1. Introduction

Nowadays, sustainability and environmental matter are the main issues for most research studies on construction materials. One of the solutions is to use reclaimed asphalt pavement (RAP) as the main recycled material used in hot mix asphalts. Some researchers [

1,

2,

3,

4] have studied the use of RAP in road construction and concluded that because of the large environmental potential and cost benefits, it is important to maximize RAP content in the mix design. According to Al-Qadi et al. [

5], the performance of pavements using properly prepared RAP was found to be satisfactory in terms of fatigue, rutting, thermal resistance, and durability.

The required thickness for pavement design depends on the pavement design method and material characteristics [

6]. Saliani et al. [

7] concluded that the surface area of mix components, like virgin aggregates, fiber, RAP, etc., impact bitumen absorption. Mix design factors, like mix duration and mix temperature, influence the rheological properties of mixes with RAP particles. Because of this, it is important to precisely characterize RAP according to particle size. Previous studies have shown that active bitumen content in coarse RAP particles is more than that for fine RAP particles [

8].

It is desirable to have a higher recycle material content in hot mix asphalt (HMA), but incorporating large quantities can make the mix stiffer and more brittle. Consequently, these mixes are less workable, harder to compact in the field, and prone to crack [

9,

10,

11,

12,

13]. Various strategies have been developed in order to increase RAP content such as incorporating a warm mix asphalt additive, adding rejuvenator agent, or a combination of mix designs [

14]. In addition, RAP size is one of the critical factors that impact the level of blending between RAP and virgin particles. The degree of blending has not been quantified clearly. McDaniel and Anderson assumed full blending happened during mixing [

15]. Some investigations were carried out to evaluate the level of interaction between RAP and virgin asphalt [

16,

17,

18] and enhance the understanding of the interaction degree, but they could not quantify it. In all above studies, RAP size by itself was not studied precisely.

On the other hand, film thickness of bitumen that surrounds RAP aggregate particles can significantly impact HMA performance. Bressi et al. [

19] proposed an initial approach to show different aging levels in RAP binder film thickness, and they proposed a methodology to detect the existence of a cluster phenomenon in RAP binder. Aging level and cluster phenomena can also impact the level of interaction between RAP and virgin materials.

Gardiner [

20] concluded that the complex modulus was not solely controlled by the stiffness of the binder, whereas several other factors, including the gradation and angularity of the aggregate, played a main role in stiffness.

The term available or effective RAP binder refers to the binder that is released from RAP, becomes fluid, and blends with a virgin binder under typical mixing temperatures [

21]. The stiffer the RAP binder, the less it will blend with the virgin binder. The binder stiffens with time mostly because of its reaction with oxygen (i.e., oxidization).

Oxygen availability depends on the pavement structure and varies from outer layers to pavement sublayers. Oxygen diffusion depth is considerable [

22]. Also, asphalt film thickness affects oxygen diffusion. Sufficient methodology has been developed to estimate the diffusion depth [

23]. Basically, using RAP in new mixes is a good idea for sustainable development, but information is still needed to understand the interaction between different components in a mix with RAP to optimize the properties of those recycled mixes. In order to have more RAP in HMA, as a greener alternative, blending degree and aging rate need to be well-understood. The objective of the present research is to study bitumen characteristics of fine and coarse RAP particles from the same RAP source and to verify the interaction between RAP bitumen and virgin bitumen according to RAP particle size.

2. Materials and Methods

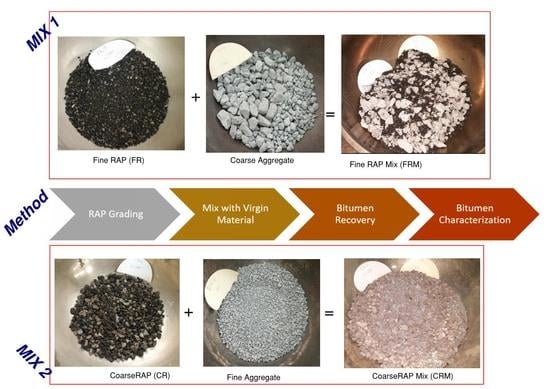

In order to reach the goal of this study, a single RAP source was selected and split in two sizes, fine RAP (FR) and coarse RAP (CR), before extracting the bitumen (with solvent). The two RAPs were then used to make mixes with virgin aggregate and virgin binder before extracting the mixed bitumen. The following steps were performed:

Performance grading (PG) for CR and FR bitumen;

Performance grading (PG) for binder blended with CR and FR (coarse RAP mix (CRM) and fine RAP mix (FRM));

Rheology behavior for CR, FR, CRM, FRM, and control mix;

A Fourier transform infrared spectroscopy (FTIR)–ATR (attenuated total reflection) analysis was done on all bitumen and bitumen mixes;

Environmental scanning electron microscopy (ESEM) image analysis was used to visualize bitumen differences on a micro scale.

In this study, a base course 20 mm mix was made with 4.5% total bitumen. The virgin bitumen used was a PG 64-28 from Bitumar (Montreal, QC, Canada). Also, RAP was supplied by Bauval (Montreal, QC, Canada).

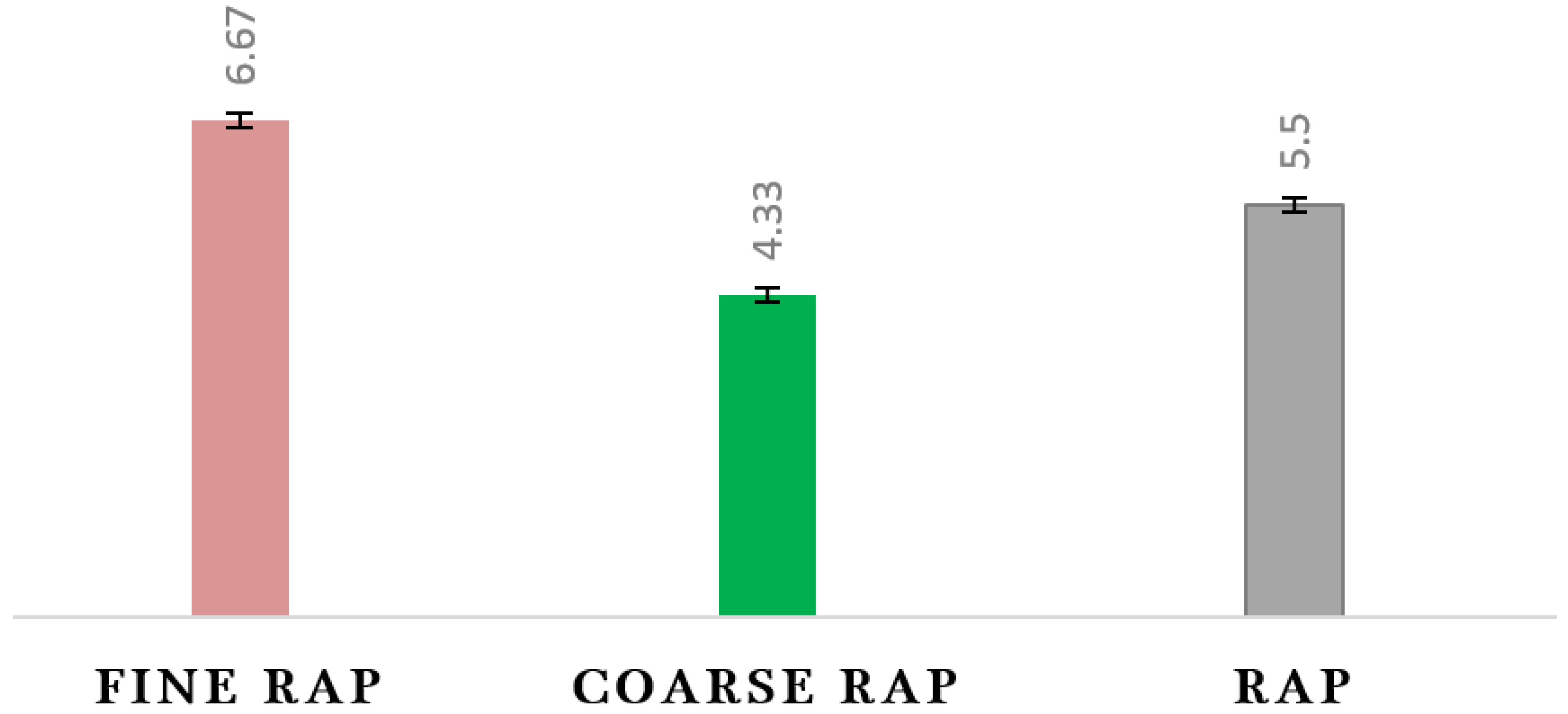

To have a clear and better understanding of the differences between fine and coarse RAP, a single source of RAP from a specific area was chosen. In this way, the potential errors according to the RAP source were reduced. Two mixes were designed and tested. These mixes contained 35% fine RAP or 54% coarse RAP. Those mixes were referred to as fine RAP (FR) mix and coarse RAP (CR) mix in this paper. Initially, it was assumed that all RAP bitumen participated in the mix. The bitumen content of fine RAP was measured with the ignition oven at 6.67%, and it was 4.33% for the coarse RAP (

Figure 1). The RAP content for each type of RAP was selected to achieve the same bitumen content of 4.5% for all mixes.

