Abstract

Concrete cracks and sulfate degradation severely compromise structural durability, highlighting the need for sustainable solutions to enhance longevity and minimize environmental impact. This study assesses the efficacy of bacterial self-healing technology utilizing Bacillus megaterium (BM) and Bacillus sphaericus (BS) in enhancing the resistance of concrete to sulfate attacks and improving its mechanical properties. Bacterial suspensions (1% and 2.5% of cement weight) were mixed with concrete containing silica fume or fly ash (10% of cement weight) and cured in freshwater or sulfate solutions (2%, 5%, and 10% concentrations). Specimens were tested for compressive strength, flexural strength, and microstructure using a Scanning Electron Microscope (SEM), Energy-Dispersive X-ray Spectroscopy (EDS), and X-ray diffraction (XRD) at various ages. The results indicate that a 2.5% bacterial content yielded the best performance, with BM surpassing BS, enhancing compressive strength by up to 41.3% and flexural strength by 52.3% in freshwater-cured samples. Although sulfate exposure initially improved early-age strength by 1.97% at 7 days, it led to an 8.5% loss at 120 days. Bacterial inclusion mitigated sulfate damage through microbially induced calcium carbonate precipitation (MICP), sealing cracks, and bolstering durability. Cracked specimens treated with BM recovered up to 93.1% of their original compressive strength, promoting sustainable, sulfate-resistant, self-healing concrete for more resilient infrastructure.

1. Introduction

Sustainable building plays a crucial role in modern communities today as it reduces environmental impacts and addresses social and economic issues within the construction field [1,2,3,4]. Pozzolans, including fly ash (FA), blast furnace slag (BFS), silica fume (SF), and metakaolin (MK), can reduce the carbon footprint of concrete structures, increase durability and strength, and lower costs and damages to the environment [5,6]. These materials set and harden like cement when mixed with lime and water but have very little binding ability on h777u own. Concrete is a commonly used construction material; it has low tensile strength and is susceptible to mechanical, physical, and chemical processes that lead to cracks in the concrete structure [7,8,9]. Cracks make the concrete more permeable, allowing moisture and aggressive substances like acids, sulfate, and chloride ions to seep in.

Sulfate ions penetrate the cementitious matrix when concrete and cement mortars are exposed to a sulfate-loaded environment during their service life [10,11,12]. The increasing sulfate ion concentration is transported into the concrete’s inside, where it interacts chemically with the hydrated cement products [13].

The primary cause of degradation in sulfate attack was shown to be a two-stage distress process on the concrete matrix. The first stage, known as chemical sulfate attack, is caused by the interaction of sulfate ions with portlandite (CH) to form gypsum, which then interacts with tricalcium aluminate (C3A) to produce ettringite precipitates in the pores of concrete. In the second stage, concrete swells, cracks, and spalls as a result of expanding forces linked to ettringite caused by high crystallization pressure [14]. Concrete is susceptible to damage from sulfate salt crystallization in this type of sulfate-induced degradation, known as physical sulfate attack (PSA) [15]. These factors destroy the concrete matrix, cause corrosion in the reinforcing material, and shorten the lifespan of the structure [16]. To extend the lifespan of concrete structures, many methods for maintenance and restoration have been developed.

Researchers are currently paying attention to self-healing concrete, which is thought to be a durable repair tool [17,18]. Concrete that heals itself has similar characteristics to the human body, including the ability to heal wounds and injuries without external intervention [19,20]. In the past ten years, research on self-healing cementitious composites has significantly increased. Two common self-healing methods are widely used for concrete self-healing: autogenous and autonomous methods.

The autonomous technique aims to modify concrete by incorporating different healing agents into the concrete matrix to allow the crack to self-heal after it forms [21]. Unlike traditional approaches, this technique can save costs because the repairing agents are pre-buried in the concrete mixture and can automatically heal cracks as they appear [22]. Both techniques use calcium carbonate (CaCO3) material deposition onto the crack surface as their principal mechanism for promoting crack healing. Both artificial (autonomous) and natural (autogenous) processes can produce this substance. Furthermore, CaCO3 has a rough crystal morphology that exhibits high propensity for surface adhesion and self-sustaining growth [22].

The bacterial-based method has demonstrated the most promising findings among all self-healing techniques because of its long-term efficacy [23,24,25]. The capability of bacteria to convert vegetative bacterial cells into spores is responsible for this long-term effectiveness, which ensures viability for more than 200 years and is responsible for this prolonged efficiency in crack repair [26,27]. Water ingress causes bacteria in a fresh crack to activate from their dormant state. They then multiply and precipitate minerals like calcite (CaCO3), which finally seals the crack. The bacteria enter a hibernation stage after the crack heals. A later-formed crack is filled by the bacteria when they reactivate. As a result, bacteria have a healing effect that lasts for a long time. This process is called microbially induced calcium carbonate precipitation (MICP) in which there is a significant reduction in the penetration of moisture, other environmental agents, and aggressive chemicals into the concrete. Microbial self-healing concrete technology has become a research hotspot in recent years with the goals of (I) decreasing repair costs, (II) reducing environmental degradation, (III) enhancing concrete durability, and (IV) improving concrete properties [28,29,30].

Self-healing in concrete is a biologically mediated process that is also influenced by abiotic and biotic factors [31,32]. Some of the important biological parameters that can influence bacterial growth are age, cell count, and physiological state—all of which are influenced by environmental parameters like pH and temperature [33]. Most bacteria will have a limited range of parameters in which they can survive; however, some bacteria, specifically spore-forming bacteria, can withstand sub-optimal conditions by remaining dormant and reactivating when the conditions are suitable. However, germination is inhibited at a pH above 12; while concrete is hydrating, the pH can be up to 13 and the temperature can be up to 90 °C, which would certainly contribute to diminished bacterial survival and limit nutrient availability, thus affecting self-healing ability [34,35,36,37,38].

Researchers have used various spore-forming bacillus strains, including Bacillus sphaericus [39,40,41], Bacillus pasteurii [42,43,44], Bacillus megaterium [45,46,47], and Bacillus Subtilis [48,49], to create self-healing concrete [50]. The self-healing of cement-based materials may be enhanced by the use of many different nutrients, such as calcium acetate [51], sodium citrate [52], calcium formate [53], and other calcium acid salts like succinate, oxalate, malate, and glyoxylate [44].

Pooja Kanaujia et al. [54] studied the effect of different sulfate concentrations on the compressive strength, flexural strength, weight analysis, density loss, and visual appearance of concrete samples. The concrete samples were immersed in sulfate solutions at different concentrations (4.0, 5.0, and 6.0 pH). It was found that the higher the concrete grade, the smaller the loss in compressive strength. The density and weight analyses confirmed the loss of both flexural and compressive strength. The concrete blocks indicated visual discoloration after 75 and 90 days.

In their study, Arun Kumar Parashar et al. [55] provide an overview of the effect of different Bacillus family bacteria concentrations ranging from 100 CFU to 108 on concrete’s durability and strength characteristics. It was concluded that bacterial presence in concrete enhanced its mechanical properties and decreased the permeability of water by filling in voids. Also, out of all the bacterial concentrations, the one with the most significant results was 105 cells/mL.

Joshi et al. [56], in their research, examined cement performance using exposure regimes in a sulfate environment for mortar prisms and concrete cubes. The calcium, urea, and nutritional broth medium concentrations were 25 mM w/v, 2% w/v, and 1.3% w/v, respectively. Compared to the control, the compressive strength of test types of cement treated and cured with bacterial solutions indicated that BAT and BST increased. The test cement that was cured by spraying it with a bacterial solution showed a 16% increase in compressive strength, whereas the treated test cement showed a 35% increase compared to the control cement.

This work involves a rigorous mechanistic investigation of sustainable self-healing concrete systems through systematic characterization of Bacillus megaterium and Bacillus sphaericus-induced calcium carbonate precipitation under sulfate-rich conditions utilizing high-end microstructural analysis (SEM-EDS-XRD) complemented by multiscale mechanical testing to quantitatively establish structure–property relationships among microbial metabolic activity, further innovating through the incorporation of industrial waste products (silica fume/fly ash) to create an optimized eco-efficient material system that simultaneously addresses three major gaps in the current state-of-the-art research: (1) quantitative measurement of enhancement of sulfate resistance through biocementation, (2) partial understanding of the stability of healing products under chemical attack, and (3) limited systematic study of recovery of mechanical properties for cracked compared to uncracked conditions. Thus, this study provides both a fundamental understanding of microbial concrete chemo-mechanics and practical solutions for durable, eco-efficient infrastructure. This research examined the effect of the bacteria type, content, curing type, and pozzolanic material type on self-healing properties using Bacillus megaterium and Bacillus sphaericus at 0%, 1%, and 2.5% by cement weight. Microstructural analysis was performed using SEM, EDS, and XRD, and the specimens’ resistance to sulfate attack was also investigated.

2. Experimental Procedure

2.1. Experimental Outline

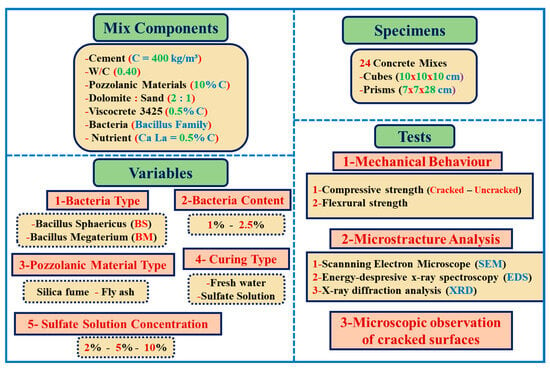

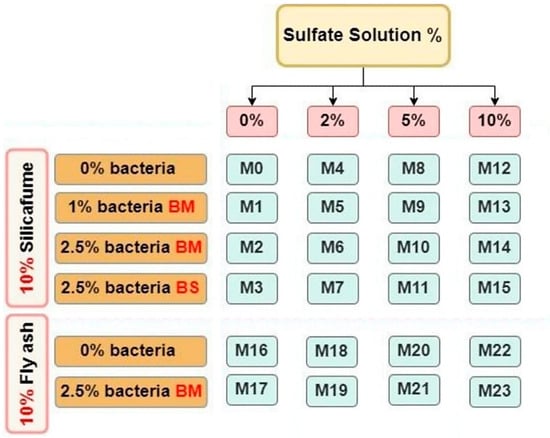

The main objective of the present work is to examine the effects of the bacteria type, content, curing type, and pozzolanic material type on self-healing properties using Bacillus megaterium and Bacillus sphaericus. These bacteria were added in different contents (1% and 2.5% by cement weight). In this study, two bacterial species from the Bacillus family (Bacillus megaterium and Bacillus sphaericus) were chosen because of their well-documented efficiency in bacterial self-healing of concrete, and they are locally available. They have high activity and the ability to precipitate calcium carbonate under alkaline conditions. Both Bacillus megaterium (BM) and Bacillus sphaericus (BS) were used at the same contents (1.0% and 2.5%) of cement weight based on previous studies showing that these rates achieve the best healing performance, and 0% was chosen as the control mix [7,57]. This study aimed to evaluate the effect of content and bacterial type on cement performance under similar conditions, ensuring a fair comparison. Each type of bacteria was evaluated for its impact on mechanical properties, sulfate resistance, and self-healing efficiency via MICP. This section describes the materials used in the concrete mixes, the casting method, the type and content of bacteria used, the methods used to prepare them, and the conditions for curing concrete specimens. It also includes tests conducted on different concrete specimens. The experimental program included pouring 24 concrete mixes containing different pozzolanic materials (silica fume or fly ash) at a percentage of 10% by cement weight. The concrete specimens were treated with freshwater and sulfate solutions at different concentrations of 2%, 5%, and 10%, as shown in Figure 1 and Figure 2. In this work, by using 2%, 5%, and 10% sulfate, mild, aggressive, and extreme scenarios are covered, which enables a comprehensive assessment of bacterial self-healing concrete and provides a clearer view of its resilience across typical field exposures [58,59,60]. Compression and flexural tests were conducted on concrete specimens loaded to failure at 7, 28, 56, and 120 days. Compression tests were also performed on pre-cracked specimens at 65% of the ultimate load after the 28-day treatment period at 56 and 120 days.

