1. Introduction

Concrete is one of the most widely used materials globally after water, and accounts for a significant portion of greenhouse gas emissions. While ultra-high-performance concrete (UHPC) represents a significant improvement in strength and durability relative to traditional concrete, the impact on CO

2 emissions and energy consumption has not been adequately addressed. This advanced material has a low permeability factor since its pores are discontinuous, which considerably lowers the intrusion of water and harmful chemicals, increasing its structural durability against environmental adversities such as corrosion and abrasion [

1]. The exceptional strength-to-weight ratio of UHPC facilitates the design and construction of slender, lightweight structures, thereby optimizing use of materials [

2,

3]. Furthermore, the inherent durability of UHPC ensures sustained structural performance, even under severe environmental conditions [

4,

5,

6,

7,

8,

9]. Consequently, UHPC offers substantial advantages in structural efficiency, sustainability, and resilience, making it an invaluable asset in contemporary construction engineering.

UHPC typically contains a high proportion of ordinary Portland cement (OPC) in its composition. The mixture proportioning of UHPC involves careful selection and precise combination of various components. OPC, which acts as the primary binder, plays a crucial role in providing the desired strength and durability to UHPC. In addition to OPC, UHPC mixtures often include other materials such as silica fume or supplementary cementitious materials (SCMs) like fly ash or ground granulated blast furnace slag [

5,

10]. These materials help improve the compactness, workability, and long-term performance of UHPC while reducing porosity. Carefully selected aggregates such as quartz flour or ultra-fine sand are also used to ensure proper particle packing and enhance mechanical properties. The overall goal in the mixture proportioning of UHPC is to achieve an optimized balance between OPC content, SCMs, aggregates, and additives to attain its exceptional strength, durability, and low permeability characteristics.

Currently, researchers have implemented different strategies to reduce the production costs of UHPC. These strategies have leveraged AI, new design methods, and different mixtures to develop more cost-effective UHPC. In a recent study, an AI-guided approach was developed to automatically discover low-carbon cost-effective UHPC [

6]. The approach was used to investigate new UHPC mixtures in two design scenarios. In the first scenario, the mixture design was optimized mainly for minimalizing embodied carbon footprint. In the second scenario, a multi-objective optimization was attained, achieving simultaneous reductions of 73% in life-cycle carbon footprint, 71% in embodied energy, and 80% in material cost [

6]. Similarly, a recent report showed that UHPC can be used to repair bridges in a cost-effective way [

11]. In that study, a step-by-step framework and life cycle cost analysis (LCCA) methodology were developed to select the repair material and quantify the lifecycle cost. A study by Yang et al. [

12] showed that the mechanical development, microstructure, and hydration process of UHPC were significantly improved by wet-grinded ultrafine ground granulated blast furnace slag (UGGBS), which can reduce the cement content and the cost of UHPC. Another study conducted by Alsalman et al. [

13] focused on producing economical UHPC mixtures using locally available materials; it found that the amount of steel fibers and the type of fine materials were influential factors in the concrete cost. Arora et al. [

14] developed a new method for designing UHPC mixtures that couples separate optimizations of the binder and aggregate phases [

14]. The method can produce UHPC mixtures with high strength and durability at a fraction of the cost of proprietary mixtures. Dong [

2] studied the use of UHPC in bridge girders and found that it can reduce concrete volume, CO

2 emissions, and lifecycle costs.

Several mixture proportions of UHPC have been examined in the literature. Typically, mixtures with a minimum compressive strength of 150 MPa are considered UPHC mixtures according to the ACI 239R-18 [

15]. However, mixtures of 120 MPa—UHPC can be used in prestressed concrete members, and even lower strength at release might be allowed for slightly prestressed structural members [

16]. The selection of specific mixture proportions can significantly influence the mechanical properties (i.e., compressive strength, modulus of elasticity, and tensile strength), durability, cost of the mixture per cubic meter, the required energy, and the CO

2 emissions of UHPC. As a result, appropriate selection of the mixture proportions can produce more eco-friendly UHPC with less emissions and energy.

UHPC mixtures can be classified into two categories: proprietary and non-proprietary. Proprietary concrete includes commercially available UHPC mixtures, whereas non-proprietary concrete represents the UHPC mixtures that are developed by using locally available materials. Non-proprietary mixtures are lower in cost than their branded counterparts, which may have implications for their adoption in projects.

The following sections outline the methodology used to collect energy, CO

2 emissions, and cost parameters of selected UHPC mixtures and the resulting calculations. Using information about the constituent materials of 10 UHPC mixtures, the energy, emissions, and cost of five proprietary and five non-proprietary mixtures were analyzed. The 10 mixtures chosen for comparison are discussed, and the proficiency of each mixture is compared. Finally, the implications and limitations of the present research are discussed. The following analysis has implications for adopting and using UHPC and will help project managers and engineers select UHPC mixtures that are both environmentally friendly and cost-effective. Current studies also highlight sustainability-focused methods relevant to UHPC research. Life cycle assessments (LCAs) of UHPC structural elements demonstrate that curing methods, binder content, and functional units significantly influence whole-life effects [

17,

18]. Comparable efforts using AI-supported mixture optimization have demonstrated that machine learning and generative algorithms can determine low-carbon, cost-effective UHPC mixtures [

19,

20].

To frame this investigation, the study is guided by the following research questions:

RQ1: What are the differences in energy consumption, CO2 emissions, and cost between proprietary and non-proprietary UHPC mixtures?

RQ2: Which constituent materials have the greatest influence on these sustainability parameters?

RQ3: Can non-proprietary UHPC mixtures serve as viable and more sustainable alternatives to proprietary UHPC for practical use?

Although previous studies on UHPC sustainability have mainly focused on specific mixture designs or typical lifecycle implications, this article offers the first comparative sustainability evaluation of proprietary and non-proprietary UHPC mixtures using consistent literature datasets for energy, emissions, and cost. By calculating trade-offs among several sustainability metrics, this study allows stronger benchmarking of UHPC selections beyond mechanical performance (e.g., compressive strength). Notably, the findings produce practical references for material selection in engineering practice, thereby highlighting how non-proprietary UHPC mixtures can propose approximately similar mechanical performance at substantially lower ecological impact and cost.

2. Methodology

The energy and CO2 emissions of selected mixtures of UHPC of different constituent materials were assessed. The analysis was completed by obtaining the energy and CO2 emissions of each constituent of the mixture based on proportions from the literature, and then, the energy and CO2 emissions of one cubic meter of concrete were determined for each mixture. It should be pointed out that the reported CO2 emission parameters already included both process-related emissions (e.g., calcination in cement production) and energy-related emissions where obtainable from the source literature. We kept energy (MJ/kg) and CO2 emissions (kg CO2/kg) as independent pointers to offer a transparent and separate comparison of the UHPC mixtures.