Once the mixes were done, the bitumen was extracted and recuperated according to ASTM D2172 standards. Bitumen was also extracted from the two RAP sources. The five resulting bitumen were:

Virgin bitumen PG64-28;

Recovered bitumen from coarse RAP particles (CR);

Recovered bitumen from fine RAP particles (FR);

Recovered bitumen from a mixture of virgin bitumen with CR (CRM); and

Recovered bitumen from a mixture of virgin bitumen with FR (FRM).

The rheology of the bitumen was tested in terms of dynamic shear modulus, and their chemical characteristics were tested with infrared spectrometry. The difference between recovered coarse RAP bitumen and recovered fine RAP bitumen was also visualized by electron microscopy.

2.1. Bitumen Characterization

Extracted bitumens were classified by their performance grade (PG). Bitumen classification in North America is based on performance-grade (PG H–L), which is selected according to the temperature. The H value corresponds to the maximum pavement temperature, at which the bitumen has enough cohesion to minimize plastic deformation of the asphalt mix, and the L value corresponds to the minimum air temperature, where the bitumen has enough elasticity to keep asphalt mix flexible at low temperatures to reduce cracking potential [

24].

2.2. Rheological Behavior

A dynamic shear rheometer (DSR) was used to determine the complex shear modulus (G*). All five bitumens were tested. AASHTO-T-315 [

25] was adopted for the analysis. This test method covered the determination of the dynamic shear modulus and phase angle of asphalt binder when tested in dynamic (oscillatory) shear using parallel plate test geometry. It was applicable to asphalt binders that have dynamic shear modulus values in the range from 100 Pa to 10 MPa. This range of modulus was typically obtained between 6 °C and 88 °C at an angular frequency of 10 rad/s. This test method was intended for determining the linear viscoelastic properties of asphalt binders, as required for specification testing, and was not intended as a comprehensive procedure for full characterization of the viscoelastic properties of asphalt binder.

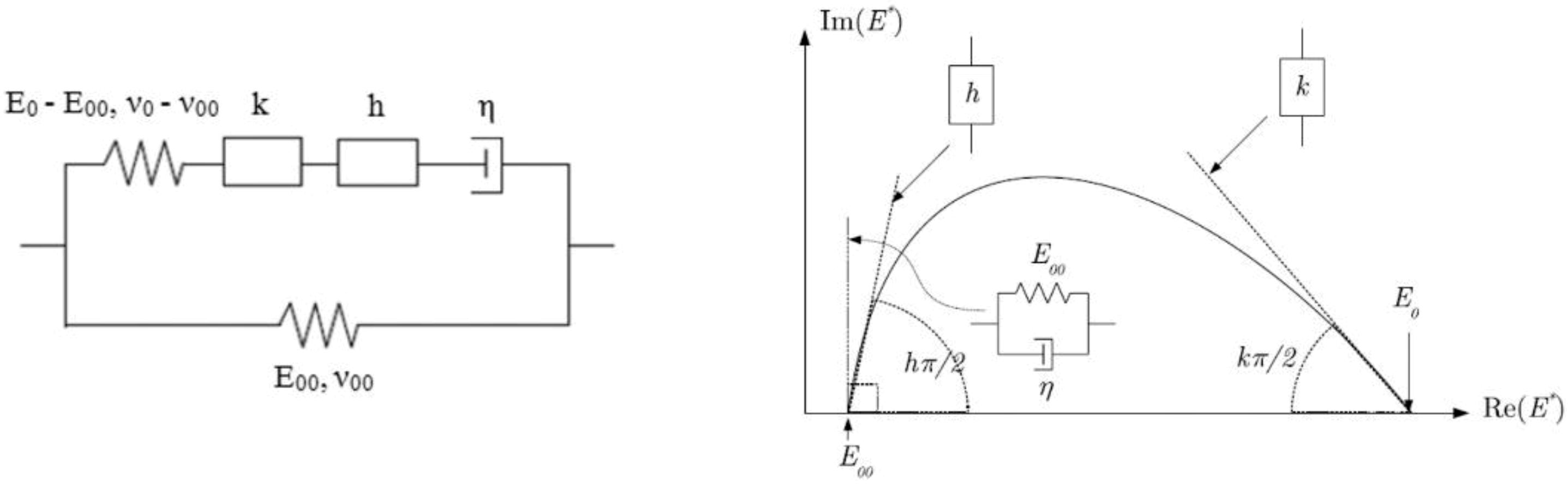

The shear modulus responses (G*) of the bitumen measured in the laboratory were first modelled with the 2S2P1D model, a generalization of the Huet–Sayegh model [

26]. Referring to the 2S2P1D model, the values of the DBN (Di Benedetto-Neifar) bodies were fixed in the Linier Visco-Elastic (LVE) domain. An alternative general model “2S2P1D” (generalization of the Huet–Sayegh model), valid for both the bituminous binders and mixes and based on a simple combination of physical elements (spring, dashpot, and parabolic elements), was proposed.

The introduced 2S2P1D model had seven constants (

Figure 2). At a given temperature T, the seven constants of the 2S2P1D model can be determined. G* is calculated following Olard and Di Benedetto [

26]:

where:

h and k are exponents such as 0 < k < h < 1;

E00 is the static modulus obtained when ωτ→0 (at low frequencies and high temperatures) with ω = 2π frequency;

E0 is the glassy modulus when ωτ→∞ (at high frequencies and low temperatures), MPa

τ is the characteristic time, which this value varies only with temperature, accounting for the time–temperature superposition principle (TTSP); and

η is the Newtonian viscosity, η = (E0 − E00)βτ.

When ωτ→0, the E*(iωt)→E00 + iω (E0 − E00)βτ × β.

2.3. Fourier Transform Infrared Spectroscopy–Attenuated Total Reflection (FTIR–ATR) Spectrometry

The FTIR–ATR analysis was performed with a Bruker Tensor 27 and a diamond ATR crystal. The analysis was performed 16 times per specimen with a 4 cm−1 resolution and a band range of 4000–600 cm−1. Around 0.5 g of bitumen was placed with a spatula (at ambient temperature) on the crystal. The crystal was cleaned with a bitumen remover after each test followed by ethanol to remove traces of the bitumen remover.

Oxidation of hydrocarbons was associated, notably, with the increase of carbonyl C=O (around 1700 cm

−1) and sulfoxide S=O (around 1030 cm

−1) bonds. The carbonyl index (%) and sulfoxide index (%) are defined in

Table 1 for C=O and S=O, respectively, with a higher value indicating relatively more oxidation. The peaks around 1460 cm

−1 and 1376 cm

−1 were for aliphatic C-CH3 groups, which served as baselines for the analysis, as they change relatively little during aging [

27].

2.4. Environmental Scanning Electron Microscopy (ESEM) Analysis

Environmental scanning electron microscopy (ESEM) observations were conducted in accordance with the settings developed previously for bitumen by Mikhailenko et al. [

28]. Bitumen specimens were observed at room temperature immediately after being removed from the cooler with a FEI Quanta 250 FEG ESEM.

3. Results and Discussion

3.1. Bitumen Performance Grade (PG)

Rheological characterizations of all extracted and recovered bitumen from FR, CR, FRM, CRM, and control mix were performed following AASHTO T 315.

