Seismic Retrofitting of RC Frames Using Viscous Dampers: Numerical Simulation and Nonlinear Response Analysis

Abstract

1. Introduction

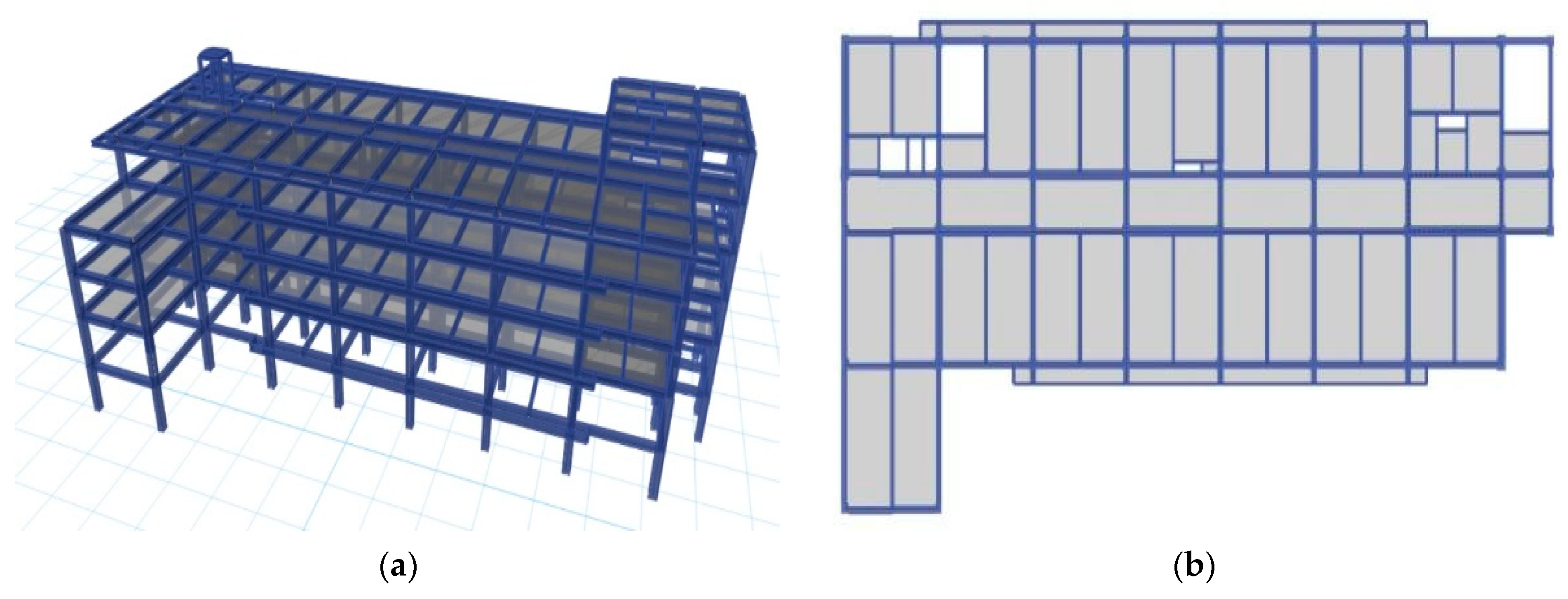

2. Project Details

2.1. Project Background

2.2. Structural Parameters

3. Performance Objectives and Analytical Methodology

3.1. Performance Objectives

- (i)

- (ii)

- Component performance: Main structural members remain elastic under frequent earthquakes; damper bracings maintain elasticity and surrounding sub-frames remain non-yielding under the maximum considered earthquake;

- (iii)

- Additional damping ratio: Significant reduction in structural seismic response through efficient energy dissipation by dampers.

