Performance Evaluation of a Sustainable Glulam Timber Rubrail and Noise Wall System Under MASH TL-3 Crash Conditions

Abstract

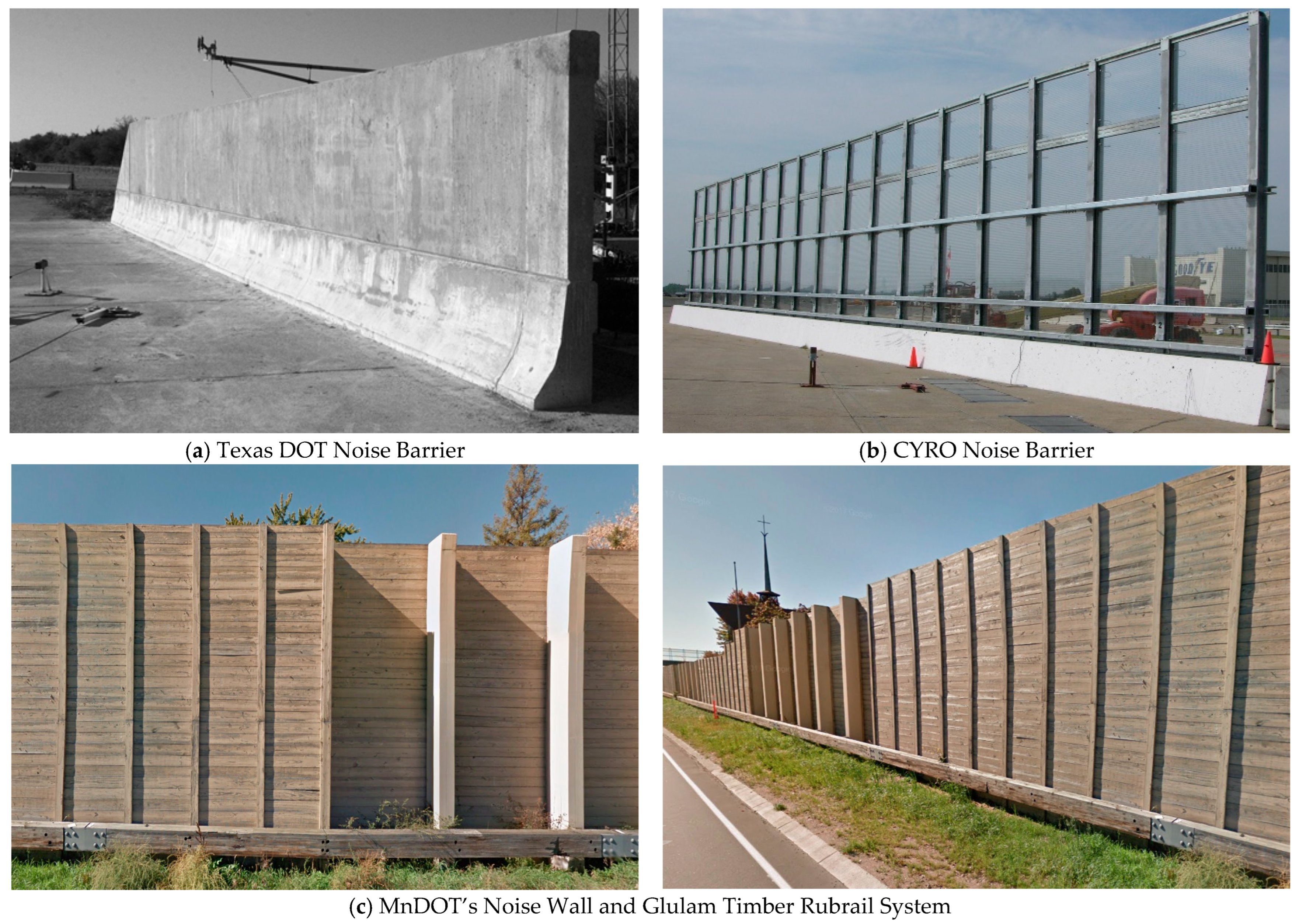

1. Introduction

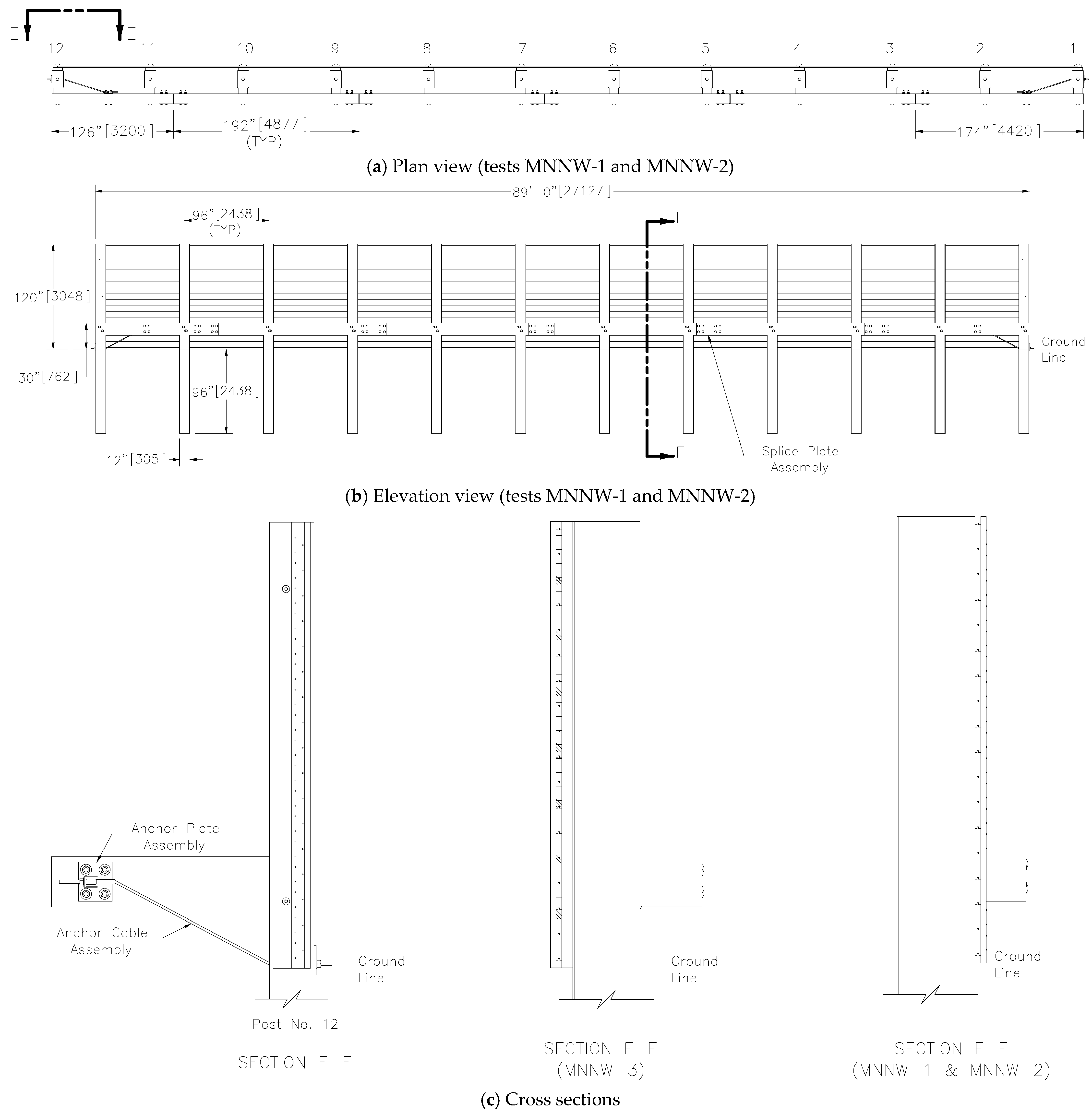

2. Design and System Details

2.1. Design

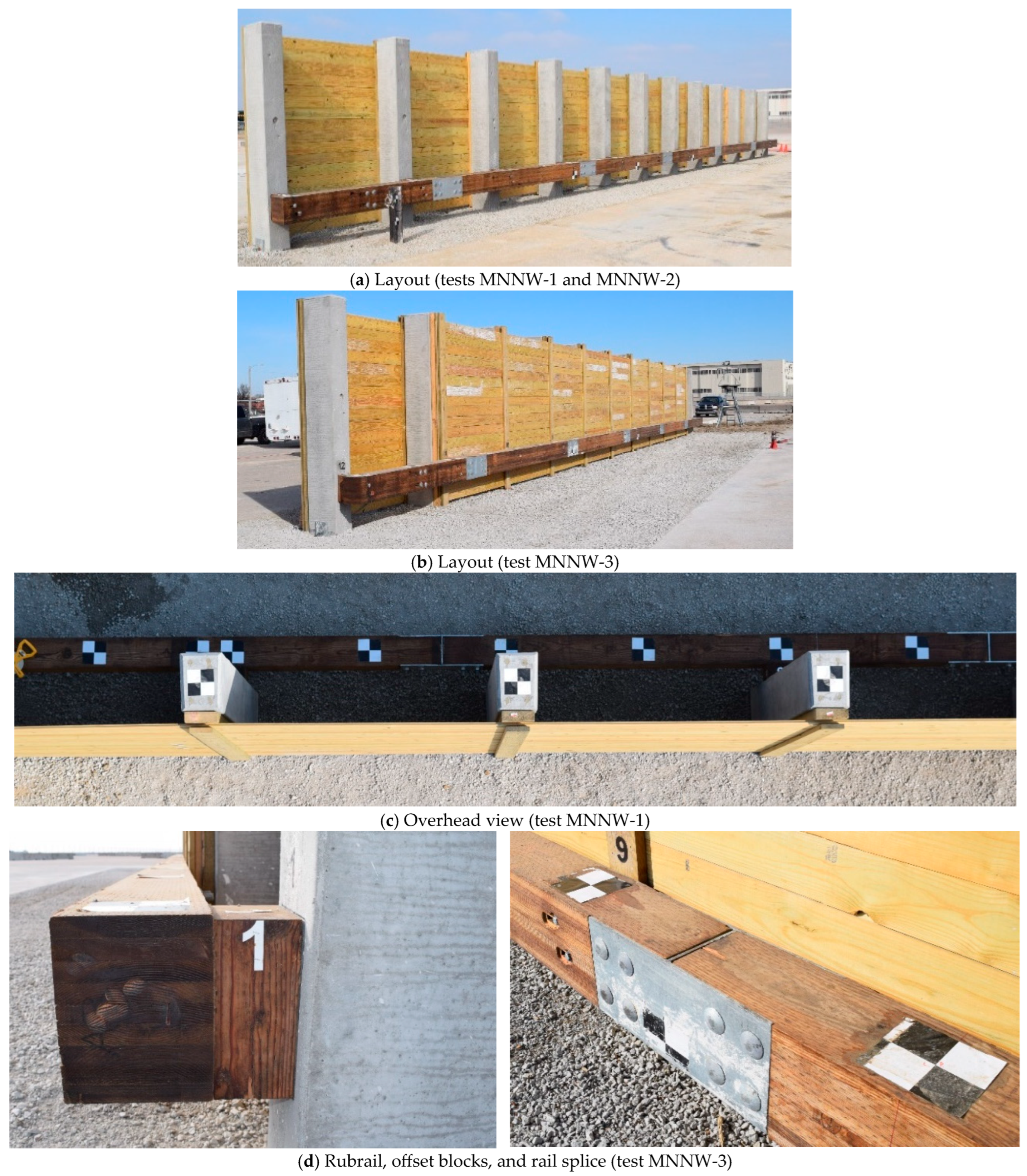

2.2. System Details

3. Test Requirements and Evaluation Criteria

4. Test Apparatus and Instrumentation

4.1. Vehicle Tow and Guidance System

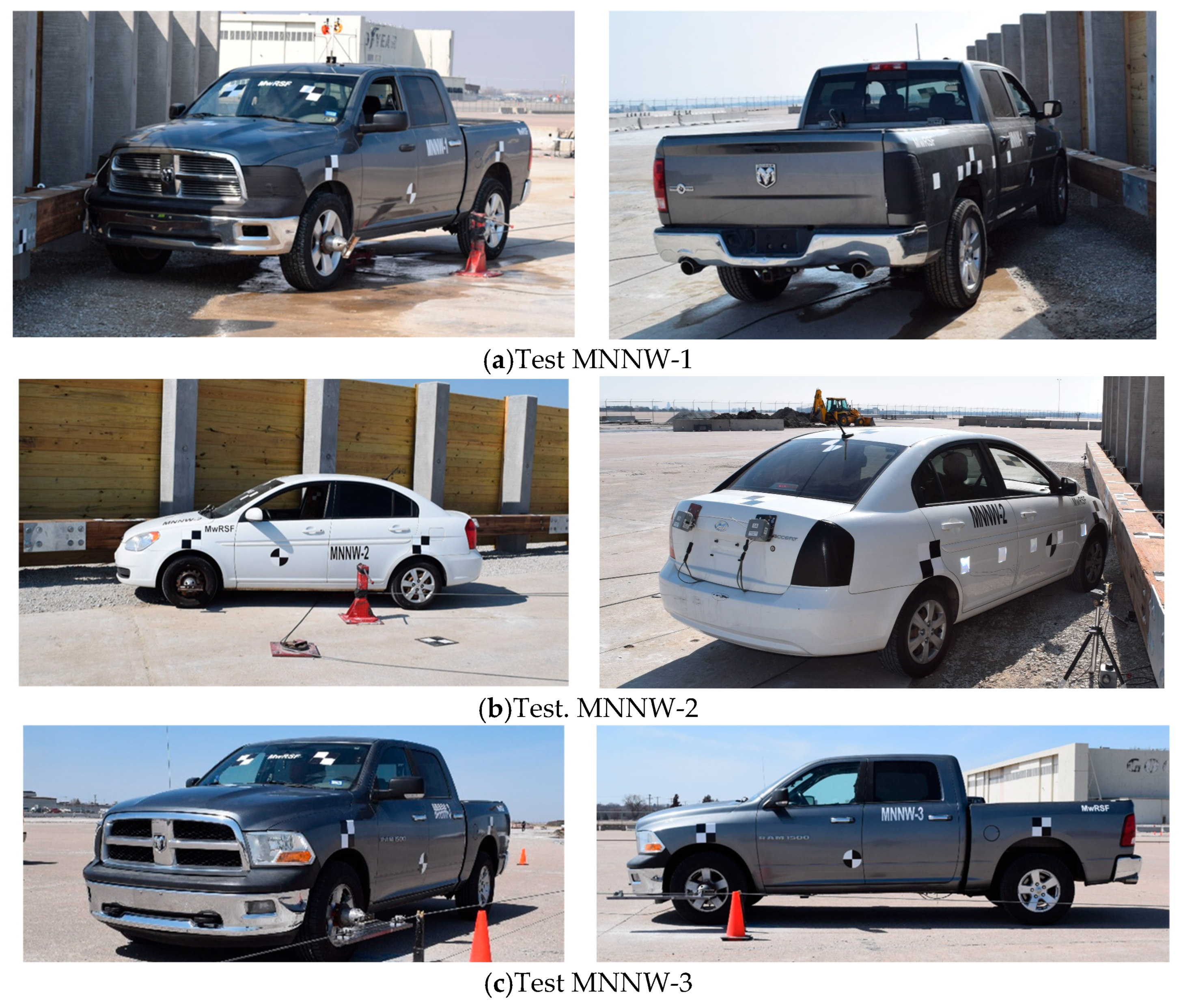

4.2. Test Vehicles

4.3. Simulated Occupants

4.4. Data Acquisition and Instrumentation

5. Full-Scale Vehicle Crash Tests

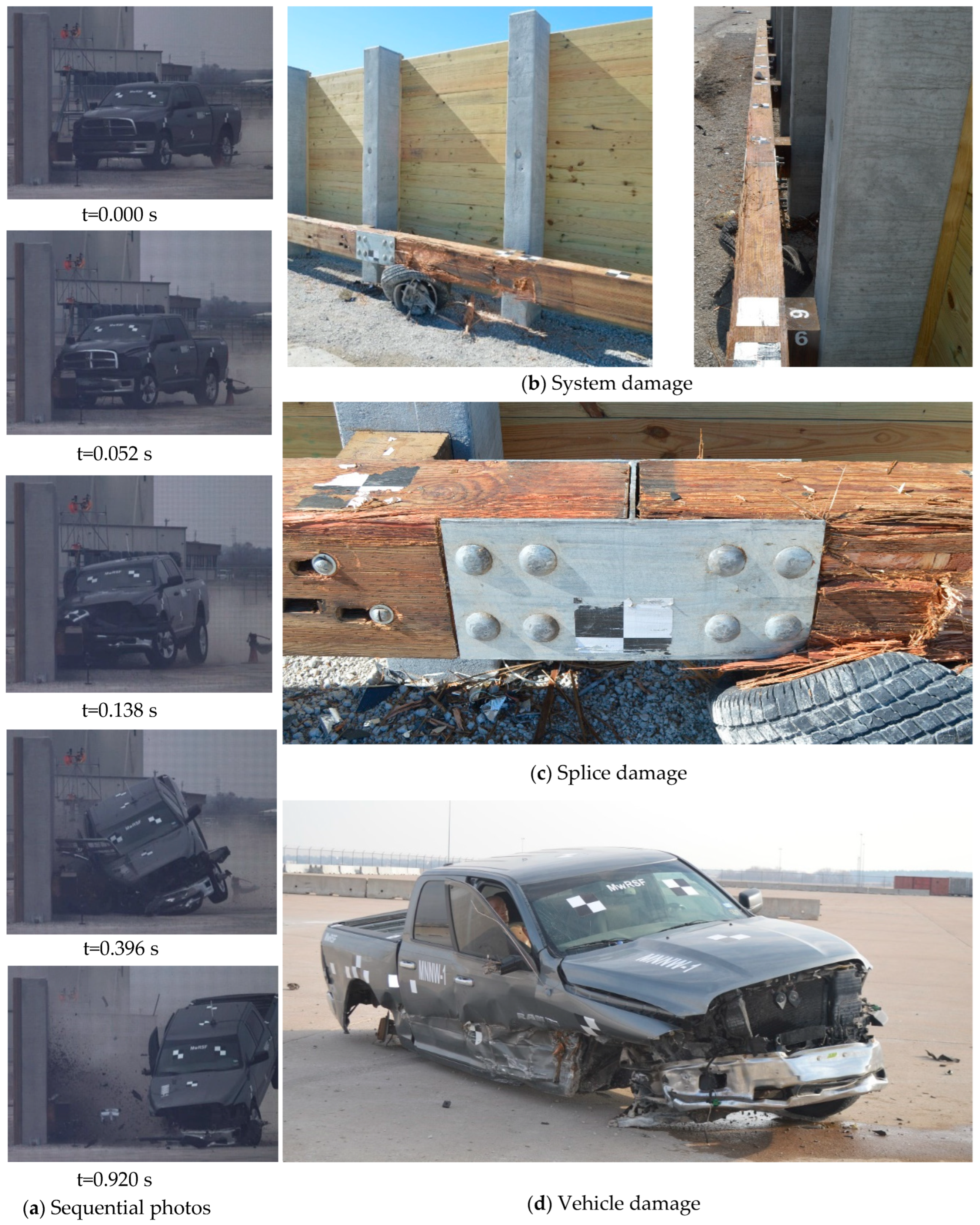

5.1. Test MNNW-1