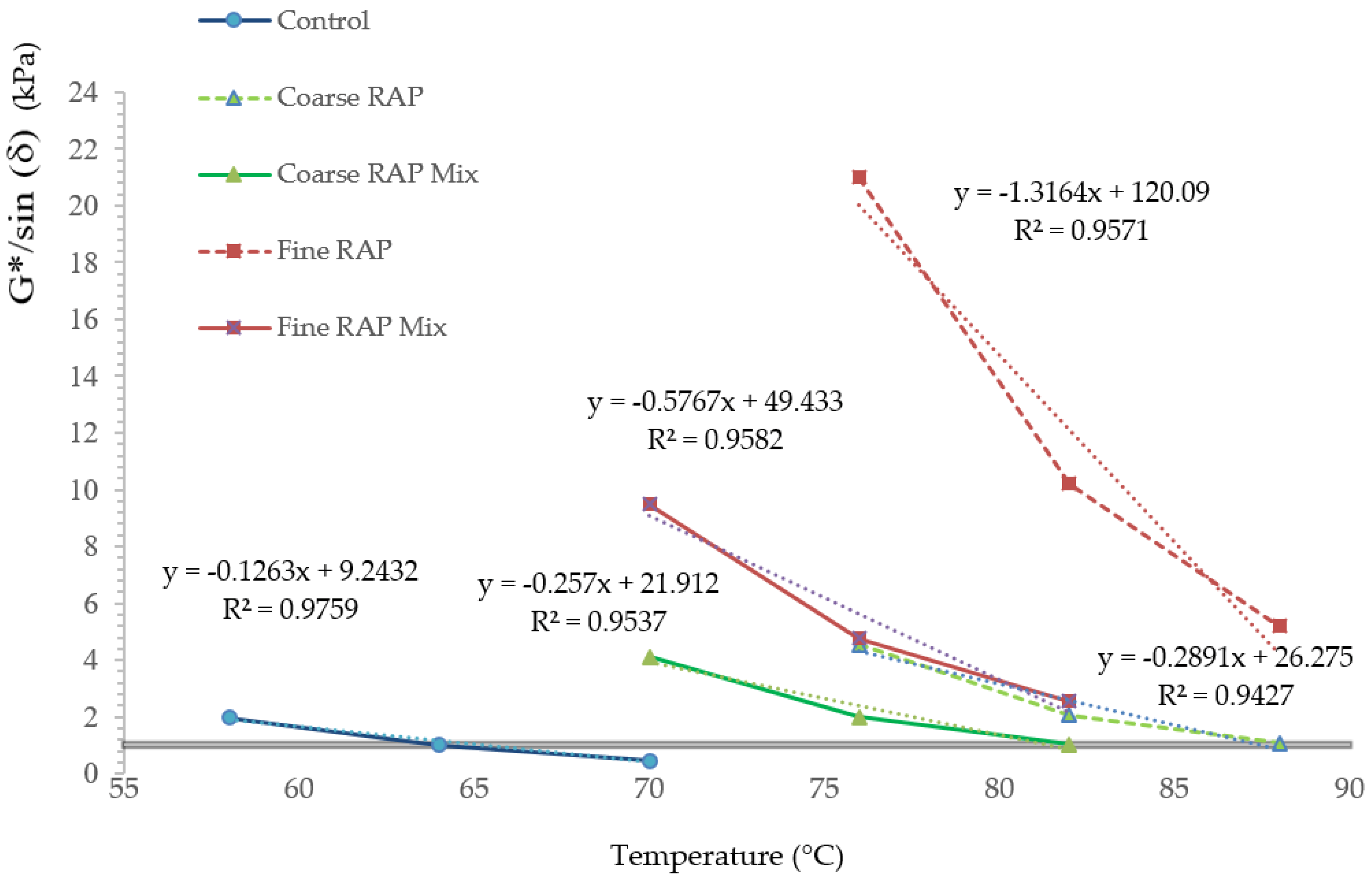

Figure 3 presents the rheological properties of each asphalt bitumen using a dynamic shear rheometer (DSR).

It was important to note that the recovered bitumen from the fine RAP was much stiffer than the recovered bitumen from the coarse RAP, even for the same RAP source that was simply split into two different groups. For example, at 76 °C and 1.6 Hz, the fine RAP bitumen was 4.6 times stiffer than the coarse RAP bitumen. Basically, the slope of each trend showed the sensitivity of that bitumen to temperature change. The control mix had the lowest sensitivity to temperature changes. Recovered bitumen from CR and CRM showed almost the same sensitivities, but recovered bitumen from FRM had less sensitivity than FR. Both CRM and FRM had the same virgin bitumen quantity (2.2%) and RAP bitumen content (2.3%). It was seen that FRM was stiffer than CRM at 76 °C (4.8 and 2 kPa, respectively), but the CRM bitumen was less sensitive than FRM to temperature change (0.25 and 0.57, respectively). In terms of the coarse and fine RAP before and after mixing with virgin bitumen, there was a huge difference from FR to FRM. This may be due to the amount of active bitumen in FR. As it was shown in a previous work [

8], more RAP bitumen was transferred from coarse RAP than fine RAP particles because fine RAP particles were covered by a clump of mastic that did not tend to participate as active bitumen in the mixture. Despite the fact that fine RAP particles had higher aged bitumen content, participation by volume was less for the bitumen surrounding the coarse RAP particles in HMA.

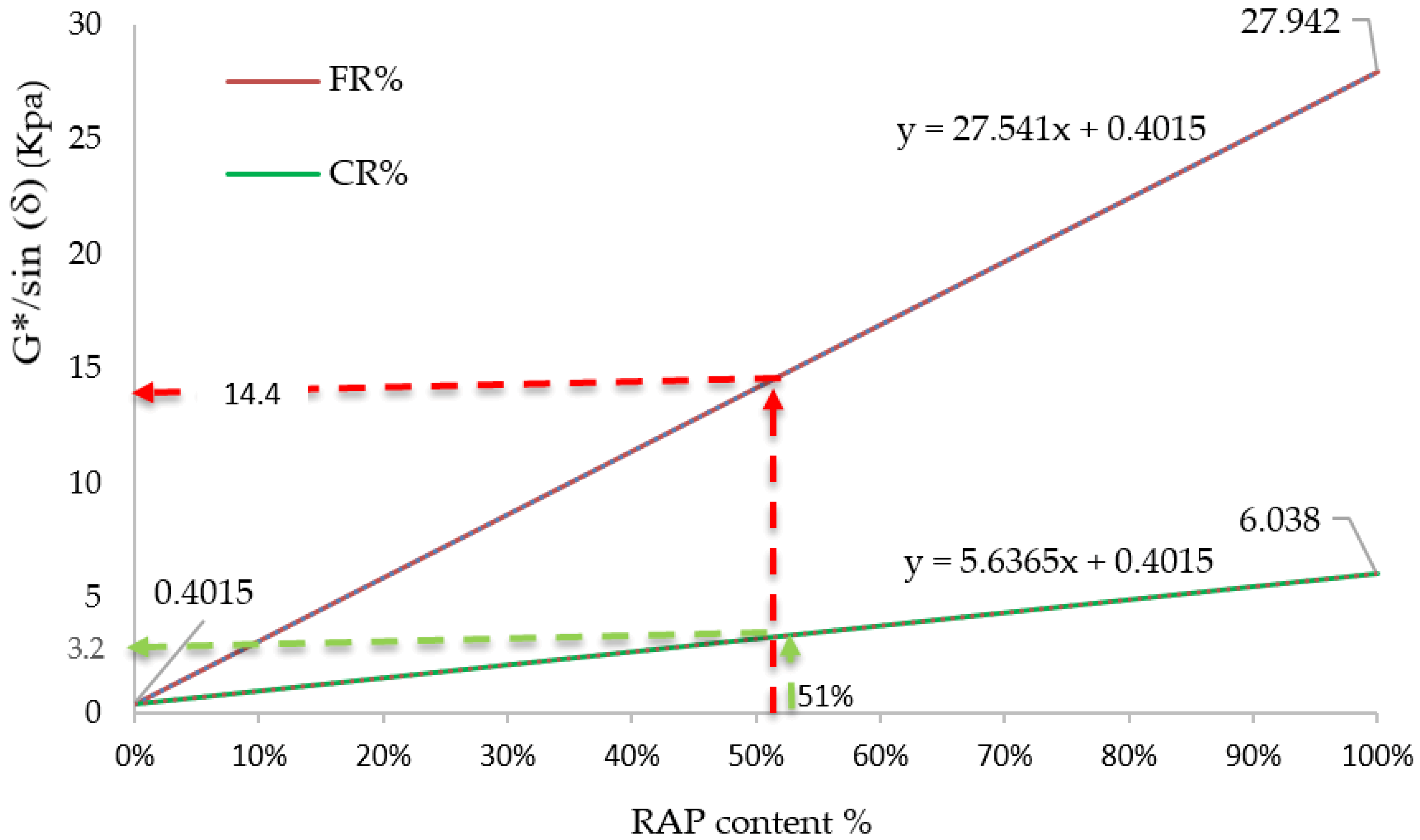

One method that has been extensively used to evaluate the PG of virgin bitumen, in adding to HMA containing a high amount of RAP, is the blending chart [

29]. In blending, it is assumed that there is a linear relationship between the amount of RAP bitumen and the rigidity (or DSR results) at a given temperature.

