Integrating Recycled Acrylonitrile–Butadiene–Styrene Plastics from Electronic Waste with Carbon Black for Sustainable Asphalt Production

Abstract

1. Introduction

2. Materials and Methods

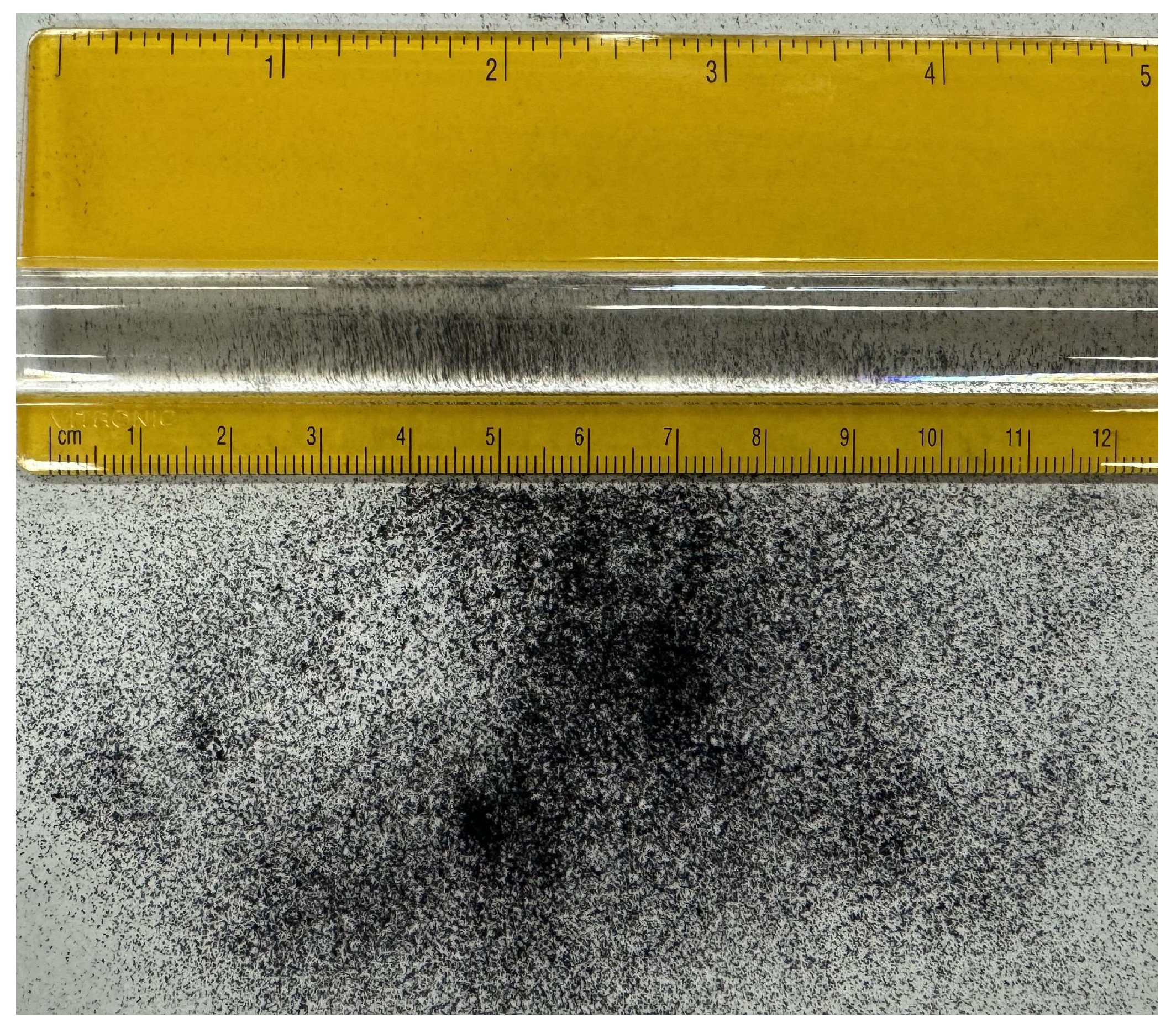

2.1. Production of Plastic-Modified Asphalt with Carbon Black

2.2. Aging Procedures

