 2013. [Google Scholar]

- ASTM C989-06: Standard Specification for Ground Granulated Blast-Furnace Slag for Use in Concrete and Mortars; ASTM International: West Conshohocken, PA, USA, 2006; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1119: Method of Test for Variability of Freshly Mixed Concrete by Measuring Mortar and Coarse Aggregate Contents; Japanese Standards Association: Tokyo, Japan, 2014. [Google Scholar]

- Japanese Standards Association. JIS A1138: Method of Making Test Sample of Concrete in the Laboratory; Japanese Standards Association: Tokyo, Japan, 2005. [Google Scholar]

- ASTM C192 /C192M-18: Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A 1101: Method of Test for Slump of Concrete; Japanese Standards Association: Tokyo, Japan, 1975. [Google Scholar]

- ASTM C143/C143M-15a: Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2015; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1115: Method of Sampling Fresh Concrete; Japanese Standards Association: Tokyo, Japan, 2014. [Google Scholar]

- ASTM C172/C172M-17: Standard Practice for Sampling Freshly Mixed Concrete; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1118: Method of Test for Air Content of Fresh Concrete by Volumetric Method; Japanese Standards Association: Tokyo, Japan, 2011. [Google Scholar]

- ASTM C231/C231M-17a: Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1156: Method of Measurement for Temperature of Fresh Concrete; Japanese Standards Association: Tokyo, Japan, 2014. [Google Scholar]

- ASTM C1064/C1064M-17: Standard Test Method for Temperature of Freshly Mixed Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1108: Method of Test for Compressive Strength of Concrete; Japanese Standards Association: Tokyo, Japan, 2006. [Google Scholar]

- ASTM C39/C39M-18: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1147: Method of Test for Setting Time by Penetration Resistance; Japanese Standards Association: Tokyo, Japan, 2007. [Google Scholar]

- ASTM C403/C403M-16: Standard Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance; ASTM International: West Conshohocken, PA, USA, 2016; Available online: www.astm.org (accessed on 5 October 2019).

- Mahmoud, N.; Mohsen, T.; Mojtaba, N. The Relationships between Setting Time and Early Age Strength of Concrete containing Silica fume, Fly ash and Slag. In Proceedings of the Third International Conference on Sustainable Construction Materials and Technologies, Kyoto Research Park, Kyoto, Japan, 18–21 August 2013; Available online: http://www.classe.info/Proceedings.htm e393.pdf (accessed on 23 April 2018).

- Sadaqat Ullah, K.; Muhammad Fadhil, N.; Tehmina, A.; Nasir, S. Effects of different mineral admixtures on the properties of fresh concrete. Sci. World J. 2014, 2014, 986567. [Google Scholar] [CrossRef]

- America Concrete Institute. ACI 517.2R Accelerated Curing of Concrete at Atmospheric Pressure-State of the Art. In ACI Manual of Concrete Practice; ACI 517.2R-87; America Concrete Institute: Farmington Hills, MI, USA, 1992. [Google Scholar]

- Japan Concrete Institute. Guidelines for Control. of Cracking of Mass Concrete; Japan Concrete Institute: Tokyo, Japan, 2016. [Google Scholar]

- Yasuyuki, K.; Hirotaka, K.; Hiroshi, W. A study on estimation of adiabatic temperature rise characteristics of high-strength concrete by simple adiabatic test. In Proceedings of the 57th Annual conference of the Japan Society of Civil Engineers, Sapporo, Hokkaido, Japan, 25–27 September 2002. [Google Scholar]

- Bonavetti, V.L.; Rahhal, V.F.; Irrassar, E.F. Studies on the carbolauminate formation in limestone filler blended cements. Cem. Concr. Res. 2001, 31, 853–859. [Google Scholar] [CrossRef]

- Deogekar, P.; Jain, A.; Mishra, S.; Nanthagopalan, P. Influence of Steam Curing Cycle on Compressive strength of Concrete. Int. J. Constr. Mater. Struct. 2013, 1, 18–28. [Google Scholar]

- Bernard, A.Z.; Miyazawa, S.; Nobukazu, N. Properties of blast-furnace cement concrete subjected to accelerated curing. In Proceedings of the 43rd Our World in Concrete and Structures of Premier Conference, Goodwood Park Hotel, Singapore, 29–31 August 2018; pp. 395–402. [Google Scholar]

| Cementitious Materials | Density (g/cm3) | Fineness (cm2/g) | Chemical Composition (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ig-loss | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | |||

