2.2. Semi-Analytical Models

Similarly, the research by [

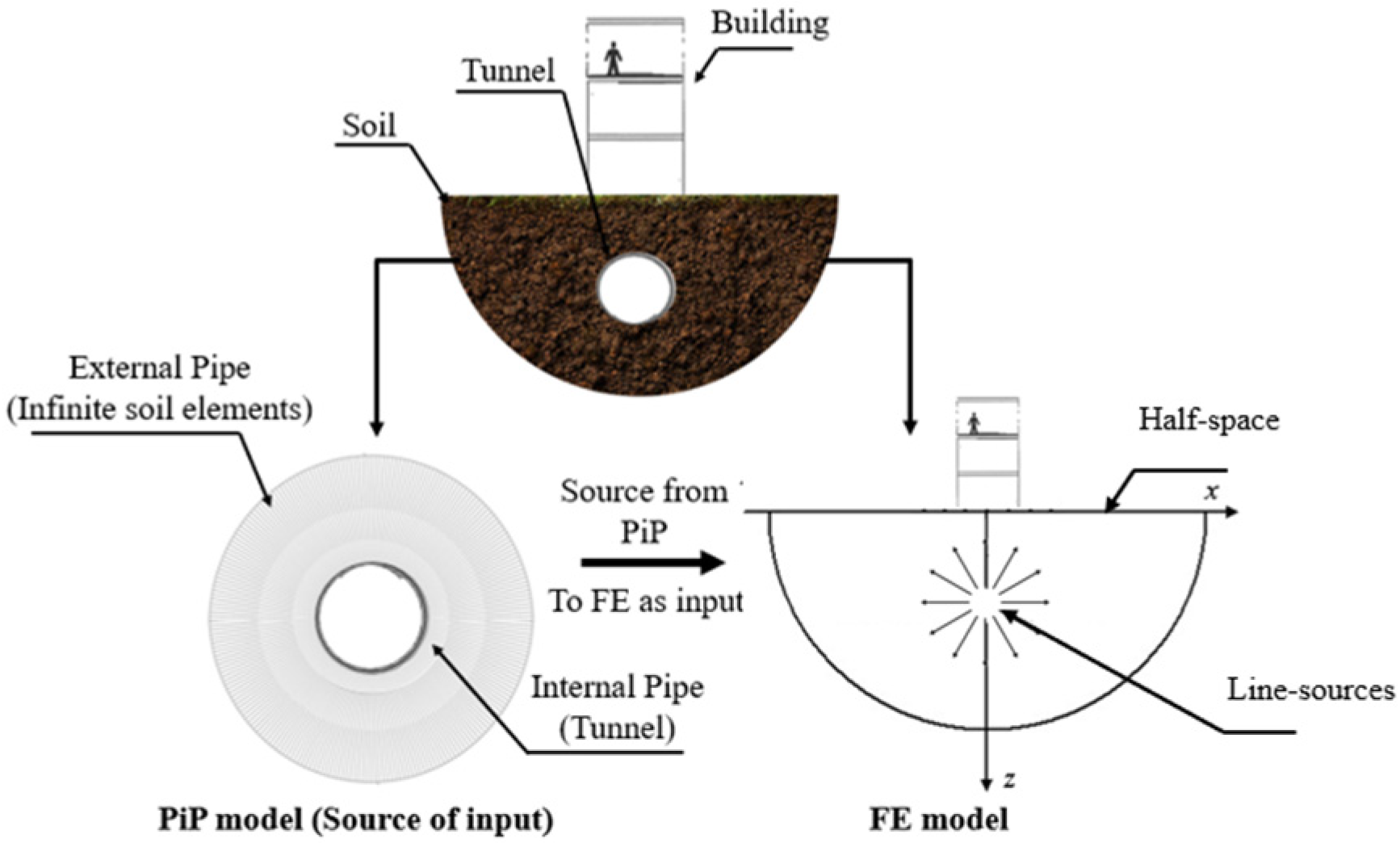

4], presented an extension of the Pipe-in-Pipe (PiP) model that allows for the incorporation of a multi-layered half-space. This model efficiently calculates vibrations by first using a full-space tunnel model to determine displacements at the tunnel-soil interface and then applying equivalent loads to a multi-layered half-space. The approach maintains computational efficiency while accurately predicting vibrations from underground tunnels, making it a valuable tool in early-stage design for vibration mitigation measures. The fictitious-force method has likewise been referenced and extended in later studies. The research by [

15] applied the approach to investigate ground vibrations from circular tunnels. The study by [

16] introduced an efficient poroelastic half-space predictor citing the FFM formulation. The work by [

17] integrated similar fictitious-force concepts into the Scope Rail prediction tool for building vibrations near high-speed rail. Recent studies have also proposed hybrid semi-analytical/numerical frameworks, such as the periodic FE-BE approach for twin tunnels incorporating fictitious-force concepts [

18]. Furthermore, the methodology by [

19] proposed a hybrid approach to address soil-structure interaction (SSI) challenges, where the ground and structure are modeled separately but connected to ensure equilibrium and compatibility conditions. This sub-structured approach, while computationally efficient, still captures the complex dynamics of vibration transmission, making it valuable for ground-borne vibration analysis.

The PiP model, commonly used in metro tunnel simulations, remains instrumental in these studies. It simulates the dynamic response of tunnels under moving train loads by treating tunnels as combinations of inner and outer pipes [

3]. By coupling the PiP model with other models, previous research has demonstrated improvements in predicting how vibrations propagate through different layers of soil and structural elements. This hybrid approach has been applied to underground metro systems, particularly in deep-buried tunnels, where soil-structure interactions are complex but vital for determining the dynamic behavior of the system. Ground vibration modeling has evolved with several advanced techniques, and the combination of PiP and other models has enhanced the understanding of vibration propagation in urban environments. Notably, the use of PiP models offers simplified yet effective simulation of tunnel-soil systems, but this method still falls short when it comes to integrating building dynamics into the vibration analysis, a crucial aspect in urban settings [

20,

21].

2.3. Numerical Models

Ground-borne vibrations caused by urban rail transit systems have been extensively studied due to their significant impact on nearby buildings and human comfort. Researchers used field measurements to assess the noise and vibration impacts of urban rail transit in Tianjin, China, showing that wheel-rail polishing and train speed reduction could mitigate indoor vibrations by up to 6 dB, with effectiveness varying by frequency [

1]. Similarly, involving field tests and numerical simulations on train-induced vibrations at metro depots highlighted the importance of understanding vibration transmission pathways [

22]. Several studies have aimed to improve prediction accuracy by integrating numerical modeling with empirical validation. For instance, combining centrifuge testing with numerical modeling to explore the effects of soil non-homogeneity on ground-borne vibrations from underground tunnels, underlines the need to account for varying soil properties with depth [

22]. The study by [

23] used both centrifuge and numerical modeling to investigate ground-borne vibrations from surface sources, with a specific focus on the variation in soil properties with depth, known as soil non-homogeneity. They demonstrated that accounting for the changing stiffness and damping of soil with increasing confining stress is crucial for accurately predicting ground-borne vibrations, particularly from surface foundations. Their work highlights the importance of considering soil non-homogeneity in both experimental and numerical simulations to ensure accurate results when studying vibration propagation [

23]. Similarly, a study by [

24] combined numerical simulations with experimental field measurements to predict building vibrations caused by subway trains. The findings highlighted the potential of using Z-vibration levels at the ground surface as input for machine learning-based predictive models, which offered faster and more accurate vibration predictions.

