Zinc Oxide as a Filler in a Hot-Mix Asphalt: Impact on Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Asphalt Mix Design

2.3. Asphalt Mastics

2.4. Mechanical Resistance Tests

3. Results

3.1. Marshall Test

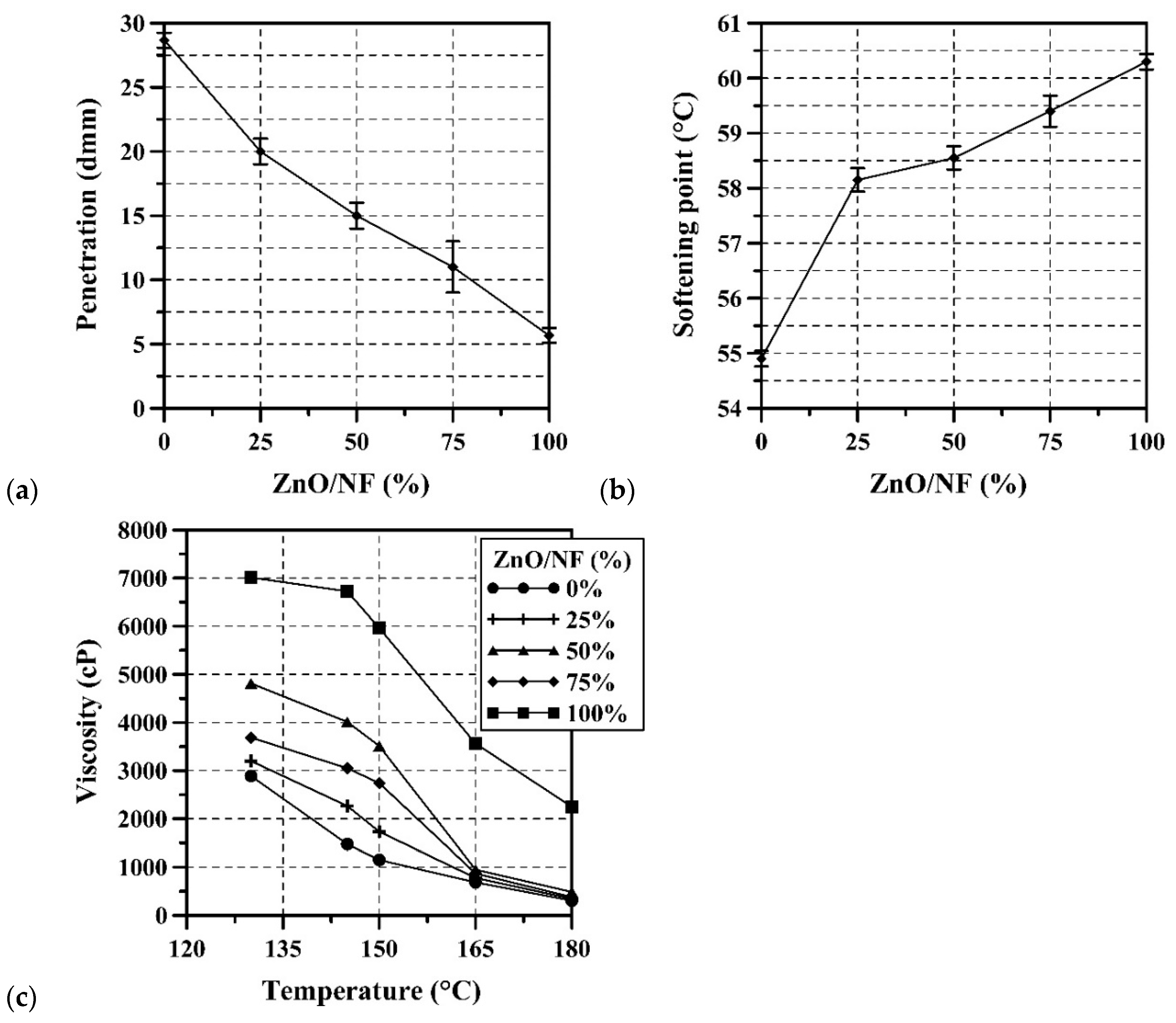

3.2. Conventional Properties of Asphalt Mastics

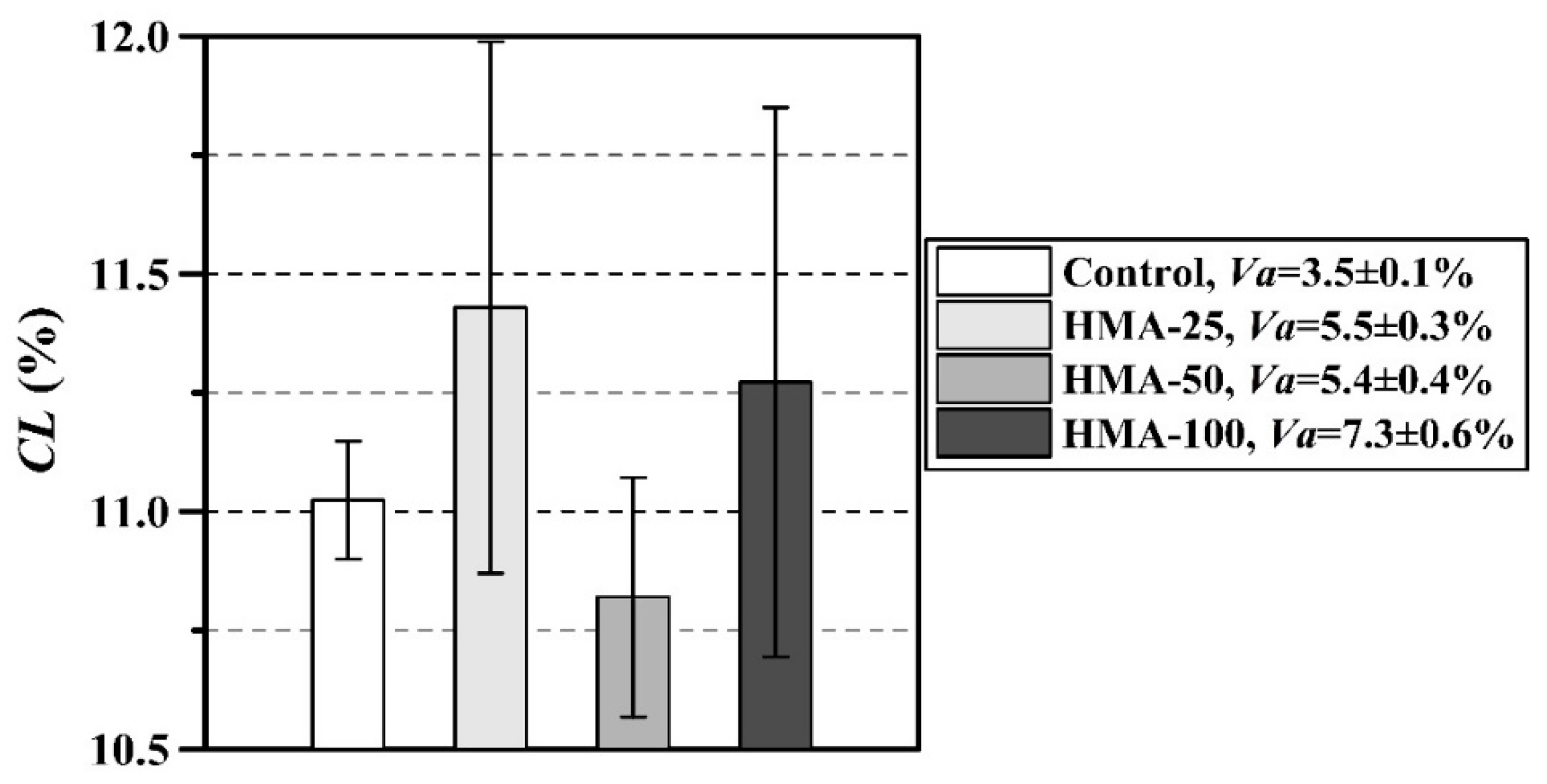

3.3. ITS and Cantabro Tests

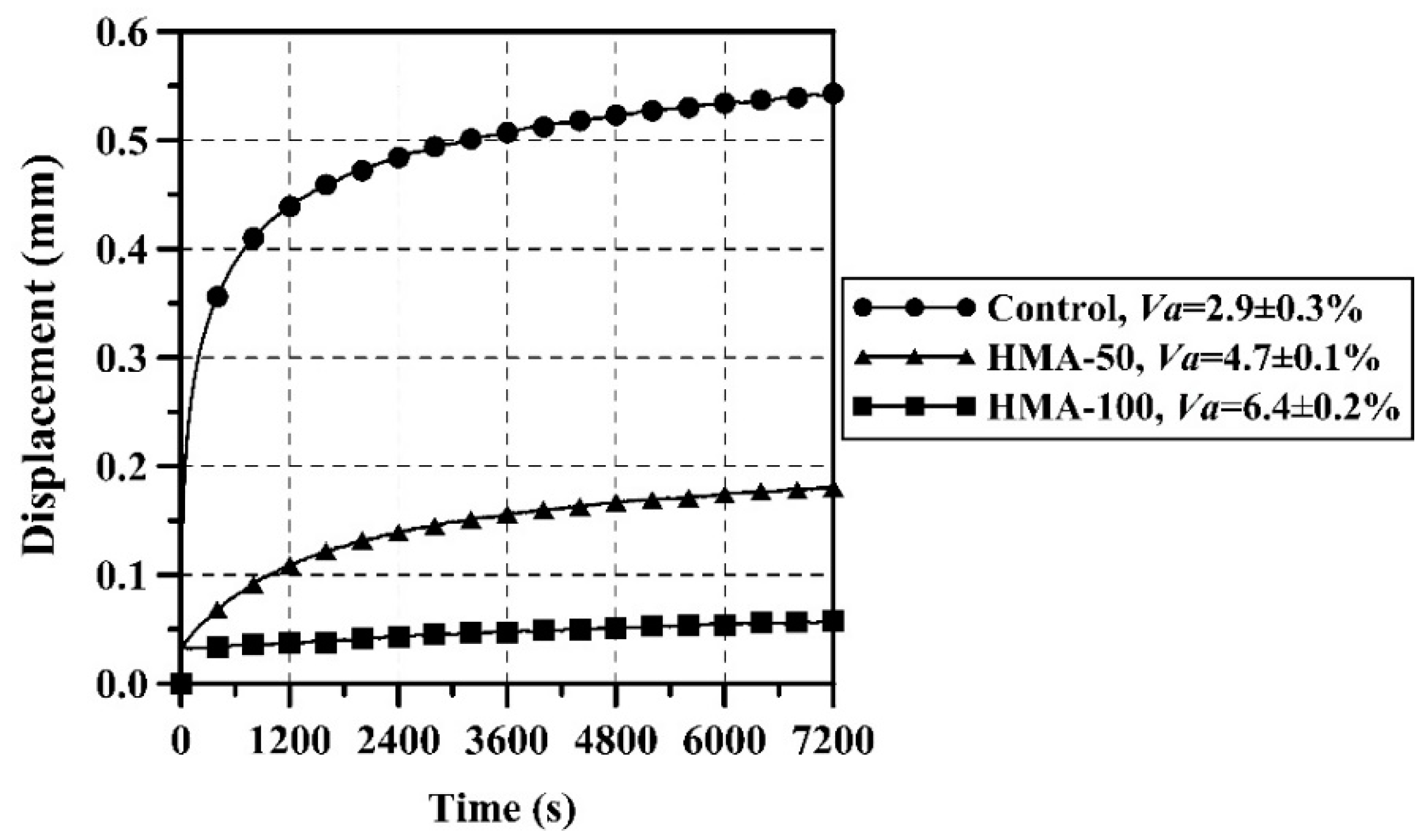

3.4. Resilient Modulus and Static Creep Tests

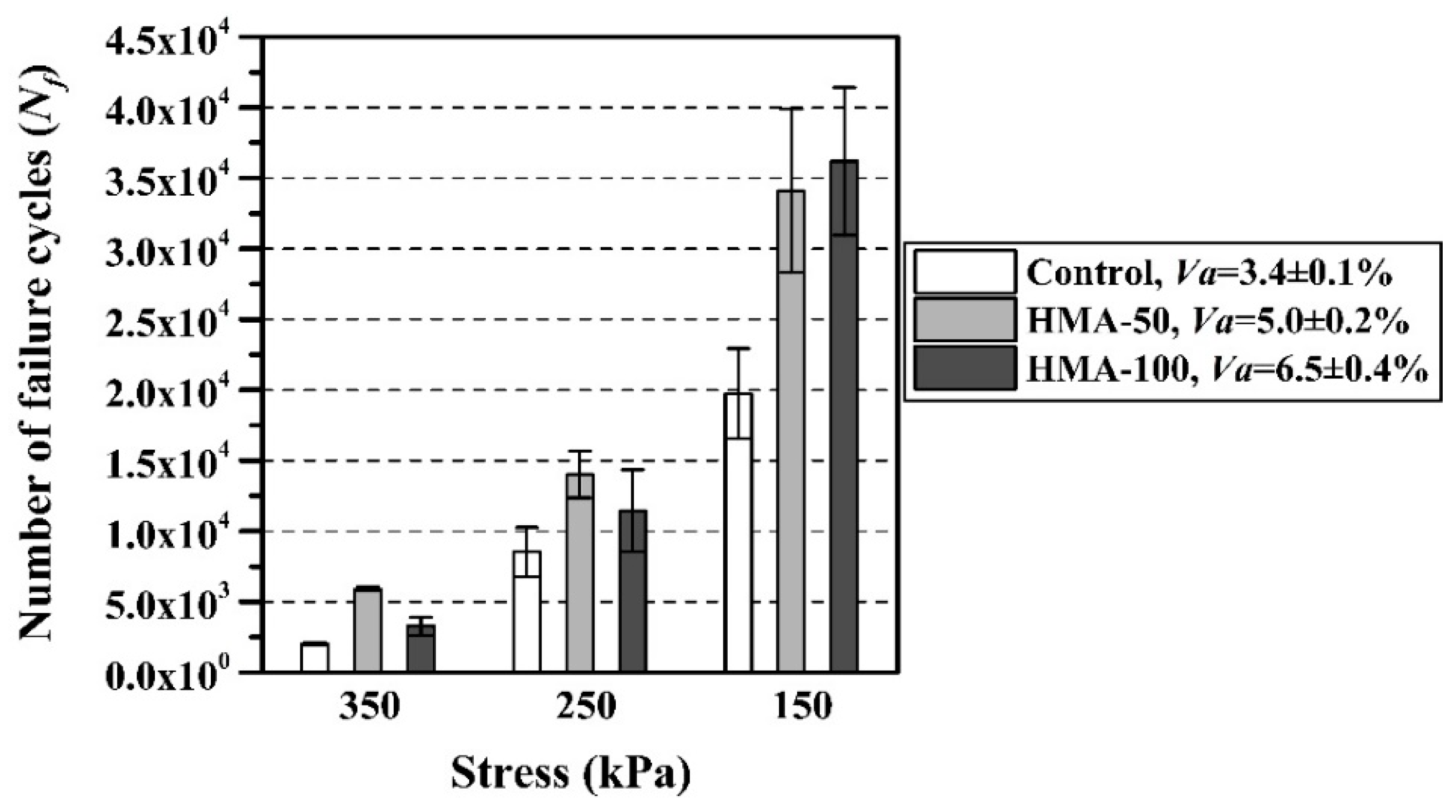

3.5. Fatigue Resistance Test

3.6. Summary of Results

4. Conclusions