Figure 1.

Outline of experimental procedure.

Figure 2.

Flow chart for concrete mixes, where M: mix, BM: Bacillus Megaterium, and BS: Bacillus sphaericus.

2.2. Materials

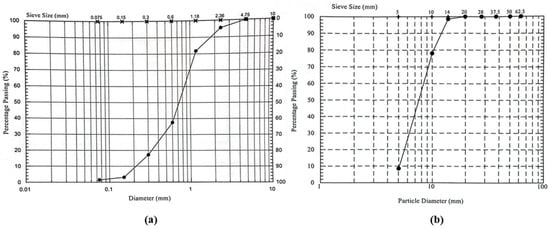

Ordinary Portland Cement (CEM-I 42.5 N) was utilized in this study according to ESS 4756-1/2013 [61]. Table 1 shows the mechanical, chemical, and physical properties of cement. The cement content was 400 kg/m3 for all mixtures. Dolomite was used as coarse aggregate with a nominal maximum size of 10 mm, washed, and allowed to dry before use. Its specific weight was 2.81, and its bulk density was 1.66 t/m3. Locally available natural siliceous sand that had a specific weight of 2.49, a bulk density of 1.78 t/m3, and a fineness modulus of 2.65 was used as fine aggregate according to ESS 1109/2021 [62]. The sieve analysis results for the fine and coarse aggregates are shown in Figure 3. In the mixing process, clean drinking water was used. Fly ash and silica fume from Sika Egypt Company were brought in for use as a mineral admixture in this study. The physical properties of the fly ash and silica fume used are described in the datasheet of the manufacturer, which is displayed in Table 2 and Table 3. For all mixtures, the silica fume and fly ash/cement ratio was 10% for all mixes. This study utilized a high-range water reducer superplasticizer concrete admixture called Sika Viscocrete-3425. This is a third-generation homogeneous concrete superplasticizer. According to ASTM-C-494-2020, types F and G meet superplasticizer requirements [63]. Table 4 displays the properties of the superplasticizers utilized in this research; the superplasticizer/cement ratio was 0.50%. The source of calcium lactate, which has the chemical formula C6H10CaO6, was Oxford Lab Fine Chem LLP. The ratio of cement to calcium lactate was 0.50%.

Table 1.

Physical, mechanical, and chemical properties of Portland cement.

Figure 3.

The sieve analysis for aggregate, (a) sand, and (b) gravel.

Table 2.

Properties of silica fume.

Table 3.

Properties of fly ash.

Table 4.

Properties of the superplasticizers used.

This study used two ureolytic bacterium types from the Bacillus family, Bacillus Megaterium (BM) and Bacillus Sphaericus (BS), as indicated in Table 5. Both of these types of Gram-positive bacteria were selected for the study since they do not have an adverse effect on human health. Through the mineralization process, Bacillus Megaterium and Bacillus Sphaericus can precipitate (CaCO3) when provided with a calcium source. Both types are capable of producing spores that can survive harsh environments and activate in the presence of water. Bacillus Megaterium and Bacillus Sphaericus were obtained from the Microbiological Resources Centre (MIRCEN), Faculty of Agriculture, Ain Shams University in Egypt. A bacterial suspension was used to partially replace the mixing water.

Table 5.

Types of bacteria used.

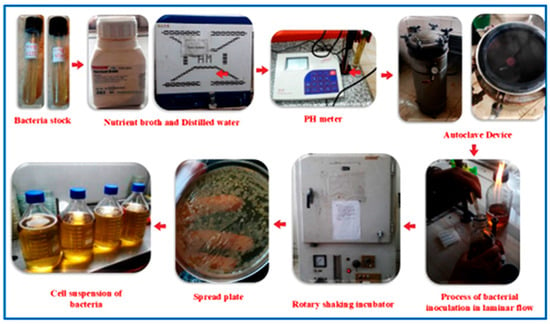

2.3. Growth of Bacterial Culture

The procedure described by Elmahdy et al. [64,65] was followed to prepare the bacterial cell suspension. The bacterial stock was obtained from the Microbiological Resources Centre and stored in the fridge until used sterilely. To create the culture medium, thirteen grams of powdered nutritional broth was dissolved in one liter of distilled water. The nutritional broth contained 5.0 g/L peptone, 5.0 g/L sodium chloride, 1.50 g/L yeast extract, and 1.5 g/L HM peptone B#. The pH was adjusted to 7.2 ± 0.2 for optimal Bacillus growth. All instruments were autoclaved before use, and using an autoclave device, the container containing the culture media was sterilized at 121 °C and a pressure of 1.5 bar for 20 min and then allowed to cool. This process ensured that the media were contaminant-free. Using a loop, bacteria were extracted from the fridge and put into the growth media flask in an AURA HZ 48 laminar flow cabinet. The flasks were incubated for three days at 150 rpm and 30 °C, resulting in turbidity that indicated bacterial growth and sporulation. After microscopic examination, bacterial cells were isolated and diluted appropriately with distilled water. Solid media recorded the bacterial colonies, diluted to a concentration of (2 × 10 to the ninth) CFU/mL. All activities were conducted at the Faculty of Veterinary Medicine, Zagazig University, Egypt. Figure 4 shows the basic steps for preparing a bacterial cell suspension.

Figure 4.

Fundamental steps to prepare a bacterial cell suspension.

2.4. Mix Design and Specimen Preparation

The quantities of each ingredient required to produce 1 m3 of concrete were determined utilizing the absolute volume approach. Table 6 shows proportions of the concrete mixes. The ratio of dolomite to sand in all concrete mixes was 2:1 by weight, the ratio of fly ash and silica fume to cement was 10%, the ratio of water to cement was 0.4, the ratio of superplasticizer to cement was 0.50%, the ratio of calcium lactate to cement was 0.50%, and the cement content was 400 kg/m3. We added two ratios of bacteria (1% and 2.5% of cement weight) to the concrete. A portion of the mixing water was substituted with bacterial suspension, and the control mix specimens were prepared in an identical manner without the addition of bacteria.

Table 6.

The proportions of the concrete mixes.

All concrete mixtures have a specific mixing method that needs to be used sequentially. The dry materials (sand, dolomite, and cement) were thoroughly mixed in a mechanical horizontal pan mixer. The materials were combined at a low speed for two minutes after introducing the required quantity of fly ash or silica fume with calcium lactate. Then, water and superplasticizer were added to the mixture gradually, and mixing was continued for approximately five minutes to ensure that everything was uniformly distributed. Water was introduced to bacterial mixtures first, followed by adding BM or BS bacteria simultaneously. Then, in accordance with ASTM C-192/C192M, after pouring three layers of concrete into molds, the layers were compacted for thirty seconds using a mechanical vibrator [66]. The samples were taken out of their mold and began curing following a day of casting in order to prepare them for testing. All of the sample mixing stages are depicted in Figure 5.

Figure 5.

Steps of sample mixing.

2.5. Curing Procedure

The next day after the concrete specimens were poured, the molds were removed from the concrete specimens, and the mix type and casting date were written on each sample. Then, the curing phase began, where the concrete specimens were immersed in different curing conditions with freshwater and magnesium sulfate solution at different concentrations (2%, 5%, and 10%). The specimens were removed from the curing water and left to dry according to the time taken to conduct compression and flexural tests at the different ages of 7, 28, 56, and 120 days.

2.6. Creation of Cracks

To identify the ultimate load in all mixes, cubic specimens measuring 100 × 100 × 100 mm were removed from the curing process after seven days of curing (three specimens were loaded until failure in each concrete mix) utilizing a hydraulic testing machine with a 2000 kN capacity. Nine cubes (three for loading until failure and six for cracking at 65% of the ultimate load) and two beams for loading until failure were extracted from each mix after the 28-day treatment period. Visual inspection revealed minor cracks in some loaded samples after loading, as shown in Figure 6. After that, the pre-cracked specimens underwent the curing process again, where bacteria started to precipitate calcium carbonate and seal the cracks. Six cubes (three without pre-cracking and three with pre-cracking after 28 days) and two beams were extracted from each mix after 56 days of treatment and loaded until failure. The following samples were extracted from each mix for loading until failure after 120 days of treatment: 6 cubes (3 cubes without pre-cracking and 3 cubes with pre-cracking after 28 days).

Figure 6.

(a) Specimen before cracking. (b) Specimen after cracking.

A stereo-microscope equipped with the OLYMPUS SZ 61 camera system was utilized to visually monitor the healing and progression of cracks. In the experiment, artificial cracks were measured in samples of varying sizes, as shown in Figure 7a, with each specimen having a different crack width at 7 and 120 days of age. The experimental device that was used to visually measure the cracks is depicted in Figure 7b. The microscope was located at the Faculty of Agriculture’s Seed and Tissue Pathology Lab at Mansoura University.

Figure 7.

(a) The creation of visible cracks, and (b) the experimental device used for measuring visible cracks.

2.7. Compressive Strength Test

The compressive strength of concrete specimens was measured after 7, 28, 56, and 120 days from the casting date in accordance with BS EN 12390-3:2019 [67]. At every testing age, three 100 × 100 × 100 mm specimen cubes were evaluated for each concrete mix. The average value of three concrete specimens was calculated for each concrete mix. The mix’s strength was determined utilizing a hydraulic testing machine with a 2000 kN capacity at various ages in the engineering faculty’s concrete lab at Zagazig University.

2.8. Flexural Strength Test

According to BS EN 12390-5:2019 [68], concrete flexural specimens were subjected to a three-point loading test on 70 × 70 × 280 mm concrete beams after 28 and 56 days of casting. The average of the concrete samples for each mixture was calculated. At different ages, the flexural strength of the concrete mixes was determined by utilizing a hydraulic testing machine with a 1000 kN capacity in the concrete lab of the engineering faculty at Zagazig University.

2.9. Microscopic Analysis Tests

SEM was used to examine sample surfaces because it provides a clear, high-quality stereoscopic image with extensive information about the sample’s microstructure. The effect of biological calcium carbonate precipitation on the concrete samples was investigated using SEM. The test was performed in Egypt at the Faculty of Agriculture at Mansoura University with a JEOL JSM-651OLV electronic microscope with a magnification of 300,000×. To examine the samples, different magnifications were used, including 4000× and 5000×. The following details explain the sample preparation process: Concrete specimens were obtained from the cracked specimens’ deepest core following a compressive strength test at 120 days of age. These samples were placed on holders using carbon adhesive after being dried at 70 °C until they achieved a constant weight. The dried specimens were coated with gold using a sputter coating evaporator to increase clarity and microstructure surface imaging. The elements of the precipitation of specimens were determined using the Oxford X-Max 20 EDS device, which was connected to the SEM.

X-ray diffraction was used to examine the anhydrous and hydrated cement phases at 120 days to analyze and examine the cementitious materials. The specimens were carefully pulverized utilizing a tubular aerosol suspension chamber and were then put on glass fiber filter paper. The experiment was conducted at the Housing and Building National Research Center using the Philips X’ Pert Pro Diffractometer MPD PW 3050/60.