2.3. Asphalt Binder Cracking Device (ABCD)

2.4. Dynamic Shear Rheometer (DSR)

2.5. Linear Amplitude Sweep (LAS)

3. Results and Discussion

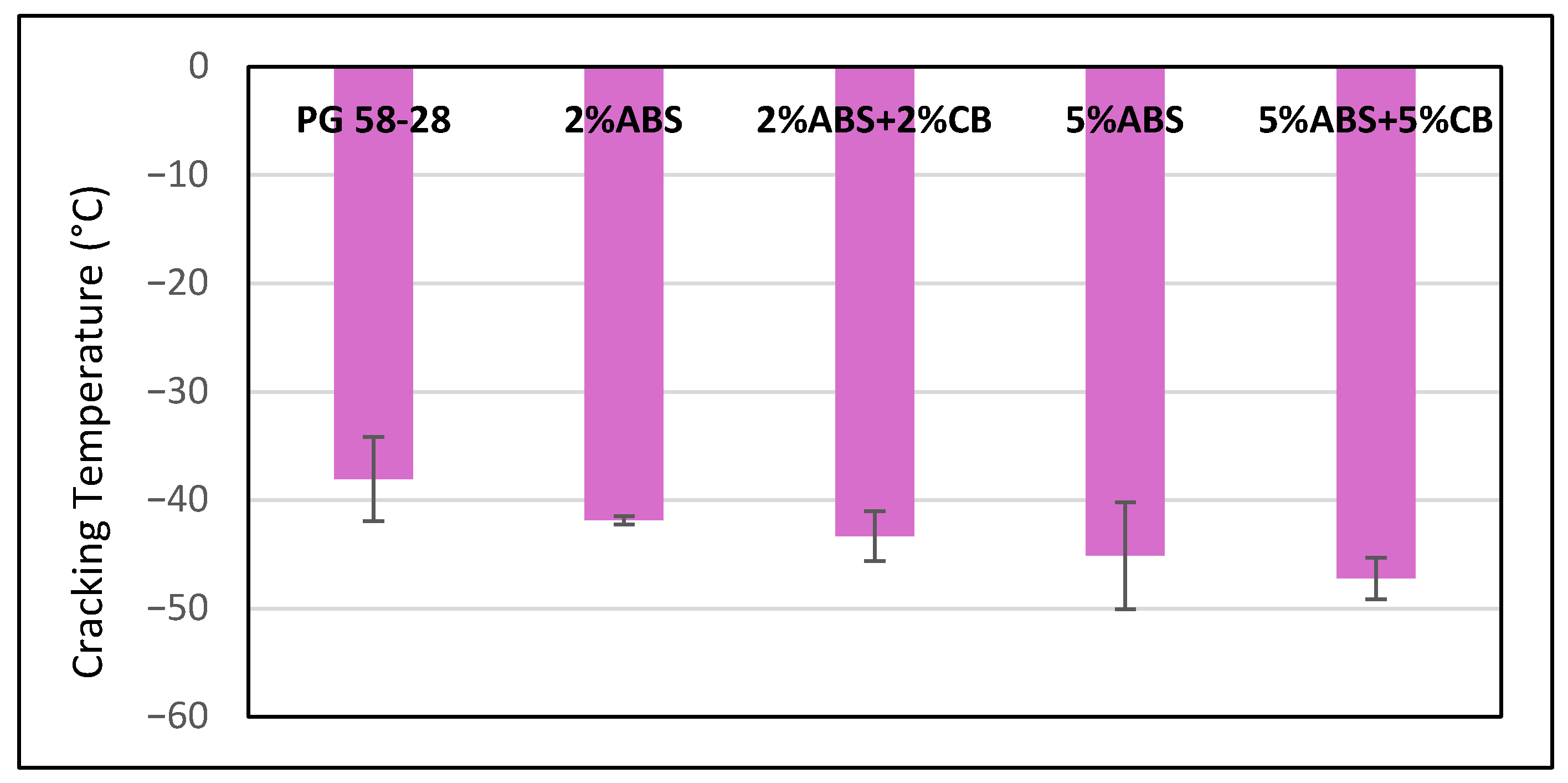

3.1. Low-Temperature Performance

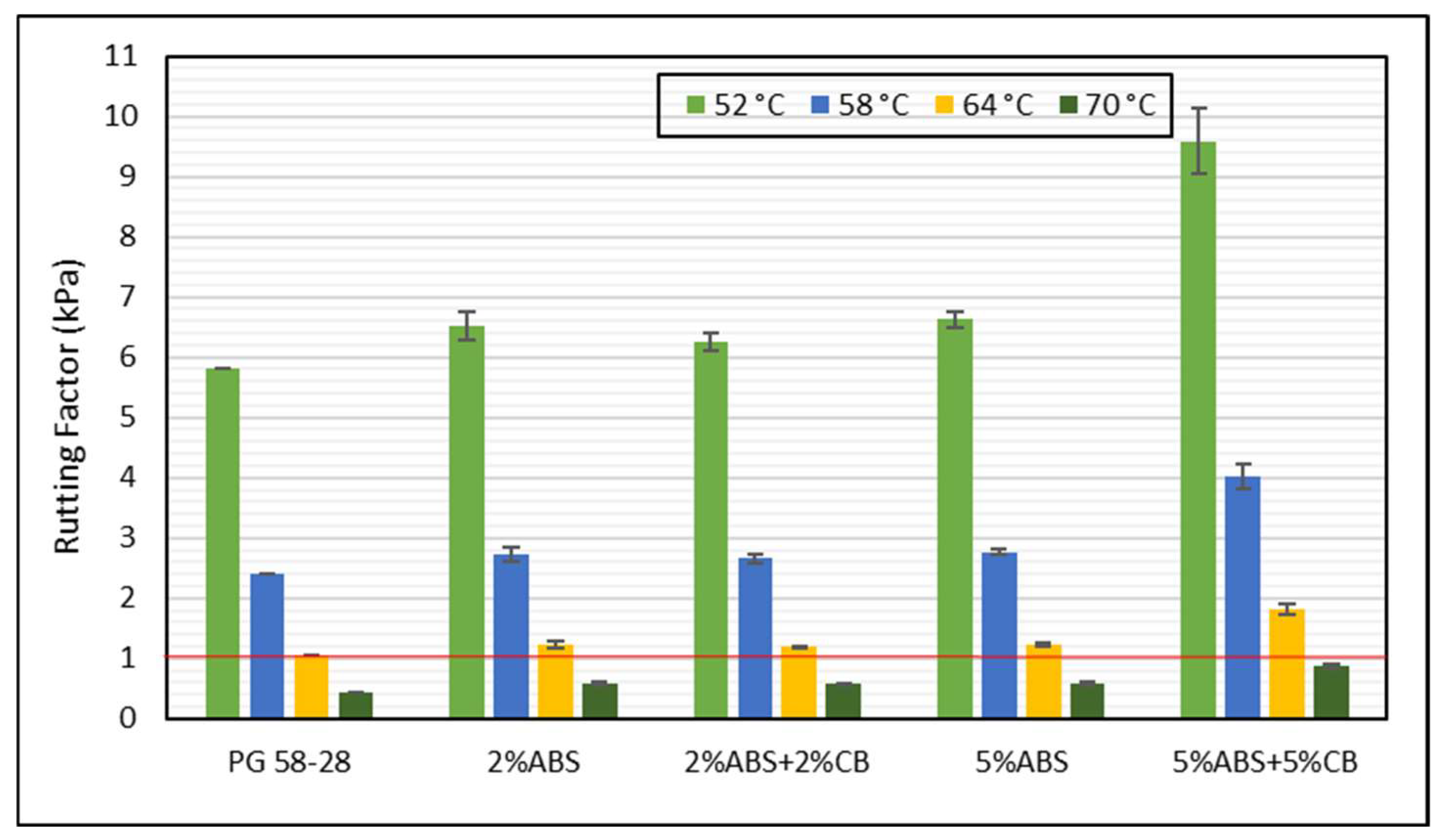

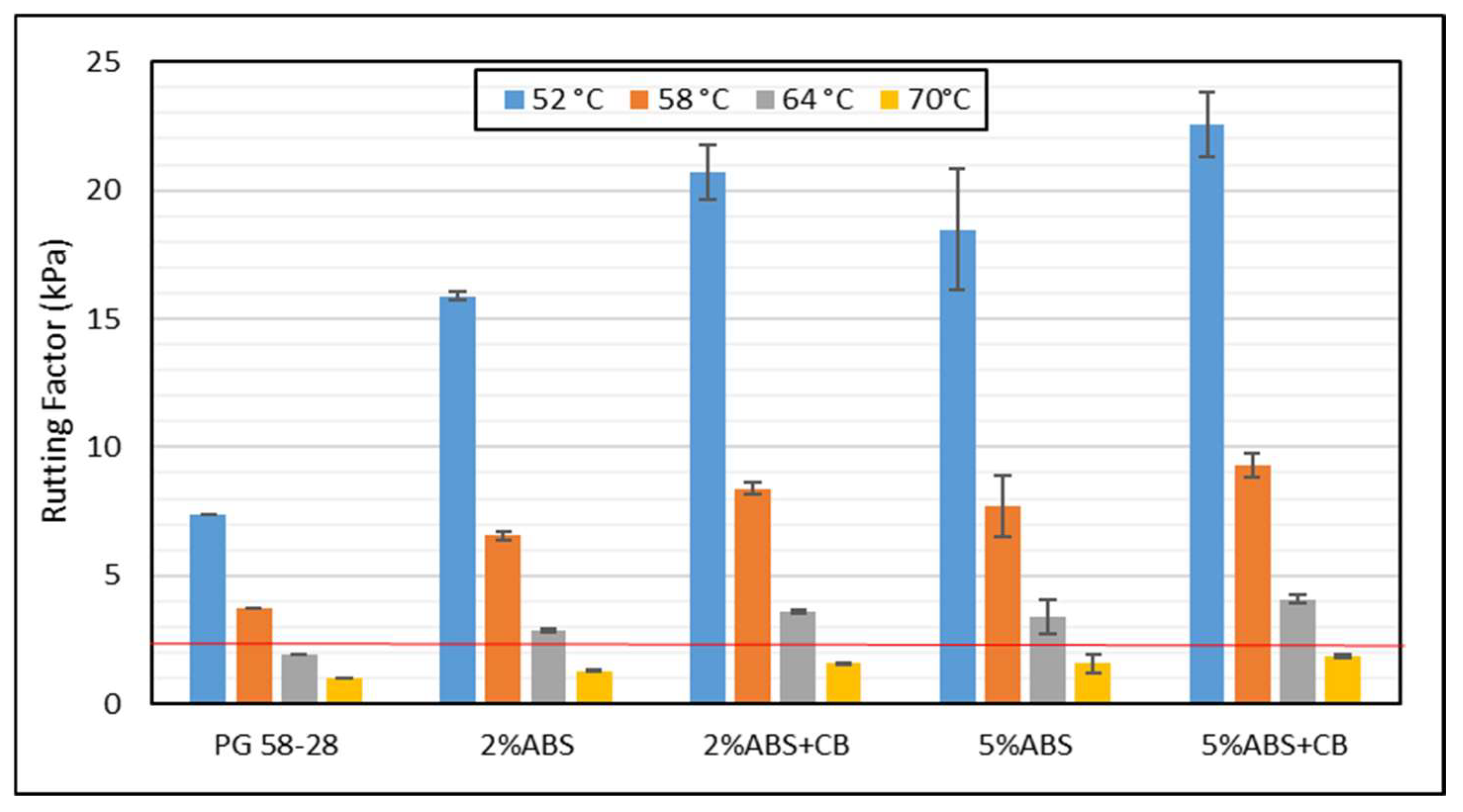

3.2. High-Temperature Performance

3.3. Intermediate-Temperature Performance

4. Conclusions and Recommendations for Future Research

- Preparation procedure and size reduction of e-waste plastics led to improvements in the cracking resistance of the base binder by resulting in lower (better) cracking temperatures; however, the incorporation of carbon black further enhanced the low-temperature performance, with the sample containing 5% ABS and 5% carbon black exhibiting the best low-temperature performance. This indicates that proper mixing conditions as well as the incorporation of carbon black can eliminate one of the major drawbacks in the application of plastics, which is poor low-temperature performance.

