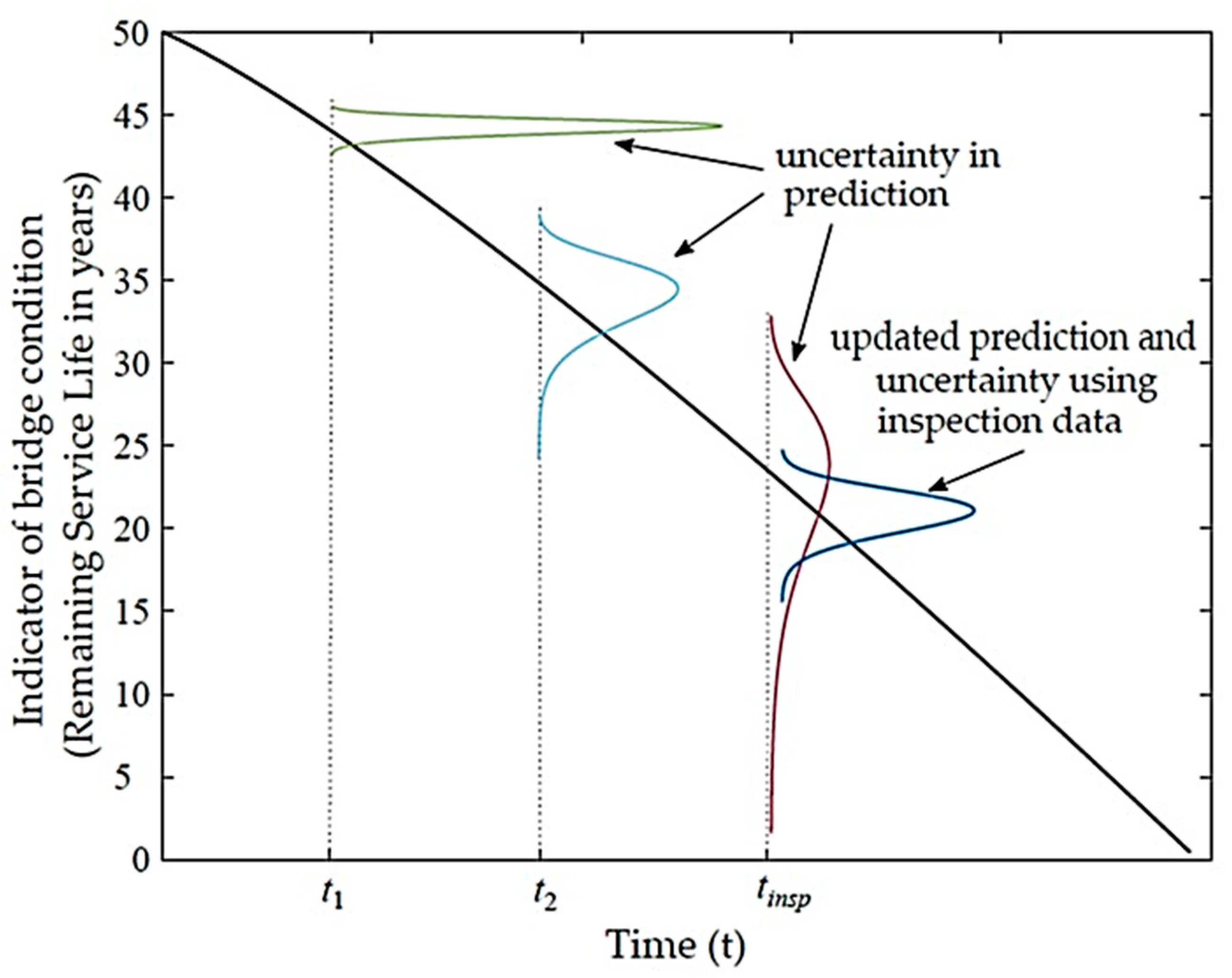

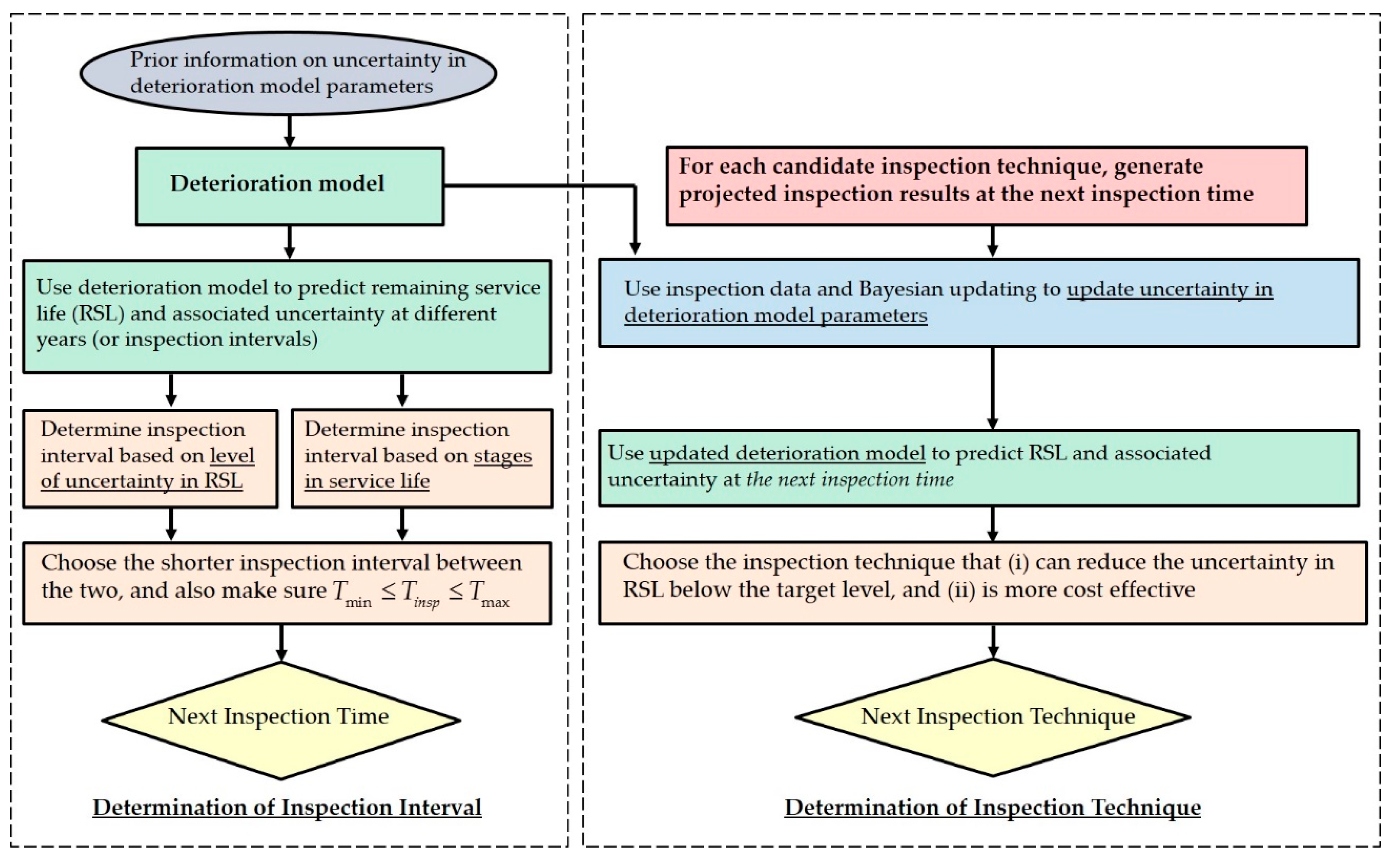

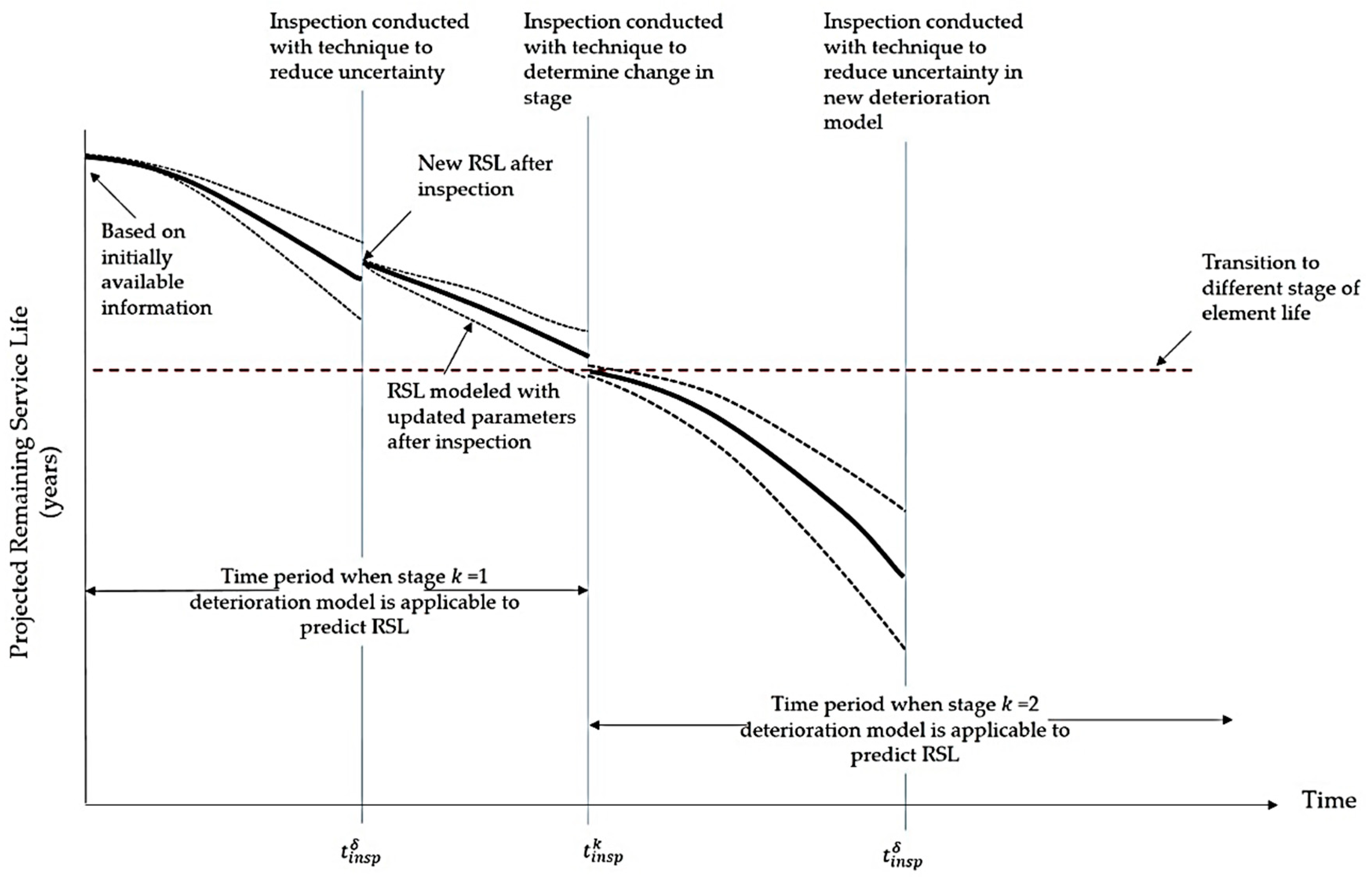

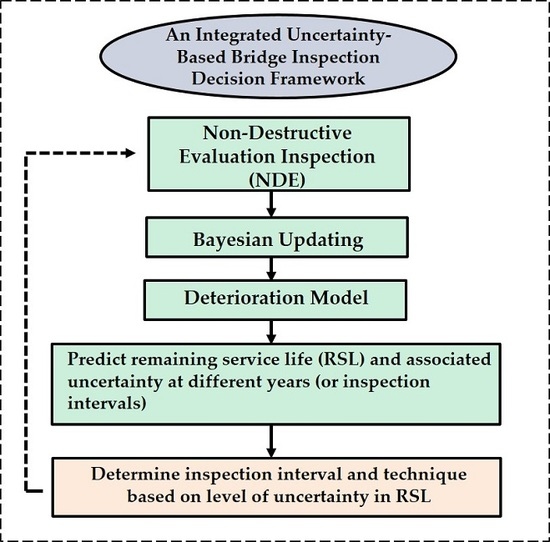

Inspection planning consists of three main steps: non-destructive inspection, the Bayesian updating process, and deterioration prediction. The inspection step involves measuring model parameters onsite using non-destructive methods. Bayesian updating is used to update the model parameters integrating the new measured data. In the deterioration prediction step, the extent of a certain deterioration stage and the probability of transitioning to a subsequent stage are estimated using models appropriate for the current state of the bridge. Using the predicted bridge condition and the uncertainty in that condition over time, the inspection time () for the next inspection is determined.