3. Results and Discussion

3.1. Specimens Without Pre-Cracking

3.1.1. Compressive Strength

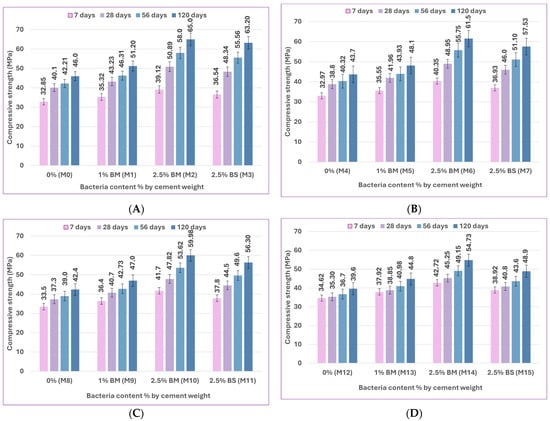

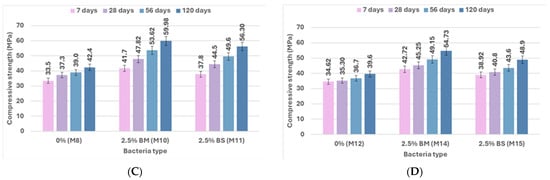

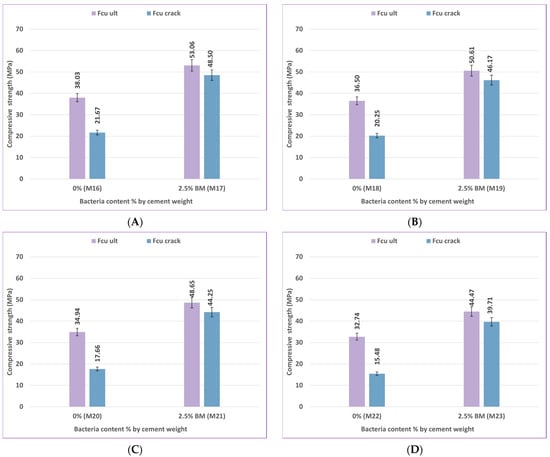

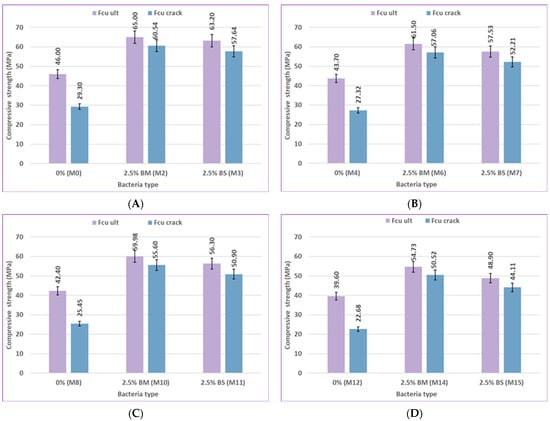

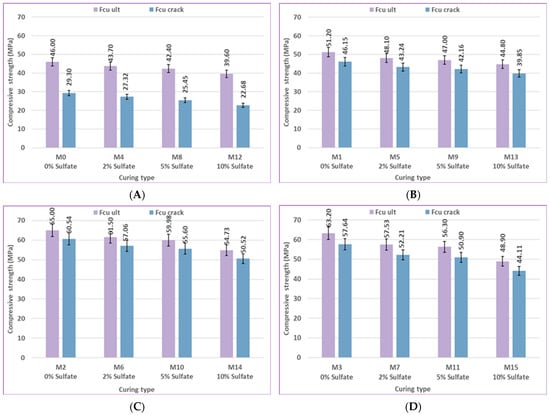

Figure 8, Figure 9, Figure 10, Figure 11, Figure 12 and Figure 13 present the compressive strength results of specimens without pre-cracking at 7, 28, 56, and 120 days, showing the effects of the bacterial content and type, pozzolanic material type, and curing type. The impact of the bacterial content on self-healing concrete’s compressive strength after being cured in freshwater and sulfate solution with different concentrations at different ages is shown in Figure 8 and Figure 9. The compressive strength of the bacterial mixes increased compared to the control mixes at 7, 28, 56, and 120 days when the concrete samples were cured in freshwater and sulfate solution at different concentrations of 2%, 5%, and 10%. The compressive strength of mix M1, which is a 1% bacteria BM, increased by 7.52%, 7.81%, 9.71%, and 11.3% compared to control mix M0. The compressive strength of mix M2, which contains 2.5% bacteria BM, was increased compared to control mix M0 by values of 19.09%, 26.91%, 37.41%, and 41.3%, respectively. The compressive strength of mix M3 containing 2.5% bacteria BS increased compared to control mix M0 by 11.23%, 20.55%, 31.63%, and 37.39%, respectively. According to previous findings, concrete samples with a bacteria content of 2.5% achieved the best compressive strength. The higher the bacterial content, the higher the compressive strength. The use of bacteria has a positive effect on increasing the compressive strength of the samples. The reason for the increase in compressive strength is the precipitation of calcium carbonate, which fills the pores in concrete and causes the size of the pores to decrease [69,70,71].

Figure 8.

The impact of bacterial content on the compressive strength of concrete for uncracked specimens of silica fume at 7, 28, 56, and 120 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 9.

The impact of bacterial content on the compressive strength of concrete for uncracked specimens of fly ash at 7, 28, 56, and 120 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

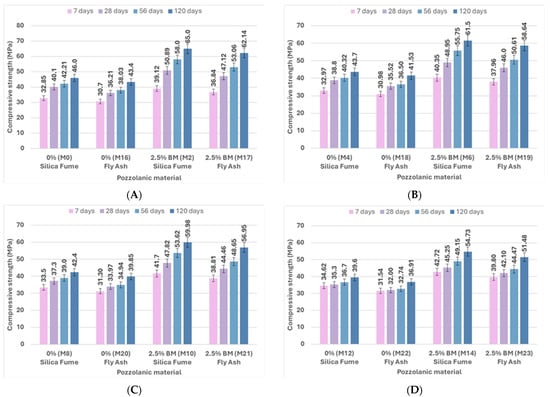

Figure 10.

The impact of bacterial type on the compressive strength of concrete for uncracked specimens of silica fume at 7, 28, 56, and 120 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 11.

The impact of pozzolanic material type on the compressive strength of concrete for uncracked specimens at 7, 28, 56, and 120 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

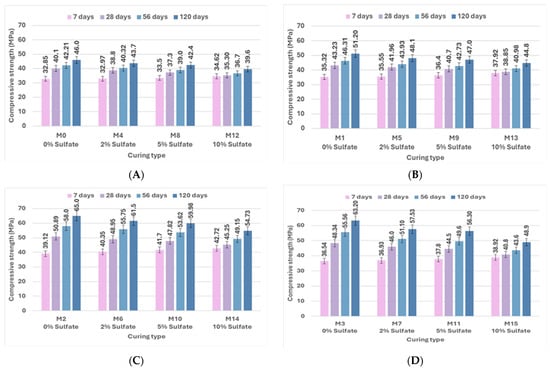

Figure 12.

The impact of curing type on the compressive strength of concrete for uncracked specimens of silica fume at 7, 28, 56, and 120 days (A) with 0% bacteria, (B) 1% bacteria BM, (C) 2.5% bacteria BM, and (D) 2.5% bacteria BS.

Figure 13.

The impact of curing type on the compressive strength of concrete for uncracked specimens of fly ash at 7, 28, 56, and 120 days (A) with 0% bacteria and (B) with 2.5% bacteria BM.

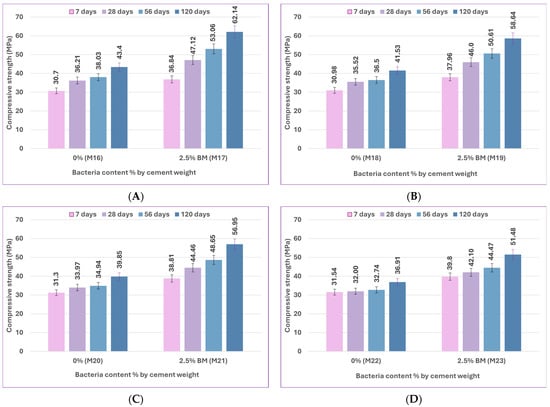

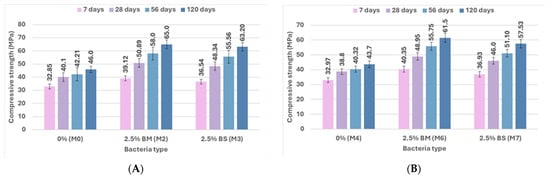

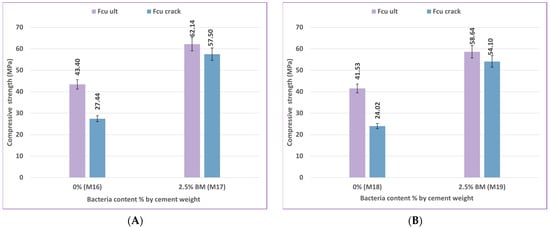

As illustrated in Figure 10, the type of bacteria (BM and BS) employed in this study has an effect on the compressive strength under different environmental conditions and at different ages of uncracked specimens. The compressive strength at 7, 28, 56, and 120 days was 19.09, 26.91, 37.41, and 41.3% higher for mix M2 containing 2.5% bacteria BM than that of control mix M0, respectively. Comparing M3, which included 2.5% of BS bacteria, to control mix M0, the compressive strength increased by 11.23%, 20.55%, 31.63%, and 37.39%. The compressive strength of concrete changed noticeably according to the type of bacteria present. The results for the Bacillus megaterium type generally show a more noticeable improvement than those for the Bacillus sphaericus type. Bacillus megaterium enhanced the production of CaCO3 to fill voids, which caused a great improvement in compressive strength. The main cause of the higher compressive strength seen in BM mixes over others is the higher content of CaCO3 [64,72,73]. Bacillus megaterium has higher activity (~690 U/mL vs. lower values in related strains) than Bacillus sphaericus. It has greater alkaline adaptability, owing to its protective spore structure, high resistance to alkaline environments, and broader pH tolerance. Additionally, it has enhanced nucleation efficiency, facilitated by a larger cell surface area and exosporium features that promote CaCO3 crystallization [74,75,76,77].

Mineral admixtures can be added to concrete to enhance the compressive strength. The type and ratio of mineral admixtures are important considerations to improve the quality of construction in concrete [78]. In this study, we used mineral admixtures, including fly ash (FA) and silica fume (SF). They are industrial by-products. According to previous studies, the amount of 10% of fly ash and silica fume has a greater effect on the strength of concrete.

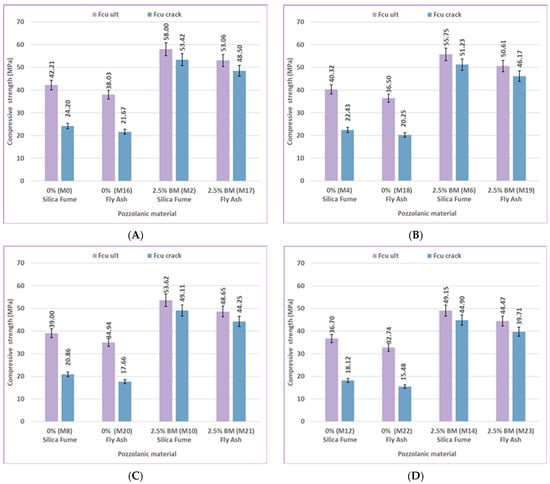

As shown in Figure 11, the compressive strength of control mix M0, which includes 0% bacteria with silica fume, increased by 7%, 10.74%, 11%, and 6% at different ages in comparison to control mix M16, which contained 0% bacteria with fly ash. The compressive strength of mix M2, which includes 2.5% bacteria BM with silica fume, showed increases of 6.19%, 8%, 9.31%, and 4.6% at 7, 28, 56, and 120 days, respectively, when compared to mix M17, which contained 2.5% bacteria BM with fly ash. It is evident that the outcomes showed the same trend for the mixtures treated with sulfate solution at different concentrations. Under different environmental conditions at various ages, silica fume generally shows a more noticeable improvement in results than fly ash because of its high reactive pozzolanic property, large surface area, high SiO2 content, and fine particles; then, it fills the pores of concrete and reduces porosity [79]. The bond between cement paste and aggregate is strengthened when silica fume is used to enhance the strength of concrete. The cement hydration product Ca(OH)2 can react with silica fume to produce a C-S-H gel with higher strength [80]. Fly ash participates in the secondary cement hydration process and produces fewer cement hydration products in the early stage due to its low activity. In the early stage, there is less chemical reaction, which causes the concrete’s compressive strength to decrease. In the later stage, as cement hydration products continue to form, the pozzolanic reaction is accelerated and promoted, significantly boosting the final strength of concrete [78].

