Sustainable Materials for Transportation Infrastructures: Comparison of Three Commercially-Available Metakaolin Products in Binary Cementitious Systems

Abstract

:1. Introduction

- Reduce costs

- Improve fresh and hardened properties of concrete, including durability

- Reduce environmental impact

- Reuse waste materials

- Enhance aesthetics

1.1. Background

1.2. Objective

- For each metakaolin product, what is the effect of replacement level on fresh and hardened concrete performance?

- Are there significant differences in effect on concrete performance between metakaolin products? If so, how large is the variation, and what are the primary contributors to the change in concrete properties?

- Can general guidelines be given for the inclusion of commercially-available metakaolin in concrete?

2. Materials and Methods

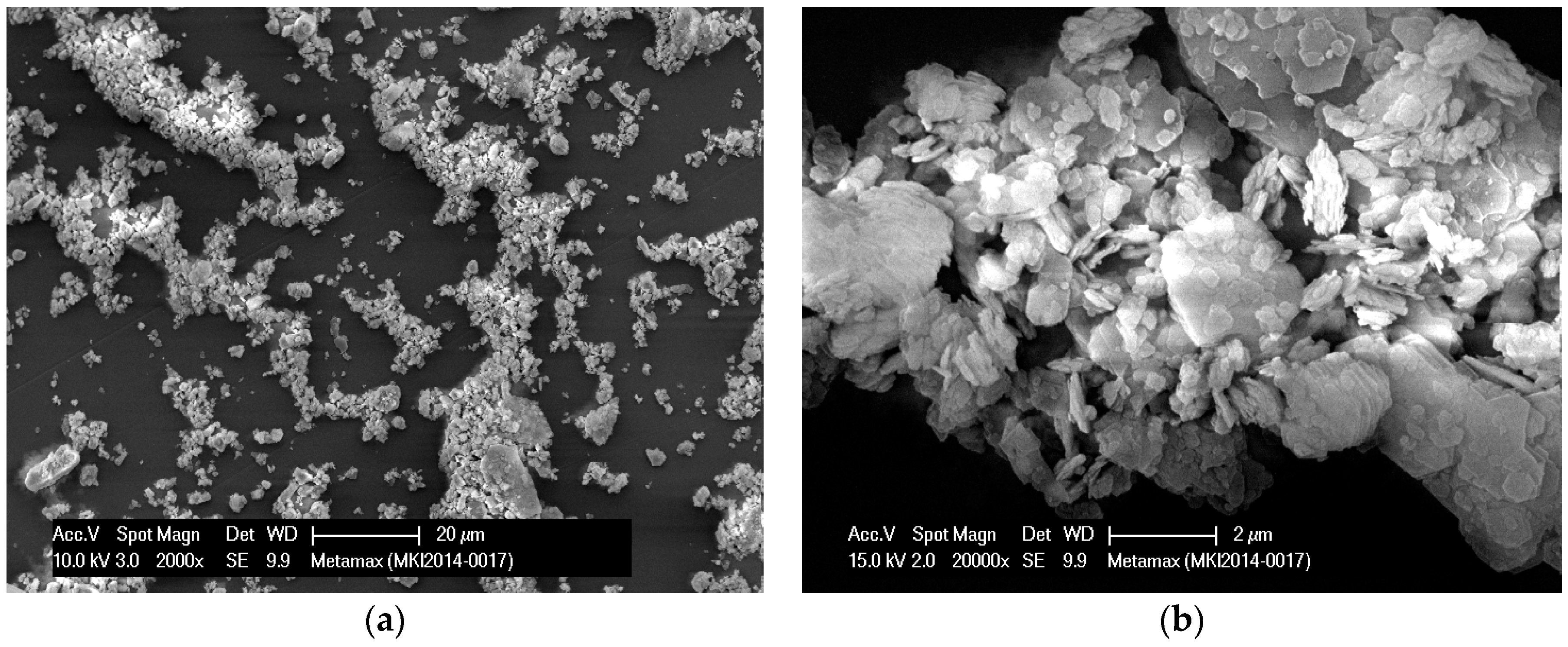

2.1. Materials

2.2. Mixture Design

2.3. Batching and Molding

2.4. Experimental Plan

2.4.1. Fresh Properties

2.4.2. Mechanical Properties

2.4.3. Durability

2.4.4. Dimensional Stability

3. Results