3.2. Analytical Methodology

4. Modeling Details

4.1. Finite Element Model Development and Validation

4.2. Element Selection, Boundary Conditions, and Floor Load

4.3. Constitutive Models

4.4. Seismic Wave Selection

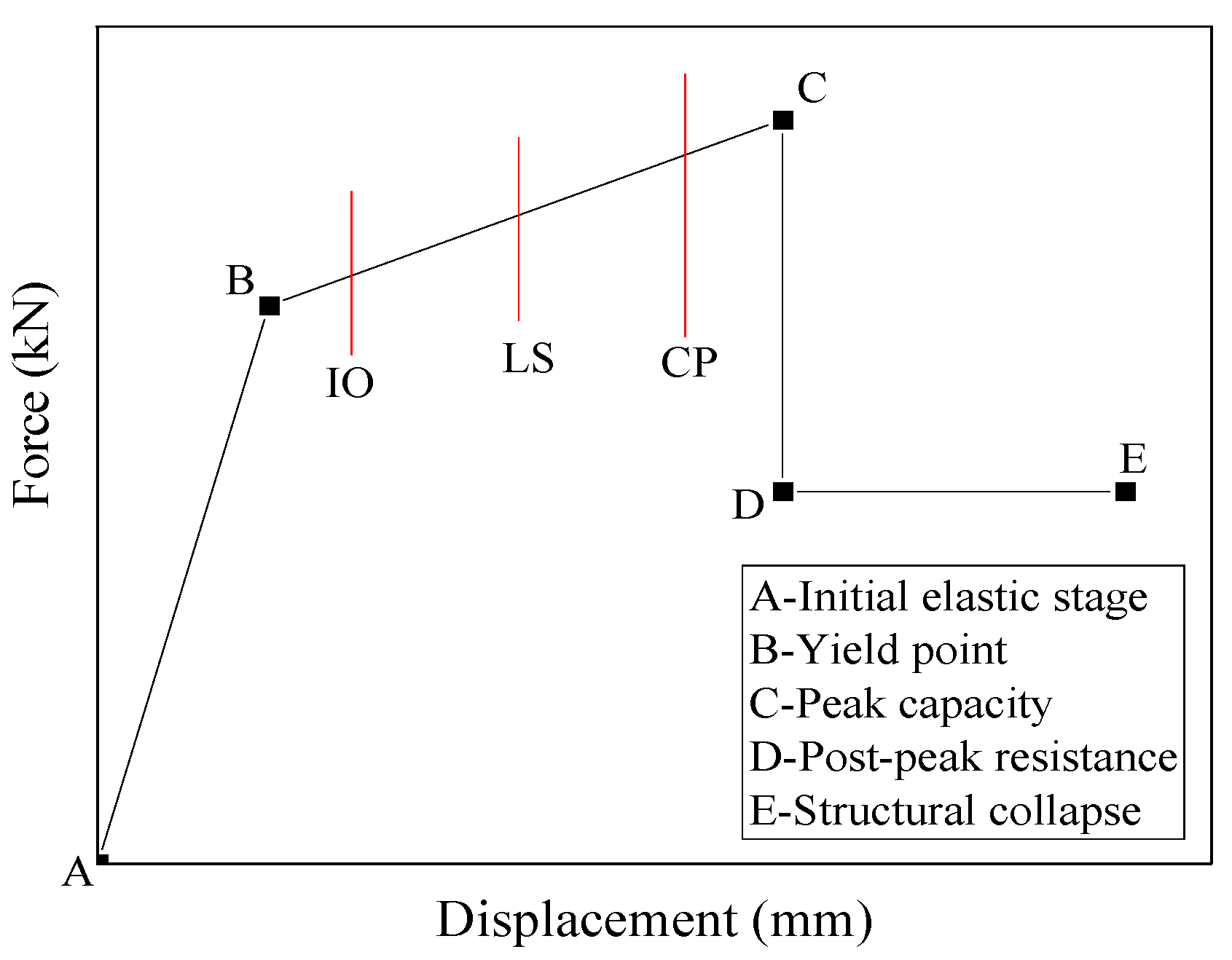

4.5. Plastic Hinge Setting

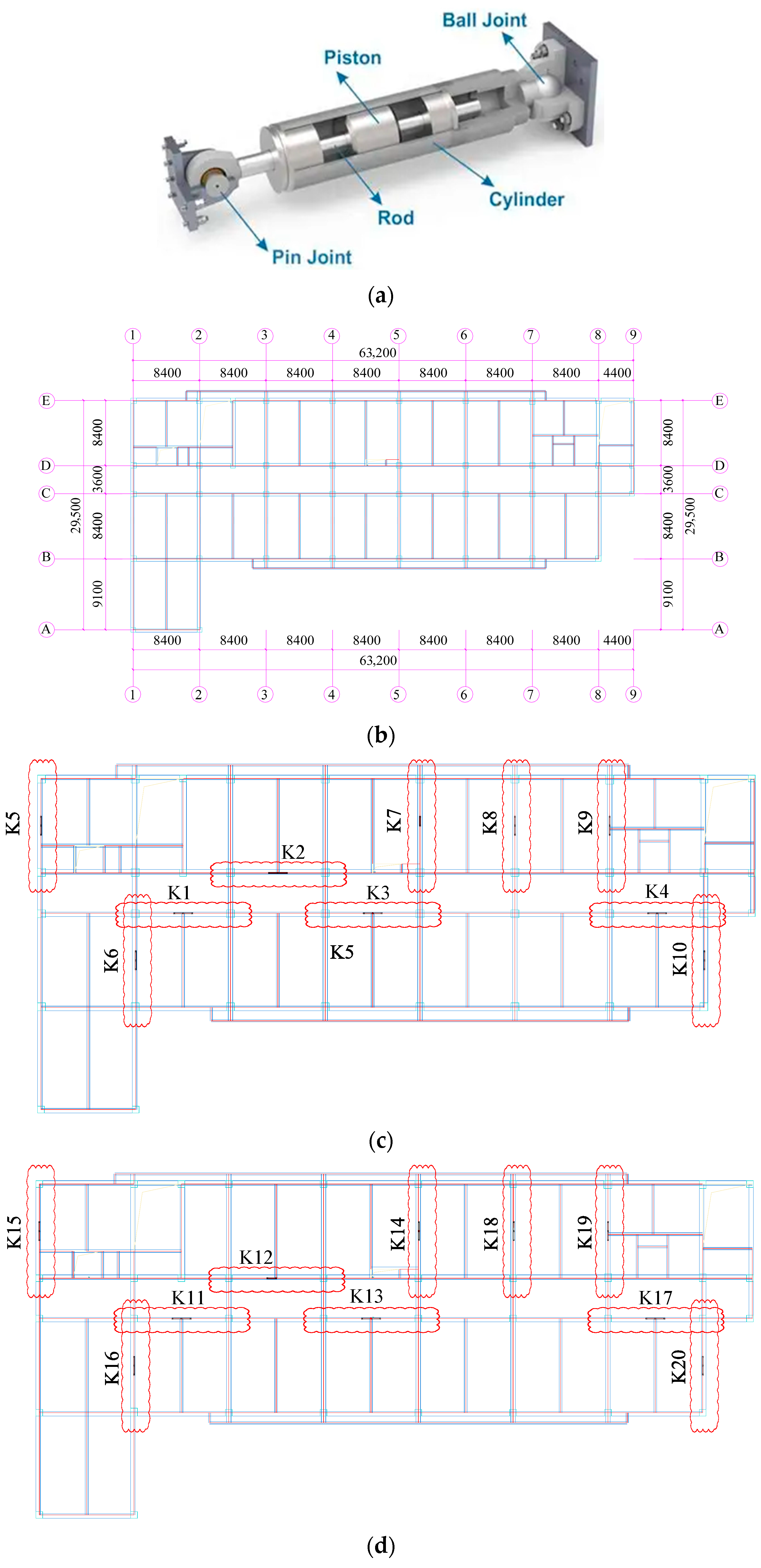

4.6. Viscous Damper Selection and Configuration