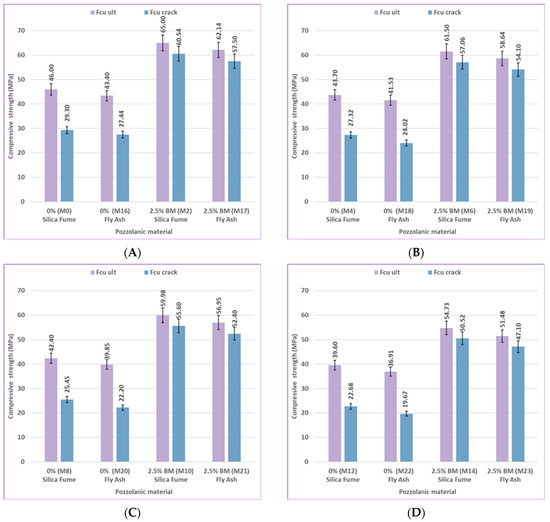

Figure 12 and Figure 13 illustrate the effect of the curing type on the compressive strength of concrete, demonstrating the significant impact of the curing environment on compressive strength. In the early stages, the compressive strength of the bacterial and control samples increased marginally when exposed to sulfate.

In comparison to control mix M0, which was cured in freshwater, the compressive strength of control mix M8, which was cured in a 5% sulfate solution concentration, increased by 1.97% at 7 days as a result of the continuous penetration of sulfate ions into the cementitious matrix. The production of expansive compounds such as gypsum, CaSO4·2H2O, and ettringite, which aid in filling holes and voids and thus increase microstructural density, is responsible for this increase in compressive strength [81,82]. When comparing the samples cured in freshwater to those exposed to sulfate solution for later ages, a gradual decrease in strength was observed. The compressive strength of control mix M8, which was cured in 5% sulfate solution concentration, decreased by 7.51%, 8.23%, and 8.5% at 28, 56, and 120 days, respectively, compared to control mix M0, which was cured in freshwater. This strength loss could be a consequence of increased sulfate penetration, leading to more expansion products accumulating in the pores of the samples. A slight improvement of 3.14% in compressive strength in M6, which contains 2.5% bacteria BM and is cured in a 2% sulfate solution concentration, was observed when compared with M2, which includes 2.5% bacteria BM and is cured in freshwater at 7 days, and then gradual decreases of 3.96%, 4.04%, and 5.69% in strength were observed at 28, 56, and 120 days, respectively.

The results also show that the reduction in compressive strength with an increasing sulfate concentration at the same curing age is a well-documented phenomenon primarily caused by sulfate-induced chemical degradation of the cementitious matrix. Sulfate ions (SO42−) penetrate the concrete and react with hydration products. Also, ettringite and gypsum are formed, which are expansive by-products. These products cause internal stress, micro-cracking, and loss of cohesion in the matrix. Higher sulfate concentrations accelerate these reactions and damage. These actions result in greater deterioration of the cement matrix and a reduction in compressive strength over time [60,83,84].

The bacterial samples did not exhibit a significant decrease in strength when exposed to sulfate, indicating that the bacteria are effective in mitigating the negative effects of sulfate by precipitating calcite, which fills the pores in the concrete. Sulfate ion penetration into the cementitious matrix was thereby greatly decreased. The formation of harmful reaction products that can lead to concrete deterioration was also reduced by the minimum infiltration of sulfate ions. Other researchers have reached a similar conclusion [76]. The compressive strength of mix M10, which contains 2.5% bacteria BM, increased by 24.48%, 28.2%, 37.49%, and 41.46% at different ages compared to control mix M8 at a 5% sulfate solution concentration. The results show that adding bacteria to concrete improved its compressive strength under different curing conditions, demonstrating the positive effect of bacterial activity.

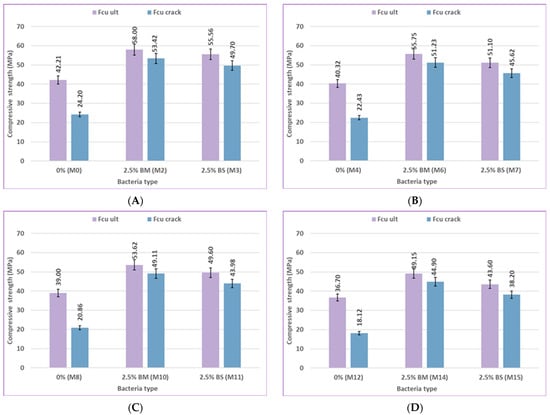

3.1.2. Flexural Strength

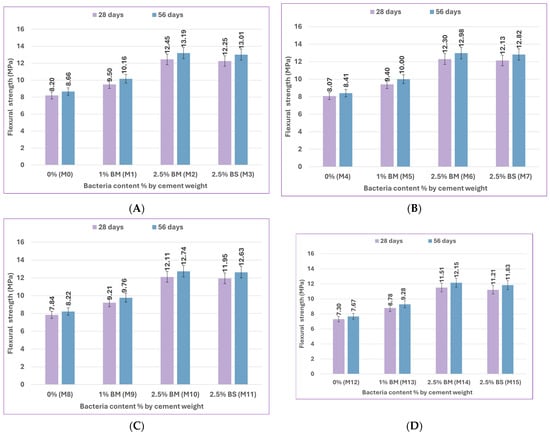

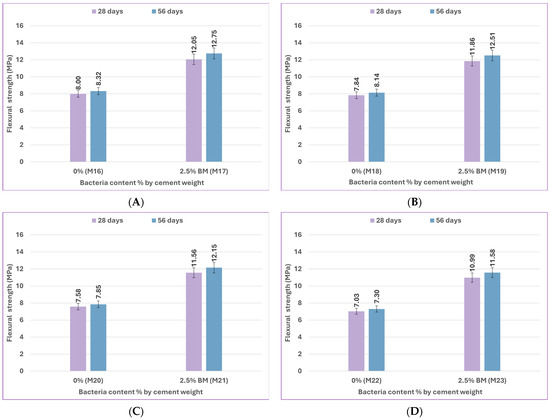

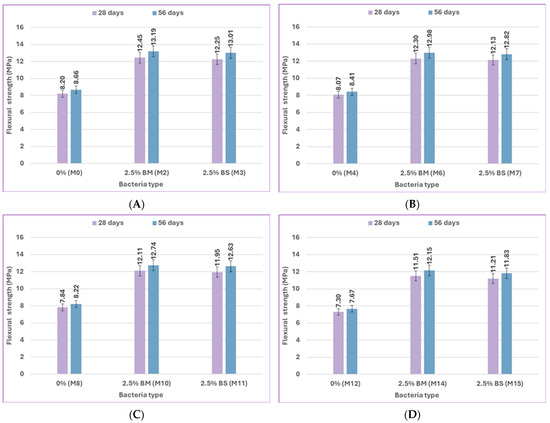

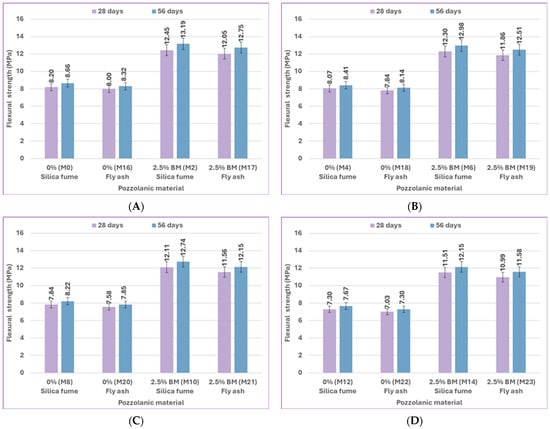

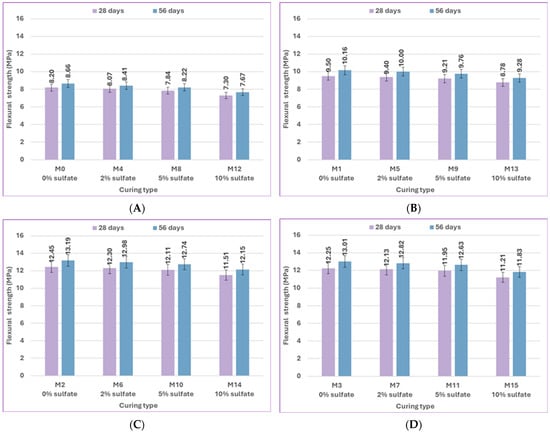

The flexural strength results for specimens without pre-cracking are presented in Figure 14, Figure 15, Figure 16, Figure 17, Figure 18 and Figure 19. The flexural strength tests were conducted on several mixes of various pozzolanic materials, bacterial contents, and types at 28 and 56 days under different environmental conditions.

Figure 14.

The impact of bacterial content on the flexural strength of concrete for uncracked specimens of silica fume at 28 and 56 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 15.

The impact of bacterial content on the flexural strength of concrete for uncracked specimens of fly ash at 28 and 56 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 16.

The impact of bacterial type on the flexural strength of concrete for uncracked specimens of silica fume at 28 and 56 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 17.

The impact of pozzolanic material type on the flexural strength of concrete for uncracked specimens at 28 and 56 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

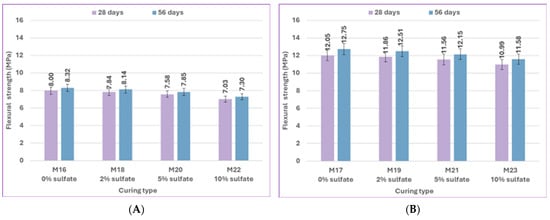

Figure 18.

The impact of curing type on the flexural strength of concrete for uncracked specimens of silica fume at 28 and 56 days (A) with 0% bacteria, (B) 1% bacteria BM, (C) 2.5% bacteria BM, and (D) 2.5% bacteria BS.

Figure 19.

The impact of curing type on the flexural strength of concrete for uncracked specimens of fly ash at 28 and 56 days (A) with 0% bacteria and (B) with 2.5% bacteria BM.

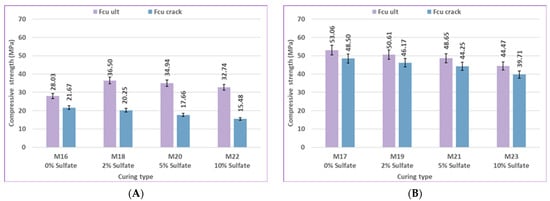

The effect of bacterial content on the flexural strength of uncracked specimens at 28 and 56 days is illustrated in Figure 14 and Figure 15. Mix M1, which included 1% bacteria BM, had a flexural strength that was 15.85% higher at 28 days and 17.32% higher at 56 days than control mix M0 when cured in freshwater. In comparison to M0, the flexural strength of M2 increased by 51.83% and 52.31% when using 2.5% bacteria BM, and the flexural strength of M3 increased by 49.39% and 50.23% when using 2.5% bacteria BS. According to previous results, a bacterial content of 2.5% gives the highest flexural strength results by increasing the amount of CaCO3 that precipitates, which improves flexural strength [85,86].

According to Figure 16, the results indicate that the flexural strength changes with variations in bacterial type from BM to BS. The flexural strength of BM types is generally better than that of BS types. With 2% sulfate, M6 used 2.5% bacteria BM, which improved flexural strength by 52.42% and 54.34% compared to control mix M4, and M7 used 2.5% bacteria BS, which increased flexural strength by 50.31% and 52.43% compared to control mix M4 at 28 and 56 days, respectively. When compared to control mix M12 at 28 and 56 days, respectively, the flexural strength of M14 increased by 57.67% and 58.41%, which contains 2.5% bacteria BM, and the flexural strength of M15 increased by 53.56% and 54.24%, which contains 2.5% bacteria BS at 10% sulfate. These results, depending on the mechanical properties of compressive strength and flexural strength, demonstrate that BM is the best because it produces more CaCO3, which fills voids and enhances mechanical properties.

The effect of pozzolanic material type on the difference in the flexural strength of uncracked specimens at 28 and 56 days is shown in Figure 17. With 5% sulfate, the flexural strength of control mix M8, which contains 0% bacteria with silica fume, increased by 3.43% and 4.71% at 28 and 56 days, representing higher flexural strength than that of control mix M20, which includes 0% bacteria with fly ash. Compared to mix M21, which contains 2.5% bacteria BM with fly ash, the flexural strength of mix M10, which includes 2.5% bacteria BM with silica fume, increased by 4.76% and 4.86% at 28 and 56 days, respectively. With 10% sulfate, compared to control mix M22, which contains 0% bacteria with fly ash, the flexural strength of control mix M12, which includes 0% bacteria with silica fume, increased by 3.84% and 5.07% at 28 and 56 days, respectively. Compared to M23, which contains 2.5% bacteria BM with fly ash, the flexural strength of M14, which includes 2.5% bacteria BM with silica fume, increased by 4.73% and 4.92% at 28 and 56 days, respectively.

