Sustainable High-Performance Geopolymer Concrete: The Role of Recycled Industrial Wastes in Strength, Durability, and Microstructure Enhancement

Abstract

1. Introduction

2. Materials and Methods

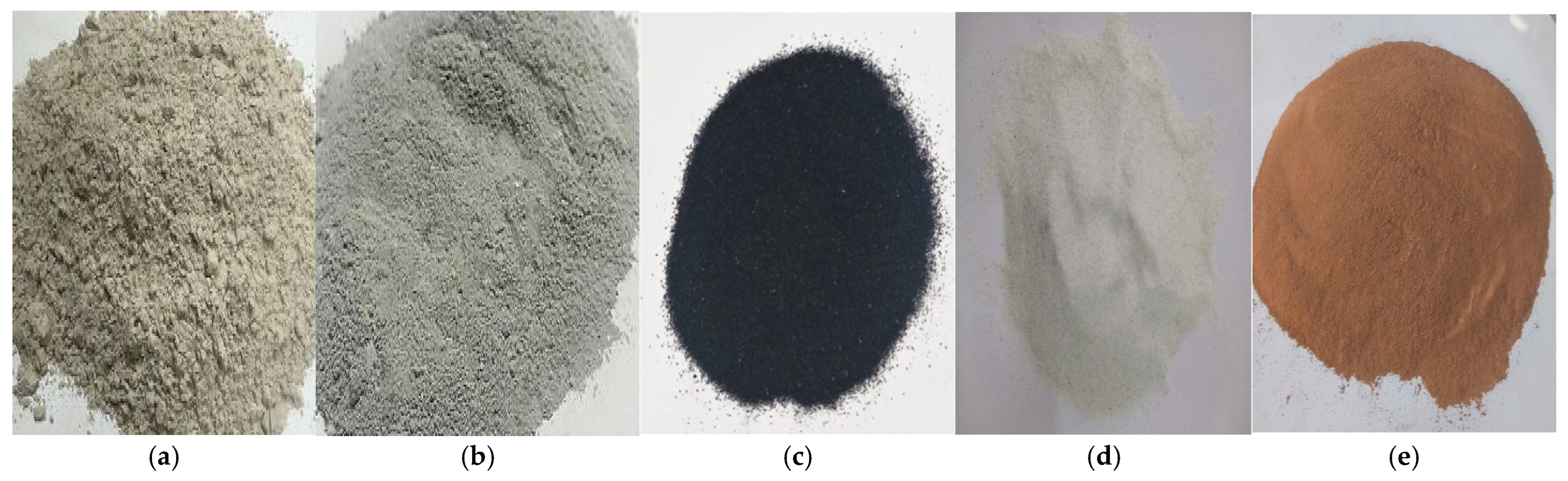

2.1. Materials Type and Characterization

2.2. Preparation of Specimens

2.3. Experimental Methods

3. Result and Discussion

3.1. Workability

3.2. Physical and Mechanical Properties

3.2.1. Unit Weight

3.2.2. Water Absorption

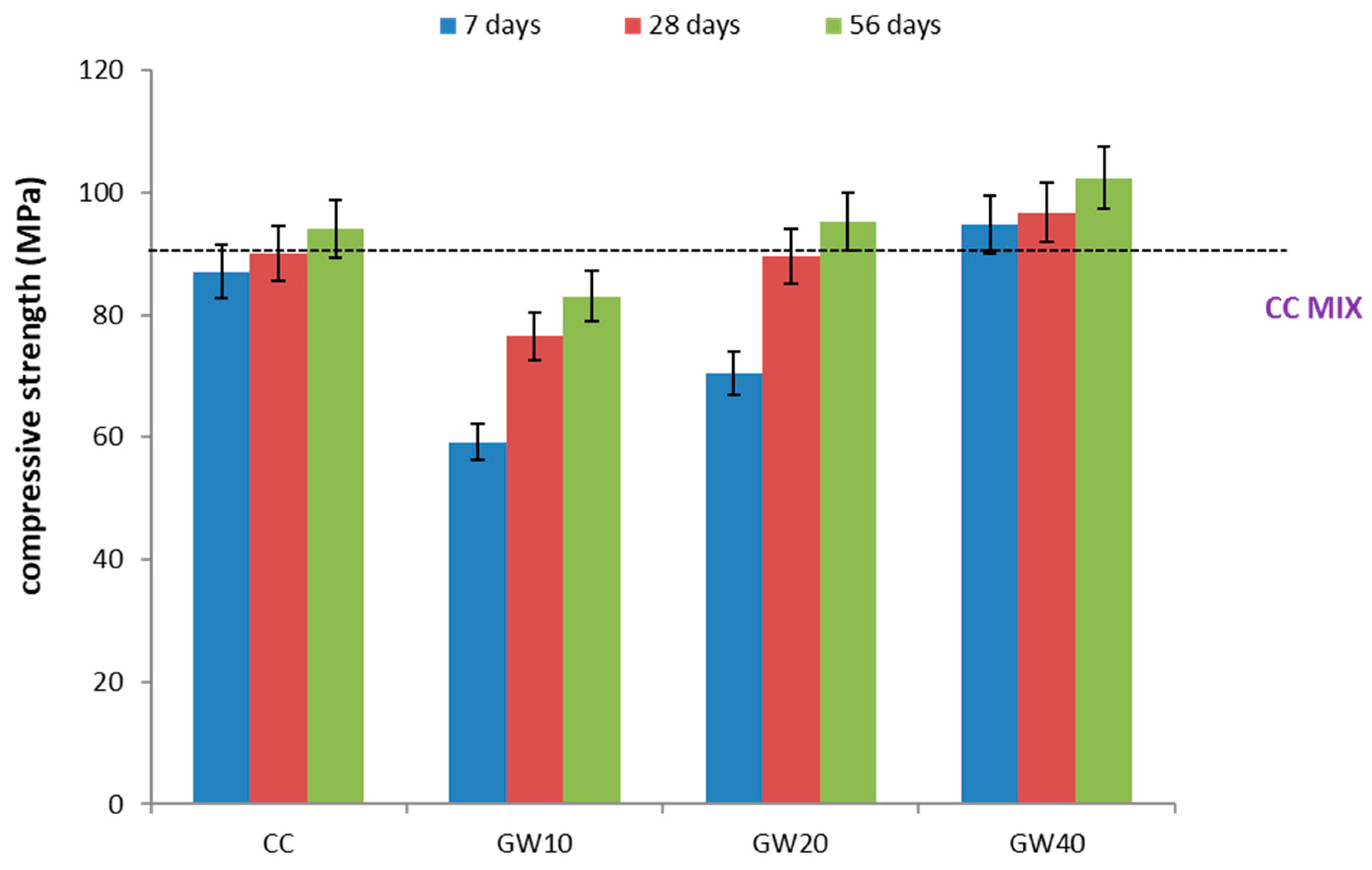

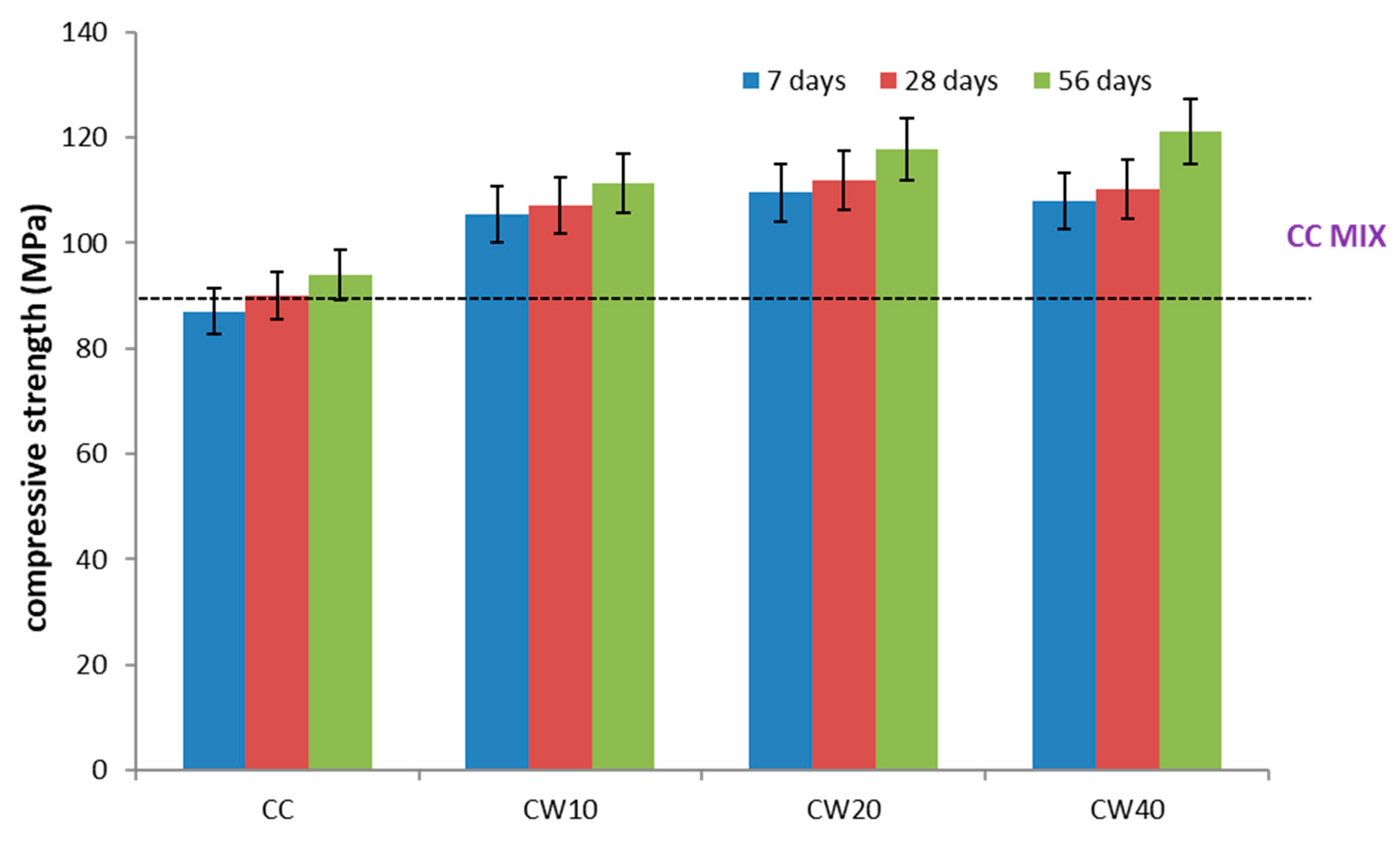

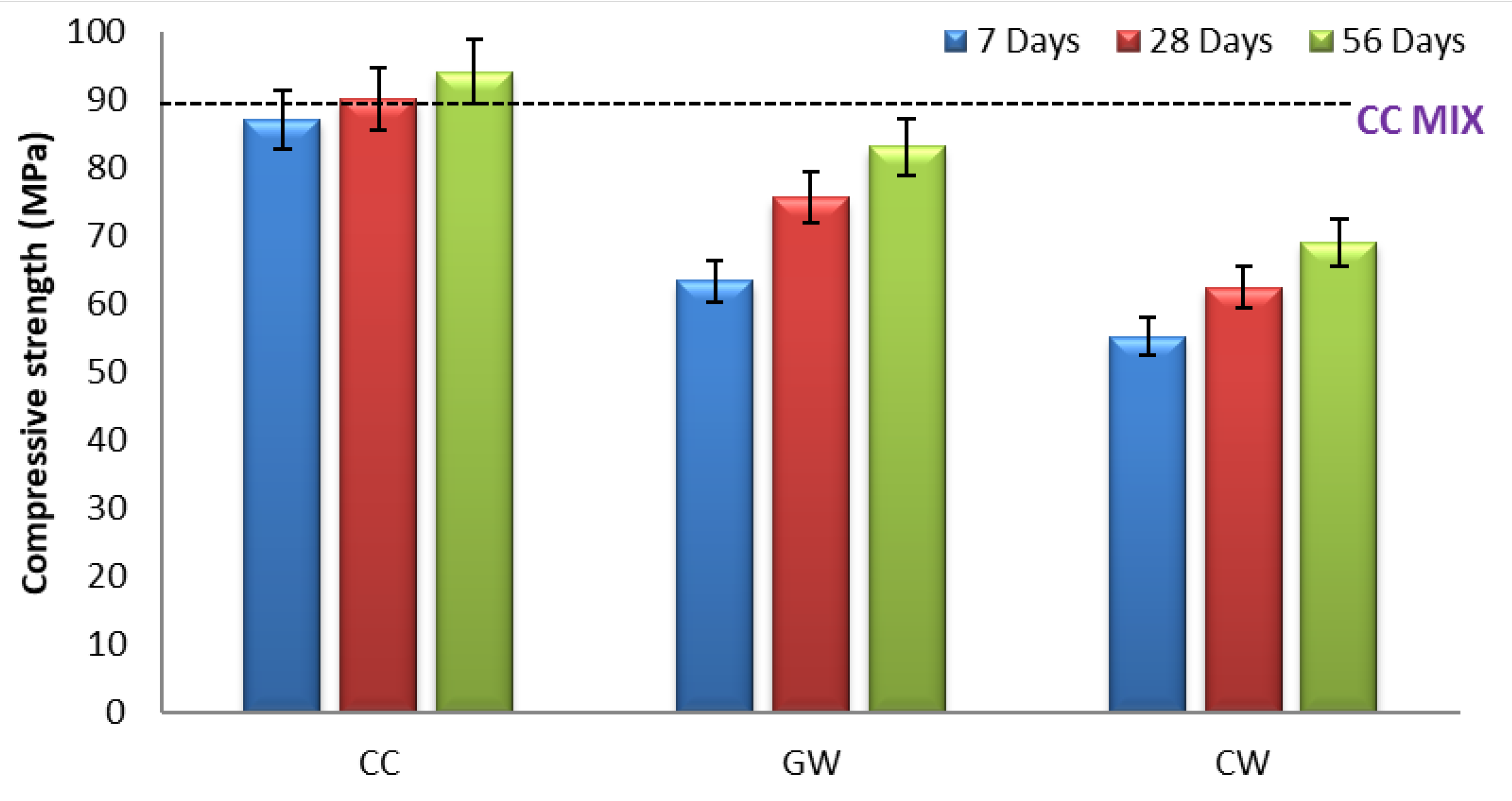

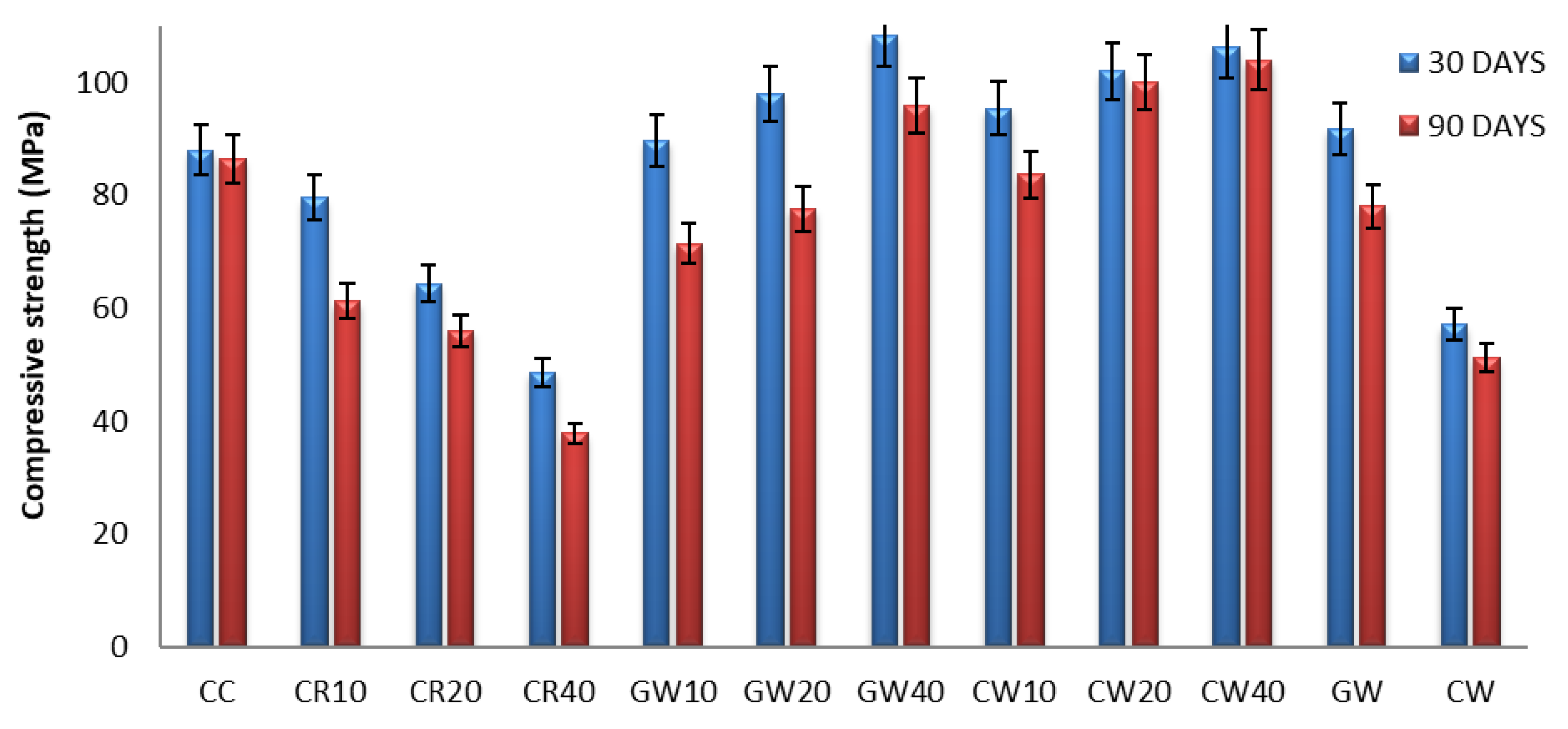

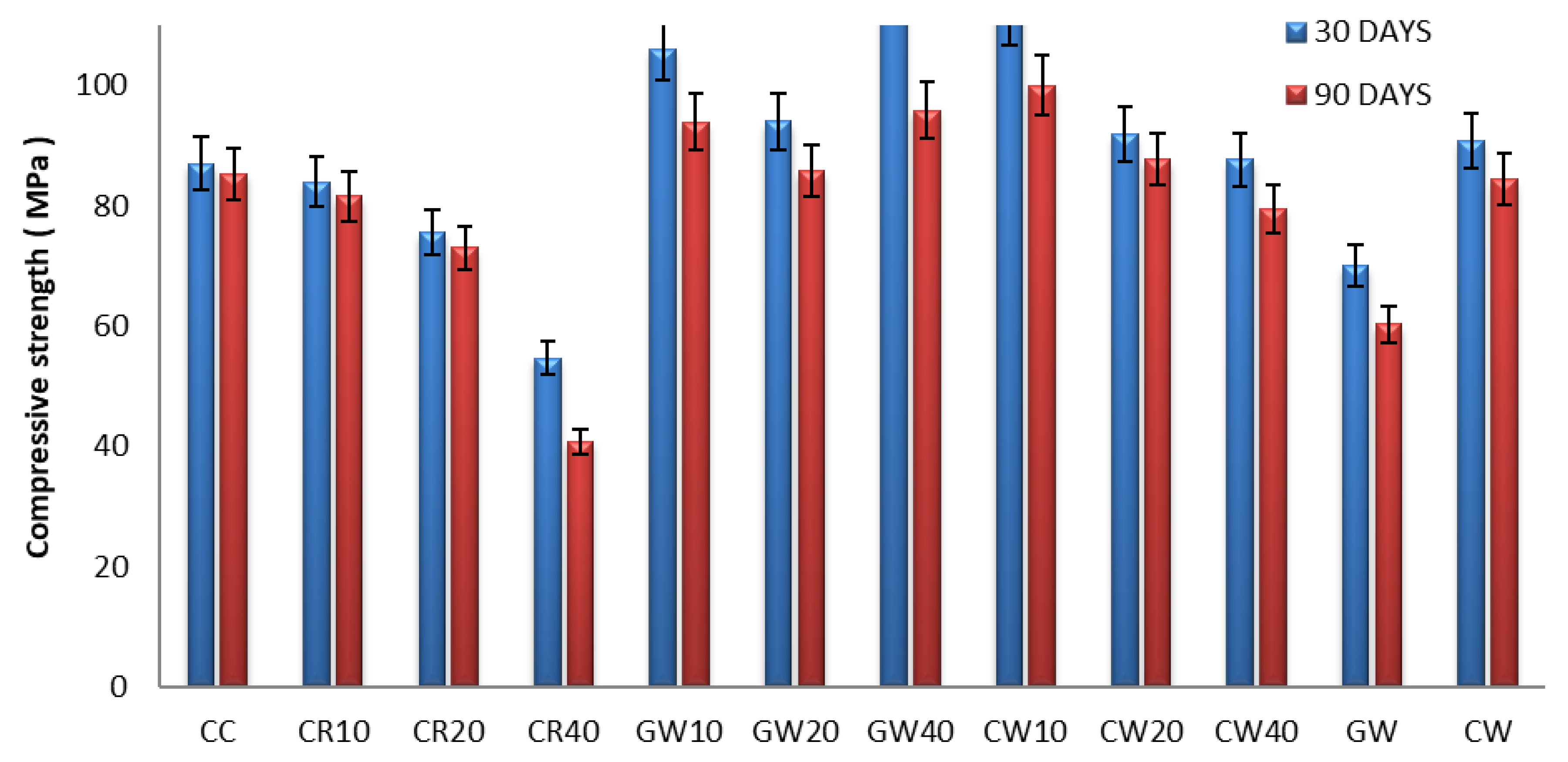

3.2.3. Compressive Strength

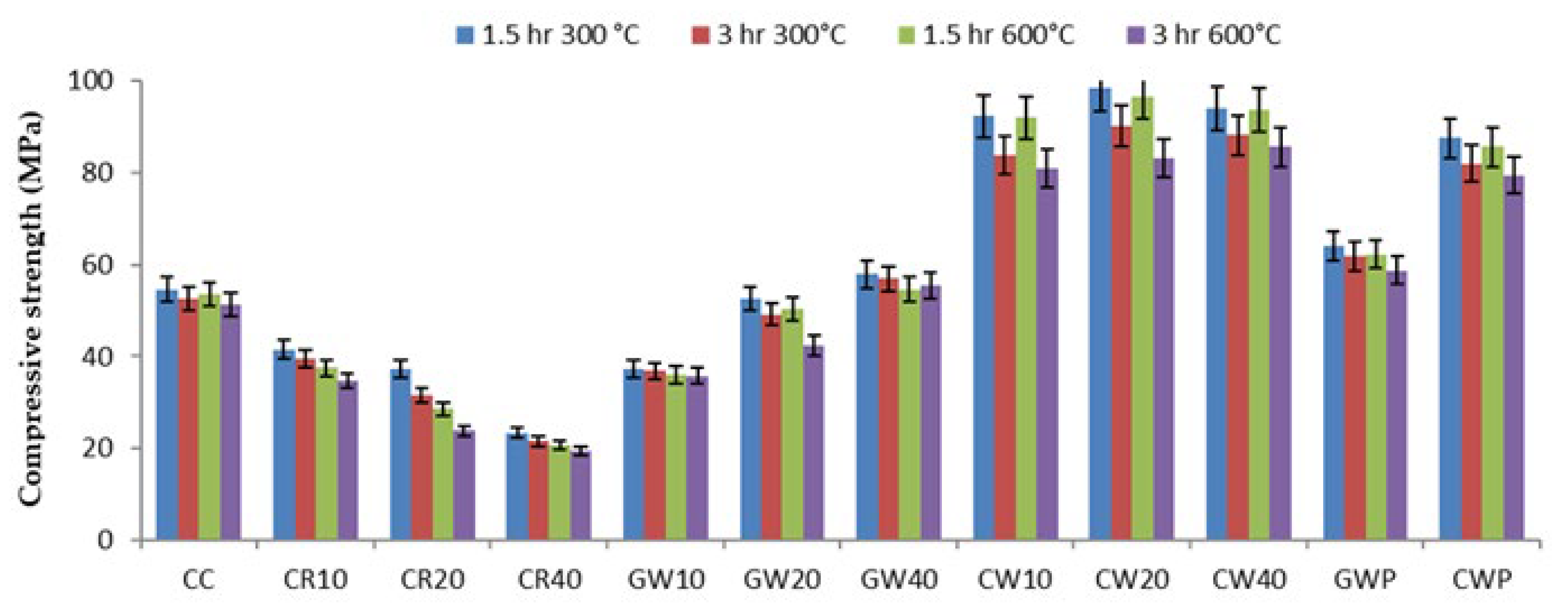

3.2.4. Residual Compressive Strength Under Elevated Temperatures

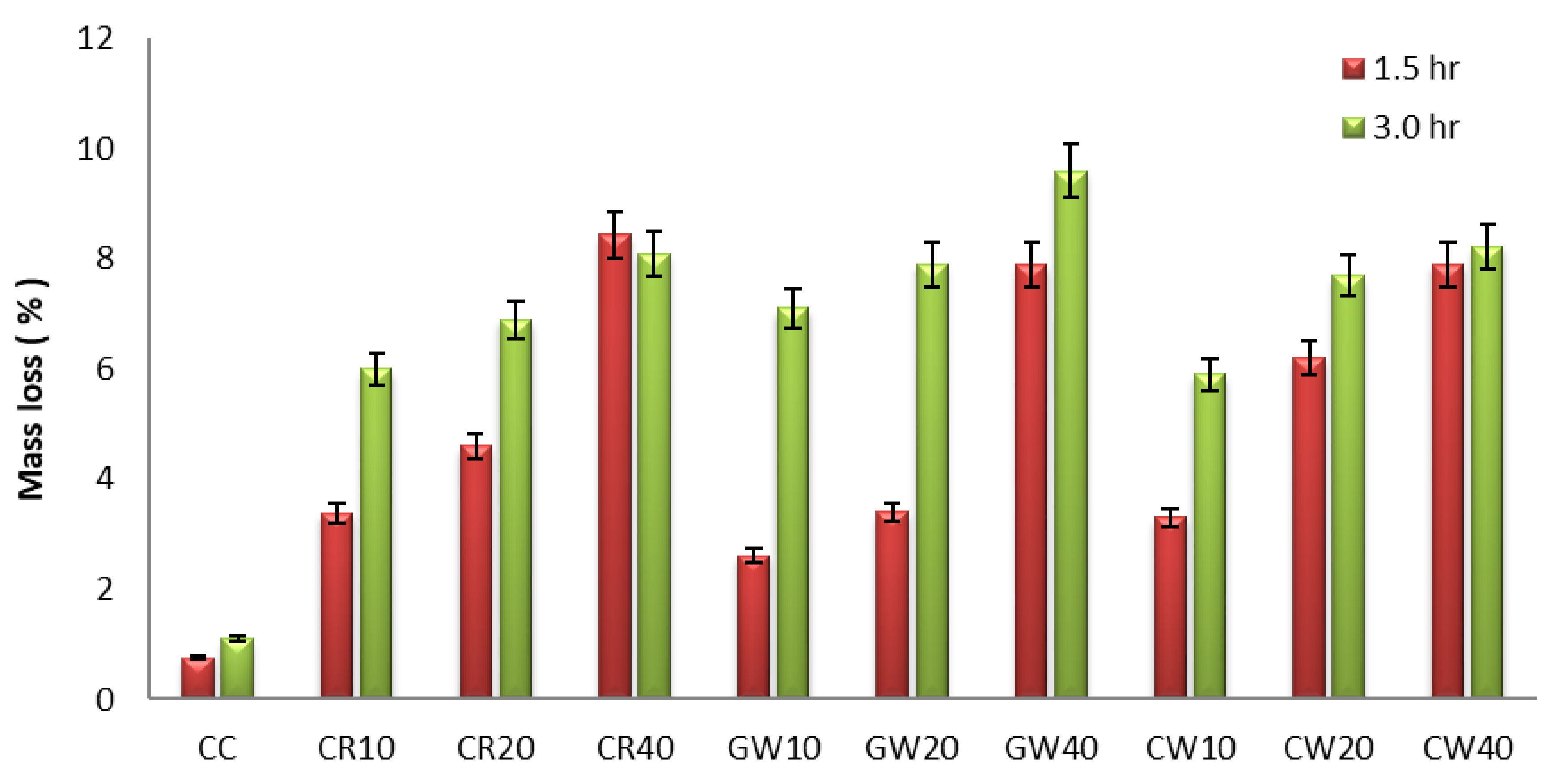

3.2.5. Thermo-Physical Appearance and Mass Change

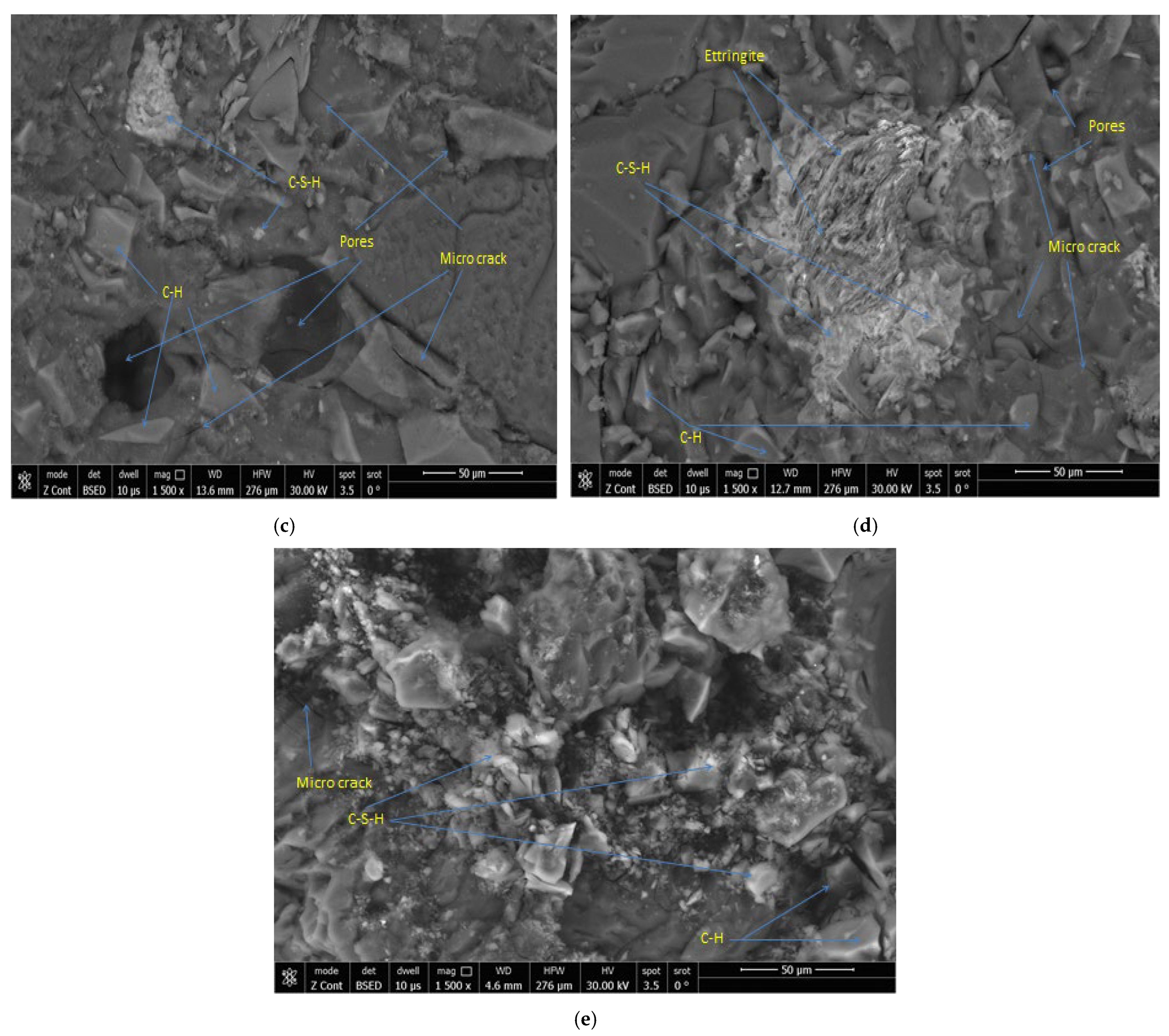