2.1. Energy Parameters

The energy consumption of one cubic meter of UHPC includes several parameters. These parameters include the binder materials, which are the most influential factor in UHPC strength, aggregates and fillers (mostly ultra-fine sand and quartz powder), admixtures (high-range water reducer), and heat curing regimen, if applicable. The binder of UHPC typically includes OPC and SCMs such as silica fume and fly ash [

21]. Based on the extant literature, we estimated the energy required for each material that used in producing UHPC. A summary of the parameters that we adopted for this research is presented in

Table 1.

2.1.1. OPC Energy Requirements

The energy required to produce OPC depends on the type of kiln used, such as wet, semi-wet, dry, or semi-dry. A general value of 4.6 MJ/kg was reported in the literature. On the other hand, 5.9, 4.6, 3.3, and 3.5 MJ/kg were stated for the wet kiln, semi-wet kiln, dry kiln, and semi-dry kiln, respectively [

22]. A similar value (5.5 MJ/kg) to the wet kiln value was reported by Murthy and Iyer [

32]. In addition, a value of 4.92 MJ/kg was reported by Bouhaya et al. [

23]. An average value of 4.8 MJ/kg was also reported, which covered different manufacturing processes of OPC [

24]. The average value of the stated values is considered in this study, i.e., 4.62 MJ/kg.

2.1.2. SMCs Energy Requirements

SMCs, which are very significant in UHPC production due to their roles in pozzolanic reactions and ability to increase packing density, are typically by-product materials, and they require less energy for their production compared to OPC. Therefore, preceding studies assumed the energy required for the production of SCMs equaled zero when estimating the entire energy of concrete [

35,

36]. In this study, values are considered for the energy of SMCs since these materials are collected, milled, and ground to attain the required marketed standards. The energies required for silica fume and fly ash are 0.036 and 0.033 MJ/kg, respectively [

27]. Some of the UHPC mixtures used white pozzolans materials or vitreous calcium aluminosilicate (VCAS) and glass powder to produce more sustainable UHPC mixtures [

37]. Either can be used as a partial replacement for cement, and they conform to the requirements of the ASTM C-1866/C-1866M-20 [

38]. The energy required to produce VCAS and glass powder is MJ/kg is 4.17 [

28].

2.1.3. Ultra-Fine Energy Requirements

Most UHPC mixtures contain ultra-fine sand and do not have coarse aggregates to eliminate the effect of the interfacial transition zone between the binder matrix and coarse aggregates [

39]. The energy required to produce one kg of sand is 0.081 MJ/kg [

29]. However, this reference does not state whether the sand is conventional or ultra-fine. On the other hand, Bouhaya et al. [

23] reported the energy required for sand used in UHPC mixtures to be 0.025 MJ/kg. In this study, the average of the two values is assumed, i.e., 0.053 MJ/kg.

2.1.4. Quartz Powder Energy Requirements

Typically, UHPC mixtures (branded types) contain quartz powder at around 10% of the total weight of the mixture. Quartz is used as a filler material to increase the packing density of the concrete and consequently reduce permeability and improve durability. Quartz flour, also known as silica flour, is considered a non-reactive pozzolanic constituent at ambient temperature. However, it is considered reactive in high temperatures and under high pH values [

40]. The energy required to produce quartz powder is reported as 0.85 MJ/kg [

29].

2.1.5. High-Range Water Reducer Energy Requirements

High-range water reducer is a must with UHPC since the water-to-binder ratio is extremely low (~0.20) [

37,

39]. The reported energy by Jones et al. [

27] to produce 1 kg of high-range water reducer was 9 MJ. On the other hand, European Federation of Concrete Admixtures Associations Ltd. (EFCA, Vigo, Spain) reported a value of 29.1 MJ/kg [

30]. An average value is considered in this study—19 MJ/kg. The energy value for HRWR implemented here is taken from the general literature and is not specific to the polycarboxylate ether-based admixtures generally used in UHPC. Given the comparatively small dosage of HRWR compared to cement and steel fibers, this presumption has only a minimal influence on the total energy of a mixture.

2.1.6. Steel Fibers Energy Requirements

Typically, UHPC mixtures contain steel fibers in the range of 2–4% by the total volume of the mixture to increase ductility and avoid the sudden explosive failure of the samples [

39]. The reported energy to produce one cubic meter of steel fibers is 103,000 MJ [

23]. Using steel density of 7800 kg/m

3 [

41], this corresponds to 13.2 MJ per kilogram of steel fibers. On the other hand, a higher value of 36 MJ/kg has also been reported [

29,

32]. The average of these two values is considered in this study, i.e., 24.6 MJ/kg. The reported energy intensity of steel fiber production varies widely depending on factors such as raw material sources, manufacturing process (e.g., cutting vs. drawing), and whether the fibers are recycled. Reported values range from 13.2 MJ/kg (Bouhaya et al. [

23]) to 36 MJ/kg (Murthy & Iyer [

32]); this study adopts the average value of 24.6 MJ/kg to reflect a general-use estimate. However, actual energy footprints may be lower for recycled or sustainably sourced fibers.

2.1.7. Heat Curing Energy Requirements

Some UHPC mixtures require heat curing to achieve the required strength, especially if early strength is essential (i.e., prestressed concrete). Most of the curing is carried out in a water bath (100% relative humidity) [

39]. Nisbet et al. [

24,

33] indicated that the energy required to cure ordinary Portland Cement Concrete at 54 °C for 24 h is 62 MJ/m

3. Any other temperatures and durations are estimated accordingly.

2.2. Emissions Parameters

Because of the energy required to produce the constituent materials of UHPC (i.e., electricity, coal, diesel, liquid petroleum), CO2 emissions are released to the environment.

2.2.1. OPC Emissions

The emission values used in this study are global averages. However, cement-related emissions can vary geographically due to differences in kiln technology, fuel type, and energy efficiency. This variability may affect the generalizability of the findings, and localized studies are recommended to calibrate these factors to specific regions. Emissions produced by OPC are considered the highest among all binder types. Cement industries contribute around 7% of the total global CO

2 emissions [

25]. The manufacturing of 1 kg of OPC release approximately 1 kg of CO

2 into the environment [

42]. A value between 0.73 to 0.85 kg-CO

2/kg is recorded in the literature [

43,

44]. Also, a worldwide average of 0.84 kg-CO

2/kg has been stated [

45]. Very similar values are reported in another study, 0.865 kg-CO

2/kg [

23]. According to The Cement Sustainability Initiative [

46], the weighted average emissions of OPC equals 0.842 kg-CO

2/kg. In addition, it is estimated that about 0.90 to 1.0 kg-CO

2/kg is generated from the production of 1 kg of cement clinker based on the type of fuels used [

25,

26]. On the other hand, in another study [

31], a value of 0.819 kg-CO

2/k was reported. In this study, the average value of all stated values is used; i.e., 0.872 kg-CO

2/kg.

