Simulation of Pantograph–Catenary Arc Temperature Field in Urban Railway and Study of Influencing Factors on Arc Temperature

Abstract

1. Introduction

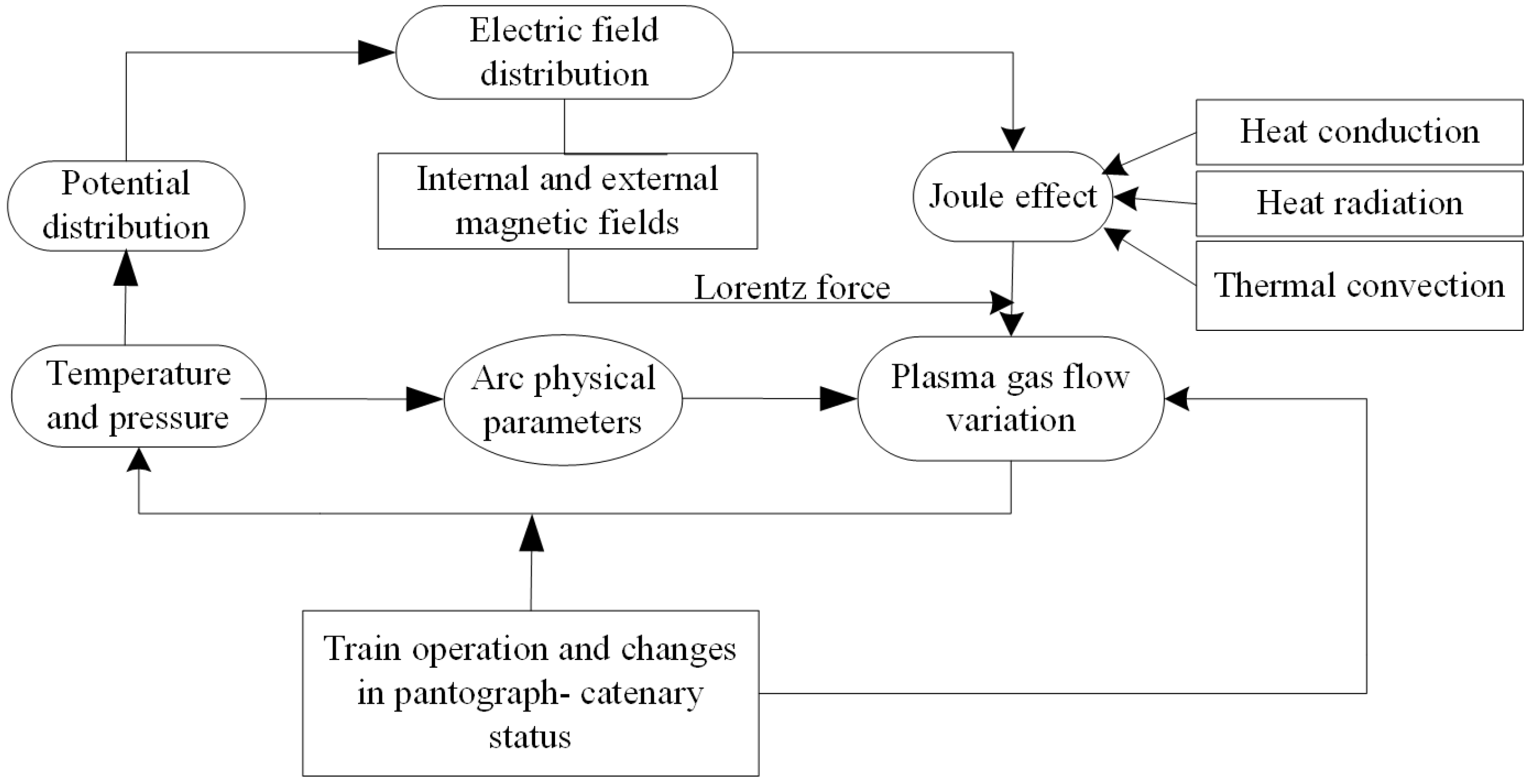

2. Simulation Modeling of PC Arcs

2.1. Physical Occurrence Process of PC Arcs

2.2. Mathematical Model of PC Arcs

- (1)

- When calculating, stability of the PC arc exists.