This confirms that in the flexural strength test, the effect of silica fume was still higher than that of fly ash. Due to their particles being finer than cement grains, silica fume particles may efficiently fill the micro-voids in bulk paste and in the transition zone. As a result, the microstructure becomes denser due to enhanced physical packing, and because of its high silicon dioxide content and extreme fineness, silica fume is extremely reactive and easily participates in pozzolanic reactions. Moreover, the accelerated pozzolanic reaction and efficient micro-filling action of silica fume result in improved bond strength between the paste and aggregate. The fly ash did not significantly improve the properties of concrete as silica fume did because of its weak pozzolanic activity and insignificant micro-filling ability.

Figure 18 and Figure 19 depict the flexural strength reduction of concrete specimens cured in various sulfate concentrations compared to the concrete specimens cured in freshwater. The flexural strength of control mix M8 cured in a 5% sulfate solution concentration decreased by 4.59% at 28 days and 5.35% at 56 days compared to control mix M0 cured in freshwater. The flexural strength of the M12 control mix, which was cured in a 10% sulfate solution concentration, showed greater decreases of 12.33% and 12.91% at 28 and 56 days, respectively, compared to the M0 control mix cured in freshwater. The main reason for strength loss is the diffusion of SO42− ions into the concrete pore structure, which then reacts with the hydrated products to form ettringite. The volume of the solid phase is greatly increased by the formation of ettringite. The needle-like nature of ettringite crystals causes significant stress, which results in macroscopic manifestations such as concrete expansion and cracking, with a few coarse cracks appearing on the surface. However, the bacterial specimens performed extremely well when exposed to sulfate. The biogenic precipitation of CaCO3 crystals significantly decreased sulfate ion access inside the cementitious matrix. In the presence of bacteria, the flexural strength of mixes M1, M2, and M3 increased by 15.85%, 51.83%, and 49.39% at 28 days and by 17.32%, 52.31%, and 50.23% at 56 days, respectively. The flexural performance of the concrete appears to be improved by the addition of bacteria, possibly due to the bacteria’s ability to repair micro-cracks.

3.2. Specimens with Pre-Cracking

Compressive Strength

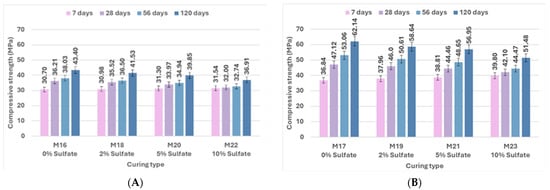

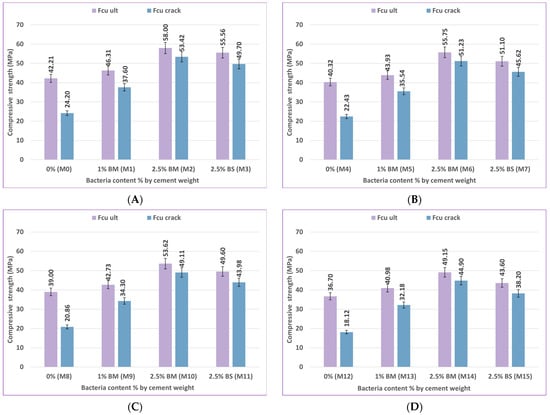

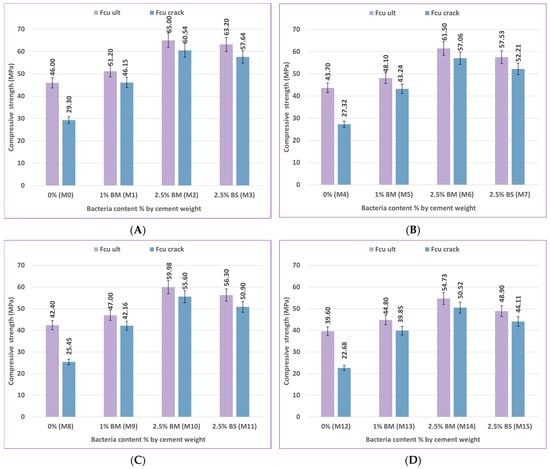

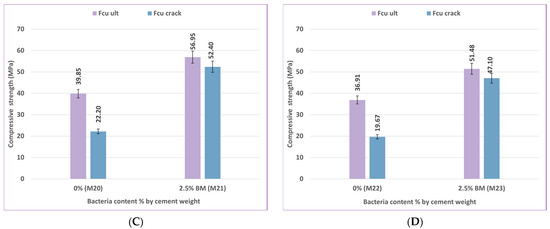

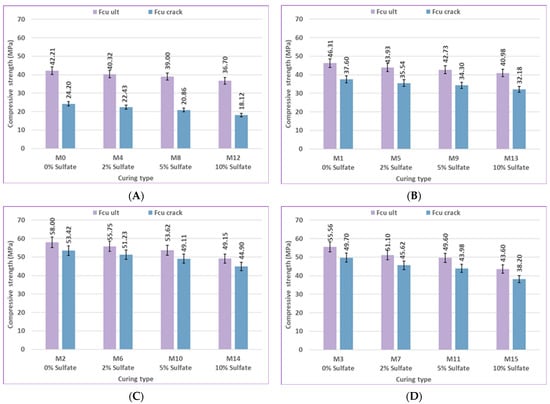

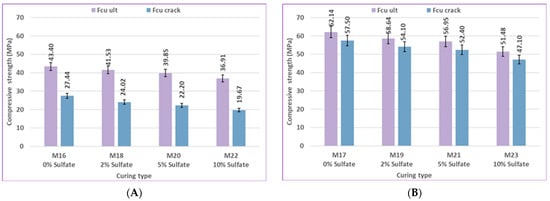

The compressive strength of uncracked and pre-cracked concrete specimens cured in freshwater and sulfate solution, with different pozzolanic materials and variable bacterial contents and types, at 56 and 120 days, is displayed in Figure 20, Figure 21, Figure 22, Figure 23, Figure 24, Figure 25, Figure 26, Figure 27, Figure 28, Figure 29, Figure 30 and Figure 31.

Figure 20.

Impact of bacterial content on concrete compressive strength for uncracked specimens and pre-cracked specimens of silica fume at 56 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 21.

Impact of bacterial content on concrete compressive strength for uncracked specimens and pre-cracked specimens of silica fume at 120 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 22.

Impact of bacterial content on concrete compressive strength for uncracked specimens and pre-cracked specimens of fly ash at 56 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 23.

Impact of bacterial content on concrete compressive strength for uncracked specimens and pre-cracked specimens of fly ash at 120 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 24.

Impact of bacterial type on concrete compressive strength for uncracked specimens and pre-cracked specimens of silica fume at 56 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 25.

Impact of bacterial type on concrete compressive strength for uncracked specimens and pre-cracked specimens of silica fume at 120 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 26.

Impact of pozzolanic material type on concrete compressive strength for uncracked specimens and pre-cracked specimens at 56 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 27.

Impact of pozzolanic material type on concrete compressive strength for uncracked specimens and pre-cracked specimens at 120 days (A) with 0% sulfate, (B) 2% sulfate, (C) 5% sulfate, and (D) 10% sulfate.

Figure 28.

Impact of curing type on concrete compressive strength for uncracked specimens and pre-cracked specimens of silica fume at 56 days (A) with 0% bacteria, (B) 1% bacteria BM, (C) 2.5% bacteria BM, and (D) 2.5% bacteria.

Figure 29.

Impact of curing type on concrete compressive strength for uncracked specimens and pre-cracked specimens of silica fume at 120 days (A) with 0% bacteria, (B) 1% bacteria BM, (C) 2.5% bacteria BM, and (D) 2.5% bacteria BS.

Figure 30.

Impact of curing type on concrete compressive strength for uncracked specimens and pre-cracked specimens of fly ash at 56 days (A) with 0% bacteria and (B) with 2.5% bacteria BM.

Figure 31.

Impact of curing type on concrete compressive strength for uncracked specimens and pre-cracked specimens of fly ash at 120 days (A) with 0% bacteria and (B) with 2.5% bacteria BM.

The effect of bacterial content on the compressive strength of pre-cracked specimens in comparison to uncracked specimens treated in freshwater and sulfate solution at 56 and 120 days is depicted in Figure 20, Figure 21, Figure 22 and Figure 23. When the bacteria content increased to 1.0% BM, 2.5% BM, and 2.5% BS for mixes M1, M2, and M3, the compressive strength of pre-cracked specimens undergoing freshwater curing increased significantly by 57.51%, 106.62%, and 96.72% at 120 days, respectively, in comparison to the sample without any bacteria. This suggests that bacteria play a crucial role in enhancing the healing of cracks and restoring the mechanical properties of concrete. This trend was also observed in specimens cured in a sulfate solution.

For instance, at 56 days, the compressive strength values of the reloaded cracked samples were 57.33%, 81.19%, 92.10%, and 89.45%, respectively, compared to the unloaded samples. At 120 days, the values were 63.70%, 90.14%, 93.14%, and 91.20%, respectively, in mixes M0, M1, M2, and M3. As the bacterial content increases due to the increase in CaCO3, the recovery ratio of the compressive strength after reloading on pre-cracked specimens in comparison to uncracked specimens of the same mix increases, as shown in [46,87,88].

Figure 24 and Figure 25 illustrate how the type of bacteria affects the compressive strength of pre-cracked specimens in comparison to uncracked specimens treated in freshwater and sulfate solution at 56 and 120 days. In comparison to uncracked specimens of the same mix at 56 and 120 days, the compressive strength test results for the reloaded cracked specimens containing bacteria BM showed an increase in strength over the specimens containing bacteria BS.

The compressive strength values of reloaded cracked specimens utilizing bacteria BM at a 2% sulfate solution are 91.89% and 92.78% of the ultimate compressive strength at 56 and 120 days, respectively, for M6. Reloaded cracked specimens with bacteria BS have compressive strengths of 89.28% and 90.75% of the ultimate compressive strength at 56 and 120 days, respectively, for M7. According to the results, Bacillus Megaterium belongs to the Bacillus family and has the ability to reduce voids and increase compressive strength. The bacterial colonies that form and the precipitation of calcite that fills the voids in the concrete, which enhances the density of the concrete, are the causes of the increase in compressive strength. Additionally, the calcite precipitation caused by bacteria and the layer of calcite deposited on the sample surface fill the pores in the concrete [47,72,89,90].

Continuous hydration was the main mechanism 56 days after the casting date, when the pozzolanic reaction was finished, because the concrete had a considerable portion of unhydrated cement particles at the early stages [91]. Compared to uncracked specimens of the same mix at 56 and 120 days, the results show that the reloaded cracked specimens containing silica fume had higher compressive strength than those containing fly ash, as shown in Figure 26 and Figure 27.

The effect of healing on cracking specimens at 0% sulfate at various ages is shown in Figure 26A and Figure 27A. The ratio of (Fcu crack)/(Fcu ult) for control mix M0, which includes 0% bacteria with silica fume, is 57.33% at 56 days and 63.70% at 120 days. At 56 and 120 days, the ratio of (Fcu crack)/(Fcu ult) is 56.98% and 63.23%, respectively, for control mix M16, which includes 0% bacteria with fly ash. Furthermore, the ratio for mix M2, which includes 2.5% bacteria BM with silica fume, is 92.10% at 56 days and 93.14% at 120 days, respectively. Lastly, the ratio of (Fcu crack)/(Fcu ult) is 91.41% and 92.53% at 56 and 120 days for mix M17, which includes 2.5% bacteria BM with fly ash.