2.2.2. SCMs Emissions

The emissions generated from SCMs are greatly smaller compared to the emissions of OPC. The emissions of silica fume and fly are 0.014 and 0.004 kg-CO

2/kg, respectively [

27]. However, other studies considered the emissions from such materials to be zero since they are by-product materials [

2,

23]. On the other hand, the emissions of glass powder and VCAS are 0.15 kg-CO

2/kg [

28].

2.2.3. Fine Sand Emissions

For sand, the reported emissions are 0.0048 kg-CO

2/kg [

29]; Bouhaya et al. [

23] reported a value of 0.001 kg-CO

2/kg. The average value of 0.0029 kg-CO

2/kg is considered in this study.

2.2.4. Quartz Powder Emissions

The emissions of quartz powder are 0.02 kg-CO

2/kg [

29].

2.2.5. High-Range Water Reducer Emissions

The emissions from producing 1 kg of admixtures were reported to be 0.38 kg-CO

2/kg [

31]. On the other hand, another value has also been reported in the literature (1.88 k-CO

2/kg) [

30]. The average value of 1.13 kg-CO

2/kg is considered in this study. Similar to the energy parameter, the CO

2 emission metrics used for HRWR imitate typical admixture data, rather than the UHPC-specific type. This generalization is less likely to influence the mixture-level emission estimations, as HRWR contributes a much smaller part of total emissions compared to other constituents such as cement and steel fibers.

2.2.6. Steel Fibers Emissions

The reported energy required to produce one cubic meter of fibers was 7300 kg-CO

2/m

3 [

23]. Given that the density of the engineering steel equals 7800 kg/m

3 [

41], the emissions from 1 kg of steel fibers are equal to 0.936 kg k-CO

2.

2.2.7. Heat Curing Emissions

The emissions related to the curing of concrete were reported as 38.5 kg-CO

2/m

3 for 24 h at 85 °C [

34].

Table A1 in

Appendix A states the energy and emissions data of all materials used in this study, with the relevant information.

2.3. Cost Parameters

Table 2 summarizes the cost of all constituent materials used in the selected mixtures that are described in the next section. The costs are obtained from previous studies [

13,

37].

2.4. Mixtures

The selection of specific mixture proportions can significantly influence the mechanical properties (i.e., compressive strength, modulus of elasticity, and tensile strength), durability, cost of the mixture per cubic meter, the required energy, and, accordingly, the CO2 emissions of UHPC. Therefore, proper selection of the proportioning may produce an eco-friendly UHPC with fewer emissions and energy. UHPC mixtures can be classified into two categories: proprietary and non-proprietary. Proprietary concrete refers to commercially available UHPC mixture, whereas non-proprietary concretes are UHPC mixtures that are developed using locally available materials.

2.4.1. Selection Criteria for UHPC Mixtures

To ensure consistency, comparability, and transparency in evaluating UHPC mixtures, the following inclusion criteria were applied:

Compressive Strength: Only mixtures achieving compressive strength ≥ 120 MPa were included, in line with ACI 239R-18 [

15] recommendations for UHPC classification;

Curing Regime: Mixtures were selected based on clearly reported curing conditions (e.g., normal, steam, or elevated-temperature curing);

Data Completeness: Only mixtures with detailed and complete information on constituent materials (including weights, binder composition, and fiber content) were included to enable energy, emissions, and cost calculations;

Literature Transparency: Excluded proprietary mixtures (e.g., AFtUFC®, BCV®, CRC®) lacked disclosed binder compositions or material breakdowns, and their ingredients were often labeled as proprietary “premix,” making them unsuitable for comparative assessment.

The five proprietary and five non-proprietary UHPC mixtures included in this study are representative of commonly referenced formulations in academic and industry literature. These mixtures span a wide range of design strategies, compressive strengths (120–188 MPa), curing approaches, and material compositions, providing a valid basis for comparison and analysis of sustainability-related performance metrics.

2.4.2. Proprietary UHPC Mixtures

There are numerous types of proprietary UHPC mixtures available on the market. Recognized products include Ductal

®, Cor-Tuf

®, BSI

®, CEMTEC

®, and CARDIFRC

® [

48,

49,

50,

51,

52,

53]. There are other marketed UHPCs such as AFtUFC

®, BCV

®, and CRC

®. However, the latter sets were not included in this study because their binder is not well stated in the literature. Referred to as “premix”, the quantities of the raw materials are not explicitly defined. Generally, the marketed UHPC included a high quantity of binder content (~900 to 1300 kg/m

3) and typically contained quartz powder. The selected mixtures in this study are summarized in

Table 3.

2.4.3. Non-Proprietary UHPC Mixtures

Due to the high cost of proprietary UHPC, which is 10 to 20 times that of conventional concrete, numerous non-proprietary UHPC mixtures have been developed with locally available materials [

39,

54,

55]. Non-proprietary mixtures, due to their lower cost, can result in more widespread applications of UHPC. Typically, these mixtures do not contain quartz powder, and some include natural gradation sand instead of ultra-fine sand. The selected mixtures used in this study are summarized in

Table 4.