3.2.6. SEM Observation

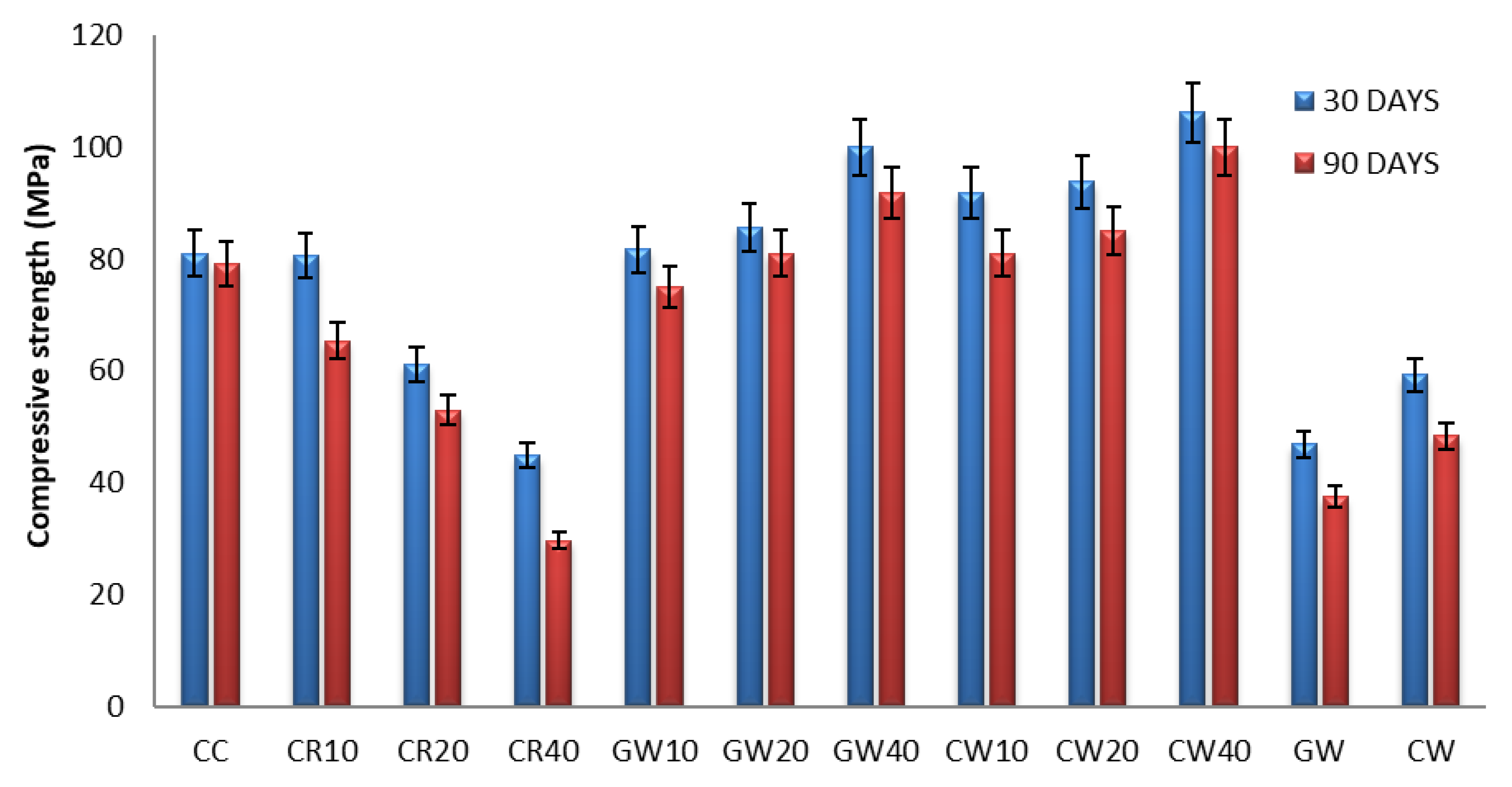

3.3. Effect of Aggressive Chemical Attacks

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abbass, A.M.; Elrahman, M.A.; Abdel-Gawwad, H.A.; Stephan, D. Critical parameters affecting the thermal resistance of alkali-activated aluminosilicate wastes: Current understanding and future directions. Environ. Sci. Pollut. Res. 2023, 30, 84874–84897. [Google Scholar] [CrossRef]

- Mokhtar, A.; Nasooti, M. A decision support tool for cement industry to select energy efficiency measures. Energy Strateg. Rev. 2020, 28, 100458. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Hamdan, S.; van Deventer, J.S.J. Microstructural changes in alkali activated fly ash/slag geopolymers with sulfate exposure. Mater. Struct. 2013, 46, 361–373. [Google Scholar] [CrossRef]