- The addition of e-waste ABS plastics improved the high-temperature rutting resistance performance by leading to higher rutting factor values when compared to the base binder. Additionally, samples containing carbon black demonstrated similar performance under unaged conditions; additionally, these samples performed better after RTFO aging, resulting in higher rutting factor values.

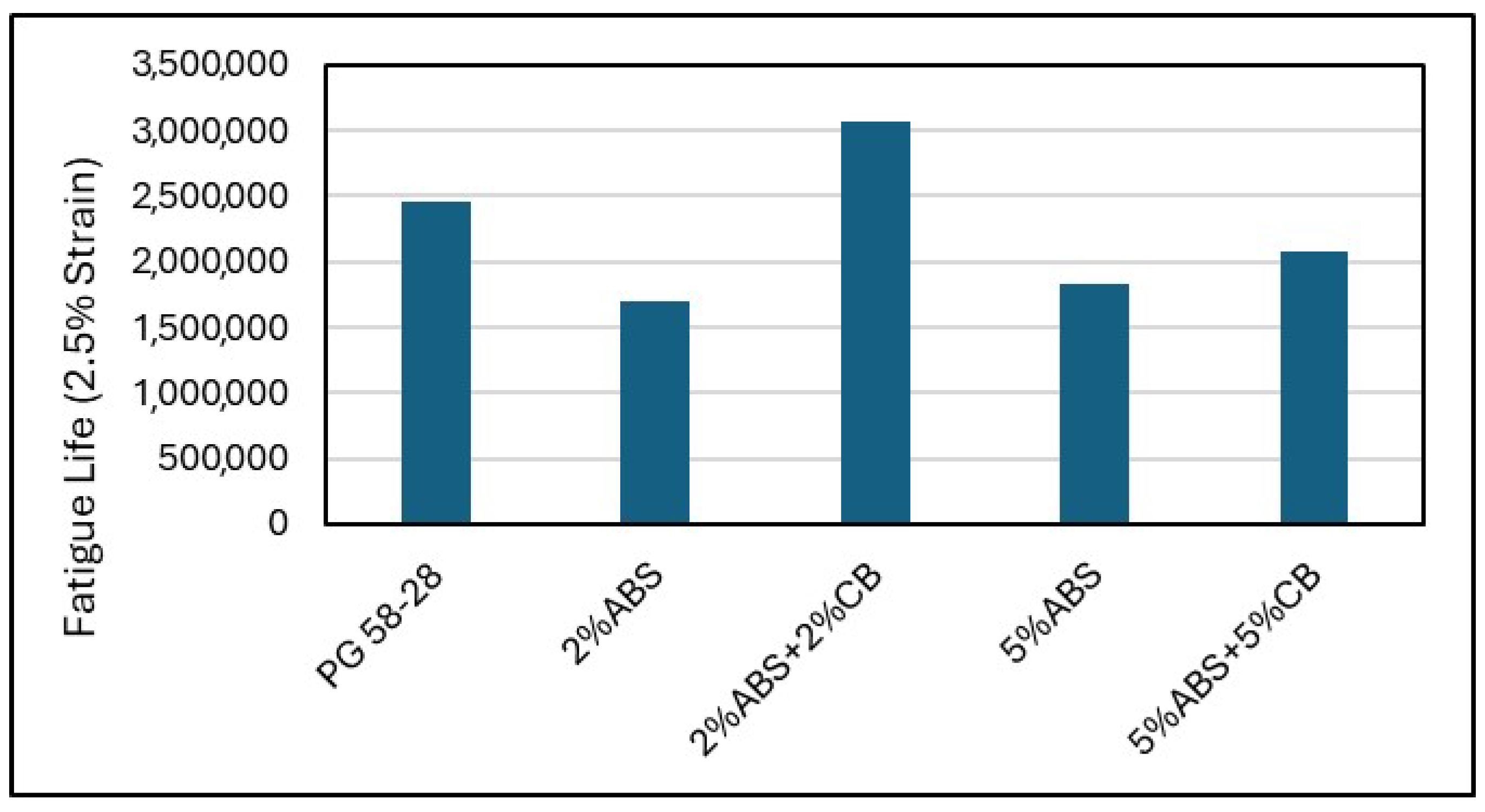

- For fatigue behavior, LAS results showed that the initial incorporation of ABS led to a lower fatigue life compared to virgin asphalt. However, when carbon black was introduced at a blending content of 2% into the ABS-modified samples, there were notable positive effects on fatigue performance under both strain levels. The improvement was particularly notable under the 2.5% strain level. Conversely, increasing the blending content of carbon black to 5% did not result in a significant improvement in samples with 5% ABS.

- The inclusion of carbon black, as well as the careful planning of the size reduction of the plastics and modification process of asphalt and plastics, proved to enhance the compatibility between these two types of materials, by leading to improved performance in terms of both high- and low-temperature behavior. Previous research also reported that carbon black contributes to better workability, compatibility, and mechanical behavior due to its favorable interaction with asphalt. Additionally, carbon-based additives have also been recognized for their inherent compatibility with bituminous materials, and it has been indicated that carbon black can reduce the density differences between polymers and asphalt [11,32,33]. Higher incorporation dosages of carbon black are recommended to lead to more effective results, particularly in regions susceptible to cold-weather distresses such as Michigan, as well as areas experiencing rutting-related distresses during warmer seasons.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bhutta, M.K.S.; Omar, A.; Yang, X. Electronic Waste: A Growing Concern in Today’s Environment. Econ. Res. Int. 2011, 2011, 1–8. [Google Scholar] [CrossRef]