Figure 4 shows a blending chart for the tested mix. To get results for all mixes at the same temperature, linear best fit curves were drawn from the results shown in

Figure 3 (all with R2 > 0.95), and results were calculated for missing temperatures. At 70 °C, G*/sin(d) value of control mix (0.4 KPa) was referred to as 0% coarse rap content, and G*/sin(d) value of CR (6.038 KPa) was referred to as 100% coarse rap content. With these two values, the linear relationship between coarse RAP bitumen content and rigidity was plotted in

Figure 4. The linear best fit curve for fine rap content was drawn at 70 °C and 1.6 Hz as well as in

Figure 4.

As shown in

Figure 4, if we compare mixes with 51% FR or CR RAP, we have G*/sin (d) values of 14.4 and 3.2 KPa respectively. It showed that a mix with CR binder had a huge difference in shear modulus from the same mix with FR. It might be because the bitumen aging rate around finer particles is faster than the binder surrounding coarse particles, but more studies are needed to precisely verify this hypothesis. It may also be because fine particles have more surface area than coarse particles. Clearly, 51% CR had the same impact as 11% FR in mixes. Thus, it was important to clarify properly characterized RAP bitumen for a given particle size before mixing with virgin materials.

3.2. Shear Modulus (G*)

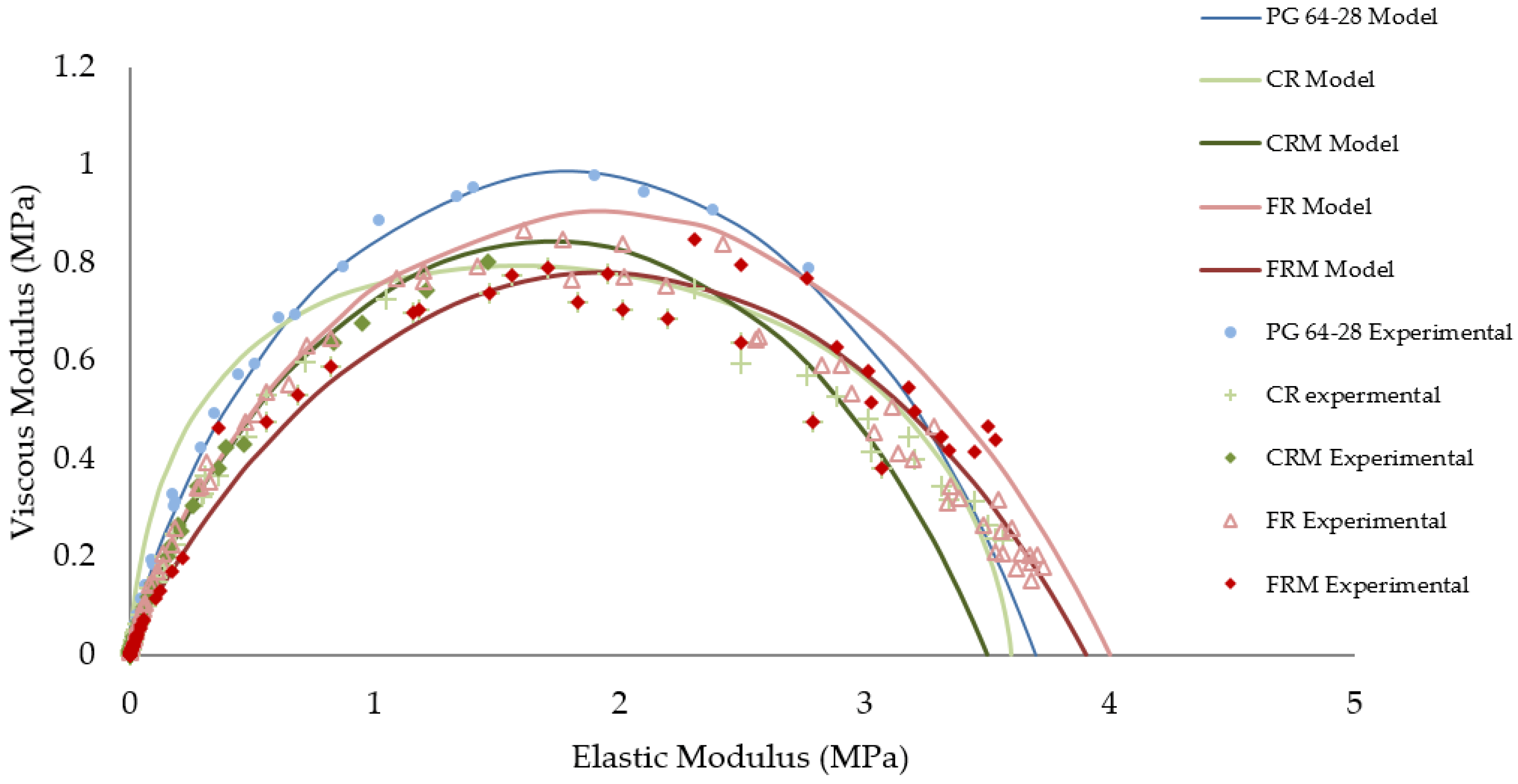

Figure 5 shows the 2S2P1D Cole–Cole plot of the shear complex modulus at different temperatures and frequencies for all recovered bitumen from CR, CRM, FR, FRM, and control mix. 2S2P1D was adopted to model the shear modulus of recovered bitumen. From

Figure 5, it seemed that the virgin bitumen (PG64-28) was more viscous than the other bitumen.

Table 2 shows the seven constant values for all four mixes. As mentioned earlier, these seven constants represented the bitumen characteristics. In general, the same binder was supposed to have equal values for the constants.

Table 2 shows that the constants were not the same, so it could be concluded that recovered binder from FR was not the same as CR. Virgin bitumen was expected to have higher viscous components. Aged binder lost some parts of its viscous components and became brittle, so it mixed with aged bitumen and had a lower viscosity than virgin bitumen.