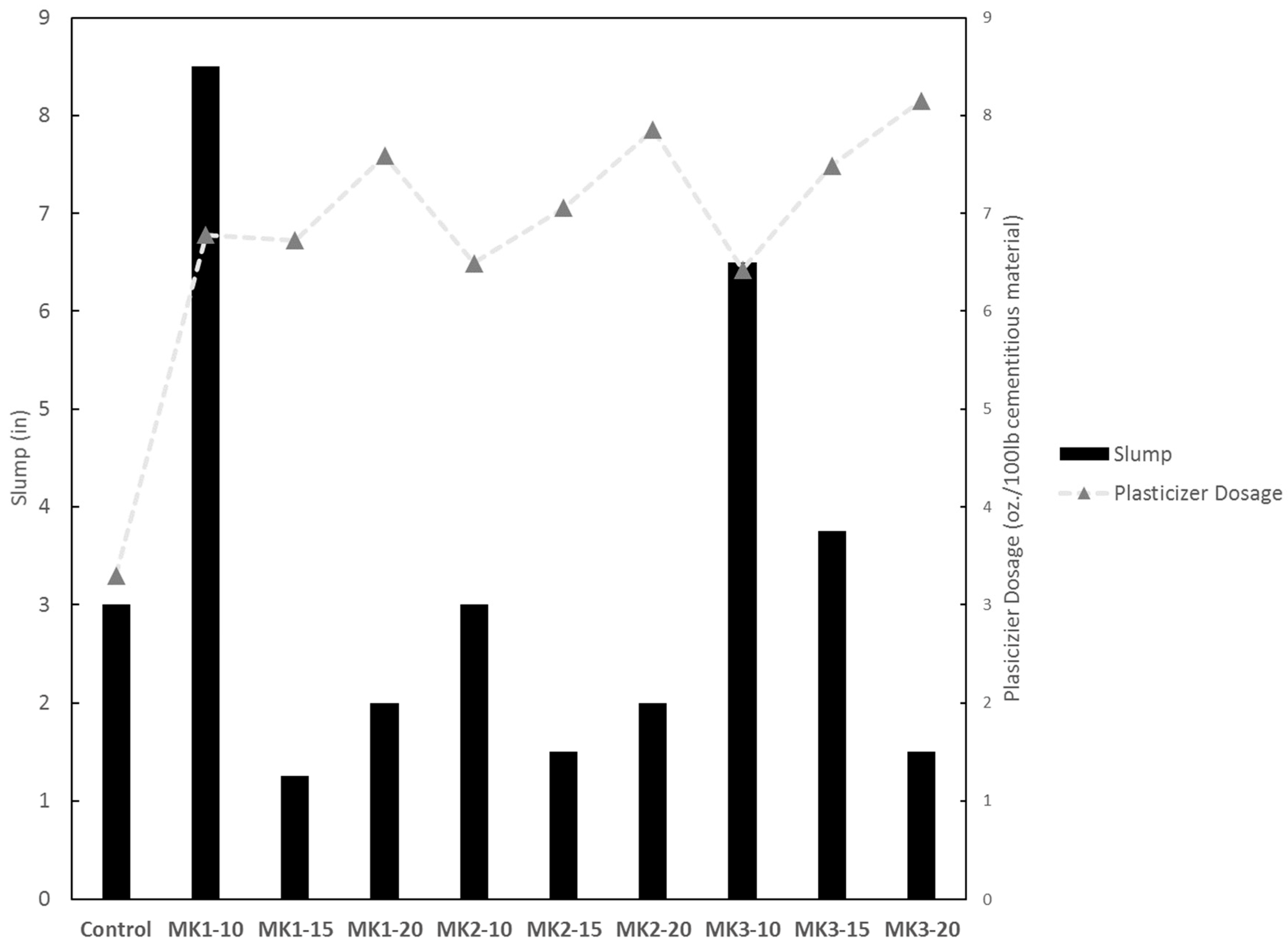

3.1. Fresh Concrete Properties

3.2. Mechanical Properties

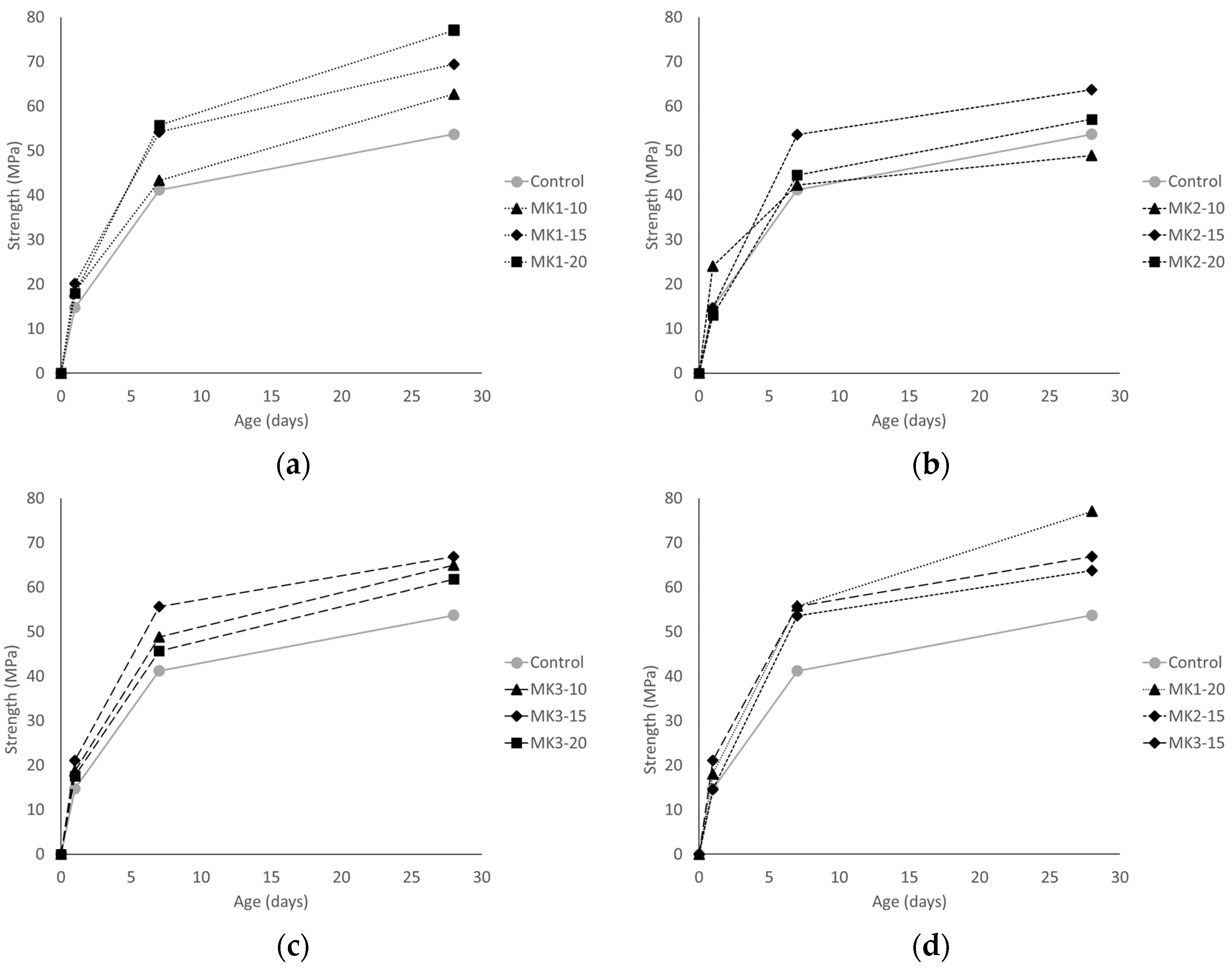

3.2.1. Compression

3.2.2. Tensile Strength

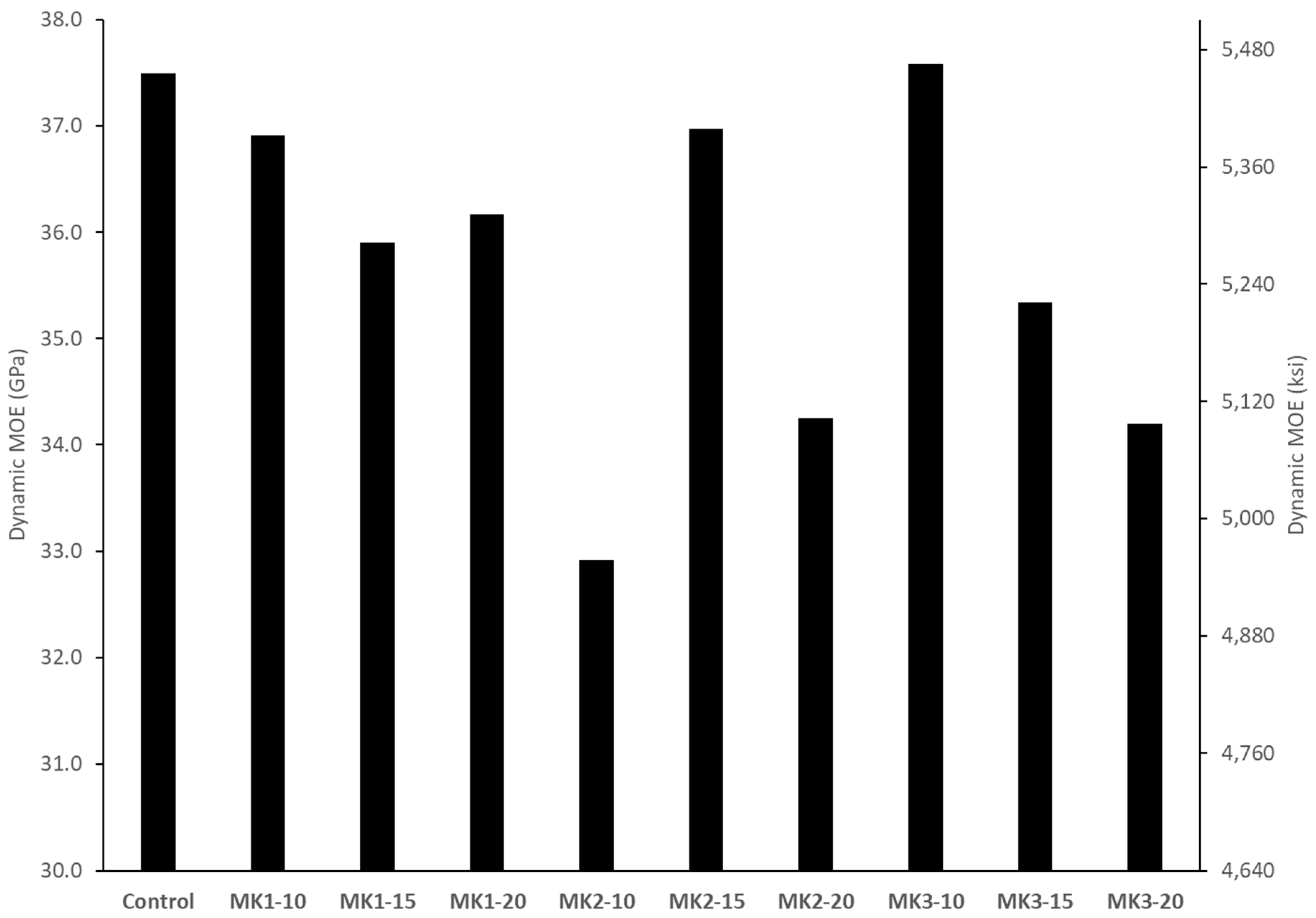

3.2.3. Dynamic Young’s Modulus

3.3. Durability

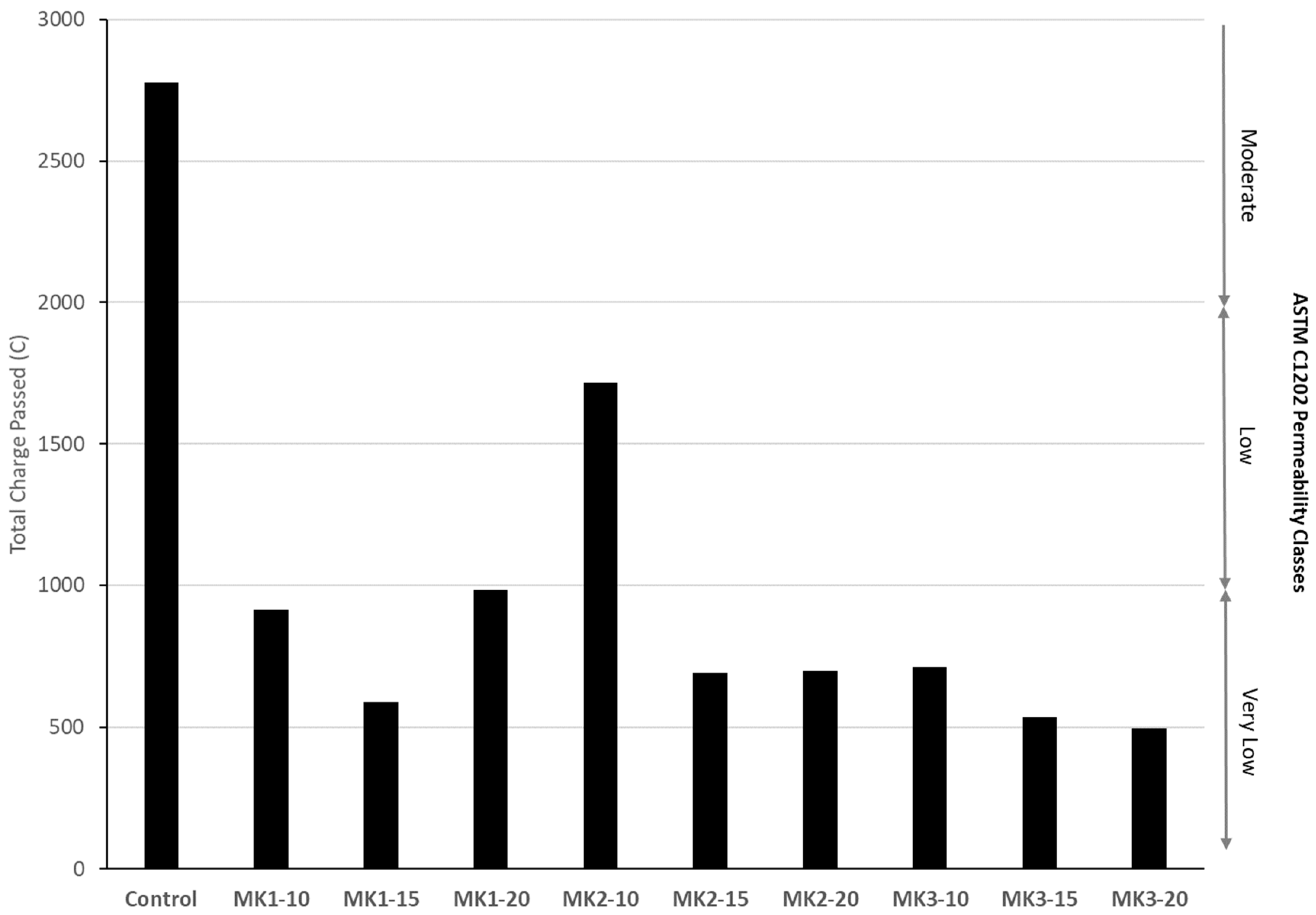

3.3.1. Chloride-Ion Penetrability

3.3.2. Alkali–Silica Reactivity

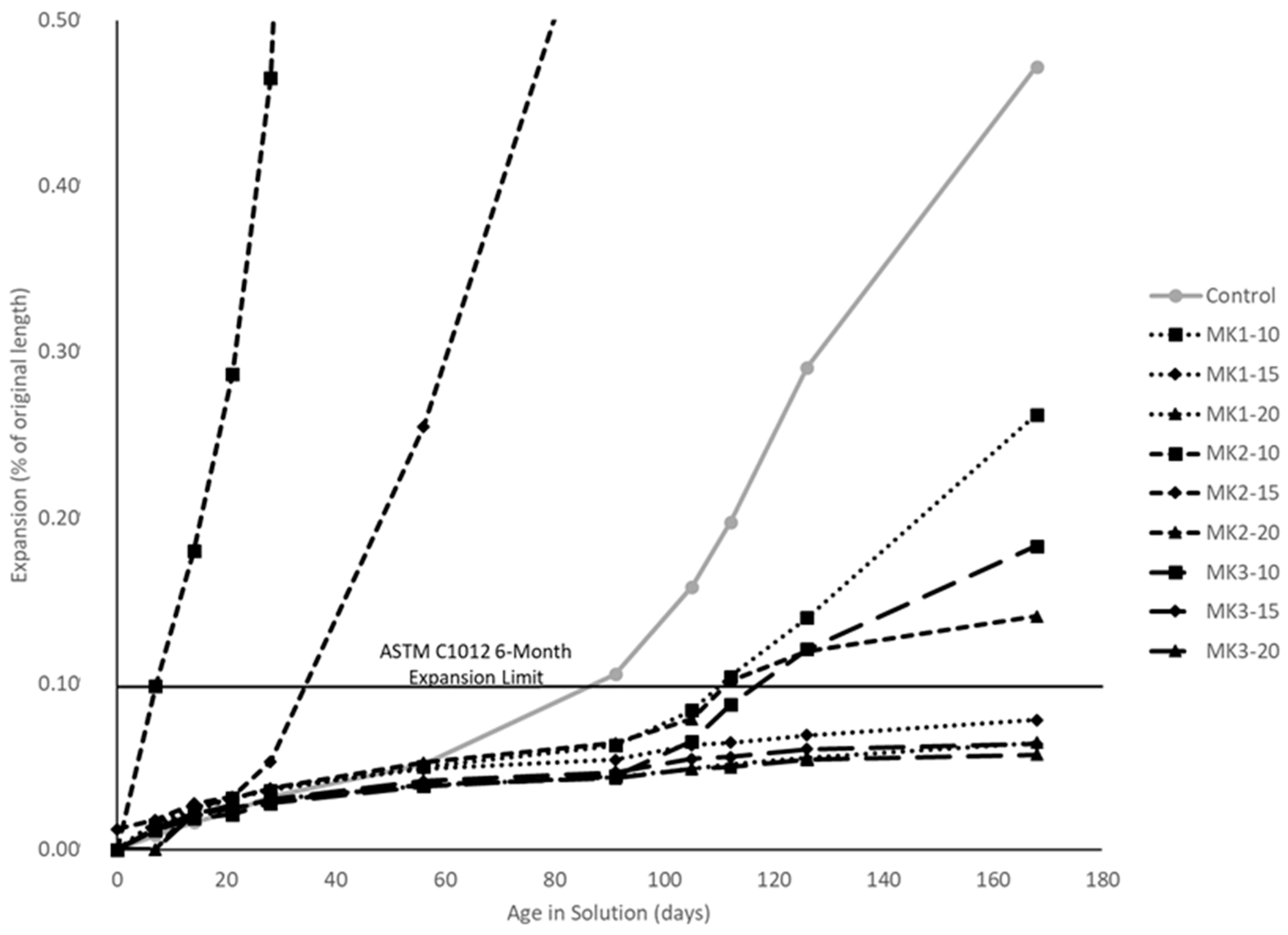

3.3.3. Sulfate Resistance

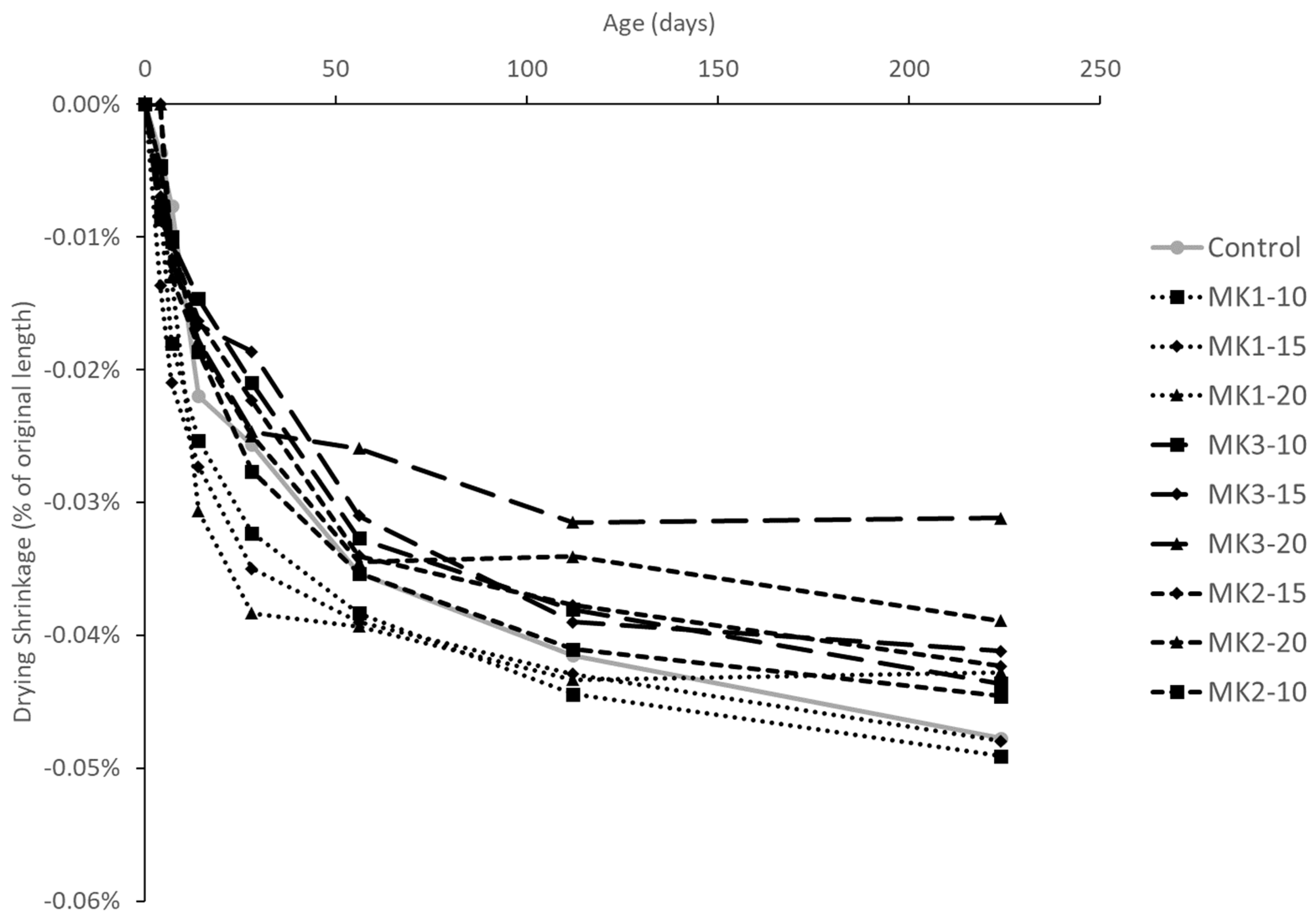

3.4. Dimensional Stability

4. Analysis of Results and Discussion

4.1. Summary

4.2. Replacement Levels

4.3. Abnormalities

- MK2’s high fineness resulted in large agglomerations which were not properly deflocculated during the batching of the concrete. This would explain tensile strengths lower than control, but not the inordinate deterioration of the sulfate mortar bars.

- An incomplete dehydroxylation of the metakaolin (see [8,33]) might have occurred because MK2’s alumina and silica contents were perhaps not as glassy as MK1 and MK3. This would explain the mechanical performance as well as the rapid destruction of MK2 sulfate mortar bars, as the non-amorphous kaolin would act as inert material. For compression and permeability, the inert kaolin would still contribute to particle packing [17], and the alumina content has shown to increase chloride-binding capacity [21,27]. Moreover, the fine material would still provide additional nucleation sites for cement hydration [18]. This does not explain why the optimum replacement level for tensile strengths was 20%. Therefore, an XRD analysis is highly recommended to verify the assumption.