- (2)

- When an arc happens, the parameters related to the arc change slowly with temperature.

- (3)

- When calculating the magnetic permeability of the PC arc plasma, it is invariable.

- (4)

- When an arc happens, the calculation process of arc plasma conforms to the local thermodynamic equilibrium state.

2.2.1. Fluid Mechanics Equations

2.2.2. Maxwell’s Electromagnetic Equation

2.2.3. Radiation Equation

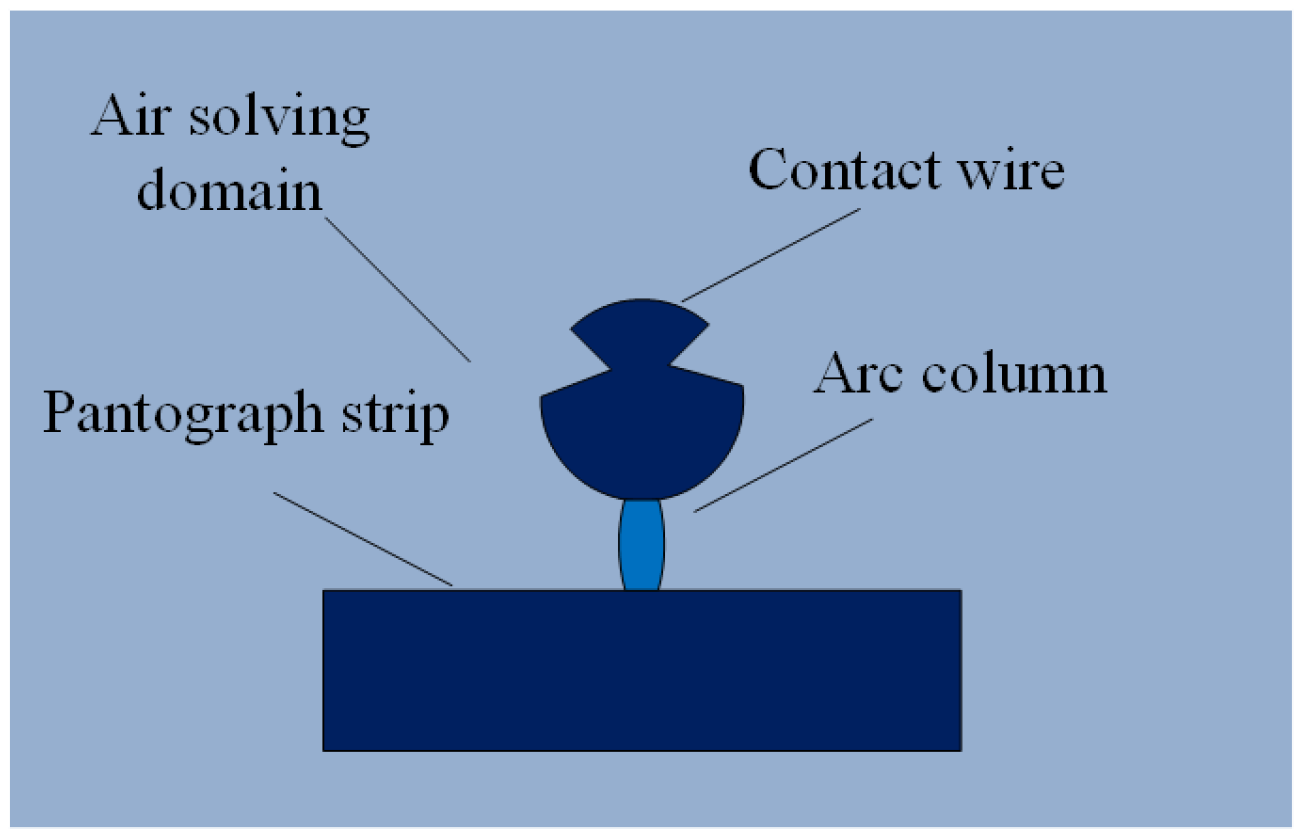

2.3. Geometric Model and Initial Conditions of PC

2.3.1. PC Geometric Model

2.3.2. Initial and Boundary Conditions

2.3.3. Mesh Generation

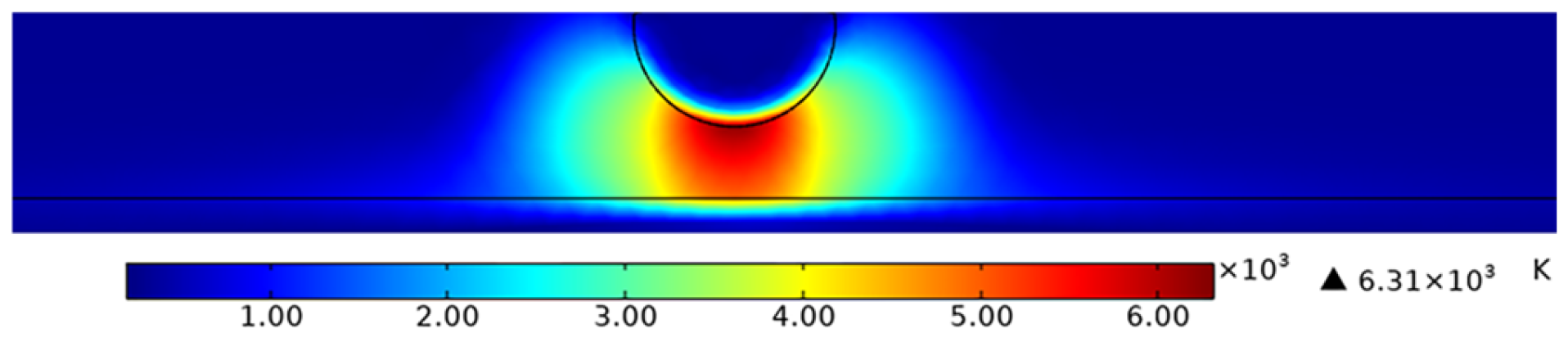