5.3.2. Inspection Planning at , (1st NDE Inspection, 1st Prediction, RSL Estimation and Choosing the Next Inspection Time ())

The first NDE inspection is assumed to be conducted after 2 years from initiation of the bridge deck life span. The two-year period is selected to reflect current bridge inspection practice. This initial period ensures that there are useful parameters to measure at the time of the first NDE inspection.

In this simulated inspection, two parameters were measured: the surface chloride concentration using a Chloride Ion Penetration test (CIP) and the concrete cover using a Pachometer. In this case, the measured surface chloride concentration (

) had a mean value of 3.5 kg/m

3 and a c.o.v equal 0.5 kg/m

3. The cover mean value was 6 cm and the c.o.v was 0.2 cm. These measured parameters, along with random variables representing the diffusion coefficient (

D) and critical chloride concentration (

), shown in

Table 2, were then used in the first prediction at

. It should be noted that to ensure a non-destructive inspection procedure, the CIP test was used to measure only the surface chlorides, and therefore would require a relatively small sample or core from the concrete deck. However, an agency could decide to measure the chloride content at a certain depth using a more destructive method and calibrate the model in Equation (10) depending on its measurements.

Monte Carlo Simulation (MCS) was used to predict the mean and standard deviation of the RSL at different time intervals. Using the parameters measured from the inspection and assumed from the concrete properties including their associated uncertainties, the time interval to reach a specific mean chloride concentration at the rebar level was predicted using the corrosion initiation prediction model Equation (11). Using specified distributions for the chloride concentration and calculating the time to reach that chloride concentration allows estimation of uncertainty in the RSL in years. For instance, a mean chloride content of 0.6 kg/m

3 will accumulate at the rebar level after almost 16 years from the arrival of chlorides on the concrete surface

, as shown in

Table 3. The 16-year predicted time is associated with a standard deviation

, which corresponds to the standard deviation of the RSL

at year 16.

In this example, the condition threshold

in Stage 1 is the corrosion initiation time and it is assumed to initiate at a critical chloride concertation (

) of 1 kg/m

3 (c.o.v. = 0.1 kg/m

3) [

54,

56]. Accordingly, using the mean and standard deviation for the time to reach a chloride content of 1 kg/m

3 the probability of corrosion initiation

was estimated at different times, as indicated in

Table 4.

The prediction made at

indicates that the chloride content is expected to reach 1 kg/m

3 at the rebar level after almost 27 years from the arrival of the chlorides on the concrete surface

and therefore corrosion is predicted to initiate around this time. In addition, at

, the duration of Stage 2 was estimated to be 7 years using the variables in

Table 2 and Equation (12). At year 2, Bayesian updating was not performed, since it is the first prediction, with no prior knowledge of the values of the model parameters.

In this example, the RSL is the summation the time spans of Stage 1

, Stage 2

and Stage 3

. The first prediction at

predicted that the mean value for the durations of Stage 1 and Stage 2 from

are 27 and 7 years, respectively. A concrete bridge deck is estimated to have a life span ranging from 40 to 60 years [

57,

58]. In this example, the life span of the concrete bridge deck was initially assumed to be 50 years. Based on the hypothetical 50-year life span and the first deterioration prediction, the time span for Stage 3 will be 16 years (

). Therefore, the RSL calculated at year 2 has a mean value of 48 years (i.e.,

). This was calculated by adding the mean value for the predicted time span of Stage 1 (27-years), to Stage 2 (7 years) and 3 (16 years), then deducting the 2 years that have elapsed from

. This indicates that the bridge deck RSL has a mean value of 48 years, before reaching the end of its service life (as decided by the agency due to excessive cracking). However, based on the results from the first prediction, the estimated RSL is associated with uncertainty. The predicted duration of Stage 1 has a standard deviation of almost

. It is noted that the only uncertainty considered when making predictions in Stage 1 is the uncertainty associated with the predicted duration for Stage 1, while the time spans of Stage 2 and 3 are considered constant until reaching Stage 2. Using the proposed inspection process will help in reducing this degree of uncertainty in RSL, as will be demonstrated.