Furthermore, the work by [

25] presented a 2.5D finite element method (FEM) as an alternative to full 3D models, which reduces computational load while maintaining accuracy in predicting ground-borne vibrations for shallow foundation buildings. While 3D models are often more accurate, they are computationally expensive, and their simplifications can result in trade-offs in certain conditions, such as variations in soil properties and tunnel depth. The work by [

3] developed a 3D tunnel model to calculate train-induced ground vibrations, significantly advancing the understanding of vibration dynamics in urban settings. Subsequent independent studies have also applied or validated the PiP framework. One study [

26] demonstrated its application for predicting ground-borne vibrations above cross-rail construction tunnels. Another work [

27] developed a computationally efficient 2.5D Green’s function model in layered half-spaces building on PiP concepts. Further research [

28] adapted the PiP model to consider more complex tunnel-soil interaction features, extending its use to cases with soil inhomogeneity and multiple tunnels. To overcome the computational limitations of fully 3D models, hybrid approaches combining FEA and boundary element methods (BEM) have been proposed. For instance, the work by [

29] used a 3D FEM-BEM approach to simulate vibrations, capturing complex vibration patterns in high-speed railway systems. The work by [

30], introduced a substructure simulation approach to analyze the dynamic interaction between tracks and layered ground. The authors in [

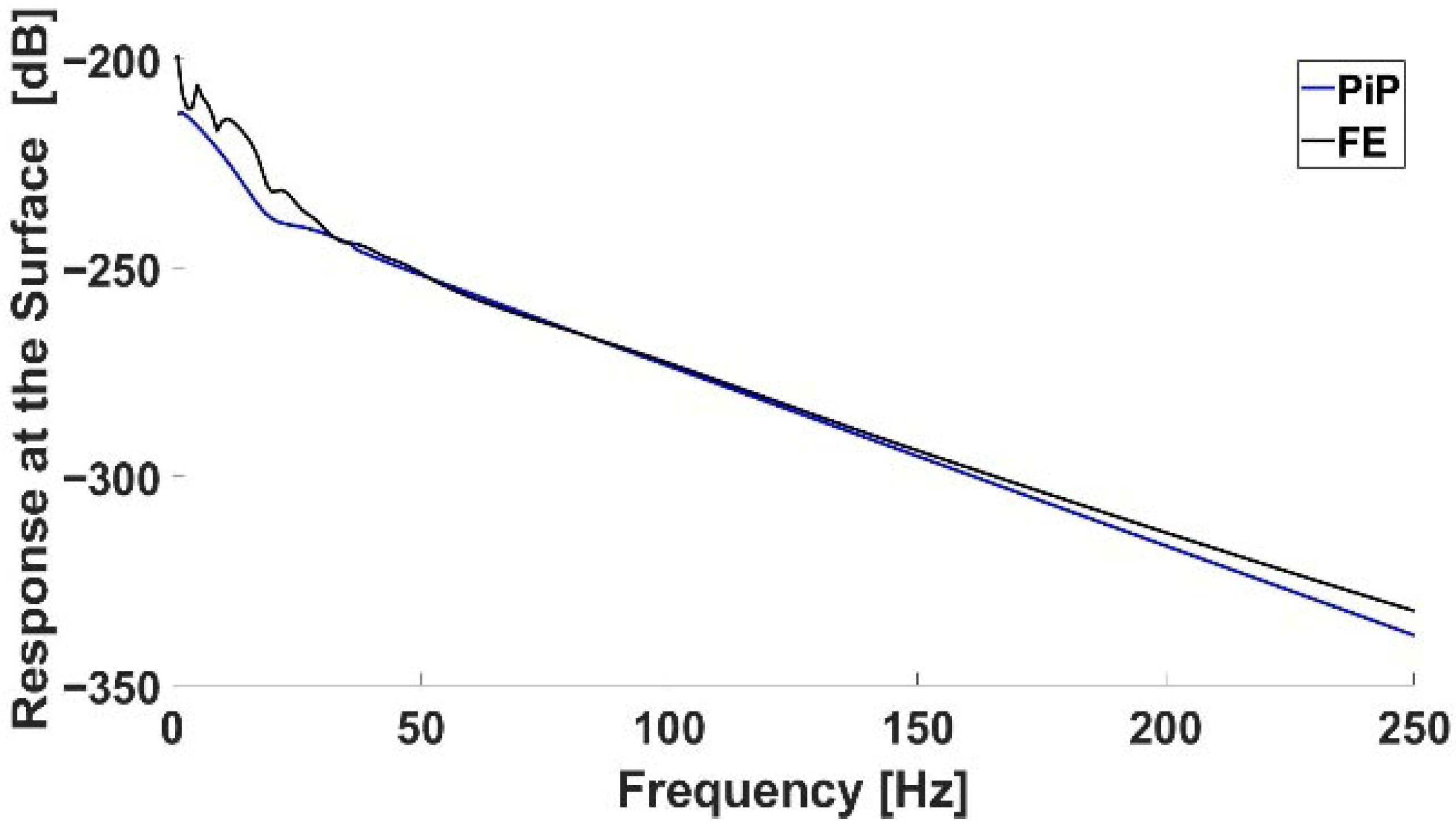

31], compared two different numerical models for predicting vibrations from underground railways: the PiP model and the coupled periodic FE-BE model. While the PiP model offered computational efficiency and a good representation of tunnel-soil interactions, it was limited to simple geometries and homogeneous soil. In contrast, the coupled periodic FE-BE model allowed for more detailed simulation of complex geometries and soil layers, though at a higher computational cost [

31]. Recent studies have focused on validating these models with real-world data to demonstrate and ensure their utility. For example, ref. [

32] conducted field experiments to measure vibrations caused by subway and road traffic systems, providing essential empirical data for validating simulation models of ground-borne vibrations. Similarly, a study by [

33], investigated the effects of using softer rail-pads in the Doha Metro system on vibration levels at the free surface and within the railway tunnel. They found that replacing the conventional stiffer rail-pads with softer web-supporting pads reduced vibration levels by approximately 10 dB for frequencies between 40 and 200 Hz- at the free surface, with higher attenuation observed between 45 and 65 Hz-. This work highlighted the potential for softer rail-pads to serve as an effective vibration mitigation strategy for underground railways. These findings are particularly relevant for environments with multiple interacting sources of vibration. Moreover, a study focused on high-speed train-induced vibrations in ballasted railway tracks used 3D numerical simulations to quantify peak particle velocities (PPVs) at various points within the track and surrounding soil [

34].