3. Results and Discussion

3.1. Energy and Emissions of Proprietary Mixtures

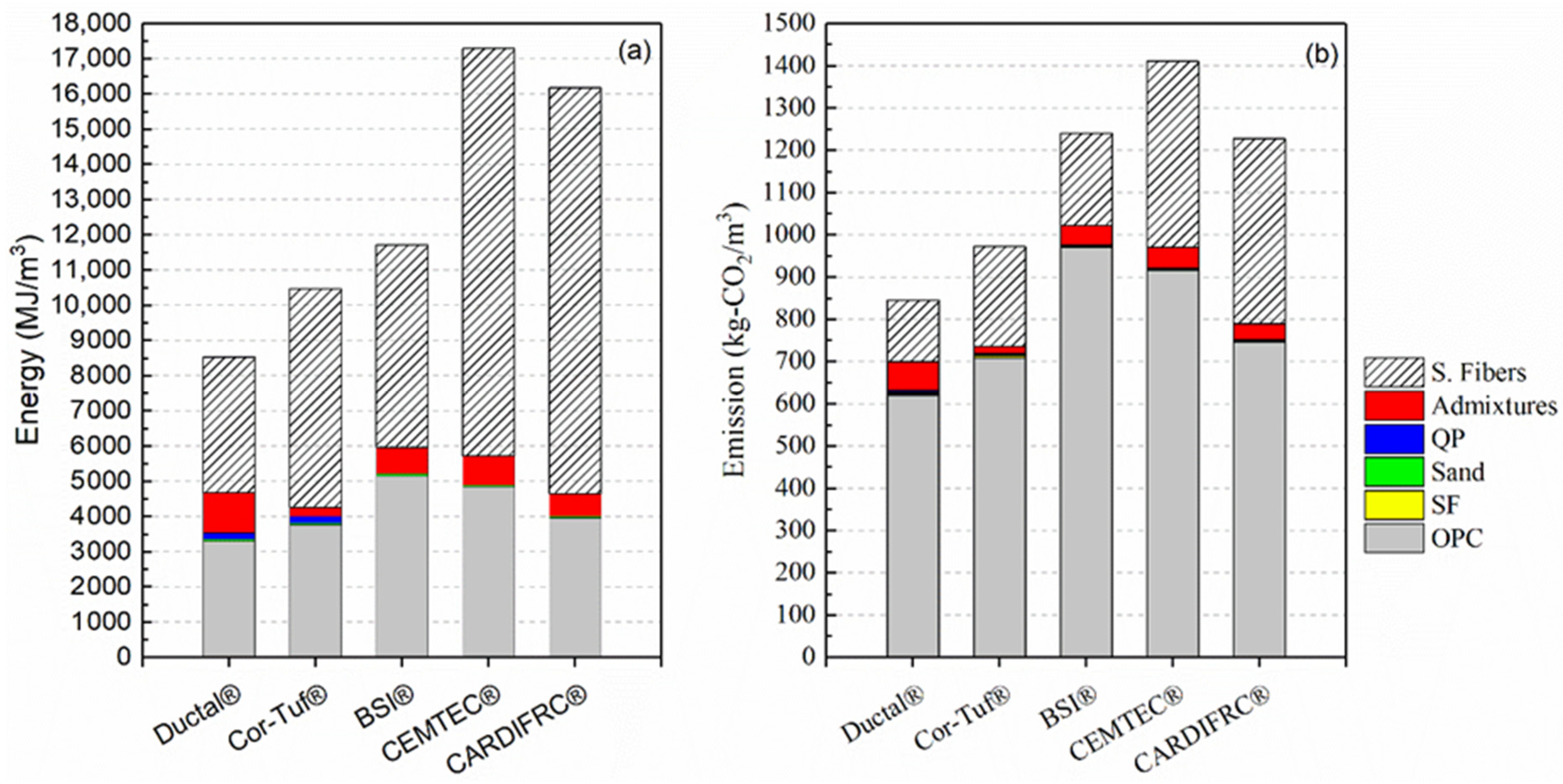

Figure 1a presents the energy of proprietary UHPC mixtures. CEMTEC

® required the highest energy—17,285.9 MJ. The major contributor to this high value is related to the use of a high percentage of steel fibers (approximately 11% by volume per one cubic meter), as shown in

Table 3. Meanwhile, OPC also contributes to the energy of CEMTEC

®, representing 28% of the total energy.

For other proprietary UHPC mixtures, steel fibers are the major contributors to the total energy, accounting for 45%, 59%, 49%, 67%, and 71% for mixtures Ductal®, Cor-Tuf®, BSI®, CEMTEC®, and CARDIFRC®, respectively. Steel fibers are needed in UHPC mixtures to enhance the tensile and flexural strengths of concrete and prevent the brittle failure of UHPC. However, if such requirements are not needed, the use of steel fibers must be minimized to reduce the total energy of the mixture.

As shown in

Figure 1a, OPC is also a key contributor to the energy of the mixtures. OPC is responsible for 39%, 36%, 44%, 28%, and 24% for mixtures Ductal

®, Cor-Tuf

®, BSI

®, CEMTEC

®, and CARDIFRC

®, respectively. Previous studies carried out on normal-strength concrete also indicated that OPC is the major contributor to the energy of concrete [

35,

56,

57]. Therefore, minimizing cement content or the utilization of blended cement may be desired to reduce this effect.

Other constituent materials such as silica fume, aggregates, high-range water reducer, and quartz powder have insignificant effects on the total energy of proprietary mixtures, as presented in

Figure 1a. The standard deviation of the results of the mixtures is approximately 3754, which indicates relatively high variability in the energy values of these concrete mixtures. The data points are spread out significantly from the mean (12,832). This implies that different mixtures have significant variations in energy consumption, which may be affected by factors such as composition, materials, or processing methods.

Figure 1b presents the CO

2 emissions of proprietary UHPC mixtures. CEMTEC

® is associated with the highest emissions at 1410.5 kg-CO

2, attributed mainly to OPC and the high percentage of steel fibers, which are responsible for approximately 65% and 32%, respectively, of the total emissions. The primary contributor to the emissions of proprietary mixtures is OPC. The contributions are 73%, 73%, 78%, 65%, and 61% for mixtures Ductal

®, Cor-Tuf

®, BSI

®, CEMTEC

®, and CARDIFRC

®, respectively. Ductal

® involves the lowest emissions since it has the lowest OPC content compared to the other proprietary mixtures. Similarly, other constituent materials have minimal influence on the total emissions of proprietary mixtures, as presented in

Figure 1b. The standard deviation of the emissions of these mixtures is approximately 227. The standard deviation shows a moderate spread in emission values and indicates that the emissions typically vary by about 227 kg CO

2 from the mean (1140).

3.2. Energy and Emissions of Non-Proprietary Mixtures

The energy consumption details for non-proprietary UHPC mixtures are illustrated in

Figure 2a, providing critical insights into the influence of key constituents on the overall sustainability profile of these mixtures. Among the analyzed mixtures, UHPC-2 exhibits the highest energy consumption of 12,099.9 MJ/m

3. This elevated energy demand is primarily driven by the inclusion of steel fibers and OPC, which account for 48% and 37% of the total energy, respectively. The substantial contribution of steel fibers reflects their energy-intensive manufacturing process, while the high energy associated with OPC stems from the calcination and clinker production stages in cement manufacturing.

In contrast, UHPC-1 and UHPC-5 display the lowest energy values, at 4218 MJ/m

3 and 5762 MJ/m

3, respectively. The absence of steel fibers in these mixtures, as detailed in

Table 4, significantly reduces their overall energy footprint. This highlights the critical role of reinforcement choices in determining the energy efficiency of UHPC. The omission of steel fibers allows these mixtures to approach energy levels comparable to normal-strength concrete, which typically falls within the range of 1911 MJ/m

3 to 2465 MJ/m

3, as reported by Alsalman et al. [

56]. The relatively low energy consumption of these mixtures positions them as more sustainable alternatives, especially in applications where the enhanced properties of UHPC (such as extreme tensile strength) are not required.