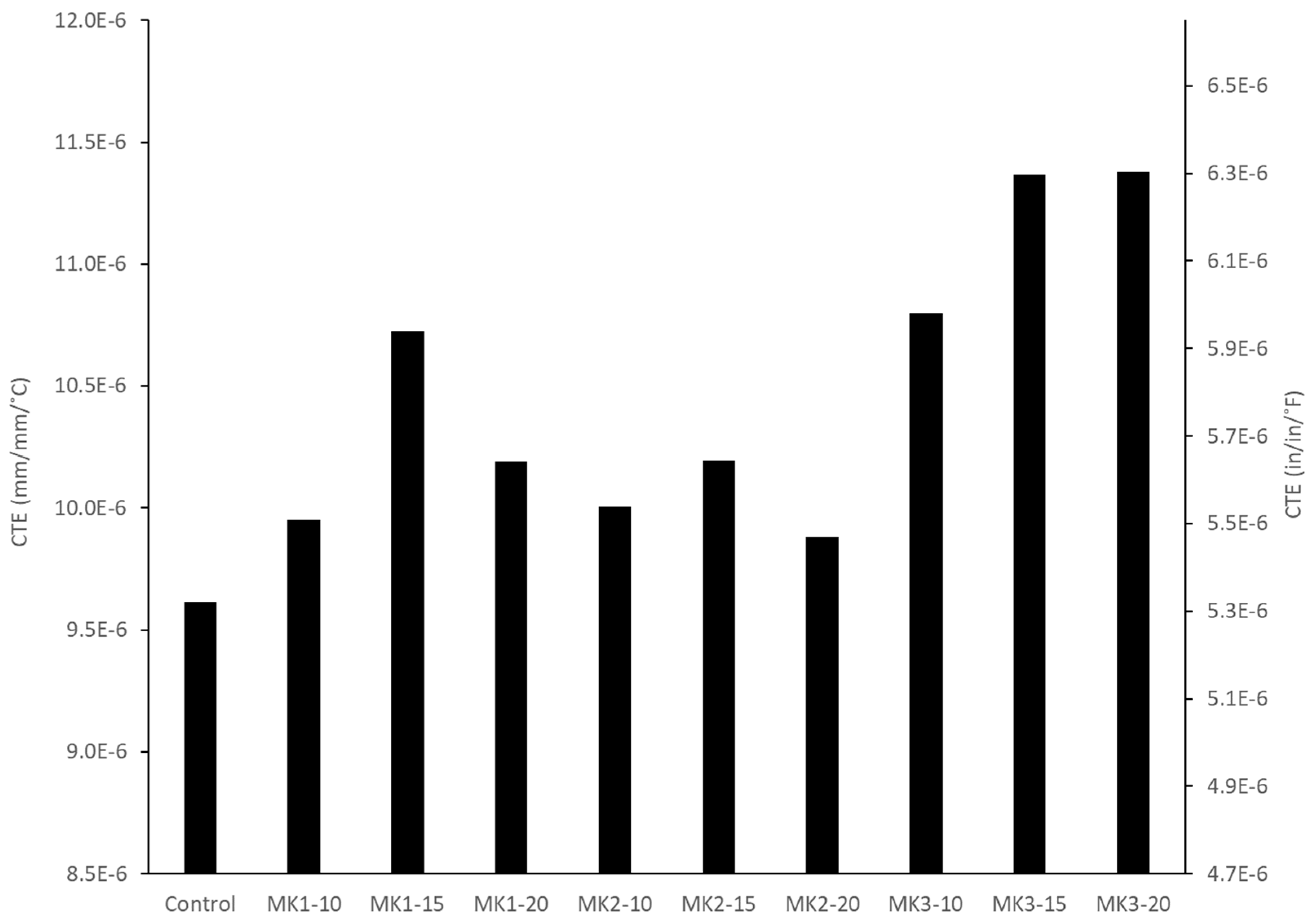

4.4. Thermal Expansion and Shrinkage

5. Conclusions

- MK1 achieves an optimum compressive strength at a 20% replacement, tensile strength at a 15% replacement and, overall, measures of durability increase systematically with increasing replacement levels. MK2 achieves an optimum compressive strength at a 15% replacement, while tensile strengths are maximized at a 20% replacement. Measures of durability of MK2 concretes vary too greatly for its use to be recommended for increased durability. MK3 performance was the most consistent amongst the metakaolins. Optimum replacements for compressive strength and tensile strengths were 15% and 20%, respectively. All measures of durability increased systematically with increasing replacement levels.

- MK2 was an obvious outlier in both mechanical and durability performance. Aside from this, MK1 performance greatly depends on the replacement level, while MK3 does not. Mechanical strengths varied at most 29% (MK1-20 and MK3-20 compression, by % of control) between MK1 and MK3. Measures of durability indicate that a replacement of 15% or higher by either MK1 or MK3 will be sufficient to ensure very low permeability and mitigate deleterious expansion resulting from ASR or sulfate attack.

- All concrete mixtures incorporating metakaolin as a replacement of cement require a high level dosage of superplasticizer (≥4 mL per 100 kg of cementitious material), with higher dosage requirements at higher replacement levels. Increased mechanical strengths are seen at all replacement levels, and are generally optimized at a 15–20% replacement level. Resistance to chlorides and other chemicals is achieved by all well-performing metakaolins at a replacement level of 15% or higher.

6. Future Work

- A quantitative investigation about the pozzolanic activity of different mixes would have been useful.

- The dispersion of high-fineness, plate-like metakaolin in concrete batching. Recommendations are provided by the Silica Fume Association [38].

- The pozzolanic reactivity for various commercially-available metakaolins in the U.S., and its effect on performance of concrete mixtures.

- The increased CTE levels and their effect on structural performance.

- Costs and benefits.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Soyka, M.J.G.P.; Conneely, D. CO2 Emissions from Cement Production; IPCC: Geneva, Switzerland, 1996. [Google Scholar]

- Gale, J.; Bradshaw, J.; Chen, Z.; Garg, A.; Gomez, D.; Rogner, H.-H.; Simbeck, D.; Williams, R. Sources of CO2; IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282. [Google Scholar] [CrossRef]

- Uwasu, M.; Hara, K.; Yabar, H. World cement production and environmental implications. Environ. Dev. 2014, 10, 36–47. [Google Scholar] [CrossRef]

- Kosmatka, S.H.; Wilson, M.L. Design and Control of Concrete Mixtures, 15th ed.; Portland Cement Association: New York, NY, USA, 2011. [Google Scholar]

- Michael, A.; Caldarone, K.A.G.; Ronald, G.B. High reactivity metakaolin (hrm): A new generation mineral admixture for high performance concrete. Concr. Int. 1994, 16, 37–41. [Google Scholar]

- Asbridge, A.H.; Jones, T.R.; Osborne, G.J. High performance metakaolin concrete: Results of large scale trials in aggressive environments. In Radical Concrete Technology, Proceedings of the International Conference Held at the University of Dundee, Scotland, UK, 24–26 June 1996; Taylor & Francis: Oxfordshire, UK; Volume 2, pp. 11–23.

- Murray, H.H.; Lyons, S.C. Correlation of Paper-Coating Quality with Degree of Crystal Perfection of Kaolinite; Indiana University: Bloomington, IN, USA, 1955. [Google Scholar]

- Elton, N.J.; Gate, L.F.; Hooper, J.J. Texture and orientation of kaolin in coatings. Clay Min. 1999, 34, 89–98. [Google Scholar] [CrossRef]

- Selmani, S.; Sdiri, A.; Bouaziz, S.; Joussein, E.; Rossignol, S. Effects of metakaolin addition on geopolymer prepared from natural kaolinitic clay. Appl. Clay Sci. 2017, 146, 457–467. [Google Scholar] [CrossRef]

- Bapat, J.D. Mineral Admixtures in Cement and Concrete; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Dinakar, P.; Sahoo, P.K.; Sriram, G. Effect of metakaolin content on the properties of high strength concrete. Int. J. Concr. Struct. Mater. 2013, 7, 215–223. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Mermerdaş, K. Improving strength, drying shrinkage, and pore structure of concrete using metakaolin. Mater. Struct. 2008, 41, 937–949. [Google Scholar] [CrossRef]