While many numerical models offer a relatively simplified approach to vibration prediction, certain environmental and structural aspects are often overlooked, leading to the underestimation of vibration levels. Six commonly disregarded factors include the presence of a second (twin) tunnel, piled foundations, discontinuous slab tracks, soil inhomogeneity, inclined soil layers, and irregular contact at the tunnel-soil interface. These factors can cause deviations in predicted vibration levels by as much as 5 dB to 20 dB compared to simplified models, highlighting significant uncertainty in the predictions [

35]. Moreover, researchers demonstrated that the uncertainty in predicting railway-induced ground-borne vibrations could reach up to ±10 dB due to small variations in soil properties, slab stiffness, and measurement positions [

36]. However, existing studies often focus on simplifying 3D models to 2.5D to reduce computational complexity. However, this can come at the cost of reduced accuracy under certain conditions, such as variations in soil properties and tunnel depth [

25]. Moreover, the application of 2.5D and hybrid FE-BE methods has shown potential in accurately predicting vibrations while maintaining manageable computational loads. However, these studies commonly disregard the full three-dimensional dynamic responses of buildings to these vibrations, focusing instead on the soil and tunnel interactions [

37,

38,

39]. The dynamic interaction of urban railway systems with their environment has been extensively studied, with a focus on mitigating vibrations through a variety of modeling techniques. Notably, the use of PiP models offers simplified yet effective simulation of tunnel-soil systems, but this method still falls short when it comes to integrating building dynamics into vibration analysis, a crucial aspect in urban settings [

40,

41]. The need for a more holistic approach is evident, as studies have increasingly pointed to the limitations of existing methodologies in fully capturing the complex dynamics of urban environments [

42,

43]. More advanced numerical studies have focused on integrated soil-tunnel-building dynamics, where both the tunnel-soil system and the above-ground structures are modeled within a unified framework [

44,

45,

46]. These approaches capture the mutual interaction between building vibration response and ground wave propagation, offering a more realistic prediction of real world applications. For example, a study in [

47] emphasized that simplified soil-tunnel-building interaction models could lead to underestimation of vibration amplitudes, especially in cases involving flexible superstructures. They demonstrated that incorporating a full 3D building model significantly altered the dynamic response of the system, particularly at higher frequency ranges above 50 Hz. Similarly, the study in [

46] analyzed cross-tunnel interaction under dynamic loading and concluded that the mutual influence of adjacent tunnels and aboveground buildings cannot be neglected in dense urban environments, as it alters the stress distribution in the surrounding soil and affects vibration propagation paths. Moreover, the researchers in [

47] developed a frequency-dependent soil-tunnel-foundation interaction model and showed that dynamic impedance functions vary significantly with building height and stiffness, emphasizing the need for integrated modeling approaches.