This analysis underscores the trade-offs between performance and sustainability. While steel fibers contribute significantly to the tensile and flexural strengths of UHPC, their inclusion leads to higher embodied energy. To achieve a balanced approach to sustainable construction, it may be necessary to explore alternative reinforcement strategies, such as recycled fibers or natural fibers, which offer lower energy footprints. Additionally, the energy-intensive nature of OPC calls for further investigation into supplementary SCMs like fly ash, slag, or silica fume, which can partially replace OPC and reduce overall energy consumption.

By carefully selecting materials and optimizing mixture designs, non-proprietary UHPC can be tailored to achieve high performance while minimizing energy demand, aligning with broader sustainability goals. This approach not only reduces environmental impact but also offers cost-effective solutions for infrastructure projects aiming to balance durability, efficiency, and ecological responsibility.

OPC is the major contributor to the total energy of these mixtures (UHPC-1 and UHPC-5), accounting for 83% and 58% of the mixtures UHPC-1 and UHPC-5, respectively. VCAS contributes 20% of the total energy of UHPC-5. For other non-proprietary mixtures, OPC is the major contributor to energy, accounting for 41%, 37%, and 35% of the total energy of mixtures UHPC-2, UHPC-3, and UHPC-4, respectively. Other parameters such as SCMs, high-range water reducer, and curing, have an insignificant impact on the total energy of the mixtures (e.g., curing accounts for only 4% and 6% of the total energy of mixtures UHPC-2 and UHPC-3). The standard deviation indicates a high variability in energy values. The energy consumption of these concrete mixtures typically deviates by about 3109 MJ/m3 from the mean. This variability may be due to differences in material composition, processing techniques, or mixture design.

The emissions data illustrated in

Figure 2b provide a comprehensive understanding of the carbon footprint associated with various non-proprietary UHPC mixtures. Among these mixtures, UHPC-2 demonstrates the highest emissions, reaching 1393 kg-CO

2/m

3. This substantial emission level is predominantly driven by ordinary Portland cement (OPC), which accounts for an overwhelming 67% of the total emissions. The high emissions contribution of OPC is attributable to the energy-intensive processes involved in cement manufacturing, including clinker production and calcination, both of which release large quantities of CO

2.

A closer examination of the other mixtures reveals that OPC remains the primary contributor to emissions across the board, with the following breakdown: UHPC-1: 94%, UHPC-3: 60% UHPC-4: 72%, and UHPC-5: 86% of total emissions, respectively. These findings emphasize that reducing OPC content in UHPC mixtures is crucial for lowering their overall CO

2 footprint. Given that OPC is responsible for such a significant portion of emissions, incorporating SCMs such as fly ash, slag, or silica fume can substantially reduce the environmental impact. Additionally, alternative low-carbon cement (e.g., limestone calcined clay cement or geopolymer cement) presents promising options for further emissions reductions [

58].

While OPC is the dominant emissions contributor, steel fibers also play a significant role when included in the mixture. In mixtures UHPC-2, UHPC-3, and UHPC-4, steel fibers account for 16%, 16%, and 17% of the total emissions, respectively. The notable contribution of steel fibers is due to the energy-intensive processes involved in the production of steel, such as ore extraction, smelting, and fabrication. Although steel fibers enhance the tensile strength and durability of UHPC, their emissions footprint cannot be overlooked.

In comparison to OPC and steel fibers, other constituent materials such as aggregates, silica micro-cement (SMCs), high-range water reducers, and curing processes exhibit a negligible impact on the total emissions. Their contributions are minimal due to their relatively low embodied carbon and the lower energy demands associated with their production and processing. This suggests that while optimizing these materials can provide incremental improvements, significant emissions reductions must focus on OPC and steel fibers.

The standard deviation of the emissions indicates moderate to high variability in the emissions data. Emissions for these concrete mixtures typically deviate by about 276 kg-CO2/m3 from the mean.