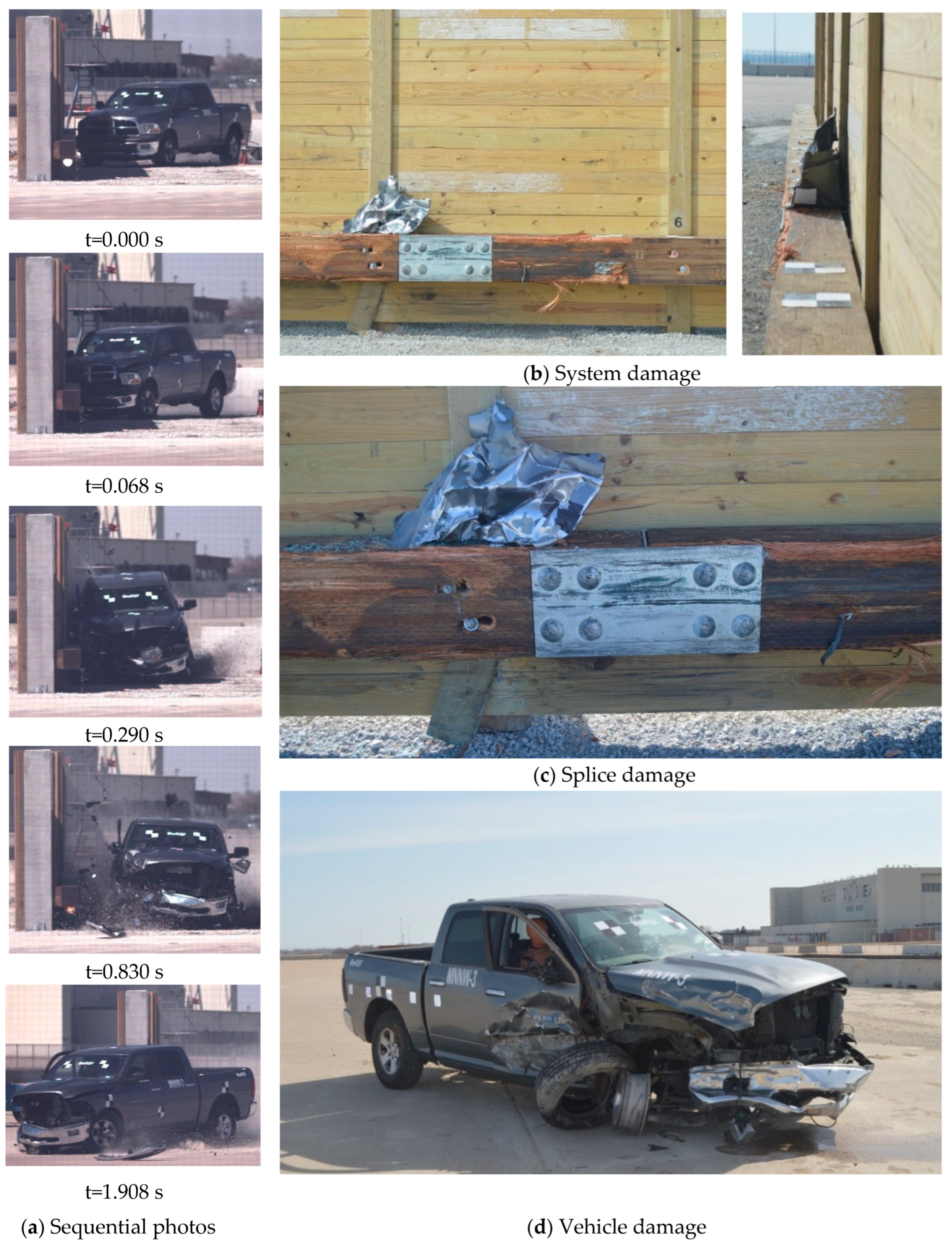

5.2. Test MNNW-2

5.3. Test MNNW-3

6. Discussion

6.1. Crash Performance and Structural Response

6.2. Comparative Performance, Service Life, and Sustainability

7. Limitations and Future Work

8. Summary, Conclusions, and Recommendations

- All tested systems (MNNW-1, MNNW-2, and MNNW-3) successfully contained and redirected 1100C and 2270P vehicles under test designation nos. 3-10 and 3-11. The structural integrity of both the rubrail and wall system was maintained, demonstrating compliance with MASH 2016 impact safety performance criteria.

- Both back-side and front-side mounted noise wall systems showed comparable crash performance. Although the front-side