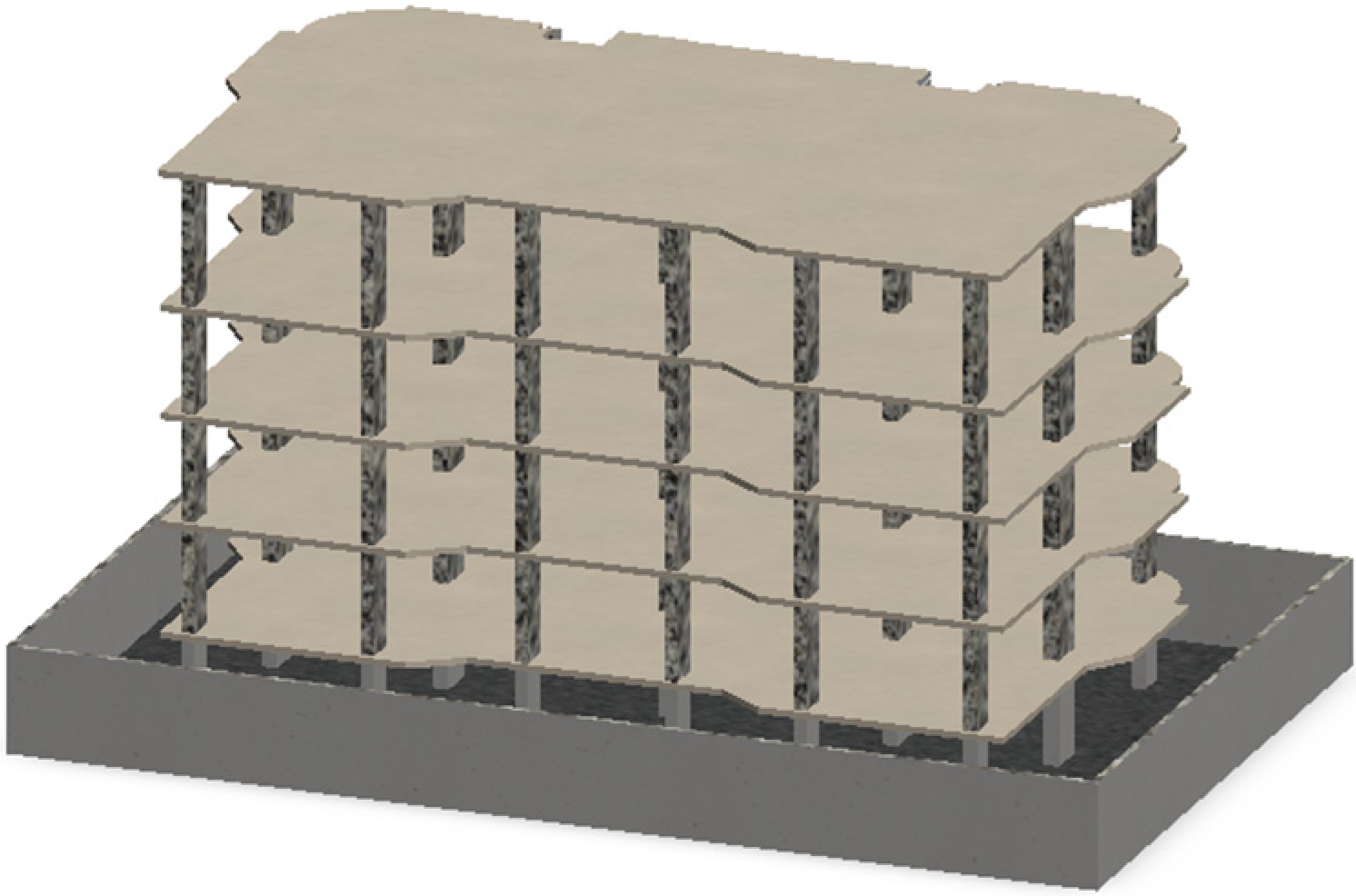

2.4. Innovation Statement

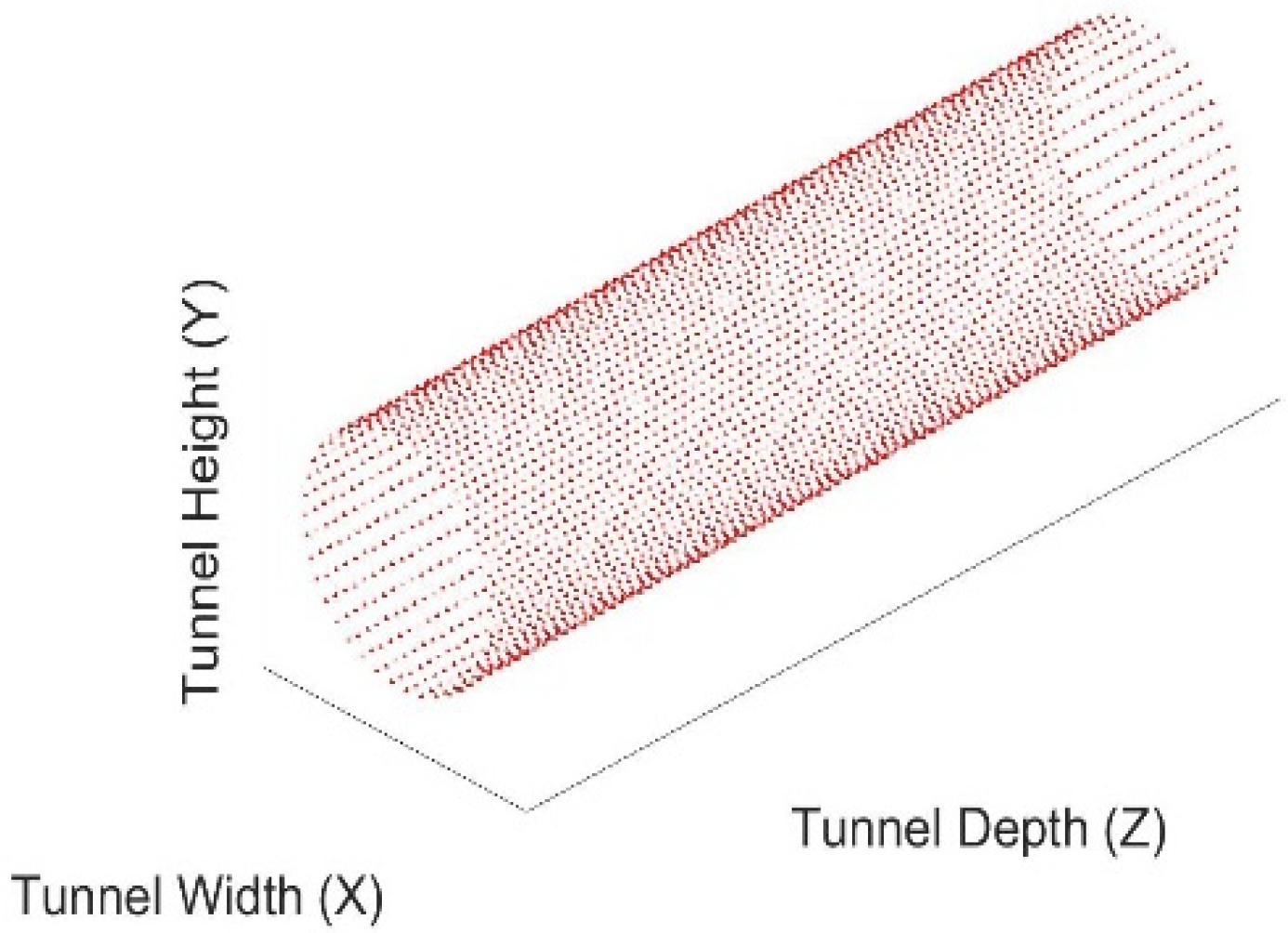

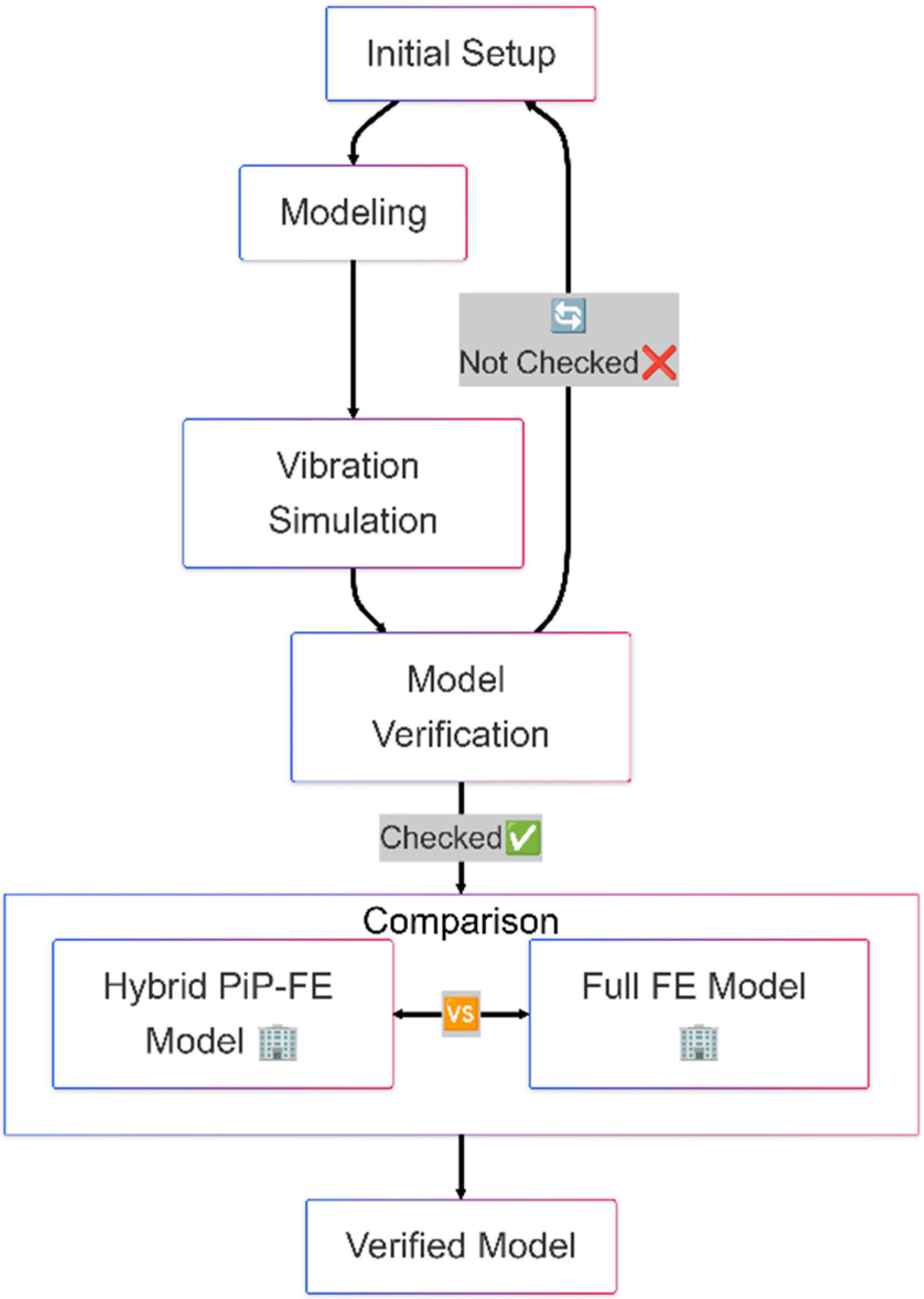

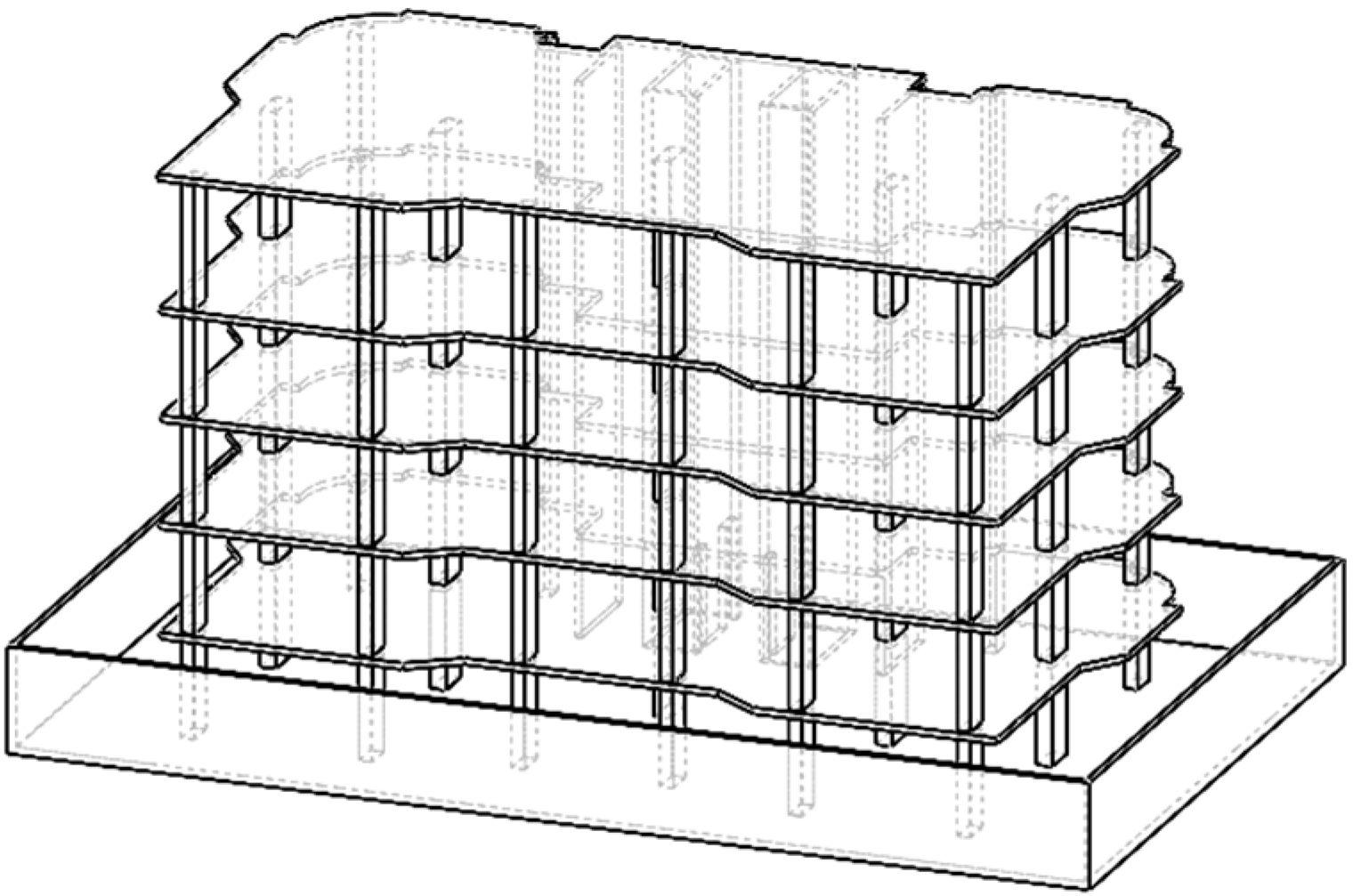

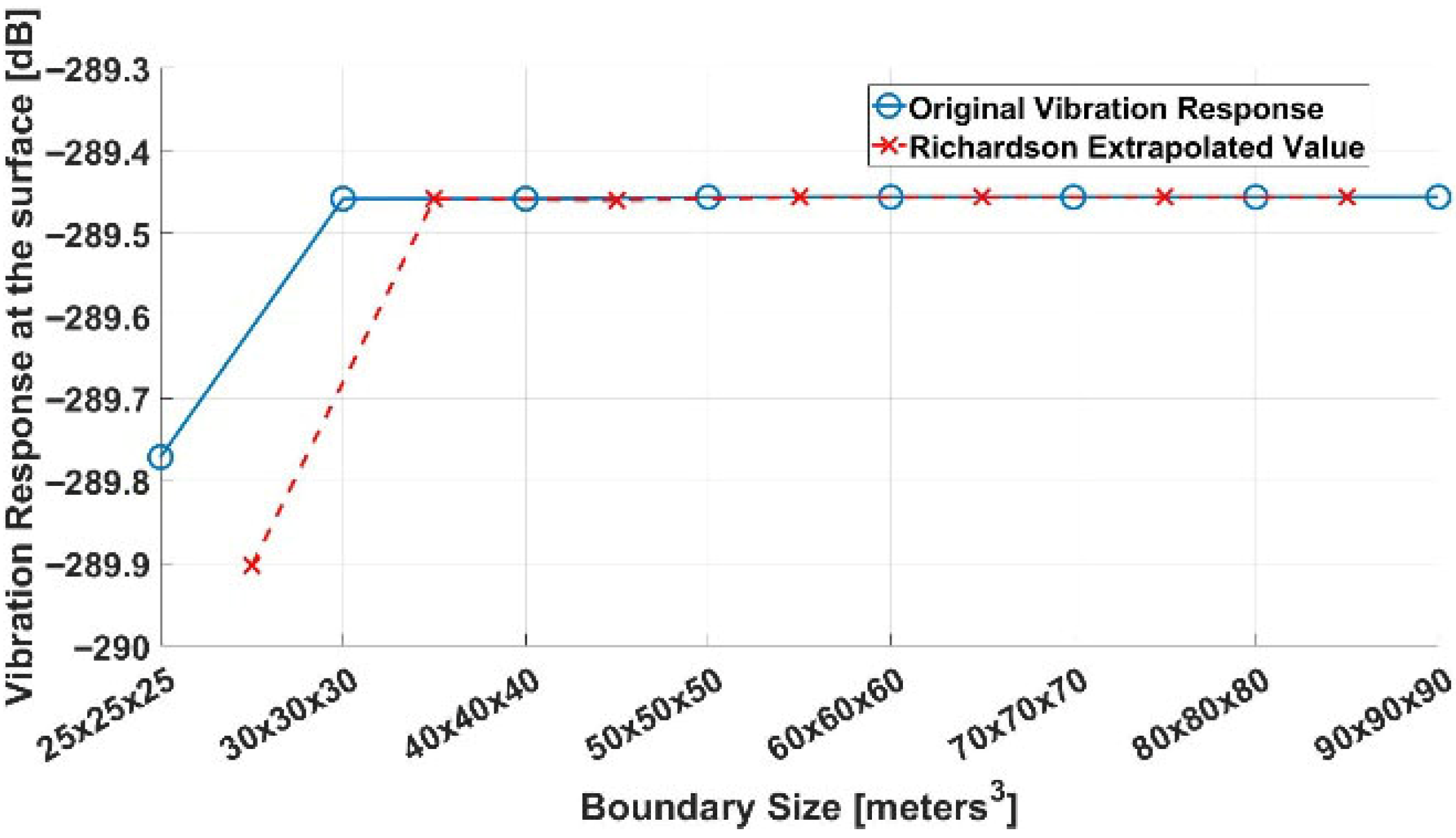

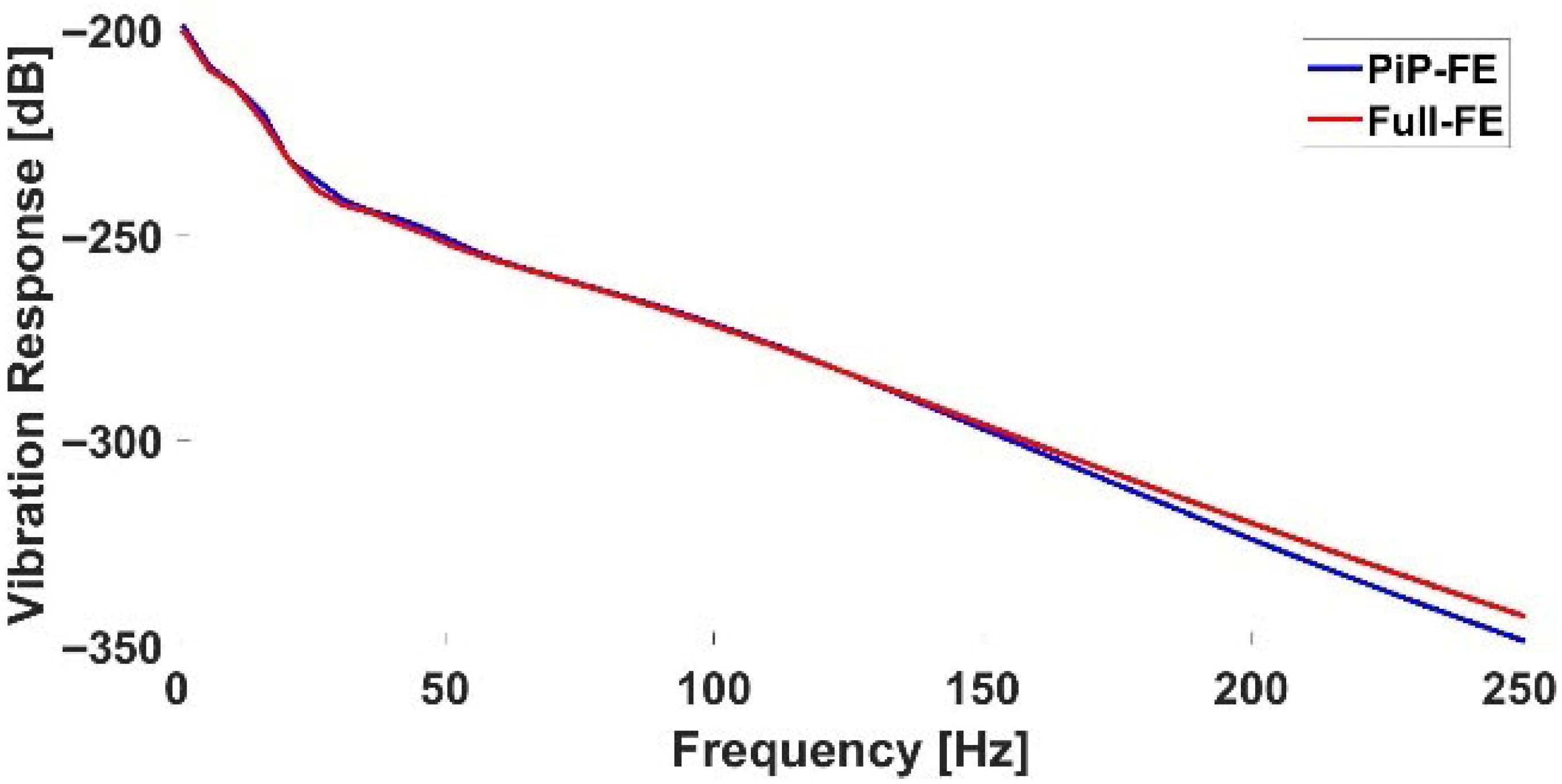

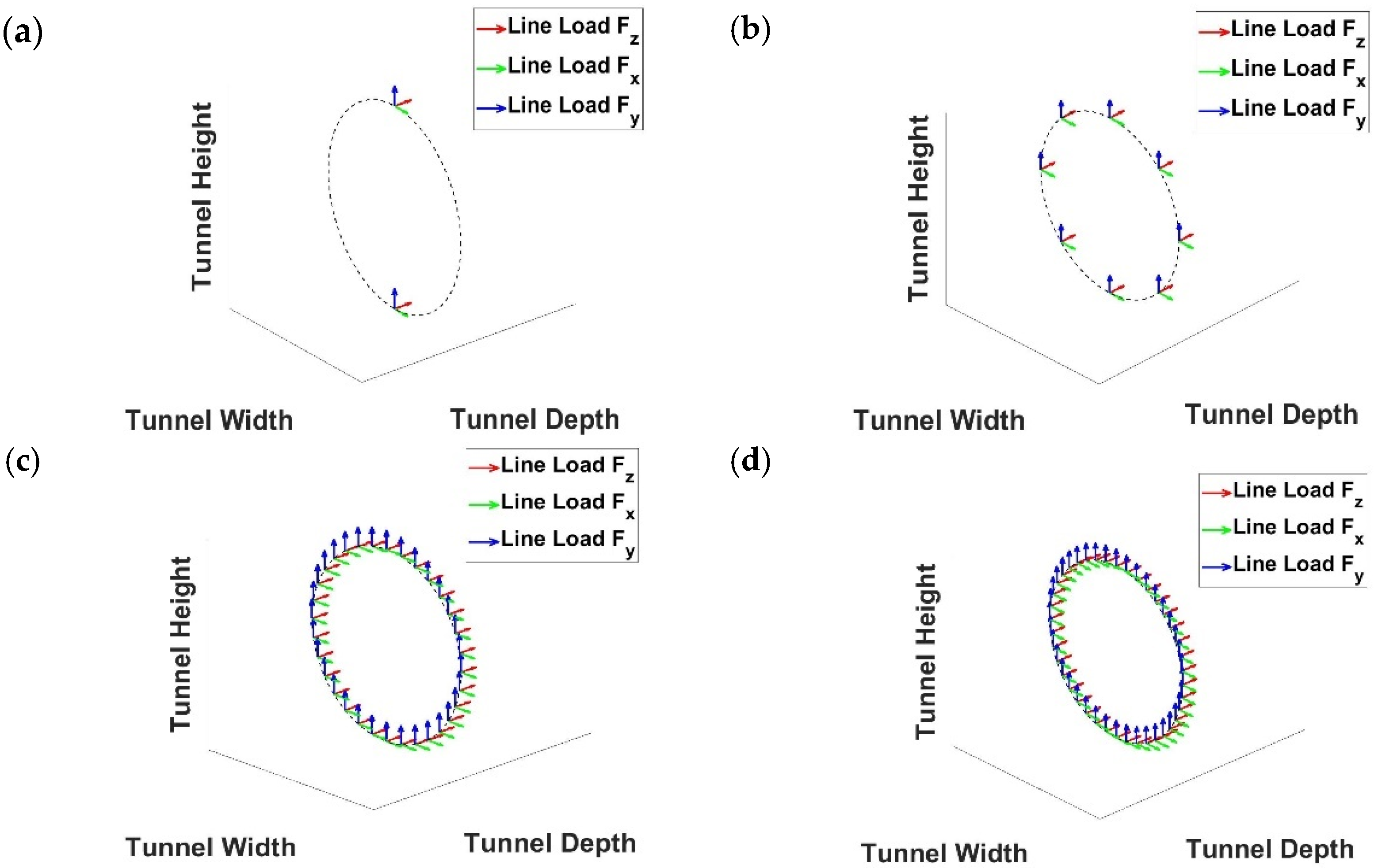

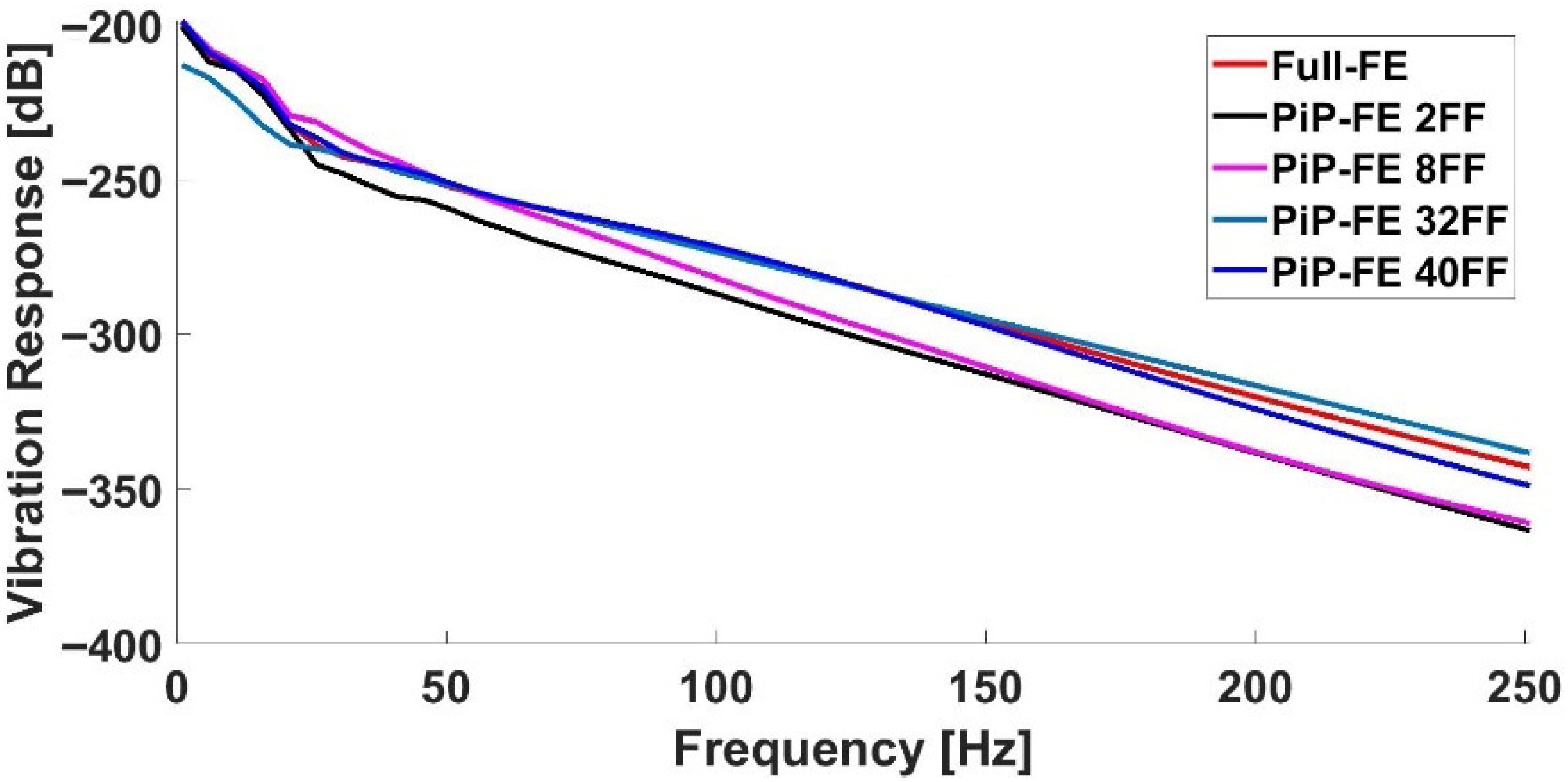

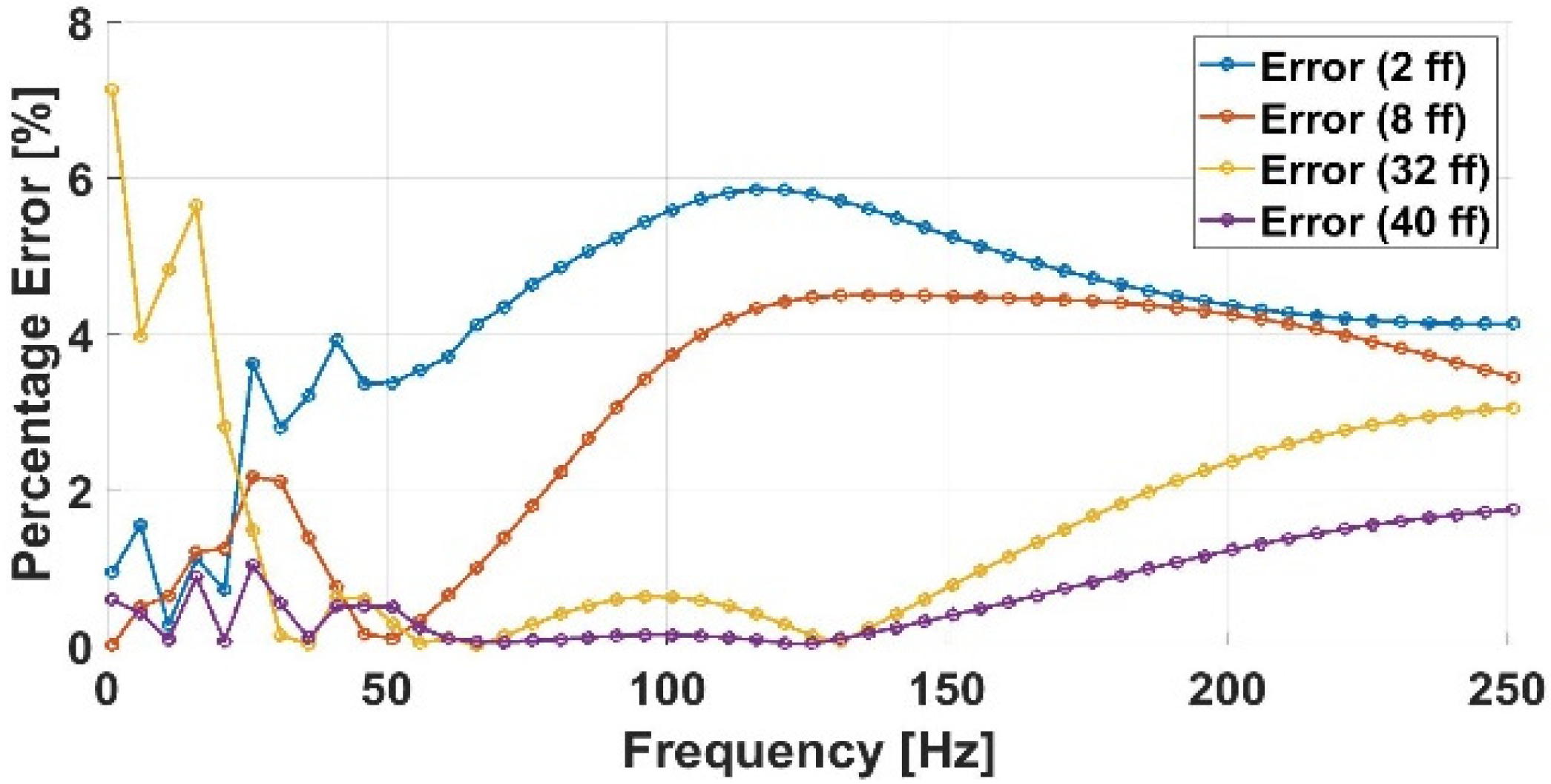

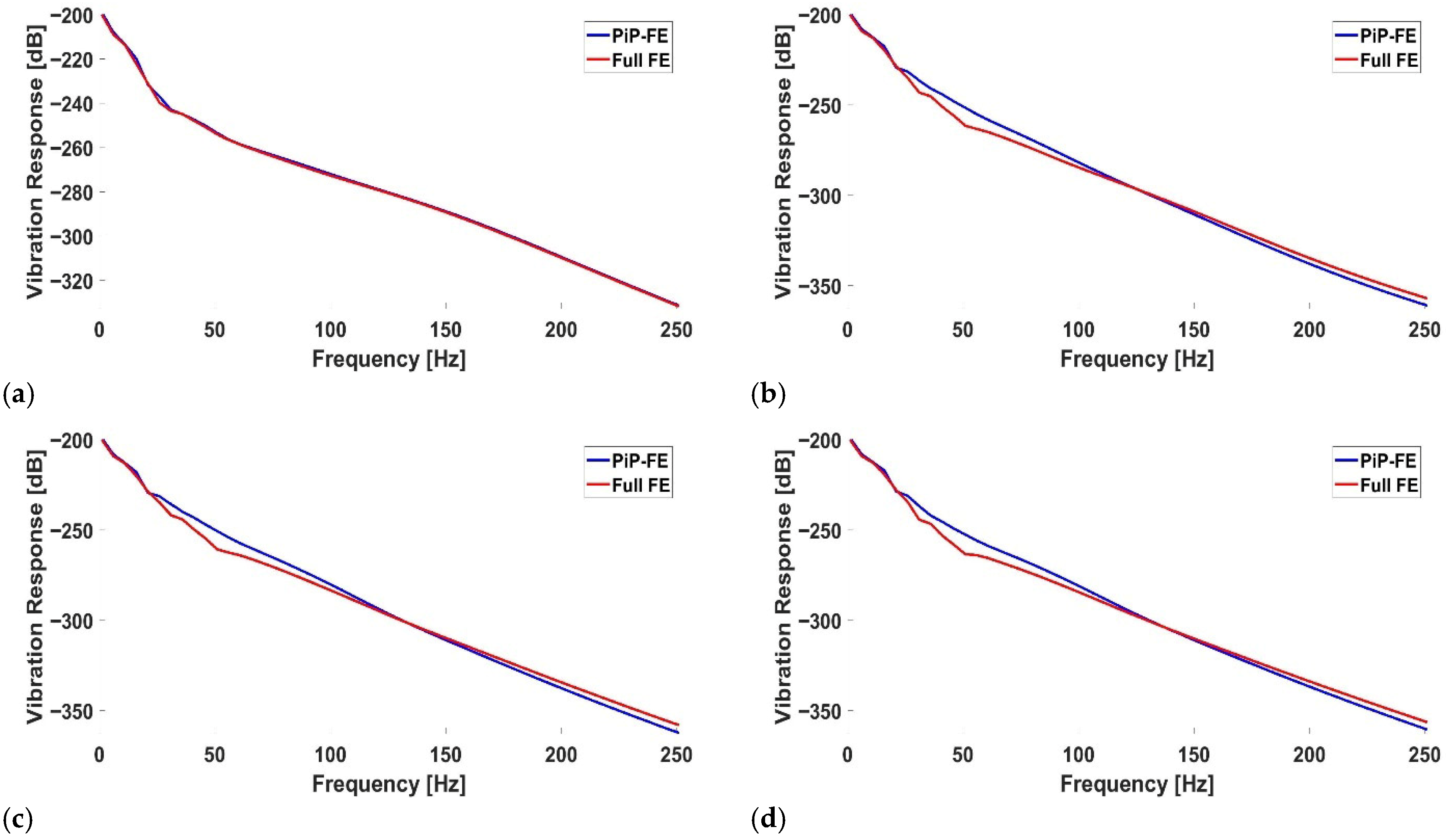