3. Analysis of Simulation Results of PC Arcs

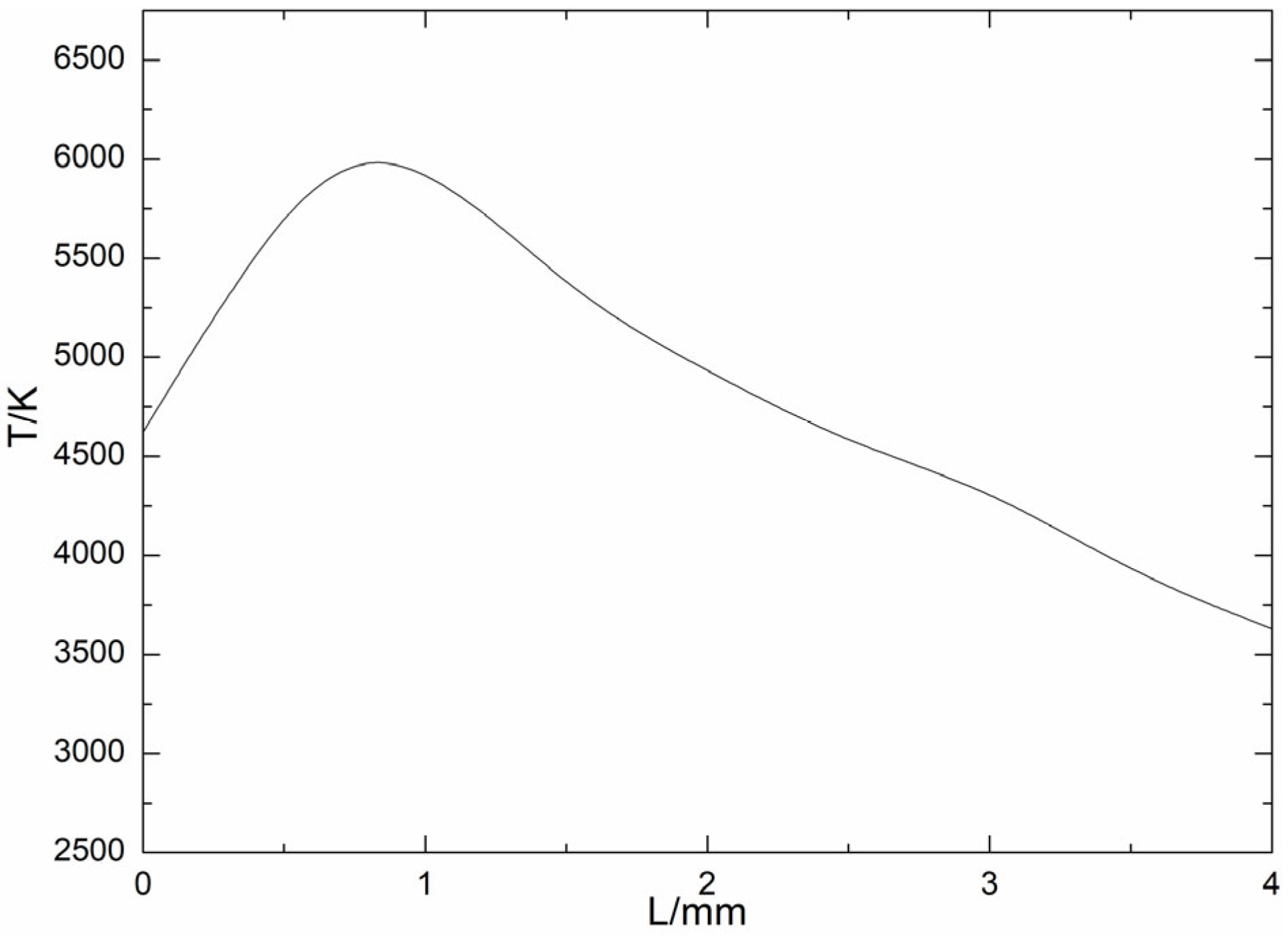

3.1. Temperature Dispersion of PC Arcs

3.2. Surface Temperature Dispersion of PC Material

3.3. PC Arc Temperature Data

4. Experimental Verification of PC Arc Model

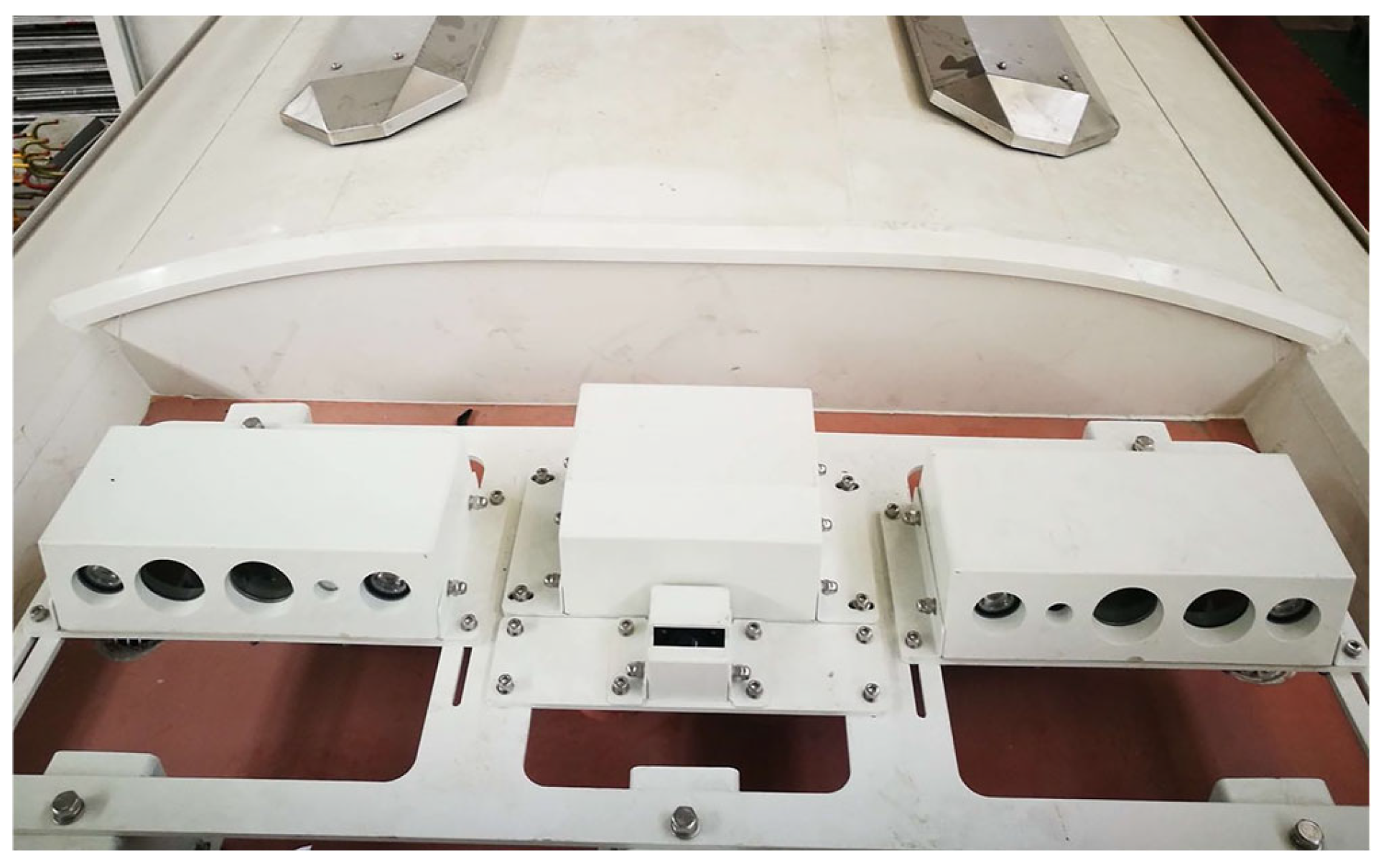

4.1. PC Arc Detection Device

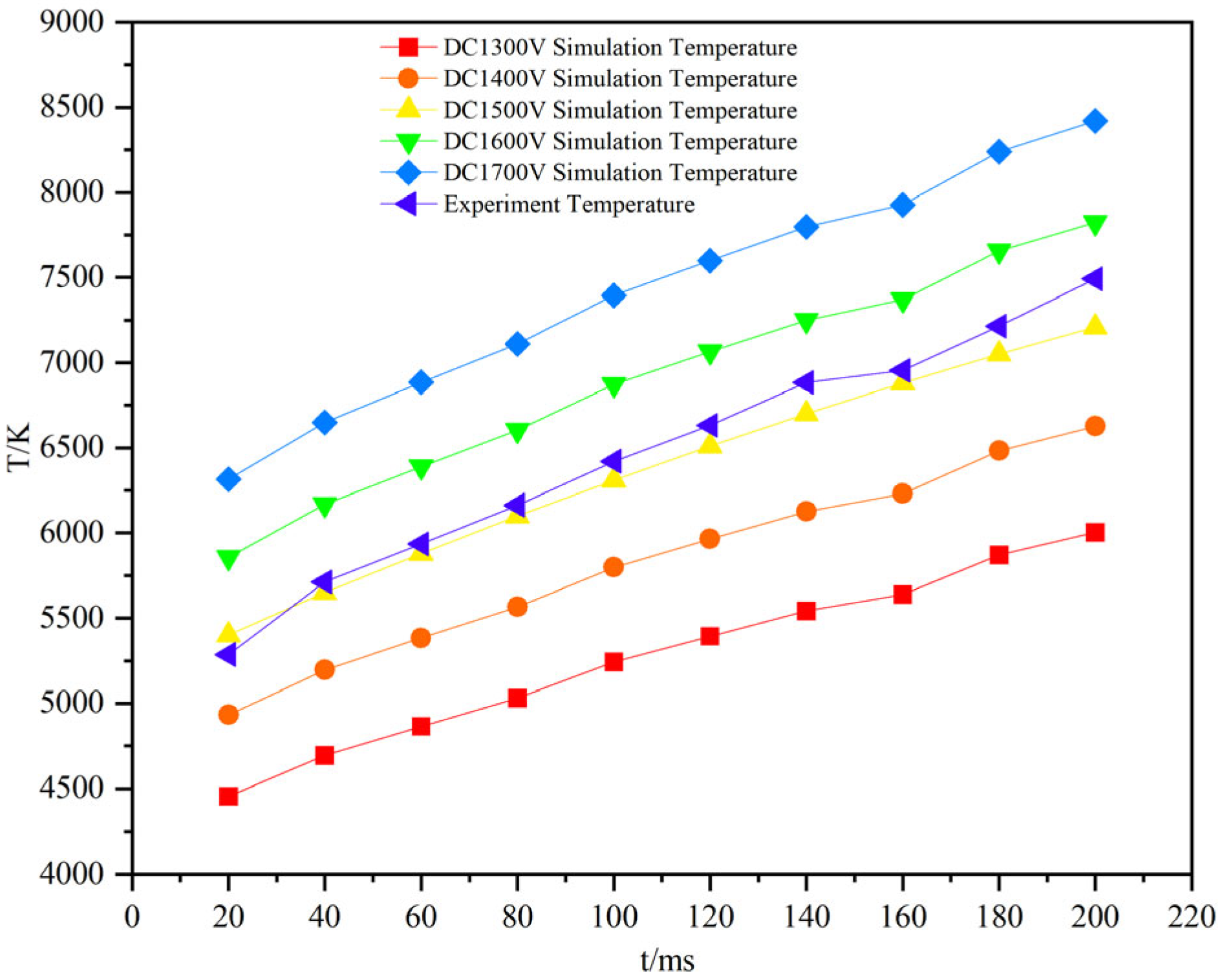

4.2. Test Data and Comparative Verification

5. Factors Affecting the Temperature of PC Arcs

5.1. Influence of PC Gap on Arc Temperature

5.2. Influence of PC Current on Arc Temperature

6. Discussion

7. Conclusions

- (1)