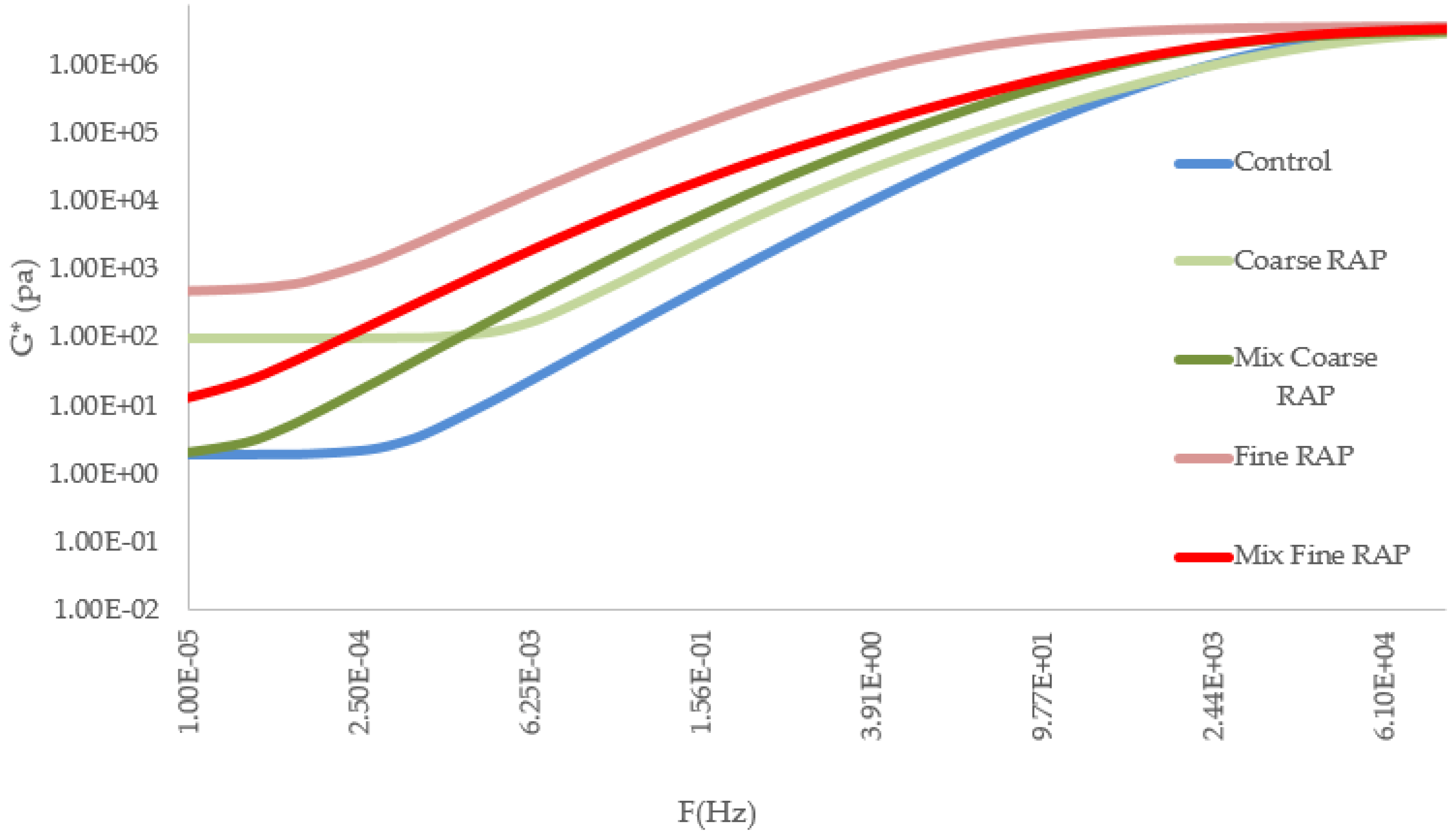

Figure 6 shows the master curve of shear modulus (Pa). The G* values of FR and CR were higher than the other mixes. Asphalt production, lifetime, and presence of air impacted the aging progress. A single source of RAP was used for CR and FR. Then, since all these factors were the same for CR and FR, the recovered bitumen was supposed to have the same master curve.

Figure 6 shows that, except for the mentioned factors, particle size may change the rheology of bitumen. This was because FR and CR mixes had higher aged bitumen content than CRM and FRM at intermediate and lower frequencies. FR was stiffer than CR, which meant that the finer RAP particles were covered by a stiffer bitumen. This could be explained as bitumen that surrounded fine particles aged faster than when they surrounded coarse particles; a higher surface area of the bitumen was exposed to oxidative aging. After mixing the coarse and fine RAP with virgin materials, master curves from recovered bitumen were plotted. Here, we again saw that FRM was stiffer than CRM at intermediate and lower frequencies.

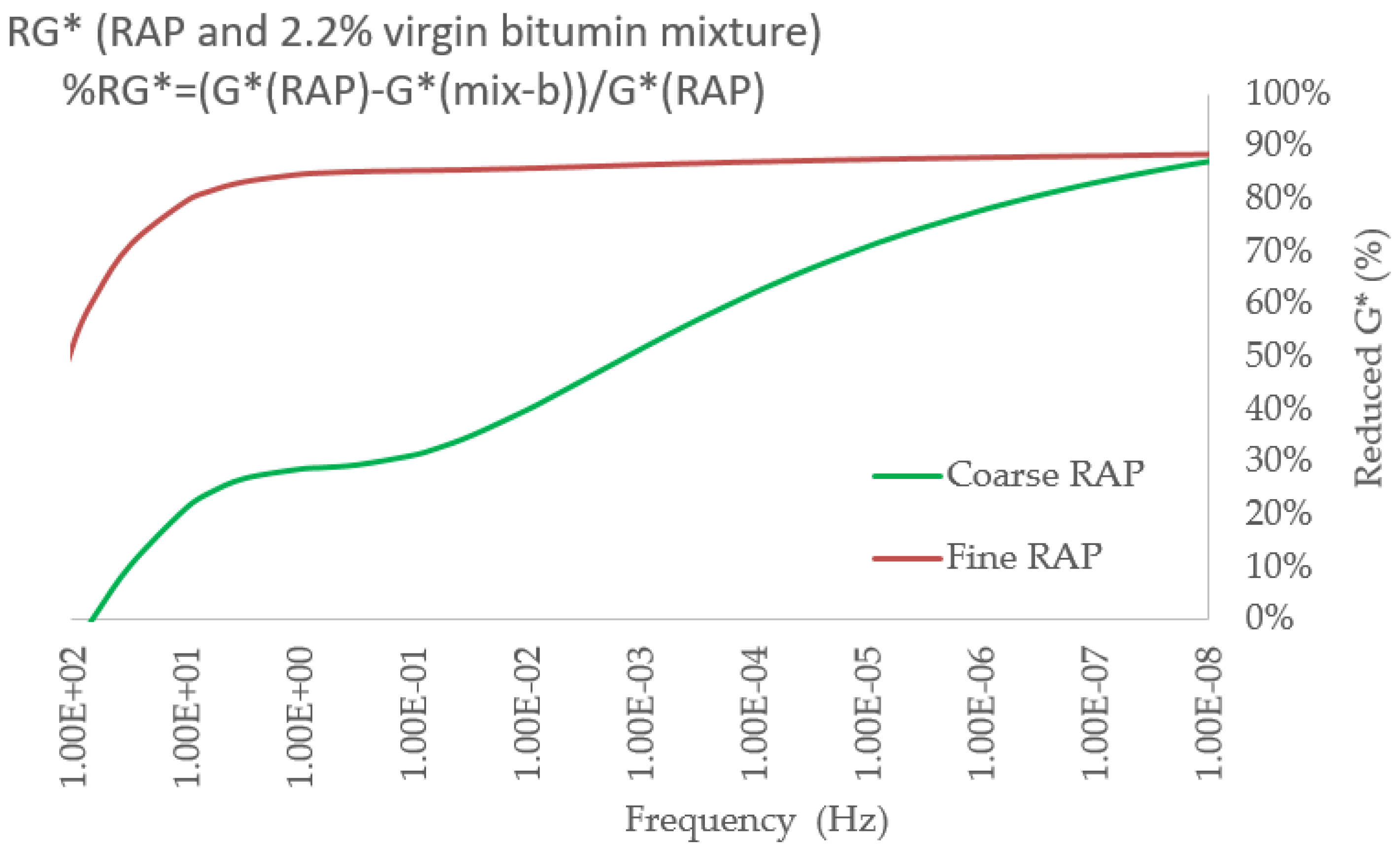

The Reduced G* (RG*) index was looked at to clarify the interaction of RAP bitumen with virgin bitumen according to RAP particles. G* was determined for CR and FR as well as for CRM and FRM. According to CRM (FRM) mix design, CR (or FR) was added to the 2.2% virgin bitumen. The difference between CR (or FR) and CRM (FRM) showed the impact of virgin bitumen on total bitumen stiffness. (RG*) is calculated by Equation (2) as a percentage:

where

RG* is the percentage of reduced G*, G*

i is the shear modulus of pure RAP, and G*

iM is the shear moduli of RAP and virgin bitumen mixes. The difference of G*

i and G*

iM showed how well the bitumen mixed together. As the aged bitumen was stiffer than virgin bitumen, eventually G*

i was supposed to be higher than G*

iM.

Figure 7 indicates the rheology transition before and after mixing RAP with virgin materials. Both CR and FR mixed with 2.2% virgin binder. Most of the influence of aged binder was observed at low frequency. The difference between aged bitumen and mixture bitumen changed from 0% to 90%. These differences meant rigidity was changed. FRM was 90% softer than FR; it increased rapidly and was constant over a wide frequency range. The impact of CR clearly differed from FR. The different trends in CR and FR could translate to the impact of each type of RAP on virgin bitumen. CR and CRM had the same rigidities at high frequency and gradually increased at low frequency. CR and FR bitumen recovered from a single source of recycled asphalt were supposed to have the same characteristics when blended with a specific amount of virgin bitumen, but the interactions were different. Aging rates were not the same between fine gradation and coarse gradation.

