Characterization and Evaluation of Agar as a Bio-Based Asphalt Binder Alternative

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.1.1. Binder Testing Samples

2.1.2. Composite Testing Samples

2.2. Rheological Properties of Agar-Based Binder

2.2.1. Rotational Viscosity

2.2.2. Dynamic Shear Rheometry

2.2.3. Penetration

2.3. Durability of Agar-Based Binder

2.3.1. Thermogravimetric Analysis

2.3.2. Fungal Biodeterioration

2.3.3. Moisture Sorption

2.4. Mechanical and Microstructural Characterization of Agar-Based Composites

2.4.1. X-Ray Tomography

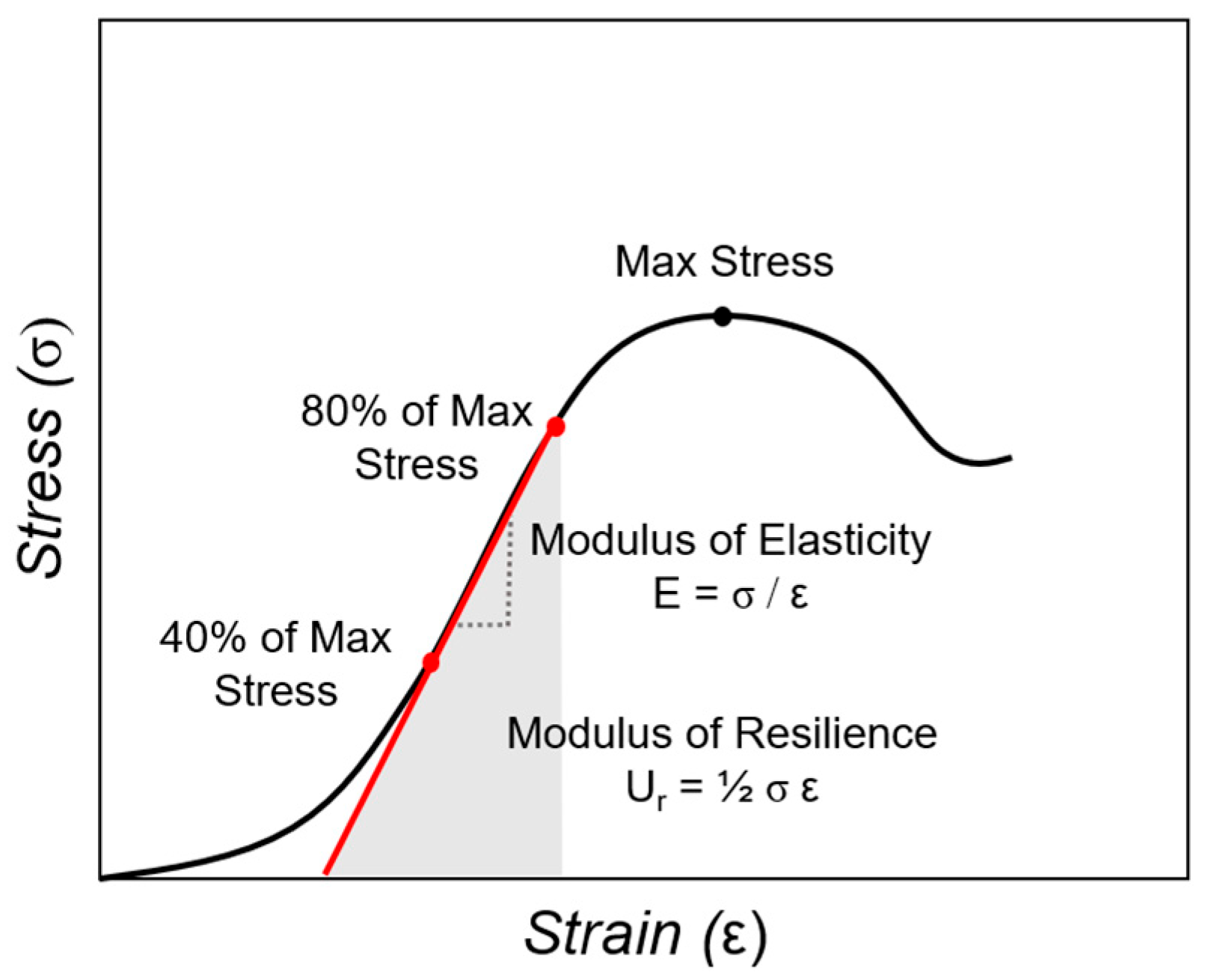

2.4.2. Unconfined Compressive Strength

2.4.3. Modulus of Elasticity and Resilience

3. Results and Discussion

3.1. Rheological Properties of Agar-Based Binder

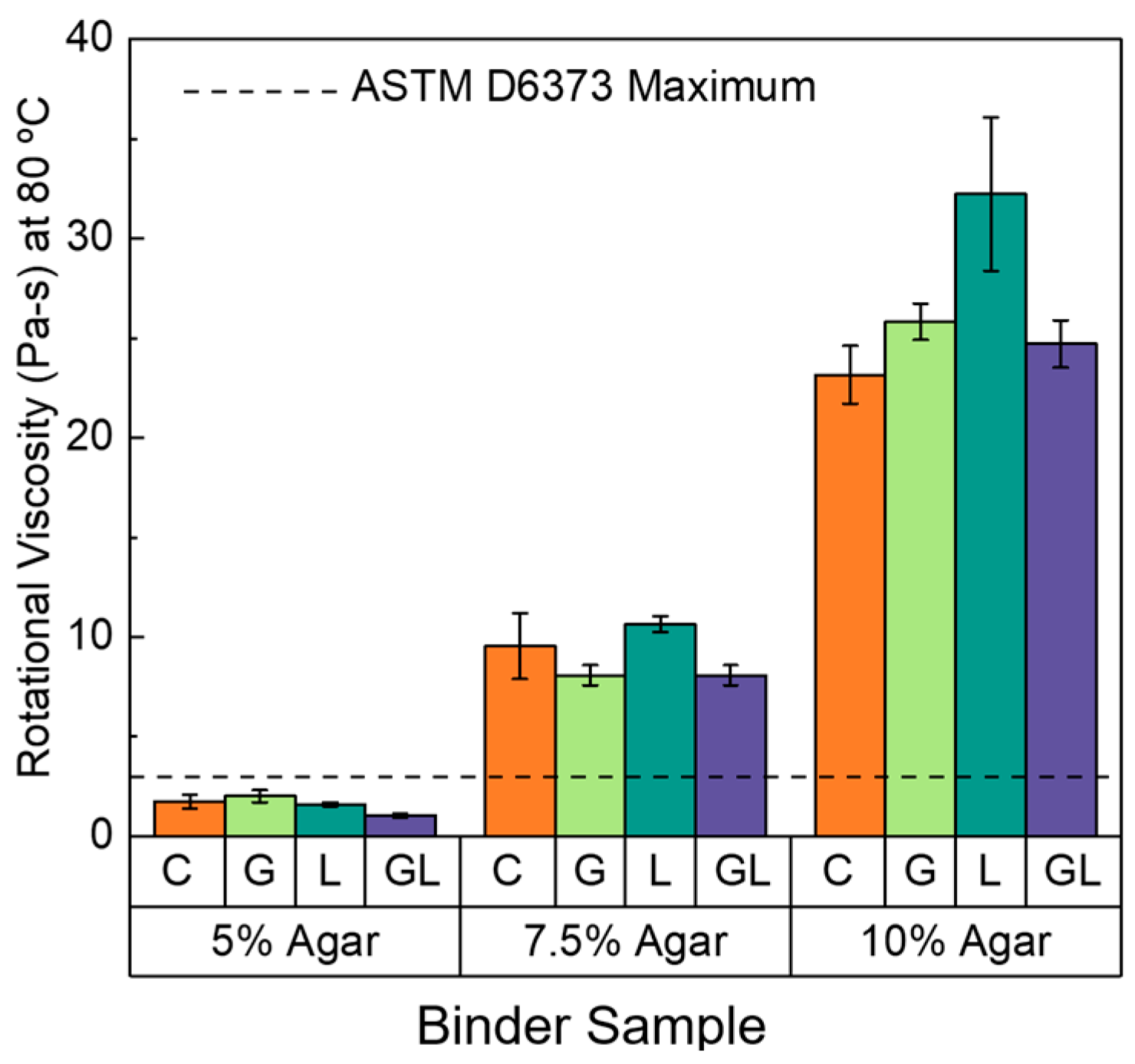

3.1.1. Rotational Viscosity

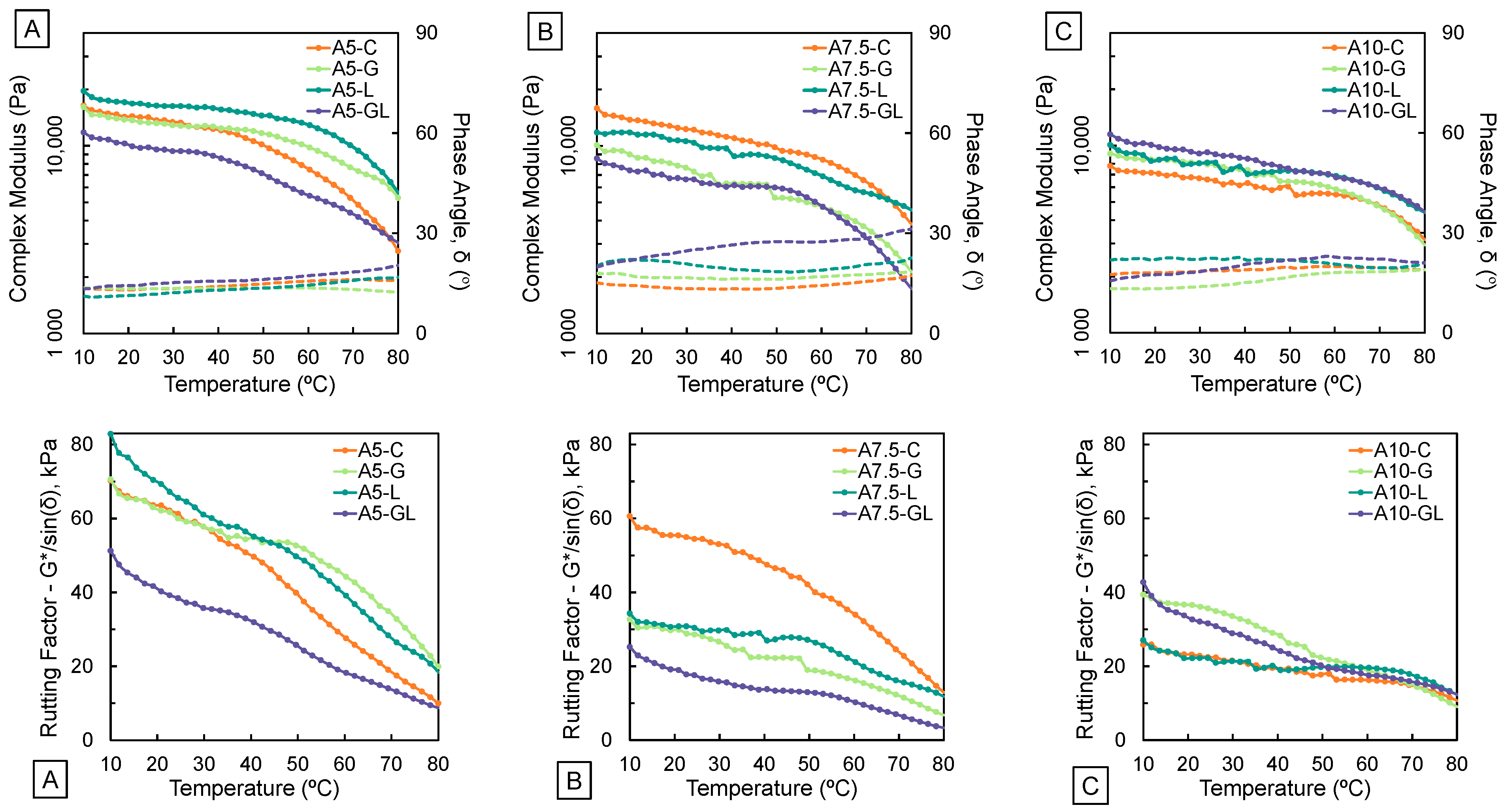

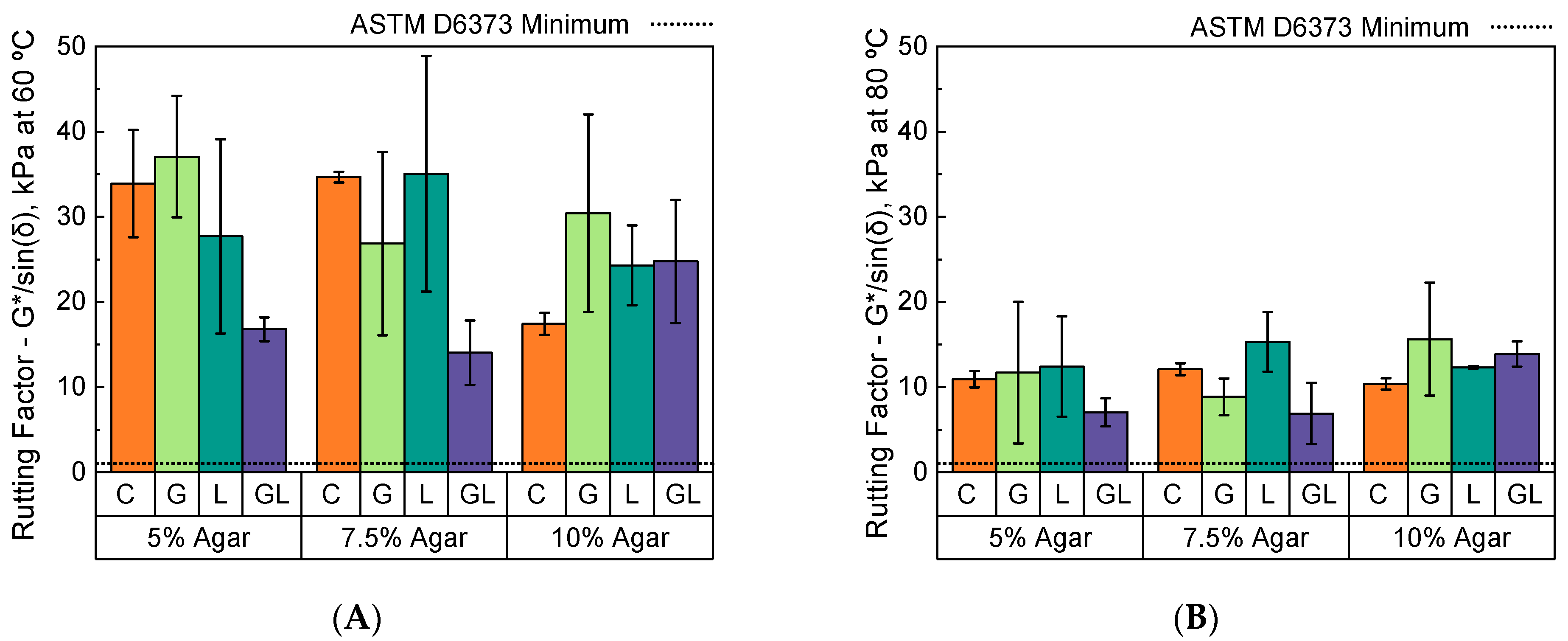