5. Nonlinear Response Analysis

5.1. Dynamic Characteristics of Structure

5.2. Nonlinear Response Analysis Under Frequent Earthquakes (FEs)

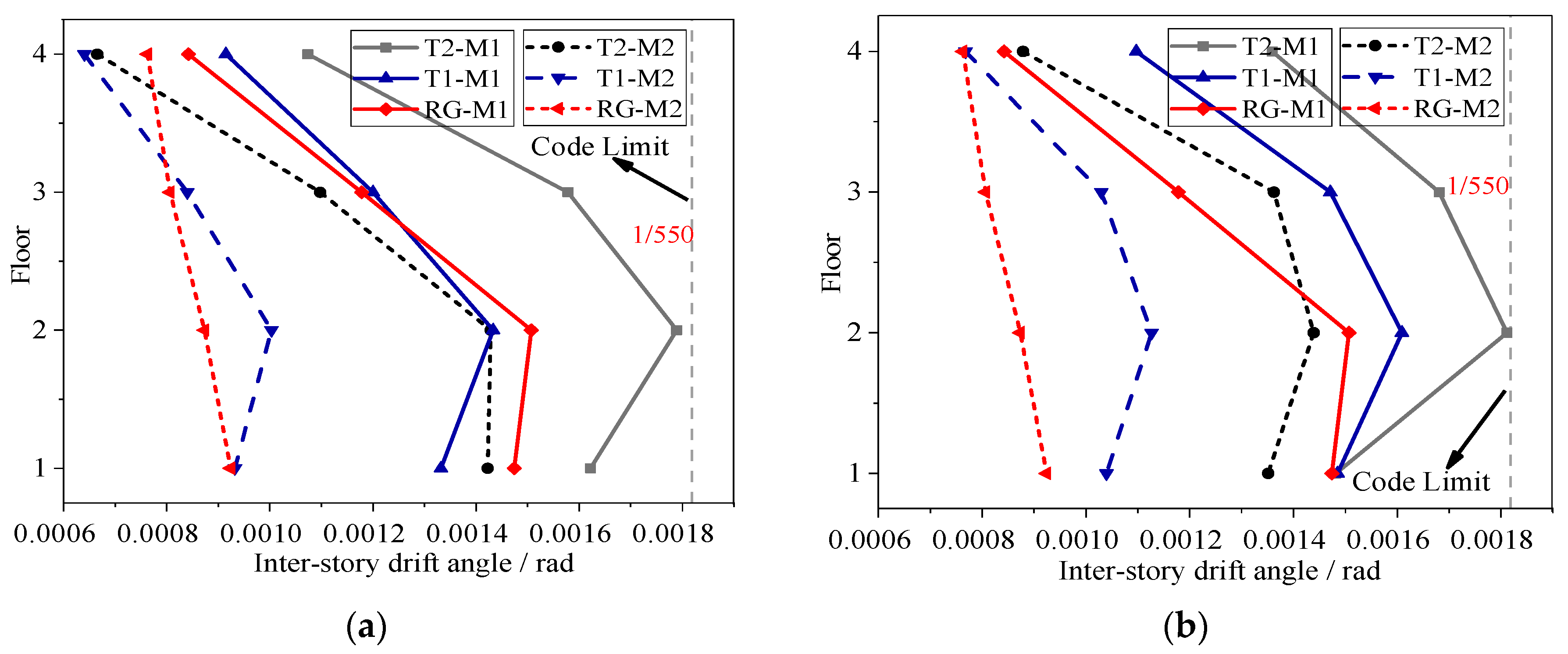

5.2.1. Structural Displacement Response

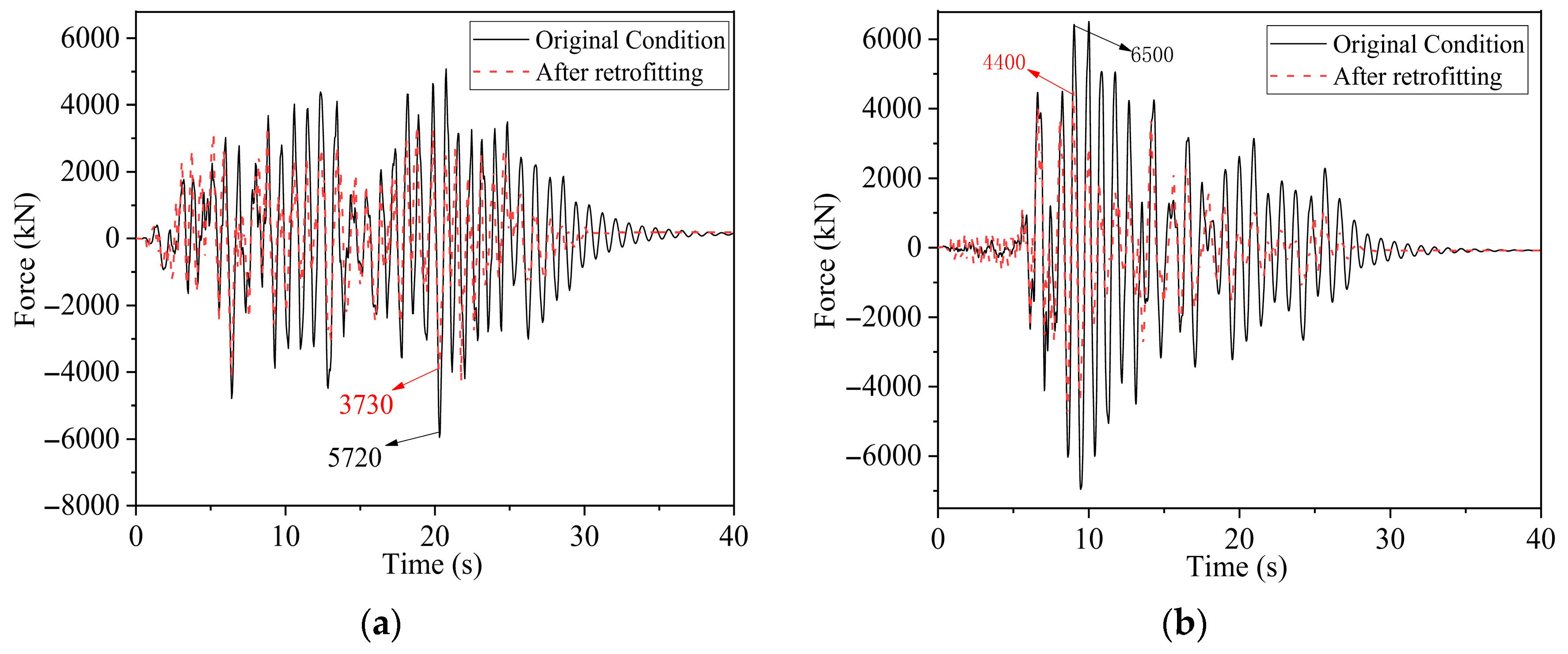

5.2.2. Base Shear Analysis

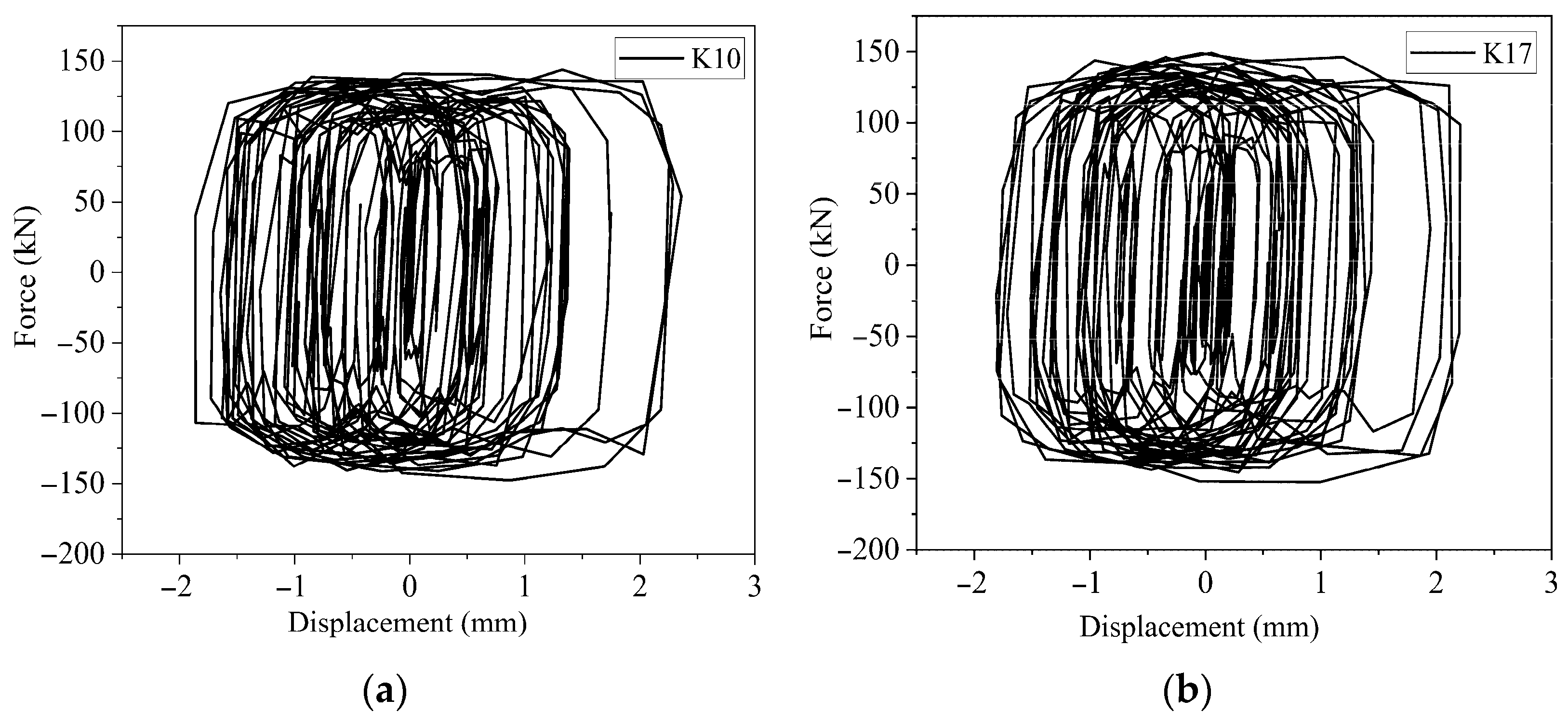

5.2.3. Force–Displacement Hysteresis Behavior