- The PC arc temperature reaches its maximum in the arc central region, and gradually decreases from the arc center to the surrounding area. The contact wire surface temperature is consistently higher than that of the pantograph strip surface.

- (2)

- The results demonstrate a correlation between arc temperature and duration. The PC arc temperature increases with arc duration, but it is not completely linear.

- (3)

- The PC arc temperature decreases with increasing PC gap but rises with higher PC current.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Zhu, F.; Qiu, R.; Tang, Y. Research on the influence of metro pantograph-catenary arc on airport instrument landing system. China Railw. Soc. 2018, 40, 97–102. [Google Scholar]

- John, M.; Mark, R.; Roberto, P. Use of dynamic analysis to investigate the behaviour of short neutral sections in the overhead line electrification. Infrastructures 2021, 6, 62. [Google Scholar] [CrossRef]

- Jiang, T.; Froseth, G.; Navik, P.; Ronnquist, A. Assessment of pantograph-catenary interaction in a railway overlap section via a novel optical-based method. Mech. Mach. Theory 2022, 177, 105045. [Google Scholar] [CrossRef]

- Jung, K.; Suh, Y. Medium voltage power supply with enhanced ignition characteristics for plasma torches. J. Power Electron. 2011, 11, 591–598. [Google Scholar] [CrossRef]

- Signorino, D.; Giordano, D.; Mariscotti, A.; Gallo, D.; Femine, A.D.; Balic, F.; Quintana, J.; Donadio, L.; Biancucci, A. Dataset of measured and commented pantograph electric arcs in DC railways. Data Brief 2020, 31, 105978. [Google Scholar] [CrossRef]

- Cho, Y.; Lim, J.; Seo, H.; Bang, S.; Choe, G. A series arc fault detection strategy for single-phase boost PFC rectifiers. J. Power Electron. 2015, 15, 1664–1672. [Google Scholar] [CrossRef]

- Hu, Y.; Gao, G.; Chen, X.; Zhang, T.; Wei, W.; Wu, G. Study on pantograph- catenary arc during pantograph lowing based on spectrum. High Volt. Eng. 2018, 44, 1668–1676. [Google Scholar]