3.1.2. Dynamic Shear Rheometry

3.1.3. Penetration

3.2. Durability of Agar-Based Binder

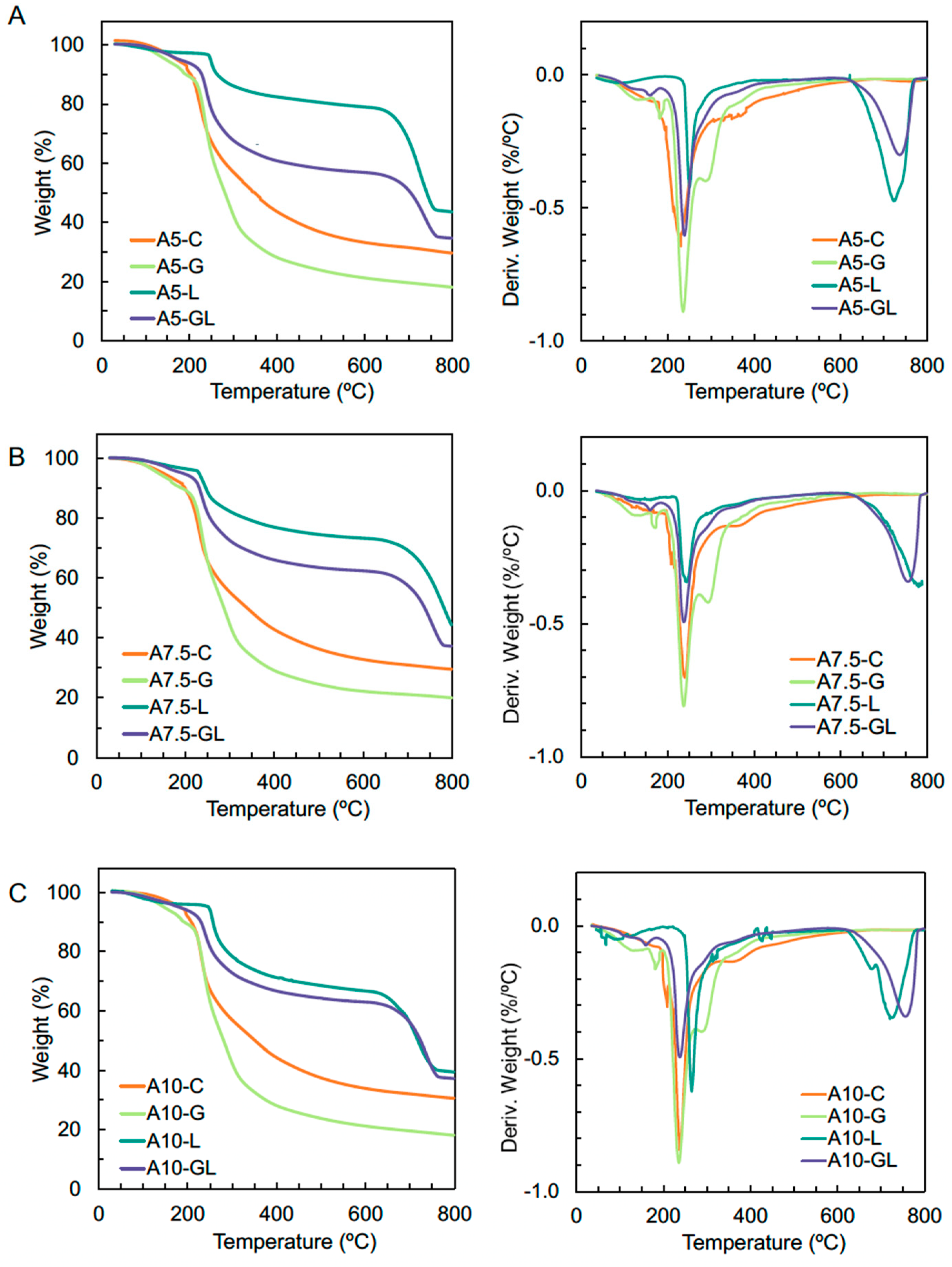

3.2.1. Thermogravimetric Analysis

3.2.2. Fungal Biodeterioration

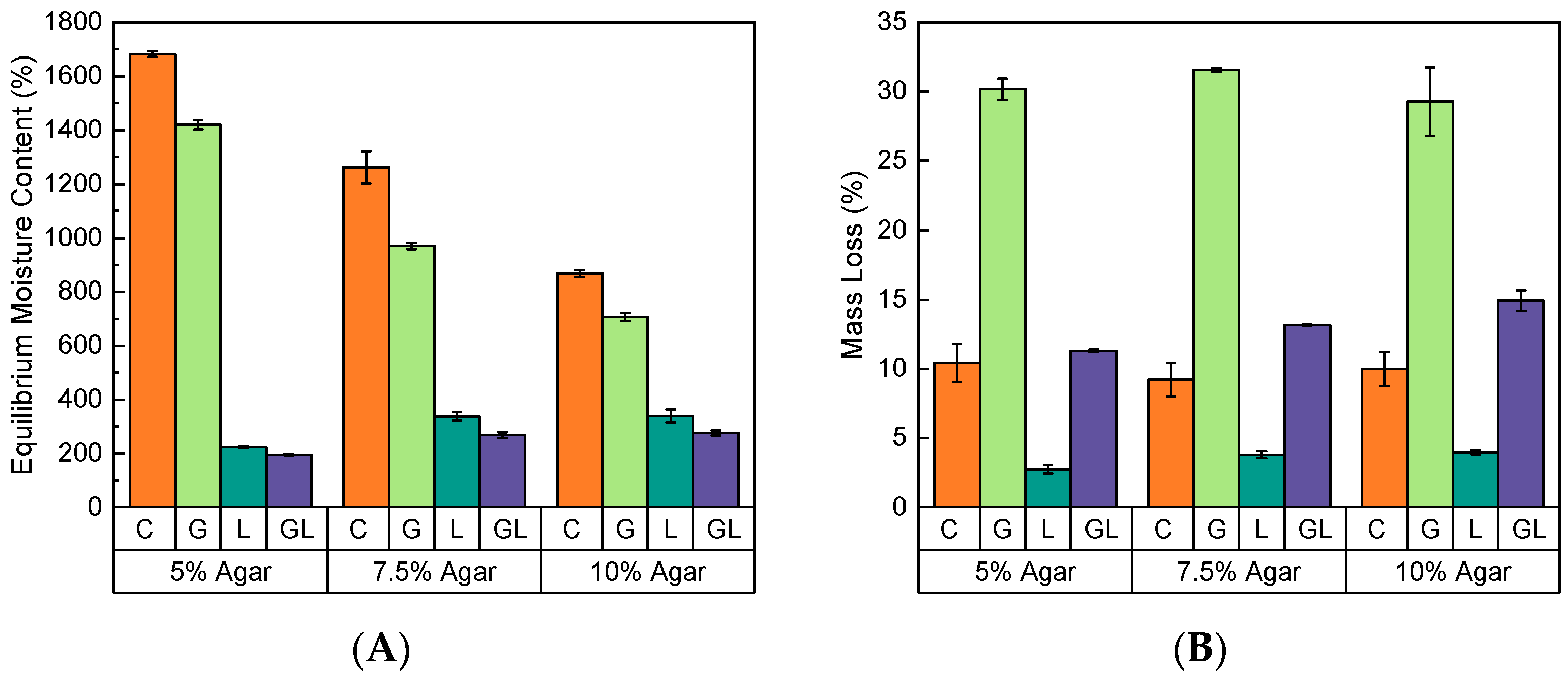

3.2.3. Moisture Sorption

3.3. Mechanical and Microstructural Characterization of Agar-Based Composites

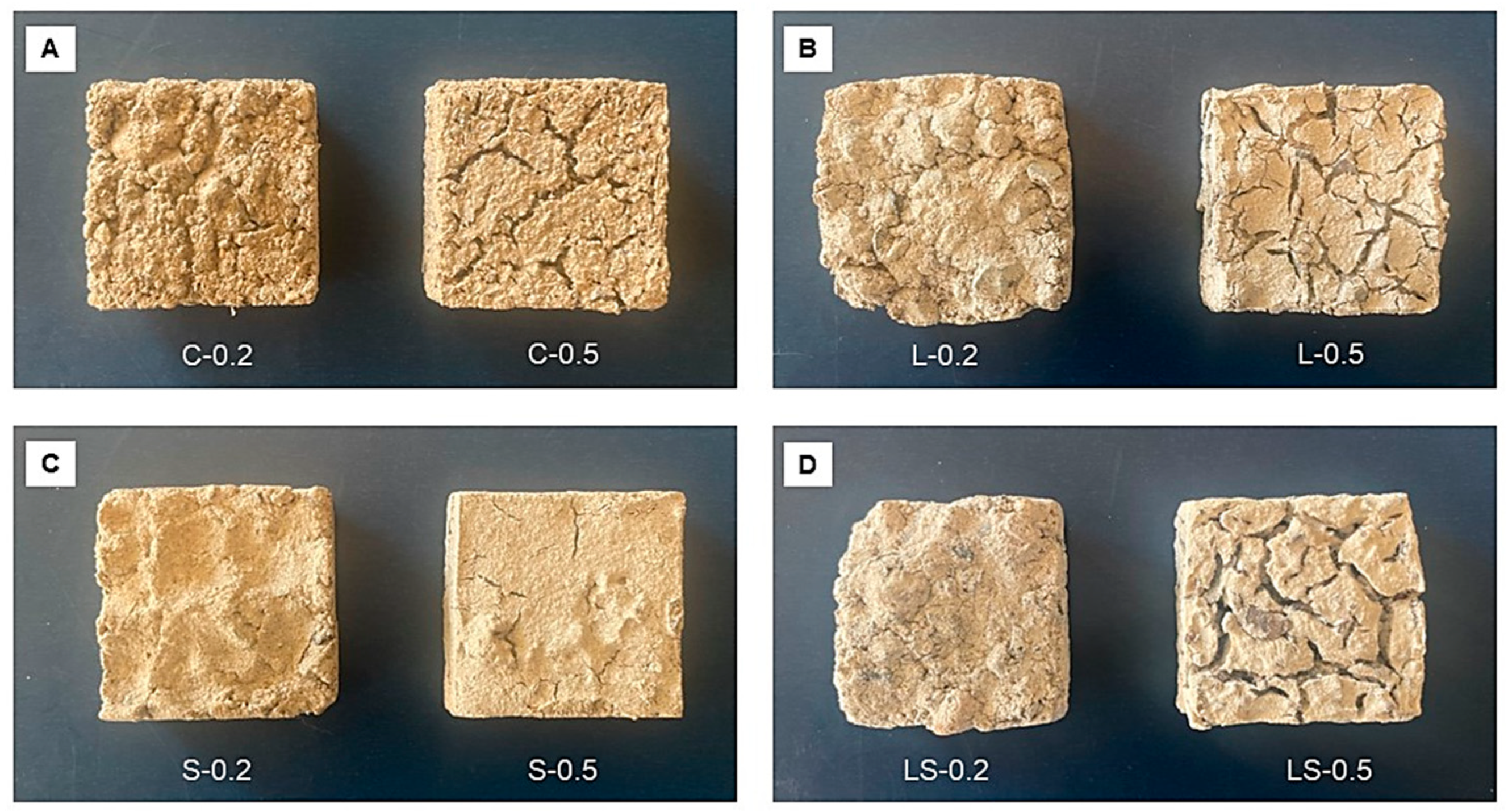

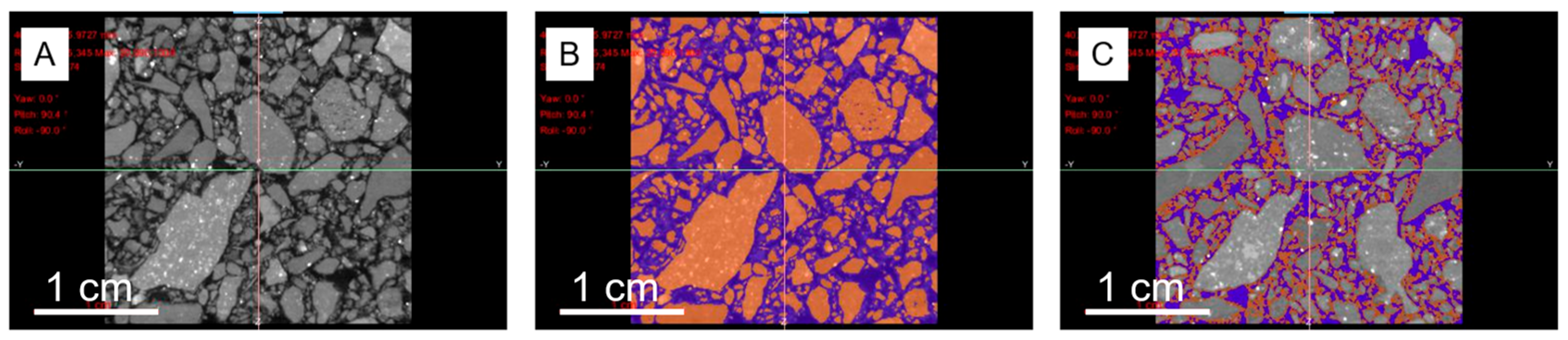

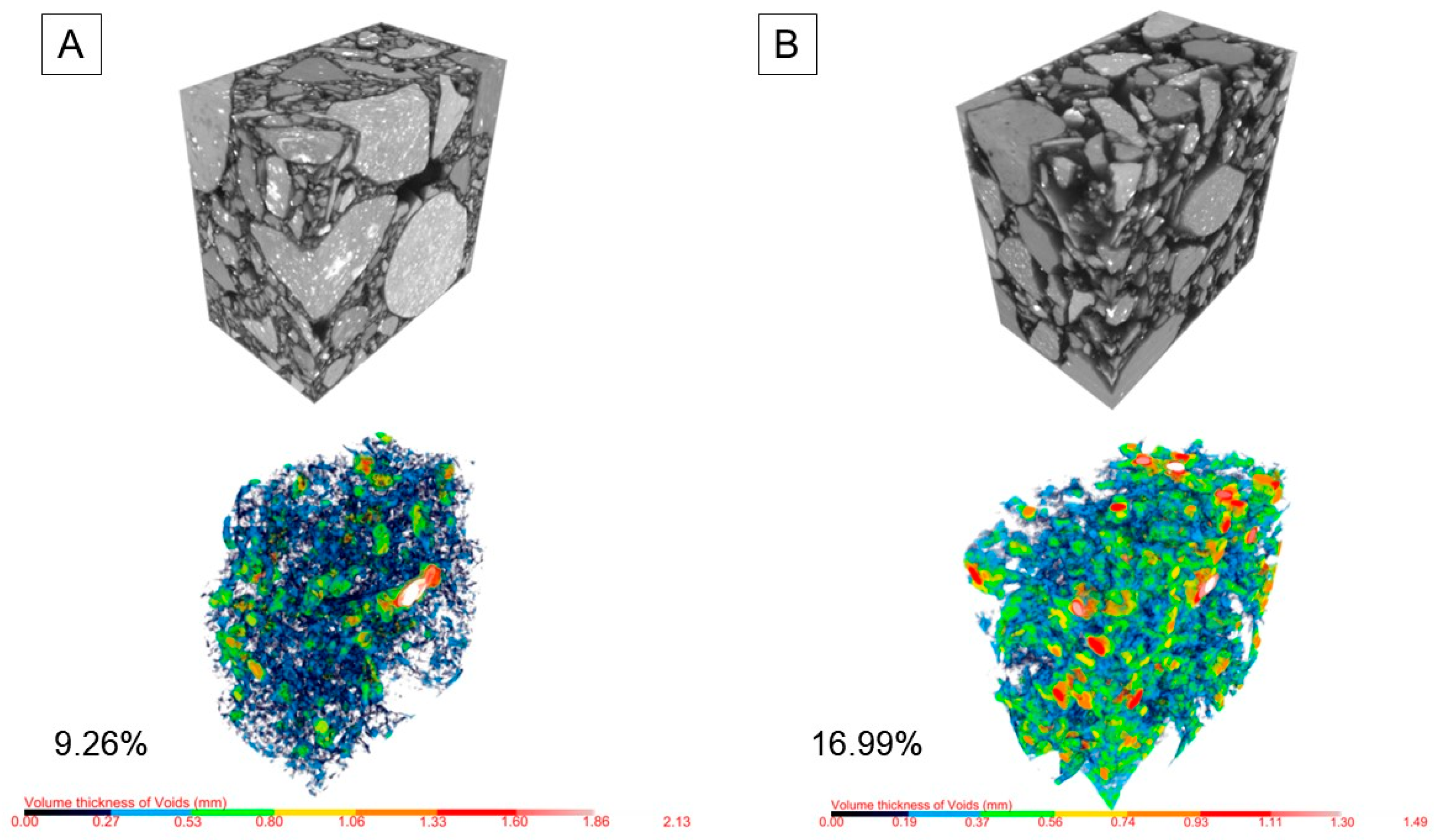