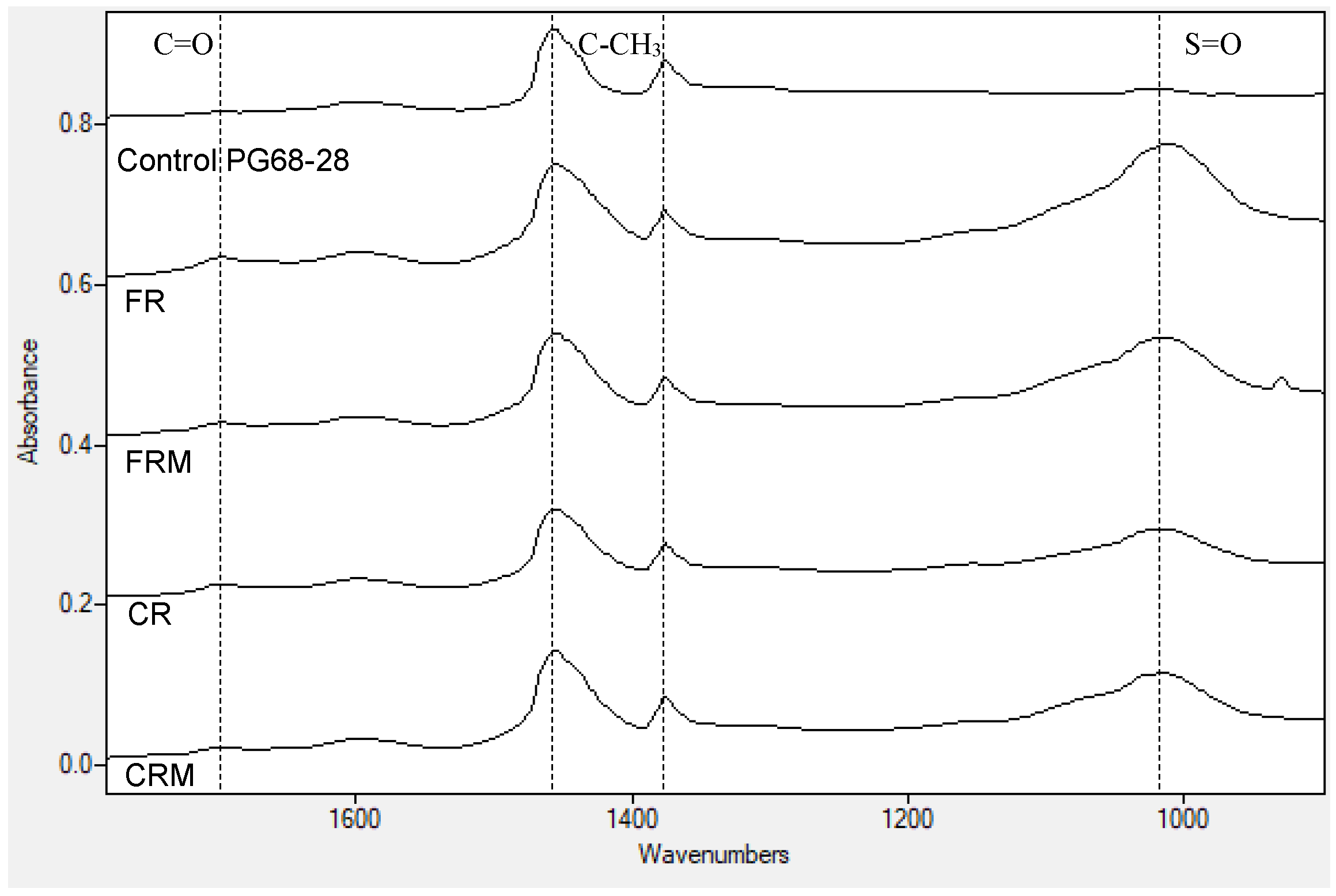

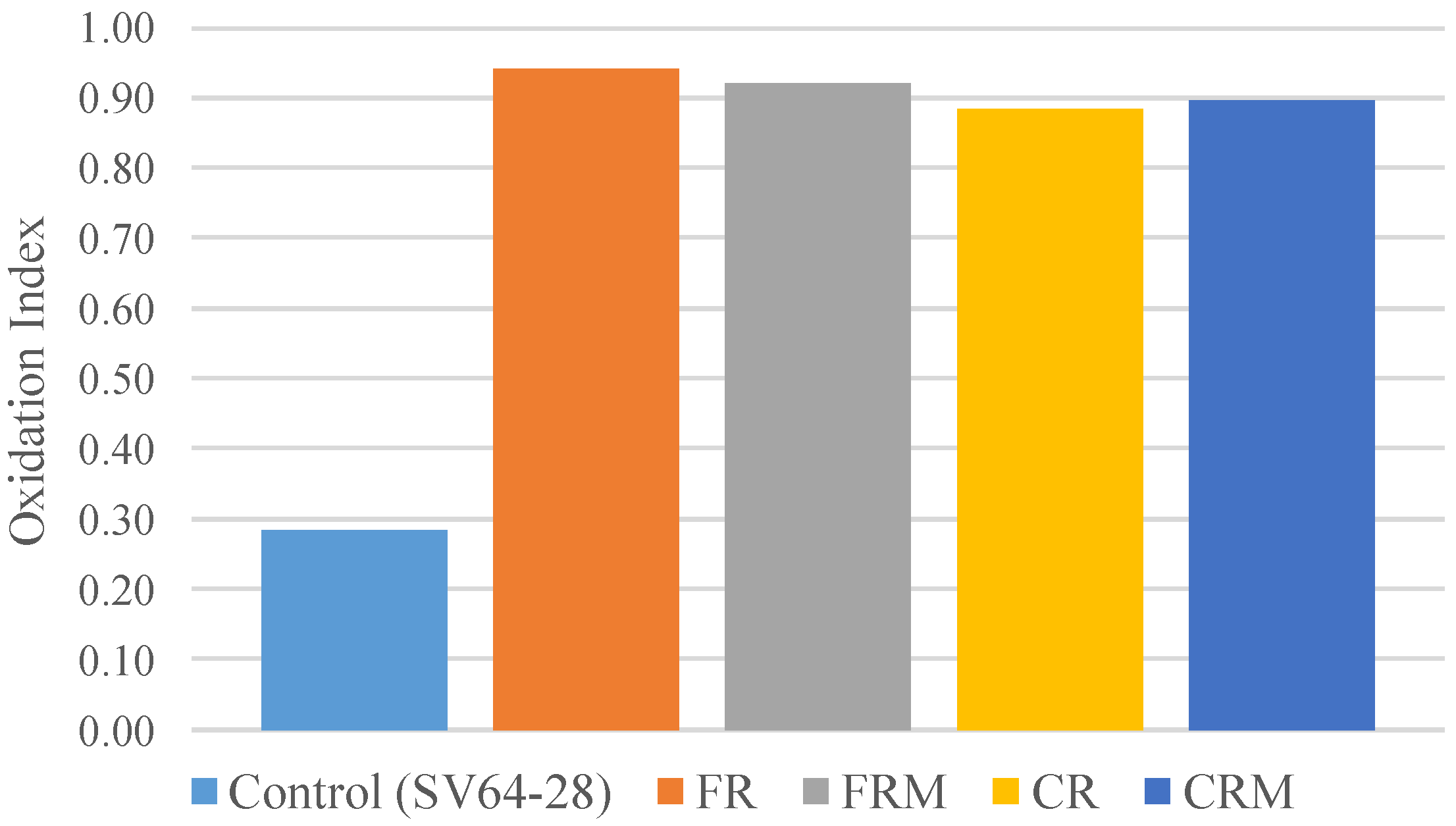

3.3. FTIR–ATR Spectrometry

The results for the FTIR–ATR analysis are presented in

Figure 8,

Figure 9 and

Figure 10. Asphalt aging was characterized by oxidization indices shown in

Table 1. The C=O and S=O indices both increased significantly with RAP and blended bitumen relative to the virgin bitumen. There was a small increase in the RAP bitumen compared to the blended bitumen in the indices. The aging indices were higher for the fine RAP, likely because of its higher surface area, compared to the course RAP, which allowed for a greater degree of aging. The sulfoxide indices for all bitumen were higher, as was typical for asphalt bitumen [

30].