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows, and the Circular Economy Potential; ITU: Geneva, Switzerland, 2020. [Google Scholar]

- Kumar, A.; Holuszko, M.; Espinosa, D.C.R. E-waste: An overview on generation, collection, legislation and recycling practices. Resour. Conserv. Recycl. 2017, 122, 32–42. [Google Scholar] [CrossRef]

- Sahajwalla, V.; Gaikwad, V. The present and future of e-waste plastics recycling. Curr. Opin. Green Sustain. Chem. 2018, 13, 102–107. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Uddin, M.N.; Chowdhury, J.I.; Ahmed, S.F.; Mofijur, M.; Uddin, M.A. A review of the recent development, challenges, and opportunities of electronic waste (e-waste). Int. J. Environ. Sci. Technol. 2023, 20, 4513–4520. [Google Scholar] [CrossRef]

- Kiddee, P.; Naidu, R.; Wong, M.H. Electronic waste management approaches: An overview. Waste Manag. 2013, 33, 1237–1250. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, H.; Jiang, X.; Polaczyk, P.; Xiao, R.; Zhang, M.; Huang, B. The utilization of waste plastics in asphalt pavements: A review. Clean. Mater. 2021, 2, 100031. [Google Scholar] [CrossRef]

- Hasan, M.R.M.; Colbert, B.; You, Z.; Jamshidi, A.; Heiden, P.A.; Hamzah, M.O. A simple treatment of electronic-waste plastics to produce asphalt binder additives with improved properties. Constr. Build. Mater. 2016, 110, 79–88. [Google Scholar] [CrossRef]

- Mohammadi, S.; Solatifar, N. Optimized Preparation and High-Temperature Performance of Composite-Modified Asphalt Binder with CR and WEO. J. Mater. Civ. Eng. 2023, 35, 04022395. [Google Scholar] [CrossRef]

- Jin, D.; Meyer, T.K.; Chen, S.; Boateng, K.A.; Pearce, J.M.; You, Z. Evaluation of lab performance of stamp sand and acrylonitrile styrene acrylate waste composites without asphalt as road surface materials. Constr. Build. Mater. 2022, 338, 127569. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using waste plastics as asphalt modifier: A review. Materials 2022, 15, 110. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Hasan, M.R.M.; Lei, Y.; Irfan, M. Rheological behavior and sensitivity of wood-derived bio-oil modified asphalt binders. Appl. Sci. 2018, 8, 919. [Google Scholar] [CrossRef]