3.3. Cost Analysis

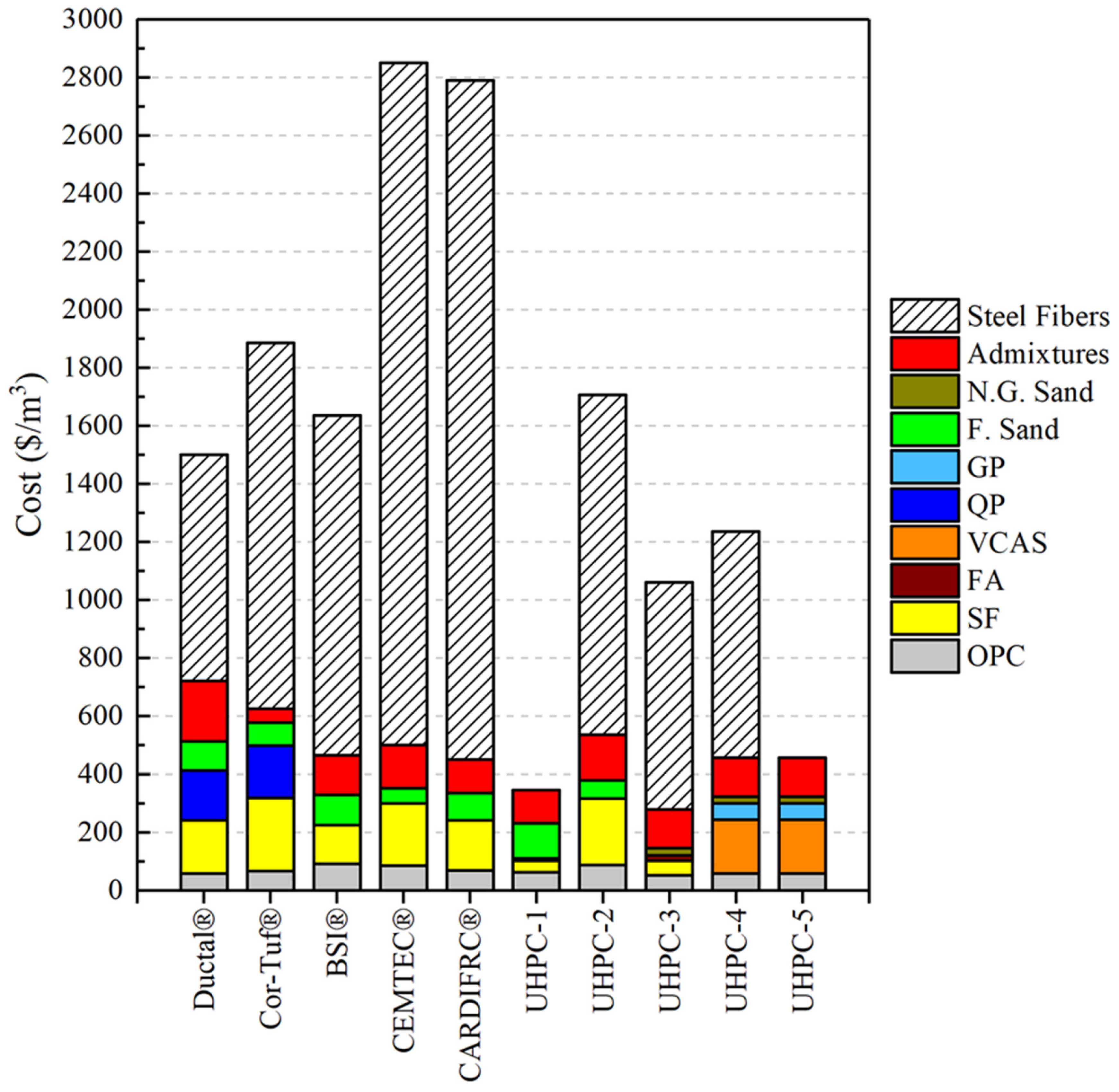

Figure 3 presents the cost of all UHPC mixtures (proprietary and non-proprietary). It can be noticed that steel fibers are the major parameter that affects the cost of UHPC. Regarding all the mixtures that contain steel fibers, including Ductal

®, Cor-Tuf

®, BSI

®, CEMTEC

®, CARDIFRC

®, UHPC-2, UHPC-3, and UHPC-4, steel fibers account for 52%, 67%, 72%, 82%, 84%, 69%, 74%, and 63% of the total cost of these mixtures, respectively). On average, steel fibers account for 70% of the total cost. Therefore, the majority of studies that focus on the development of UHPC specify 2% to 3% of steel fibers by the total volume of the mixture [

13,

21,

48] as an optimum ratio. The highest-cost mixtures are CEMTEC

® (USD 2852/m

3) and CARDIFRC

® (USD 2791/m

3) since these mixtures incorporate high percentages of steel fibers: 11% and 6%, respectively. Ductal

® has the lowest cost compared to other proprietary UHPC mixtures (USD 1500/m

3), and steel fibers account for 52% of the total cost. On average, silica fumes represent 10% of the total cost of proprietary mixtures.

On the other hand, the lowest-cost non-proprietary mixture is UHPC-1 (USD 347/m

3). Fine sand and high-range water reducer admixture account for 35% and 33% of the total cost of UHPC-1, respectively. UHPC-4 and UHPC-5 have the same mixture proportions, such as cement, aggregate, glass powder, VCAS, high-range water reducer, etc., except for steel fiber. However, UHPC-4 has 2% steel fibers by volume, and UHPC-5 has 0% steel fibers, as presented in

Table 4. The costs for UHPC-4 and UHPC-5 are USD 1236 and USD 456; steel fibers increase the cost by 171%. For UHPC-5, VCAS and glass powder contribute 40% and 12% of the total cost, respectively. The average contribution of OPC to the cost of proprietary and non-proprietary mixtures is 4% and 9%, respectively.

3.4. Proficiency Analysis of Proprietary and Non-Proprietary Mixtures

Table 5 provides a comparative analysis of the proficiency of proprietary and non-proprietary UHPC (ultra-high-performance concrete) mixtures, evaluating their energy consumption, CO

2 emissions, and raw material costs needed to achieve 1 MPa of compressive strength. Among all the evaluated mixtures, UHPC-1 emerges as the most efficient in terms of energy, emissions, and cost. Specifically, UHPC-1 demonstrates significant reductions in energy consumption—65%, 47%, 56%, and 27% lower compared to UHPC-2, UHPC-3, UHPC-4, and UHPC-5, respectively. This notable efficiency can be attributed to optimized material proportions and possibly, the use of SCMs that reduce the need for energy-intensive components like cement and steel fibers.

Additionally, UHPC-1 exhibits a favorable profile regarding emissions, producing 49%, 24%, 20%, and 5% less CO2 compared to UHPC-2, UHPC-3, UHPC-4, and UHPC-5, respectively. This reduction in emissions is likely to result from minimized use of ordinary Portland cement (OPC), which is a significant contributor to CO2 output. Furthermore, in terms of cost efficiency, UHPC-1 proves advantageous, with raw material costs 80%, 67%, 72%, and 24% lower than those of UHPC-2, UHPC-3, UHPC-4, and UHPC-5, respectively. This combination of reduced energy use, lower emissions, and minimized costs makes UHPC-1 a compelling choice for applications where sustainability and economy are priorities.

Conversely, CEMTEC® stands out as the least efficient mixture in terms of both energy and cost, requiring 102.9 MJ/MPa and incurring costs of USD 17/MPa. This inefficiency is primarily due to the high ratio of steel fibers in the mixture, which significantly increases energy consumption and material costs. The presence of steel fibers, while beneficial for mechanical properties like tensile strength and ductility, imposes a considerable environmental and economic burden due to their energy-intensive production process.

On the other hand, UHPC-2 demonstrates the highest CO2 emissions (1077 kg/MPa), which can be attributed to its high OPC content. The reliance on OPC in UHPC-2 highlights the need for alternative binders or SCMs to mitigate environmental impacts while maintaining performance. In contrast, Ductal® achieves the lowest energy demand among proprietary mixtures, consuming 3%, 15%, 20%, and 33% less energy compared to Cor-Tuf®, BSI®, CEMTEC®, and CARDIFRC®, respectively. This suggests that Ductal® employs a more energy-efficient mix design, potentially through careful selection and proportioning of constituents or optimized curing methods.

Interestingly, while Ductal® excels in energy efficiency, Cor-Tuf® is the most cost-efficient proprietary mixture. This indicates that while energy savings may not always directly translate to cost reductions, Cor-Tuf® mixture design effectively balances raw material costs without compromising performance.