configuration was tested only under 3-11 impact conditions, the similarity in performance to the back-side system suggests it would also meet 3-10 requirements.

- The tested systems incorporated embedment depths greater than the MnDOT minimum standard of 1.8 m [29,30] and taller wall elements, resulting in stiffer behavior and acceptable safety performance. These results indicate that systems with equal or greater embedment and stiffness are likely to meet MASH TL-3 criteria, while reduced embedment depths may increase deflections but still remain within acceptable limits.

- Both round-head bolts recessed 3 mm and hex head bolts recessed 16 mm performed acceptably in the rubrail-to-post connection [31], demonstrating that either option is suitable for field applications without compromising crashworthiness.

- The transition between front-side and back-side mounted segments presents a potential vehicle snagging risk due to the overlap of structural components. While no significant snagging was observed, future research should further investigate this area and evaluate protective treatments at transitions and system ends to minimize vehicle interaction hazards.

- Overall, these findings demonstrate that glulam noise wall and rubrail systems can provide sustainable alternatives to conventional roadside barriers, thereby contributing to sustainable infrastructure development while meeting modern crashworthiness requirements.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Martinez-Orozco, J.M.; Barba, A. Determination of insertion loss of noise barriers in Spanish roads. Appl. Acoust. 2022, 186, 108435. [Google Scholar] [CrossRef]

- Silva, L.T.; Oliveira, I.S.; Silva, J.F. The impact of urban noise on primary schools: Perceptive evaluation and objective assessment. Appl. Acoust. 2016, 106, 2–9. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, R.; Cao, Z.; Wang, X.; Li, X. Acoustic performance of a semi-closed noise barrier installed on a high-speed railway bridge: Measurement and analysis considering actual service conditions. Measurement 2019, 138, 386–399. [Google Scholar] [CrossRef]

- Meyer, M.D.; Weigel, B. Climate change and transportation engineering: Preparing for a sustainable future. J. Transp. Eng. 2011, 137, 393–403. [Google Scholar] [CrossRef]

- Žemaitis, P.; Linkevičius, E.; Aleinikovas, M.; Tuomasjukka, D. Sustainability impact assessment of glue laminated timber and concrete-based building materials production chains: A Lithuanian case study. J. Clean. Prod. 2021, 321, 129005. [Google Scholar] [CrossRef]

- Maxineasa, S.G.; Entuc, I.-S.; Taranu, N.; Florenta, I.; Secu, A. Environmental performances of different timber structures for pitched roofs. J. Clean. Prod. 2018, 175, 164–175. [Google Scholar] [CrossRef]