The effect of curing type on the compressive strength of cracked samples compared to uncracked samples cured in both freshwater and sulfate solution at 56 and 120 days is depicted in Figure 28, Figure 29, Figure 30 and Figure 31. In comparison to uncracked specimens of the same mix at 56 and 120 days, the compressive strength of the reloaded cracked specimens decreases as the concentration of sulfate solution increases when curing in different sulfate concentrations; this is because of the reaction between (SO4)2 and the hydration products in the hardened cement paste, which produces expansive ettringite.

For instance, as shown in Figure 28A, the compressive strengths of the pre-cracked specimens in comparison to uncracked specimens were 57.33%, 55.63%, 53.49%, and 49.37% for mixes M0, M4, M8, and M12 at 56 days and 63.70%, 62.52%, 60.02%, and 57.27% at 120 days, respectively. The results also show that compared to the specimens without pre-cracking, the reloaded cracked specimens containing bacteria had a higher compressive strength than those without bacteria when exposed to sulfate. The compressive strengths of the reloaded cracked specimens were 55.63% and 91.89% for mixes M4 and M6 at 56 days and 62.52% and 92.78% at 120 days, respectively, in comparison to the uncracked specimens, indicating the effectiveness of bacteria in reducing the adverse effects of sulfate resulting from calcite precipitation. Below is a detailed explanation of the mechanism by which bacterial inclusion mitigates sulfate-induced damage through microbially induced calcium carbonate precipitation (MICP).

The mechanism of MICP is responsible for the crack healing and durability improvements observed in bacterial concrete. Bacteria from the Bacillus family, like Bacillus megaterium and Bacillus sphaericus, hydrolyze urea in concrete’s alkaline environment to produce ammonium and carbonate ions. The carbonate ions react with calcium ions, which are present in the pore solution or released during cement hydration; calcium carbonate (CaCO3) is precipitated. CaCO3 crystals effectively seal holes and micro-cracks, preventing the development of expansive ettringite and restricting external sulfates. Moreover, the biomineralization process improves sulfate resistance and matrix density with time [56,60,92].

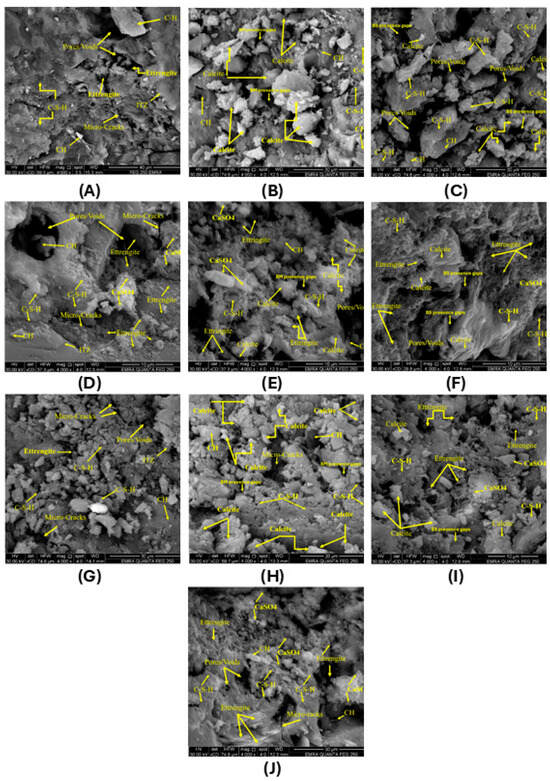

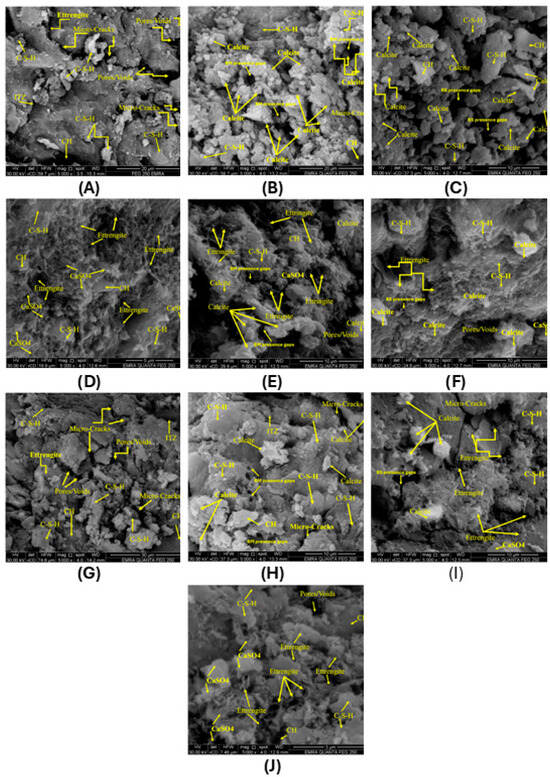

3.3. Scanning Electron Microscope (SEM)

Scanning Electron Microscopy (SEM) was employed to elucidate the microstructural evolution of the concrete mixtures, providing crucial information regarding the impact of bacterial activity, pozzolanic additions, and sulfate exposure on the density, durability, and self-healing potential of the matrix. Figure 32 and Figure 33 illustrate the findings using 4000× and 5000× magnifications to verify the precipitation of calcite. The control samples, without bacteria, namely M0 using silica fume and M16 using fly ash, possess porous microstructures with well-defined micro-cracks and voids. Evidence of hydration products like calcium silicate hydrate (C-S-H) and calcium hydroxide (CH) but the lack of calcite indicates the presence of continuous hydration but no biomineralization, and the poor Interfacial Transition Zones (ITZs) indicate mechanical weakness along with ineffective self-healing.

Figure 32.

SEM images (4000×) of (A) M0, (B) M2, (C) M3, (D) M8, (E) M10, (F) M11, (G) M16, (H) M17, (I) M21, and (J) M20.

Figure 33.

SEM images (5000×) of (A) M0, (B) M2, (C) M3, (D) M8, (E) M10, (F) M11, (G) M16, (H) M17, (I) M21, and (J) M20.

In the presence of bacteria, as in M2, M3, and M17, a miraculous change is observed. These mixes not only show hydration products but also extensive calcite reservoirs and typical bacterial presence voids, which suggest microbial-induced calcite precipitation (MICP). The presence of calcite helps fill micro-voids and seal micro-cracks, densifying and hardening the matrix [93,94,95]. In particular, Bacillus megaterium (BM) and Bacillus sphaericus (BS) were equally effective in achieving densification but with remnants of micro-cracking. The presence of silica fume or fly ash with bacterial activity enhances the pozzolanic reaction and self-healing property, and therefore, such mixes are better in the structural sense compared to the respective control mixes.

Under sulfate exposure, control specimens M8 and M20 without bacteria form ettringite and calcium sulfate (CaSO4)-dominant microstructures with residual porosity and cracking. These anticipated sulfate reaction products are expansive and can be detrimental to long-term durability. However, the presence of bacteria in sulfate-exposed mixes, such as M10, M11, and M21, is revealed by SEM micrographing to co-occur with ettringite and bacterially precipitated calcite. The pores and cracks are filled with calcite even in the case of sulfate attack, indicating that bacterial action minimizes sulfate-induced damage to a certain level. Though the sulfate attack still progresses, densification resulting from MICP and increased C-S-H growth, especially in the case of silica fume or fly ash, demonstrates greater resistance to degradation.

Generally, SEM analysis reveals that bacterial ingestion, especially with sulfate, induces concrete matrix healing and densification. It significantly enhances microstructural integrity compared to control mixes. When mixed with supplementary cementitious materials, such as silica fume or fly ash, it enhances hydration, reduces porosity, and slows sulfate attack, with the potential for long-term self-healing properties in concrete.

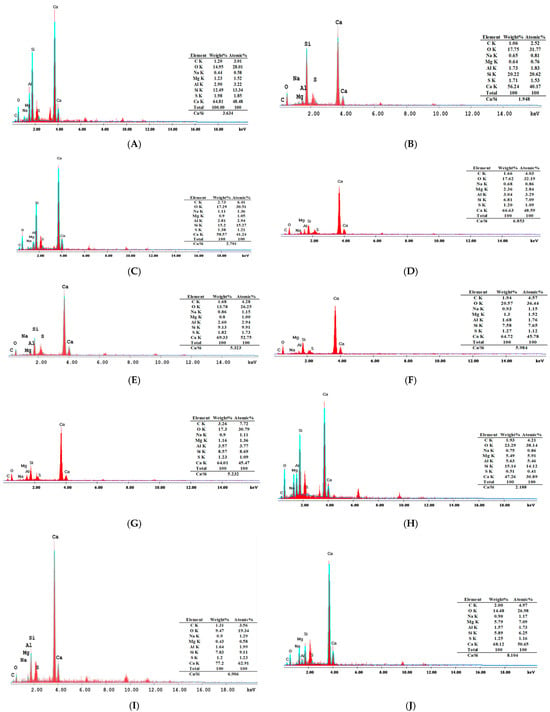

3.4. Energy-Dispersive X-Ray Spectroscopy (EDS)

EDS analysis provides valuable insights into the chemical composition and microstructural characteristics of self-healing concrete mixes, particularly when exposed to sulfate, which simulates extreme environmental conditions. Figure 34 displays the EDS test findings. In this regard, the calcium-to-silicon (Ca/Si) ratio is a convenient indicator of the quality and kind of resulting hydration products formed, especially the all-important calcium silicate hydrate (C-S-H) gel responsible for strength development and durability. Also, Ca/Si ratio values that are too high are said to indicate the existence of excess calcium phases, which would be unfavorable to mechanical strength and durability [88,96]. In situations where the concrete is exposed to solutions of sulfates, such as in mixes indicated by additions of sulfate, the foreign sulfates would react with calcium hydroxide and other hydrating phases to produce expansive forms such as ettringite and gypsum. The reaction can add more Ca to the matrix or cause low-density, poor structures, thereby affecting both mechanical performance and durability.

Figure 34.

EDS spectra at 120 days for (A) M0, (B) M2, (C) M3, (D) M8, (E) M10, (F) M11, (G) M16, (H) M17, (I) M21, and (J) M20.

For an analysis of the control mix with silica fume (M0), the Ca/Si ratio is 3.634, which implies that while there is pozzolanic reaction between silica fume and calcium hydroxide, free calcium is not fully utilized, and some is present in portlandite or a secondary product form. As Bacillus sphaericus is added to M3, the Ca/Si ratio decreases to 2.701, which shows greater utilization of free calcium, likely due to microbial-induced calcium carbonate precipitation (MICP), which leads to densification of the matrix. However, for mix M11 using 2.5% of Bacillus Sphaericus and silica fume exposed to sulfate attack with a 5% sulfate solution, the Ca/Si ratio increases significantly to 5.984. This jump indicates that the ingression of sulfate promotes the formation of structurally suboptimal but calcium-rich phases, thereby eliminating the potentially beneficial effects of MICP and silica.

Similarly, in the Bacillus megaterium series, mix M2 using 2.5% of Bacillus Megaterium and silica fume has a low Ca/Si ratio of 1.948, which reflects highly effective pozzolanic and microbial activity under non-aggressive conditions, meaning there is likely to be a dense and strong C-S-H matrix. When exposure to sulfate occurs in M10 using 2.5% of Bacillus Megaterium and silica fume, the Ca/Si ratio is 5.323. In this case, it is seen that while BM still causes some healing, the exterior’s sulfate ions dominate the matrix to form expansive and less cohesive compounds. Also, mix M21, using 2.5% Bacillus Megaterium and fly ash, has an even higher Ca/Si ratio of 6.906, which means that in the state of sulfate attack, the more delayed reactivity of fly ash is not sufficient to adequately encrust the increasing calcium.

Surprisingly enough, the sulfate-free control mix with fly ash mix M16 has a Ca/Si ratio of 5.232, and the same components exposed to sulfate in mix M20 cause the ratio to jump significantly to 8.104. This sharp increase testifies to the vulnerability of fly ash-based materials to sulfate attack in the absence of other microbial additives. For comparison, M17, using 2.5% Bacillus megaterium and fly ash, when unexposed to sulfates, possesses a comparatively low Ca/Si ratio of 2.188, which attests to the beneficial role played by BM in enhancing hydration and preventing free calcium accumulation.