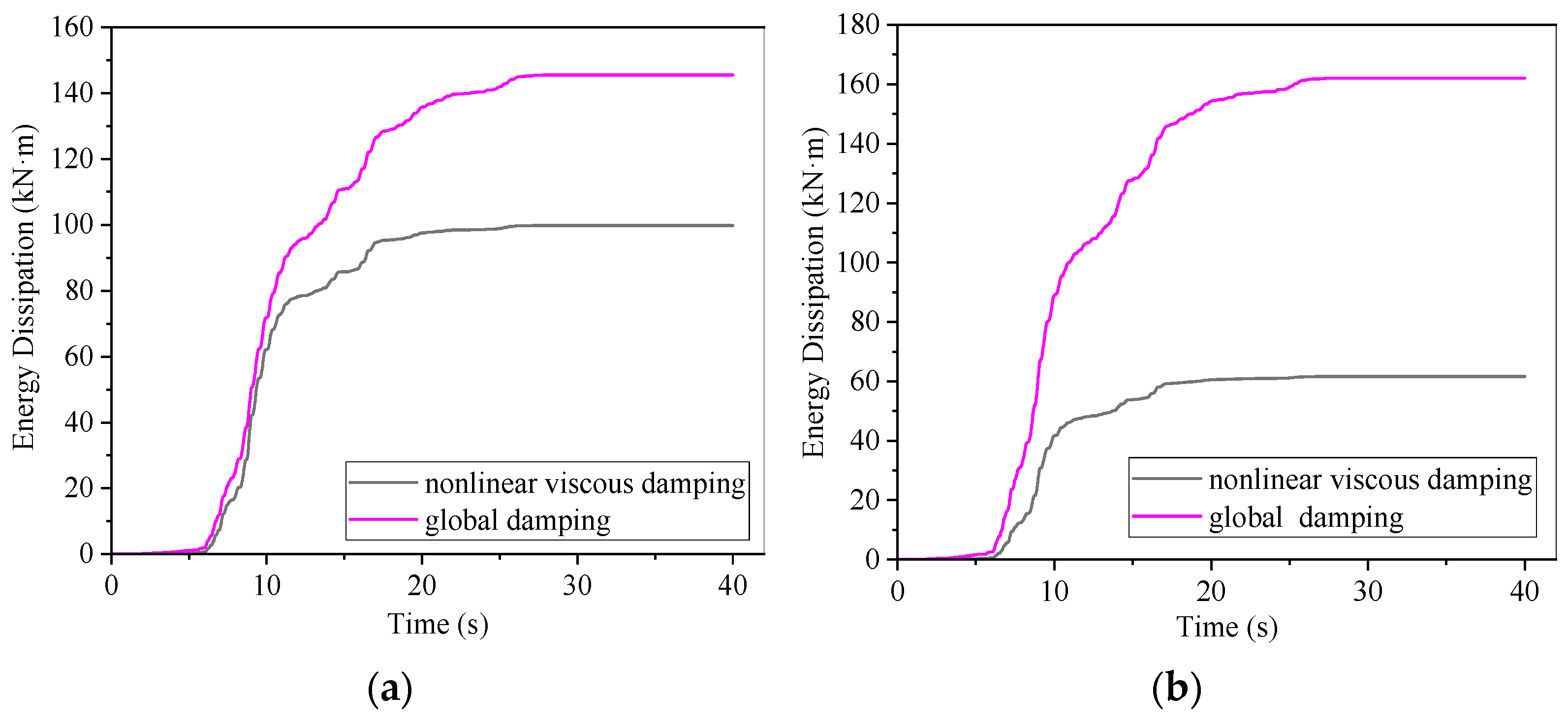

5.2.4. Energy Dissipation and Additional Damping Ratios

5.3. Nonlinear Response Analysis Under Maximum Considered Earthquake (MCE)

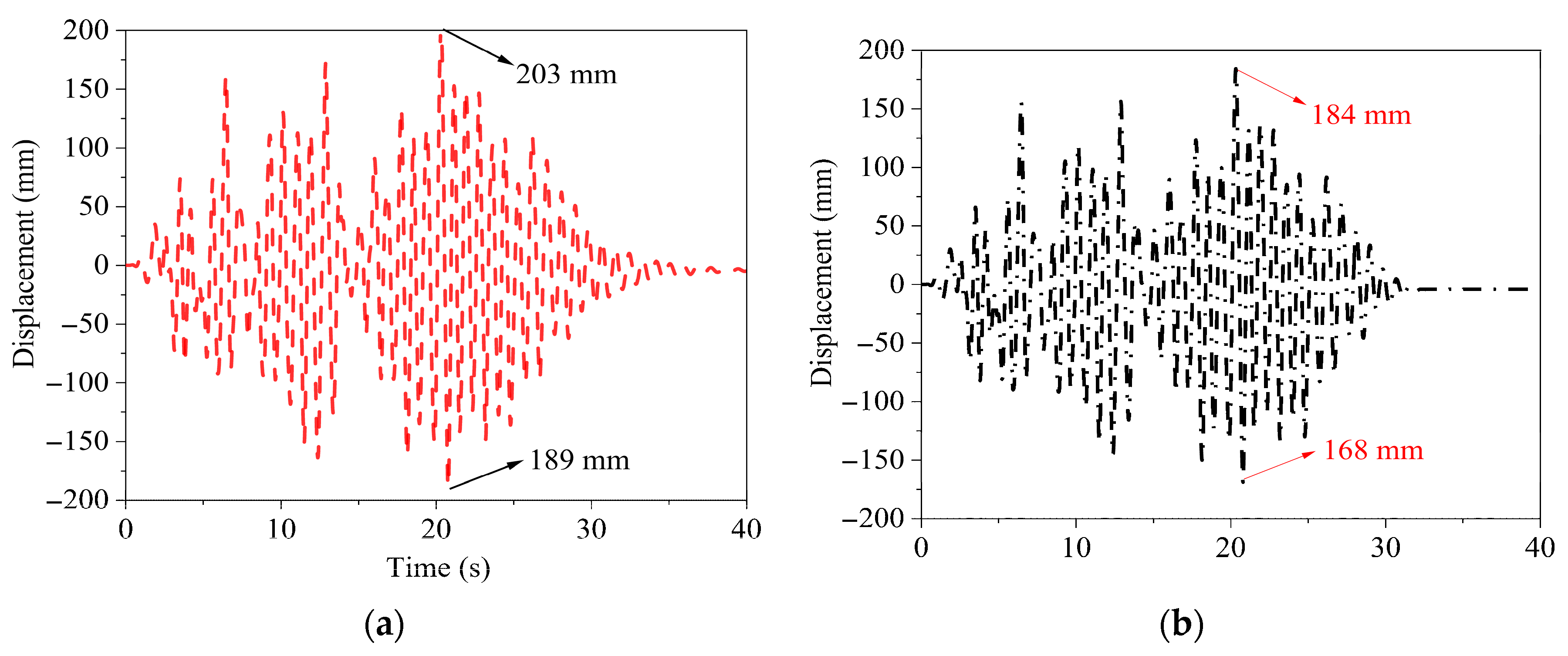

5.3.1. Nonlinear Displacement Response

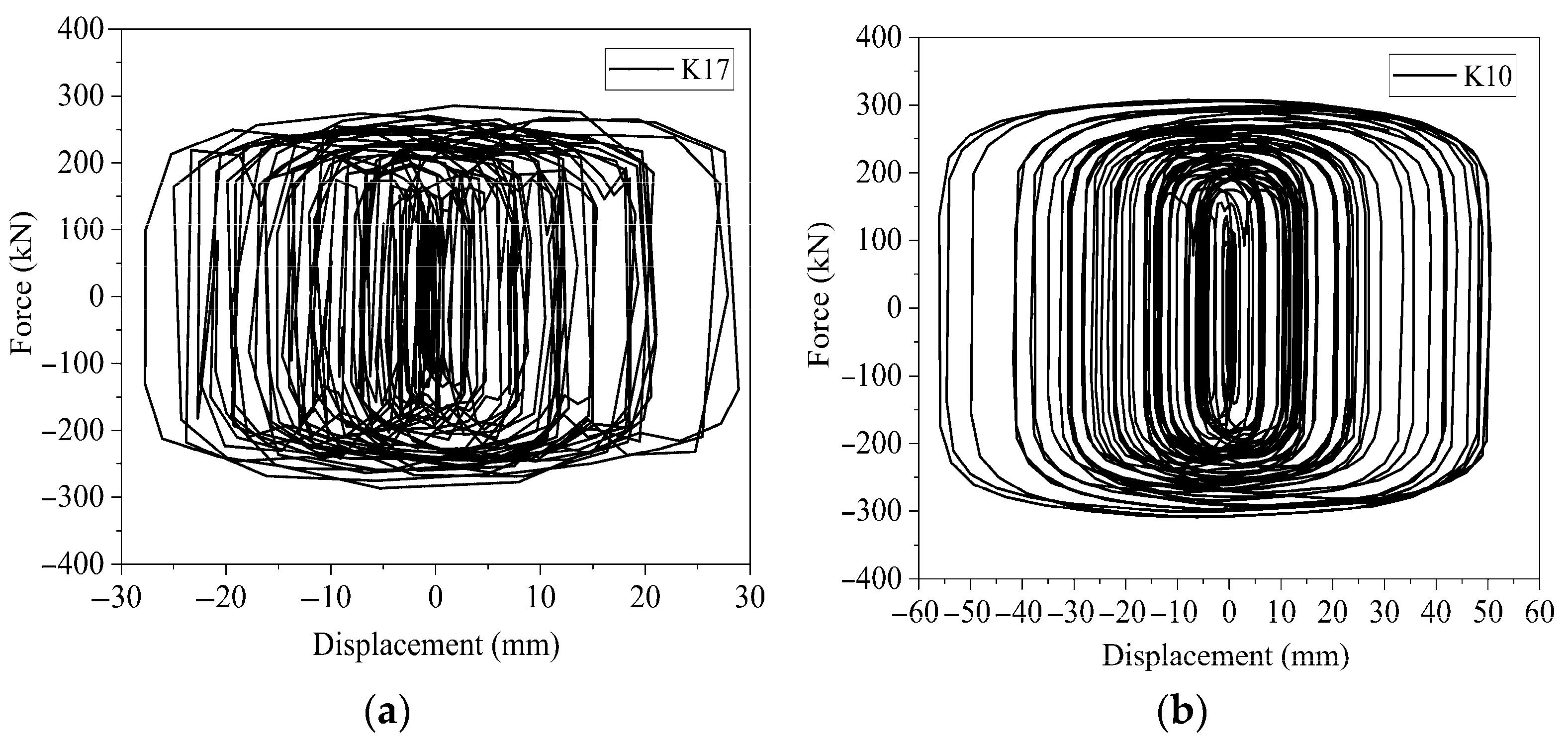

5.3.2. Force–Displacement Hysteresis Behavior

5.3.3. Energy Dissipation and Additional Damping Ratios

5.3.4. Analysis of Structural Nonlinear Behavior Development

6. Discussion

- (i)

- Performance Benchmarking: By directly comparing damped and undamped structural responses using nonlinear time-history analysis, the study establishes clear performance metrics (e.g., 66.7–74% energy dissipation contribution) that were previously lacking for RC frames.