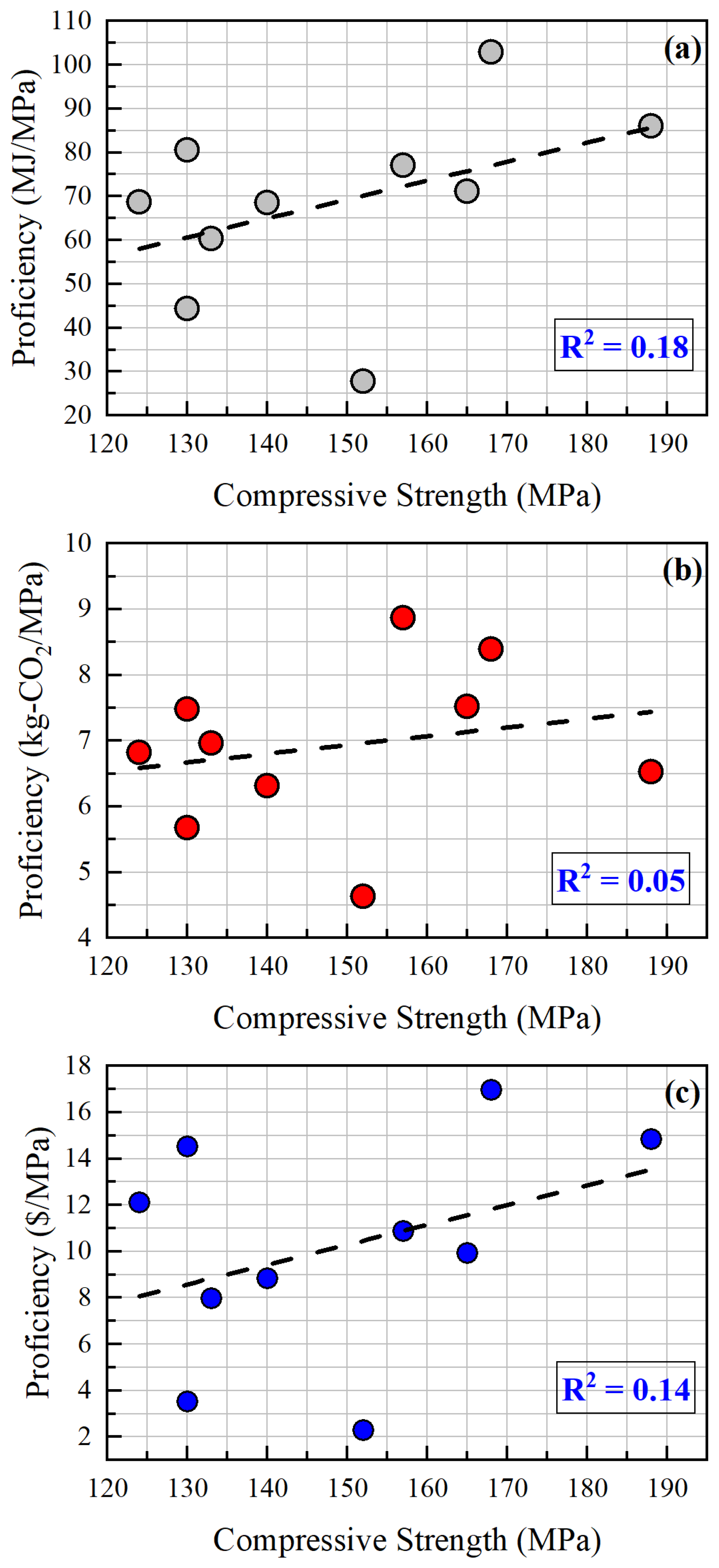

As shown in

Figure 4, regression trendlines were added to assess probable correlations between compressive strength and sustainability metrics. The obtained R

2 values were 0.18 (energy-based proficiency), 0.05 (CO

2-based proficiency), and 0.14 (cost-based proficiency). All three values are well below 0.20, confirming very weak explanatory power. This specifies that compressive strength accounts for only a small part of the variability in sustainability performance. Consequently, enhancements in compressive strength alone do not necessarily translate into improved ecological or economic results, and mixture composition (binder selection, SCMs, and curing methods) remains the main factor affecting sustainability. It should be noted that the two non-proprietary mixes without steel fibers contribute to the observed scatter. Excluding them would result in a modest improvement in correlation (particularly for energy); nevertheless, the full dataset was considered to ensure reliability and reasonable comparison across all mixtures.

In conclusion, achieving an efficient UHPC mixture depends on the strategic selection and proportioning of materials, considering the intended function and performance goals. This balance requires careful consideration of energy-intensive constituents like OPC and steel fibers, as well as exploring alternative materials and innovative designs to optimize sustainability and economic viability.

4. Sensitivity Analysis

To assess the robustness of this study’s conclusions, a sensitivity analysis was conducted by varying key input parameters that significantly influence UHPC performance and sustainability, namely, the content of OPC and steel fibers. These constituents are recognized to contribute the most to energy consumption, CO2 emissions, and cost.

4.1. Variation in Cement Content

The OPC content was varied by ±20% from the baseline values in representative proprietary and non-proprietary mixtures. The results indicate the following:

This affirms the dominant role OPC plays in the sustainability metrics of UHPC mixtures.

4.2. Variation in Steel Fiber Content

Steel fibers varied from 0% to 4% by volume fraction of the mixture, covering the typical range used in UHPC mixtures. The analysis resulted in the following findings:

Mixtures with no steel fibers (e.g., UHPC-1 and UHPC-5) had energy and emissions reduced by up to 50–65%, and costs reduced by more than 60% compared to mixtures with high fiber content (e.g., CEMTEC® and CARDIFRC®).

These results highlight the importance of optimizing steel fiber content for more sustainable design.

4.3. Implications

The sensitivity analysis proves that OPC and steel fibers are the most significant parameters influencing UHPC sustainability. A small lessening in these contributions can substantially reduce the environmental footprint and cost. This analysis also supports the current study’s main conclusion that strategic mixture design can produce more sustainable UHPC without compromising the main properties of UHPC.

4.4. ±20% One-at-a-Time Sensitivity Analysis

To evaluate the robustness of our findings, we performed a one-at-a-time sensitivity analysis by changing the two most influential parameters—OPC content and steel fiber content—by ±20%.

Table 6 summarizes the effects of these variations on total energy, emissions, and cost using a representative mixture.

These results confirm that small changes in OPC and steel fiber have significant influences on sustainability metrics, highlighting the importance of mixture optimization.

4.5. Visual Summary

To complement the numerical results in

Section 4.1,

Section 4.2,

Section 4.3 and

Section 4.4,

Figure 5 shows a bar chart assessment of the sensitivity analysis conclusions. The bars show the relative changes in total energy, emissions, and cost under ±20% variation of OPC and fiber content. The visualization obviously demonstrates that OPC variation exerts a much stronger influence on sustainability indicators than steel fibers, with increases in OPC leading to disproportionate rises in both energy demand and emissions. However, variation in steel fiber content yields slight shifts, principally in cost. The bar graph in

Figure 5 provides a summarizing visual confirmation of the numerical sensitivity results and highlights the robustness of the conclusions.