- Mohammadi, S.; Jin, D.; Kulas, D.; Zolghadr, A.; Shonnard, D.R.; You, Z. Role of Pyrolysis Wax on Enhancing the Performance of Waste Plastic Modified Asphalt Prepared with the Wet Modification Process. Transp. Res. Rec. 2025. [Google Scholar] [CrossRef]

- Casado-Barrasa, R.; Lastra-González, P.; Indacoechea-Vega, I.; Castro-Fresno, D. Assessment of carbon black modified binder in a sustainable asphalt concrete mixture. Constr. Build. Mater. 2019, 211, 363–370. [Google Scholar] [CrossRef]

- Cong, P.; Xu, P.; Chen, S. Effects of carbon black on the anti aging, rheological and conductive properties of SBS/asphalt/carbon black composites. Constr. Build. Mater. 2014, 52, 306–313. [Google Scholar] [CrossRef]

- Muthukumar, S. Stability study on eco-friendly flexible pavement using e-waste and hips. Int. J. Civ. Eng. Technol. 2017, 8, 956–965. Available online: https://iaeme.com/Home/article_id/IJCIET_08_10_100 (accessed on 10 December 2023).

- Ahmedzade, P.; Fainleib, A.; Günay, T.; Starostenko, O.; Kovalinska, T. Effect of gamma-irradiated recycled low-density polyethylene on the high- and low-temperature properties of bitumen. Int. J. Polym. Sci. 2013, 2013. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Fainleib, A.; Günay, T.; Grygoryeva, O. Modification of bitumen by electron beam irradiated recycled low density polyethylene. Constr. Build. Mater. 2014, 69, 1–9. [Google Scholar] [CrossRef]

- Jun, L.; Yuxia, Z.; Yuzhen, Z. The research of GMA-g-LDPE modified Qinhuangdao bitumen. Constr. Build. Mater. 2008, 22, 1067–1073. [Google Scholar] [CrossRef]

- Pérez-Lepe, A.; Martínez-Boza, F.J.; Attané, P.; Gallegos, C. Destabilization mechanism of polyethylene-modified bitumen. J. Appl. Polym. Sci. 2006, 100, 260–267. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, L.; Gupta, M.; Chauhan, G.S. Polymer-modified bitumen of recycled LDPE and maleated bitumen. J. Appl. Polym. Sci. 2013, 127, 67–78. [Google Scholar] [CrossRef]

- Vargas, M.A.; Vargas, M.A.; Sánchez-Sólis, A.; Manero, O. Asphalt/polyethylene blends: Rheological properties, microstructure and viscosity modeling. Constr. Build. Mater. 2013, 45, 243–250. [Google Scholar] [CrossRef]

- Wen-Qi, W.; Hai-Bo, D.T.; Ze, W. Effects of Gamma-Irradiated Recycled Low-Density Polyethylene on the Creep and Recovery Properties of Asphalt. J. Highw. Transp. Res. Dev. (Engl. Ed.) 2018, 12, 13–18. [Google Scholar]

- Yadollahi, G.; Sabbagh, H. Mollahosseini Improving the performance of Crumb Rubber bitumen by means of Poly Phosphoric Acid (PPA) and Vestenamer additives. Constr. Build. Mater. 2011, 25, 3108–3116. [Google Scholar] [CrossRef]

- Colbert, B.W.; You, Z. Properties of Modified Asphalt Binders Blended with Electronic Waste Powders. J. Mater. Civ. Eng. 2012, 24, 1261–1267. [Google Scholar] [CrossRef]

- Plastic Melting Temperature Chart, Sea Sky Media. 2023. Available online: https://www.seaskymedical.com/plastic-melting-temperature-chart (accessed on 1 November 2024).

- AASHTO T240; Standard Method of Test for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film Oven Test). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2009.

- AASHTO R28; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T315; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- AASHTO T391-20; Estimating Fatigue Resistance of Asphalt Binders Using the Linear Amplitude Sweep Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2021.