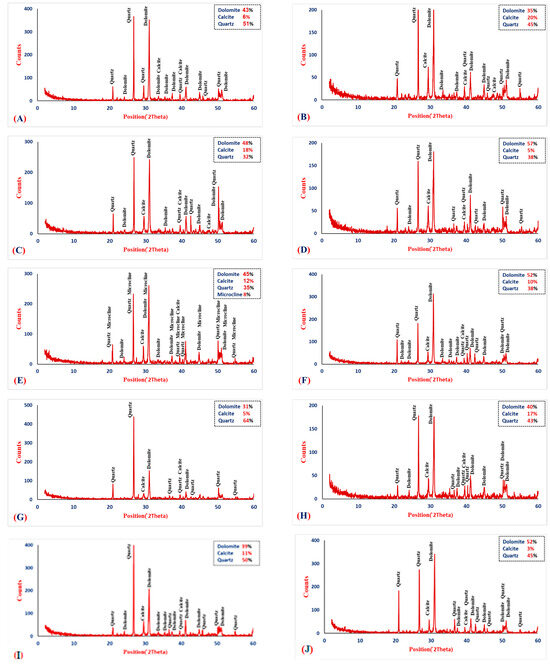

3.5. X-Ray Diffraction Analysis

X-ray diffraction (XRD) was performed to analyze the mineralogical composition and crystalline phases of self-healing concrete of varying types of bacteria, pozzolanic material, and sulfate exposure. The diffraction patterns of XRD are depicted in Figure 35 between the control and bacteria specimens at the age of 120 days regarding mixes M0, M2, M3, M8, M10, M11, M16, M17, M20, and M21. Quartz, calcite, and dolomite are the prominent crystalline phases found in all mixes. The minerals reflect hydration behavior, microbial-induced calcium carbonate precipitation (MICP), and the influence of pozzolanic reactions and sulfate exposure.

Figure 35.

X-ray diffraction analysis of (A) M0, (B) M2, (C) M3, (D) M8, (E) M10, (F) M11, (G) M16, (H) M17, (I) M21, and (J) M20.

A high quartz content (51%) and a prevailing dolomite peak (43%) and low calcite content (6%) are found in control mix M0 without bacteria, using silica fume and subjected to freshwater curing. This blend is an expression of an ordinary hydration reaction and pozzolanic activity where C-S-H gel formation prevails over widespread crystalline calcite formation. With the inclusion of 5% sulfate solution curing, as in control mix M20 using fly ash, the calcite content is very low at 3%, and it indicates that sulfate could be inhibiting the growth of calcite or enabling the growth of other secondary products, although none were identified as major peaks.

In mix M2, when using 2.5% of Bacillus Megaterium and silica fume, calcite is supplemented remarkably to 20%, with 35% dolomite and 45% quartz, which demonstrates a remarkable MICP effect. This is also observed in mix M17 with the same contents but using fly ash, wherein there is calcite (17%) and dolomite (40%). The results indicate that Bacillus Megaterium is able to induce calcium carbonate precipitation efficiently, in particular in sulfate-free conditions and independent of the type of pozzolanic material. Furthermore, mix M2, which contains 2.5% bacteria BM, has several peaks for quartz and calcite, as shown in Figure 35B. One possible explanation for its apparent increased strength in comparison to control mix M0 is more calcite. This suggests that bacteria may have an impact on the production and availability of these minerals, which might lead to greater strength and the capacity to seal cracks [52,88,97,98]. On the other hand, mix M10, using 2.5% of Bacillus Megaterium and silica fume exposed to 5% of the sulfate solution, showed extensive calcite formation (12%) under exposure conditions of sulfates, indicating the partial sulfate tolerance of Bacillus Megaterium and the ability to continue bio-mineralization activity. Apart from this, the microcline content (8%) may be explained in terms of enhanced interaction among bacteria, pozzolanic silica, and alkalis, resulting in the formation of secondary minerals.

Mixes with Bacillus Sphaericus, such as mix M11 using 2.5% of Bacillus Sphaericus and silica fume exposed to 5% of the sulfate solution, and M3 using 2.5% of Bacillus Sphaericus and silica fume subjected to freshwater curing, demonstrate different performances. M11 had medium calcite (10%) and high dolomite (52%) contents, whereas M3 had 18% calcite and 48% dolomite. This reveals that Bacillus Sphaericus also participates in MICP, although its effectiveness is remarkably less compared to that of Bacillus Megaterium, particularly when exposed to sulfate. But in sulfate-free medium (M3), the increase in calcite confirms that BS can effectively activate self-healing.

Comparing mix M21 using 2.5% Bacillus Megaterium and control mix M20 with fly ash and exposed to 5% of the sulfate solution in the two mixes, the role of sulfate and bacterial strain interactions is clarified. M21, a bacterial inclusion, showed 11% calcite (moderate calcite) under different sulfate conditions, proving that BM preserves MICP activity in more unfavorable conditions better than control M20, which showed only 3% calcite. This is due to sulfate providing protection from penetration of the bio-deposited calcite and a reduction in degrading processes from within.

Generally, XRD analysis clearly indicates the presence of bacteria, especially Bacillus Megaterium, implying that extensive precipitation of calcite is evidence of active MICP processes. This is most effective in sulfate-free mixes and where silica fume is used as a pozzolanic material. Sulfate exposure will reduce calcite formation but not eliminate it, especially when highly aggressive bacteria such as BM are present. In addition, silica fume is shown to offer a better environment for microbial development compared to fly ash, which may be due to its higher pozzolanic activity and smaller particle size, allowing it to better absorb nutrients and support microbial colonization. The findings demonstrate the synergistic action of microbial and pozzolanic activity in enhancing the durability of concrete under severe conditions and in promoting self-healing.

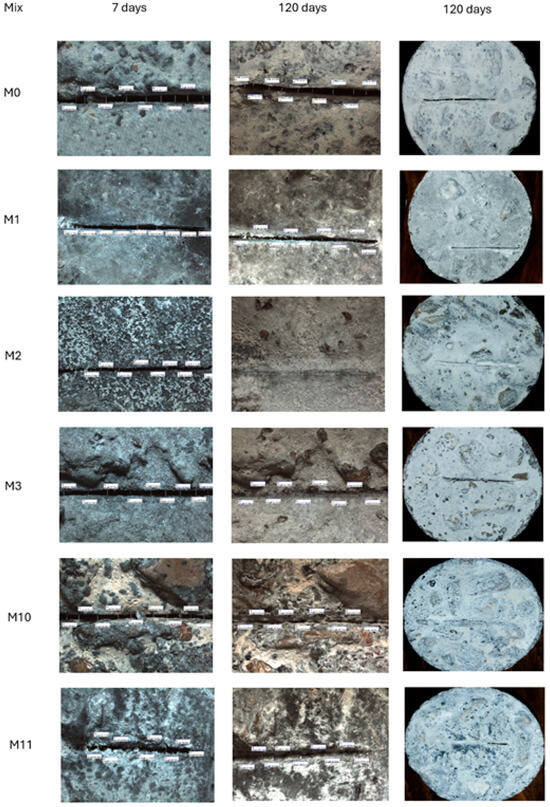

3.6. Surface Crack Healing Analysis

Figure 36 displays images of microscopic crack healing for control and microbial specimens with varying bacterial contents of Bacillus megaterium and Bacillus sphaericus. These specimens were cured in sulfate solutions and freshwater for 120 days. Through mineral precipitation, it is evident that the crack width decreases in every instance. However, the control specimen’s crack width did not significantly change, indicating that this crack healing was limited. Control of concrete crack healing is most likely caused by autogenous healing, a feature of cementitious materials. Autogenous healing explains this by hydrating unhydrated cement particles or carbonating dissolved calcium hydroxide to heal cracks when water is present. Some of the cracks were partly filled with this white precipitate, and white products were observed surrounding the cracks in the bacterial concrete. This was determined by microstructural analysis to be the precipitation of calcite. Table 7 displays the healing rate percentages for mixes M0, M1, M2, M3, M10, and M11, which were computed using Equation (1), as utilized in [97,98]. The results show a favorable correlation between the higher bacterial content in both Bacillus megaterium and Bacillus sphaericus and the crack healing rate. For instance, in mix M2, which contains 2.5% bacteria BM, the cracks displayed a healing % of 100% at 120 days. On the other hand, mix M1, which includes 1% bacteria BM, showed a healing percentage of 73.19% at 120 days. Bacillus megaterium bacteria have a greater efficiency of crack healing than Bacillus sphaericus bacteria. For instance, in M2, which contains 2.5% bacteria BM, the healing efficiency is 100% at 120 days, whereas in M3, which includes 2.5% bacteria BS, the healing efficiency is 84.33% at 120 days.

Figure 36.

The effect of bacteria (BM and BS) on crack healing progress under different environmental conditions.

Table 7.

Crack healing efficiency at 120 days.

Bacteria BM showed a healing percentage of 73.19% at 120 days. Bacillus megaterium bacteria have a greater efficiency of crack healing than Bacillus sphaericus bacteria. For instance, in M2, which contains 2.5% bacteria BM, the healing efficiency is 100% at 120 days, whereas in M3, which contains 2.5% bacteria BS, the healing efficiency is 84.33% at 120 days.

From the analysis of the results from the tests on both compressive and flexural strength, it can be concluded that there is increased strength within concrete samples containing bacteria. The sample that demonstrated the highest strength contained 2.5% Bacillus megaterium (M2). Scanning Electron Microscopy (SEM) showed that bacteria were evident in the mixes that were exposed to sulfate, as well as bacterially precipitated calcite and ettringite, which filled the pores and cracks, even under sulfate attack. Energy-Dispersive X-ray Spectroscopy (EDS) gave examples of the chemical composition and microstructure of the self-healing concrete in sulfate environments. The Ca/Si ratio is an indicator of both mechanical strength and durability, and the lowest Ca/Si ratio of 1.94 was recorded for the mix containing 2.5% Bacillus megaterium (M2) and indicates high pozzolanic and microorganism activity. The mineral identification and crystalline phase of the self-healing concrete were determined through X-ray diffraction (XRD) analysis, and we observed a strong effect of microbial-induced calcium carbonate precipitation (MICP) with 2.5% Bacillus megaterium (M2). This indicates complete agreement with the results of the compression, flexural, and microstructural tests.

4. Conclusions

This study evaluated the effectiveness of Bacillus megaterium (BM) and Bacillus sphaericus (BS) in enhancing the durability of sustainable concrete against sulfate attack through microbially induced calcium carbonate precipitation (MICP). The main conclusions are as follows:

- A 2.5% bacterial concentration (by cement weight) maximized strength and self-healing efficiency.

- Bacillus megaterium outperformed Bacillus sphaericus, enhancing compressive strength by 41.3% and flexural strength by 52.3%.

- Silica fume’s pozzolanic reactivity and micro-filling action improved concrete density and bond strength more effectively than fly ash.

- Sulfate exposure initially increased early strength through pore filling but caused long-term degradation (an 8.5% loss at 120 days) due to ettringite expansion.

- BM-treated specimens restored 93.1% of compressive strength post-cracking, demonstrating robust self-healing.

- Bacterial calcite precipitation reduced ettringite formation by 30%, mitigating sulfate-induced damage.

- Calcium lactate at 0.5% cement weight was critical for sustaining bacterial activity and MICP.

- Bacterial concrete retained strength in sulfate environments (2–10% concentrations) better than control mixes.

- Bacterial spores remained viable beyond 120 days, offering prolonged self-healing capability without reapplication.

Author Contributions

Conceptualization S.S.E.A., M.A.R.E. and A.A.E. (Ahmed A. Elshami); Methodology, S.S.E.A., I.A., M.A.R.E. and A.A.E. (Ahmed A. Elshami); Validation, S.S.E.A., M.A.R.E. and A.A.E. (Ahmed A. Elakhras); Formal Analysis, M.A.R.E., A.A.E. (Ahmed A. Elakhras) and I.A.; Investigation, I.A. and A.A.E. (Ahmed A. Elshami); Data Curation, M.A.R.E., I.A. and A.A.E. (Ahmed A. Elshami); Writing—Original Draft, I.A., M.A.R.E., A.A.E. (Ahmed A. Elshami) and A.A.; Writing—Review and Editing, S.S.E.A., M.A.R.E., I.A., A.A.E. (Ahmed A. Elshami), A.A.E. (Ahmed A. Elakhras) and A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Consent was obtained from all individual participants included in this study. All the authors agree that the article will be published after acceptance.