- Petruch, M.; Walcher, D. Timber for future? Attitudes towards timber construction by young millennials in Austria: Marketing implications from a representative study. J. Clean. Prod. 2021, 294, 126324. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO LRFD Bridge Design Specifications, 9th ed.; AASHTO: Washington, DC, USA, 2020. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). Manual for Assessing Safety Hardware; AASHTO: Washington, DC, USA, 2016. [Google Scholar]

- Li, X.; Ashraf, M.; Li, H.; Zheng, X.; Wang, H.; Al-Deen, S.; Hazell, P.J. An experimental investigation on parallel bamboo strand lumber specimens under quasi static and impact loading. Constr. Build. Mater. 2019, 228, 116724. [Google Scholar] [CrossRef]

- Bullard, D.L.; Buth, C.E.; Williams, W.F.; Menges, W.L.; Schoeneman, S.K. NCHRP REPORT 350 Evaluation of the T501 Bridge Rail with Soundwall; FHWA/TX-01/408460-F; Texas Transportation Institute, Texas A&M University System: College Station, TX, USA, 2001. [Google Scholar]

- Ross, H.E.; Sicking, D.L.; Zimmer, R.A.; Michie, J.D. Recommended Procedures for the Safety Performance Evaluation of Highway Features; Transportation Research Board: Washington, DC, USA, 1993. [Google Scholar]

- Polivka, K.A.; Hascall, J.A.; Faller, R.K.; Rohde, J.R.; Holloway, J.C.; Sicking, D.L.; Kurz, K. Design and Evaluation of CYRO’s Paraglas Soundstop TL-4 Noise Barrier System; Transp. Res. Rep. No. TRP-03-160-05; Midwest Roadside Safety Facility, University of Nebraska–Lincoln: Lincoln, NE, USA, 2005. [Google Scholar]

- Faller, R.K.; Polivka, K.A.; Humphries, E.; Kurz, K.; Sicking, D.L.; Hascall, J.A. Test level 4 noise wall for attachment to concrete traffic barriers. Transp. Res. Rec. 2006, 1984, 56–68. [Google Scholar] [CrossRef]

- Polivka, K.A.; Rohde, J.R.; Faller, R.K.; Hollaway, J.C.; Sicking, D.L. Design and Evaluation of Minnesota’s Timber Rub-Rail Noise Barriers; Midwest Roadside Safety Facility, University of Nebraska–Lincoln: Lincoln, NE, USA, 2005. [Google Scholar]

- Bligh, R.P.; Briaud, J.L.; Abu-Odeh, A.; Seaz, D.O.; Maddah, L.S.; Kim, K.M. Design Guidelines for Test Level 3 (TL-3) Through Test Level 5 (TL-5) Roadside Barrier Systems Placed on Mechanically Stabilized Earth (MSE) Retaining Wall; Texas A&M Transportation Institute: College Station, TX, USA, 2017. [Google Scholar]

- American Wood Council. NDS National Design Specification for Wood Construction: With Commentary; American Wood Council: Washington, DC, USA, 2015. [Google Scholar]

- Hinch, J.; Yang, T.L.; Owings, R. Guidance Systems for Vehicle Testing; ENSCO, Inc.: Springfield, VA, USA, 1986. [Google Scholar]

- Center of Gravity Test Code—SAE J874 March 1981, SAE Handbook Vol. 4; Society of Automotive Engineers, Inc.: Warrendale, PA, USA, 1986.

- MacInnis, D.; Cliff, W.; Ising, K. A Comparison of the Moment of Inertia Estimation Techniques for Vehicle Dynamics Simulation; SAE Tech. Pap. Ser. 970951; Society of Automotive Engineers, Inc.: Warrendale, PA, USA, 1997. [Google Scholar]

- Society of Automotive Engineers (SAE). Instrumentation for Impact Test—Part 1—Electronic Instrumentation; SAE J211/1 MAR95; SAE: Warrendale, PA, USA, 2007. [Google Scholar]

- CEN (European Committee for Standardization). EN 1317-1:2010; Road Restraint Systems—Part 1: Terminology and General Criteria for Test Methods. European Committee for Standardization: Brussels, Belgium, 2010.