- Abdel-Gawwad, H.A.; Abbass, A.M.; Al-Kroom, H.; Sikora, P.; El-Khayatt, A.M.; Elrahman, M.A.; Stephan, D. Understanding the role of andesite igneous rock in enhancing the performance of alkali-activated ultrafine slag exposed to normal and elevated temperatures. Constr. Build. Mater. 2023, 409, 133847. [Google Scholar] [CrossRef]

- Mahmoodi, O.; Siad, H.; Lachemi, M.; Dadsetan, S.; Sahmaran, M. Development of optimized binary ceramic tile and concrete wastes geopolymer binders for in-situ applications. J. Build. Eng. 2021, 43, 102906. [Google Scholar] [CrossRef]

- Saxena, R.; Gupta, T. Assessment of mechanical, durability and microstructural properties of geopolymer concrete containing ceramic tile waste. J. Mater. Cycles Waste Manag. 2022, 24, 725–742. [Google Scholar] [CrossRef]

- Lyu, X.; Elchalakani, M.; Ahmed, T.; Sadakkathulla, M.A.; Youssf, O. Residual strength of steel fibre reinforced rubberised UHPC under elevated temperatures. J. Build. Eng. 2023, 76, 107173. [Google Scholar] [CrossRef]

- Gravina, R.J.; Xie, T.; Roychand, R.; Zhuge, Y.; Ma, X.; Mills, J.E.; Youssf, O. Bond behaviour between crumb rubberized concrete and deformed steel bars. Structures 2021, 34, 2115–2133. [Google Scholar] [CrossRef]

- Ambily, P.S.; Ravisankar, K.; Umarani, C.; Dattatreya, J.K.; Iyer, N.R. Development of ultra-high-performance geopolymer concrete. Mag. Concr. Res. 2014, 66, 82–89. [Google Scholar] [CrossRef]

- Hassanli, R.; Youssf, O.; Mills, J.E. Seismic performance of precast posttensioned segmental FRP-confined and unconfined crumb rubber concrete columns. J. Compos. Constr. 2017, 21, 4017006. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Ellatief, M.A.; Heneigel, A.M.; Elrahman, M.A. Characteristics of eco-friendly ultra-high-performance geopolymer concrete incorporating waste materials. Ceram. Int. 2022, 48, 19662–19674. [Google Scholar] [CrossRef]

- Park, Y.; Abolmaali, A.; Kim, Y.H.; Ghahremannejad, M. Compressive strength of fly ash-based geopolymer concrete with crumb rubber partially replacing sand. Constr. Build. Mater. 2016, 118, 43–51. [Google Scholar] [CrossRef]