Data Availability Statement

All data are reported in this manuscript.

Acknowledgments

This work represents the experimental portion of the first author’s M.Sc. thesis.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Reda, R.M.; Mahmoud, H.S.E.; Ahmad, S.S.E.; Sallam, H.E.-D.M. Mechanical properties of sustainable concrete comprising various wastes. Sci. Rep. 2023, 13, 13234. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Alqedra, M.A.; Mo, K.H.; Sumesh, M. Evaluation of Industrial By-Products as Sustainable Pozzolanic Materials in Recycled Aggregate Concrete. Sustainability 2017, 9, 767. [Google Scholar] [CrossRef]

- Khan, M.; McNally, C. A holistic review on the contribution of civil engineers for driving sustainable concrete construction in the built environment. Dev. Built Environ. 2023, 16, 100273. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Irfan-ul-Hassan, M.; Khan, M.; Zhang, J.-L. Efficiency of supplementary cementitious materials and natural fiber on mechanical performance of concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Shekarchi, M.; Ahmadi, B.; Azarhomayun, F.; Shafei, B.; Kioumarsi, M. Natural zeolite as a supplementary cementitious material—A holistic review of main properties and applications. Constr. Build. Mater. 2023, 409, 133766. [Google Scholar] [CrossRef]

- Becerra-Duitama, J.A.; Rojas-Avellaneda, D. Pozzolans: A review. Eng. Appl. Sci. Res. 2022, 49, 495–504. [Google Scholar] [CrossRef]

- Jaf, D.K.; Abdulrahman, P.I. A Review on Self-Healing Concrete. Adv. Mater. Res. 2023, 1175, 139–148. [Google Scholar] [CrossRef]

- Riad, I.M.; Elshami, A.A.; Elshikh, M.M.Y. Influence of concentration and proportion prepared bacteria on properties of self-healing concrete in sulfate environment. Innov. Infrastruct. Solut. 2021, 7, 71. [Google Scholar] [CrossRef]

- Pinto, A.; González-Fonteboa, B.; Seara-Paz, S.; Martínez-Abella, F. Effects of bacteria-based self-healing nutrients on hydration and rheology of cement pastes. Constr. Build. Mater. 2023, 404, 133142. [Google Scholar] [CrossRef]

- Aruya, G.A.; Chukwuemezie, V.K. Causes of Cracks on Concrete Structures and Repair Methods. Int. J. Eng. Res. Appl. 2022, 7, 28–38. [Google Scholar]

- Mondal, S.; Das, P.; Chakraborty, A.K. Application of bacteria in concrete. Mater. Today Proc. 2017, 4, 9833–9836. [Google Scholar] [CrossRef]

- Massaad, G.; Rozière, E.; Loukili, A.; Izoret, L. Advanced testing and performance specifications for the cementitious materials under external sulfate attacks. Constr. Build. Mater. 2016, 127, 918–931. [Google Scholar] [CrossRef]

- Whittaker, M.; Black, L. Current knowledge of external sulfate attack. Adv. Cem. Res. 2015, 27, 532–545. [Google Scholar] [CrossRef]

- Nehdi, M.; Hayek, M. Behavior of blended cement mortars exposed to sulfate solutions cycling in relative humidity. Cem. Concr. Res. 2005, 35, 731–742. [Google Scholar] [CrossRef]

- Haynes, H.; Bassuoni, M. Physical Salt Attack on Concrete. Concr. Int. 2011, 33, 38–42. [Google Scholar]

- Dinarvand, P.; Rashno, A. Review of the potential application of bacteria in self-healing and the improving properties of concrete/mortar. J. Sustain. Cem.-Based Mater. 2021, 11, 250–271. [Google Scholar] [CrossRef]

- Amran, M.; Onaizi, A.M.; Fediuk, R.; Vatin, N.I.; Muhammad Rashid, R.S.; Abdelgader, H.; Ozbakkaloglu, T. Self-healing concrete as a prospective construction material: A review. Materials 2022, 15, 3214. [Google Scholar] [CrossRef]

- Jakhrani, S.H.; Qudoos, A.; Kim, H.G.; Jeon, I.K.; Ryou, J.S. Review on the self-healing concrete-approach and evaluation techniques. J. Ceram. Process. Res. 2019, 20, 1–18. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Shaikh, F.U.A. Review on performance evaluation of autonomous healing of geopolymer composites. Infrastructures 2021, 6, 94. [Google Scholar] [CrossRef]

- Mohamed, A.; Zhou, Y.; Bertolesi, E.; Liu, M.; Liao, F.; Fan, M. Factors influencing self-healing mechanisms of cementitious materials: A review. Constr. Build. Mater. 2023, 393, 131550. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Formagini, S.; Serna, P. Self-healing concrete-what is it good for? Mater. Construcción 2021, 71, e237. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Feng, T.; Zhou, M.; Zhao, L.; Zhou, A.; Li, Z. Immobilizing bacteria in expanded perlite for the crack self-healing in concrete. Constr. Build. Mater. 2017, 148, 610–617. [Google Scholar] [CrossRef]

- Mondal, S.; Ghosh, A. Microbial concrete as a sustainable option for infrastructural development in emerging economies. In Proceedings of the ASCE India Conference 2017, New Delhi, India, 12–14 December 2017; pp. 413–423. [Google Scholar] [CrossRef]

- Tziviloglou, E.; Wiktor, V.; Jonkers, H.; Schlangen, E. Bacteria-based self-healing concrete to increase liquid tightness of cracks. Constr. Build. Mater. 2016, 122, 118–125. [Google Scholar] [CrossRef]

- Javeed, Y.; Goh, Y.; Mo, K.H.; Yap, S.P.; Leo, B.F. Microbial self-healing in concrete: A comprehensive exploration of bacterial viability, implementation techniques, and mechanical properties. J. Mater. Res. Technol. 2024, 29, 2376–2395. [Google Scholar] [CrossRef]

- Vijay, K.; Murmu, M. Effect of calcium lactate on compressive strength and self-healing of cracks in microbial concrete. Front. Struct. Civ. Eng. 2019, 13, 515–525. [Google Scholar] [CrossRef]

- Feng, J.; Chen, B.; Sun, W.; Wang, Y. Microbial induced calcium carbonate precipitation study using Bacillus subtilis with application to self-healing concrete preparation and characterization. Constr. Build. Mater. 2021, 280, 122460. [Google Scholar] [CrossRef]

- De Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar] [CrossRef]

- El-Newihy, A.; Azarsa, P.; Gupta, R.; Biparva, A. Effect of polypropylene fibers on self-healing and dynamic modulus of elasticity recovery of fiber reinforced concrete. Fibers 2018, 6, 9. [Google Scholar] [CrossRef]

- Jena, S.; Basa, B.; Panda, K.C.; Sahoo, N.K. Impact of Bacillus subtilis bacterium on the properties of concrete. Mater. Today Proc. 2020, 32, 651–656. [Google Scholar] [CrossRef]

- He, J.; Shi, X. Developing an abiotic capsule-based self-healing system for cementitious materials: The state of knowledge. Constr. Build. Mater. 2017, 156, 1096–1113. [Google Scholar] [CrossRef]

- Lu, S.; Chen, M.; Dang, Y.; Cao, L.; He, J.; Zhong, J. Bacterial self healing cement based materials: Mechanism at nanoscale. AIP Adv. 2019, 9, 105312. [Google Scholar] [CrossRef]

- Bundur, Z.B.; Kirisits, M.J.; Ferron, R.D. Use of pre-wetted lightweight fine expanded shale aggregates as internal nutrient reservoirs for microorganisms in bio-mineralized mortar. Cem. Concr. Compos. 2017, 84, 167–174. [Google Scholar] [CrossRef]

- Khodadadi Tirkolaei, H.; Bilsel, H. Estimation on ureolysis-based microbially induced calcium carbonate precipitation progress for geotechnical applications. Mar. Georesour. Geotechnol. 2017, 35, 34–41. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Ghorbel, E.; Fares, H.; Cousture, A. Bacterial self-healing of concrete and durability assessment. Cem. Concr. Compos. 2019, 104, 103340. [Google Scholar] [CrossRef]

- Wang, J.; Jonkers, H.M.; Boon, N.; De Belie, N. Bacillus sphaericus LMG 22257 is physiologically suitable for self-healing concrete. Appl. Microbiol. Biotechnol. 2017, 101, 5101–5114. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Son, H.; Park, S.; Lee, H.-K. Effects of biological admixtures on hydration and mechanical properties of Portland cement paste. Constr. Build. Mater. 2020, 235, 117461. [Google Scholar] [CrossRef]

- Wong, P.Y.; Mal, J.; Sandak, A.; Luo, L.; Jian, J.; Pradhan, N. Advances in microbial self-healing concrete: A critical review of mechanisms, developments, and future directions. Sci. Total Environ. 2024, 947, 174553. [Google Scholar] [CrossRef]

- Reddy, B.M.S.; Revathi, D. An experimental study on effect of Bacillus sphaericus bacteria in crack filling and strength enhancement of concrete. Mater. Today Proc. 2019, 19, 803–809. [Google Scholar] [CrossRef]

- Nagar, P.A.; Gupta, N.; Kishore, K.; Parashar, A.K. Coupled effect of B. Sphaericus bacteria and calcined clay mineral on OPC concrete. Mater. Today Proc. 2021, 44, 113–117. [Google Scholar] [CrossRef]

- Priya, T.S.; Ramesh, N.; Agarwal, A.; Bhusnur, S.; Chaudhary, K. Strength and durability characteristics of concrete made by micronized biomass silica and Bacteria-Bacillus sphaericus. Constr. Build. Mater. 2019, 226, 827–838. [Google Scholar] [CrossRef]

- Jafarnia, M.S.; Saryazdi, M.K.; Moshtaghioun, S.M. Use of bacteria for repairing cracks and improving properties of concrete containing limestone powder and natural zeolite. Constr. Build. Mater. 2020, 242, 118059. [Google Scholar] [CrossRef]

- Chen, B.; Sun, W.; Sun, X.; Cui, C.; Lai, J.; Wang, Y.; Feng, J. Crack sealing evaluation of self-healing mortar with Sporosarcina pasteurii: Influence of bacterial concentration and air-entraining agent. Process Biochem. 2021, 107, 100–111. [Google Scholar] [CrossRef]

- Ryparová, P.; Tesárek, P.; Schreiberová, H.; Prošek, Z. The effect of temperature on bacterial self-healing processes in building materials. In IOP Conference Series: Materials Science and Engineering, Proceedings of the Development of Materials Science in Research and Education (DMSRE29), Nová Lesná, Slovakia, 2–6 September 2019; IOP Publishing Ltd.: Bristol, UK, 2020; p. 012012. [Google Scholar] [CrossRef]

- Su, Y.; Zheng, T.; Qian, C. Application potential of Bacillus megaterium encapsulated by low alkaline sulphoaluminate cement in self-healing concrete. Constr. Build. Mater. 2021, 273, 121740. [Google Scholar] [CrossRef]

- Bifathima, S.; Vara Lakshmi, T.V.S.; Matcha, B.N. Self healing concrete by adding Bacillus megaterium MTCC with glass & steel fibers. Civ. Environ. Eng. 2020, 16, 184–197. [Google Scholar] [CrossRef]

- Nagarajan, V.; Prabhu, T.K.; Shankar, M.G.; Jagadesh, P. A study on the strength of the bacterial concrete embedded with Bacillus megaterium. Int. Res. J. Eng. Technol. 2017, 4, 1784–1788. [Google Scholar]

- Vijay, K.; Murmu, M. Experimental study on bacterial concrete using Bacillus subtilis micro-organism. In Emerging Trends in Civil Engineering: Select Proceedings of ICETCE 2018; Springer: Singapore, 2020; pp. 245–252. [Google Scholar] [CrossRef]