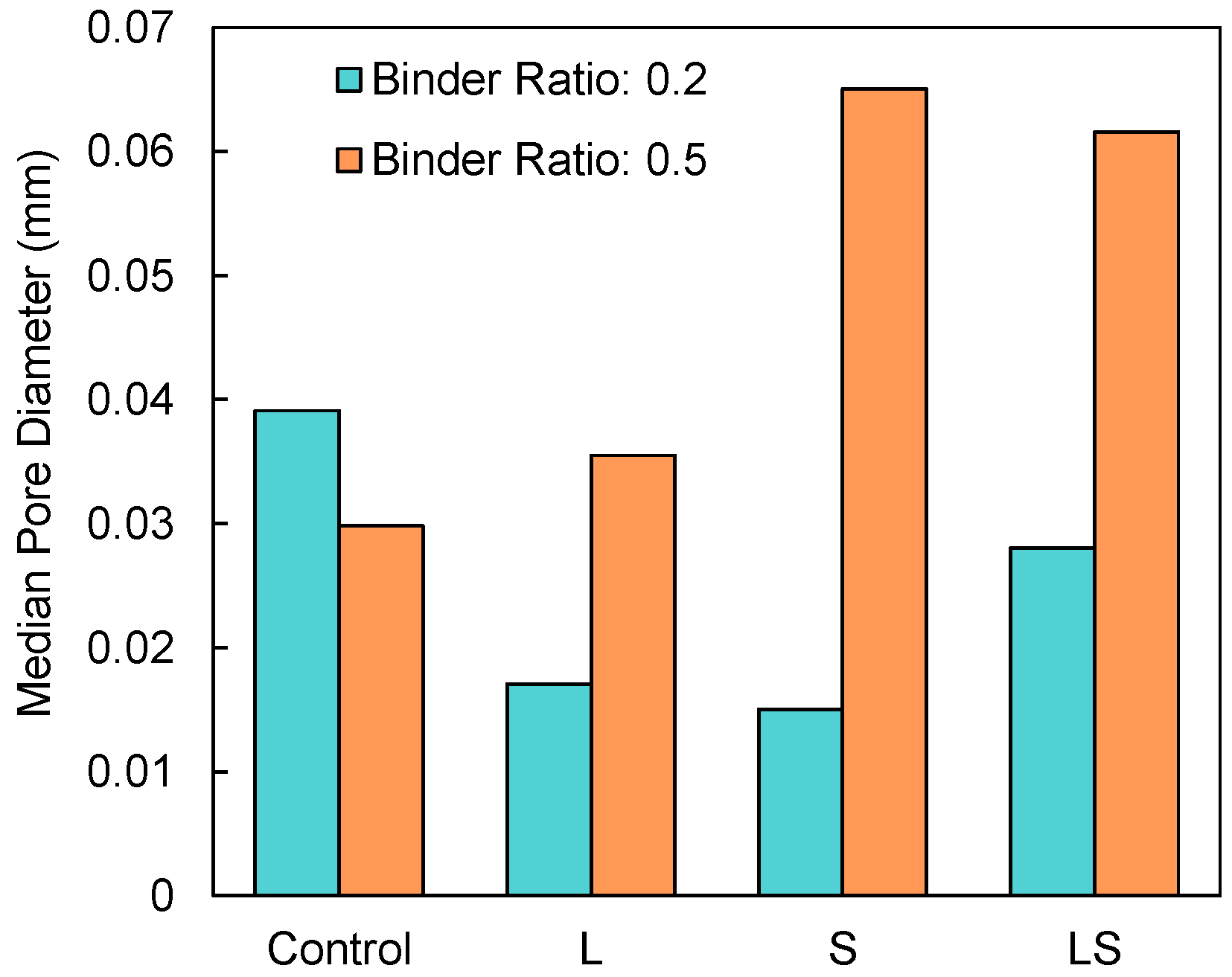

3.3.1. X-Ray Tomography

3.3.2. Unconfined Compressive Strength

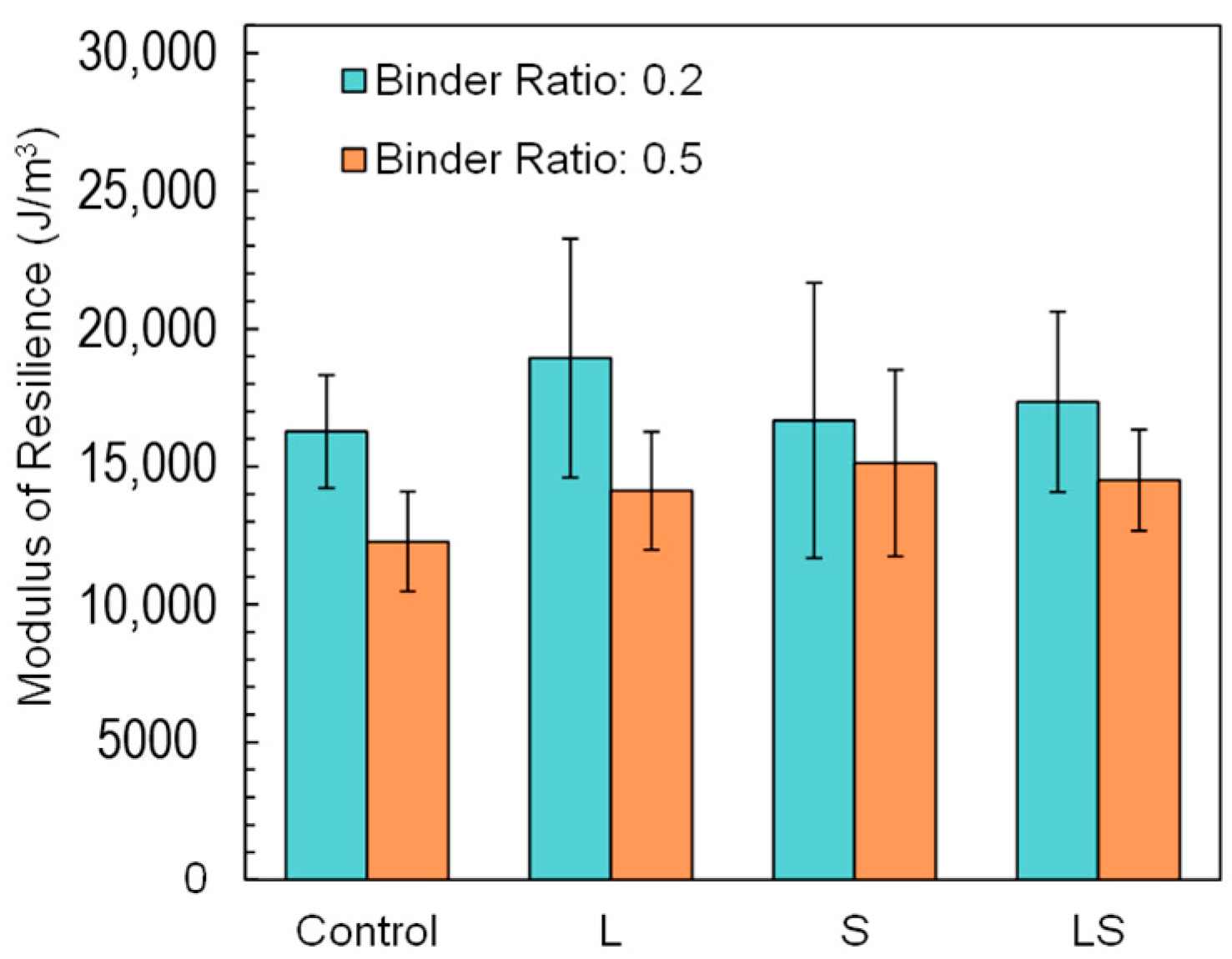

3.3.3. Modulus of Resiliency

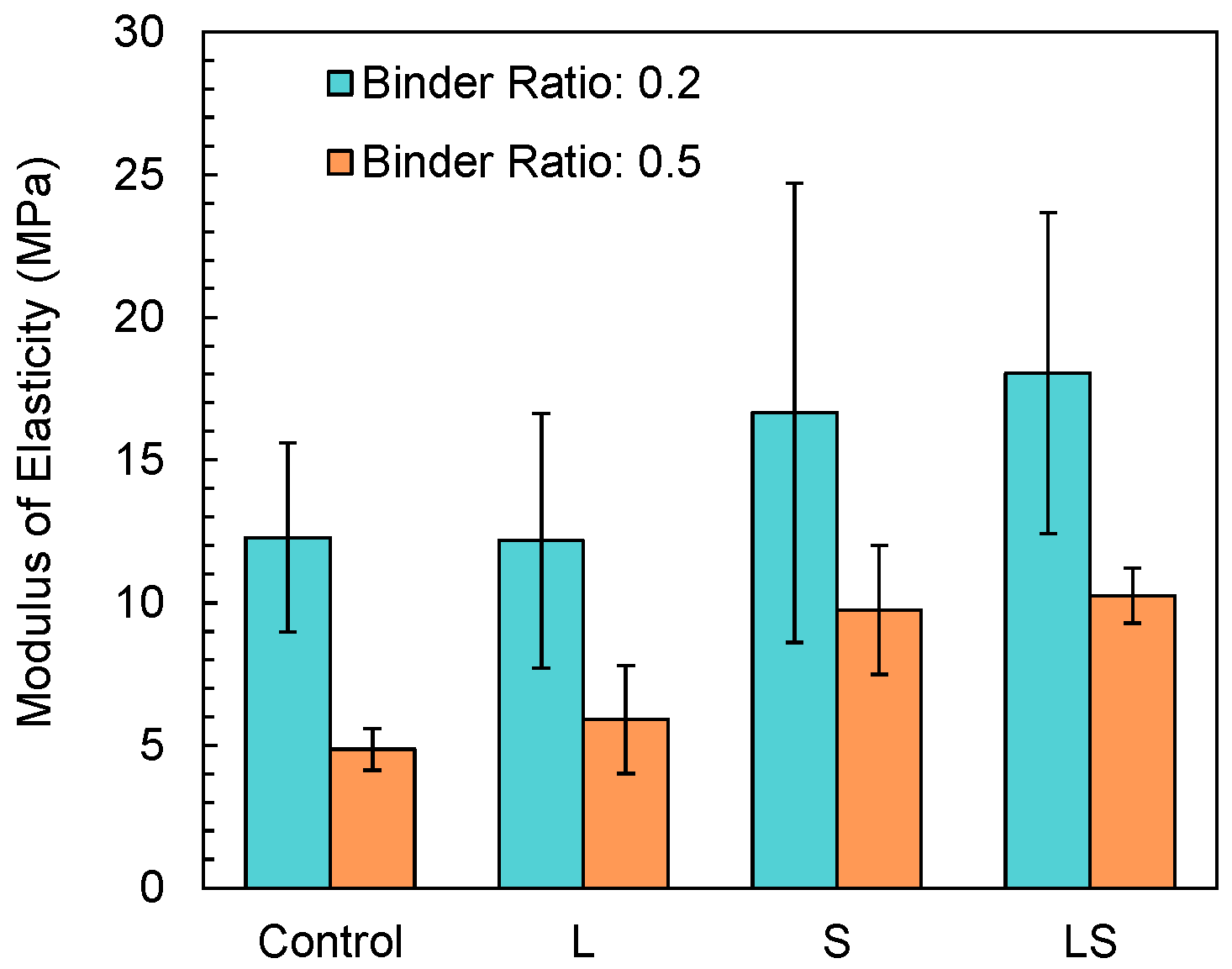

3.3.4. Modulus of Elasticity

4. Conclusions

- All 5% w/w agar-based binders passed the rotational viscosity (RV) threshold set by the performance-grade (PG) specification (<3 Pa·s), while all 7.5% and 10% w/w samples exceeded that same threshold. In general, agar-based binders exhibited more viscous behavior than traditional asphalt binders. However, RV testing of agar-based binders was completed at a lower temperature than stipulated by the PG specification (i.e., 80 °C vs. 135 °C). The lower temperature compatibility of agar-based materials indicates the possibility of lower mixing and compaction temperatures and an increase in energy efficiency of production as compared to petroleum-based binder production.