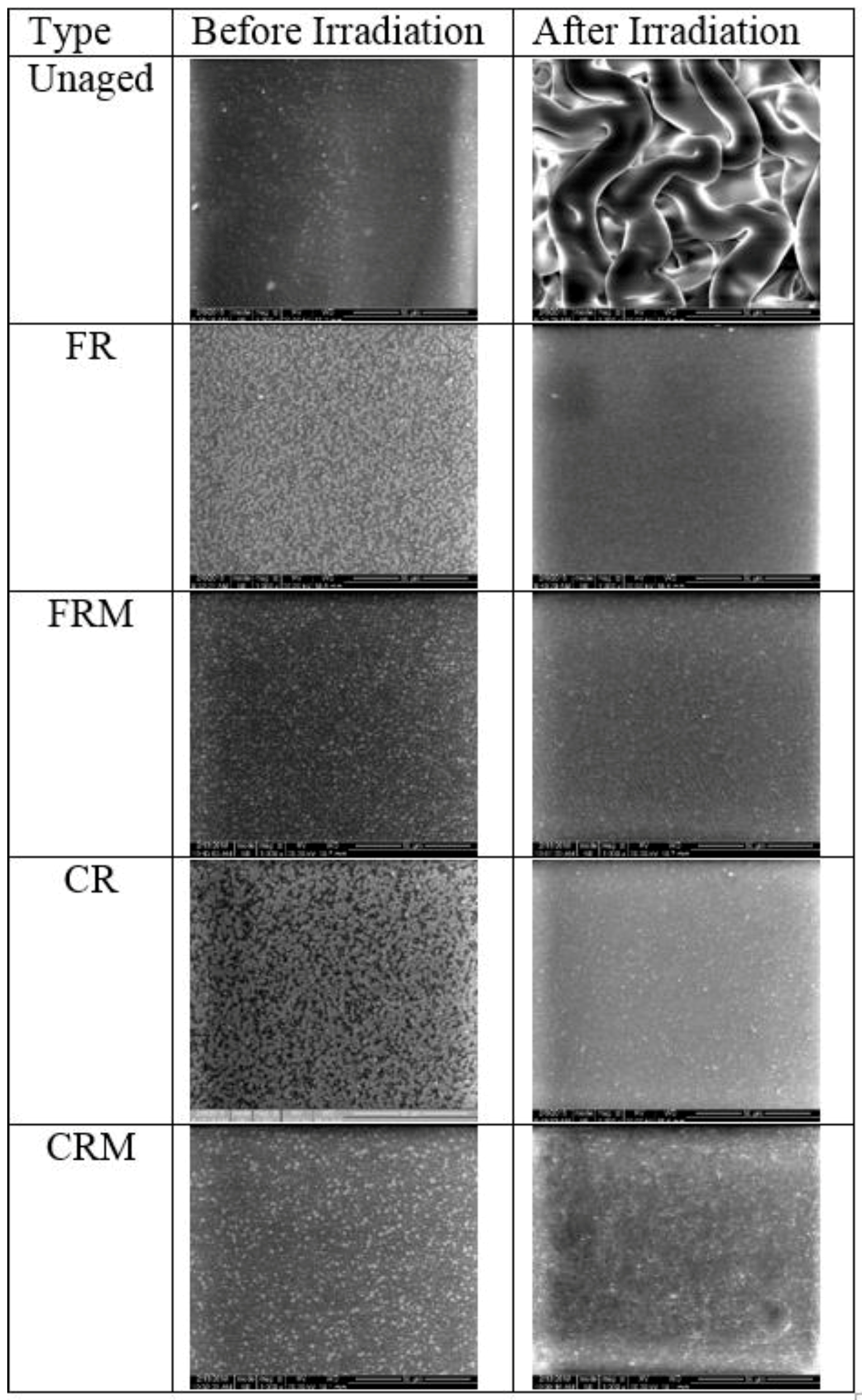

3.4. Environmental Scanning Electron Microscopy (ESEM) Analysis

The images from the ESEM analysis are shown in

Figure 11, before electron beam irradiation and after stabilization of the sample. The bitumen before irradiation showed a ‘bee’ type structure, similar to the one found in AFM observations [

31,

32], which was denser in the RAP bitumen compared to the virgin and blended bitumen.

After the sample was exposed to the electron beam, and the accumulation of energy irradiated the sample, the asphalt bitumen tended to reveal a ‘fibril’ microstructure as lighter components of the bitumen dispersed [

33], which was the case for the virgin bitumen. However, both the blended and RAP bitumen responded much less to beam irradiation. This was likely because the microstructure of the bitumen stiffened from aging, and the molecular mobility was reduced. This made revealing the microstructure by ESEM irradiation a slower and more difficult process with the settings that were used.

4. Conclusions

It is common to use green alternatives in asphalt mix designs such as recycled asphalt, crumb rubber, etc. Several studies showed the advantages of RAP in hot mix asphalt. Still, there is no clear vision of the impact RAP size has on HMA behavior. In this study, a single Quebec source of RAP was separated into coarse and fine particles and mixed in with bitumen pavement mixture. Properties of the asphalt mixes were evaluated by the complex modulus test and DSR. Also, the ignition test (ASTM D6307) was used to quantify bitumen content in the RAP, FTIR spectrometry was used for chemical properties of the bitumen, while ESEM image analysis was used to visualize the differences of the virgin and RAP bitumen at a microscopic level.

FRM was designed with 35% fine RAP particles, including 2.3% aged bitumen and 2.2% virgin bitumen. CRM was designed with 54% coarse RAP particles, including 2.3% aged bitumen and 2.2% virgin bitumen. Recovered bitumen (4.3%) was measured for CR particles, and bitumen content was 6.6% for FR particles. Designed mixes were compared with the control mix, and the following results were achieved:

FR-recovered bitumen is more sensitive to temperature changes than virgin and CR-recovered bitumen.

FR-recovered bitumen is stiffer than CR-recovered bitumen. Also, FRM-recovered bitumen is stiffer than CRM-recovered bitumen. This shows that the bitumen grade of coarse particles is not the same as fine particles in RAP.

Reduced G* (RG*) was looked at to clarify the interaction of RAP bitumen with virgin bitumen according to RAP particles. The CR reduced factor was higher than FR; CR bitumen and CRM bitumen were more similar than FR and FRM. This factor might be applied in mixing designs to predict the stiffness of HMA with the inclusion of RAP, which is the case for future studies.

Aging rates in fine particles are faster than coarse particles because fine RAP has a higher surface area.

Results for the FTIR–ATR analysis showed aging indices are higher for the fine RAP, likely because of its higher surface area compared to the course, which allowed for a greater degree of aging.

Images from the ESEM analysis shows both the blended and RAP bitumen respond much less to beam irradiation. This is likely because the bitumen microstructure stiffened from aging.

More work is needed to better understand the impact of RAP gradation. The results shown here definitely give new information about different RAP bitumen contained in different sizes, but new tests with several other RAP size are needed to confirm the results presented here.

Author Contributions

S.S.S. conceived of the presented idea. A.C. and H.B. developed the theory and verified the analytical methods and supervised the project. S.S.S. wrote the original draft; and P.M. wrote, reviewed, and edited the manuscript. All authors discussed the results and contributed to the final manuscript.

Funding

This research was funded by The Pavements and Bituminous Materials Laboratory (LCMB).