- Ma, Y.; Wang, S.; Zhou, H.; Hu, W.; Polaczyk, P.; Zhang, M.; Huang, B. Compatibility and rheological characterization of asphalt modified with recycled rubber-plastic blends. Constr. Build. Mater. 2021, 270, 121416. [Google Scholar] [CrossRef]

- Li, C.; Fan, Z.; Wu, S.; Li, Y.; Gan, Y.; Zhang, A. Effect of carbon black nanoparticles from the pyrolysis of discarded tires on the performance of asphalt and its mixtures. Appl. Sci. 2018, 8, 624. [Google Scholar] [CrossRef]

- Rafi, J.; Kamal, M.A.; Ahmad, N.; Hafeez, M.; Haq, M.F.U.; Asif, S.A.; Shabbir, F.; Zaidi, S.B.A. Performance evaluation of Carbon black nano-particle reinforced asphalt mixture. Appl. Sci. 2018, 8, 1114. [Google Scholar] [CrossRef]

- Li, H.; Cui, C.; Temitope, A.A.; Feng, Z.; Zhao, G.; Guo, P. Effect of SBS and crumb rubber on asphalt modification: A review of the properties and practical application. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 836–863. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Z.; Wu, S.; Xie, J.; Yang, C.; Li, N.; Cui, P. Road performance, VOCs emission and economic benefit evaluation of asphalt mixture by incorporating steel slag and SBS/CR composite modified asphalt. Case Stud. Constr. Mater. 2023, 18, e01929. [Google Scholar] [CrossRef]

- Yao, L.; Leng, Z.; Lan, J.; Chen, R.; Jiang, J. Environmental and economic assessment of collective recycling waste plastic and reclaimed asphalt pavement into pavement construction: A case study in Hong Kong. J. Clean. Prod. 2022, 336, 130405. [Google Scholar] [CrossRef]

| Asphalt Sample | ABS Content | Carbon Black Content |

|---|---|---|

| 2%ABS | 2% | 0% |

| 2%ABS + 2%CB | 2% | 2% |

| 5%ABS | 5% | 0% |

| 5%ABS + 5%CB | 5% | 5% |

| Temperature | 25 °C | 22 °C | 19 °C | 16 °C | 13 °C |

|---|---|---|---|---|---|

| PG58-28 | 4602 | 6509 | 8909 | 11,965 | 15,941 |

| PG58-28 + 2% ABS | 3599 | 5322 | 7679 | 10,788 | 14,756 |

| PG58-28 + 5% ABS | 4579 | 6417 | 8976 | 12,419 | 16,841 |

| PG58-28 + 2% ABS + 2% CB | 4193 | 5884 | 8088 | 10,954 | 14,646 |

| PG58-28 + 5% ABS + 5% CB | 5847 | 8303 | 11,373 | 15,313 | 20,370 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadi, S.; Jin, D.; You, Z. Integrating Recycled Acrylonitrile–Butadiene–Styrene Plastics from Electronic Waste with Carbon Black for Sustainable Asphalt Production. Infrastructures 2025, 10, 181. https://doi.org/10.3390/infrastructures10070181

Mohammadi S, Jin D, You Z. Integrating Recycled Acrylonitrile–Butadiene–Styrene Plastics from Electronic Waste with Carbon Black for Sustainable Asphalt Production. Infrastructures. 2025; 10(7):181. https://doi.org/10.3390/infrastructures10070181

Chicago/Turabian StyleMohammadi, Sepehr, Dongzhao Jin, and Zhanping You. 2025. "Integrating Recycled Acrylonitrile–Butadiene–Styrene Plastics from Electronic Waste with Carbon Black for Sustainable Asphalt Production" Infrastructures 10, no. 7: 181. https://doi.org/10.3390/infrastructures10070181

APA StyleMohammadi, S., Jin, D., & You, Z. (2025). Integrating Recycled Acrylonitrile–Butadiene–Styrene Plastics from Electronic Waste with Carbon Black for Sustainable Asphalt Production. Infrastructures, 10(7), 181. https://doi.org/10.3390/infrastructures10070181