- When using ZnO as a replacement for NF, the OAC of the HMA decreases by 0.5%. At this percentage, the HMAs with ZnO (HMA-25, HMA-50, and HMA-100) are more porous (Va increases), but exhibit the following with respect to the Control HMA:

- ○

- Similar resistance under monotonic loading in the Marshall test (similar S and S/F ratio).

- ○

- Increased ITSD, ITSC, and TSR, indicating increased binder–aggregate adhesion, and increased resistance to moisture damage.

- ○

- Similar CL or resistance to abrasion and raveling.

- Under cyclic loading, HMA-50 and HMA-100 exhibit the following:

- ○

- Higher stiffness under cyclic loading (higher RM). However, from a statistical point of view, HMA-50 exhibited higher RM with respect to HMA-100 and Control HMA, while the latter two mixtures tended to experience a similar RM.

- ○

- Higher resistance to permanent deformation measured in the static creep test. This resistance tends to increase with the increasing replacement of NF by ZnO.

- ○

- Higher fatigue resistance under stress-controlled conditions; the highest resistance was obtained with HMA-50.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dan, L.; Chuanfeng, Z.; Yong, Q.; Heng, B.; Keyao, L.; Junfei, H. Analysing the effects of the mesoscopic characteristics of mineral powder fillers on the cohesive strength of asphalt mortars at low temperatures. Constr. Build. Mater. 2014, 65, 330–337. [Google Scholar] [CrossRef]

- Veytskin, Y.; Bobko, C.; Castorena, C.; Kim, Y.R. Nanoindentation investigation of asphalt binder and mastic cohesion. Constr. Build. Mater. 2015, 100, 163–171. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Rondón-Quintana, H.A.; Muniz de Farias, M. Behavior of asphalt mastics containing different materials as filler. Can. J. Civ. Eng. 2021, 48, 347–355. [Google Scholar] [CrossRef]