The use of the Pipe-in-Pipe (PiP) model, despite its representation of infinitely invariant conditions, is chosen for its computational efficiency and robustness in handling complex tunnel geometries and soil interactions. This is crucial as PiP models integrate well with finite element methods (FEM), which model the surrounding buildings and soil using discrete elements. This hybrid modeling approach addresses the incompatibility between the infinite conditions of PiP and the finite elements of building models by ensuring that both models work cohesively to predict vibrations accurately. This study introduces a 3D simulation framework that enhances the PiP model’s computational efficiency by integrating it with Finite Element Analysis (FEA) to include a detailed 3D model of actual building structures. The hybrid PiP-FE model is particularly valued for its speed and reliability in early-stage design and vibration mitigation strategies crucial for rapid predictions in large areas with underground tunnel systems. This approach not only reduces computational demands but also effectively incorporates multi-story buildings, addressing a significant oversight in previous research. By leveraging the strengths of both PiP and FEA, this methodology provides a comprehensive understanding of how vibrations from metro tunnels propagate through soil into buildings, allowing for precise predictions of their impacts. Moreover, the adaptability of this framework ensures that it can be applied to other modeling scenarios, making it a versatile tool for other applications related to ground-borne vibrations.

The paper is structured as follows:

Section 3 outlines the methodology, including the integration of the PiP model with FEA using APDL.

Section 4 presents the 3D simulation results, focusing on vibration propagation through soil and buildings.

Section 5 compares the PiP-FEA model with fully detailed 3D simulations to validate its efficiency and accuracy. Finally,

Section 6 and

Section 7 discuss and conclude with key findings and recommendations for future research.