- (ii)

- Practical Implementation Guidelines: The validated perimeter-based damper configuration addresses a critical gap in the literature by providing engineers with a replicable design strategy that balances torsional resistance and energy dissipation uniformity.

- (iii)

- The nonlinear response analysis method employed in this study is superior to traditional response spectrum methods, because it considers earthquake motion duration, peak acceleration, and spectral characteristics.

7. Conclusions

- (1)

- Effective drift control: VFDs reduced inter-story drift angles by 10–40% under FEs and 33–37% under the MCE, ensuring compliance with stringent code limits (1/50 under the MCE). This demonstrates their efficacy in mitigating deformation-induced damage.

- (2)

- Force and energy dissipation: Base shear reductions of 34.6% (X) and 32.3% (Y) under FEs highlight VFDs’ ability to redistribute seismic forces. Dampers contributed 66.7% (X) and 40% (Y) of total energy dissipation under FEs, increasing to 74% (X) and 47% (Y) under the MCE, with additional damping ratios of 3.3–3.7% (X) and 2.0–2.4% (Y).

- (3)

- Damage mitigation: Plastic hinge formation was delayed and controlled, preventing collapse-level damage. The structure remained within the Life Safety (LS) to Collapse Prevention (CP) performance range under the MCE.

- (4)

- Practical implications: The study provides a validated framework for retrofitting RC frames in critical infrastructure (e.g., schools, hospitals) in seismic zones. The symmetric, perimeter-based damper configuration proved effective, offering a replicable design strategy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Zhang, J. Design And Analysis of Energy Dissipation and Vibration Reduction of Reinforced Concrete Frame Structure. Highlights Sci. Eng. Technol. 2023, 51, 21–26. [Google Scholar] [CrossRef]

- Qu, Z.; Zhu, B.; Cao, Y.; Fu, H. Rapid report of seismic damage to buildings in the 2022 M 6.8 Luding earthquake, China. Earthq. Res. Adv. 2023, 3, 11–30. [Google Scholar] [CrossRef]

- De Stefano, M.; Tanganelli, M.; Viti, S. Variability in Concrete Mechanical Properties as a Source of In-Plan Irregularity for Existing RC Framed Structures. Eng. Struct. 2014, 59, 161–172. [Google Scholar] [CrossRef]

- Ye, L.; Lu, X. Analysis on seismic damage of buildings in the Wenchuan earthquake. J. Build. Struct. 2008, 29, 1–9. [Google Scholar] [CrossRef]

- Pan, Y.; Fan, Y.; Ren, Y.; Yang, B.; Hou, J.; Xiong, Y. Typical seismic damage investigation and analysis in Mountain area after Ms 6.1 Lushan earthquake. China Civ. Eng. J. 2023, 56, 35–48. [Google Scholar] [CrossRef]

- Vitiello, U.; Asprone, D.; Di Ludovico, M.; Prota, A. Life-Cycle Cost Optimization of the Seismic Retrofit of Existing RC Structures. Bull. Earthq. Eng. 2017, 15, 2245–2271. [Google Scholar] [CrossRef]

- Ma, P.; Xin, R.; Yao, J. Assessment of Failure Mode and Seismic Performance of Damaged Masonry Structures Retrofitted with Grout-Injected Ferrocement Overlay Reinforcement (GFOR). Constr. Build. Mater. 2021, 305, 124778. [Google Scholar] [CrossRef]

- Giancarlo, M.; Gaetano, M.; Andrea, P.; Marisa, P. In-Plane Shear Performance of Masonry Panels Strengthened with FRP. Compos. Part B Eng. 2007, 38, 887–901. [Google Scholar] [CrossRef]

- Zhou, D.; Lei, Z.; Wang, J. In-Plane Behavior of Seismically Damaged Masonry Walls Repaired with External BFRP. Compos. Struct. 2013, 102, 9–19. [Google Scholar] [CrossRef]

- Ma, P.; Xin, R.; Yao, J. An Investigation of Bond Behavior between Composite Materials (CFRP, GWMM, KPGC) and Substrates (Brick and Concrete) for Strengthening Existing Masonry Structures. Constr. Build. Mater. 2023, 409, 134019. [Google Scholar] [CrossRef]

- Cheng, S.; Yin, S.; Jing, L. Comparative Experimental Analysis on the In-Plane Shear Performance of Brick Masonry Walls Strengthened with Different Fiber Reinforced Materials. Constr. Build. Mater. 2020, 259, 120387. [Google Scholar] [CrossRef]

- Deng, M.; Yang, S. Cyclic Testing of Unreinforced Masonry Walls Retrofitted with Engineered Cementitious Composites. Constr. Build. Mater. 2018, 177, 395–408. [Google Scholar] [CrossRef]

- Yang, X.; Gao, W.-Y.; Dai, J.-G.; Lu, Z.-D. Shear Strengthening of RC Beams with FRP Grid-Reinforced ECC Matrix. Compos. Struct. 2020, 241, 112120. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Bournas, D.A. TRM vs FRP Jacketing in Shear Strengthening of Concrete Members Subjected to High Temperatures. Compos. Part B Eng. 2016, 106, 190–205. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. TRM versus FRP in Flexural Strengthening of RC Beams: Behaviour at High Temperatures. Constr. Build. Mater. 2017, 154, 424–437. [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Triantafillou, T.C.; Papathanasiou, M.; Karlos, K. Textile Reinforced Mortar (TRM) versus FRP as Strengthening Material of URM Walls: Out-of-Plane Cyclic Loading. Mater. Struct. 2007, 41, 143–157. [Google Scholar] [CrossRef]

- De Felice, G.; De Santis, S.; Garmendia, L.; Ghiassi, B.; Larrinaga, P.; Lourenço, P.B.; Oliveira, D.V.; Paolacci, F.; Papanicolaou, C.G. Mortar-Based Systems for Externally Bonded Strengthening of Masonry. Mater. Struct. 2014, 47, 2021–2037. [Google Scholar] [CrossRef]

- Benavent-Climent, A.; Oliver-Saiz, E.; Donaire-Ávila, J. Seismic Retrofitting of RC Frames Combining Metallic Dampers and Limited Strengthening with FRP/SRP Applying Energy-Based Methods. Soil Dyn. Earthq. Eng. 2024, 177, 108432. [Google Scholar] [CrossRef]

- Alhamdany, A.M.A.; Dilsiz, A. Comparative Evaluation of Shear Walls and Fluid Viscous Dampers in Seismic Retrofitting of RC Public School Buildings. Structures 2025, 72, 108231. [Google Scholar] [CrossRef]

- Li, Z.; Shu, G. Optimal Placement of Metallic Dampers for Seismic Upgrading of Multistory Buildings Based on a Cost-effectiveness Criterion Using Genetic Algorithm. Struct. Des. Tall Build. 2019, 28, e1595. [Google Scholar] [CrossRef]