- Berthelson, P.; Ghassemi, P.; Wood, J.W.; Liu, Y.; Al-Graitti, A.J.; Jones, M.D.; Chowdhury, S.; Prabhu, R.K. Evaluation of Occupant Neck Injury Response to Varied Impact Conditions Using a Finite Element-Mathematical Surrogate Modeling Approach. Int. J. Crashworthiness 2022, 27, 1726–1742. [Google Scholar] [CrossRef]

- Deng, X.-Q.; Du, Z.; Feng, H.; Wang, S.; Luo, H.; Liu, Y. Investigation on the Modeling and Reconstruction of Head Injury Accident Using ABAQUS/Explicit. Bioengineering 2022, 9, 723. [Google Scholar] [CrossRef]

- Kumar, V.; Lo Ricco, M.; Bergman, R.D.; Nepal, P.; Poudyal, N.C. Environmental Impact Assessment of Mass Timber, Structural Steel, and Reinforced Concrete Buildings Based on the 2021 International Building Code Provisions. Build. Environ. 2024, 251, 111195. [Google Scholar] [CrossRef]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A Comparative Cradle-to-Gate Life Cycle Assessment of Mid-Rise Office Building Construction Alternatives: Laminated Timber or Reinforced Concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The Wood from the Trees: The Use of Timber in Construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Life Cycle Primary Energy Implication of Retrofitting a Wood-Framed Apartment Building to Passive House Standard. Resour. Conserv. Recycl. 2010, 54, 1152–1160. [Google Scholar] [CrossRef]

- Minnesota Department of Transportation. Glue Laminated Rubrail (Concrete Posts); Minnesota Department of Transportation: Saint Paul, MN, USA, 2014. [Google Scholar]

- Minnesota Department of Transportation. Wood Planking Noise Wall with Concrete Posts; Minnesota Department of Transportation: Saint Paul, MN, USA, 2016. [Google Scholar]

- Schmidt, J.D.; Asselin, N.; Faller, R.K.; Fallet, W.G.; Holloway, J.C.; Lechtenberg, K.A. Evaluation of the Minnesota Noise Wall and Rubrail System; Midwest Roadside Safety Facility, University of Nebraska–Lincoln: Lincoln, NE, USA, 2019. [Google Scholar]

| Evaluation Criteria | Test MNNW-1 | Test MNNW-2 | Test MNNW-3 | MASH 2016 Limits | |

|---|---|---|---|---|---|

| OIV, m/s | Longitudinal | −7.34 | −7.23 | −8.12 | ±12.2 (±40) |

| Lateral | −7.95 | −8.66 | −7.46 | ±12.2 (±40) | |

| ORA, g’s | Longitudinal | −7.59 | −6.2 | −8.2 | ±20.49 |

| Lateral | −7.33 | −4.55 | −6.64 | ±20.49 | |

| MAX. ANGULAR DISPL. deg. | Roll | 26.7 | −3.3 | 6.7 | ±75 |

| Pitch | −21 | −2.9 | 6.1 | ±75 | |

| Yaw | 30.1 | −37.2 | −33.7 | not required | |

| THIV, m/s | 10.34 | 9.9 | 10.78 | not required | |

| PHD, g’s | 9.14 | 6.17 | 11.47 | not required | |

| ASI | 1.46 | 2.14 | 1.53 | not required | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yosef, T.Y.; Faller, R.K.; Alomari, Q.A.; Schmidt, J.D.; Atash Bahar, M. Performance Evaluation of a Sustainable Glulam Timber Rubrail and Noise Wall System Under MASH TL-3 Crash Conditions. Infrastructures 2025, 10, 226. https://doi.org/10.3390/infrastructures10090226

Yosef TY, Faller RK, Alomari QA, Schmidt JD, Atash Bahar M. Performance Evaluation of a Sustainable Glulam Timber Rubrail and Noise Wall System Under MASH TL-3 Crash Conditions. Infrastructures. 2025; 10(9):226. https://doi.org/10.3390/infrastructures10090226

Chicago/Turabian StyleYosef, Tewodros Y., Ronald K. Faller, Qusai A. Alomari, Jennifer D. Schmidt, and Mojtaba Atash Bahar. 2025. "Performance Evaluation of a Sustainable Glulam Timber Rubrail and Noise Wall System Under MASH TL-3 Crash Conditions" Infrastructures 10, no. 9: 226. https://doi.org/10.3390/infrastructures10090226

APA StyleYosef, T. Y., Faller, R. K., Alomari, Q. A., Schmidt, J. D., & Atash Bahar, M. (2025). Performance Evaluation of a Sustainable Glulam Timber Rubrail and Noise Wall System Under MASH TL-3 Crash Conditions. Infrastructures, 10(9), 226. https://doi.org/10.3390/infrastructures10090226