- Justice, J.M.; Kurtis, K.E. Influence of metakaolin surface area on properties of cement-based materials. J. Mater. Civ. Eng. 2007, 19, 762–771. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Yazıcı, Ş.; Arel, H.Ş.; Anuk, D. Influences of metakaolin on the durability and mechanical properties of mortars. Arab. J. Sci. Eng. 2014, 39, 8585–8592. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A. Cement Replacement Materials; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Wild, S.; Khatib, J.M.; Jones, A. Relative strength, pozzolanic activity and cement hydration in superplasticised metakaolin concrete. Cem. Concr. Res. 1996, 26, 1537–1544. [Google Scholar] [CrossRef]

- Gleize, P.J.P.; Cyr, M.; Escadeillas, G. Effects of metakaolin on autogenous shrinkage of cement pastes. Cem. Concr. Compos. 2007, 29, 80–87. [Google Scholar] [CrossRef]

- Sabir, B.B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Badogiannis, E.; Aggeli, E.; Papadakis, V.G.; Tsivilis, S. Evaluation of chloride-penetration resistance of metakaolin concrete by means of a diffusion—Binding model and of the k-value concept. Cem. Concr. Compos. 2015, 63, 1–7. [Google Scholar] [CrossRef]

- Khatib, J.M.; Hibbert, J.J. Selected engineering properties of concrete incorporating slag and metakaolin. Constr. Build. Mater. 2005, 19, 460–472. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Chow, P.; Memon, S. Microstructure, hydration and nanomechanical properties of concrete containing metakaolin. Constr. Build. Mater. 2015, 95, 696–702. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Karaboğa, F.; Mermerdaş, K. Corrosion behavior of reinforcing steel embedded in chloride contaminated concretes with and without metakaolin. Compos. Part B Eng. 2013, 45, 1288–1295. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Bahrami Jovein, H. Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Constr. Build. Mater. 2012, 30, 470–479. [Google Scholar] [CrossRef]

- Ramlochan, T.; Thomas, M.; Gruber, K.A. The effect of metakaolin on alkali–silica reaction in concrete. Cem. Concr. Res. 2000, 30, 339–344. [Google Scholar] [CrossRef]

- Wang, G.M.; Kong, Y.; Shui, Z.H.; Li, Q.; Han, J.L. Experimental investigation on chloride diffusion and binding in concrete containing metakaolin. Corros. Eng. Sci. Technol. 2014, 49, 282–286. [Google Scholar] [CrossRef]

- Li, Z.; Ding, Z. Property improvement of portland cement by incorporating with metakaolin and slag. Cem. Concr. Res. 2003, 33, 579–584. [Google Scholar] [CrossRef]

- ACI Committee, American Concrete Institute, and International Organization for Standardization. 211.1-91: Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1991. [Google Scholar]

- Paiva, H.; Velosa, A.; Cachim, P.; Ferreira, V.M. Effect of metakaolin dispersion on the fresh and hardened state properties of concrete. Cem. Concr. Res. 2012, 42, 607–612. [Google Scholar] [CrossRef]

- Janneth Torres, A.; Mejía de Gutiérrez, R.; Gutiérrez, C. The performance of mortar containing added metakaolin regarding sulfate action. Ing. Investig. 2008, 28, 117–122. [Google Scholar]

- Lee, H.S.; Wang, X.Y.; Zhang, L.N.; Koh, K.T. Analysis of the Optimum Usage of Slag for the Compressive Strength of Concrete. Materials. 2015, 18, 1213–1229. [Google Scholar] [CrossRef] [PubMed]

- Brindley, G.W.; Nakahira, M. The Role of Water Vapour in the Dehydroxylation of Clay Minerals; The Pennsylvania State University: State College, PA, USA, 1957. [Google Scholar]

- Shui, Z.-H.; Zhang, R.; Chen, W.; Xuan, D.-X. Effects of mineral admixtures on the thermal expansion properties of hardened cement paste. Constr. Build. Mater. 2010, 24, 1761–1767. [Google Scholar] [CrossRef]

- Sabih, G.; Tarefder, R.A. Impact of variability of mechanical and thermal properties of concrete on predicted performance of jointed plain concrete pavements. Int. J. Pavement Res. Technol. 2016, 9, 436–444. [Google Scholar] [CrossRef]

- Sullivan, M.S. Comparison of Commercially-Available Metakaolins and Slags in Binary and Ternary Concrete Mixtures. Master’s Thesis, The University of Georgia, Athens, GA, USA, 2018. [Google Scholar]

- Brooks, J.J.; Johari, M.A.M. Effect of metakaolin on creep and shrinkage of concrete. Cem. Concr. Compos. 2001, 23, 495–502. [Google Scholar] [CrossRef]

- The Silica Fume Association. Making Silica-Fume Concrete in the Laboratory. Available online: http://www.silicafume.org/pdf/concrete-labmix.pdf (accessed on 24 March 2018).

| State | Products Approved | |

|---|---|---|

| 1 | California | MK2 |

| 2 | Florida | MK1, MK3 |

| 3 | Georgia | MK1 |

| 4 | Illinois | MK2 |

| 5 | Montana | * |

| 6 | Nebraska | * |

| 7 | Nevada | * |

| 8 | New York | * |

| 9 | North Carolina | MK2 |

| 10 | Oregon | * |

| 11 | Pennsylvania | MK1 |

| 12 | Texas | * |

| 13 | Utah | * |

| 14 | Virginia | MK1, MK2 |

| 15 | Wisconsin | * |

| 16 | Wyoming | * |

| Cement | MK1 | MK2 | MK3 | ||

|---|---|---|---|---|---|

| Chemical | SiO2 (%) | 19.70 | 50.75 | 54–56 | 51.66 |

| Al2O3 (%) | 4.70 | 45.91 | 40–42 | 43.99 | |

| Fe2O3 (%) | 3.00 | 0.45 | <1.4 | 0.47 | |

| CaO (%) | 63.30 | 0.06 | <0.1 | 0.01 | |

| MgO (%) | 3.10 | 0.00 | <0.1 | 0.03 | |

| Na2O (%) | <0.1 | 0.23 | <0.05 | 1.89 | |

| TiO2 (%) | <0.1 | 1.87 | <3 | 1.89 | |

| SO3 (%) | 3.20 | 0.08 | <0.05 | - | |

| Physical | Specific Gravity | 3.16 | 2.60 | 2.60 | 2.50 |

| L.O.I. (%) | 2.70 | 0.42 | <1.0 | 0.50 | |

| Specific Surface (BET) | 387 m2/kg | 14,200 m2/kg | 20,000 m2/kg | 11,000 m2/kg |