To choose the time interval for the next inspection, three governing factors were considered: (1) a maximum time of 6 years between inspections (i.e., ), (2) the standard deviation of the RSL exceeds 2 years (i.e., ), and (3) the probability of corrosion initiation exceeding 40% (i.e., ). Once any of the thresholds is reached, an inspection should be conducted. In practice, these thresholds should be decided by the agency or the bridge management team based on their management needs, and these thresholds could change over time as the agency became more familiar with this inspection planning process. In this example, 2 years was selected as the standard deviation threshold so as not to introduce too much uncertainty into short term budget planning. The probability threshold of 40% was chosen as a way to check on the bridge before the mean expected time for corrosion to initiate. An agency might decide that they were not interested in catching corrosion initiation at very early stages and they would prefer to wait until the probability of corrosion was 80% or 90% before conducting an inspection. This demonstrates the flexibility of the proposed inspection planning process and how it can be tailored to a specific agency’s needs and budget.

The first prediction results in

Table 4 show that the probability

will reach 40% after 24 years, whereas, regarding the standard deviation criterion, the next inspection should be conducted at year 8 (measured from

) when a standard deviation exceeding 2 years has been reached, and which happens to correspond to the 6 years maximum interval between inspection (with the previous inspection conducted at year 2). Thus, the next inspection will be conducted at

, and CIP and Pachometer non-destructive methods will be used as the bridge deck is still expected to be in Stage 1.

5.3.3. Inspection Planning at , (2nd NDE Inspection, Bayesian Updating of Parameters, 2nd Prediction, RSL Estimation, and Choosing the Next Inspection Time ())

To continue the demonstration example, another simulated inspection is assumed at year 8. A Pachometer and CIP were once again used to measure the concrete cover and the surface chloride content, respectively. The simulated inspection finds the surface chloride content () higher than the previous measured amount at by 5% and the cover is less than the design value by the same percentage. For simplicity in this example the standard deviation of the measured surface chlorides and concrete cover were assumed to depend only on the accuracy and error factor of the equipment; since no inspection measurements or data from calibration of an NDE technique were available (i.e., refer to Equations (3) and (4), and ). However, in reality, the accuracy of the inspection can also depend on the proficiency of the inspectors, the number of measurements conducted and the dispersion between measurements.

In the Bayesian updating process, the measured parameter values and associated uncertainty at year 2 correspond to the prior , while the new measured values at year 8 correspond to the data. Using both sets of information, a posterior mean and standard deviation for the surface chloride concentration and concrete cover were calculated using Bayesian updating. Table 8 at the end of the example summarizes the values of the updated bridge deck parameters at each inspection time investigated.

Using samples from the posterior distribution for the bridge deck parameters, along with samples for the other Stage 1 model parameters, MCS was used for the second prediction.

Table 5 and

Table 6 show the second prediction results.

The results of the second prediction at using the updated parameters show that the expected time for corrosion initiation was reduced from 27 to 24.3 years and the standard deviation of the expected corrosion initiation time decreased to almost 4.6 years rather than 7 years. Based on the hypothetical 50-year life span of the bridge deck, the RSL after 8 years should be equal to 42 years. However, due to the simulated inspection measurements and the second prediction at year 8, the mean RSL decreased by 3 years to be 39 years (i.e., ), associated with a standard deviation . This shows that updating the model parameters using the inspection results had the desired effect of decreasing the level of uncertainty (i.e., decrease in the standard deviation) associated with the prediction of deterioration and RSL estimation.

Applying the same inspection planning criteria to year 8, the results in

Table 5 show that based on the standard deviation criterion, the next inspection should be conducted at year 11, which corresponds to a 3-year interval between inspections. On the other hand, based on the probability

, the next inspection should be done at year 23. Therefore, the next inspection was assumed to be conducted at year 11.