- Guo, M.; Tan, Y. Interaction between asphalt and mineral fillers and its correlation to mastics’ viscoelasticity. Int. J. Pavement Eng. 2021, 22, 1–10. [Google Scholar] [CrossRef]

- Jia, Y.; Yang, Y.; Zhou, T.; Gao, Y.; Wang, S.; Wei, Z. Stiffening effect of filler on asphalt mastic composite: A new insight based on nearest surface function. Constr. Build. Mater. 2022, 344, 128177. [Google Scholar] [CrossRef]

- Rys, D.; Szydlowski, C. Consideration of pseudo strain energy in determination of fatigue life and microdamage healing of asphalt mastics. Int. J. Fatigue 2024, 181, 108164. [Google Scholar] [CrossRef]

- Tenza-Abril, A.J.; Saval, J.M.; Cuenca, A. Using sewage-sludge ash as filler in bituminous mixes. J. Mater. Civ. Eng. 2015, 27, 04014141. [Google Scholar] [CrossRef]

- Robati, M.; Carter, A.; Perraton, D. New conceptual model for filler stiffening effect on asphalt mastic of microsurfacing. J. Mater. Civ. Eng. 2015, 27, 04015033. [Google Scholar] [CrossRef]

- Al-Khateeb, G.G.; Irfaeya, M.F.; Khedaywi, T.S. A new simplified micromechanical model for asphalt mastic behavior. Constr. Build. Mater. 2017, 149, 587–598. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, S.; Liu, Q.; Xie, J.; Yang, C.; Wan, P.; Guo, S.; Ma, W. Characteristics of calcareous sand filler and its influence on physical and rheological properties of asphalt mastic. Constr. Build. Mater. 2021, 301, 124112. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, S.; Tebaldi, G.; Romeo, E. Role of mineral filler in asphalt mixture. Road Mater. Pavement Des. 2022, 23, 247–286. [Google Scholar] [CrossRef]

- Steineder, M.; Hofko, B. Assessing the impact of filler properties, moisture, and aging regarding fatigue resistance of asphalt mastic. Road Mater. Pavement Des. 2023, 24, 2811–2826. [Google Scholar] [CrossRef]

- Ulutas, K.; Bozoglu, D.; Yakut, S.; Deligoz, H.; Sitilbay, B.; Karasahin, M.; Deger, D. Determination of optimum limestone filler content in asphalt mastic by dielectric spectroscopy. Road Mater. Pavement Des. 2024, 25, 2772–2787. [Google Scholar] [CrossRef]

- Antunes, V.; Freire, A.C.; Quaresma, L.; Micaelo, R. Influence of the geometrical and physical properties of filler in the filler–bitumen interaction. Constr. Build. Mater. 2015, 76, 322–329. [Google Scholar] [CrossRef]

- Antunes, V.; Freire, A.C.; Quaresma, L.; Micaelo, R. Effect of the chemical composition of fillers in the filler–bitumen interaction. Constr. Build. Mater. 2016, 104, 85–91. [Google Scholar] [CrossRef]

- Pei, J.; Fan, Z.; Wang, P.; Zhang, J.; Xue, B.; Li, R. Micromechanics prediction of effective modulus for asphalt mastic considering inter-particle interaction. Constr. Build. Mater. 2015, 101, 209–216. [Google Scholar] [CrossRef]

- Cheng, Y.; Tao, J.; Jiao, Y.; Tan, G.; Guo, Q.; Wang, S.; Ni, P. Influence of the properties of filler on high and medium temperature performances of asphalt mastic. Constr. Build. Mater. 2016, 118, 268–275. [Google Scholar] [CrossRef]

- Zulkati, A.; Diew, W.Y.; Delai, D.S. Effects of fillers on properties of asphalt-concrete mixture. J. Transp. Eng. 2012, 138, 902–910. [Google Scholar] [CrossRef]

- Das, A.K.; Singh, D. Investigation of rutting, fracture and thermal cracking behavior of asphalt mastic containing basalt and hydrated lime fillers. Constr. Build. Mater. 2017, 141, 442–452. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Utilization of solid waste materials as alternative fillers in asphalt mixes: A review. Constr. Build. Mater. 2020, 234, 117271. [Google Scholar] [CrossRef]