- Parulekar, Y.M.; Reddy, G.R. Passive response control systems for seismic response reduction: A state-of-the-art review. Int. J. Str. Stab. Dyn. 2009, 09, 151–177. [Google Scholar] [CrossRef]

- Zhou, Y.; Shang, C.; Zhang, C. Progress in research and application of energy-dissipated technology. Build. Struct. 2019, 49, 33–48. [Google Scholar] [CrossRef]

- Zhou, Y.; Shang, C.; Fang, D.; Tang, F. Advances in research and application of energy dissipation technology: Insights from the 18th World Conference on Earthquake Engineering. World Earthq. Eng. 2025, 41, 58–71. [Google Scholar] [CrossRef]

- Shao, Z.; Liu, Q.; Pan, Z.; Wang, W. Research on the earthquake trend in China’s land area in the next 1–3 years and the prediction of the urgency of earthquake occurrence in long-term hazardous areas. Earthquake 2025, 45, 214–261. [Google Scholar]

- Lv, D.; Wang, C.; Dong, Y.; Feng, Y. Research progress of uniform-risk seismic design theory of building structures. J. Build. Struct. 2024, 45, 1–30. [Google Scholar] [CrossRef]

- Pan, Y.; Gao, H.; Xiong, Y.; Wu, X. Seismic damage investigation and analysis of energy-dissipated and seismically isolated buildings in Ms 6.8 Luding earthquake. J. Build. Struct. 2023, 44, 122–136. [Google Scholar] [CrossRef]

- Ye, L.; Liu, Y.; Dai, G. Application study of energy dissipation and vibration reduction technology of medical buildings in high intensity area. Build. Struct. 2023, 53, 100–105, 130. [Google Scholar] [CrossRef]

- Hou, H.; Wang, Q.; Zhang, X. Application of combination damping technology in seismic strengthening of a hospital building. Earthq. Resist. Eng. Retrofit. 2025, 47, 125–131, 147. [Google Scholar] [CrossRef]

- Lan, X.; Zhang, X.; Shao, Y.; Zhang, L.; Su, H.; Pan, W. Study on the influence of viscous damper parameters on the damping efficiency of frame structure. J. Nat. Disasters 2024, 33, 176–187. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Y.; Tian, H.; Li, C.; Liu, B. Design of energy dissipation and damper optimization for a high-rise building. China Earthq. Eng. J. 2023, 45, 835–844. [Google Scholar] [CrossRef]

- Zhou, Y.; Qiao, S.; Shu, Z. Practical energy dissipation design of steel structures with viscous dampers. Earthq. Eng. Eng. Dyn. 2022, 42, 1–10. [Google Scholar] [CrossRef]

- Xue, J.; Zhang, C.; Wei, L.; Sui, Y.; Liang, Y.; Luo, Z. Analysis of damping effect of super high-rise frame-core tube structure with viscous damper. J. Xi’an Univ. Archit. Technol. 2020, 52, 21–29. [Google Scholar] [CrossRef]

- Shao, B.; Zou, H.; Lin, J.; Yao, F.; Wang, L.; Cui, J.; Xu, H. Research on the Viscous Damping Effect of Concentrically Braced Concrete-Filled Steel Tubular Frame Structure. Prog. Steel Build. Struct. 2023, 25, 75–84. [Google Scholar] [CrossRef]

- He, W.; Huang, X.; Zhang, Q.; Xu, H.; Liu, W. Theoretical and experimental investigation on high-performance viscous damper. J. Vib. Eng. 2021, 34, 879–888. [Google Scholar] [CrossRef]

- Aghlara, R.; Tahir, M.M. A Passive Metallic Damper with Replaceable Steel Bar Components for Earthquake Protection of Structures. Eng. Struct. 2018, 159, 185–197. [Google Scholar] [CrossRef]

- Javadinasab Hormozabad, S.; Zahrai, S. Innovative Adaptive Viscous Damper to Improve Seismic Control of Structures. J. Vib. Control 2019, 25, 1833–1851. [Google Scholar] [CrossRef]

- Li, C.; Wu, X.; Hu, W.; Zhang, X. Application of performance-based seismic retrofit for reinforcement and reconstruction of existing structure. Build. Struct. 2022, 52, 2079–2083. [Google Scholar] [CrossRef]

- Zhang, X.; Yue, Q. Development on theory and technology on the evaluation, strengthening and retrofitting of existing structures. J. Shandong Jianzhu Univ. 2021, 36, 76–82. [Google Scholar]

- Asgari, A.; Bagheri, M.; Hadizadeh, M. Advanced Seismic Analysis of Soil-Foundation-Structure Interaction for Shallow and Pile Foundations in Saturated and Dry Deposits: Insights from 3D Parallel Finite Element Modeling. Structures 2024, 69, 107503. [Google Scholar] [CrossRef]

- Forcellini, D. Key Parameters to Model the Mutual Effects Between Base Isolation (BI) and Soil–Structure Interaction (SSI). Appl. Sci. 2024, 14, 11703. [Google Scholar] [CrossRef]

- Bray, J.D.; Sancio, R.B.; Durgunoglu, T.; Onalp, A.; Youd, T.L.; Stewart, J.P.; Seed, R.B.; Cetin, O.K.; Bol, E.; Baturay, M.B.; et al. Subsurface Characterization at Ground Failure Sites in Adapazari, Turkey. J. Geotech. Geoenviron. Eng. 2004, 130, 673–685. [Google Scholar] [CrossRef]

- Moss, R.E.S.; Collins, B.D.; Whang, D.H. Retesting of Liquefaction/Nonliquefaction Case Histories in the Imperial Valley. Earthq. Spectra 2005, 21, 179–196. [Google Scholar] [CrossRef]

- GBJ 11-1989; Specifications for Antiseismic Construction Design. General Administration of Quality Supervision: Beijing, China, 1989.

- GB 50011-2010; Code for Seismic Design of Buildings. China Architecture & Building Press: Beijing, China, 2010.

- Regulations on Seismic Management of Construction Engineering (State Decree No. 744). Available online: https://www.gov.cn/gongbao/content/2021/content_5631815.htm (accessed on 28 June 2025).

- He, X.; Zhou, Y.; Tian, Y.; Wang, W. Research on application of hybrid energy dissipation technology in a public medical structure based on “ Regulation on the administration of earthquake resistance of construction projects” issued by the government. Earthq. Resist. Eng. Retrofit. 2024, 46, 33–42. [Google Scholar] [CrossRef]

- GB 50009-2012; Load Code for the Design of Building Structures. China Architecture & Building Press: Beijing, China, 2013.