- Dynamic shear rheometry (DSR) revealed that all agar-based binders in this study exhibited adequate stiffness to resist early-age rutting at temperatures up to 80 °C. Agar-based materials generally illustrated a higher complex modulus and lower phase angle than traditional asphalt binders, which is advantageous for rutting. Relatedly, the high magnitude of the complex moduli at testing temperatures might indicate the possibility of low-temperature and fatigue-induced cracking.

- Penetration measurements performed on fully submerged, unaged agar-based binders ranged from 162 to greater than 350. While penetration readings were generally higher than those associated with traditional asphalt binders used in road applications, the results indicated that penetration consistency might be tailorable with the use of additives, such as ground limestone.

- Thermogravimetric analysis illustrated that all agar-based binders were thermally stable up to 210 °C. The onset of thermal decomposition occurs at a slightly lower temperature for agar-based binders as compared to petroleum-based materials (i.e., 210 °C vs. 250–300 °C).

- When subjected to ASTM G21 testing, agar-based binders without glycerol addition exhibited improved resistance to biodeterioration as compared to a positive control (i.e., cellulose). Samples with glycerol addition showed substantial growth, indicating that glycerol served as an effective carbon source for the growth of heterotrophic microorganisms.

- Moisture diffused rapidly in agar-based binders and the equilibrated moisture content for agar-based samples relative to conditioned mass ranged from 196% to 1682%. Relative to fresh-state sample mass, rehydrated agar-based binders swelled to between 55 and 97% moisture content. Limestone significantly reduced moisture sorption and improved mass loss during testing. However, glycerol plasticizer was found to leach from agar-based binder samples in isothermal sorption testing.

- As shown in X-ray tomography, agar-based material-coated aggregate particles, resulting in increased sample density and frictional contact between particles. Results indicate there is likely the existence of an optimum aggregate composition and binder content. Further, X-ray tomography illustrated the formation of large fractures due to shrinkage stresses in samples with a 0.5 agar binder content. Coupled with results from porosity measurements and mechanical data, this suggests that a 0.5 binder content (i.e., by mass) surpasses the optimal agar proportion for the aggregate and filler compositions studied herein.

- In microstructural evaluation, several trends are visible in porosity measurements. The porosity of agar-based composites ranged from 5.79 to 16.99% for control samples, 6.25 to 15.21% for limestone-containing samples (L), 3.39 to 9.92% for sand-containing samples (S), and 5.60 to 16.55% for limestone- and sand-containing (LS) samples. An increase in binder content led to an increase in the volume of pores and pore size. The inclusion of sand led to a decrease in the porosity of samples and porosity of sand reinforced samples with a 0.2 and 0.5 binder content was 2.4–4.5% and 6.9–7.1% lower than comparable control samples (i.e., C-0.2 and C-0.5), respectively. Conversely, the porosity of limestone- and sand-reinforced samples was greater than the porosity of samples with only sand.

- In mechanical characterization, the compressive strength of samples ranged from 431 to 780 kPa, 500 to 913 kPa, 699 to 1042 kPa, and 679 to 978 kPa for control, L, S, and LS samples, respectively. The average modulus of resilience of samples ranged from 12,275 J/m3 (i.e., sample C-0.5) to 18,934 J/m3 (i.e., sample L-0.2) and the average modulus of elasticity ranged from 4.87 MPa (i.e., sample C-0.5) to 18.03 MPa (i.e., sample LS-0.2). The use of a higher biopolymer content led to increased shrinking stresses and 0.5 binder content samples consistently illustrated lower mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Asphalt Paving Association of Iowa. Asphalt Paving Design Guide; Asphalt Paving Association of Iowa: West Des Moines, IA, USA, 2020. [Google Scholar]

- Penki, R.; Rout, S.K. Next-Generation Bitumen: A Review on Challenges and Recent Developments in Bio-Bitumen Preparation and Usage. Biomass Conv. Bioref. 2023, 13, 9583–9600. [Google Scholar] [CrossRef]

- Fini, E.H.; Al-Qadi, I.L.; You, Z.; Zada, B.; Mills-Beale, J. Partial Replacement of Asphalt Binder with Bio-Binder: Characterisation and Modification. Int. J. Pavement Eng. 2012, 13, 515–522. [Google Scholar] [CrossRef]

- Ahmed, R.B.; Hossain, K. Waste Cooking Oil as an Asphalt Rejuvenator: A State-of-the-Art Review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar] [CrossRef]

- He, M.; Tu, C.; Cao, D.W.; Chen, Y.J. Comparative Analysis of Bio-Binder Properties Derived from Different Sources. Int. J. Pavement Eng. 2019, 20, 792–800. [Google Scholar] [CrossRef]

- Armisen, R.; Galatas, F.; Spain, H.S.A. Agar. In Handbook of Hydrocolloids; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Smitha, S.; Rangaswamy, K.; Keerthi, D.S. Triaxial Test Behaviour of Silty Sands Treated with Agar Biopolymer. Int. J. Geotech. Eng. 2021, 15, 484–495. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.-C. Soil Strengthening Using Thermo-Gelation Biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Khatami, H.R.; O’Kelly, B.C. Improving Mechanical Properties of Sand Using Biopolymers. J. Geotech. Geoenviron. Eng. 2013, 139, 1402–1406. [Google Scholar] [CrossRef]

- Fatehi, H.; Ong, D.E.L.; Yu, J.; Chang, I. Biopolymers as Green Binders for Soil Improvement in Geotechnical Applications: A Review. Geosciences 2021, 11, 291. [Google Scholar] [CrossRef]

- Verma, A.K.; Prasad, A.; Bonal, N.S. Investigation of the Long-Term Shear Strength Behavior of Municipal Solid Waste Fines Stabilized with Biopolymer: An Experimental Study. J. Environ. Chem. Eng. 2023, 11, 109805. [Google Scholar] [CrossRef]

- Kantesaria, N.; Chandra, P.; Sachan, A. Stabilization of Expansive Soil Using Agar Biopolymer. In Proceedings of the IFCEE 2021: From Traditional to Emerging Geotechnics, Dallas, TX, USA, 10–14 May 2021; American Society of Civil Engineers: Reston, VA, USA, 2021; pp. 272–281. [Google Scholar]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A State-of-the-Art Review of Polymers Used in Soil Stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.C.; Bellotto, M.; Woloszyn, M.; Dotelli, G. Natural Additives and Biopolymers for Raw Earth Construction Stabilization—A Review. Constr. Build. Mater. 2021, 304, 124507. [Google Scholar] [CrossRef]

- ASTM D75; Standard Practice for Sampling Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Smitha, S.; Sachan, A. Use of Agar Biopolymer to Improve the Shear Strength Behavior of Sabarmati Sand. Int. J. Geotech. Eng. 2016, 10, 387–400. [Google Scholar] [CrossRef]

- Arham, R.; Salengke, S.; Metusalach, M.; Mulyati, M.T. Optimization of Agar and Glycerol Concentration in the Manufacture of Edible Film. Int. Food Res. J. 2018, 25, 1845–1851. [Google Scholar]

- ASTM D6373; Standard Specification for Performance-Graded Asphalt Binder. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- ASTM D946; Standard Specification for Penetration-Graded Asphalt Binder for Use in Pavement Construction. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- Mao, B.; Bentaleb, A.; Louerat, F.; Divoux, T.; Snabre, P. Heat-Induced Aging of Agar Solutions: Impact on the Structural and Mechanical Properties of Agar Gels. Food Hydrocoll. 2017, 64, 59–69. [Google Scholar] [CrossRef]

- Gudimettla, J.M.; Cooley, L.A.; Brown, E.R. Workability of Hot-Mix Asphalt. Transp. Res. Rec. 2004, 1891, 229–237. [Google Scholar] [CrossRef]

- Dessouky, S.; Pothuganti, A.; Walubita, L.F.; Rand, D. Laboratory Evaluation of the Workability and Compactability of Asphaltic Materials Prior to Road Construction. J. Mater. Civ. Eng. 2013, 25, 810–818. [Google Scholar] [CrossRef]

- ASTM D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- Mallick, R.B.; El-Korchi, T. (Eds.) Pavement Engineering: Principles and Practice, 3rd ed.; CRC Press LLC: Boca Raton, FL, USA, 2018. [Google Scholar]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- Williams, E.G. When to Use What Grade of Asphalt and Why. Mater. Sci. 1961, 218–228. Available online: https://docs.lib.purdue.edu/cgi/viewcontent.cgi?article=3067&context=roadschool (accessed on 13 August 2025).