5. Sustainability of UHPC Mixtures

In the context of sustainability, this study evaluates the environmental and economic efficiency of 10 UHPC mixtures: 5 proprietary and 5 non-proprietary. By analyzing constituent materials and using parameters from the literature, we calculated the energy consumption, CO2 emissions, and cost associated with producing one cubic meter of each mixture. The results highlight that UHPC-1, a non-proprietary mixture, demonstrated the highest sustainability in terms of energy efficiency, emissions reduction, and cost-effectiveness. Conversely, CEMTEC®, a proprietary mixture, exhibited the highest energy consumption and cost, making it the least sustainable. In terms of emissions, only UHPC-2 surpasses CEMTEC® in inefficiency. Further analysis at the material level reveals that steel fibers significantly impact the sustainability of UHPC mixtures, contributing up to 70% of the total cost and a substantial share of energy use and CO2 emissions. OPC is another major driver of both energy consumption and emissions. In contrast, materials like silica micro-cement (SMCs) and high-range water reducers, as well as curing processes, have minimal influence on total emissions. Interestingly, no correlation was found between the efficiency parameters (energy, emissions, and cost) and the strength of the mixtures, indicating opportunities for developing more sustainable UHPC without compromising performance. These findings offer valuable insights for researchers and practitioners aiming to enhance the sustainability of UHPC by optimizing material choices and mixture designs. As a result, to produce UHPC mixtures while maintaining sustainability requirements, a comprehensive approach is required that includes optimizing material choices, reducing energy and emissions, ensuring cost efficiency, and promoting durability and recycling. Reducing the use of OPC and limiting the incorporation of steel fibers are the key factors in producing a sustainable UHPC. The incorporation of a high volume of supplementary cementitious materials, such as fly ash, silica fume, slag, or blended cement, can substantially minimize the OPC content in the mixture. Conversely, while aggregates have a minimal impact on the sustainability of UHPC mixtures, incorporating recycled aggregates into the mixture design can enhance sustainability by reducing the demand for virgin materials and minimizing environmental impact. In addition, the incorporation of such materials can reduce the cost as well. By implementing these strategies, the construction industry can significantly reduce its environmental footprint and enhance the long-term sustainability of built environments.

6. Limitations and Implications for Researchers

The significant impact of both steel fibers and OPC on energy and emissions highlights the need for researchers to continue to develop mixtures that minimize their use. While OPC is a cost-effective material, the environmental impact may be a catalyst for finding substitutes, especially as sustainability goals become more common for infrastructure projects.

While the present research provides an estimate of the energy, emissions, and cost of 10 UHPC mixtures, it has some notable limitations. First, the energy and emissions parameters were gathered from the extant literature and not directly calculated. Reliance on literature-based datasets can lead to possible inaccuracies, as reported values might vary depending on region, methodological presumptions, or database updates. Future research may consider replicating these conclusions by calculating parameters under controlled experimental or region-specific conditions. Second, the costs of the constituent materials were obtained in 2020, at the time that this research related to UHPC was conducted in Arkansas. Price fluctuations over time and regional market variability could influence cost assessments, and consequently, updated regional cost assessments are encouraged in future research. Third, this study does not account for the environmental or economic impacts associated with transporting raw materials or finished UHPC mixtures. Given the heavyweight and often long-distance shipping of construction materials, transportation emissions and costs could significantly increase the total embodied energy and overall sustainability footprint. Future studies should incorporate transportation models to provide a more holistic and practical assessment.

7. Implications for Practitioners

The results of this analysis can guide project managers and engineers in their selection of UHPC mixtures. According to the proficiency analysis, most non-proprietary mixtures are more efficient in terms of energy, efficiency, and cost than proprietary mixtures. UHPC-2 is the one exception. UHPC-1 is the optimal choice to maximize strength in light of energy, emissions, and cost. Ductal® is the most efficient proprietary mixture. While the aggregates, admixtures, and SCMs used in the various mixtures have significant impacts on cost, they do not significantly affect the energy or emissions of the mixtures. Additionally, the efficiency parameters are not correlated with concrete strength. Together, these results provide evidence that decision-makers can select the mixture that best meets their environmental project goals without sacrificing financial performance.

8. Recommendations for Future Work

The following recommendations may be considered for future research:

Researchers should investigate the influence of transportation on the total energy, emissions, and cost of UHPC mixtures, accounting for the transportation of raw materials and final products could provide a more comprehensive assessment of the environmental impact.

This study should be validated using local energy and emissions parameters specific to the regions where the UHPC will be produced and applied. Additionally, the local costs of materials should be considered to ensure accuracy and relevance in different geographic contexts.

Research into the use of alternative, low-carbon materials such as supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume can reduce reliance on ordinary Portland cement (OPC) and steel fibers, which are major contributors to energy consumption and emissions.

Experimental measurements should be carried out to calculate the energy consumption, emissions, and cost of UHPC mixtures, rather than relying solely on secondary data from the literature. This will enhance the robustness and accuracy of the findings.

Researchers can explore new methods for optimizing mixture proportions, including AI-guided designs or novel curing techniques, to achieve better sustainability and cost-efficiency.

Life cycle assessments (LCAs) should be conducted to evaluate the long-term energy, emissions, and cost implications of UHPC mixtures over their service life, including maintenance and durability considerations.

Researchers should iunvestigate the incorporation of recycled aggregates to minimize the environmental impact and reduce costs while maintaining structural performance. To enhance sustainability, future research may explore the use of recycled steel fibers or alternative natural fibers such as basalt, coconut, or hemp. These alternatives can significantly reduce the embodied energy and CO2 emissions while retaining acceptable mechanical performance, particularly in non-structural or low-load applications.

The efficiency of UHPC in various structural applications, such as bridges, high-rise buildings, and repair projects, should be studied to determine the most sustainable and cost-effective use cases.

9. Conclusions

This study compared proprietary and non-proprietary UHPC mixtures in terms of energy demand, CO2 emissions, and cost, with the following main findings:

Comparative summary: While proprietary UHPC mixtures normally experienced higher compressive strength, they were also associated with greater energy, emissions, and cost. On the other hand, non-proprietary mixtures accomplished comparable mechanical performance with lower overall environmental and economic weights;

Practical recommendations: From a sustainability standpoint, non-proprietary UHPC provides a more balanced option for structural applications where marginal strength gains do not justify considerably higher influences. Proprietary mixtures may remain desirable for projects requiring maximum strength-to-volume efficiency (e.g., prestressed bridge elements). However, for most traditional practices, non-proprietary substitutes offer a cost-effective and lower-carbon footprint;

Key takeaways for practice: The findings highlight that material selection should not be based exclusively on mechanical properties. However, integrating sustainability metrics into engineering practice allows more informed decisions that align with both performance and environmental objectives. For planners and designers, adopting non-proprietary UHPC can help decrease emissions and costs, thus supporting broader green construction initiatives.

Generally, this study demonstrates the value of comparative sustainability assessments in guiding UHPC mixture selection. Future research should expand the scope by including transportation impacts, regional emission baselines, and life cycle assessments to deliver a more complete framework for sustainable material design.