| Mixture Code | Cement (kg) | Metakaolin (kg) | Coarse Aggregate (kg) | Fine Aggregate (kg) | Water (kg) | Air (%) | Superplasticizer (mL per kg of Cementitious Material) |

|---|---|---|---|---|---|---|---|

| Control | 422 | 0 | 985 | 723 | 182 | 4% | 2.2 |

| MK1-10 | 380 | 42 | 985 | 715 | 182 | 4% | 4.4 |

| MK1-15 | 358 | 63 | 985 | 711 | 182 | 4% | 4.4 |

| MK1-20 | 338 | 84 | 985 | 708 | 182 | 4% | 4.9 |

| MK2-10 | 380 | 42 | 985 | 715 | 182 | 4% | 4.2 |

| MK2-15 | 358 | 63 | 985 | 711 | 182 | 4% | 4.6 |

| MK2-20 | 338 | 84 | 985 | 708 | 182 | 4% | 5.1 |

| MK3-10 | 380 | 42 | 985 | 715 | 182 | 4% | 4.2 |

| MK3-15 | 358 | 63 | 985 | 711 | 182 | 4% | 4.9 |

| MK3-20 | 338 | 84 | 985 | 708 | 182 | 4% | 5.3 |

| Properties | Tests Replacement Level | Ctrl | MK1 Product | MK2 Product | MK3 Product | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0% | 10% | 15% | 20% | 10% | 15% | 20% | 10% | 15% | 20% | ||

| Fresh | Air content (%) | 4.1 | 4.5 | 3.8 | 3.6 | 8.5 | 3.9 | 3.6 | 3.5 | 3.1 | 2.6 |

| Fresh | Unit weight (kg/m3) | 2345 | 2367 | 2313 | 2297 | 2310 | 2399 | 2319 | 2313 | 2307 | 2310 |

| Hardened | 28-day Compression | 53.7 | 62.7 | 69.4 | 77.0 | 48.9 | 57.0 | 63.7 | 64.9 | 66.9 | 61.8 |

| (MPa) | |||||||||||

| Properties | Mean | Standard Deviation | Outlier (p > 0.05%) |

|---|---|---|---|

| 28-day Compression | 63.59 | 7.822 | MK2-10 |

| MOR | 5.162 | 0.7851 | MK1-15 |

| Split Cylinder Tension | 3.124 | 0.3336 | MK1-15 |

| Dynamic MOE | 35.59 | 1.5443 | MK2-10 |

| RCPT | 815.0 | 374.82 | MK2-10 |

| Properties | Tests (Replacement Level) | MK1 Product | MK2 Product | MK3 Product | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 15% | 20% | 10% | 15% | 20% | 10% | 15% | 20% | ||

| Mechanical | Compression (28-day) | ↑ | ↑ | ↑ | ↓ | ↑ | ↑ | ↑ | ↑ | ↑ |

| (% change) | 17% | 29% | 44% | −9% | 19% | 6% | 21% | 25% | 15% | |

| Split-Cylinder Tension | ↑ | ↑ | ↑ | ↓ | ↓ | ↑ | ↑ | ↔ | ↑ | |

| (% change) | 18% | 30% | 14% | −8% | −1% | 3% | 7% | 0% | 13% | |

| MOR | ↓ | ↑ | ↑ | ↓ | ↓ | ↑ | ↑ | ↑ | ↑ | |

| (% change) | −10% | 38% | 20% | −1% | −16% | 1% | 5% | 5% | 6% | |

| Dynamic MOE | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↔ | ↓ | ↓ | |

| (% change) | −2% | −4% | −4% | −12% | −1% | −9% | 0% | −6% | −9% | |

| Durability | RCPT Permeability | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ |

| (% change) | −67% | −79% | −65% | −38% | −75% | −75% | −74% | −81% | −81% | |

| Sulfate Resistance | - | - | - | - | - | - | - | - | - | |

| Pass (P) or Fail (F) | F | P | P | F | F | F | F | P | P | |

| ASR Resistance | - | - | - | - | - | - | - | - | - | |

| Pass (P) or Fail (F) | F | P | P | F | P | P | P | P | P | |

| Dimensional Stability | CTE | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ |

| (% change) | 4% | 12% | 6% | 4% | 6% | 3% | 12% | 18% | 18% | |

| Shrinkage | ↑ | ↔ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | |

| (% change) | 3% | 0% | −10% | −7% | −11% | −19% | −9% | −15% | −35% | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sullivan, M.S.; Chorzepa, M.G.; Hamid, H.; Durham, S.A.; Kim, S.S. Sustainable Materials for Transportation Infrastructures: Comparison of Three Commercially-Available Metakaolin Products in Binary Cementitious Systems. Infrastructures 2018, 3, 17. https://doi.org/10.3390/infrastructures3030017

Sullivan MS, Chorzepa MG, Hamid H, Durham SA, Kim SS. Sustainable Materials for Transportation Infrastructures: Comparison of Three Commercially-Available Metakaolin Products in Binary Cementitious Systems. Infrastructures. 2018; 3(3):17. https://doi.org/10.3390/infrastructures3030017

Chicago/Turabian StyleSullivan, Matthew S., Mi G. Chorzepa, Hiwa Hamid, Stephan A. Durham, and S. Sonny Kim. 2018. "Sustainable Materials for Transportation Infrastructures: Comparison of Three Commercially-Available Metakaolin Products in Binary Cementitious Systems" Infrastructures 3, no. 3: 17. https://doi.org/10.3390/infrastructures3030017

APA StyleSullivan, M. S., Chorzepa, M. G., Hamid, H., Durham, S. A., & Kim, S. S. (2018). Sustainable Materials for Transportation Infrastructures: Comparison of Three Commercially-Available Metakaolin Products in Binary Cementitious Systems. Infrastructures, 3(3), 17. https://doi.org/10.3390/infrastructures3030017