- Billington, S.L.; Srubar, W.V.; Michel, A.T.; Miller, S.A. Renewable Biobased Composites for Civil Engineering Applications. Sustain. Compos. Fibers Resins Appl. 2014, 2, 313–348. [Google Scholar]

- ASTM G21; Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- ASTM D570; Test Method for Water Absorption of Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- Liu, J.; Wang, Y.; Wang, S.; Liu, Q.; Yu, B.; Wang, Q. Use of X-Ray Computed Tomography to Evaluate the Gradual Behaviour of Air Voids in Asphalt Mixtures during Permanent Deformation. Int. J. Pavement Eng. 2023, 24, 2134570. [Google Scholar] [CrossRef]

- Miljković, M.; Griffa, M.; Münch, B.; Plamondon, M.; Lura, P. Mesostructural Evolution of Fine-Aggregate Bitumen Emulsion–Cement Composites by X-Ray Tomography. Int. J. Pavement Eng. 2024, 25, 2283610. [Google Scholar] [CrossRef]

- ASTM D7063; Standard Test Method for Effective Porosity and Effective Air Voids of Compacted Bituminous Paving Mixture Samples. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- du Plessis, A.; Boshoff, W.P. A Review of X-Ray Computed Tomography of Concrete and Asphalt Construction Materials. Constr. Build. Mater. 2019, 199, 637–651. [Google Scholar] [CrossRef]

- Frazier, S.D.; Matar, M.G.; Osio-Norgaard, J.; Aday, A.N.; Delesky, E.A.; Srubar, W.V. Inhibiting Freeze-Thaw Damage in Cement Paste and Concrete by Mimicking Nature’s Antifreeze. Cell Rep. Phys. Sci. 2020, 1, 100060. [Google Scholar] [CrossRef]

- Koenig, A. Analysis of Air Voids in Cementitious Materials Using Micro X-Ray Computed Tomography (µXCT). Constr. Build. Mater. 2020, 244, 118313. [Google Scholar] [CrossRef]

- Xu, X.; Xu, S.; Jin, L.; Song, E. Characteristic Analysis of Otsu Threshold and Its Applications. Pattern Recognit. Lett. 2011, 32, 956–961. [Google Scholar] [CrossRef]

- ORS, Object Research System. DragonFly Release Notes; ORS: Montreal, QC, Canada, 2019; pp. 1–68. [Google Scholar]

- Goodno, B.J.; Gere, J.M. Mechanics of Materials; Cengage Learning: Stamford, CT, USA, 2021. [Google Scholar]

- Hossain, M.S.; Kim, W.S. Estimation of Subgrade Resilient Modulus Using the Unconfined Compression Test; Virginia Center for Transportation Innovation and Research: Charlottesville, VA, USA, 2014. [Google Scholar]

- Hanz, A.J.; Bahia, H.U. Asphalt Binder Contribution to Mixture Workability and Application of Asphalt Lubricity Test to Estimate Compactability Temperatures for Warm-Mix Asphalt. Transp. Res. Rec. 2013, 2371, 87–95. [Google Scholar] [CrossRef]

- Fernández, E.; López, D.; Mijangos, C.; Duskova-Smrckova, M.; Ilavsky, M.; Dusek, K. Rheological and Thermal Properties of Agarose Aqueous Solutions and Hydrogels. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 322–328. [Google Scholar] [CrossRef]

- Yu, Z.; Zhan, J.; Wang, H.; Zheng, H.; Xie, J.; Wang, X. Analysis of Influencing Factors on Viscosity of Agar Solution for Capsules. J. Phys.Conf. Ser. 2020, 1653, 012059. [Google Scholar] [CrossRef]

- Vieira, M.G.A.; da Silva, M.A.; dos Santos, L.O.; Beppu, M.M. Natural-Based Plasticizers and Biopolymer Films: A Review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef]

- Yang, L.; Paulson, A.T. Mechanical and Water Vapour Barrier Properties of Edible Gellan Films. Food Res. Int. 2000, 33, 563–570. [Google Scholar] [CrossRef]

- Kheradmand, B.; Muniandy, R.; Hua, L.T.; Yunus, R.B.; Solouki, A. An Overview of the Emerging Warm Mix Asphalt Technology. Int. J. Pavement Eng. 2014, 15, 79–94. [Google Scholar] [CrossRef]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm Mix Asphalt: An Overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Norziah, M.H.; Foo, S.L.; Karim, A.A. Rheological Studies on Mixtures of Agar (Gracilaria Changii) and κ-Carrageenan. Food Hydrocoll. 2006, 20, 204–217. [Google Scholar] [CrossRef]

- Somboon, N.; Karrila, T.T.; Kaewmanee, T.; Karrila, S.J. Properties of Gels from Mixed Agar and Fish Gelatin. Int. Food Res. J. 2014, 21, 485–492. [Google Scholar]

- Labropoulos, K.C.; Rangarajan, S.; Niesz, D.E.; Danforth, S.C. Dynamic Rheology of Agar Gel Based Aqueous Binders. J. Am. Ceram. Soc. 2001, 84, 1217–1224. [Google Scholar] [CrossRef]

- Ghebremedhin, M.; Seiffert, S.; Vilgis, T.A. Physics of Agarose Fluid Gels: Rheological Properties and Microstructure. Curr. Res. Food Sci. 2021, 4, 436–448. [Google Scholar] [CrossRef]

- Zhang, L.; Xing, C.; Gao, F.; Li, T.; Tan, Y. Using DSR and MSCR Tests to Characterize High Temperature Performance of Different Rubber Modified Asphalt. Constr. Build. Mater. 2016, 127, 466–474. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Liu, C.; Ge, D.; You, Z.; Yu, M. High-Temperature Rheological Behavior and Fatigue Performance of Lignin Modified Asphalt Binder. Constr. Build. Mater. 2020, 230, 117063. [Google Scholar] [CrossRef]

- Naveed, H.; ur Rehman, Z.; Hassan Khan, A.; Qamar, S.; Akhtar, M.N. Effect of Mineral Fillers on the Performance, Rheological and Dynamic Viscosity Measurements of Asphalt Mastic. Constr. Build. Mater. 2019, 222, 390–399. [Google Scholar] [CrossRef]

- Chen, Z.; Yi, J.; Chen, Z.; Feng, D. Properties of Asphalt Binder Modified by Corn Stalk Fiber. Constr. Build. Mater. 2019, 212, 225–235. [Google Scholar] [CrossRef]

- Lv, S.; Xia, C.; Yang, Q.; Guo, S.; You, L.; Guo, Y.; Zheng, J. Improvements on High-Temperature Stability, Rheology, and Stiffness of Asphalt Binder Modified with Waste Crayfish Shell Powder. J. Clean. Prod. 2020, 264, 121745. [Google Scholar] [CrossRef]

- Madera-Santana, T.J.; Robledo, D.; Azamar, J.A.; Ríos-Soberanis, C.R.; Freile-Pelegrín, Y. Preparation and Characterization of Low Density Polyethylene-Agar Biocomposites: Torque-Rheological, Mechanical, Thermal and Morphological Properties. Polym. Eng. Sci. 2010, 50, 585–591. [Google Scholar] [CrossRef]

- Nishinari, K.; Fang, Y. Relation between Structure and Rheological/Thermal Properties of Agar. A Mini-Review on the Effect of Alkali Treatment and the Role of Agaropectin. Food Struct. 2017, 13, 24–34. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.-S. Catalytic Pyrolysis of Plastic Waste: Moving Toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7, 27. [Google Scholar] [CrossRef]

- Bonati, A.; Merusi, F.; Polacco, G.; Filippi, S.; Giuliani, F. Ignitability and Thermal Stability of Asphalt Binders and Mastics for Flexible Pavements in Highway Tunnels. Constr. Build. Mater. 2012, 37, 660–668. [Google Scholar] [CrossRef]

- Ragab, A.A.; Farag, R.K.; Kandil, U.F.; El-Shafie, M.; Saleh, A.M.M.; El-Kafrawy, A.F. Thermo-Mechanical Properties Improvement of Asphalt Binder by Using Methylmethacrylate/Ethylene Glycol Dimethacrylate. Egypt. J. Pet. 2016, 25, 397–407. [Google Scholar] [CrossRef]

- Nissa, R.C.; Fikriyyah, A.K.; Abdullah, A.H.D.; Pudjiraharti, S. Preliminary Study of Biodegradability of Starch-Based Bioplastics Using ASTM G21-70, Dip-Hanging, and Soil Burial Test Methods. IOP Conf. Ser. Earth Environ. Sci. 2019, 277, 012007. [Google Scholar] [CrossRef]