- Abd-Elaal, E.-S.; Araby, S.; Mills, J.E.; Youssf, O.; Roychand, R.; Ma, X.; Zhuge, Y.; Gravina, R.J. Novel approach to improve crumb rubber concrete strength using thermal treatment. Constr. Build. Mater. 2019, 229, 116901. [Google Scholar] [CrossRef]

- Perez-Cortes, P.; Escalante-Garcia, J.I. Gel composition and molecular structure of alkali-activated metakaolin-limestone cements. Cem. Concr. Res. 2020, 137, 106211. [Google Scholar] [CrossRef]

- Huseien, G.F.; Hamzah, H.K.; Sam, A.R.M.; Khalid, N.H.A.; Shah, K.W.; Deogrescu, D.P.; Mirza, J. Alkali-activated mortars blended with glass bottle waste nano powder: Environmental benefit and sustainability. J. Clean. Prod. 2020, 243, 118636. [Google Scholar] [CrossRef]

- Medina, C.; de Rojas, M.I.S.; Frías, M. Freeze-thaw durability of recycled concrete containing ceramic aggregate. J. Clean. Prod. 2013, 40, 151–160. [Google Scholar] [CrossRef]

- Gomes, M.; de Brito, J. Structural concrete with incorporation of coarse recycled concrete and ceramic aggregates: Durability performance. Mater. Struct. 2009, 42, 663–675. [Google Scholar] [CrossRef]

- Anderson, D.J.; Smith, S.T.; Au, F.T.K. Mechanical properties of concrete utilising waste ceramic as coarse aggregate. Constr. Build. Mater. 2016, 117, 20–28. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E. Static cyclic behaviour of FRP-confined crumb rubber concrete columns. Eng. Struct. 2016, 113, 371–387. [Google Scholar] [CrossRef]

- Lasseuguette, E.; Burns, S.; Simmons, D.; Francis, E.; Chai, H.; Koutsos, V.; Huang, Y. Chemical, microstructural and mechanical properties of ceramic waste blended cementitious systems. J. Clean. Prod. 2019, 211, 1228–1238. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Manag. 2009, 29, 655–659. [Google Scholar] [CrossRef] [PubMed]