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical Stress—Strain Model for Confined Concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, P.; Liu, J.; Zhang, L. Hysteretic shear model based on Park three—Parameter hysteretic model. World Earthq. Eng. 2012, 28, 80–88. [Google Scholar]

- Long, Z.; Shen, W. A Maxwell Inerter Damper for Civil Structures: Modeling and Testing. Eng. Struct. 2025, 339, 120685. [Google Scholar] [CrossRef]

- Ikeda, Y.; Uhara, N. Application of Pole Allocation to Optimize Passive Viscous Dampers Represented by the Maxwell Model. Soil Dyn. Earthq. Eng. 2025, 188, 109037. [Google Scholar] [CrossRef]

- ASCE 41-17; Seismic Evaluation and Retrofit of Existing Buildings. American Society of Civil Engineers: Reston, VA, USA, 2017.

- Wu, K.; Chen, X.; Tao, Z.; Kong, L. Design method and engineering application of combined energy dissipation structure. J. Guangxi Univ. (Nat. Sci. Ed.) 2021, 46, 831–843. [Google Scholar] [CrossRef]

- Yuan, P.; Song, G.; Cao, X.; Wang, W.; Jiang, B.; Li, X. Shock-absorbing reinforcement design of a frame structure of Sinovac. Earthq. Resist. Eng. Retrofit. 2024, 46, 63–68. [Google Scholar] [CrossRef]

- Liao, X. Research on structure dynamic response analysis method. Build. Struct. 2016, 46, 22–26, 9. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, T.; Wang, Z.; Meng, L.; Xu, G.; Zhang, J.; Dou, X. Parametric identification of Maxwell model for viscous damper based on real-time hybrid tests. J. Vib. Shock 2025, 44, 45–53, 106. [Google Scholar] [CrossRef]

- JGJ 297-2013; Technical Specification for Seismic Energy Dissipation of Buildings. China Architecture & Building Press: Beijing China, 2013.

- Whittle, J.K.; Williams, M.S.; Karavasilis, T.L.; Blakeborough, A. A Comparison of Viscous Damper Placement Methods for Improving Seismic Building Design. J. Earthq. Eng. 2012, 16, 540–560. [Google Scholar] [CrossRef]

- Wang, C.; Yu, X.; Wang, J.; Liu, F. Elastic-plastic analysis of a high-rise commercial and residential building in Zhuzhou under a rare earthquake. Earthq. Resist. Eng. Retrofit. 2024, 46, 10–16. [Google Scholar] [CrossRef]

- FEMA 356; Prestandard and Commentary for the Seismic Rehabilitation of Buildings. Federal Emergency Management Agency: Washington, DC, USA, 2000.

- Asgari, A.; Ahmadtabar Sorkhi, S.F. Wind Turbine Performance under Multi-Hazard Loads: Wave, Wind, and Earthquake Effects on Liquefiable Soil. Results Eng. 2025, 26, 104647. [Google Scholar] [CrossRef]

| Mass (t) | PKPM (kg) | ETABS (kg) | Error (%) |

|---|---|---|---|

| Dead load | 9213 | 9035 | 2 |

| Live load | 655 | 655 | 0 |

| Total mass | 9868 | 9690 | 2 |

| Mode | PKPM (s) | ETABS (s) | Error (%) |

|---|---|---|---|

| First mode | 0.82 | 0.880 | 7 |

| Second mode | 0.81 | 0.87 | 7 |

| Third mode | 0.77 | 0.810 | 5 |

| Floor | PKPM (kN) | ETABS (kN) | Error (%) | |||

|---|---|---|---|---|---|---|

| X-Direction | Y-Direction | X-Direction | Y-Direction | X-Direction | Y-Direction | |

| 1F | 3751 | 3692 | 3500 | 3474 | 7 | 6 |

| 2F | 6095 | 5959 | 5690 | 5566 | 7 | 7 |

| 3F | 7898 | 7688 | 7334 | 7134 | 7 | 7 |

| 4F | 9144 | 8894 | 8412 | 8120 | 8 | 9 |

| ID | Earthquake Name | PGA (g) | Time Period (s) | Earthquake Ground Motion Duration (s) |

|---|---|---|---|---|

| T1 | Northridge-01_NO_942 | 0.11 | 0.39 | 58.04 |

| T2 | Irpinia, Italy-01_NO_291 | 0.1 | 0.41 | 76.80 |

| RG | Artificial ground wave | 0.07 | 0.40 | 30.00 |

| Floor | Number | Related Parameters | ||||

|---|---|---|---|---|---|---|

| X-Direction | Y-Direction | Damping Coefficient | Damping Exponent | Design Damping Force | Damper Stroke | |

| 3F | 2 | 4 | 600 kN·m/s | 0.3 | 400 kN·mm | 50 mm |

| 2F | 4 | 6 | ||||

| 1F | 4 | 6 | ||||

| In total | 26 | |||||

| Mode | Period (s) | Directions of Vibration Modes | ||

|---|---|---|---|---|

| Ux | Uy | Uz | ||

| 1 | 0.885 | 0.001 | 0.743 | 0.000 |

| 2 | 0.876 | 0.782 | 0.001 | 0.000 |

| 3 | 0.816 | 0.001 | 0.027 | 0.000 |

| Floor | Original Condition | After Retrofitting | Decreasing Amplitude Ratio | ||||

|---|---|---|---|---|---|---|---|

| X-Direction | Y-Direction | X-Direction | Y-Direction | X-Direction | Y-Direction | Mean | |

| 4F | 1/931 | 1/680 | 1/1503 | 1/1138 | 38% | 40% | 39% |

| 3F | 1/634 | 1/595 | 1/911 | 1/734 | 30% | 19% | 24% |

| 2F | 1/559 | 1/552 | 1/700 | 1/695 | 20% | 21% | 20% |

| 1F | 1/616 | 1/665 | 1/703 | 1/740 | 12% | 10% | 11% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, P.; Yuan, S. Seismic Retrofitting of RC Frames Using Viscous Dampers: Numerical Simulation and Nonlinear Response Analysis. Infrastructures 2025, 10, 235. https://doi.org/10.3390/infrastructures10090235

Ma P, Yuan S. Seismic Retrofitting of RC Frames Using Viscous Dampers: Numerical Simulation and Nonlinear Response Analysis. Infrastructures. 2025; 10(9):235. https://doi.org/10.3390/infrastructures10090235

Chicago/Turabian StyleMa, Pengfei, and Shangke Yuan. 2025. "Seismic Retrofitting of RC Frames Using Viscous Dampers: Numerical Simulation and Nonlinear Response Analysis" Infrastructures 10, no. 9: 235. https://doi.org/10.3390/infrastructures10090235

APA StyleMa, P., & Yuan, S. (2025). Seismic Retrofitting of RC Frames Using Viscous Dampers: Numerical Simulation and Nonlinear Response Analysis. Infrastructures, 10(9), 235. https://doi.org/10.3390/infrastructures10090235