- Lei, D.; Zhang, T.; Duan, X.; Gao, G.; Wei, W.; Wu, G. Study on the influence of train running speed on electric characteristics of pantograph-catenary arc. J. China Railw. Soc. 2019, 41, 50–56. [Google Scholar]

- Liu, X.; Zhou, C.; Wang, D.; Zhou, X.; Hu, M.; Guan, X.; Zhang, W.; Zheng, Y.; Gao, M.; Yang, W.; et al. Effect of Arc Erosion under Different Currents on Wear Mechanism of Impregnated Copper Carbon Skateboard/Cr-Zr-Cu Contact Wire. Tribology 2024, 44, 189–199. [Google Scholar]

- Xu, J. Physical Field Simulation Analysis of Pantograph-Catenary Arc. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2012. [Google Scholar]

- Fan, F.; Wank, A.; Seferi, Y.; Stewart, B. Pantograph Arc Location Estimation Using Resonant Frequencies in DC Railway Power Systems. IEEE Trans. Transp. Electrif. 2021, 7, 3083–3095. [Google Scholar] [CrossRef]

- Hao, J.; Gao, G.; Xu, P.; Wei, W.; Hu, Y.; Wu, G. Coupled model of pantograph-catenary arc and electrode considering electrode melting. High Volt. Eng. 2018, 44, 1668–1676. [Google Scholar]

- Yu, X. Development and Application of Urban Rail Transit Pantograph-Catenary Arc Detection System Based on Sun Blind Area. Ph.D. Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2021. [Google Scholar]

- Xu, Z.; Gao, G.; Wei, W.; Yang, Z.; Xie, W.; Dong, K.; Ma, Y.; Yang, Y.; Wu, G. Characteristics of pantograph-catenary arc under low air pressure and strong airflow. High Volt. 2022, 7, 369–381. [Google Scholar] [CrossRef]

- Zhou, H.; Duan, F.; Liu, Z.; Chen, L.; Song, Y.; Zhang, Y. Study on electric spark discharge between pantograph and catenary in electrified railway. IET Electr. Syst. Transp. 2022, 12, 128–142. [Google Scholar] [CrossRef]

- Shi, H.; Chen, G.; Yang, Y. A comparative study on pantograph-catenary models and effect of parameters on pantograph-catenary dynamics under crosswind. J. Wind. Eng. Ind. Aerodyn. 2021, 211, 104587. [Google Scholar] [CrossRef]

- Gao, S. Automatic detection and monitoring system of pantograph-catenary in china’s high-speed railways. IEEE Trans. Instrum. Meas. 2020, 70, 3502012. [Google Scholar] [CrossRef]

- Li, Y.; Jin, T.; Liu, L.; Yuan, K. Dynamic performance simulation and stable current collection analysis of a pantograph catenary system for trolley wire overhead electrically actuated LHD. Energies 2020, 13, 1015. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Liu, Z.; Wang, R. A spatial coupling model to study dynamic performance of pantograph-catenary with vehicle-track excitation. Mech. Syst. Signal Process. 2021, 151, 107336. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, Z.; Xiong, J.; Duan, F. Characteristic analysis of pantograph-catenary detachment arc based on double-pantograph-catenary dynamics in electrified railways. IET Electr. Syst. Transp. 2022, 12, 238–250. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Z.; Lu, C.; Mu, Y.; Wei, W.; Gao, G.; Wu, G. Research on Motion Characteristics of Offline Arc in Pantograph Catenary System Under Low Air pressure Environment. Proc. CSEE 2021, 41, 5412–5421. [Google Scholar]

- Seferi, Y.; Blair, S.M.; Mester, C.; Stewart, B.G. A novel arc detection method for DC railway systems. Energies 2021, 14, 444. [Google Scholar] [CrossRef]

- Wu, G.; Gao, G.; Wei, W.; Yang, Z. The Electrical Contact of the Pantograph-Catenary System, 1st ed.; Springer: Singapore, 2019; pp. 142–144. [Google Scholar]