- Rashad, A.M.; Essa, G.M.F.; Abdel-Gawwad, H.A. An investigation of alkali-activated slag pastes containing recycled glass powder under the effect of elevated temperatures. Environ. Sci. Pollut. Res. 2022, 29, 28647–28660. [Google Scholar] [CrossRef] [PubMed]

- Torkittikul, P.; Chaipanich, A. Utilization of ceramic waste as fine aggregate within Portland cement and fly ash concretes. Cem. Concr. Compos. 2010, 32, 440–449. [Google Scholar] [CrossRef]

- Guerra, I.; Vivar, I.; Llamas, B.; Juan, A.; Moran, J. Eco-efficient concretes: The effects of using recycled ceramic material from sanitary installations on the mechanical properties of concrete. Waste Manag. 2009, 29, 643–646. [Google Scholar] [CrossRef] [PubMed]

- Higashiyama, H.; Yagishita, F.; Sano, M.; Takahashi, O. Compressive strength and resistance to chloride penetration of mortars using ceramic waste as fine aggregate. Constr. Build. Mater. 2012, 26, 96–101. [Google Scholar] [CrossRef]

- Roychand, R.; Gravina, R.J.; Zhuge, Y.; Ma, X.; Youssf, O.; Mills, J.E. A comprehensive review on the mechanical properties of waste tire rubber concrete. Constr. Build. Mater. 2020, 237, 117651. [Google Scholar] [CrossRef]

- Ghaleh, M.B.; Asadi, P.; Eftekhar, M.R. Life cycle assessment based method for the environmental and mechanical evaluation of waste tire rubber concretes. Sci. Rep. 2025, 15, 10687. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber–an overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef]

- Aly, A.M.; El-Feky, M.S.; Kohail, M.; Nasr, E.-S.A.R. Performance of geopolymer concrete containing recycled rubber. Constr. Build. Mater. 2019, 207, 136–144. [Google Scholar] [CrossRef]

- Wik, A.; Dave, G. Occurrence and effects of tire wear particles in the environment–A critical review and an initial risk assessment. Environ. Pollut. 2009, 157, 1–11. [Google Scholar] [CrossRef]

- Elemam, W.E.; Agwa, I.S.; Tahwia, A.M. Reusing ceramic waste as a fine aggregate and supplemental cementitious material in the manufacture of sustainable concrete. Buildings 2023, 13, 2726. [Google Scholar] [CrossRef]

- Reddy, M.V. Investigations on stone dust and ceramic scrap as aggregate replacement in concrete. Int. J. Civ. Struct. Eng. 2010, 1, 661–666. [Google Scholar]

- Zeng, Z.; Wan, C. Research on the basic properties of recycled ceramic aggregate. In Proceedings of the 2011 International Conference on Consumer Electronics, Communications and Networks (CECNet), Xianning, China, 16–18 April 2011; pp. 2547–2550. [Google Scholar]

- Cabral, A.E.B.; Schalch, V.; Molin, D.C.C.D.; Ribeiro, J.L.D. Mechanical properties modeling of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 421–430. [Google Scholar] [CrossRef]

- De Brito, J.; Pereira, A.S.; Correia, J.R. Mechanical behaviour of non-structural concrete made with recycled ceramic aggregates. Cem. Concr. Compos. 2005, 27, 429–433. [Google Scholar] [CrossRef]

- Sheehan, P.J.; Warmerdam, J.M.; Ogle, S.; Humphrey, D.N.; Patenaude, S.M. Evaluating the risk to aquatic ecosystems posed by leachate from tire shred fill in roads using toxicity tests, toxicity identification evaluations, and groundwater modeling. Environ. Toxicol. Chem. 2006, 25, 400–411. [Google Scholar] [CrossRef] [PubMed]

- Roberts, D.E.; Mandelkern, L. The melting temperature of natural rubber networks. J. Am. Chem. Soc. 1960, 82, 1091–1095. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Kovářík, T.; Rieger, D.; Kadlec, J.; Křenek, T.; Kullová, L.; Pola, M.; Bělský, P.; Franče, P.; Říha, J. Thermomechanical properties of particle-reinforced geopolymer composite with various aggregate gradation of fine ceramic filler. Constr. Build. Mater. 2017, 143, 599–606. [Google Scholar] [CrossRef]

- Zhang, L.; Shen, H.; Xu, K.; Huang, W.; Wang, Y.; Chen, M.; Han, B. Effect of ceramic waste tile as a fine aggregate on the mechanical properties of low-carbon ultrahigh performance concrete. Constr. Build. Mater. 2023, 370, 130595. [Google Scholar] [CrossRef]

- Mahmoodi, O.; Siad, H.; Lachemi, M.; Dadsetan, S.; Şahmaran, M. Optimized application of ternary brick, ceramic and concrete wastes in sustainable high strength geopolymers. J. Clean. Prod. 2022, 338, 130650. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Dave, U.; Pienaar, J. Freeze/thaw performance of concrete using granulated rubber crumb. J. Green Build. 2011, 6, 83–92. [Google Scholar] [CrossRef]

- AS 1012.3.5; Methods of Testing Concrete—Determination of Properties Related to the Consistency of Concrete—Slump Flow, T500 and J-Ring Test. Standards Australia: Sydney, NSW, Australia, 2015.

- ASTM C1240-11; Standard Specification for Silica Fume Used in Cementitious Mixtures. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM C109/C109M-02; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM C 1585–13; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- Amin, M.; Tayeh, B.A.; Agwa, I.S. Effect of using mineral admixtures and ceramic wastes as coarse aggregates on properties of ultrahigh-performance concrete. J. Clean. Prod. 2020, 273, 123073. [Google Scholar] [CrossRef]

- Reda Taha, M.M.R.; El-Dieb, A.S.; El-Wahab, M.A.A.; Abdel-Hameed, M.E. Mechanical, fracture, and microstructural investigations of rubber concrete. J. Mater. Civ. Eng. 2008, 20, 640–649. [Google Scholar] [CrossRef]

- Huang, L.; Liu, J.-C.; Cai, R.; Ye, H. Mechanical degradation of ultra-high strength alkali-activated concrete subjected to repeated loading and elevated temperatures. Cem. Concr. Compos. 2021, 121, 104083. [Google Scholar] [CrossRef]

- Liaing, C.; Li, B.; Guo, M.-Z.; Hou, S.; Wang, S.; Gao, Y.; Wang, X. Effects of early-age carbonation curing on the properties of cement-based materials: A review. J. Build. Eng. 2024, 84, 108495. [Google Scholar] [CrossRef]

- Rashad, A.M.; Essa, G.M.F. Effect of ceramic waste powder on alkali-activated slag pastes cured in hot weather after exposure to elevated temperature. Cem. Concr. Compos. 2020, 111, 103617. [Google Scholar] [CrossRef]

- Zhao, Q.; Niu, F.; Liu, J.; Yin, H. Research Progress of Natural Rubber Wet Mixing Technology. Polymers 2024, 16, 1899. [Google Scholar] [CrossRef]

- Liang, J.; Liu, K.; Wang, C.; Wang, X.; Liu, J. Mechanical properties of steel fiber-reinforced rubber concrete after elevated temperature. Sci. Rep. 2025, 15, 6965. [Google Scholar] [CrossRef]