Acknowledgments

This work was supported by The Pavements and Bituminous Materials Laboratory (LCMB) and the Centre for Pavement and Transportation Technology (CPATT). The authors would like to thank the companies in Quebec that provided us with the materials for the project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- McDaniel, R.S.; Shah, A.; Huber, G.A.; Copeland, A. Effects of reclaimed asphalt pavement content and virgin binder grade on properties of plant produced mixtures. Road Mater. Pavement Des. 2012, 13 (Suppl. 1), 161–182. [Google Scholar] [CrossRef]

- Mogawer, W.; Austerman, A.; Mohammad, L.; Kutay, M.E. Evaluation of high RAP-WMA asphalt rubber mixtures. Road Mater. Pavement Des. 2013, 14 (Suppl. 2), 129–147. [Google Scholar] [CrossRef]

- Sias Daniel, J.; Gibson, N.; Tarbox, S.; Copeland, A.; Andriescu, A. Effect of long-term ageing on RAP mixtures: Laboratory evaluation of plant-produced mixtures. Road Mater. Pavement Des. 2013, 14 (Suppl. 2), 173–192. [Google Scholar] [CrossRef]

- Visintine, B.; Khosla, N.P.; Tayebali, A. Effects of higher percentage of recycled asphalt pavement on pavement performance. Road Mater. Pavement Des. 2013, 14, 432–437. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Carpenter, S.H.; Roberts, G.; Ozer, H.; Aurangzeb, Q.; Elseifi, M. Determination of Usable Residual Asphalt Binder in RAP; Illinois Center for Transportation (ICT): Rantoul, IL, USA, 2009. [Google Scholar]

- Perraton, D.; Baaj, H.; Carter, A. Comparison of Some Pavement Design Methods from a Fatigue Point of View: Effect of Fatigue Properties of Asphalt Materials. Road Mater. Pavement Des. 2010, 11, 833–861. [Google Scholar] [CrossRef]

- Saliani, S.S.; Carter, A.; Baaj, H.; Badeli, S. Investigation of the tensile strength of hot mix asphalt incorporating pulp aramid fiber. In Proceedings of the Sixth-Second Annual Conference of the Canadian Technical Asphalt Association (CTAA), Halifax, NS, Canada, 12–15 November 2017. [Google Scholar]

- Saliani, S.S.; Carter, A.; Baaj, H. Investigation of the impact of rap gradation on the effective binder content in hot mix asphalt. In Proceedings of the CSCE Annual Conference, London, ON, Canada, 1–6 June 2016. [Google Scholar]

- Kim, S.; Byron, T.; Sholar, G.A.; Kim, J. Evaluation of Use of High Percentage of Reclaimed Asphalt Pavement (RAP) for Superpave MixturesI; Report No. FL/DOT/SMO/07-507; Florida Department of Transportation: Tallahassee, FL, USA, 2007; Volume 103.

- Mogawer, W.; Bennert, T.; Daniel, J.; Bonaquist, R.; Austerman, A.J.; Booshehrian, A. Performance characteristics of plant produced high RAP mixtures. Road Mater. Pavement 2012, 13 (Suppl. 2), 183–208. [Google Scholar] [CrossRef]

- Munoz, J.S.C.; Kaseer, F.; Arambula, E.; Martin, A.E. Use of the resilient modulus test to characterize asphalt mixtures with recycled materials and recycling agents. Transp. Res. Rec. J. Transp. Res. Board 2015, 2506, 45–53. [Google Scholar] [CrossRef]

- Kaseer, F.; Yin, F.; Arámbula-Mercado, E.; Martin, A.E. Stiffness characterization of asphalt mixtures ith high recycled materials contents and recycling agents. Transp. Res. Rec. J. Transp. Res. Board 2017, 2633, 58–68. [Google Scholar] [CrossRef]

- Kaseer, F.; Cucalon, L.G.; Arámbula-Mercado, E.; Martin, A.E.; Epps, J. Practical tools for optimizing recycled materials content and recycling agent dosage for improved short-and long-term performance of rejuvenated binder blends and mixtures. J. Assoc. Asph. Paving Technol. 2018, 33–34, 87. [Google Scholar]

- Kaseer, F.; Martin, A.E.; Arámbula-Mercado, E. Use of recycling agents in asphalt mixtures with high recycled materials contents in the United States: A literature review. Constr. Build. Mater. 2019, 211, 974–987. [Google Scholar] [CrossRef]

- McDaniel, R.S.; Soleymani, H.; Anderson, R.M.; Turner, P.; Peterson, R. Recommended Use of Reclaimed Asphalt Pavement in the SuperPave™ Mixture Design Method; NCHRP Final Report (9–12), TRB; National Research Council: Washington, DC, USA, 2000.

- Bennert, T.; Dongre, R. A Back Calculation Method to Determine “Effective” Asphalt Binder Properties of RAP Mixtures; Transportation Research Board: Washington, DC, USA, 2010. [Google Scholar]

- Bonaquist, R. New Approach for the Design of High RAP HMA. Presented at the 2005 Northeast Asphalt User’s Producer’s Group Meeting, Burlington, NJ, USA, 19–20 October 2005. [Google Scholar]

- Rowe, G. Phase angle determination and interrelationships within bituminous materials. In Proceedings of the 7th International RILEM Symposium on Advanced Testing and Characterization of Bituminous Materials, Rhodes, Greece, 27–29 May 2009. [Google Scholar]

- Bressi, S.; Cavalli, M.C.; Partl, M.N.; Tebaldi, G.; Dumont, A.G.; Poulikakos, L.D. Particle clustering phenomena in hot asphalt mixtures with high content of reclaimed asphalt pavements. Constr. Build. Mater. 2015, 100, 207–217. [Google Scholar] [CrossRef]

- Stroup-Gardiner, M.; Wagner, C. Use of reclaimed asphalt pavement in Superpave hot-mix asphalt applications. Transp. Res. Rec. 1999, 1681, 1–9. [Google Scholar] [CrossRef]

- Kaseer, F.; Arámbula-Mercado, E.; Martin, A.E. A Method to Quantify Reclaimed Asphalt Pavement Binder Availability (Effective RAP Binder) in Recycled Asphalt Mixes; Transportation Research Record: Washington, DC, USA, 2019; p. 0361198118821366.

- Jin, X.; Cui, Y.; Glover, C.J. Modeling Asphalt Oxidation in Pavement with Field Validation. Pet. Sci. Technol. 2013, 31, 1398–1405. [Google Scholar] [CrossRef]

- Rose, A.A.; Arambula, E.; Howell, T.; Glover, C.J. An X-Ray CT Validated Laboratory Measurement Method for Air Voids Distribution over Depth in Asphalt Pavement: A Step toward Simplified Oxidation Modeling. Pet. Sci. Technol. 2014, 32, 3020–3028. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials-PP6. Practice for Grading or Verifying the Performance Grade of an Asphalt Binder; AASHTO Provisional Standards; AASHTO: Washington, DC, USA, 1994. [Google Scholar]

- American Association of State Highway and Transportation Officials-T-315. Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); AASHTO Provisional Standards; AASHTO: Washington, DC, USA, 2012. [Google Scholar]

- Olard, F.; Di Benedetto, H. General “2S2P1D” model and relation between the linear viscoelastic behaviours of bituminous binders and mixes. Road Mater. Pavement Des. 2003, 4, 185–224. [Google Scholar]

- Mikhailenko, P.; Bertron, A.; Ringot, E. Methods for Analyzing the Chemical Mechanisms of Bitumen Aging and Rejuvenation with FTIR Spectrometry; RILEM Publications: Ancona, Italy, 2015. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Kadhim, H.; Baaj, H.; Tighe, S. Observation of asphalt binder microstructure with ESEM. J. Microsc. 2017, 267, 347–355. [Google Scholar] [CrossRef] [PubMed]

- McDaniel, R.; Soleymani, H. Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Method; NCHRP Web Document; National Cooperative Highway Research Program: Washington, DC, USA, 2000; Available online: http://onlinepubs.trb.org/Onlinepubs/nchrp/nchrp_w30-a.pdf (accessed on 5 May 2017).

- Hofko, B.; Porot, L.; Falchetto Cannone, A.; Poulikakos, L.; Huber, L.; Lu, X.; Grothe, H. FTIR spectral analysis of bituminous binders: Reproducibility and impact of ageing temperature. Mater. Struct. 2018, 51, 45. [Google Scholar] [CrossRef]

- Das, P.K.; Baaj, H.; Tighe, S.; Kringos, N. Atomic force microscopy to investigate asphalt binders: A state-of-the-art review. Road Mater. Pavement Des. 2016, 17, 693–718. [Google Scholar] [CrossRef]

- Oenen, H.; Besamusca, J.; Fischer, H.R.; Poulikakos, L.D.; Planche, J.-P.; Das, P.K.; Chailleux, E. Laboratory investigation of bitumen based on round robin DSC and AFM tests. Mater. Struct. 2013, 47, 1205–1220. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Kou, C.; Baaj, H.; Poulikakos, L.; Cannone-Falchetto, A.; Besamusca, J.; Hofko, B. Comparison of ESEM and physical properties of virgin and laboratory aged asphalt binders. Fuel 2019, 235, 627–638. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).