- Yu, X.; Song, M.; Wang, Z. Simulation and Verification of Effect of Arc Duration on Arc Temperature Based on COMSOL. Machines 2023, 11, 289. [Google Scholar] [CrossRef]

- Yu, X.; Song, M.; Wang, Z. Simulation Study on Surface Temperature Distribution of Collector Strip Material under Pantograph-Catenary Arc of Urban Rail. IEEE Access 2023, 11, 68358–68365. [Google Scholar] [CrossRef]

| Projects | Cu–Sn Contact Wire | Copper-Impregnated Pantograph Strip |

|---|---|---|

| Density/(kg/m3) | 9020 | 2320 |

| Specific heat/(J/(kg·K)) | 384 | 478 |

| Heat conduction coefficient/(W/(m·K)) | 398 | 6 |

| Time/(ms) | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 |

| DC1300 V Temperature/(K) | 4454 | 4693 | 4865 | 5030 | 5242 | 5394 | 5542 | 5638 | 5870 | 6003 |

| DC1400 V Temperature/(K) | 4933 | 5196 | 5384 | 5566 | 5798 | 5965 | 6127 | 6231 | 6483 | 6627 |

| DC1500 V Temperature/(K) | 5400 | 5650 | 5880 | 6100 | 6310 | 6510 | 6700 | 6880 | 7050 | 7210 |

| DC1600 V Temperature/(K) | 5857 | 6169 | 6390 | 6603 | 6872 | 7065 | 7250 | 7370 | 7658 | 7823 |

| DC1700 V Temperature/(K) | 6315 | 6649 | 6885 | 7110 | 7396 | 7600 | 7799 | 7928 | 8240 | 8422 |

| Detection Serial Number | Moving Direction | Detection Time Period | Average Ambient Temperature/°C | Operating Duration/min | Average Speed/(km·h−1) | Maximum Instantaneous Speed/(km·h−1) |

|---|---|---|---|---|---|---|

| 1 | Up-bound | Solar maximum period | 19.8 | 48′42″ | 34.6 | 78.7 |

| 2 | Down-bound | Solar maximum period | 16.5 | 48′56″ | 34.2 | 77.6 |

| 3 | Up-bound | Night operations regime | 15.4 | 47′49″ | 35.1 | 79.8 |

| 4 | Down-bound | Night operations regime | 17.6 | 46′55″ | 35.4 | 77.2 |

| Time/(ms) | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 |

| Temperature/(K) | 5286 | 5712 | 5935 | 6163 | 6421 | 6631 | 6884 | 6954 | 7215 | 7492 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, X.; Su, Y.; Song, M.; Yang, J.; Song, L.; Wang, Z.; Liu, Y.; Wei, C.; Cheng, Y. Simulation of Pantograph–Catenary Arc Temperature Field in Urban Railway and Study of Influencing Factors on Arc Temperature. Infrastructures 2025, 10, 237. https://doi.org/10.3390/infrastructures10090237

Yu X, Su Y, Song M, Yang J, Song L, Wang Z, Liu Y, Wei C, Cheng Y. Simulation of Pantograph–Catenary Arc Temperature Field in Urban Railway and Study of Influencing Factors on Arc Temperature. Infrastructures. 2025; 10(9):237. https://doi.org/10.3390/infrastructures10090237

Chicago/Turabian StyleYu, Xiaoying, Yang Su, Mengjie Song, Junrui Yang, Liying Song, Ze Wang, Yixiao Liu, Caizhuo Wei, and Yongjia Cheng. 2025. "Simulation of Pantograph–Catenary Arc Temperature Field in Urban Railway and Study of Influencing Factors on Arc Temperature" Infrastructures 10, no. 9: 237. https://doi.org/10.3390/infrastructures10090237

APA StyleYu, X., Su, Y., Song, M., Yang, J., Song, L., Wang, Z., Liu, Y., Wei, C., & Cheng, Y. (2025). Simulation of Pantograph–Catenary Arc Temperature Field in Urban Railway and Study of Influencing Factors on Arc Temperature. Infrastructures, 10(9), 237. https://doi.org/10.3390/infrastructures10090237