- Nadelman, E.I. Hydration and Microstructural Development of Portland Limestone Cement-Based Materials. Ph.D. Dissertation, Georgia Institute of Technology, Atlanta, GA, USA, 2016. [Google Scholar]

- Elyamany, H.E.; Elmoaty, M.A.; Elshaboury, A.M. Magnesium sulfate resistance of geopolymer mortar. Constr. Build. Mater. 2018, 184, 111–127. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Ouda, M.M.; Abdellatief, M.; Elemam, W.E. The mechanical performance of sustainable high performance concrete containing hybrid polypropylene fibers and exposed to elevated temperatures. Mansoura Eng. J. 2024, 49, 17. [Google Scholar] [CrossRef]

- Hakeem, I.Y.; Zaid, O.; Arbili, M.M.; Alyami, M.; Alhamami, A.; Alharthai, M. A state-of-the-art review of the physical and durability characteristics and microstructure behavior of ultra-high-performance geopolymer concrete. Heliyon 2024, 10, e24263. [Google Scholar] [CrossRef] [PubMed]

- Liaing, C.; Bao, J.; Gu, F.; Lu, J.; Ma, Z.; Hou, S.; Duan, Z. Determining the importance of recycled aggregate characteristics affecting the elastic modulus of concrete by modeled recycled aggregate concrete: Experiment and numerical simulation. Cem. Concr. Compos. 2025, 162, 106118. [Google Scholar] [CrossRef]

- Liu, H.; Jing, W.; Qin, L.; Duan, P.; Zhang, Z.; Guo, R.; Li, W. Thermal stability of geopolymer modified by different silicon source materials prepared from solid wastes. Constr. Build. Mater. 2022, 315, 125709. [Google Scholar] [CrossRef]

- Calgaro, L. Stabilized Materials from Contaminated Waste Recycling: Characterization, Immobilization, and Leaching of Contaminants. Ph.D. Dissertation, Università Ca’ Foscari Venezia, Venice, Italy, 2020. [Google Scholar]

| Notations | Oxides wt. % | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | Na2O | K2O | SrO | TiO2 | P2O5 | Mn2O3 | LOI | |

| Slag | 43.0 | 32.8 | 13.4 | 0.4 | 1.9 | 5.5 | 0.4 | 0.3 | 0.8 | 0.6 | <0.1 | 0.1 | 0.8 |

| Silica fume | 0.3 | 97.8 | 0.1 | - | - | 0.7 | 0.4 | 0.6 | - | - | - | - | 5.1 |

| Quartz sand | 0.41 | 95.5 | 0.34 | 0.1 | - | 0.71 | 0.027 | 0.085 | - | 0.013 | 0.003 | 0.001 | 3.45 |

| Ceramic waste | 2.73 | 68.99 | 8.98 | 3.97 | - | - | 1.04 | 1.75 | - | - | - | - | - |

| Glass waste | 11.7 | 72.61 | 1.38 | 0.48 | 0.09 | 0.56 | 13.12 | 0.38 | - | 0.04 | - | - | 0.22 |

| Mix Code | Binder | Fine Aggregates | The Alkaline Activator | SP | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SF | Slag | GWP | CWP | Quartz Sand | CR | GW | CW | SH | SS | ||

| CC | 10 | 90 | - | - | 100 | - | - | - | 12.86 | 32.14 | 1.5 |

| CR10 | 10 | 90 | - | - | 90 | 10 | - | - | 12.86 | 32.14 | 1.5 |

| CR20 | 10 | 90 | - | - | 80 | 20 | - | - | 12.86 | 32.14 | 1.5 |

| CR40 | 10 | 90 | - | - | 60 | 40 | - | - | 12.86 | 32.14 | 1.5 |

| GW10 | 10 | 90 | - | - | 90 | - | 10 | - | 12.86 | 32.14 | 1.5 |

| GW20 | 10 | 90 | - | - | 80 | - | 20 | - | 12.86 | 32.14 | 1.5 |

| GW40 | 10 | 90 | - | - | 60 | - | 40 | - | 12.86 | 32.14 | 1.5 |

| CW10 | 10 | 90 | - | - | 90 | - | - | 10 | 12.86 | 32.14 | 1.5 |

| CW20 | 10 | 90 | - | - | 80 | - | - | 20 | 12.86 | 32.14 | 1.5 |

| CW40 | 10 | 90 | - | - | 60 | - | - | 40 | 12.86 | 32.14 | 1.5 |

| GWP | - | 90 | 10 | - | 100 | - | - | - | 12.86 | 32.14 | 1.5 |

| CWP | - | 90 | - | 10 | 100 | - | - | - | 12.86 | 32.14 | 1.5 |

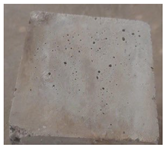

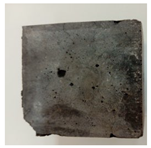

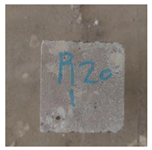

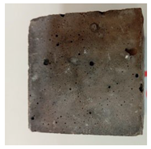

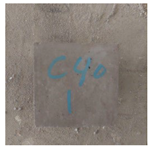

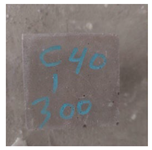

| Temp. | 300 °C | 600 °C | ||

|---|---|---|---|---|

| Duration | 1.5 h | 3.0 h | 1.5 h | 3.0 h |

| R10 |  |  |  |  |

| R20 |  |  |  |  |

| R40 |  |  |  |  |

| G10 |  |  |  |  |

| G20 |  |  |  |  |

| G40 |  |  |  |  |

| C10 |  |  |  |  |

| C20 |  |  |  |  |

| C40 |  |  |  |  |

| GWP |  |  |  |  |

| CWP |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Youssf, O.; Abbass, A.M.; Ahmed, A.K.; Tahwia, A.M. Sustainable High-Performance Geopolymer Concrete: The Role of Recycled Industrial Wastes in Strength, Durability, and Microstructure Enhancement. Infrastructures 2025, 10, 241. https://doi.org/10.3390/infrastructures10090241

Youssf O, Abbass AM, Ahmed AK, Tahwia AM. Sustainable High-Performance Geopolymer Concrete: The Role of Recycled Industrial Wastes in Strength, Durability, and Microstructure Enhancement. Infrastructures. 2025; 10(9):241. https://doi.org/10.3390/infrastructures10090241

Chicago/Turabian StyleYoussf, Osama, Ahmed Mohamed Abbass, Ahmed K. Ahmed, and Ahmed M. Tahwia. 2025. "Sustainable High-Performance Geopolymer Concrete: The Role of Recycled Industrial Wastes in Strength, Durability, and Microstructure Enhancement" Infrastructures 10, no. 9: 241. https://doi.org/10.3390/infrastructures10090241

APA StyleYoussf, O., Abbass, A. M., Ahmed, A. K., & Tahwia, A. M. (2025). Sustainable High-Performance Geopolymer Concrete: The Role of Recycled Industrial Wastes in Strength, Durability, and Microstructure Enhancement. Infrastructures, 10(9), 241. https://doi.org/10.3390/infrastructures10090241