| OPC (N) | 3.16 | 3200 | 0.94 | 20.84 | 5.49 | 3.07 | 63.89 | 1.97 | 2.4 | 0.4 | 0.32 |

| S3000 | 2.90 | 3350 | 0.25 | 34.01 | 14.28 | 0.33 | 42.61 | 6.23 | - | 0.2 | 0.35 |

| S4000 | 2.90 | 4580 | 0.09 | 33.90 | 14.16 | 0.30 | 42.92 | 6.24 | - | 0.19 | 0.32 |

| L | 2.71 | 7420 | 43.40 | - | 0.08 | - | 55.3 | 0.23 | 0.0 | - | - |

| G | 2.90 | 4100 | 1.10 | 0.90 | 0.20 | 0.10 | 39.7 | 0.10 | 58.0 | - | - |

| F. G | 2.90 | 9680 | 1.10 | 0.90 | 0.20 | 0.10 | 39.7 | 0.10 | 58.0 | - | - |

| Proportion | Blending (%) | Total (%) by Mass | ||||

|---|---|---|---|---|---|---|

| N | S | L | G | F. G | ||

| NS | 75 | 25.00 | - | - | - | 100 |

| NSG | 75 | 23.25 | - | 1.75 | - | 100 |

| NSF.G | 75 | 23.25 | - | - | 1.75 | 100 |

| NSL | 75 | 22.50 | 2.50 | - | - | 100 |

| NSLG | 75 | 20.75 | 2.50 | 1.75 | - | 100 |

| NSLF.G | 75 | 20.75 | 2.50 | - | 1.75 | 100 |

| Proportion | W/B (%) | s/a (%) | Amounts of Contents (kg/m3) | Chemical Admixture AEWR (B X %) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Water | Binder (B) | s | g | ||||||||

| N | S | L | G | F. G | |||||||

| NS | 50 | 47 | 175 | 262.5 | 87.5 | - | - | - | 812 | 933 | 1.0 |

| NSG | 50 | 47 | 175 | 262.5 | 81.4 | - | 6.1 | - | 812 | 933 | 1.0 |

| NSF.G | 50 | 47 | 175 | 262.5 | 81.4 | - | - | 6.1 | 812 | 933 | 1.0 |

| NSL | 50 | 47 | 175 | 262.5 | 78.6 | 8.6 | - | - | 811 | 933 | 1.0 |

| NSLG | 50 | 47 | 175 | 262.5 | 72.6 | 8.6 | 6.1 | - | 811 | 933 | 1.0 |

| NSLF.G | 50 | 47 | 175 | 262.5 | 72.6 | 8.6 | - | 6.1 | 811 | 933 | 1.0 |

| Mix Proportion | Slump (cm) | Air Content (%) | Temperature (°C) | |||

|---|---|---|---|---|---|---|

| S3000 | S4000 | S3000 | S4000 | S3000 | S4000 | |

| NS | 19.3 | 19.2 | 5.8 | 5.5 | 18.5 | 28.0 |

| NSG | 19.0 | 19.7 | 5.5 | 6.4 | 19.5 | 28.5 |

| NSF.G | 18.2 | 19.2 | 5.6 | 4.8 | 20.0 | 28.5 |

| NSL | 17.7 | 20.7 | 4.4 | 6.5 | 19.0 | 26.5 |

| NSLG | 18.5 | 20.5 | 4.5 | 5.4 | 19.0 | 26.0 |

| NSLF.G | 19.4 | 20.0 | 4.6 | 5.0 | 20.0 | 26.0 |

| Mix Proportion | Initial Setting Time (hours) | Final Setting Time (hours) | ||

|---|---|---|---|---|

| S3000 | S4000 | S3000 | S4000 | |

| NS | 7.03 | 5.70 | 10.42 | 7.50 |

| NSG | 6.83 | 5.21 | 9.83 | 7.25 |

| NSF.G | 7.36 | 5.27 | 9.90 | 7.57 |

| NSL | 6.38 | 5.92 | 9.27 | 8.65 |

| NSLG | 6.93 | 5.80 | 9.58 | 8.25 |

| NSLF.G | 6.64 | 5.60 | 9.58 | 8.15 |

| Mix Proportion | W/B (%) | Q∞ (°C) | rAT | SAT | t0,Q |

|---|---|---|---|---|---|

| NS | 50 | 42.14 | 1.179 | 1.0 | 0.183 |

| NSLF.G | 50 | 45.14 | 1.378 | 1.0 | 0.177 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zulu, B.A.; Miyazawa, S.; Nito, N. Properties of Blast-Furnace Slag Cement Concrete Subjected to Accelerated Curing. Infrastructures 2019, 4, 69. https://doi.org/10.3390/infrastructures4040069

Zulu BA, Miyazawa S, Nito N. Properties of Blast-Furnace Slag Cement Concrete Subjected to Accelerated Curing. Infrastructures. 2019; 4(4):69. https://doi.org/10.3390/infrastructures4040069

Chicago/Turabian StyleZulu, Bernard A., Shingo Miyazawa, and Nobukazu Nito. 2019. "Properties of Blast-Furnace Slag Cement Concrete Subjected to Accelerated Curing" Infrastructures 4, no. 4: 69. https://doi.org/10.3390/infrastructures4040069

APA StyleZulu, B. A., Miyazawa, S., & Nito, N. (2019). Properties of Blast-Furnace Slag Cement Concrete Subjected to Accelerated Curing. Infrastructures, 4(4), 69. https://doi.org/10.3390/infrastructures4040069