- Yemashova, N.A.; Murygina, V.P.; Zhukov, D.V.; Zakharyantz, A.A.; Gladchenko, M.A.; Appanna, V.; Kalyuzhnyi, S.V. Biodeterioration of Crude Oil and Oil Derived Products: A Review. Rev. Environ. Sci. Biotechnol. 2007, 6, 315–337. [Google Scholar] [CrossRef]

- Obahiagbon, K.O.; Amenaghawon, A.N.; Onyia, C. Prevention of Biodeterioration of Crude Oil in Tanks Using Anti-Microbial Agents. Int. J. Sci. Res. Environ. Sci. 2014, 2, 56–62. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; Duan, B.; Yu, Z.; Cheng, T.; Yu, L.; Liu, L.; Liu, K. Polymer–Water Interaction Enabled Intelligent Moisture Regulation in Hydrogels. J. Phys. Chem. Lett. 2021, 12, 2587–2592. [Google Scholar] [CrossRef]

- Rani, G.U.; Konreddy, A.K.; Mishra, S. Novel Hybrid Biosorbents of Agar: Swelling Behaviour, Heavy Metal Ions and Dye Removal Efficacies. Int. J. Biol. Macromol. 2018, 117, 902–910. [Google Scholar] [CrossRef]

- Kusmono; Abdurrahim, I. Water Sorption, Antimicrobial Activity, and Thermal and Mechanical Properties of Chitosan/Clay/Glycerol Nanocomposite Films. Heliyon 2019, 5, e02342. [Google Scholar] [CrossRef] [PubMed]

- Dave, P.N.; Gor, A. Chapter 3—Natural Polysaccharide-Based Hydrogels and Nanomaterials: Recent Trends and Their Applications. In Handbook of Nanomaterials for Industrial Applications; Mustansar Hussain, C., Ed.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2018; pp. 36–66. ISBN 978-0-12-813351-4. [Google Scholar]

- Utech, S.; Boccaccini, A.R. A Review of Hydrogel-Based Composites for Biomedical Applications: Enhancement of Hydrogel Properties by Addition of Rigid Inorganic Fillers. J. Mater. Sci. 2016, 51, 271–310. [Google Scholar] [CrossRef]

- Jones, A.; Zeller, M.A.; Sharma, S. Thermal, Mechanical, and Moisture Absorption Properties of Egg White Protein Bioplastics with Natural Rubber and Glycerol. Prog. Biomater. 2013, 2, 12. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.-F.; Linde, E.; Hedenqvist, M.S. Plasticiser Loss from Plastic or Rubber Products through Diffusion and Evaporation. Npj Mater. Degrad. 2019, 3, 18. [Google Scholar] [CrossRef]

- Chen, J.-S.; Yang, C.H. Porous Asphalt Concrete: A Review of Design, Construction, Performance and Maintenance. Int. J. Pavement Res. Technol. 2020, 13, 601–612. [Google Scholar] [CrossRef]

- Moretti, L.; Di Mascio, P.; Fusco, C. Porous Concrete for Pedestrian Pavements. Water 2019, 11, 2105. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, N.; Akram, O.; Fang, C.; Ghani, M.U.; Ijaz, Z.; Noshin, S.; Madni, M.F. Geotechnical Behavior of High-Plastic Clays Treated with Biopolymer: Macro–Micro-Study. Environ. Earth Sci. 2023, 82, 91. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Akbulut, N.; Demir, S.; Yildiz, O. Use of a Biopolymer for Road Pavement Subgrade. Sustainability 2023, 15, 8231. [Google Scholar] [CrossRef]

- Jang, J. A Review of the Application of Biopolymers on Geotechnical Engineering and the Strengthening Mechanisms between Typical Biopolymers and Soils. Adv. Mater. Sci. Eng. 2020, 2020, 1465709. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical Characterization of Biobinder from Swine Manure: Sustainable Modifier for Asphalt Binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

| Characteristics of Interest | Methods |

|---|---|

| Rheological properties of agar-based binder | Rotational Viscosity (ASTM D4402) |

| Dynamic Shear Rheometry (ASTM D7175) | |

| Penetration (ASTM D5) | |

| Durability of agar-based binder | Thermogravimetric Analysis (TGA) |

| Biodeterioration Resistance (ASTM G21) | |

| Moisture Sorption Characteristics (ASTM D570) | |

| Mechanical and microstructural characterization of agar-based composites | X-Ray Tomography Testing |

| Compressive Strength Testing | |

| Resilient and Elastic Moduli Characterization |

| Sample | Deionized Water (mL) | Agar (g) | Glycerol (mL) | Limestone (g) |

|---|---|---|---|---|

| A5-C | 200 | 10 | - | - |

| A5-G | 200 | 10 | 3.2 | - |

| A5-L | 200 | 10 | - | 30 |

| A5-GL | 200 | 10 | 3.2 | 30 |

| A7.5-C | 200 | 15 | - | - |

| A7.5-G | 200 | 15 | 4.8 | - |

| A7.5-L | 200 | 15 | - | 30 |

| A7.5-GL | 200 | 15 | 4.8 | 30 |

| A10-C | 200 | 20 | - | - |

| A10-G | 200 | 20 | 6.4 | - |

| A10-L | 200 | 20 | - | 30 |

| A10-GL | 200 | 20 | 6.4 | 30 |

| Subset | Sample Name | 5% w/w Agar Binder | Aggregate | Limestone | Sand |

|---|---|---|---|---|---|

| Control | C-0.2 | 0.20 | 1.00 | - | - |

| C-0.5 | 0.50 | 1.00 | - | - | |

| Limestone filler | L-0.2 | 0.20 | 0.95 | 0.05 | - |

| L-0.5 | 0.50 | 0.95 | 0.05 | - | |

| Sand filler | S-0.2 | 0.20 | 0.80 | - | 0.20 |

| S-0.5 | 0.50 | 0.80 | - | 0.20 | |

| Limestone and sand filler | LS-0.2 | 0.20 | 0.75 | 0.05 | 0.20 |

| LS-0.5 | 0.50 | 0.75 | 0.05 | 0.20 |

| Rating | Observed Growth on Specimens |

|---|---|

| 0 | None |

| 1 | Traces of growth (<than 10% of sample area) |

| 2 | Light growth (10–30% of sample area) |

| 3 | Medium growth (30–60% of sample area) |

| 4 | Heavy growth (60% to complete coverage) |

| Agar-to-Water Concentration | C | G | L | GL |

|---|---|---|---|---|

| 5% Agar | >350 | >350 | >350 | >350 |

| 7.5% Agar | >350 | >350 | 225 ± 8 | 162 ± 12 |

| 10% Agar | 211 ± 12 | 217 ± 2 | 167 ± 3 | 162 ± 8 |

| Pairwise Sample Comparison | Z | p-Value |

|---|---|---|

| C-L | −0.9564 | 0.338 |

| C-LS | −2.2570 | 0.024 * |

| L-LS | −1.3007 | 0.193 |

| C-S | −2.5248 | 0.011 * |

| L-S | −1.5684 | 0.117 |

| LS-S | −0.2679 | 0.789 |

| Source of Variation | df | SS | H | p Value |

|---|---|---|---|---|

| Binder Content | 1 | 1060.9 | 7.76 | 0.00533 * |

| Aggregate and Filler Composition | 3 | 193.0 | 1.41 | 0.70256 |

| Interaction | 3 | 314.3 | 2.30 | 0.51246 |

| Residuals (Within Group) | 32 | 3761.2 |

| Source of Variation | df | SS | H | p Value |

|---|---|---|---|---|

| Binder Content | 1 | 2371.6 | 17.35 | 3.0 × 10−5 * |

| Aggregate and Filler Composition | 3 | 965.8 | 7.07 | 0.0698 |

| Interaction | 3 | 166.6 | 1.22 | 0.7485 |

| Residuals (Within Group) | 32 | 1826.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frey, M.R.; Williams, S.L.; Srubar, W.V., III; Torres-Machi, C. Characterization and Evaluation of Agar as a Bio-Based Asphalt Binder Alternative. Infrastructures 2025, 10, 223. https://doi.org/10.3390/infrastructures10090223

Frey MR, Williams SL, Srubar WV III, Torres-Machi C. Characterization and Evaluation of Agar as a Bio-Based Asphalt Binder Alternative. Infrastructures. 2025; 10(9):223. https://doi.org/10.3390/infrastructures10090223

Chicago/Turabian StyleFrey, Melissa R., Sarah L. Williams, Wil V. Srubar, III, and Cristina Torres-Machi. 2025. "Characterization and Evaluation of Agar as a Bio-Based Asphalt Binder Alternative" Infrastructures 10, no. 9: 223. https://doi.org/10.3390/infrastructures10090223

APA StyleFrey, M. R., Williams, S. L., Srubar, W. V., III, & Torres-Machi, C. (2025). Characterization and Evaluation of Agar as a Bio-Based Asphalt Binder Alternative. Infrastructures, 10(9), 223. https://doi.org/10.3390/infrastructures10090223