- Wu, W.; Jiang, W.; Yuan, D.; Lu, R.; Shan, J.; Xiao, J.; Ogbon, A.W. A review of asphalt-filler interaction: Mechanisms, evaluation methods, and influencing factors. Constr. Build. Mater. 2021, 299, 124279. [Google Scholar] [CrossRef]

- Wei, Z.; Jia, Y.; Wang, S.; Zhou, Z.; Zhang, Z.; Wang, X.; Huang, X.; Gao, Y. Influence of iron tailing filler on rheological behavior of asphalt mastic. Constr. Build. Mater. 2022, 352, 129047. [Google Scholar] [CrossRef]

- Belayali, F.; Maherzi, W.; Benzerzour, M.; Abriak, N.E. Influence of the physical and chemical characteristics of sediment fillers on the properties of mastic asphalt. Powder Technol. 2023, 421, 118393. [Google Scholar] [CrossRef]

- Mwanza, A.D.; Hao, P.; Wang, H. Effects of type and content of mineral fillers on the consistency properties of asphalt mastic. J. Test. Eval. 2012, 40, 1094–1102. [Google Scholar] [CrossRef]

- Nassar, A.I.; Mohammed, M.K.; Thom, N.; Parry, T. Mechanical, durability and microstructure properties of Cold Asphalt Emulsion Mixtures with different types of filler. Constr. Build. Mater. 2016, 114, 352–363. [Google Scholar] [CrossRef]

- Lesueur, D.; Teixeira, A.; Lázaro, M.M.; Andaluz, D.; Ruiz, A. A simple test method in order to assess the effect of mineral fillers on bitumen ageing. Constr. Build. Mater. 2016, 117, 182–189. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Ruge, J.C.; Patiño, D.F.; Vacca, H.A.; Reyes, F.A.; Muniz de Farias, M. Use of blast furnace slag as a substitute for the fine fraction of aggregates in an asphalt mixture. J. Mater. Civ. Eng. 2018, 30, 04018244. [Google Scholar] [CrossRef]

- Al-Mistarehi, B.W.; Khadaywi, T.S.; Hussein, A.K. Investigating the effects on creep and fatigue behavior of asphalt mixtures with recycled materials as fillers. J. King Saud U—Eng. Sci. 2021, 33, 355–363. [Google Scholar] [CrossRef]

- Wei, Z.; Jia, Y.; Wang, S.; Li, Z.; Li, Y.; Wang, X.; Gao, Y. Utilization of iron ore tailing as an alternative mineral filler in asphalt mastic: High-temperature performance and environmental aspects. J. Clean Prod. 2022, 335, 130318. [Google Scholar] [CrossRef]

- Zhong, T.; Zheng, Y.; Chen, Z.; Yao, L.; Zhang, W.; Zhu, Y.; Fu, L. Utilization of steel slag as coarse aggregate and filler in stone mastic asphalt (SMA) mixture: Engineering performance, environmental impact and economic benefits analysis. J. Clean Prod. 2024, 450, 141891. [Google Scholar] [CrossRef]

- Ipekyol, A.; Tortum, A.; Rasouli, R.; Yazdani, M. Evaluating fatigue and crack resistance of asphalt mixture containing zinc tailing aggregates. Case Stud. Constr. Mater. 2022, 17, e01384. [Google Scholar] [CrossRef]

- Patnaik, P. Handbook of Inorganic Chemicals; McGraw Hill: New York, NY, USA, 2003. [Google Scholar]

- Yang, L.; Zhou, J.E. Preparation and characterization of nano-zinc oxide. J. Mater. Process Technol. 2007, 189, 379–383. [Google Scholar] [CrossRef]

- Mueller, N.C.; Nowack, B. Exposure modeling of engineered nanoparticles in the environment. Environ. Sci. Technol. 2008, 42, 4447–4453. [Google Scholar] [CrossRef]

- Rocha Segundo, I.; Ferreira, C.; Freitas, E.F.; Carneiro, J.O.; Fernandes, F.; Landi Júnior, S.; Costa, M.F. Assessment of photocatalytic, superhydrophobic and self-cleaning properties on hot mix asphalts coated with TiO2 and/or ZnO aqueous solutions. Constr. Build. Mater. 2018, 166, 500–509. [Google Scholar] [CrossRef]

- Le Pivert, M.; Kerivel, O.; Zerelli, B.; Leprince-Wang, Y. ZnO nanostructures based innovative photocatalytic road for air purification. J. Clean Prod. 2021, 318, 128447. [Google Scholar] [CrossRef]

- Rad, S.M.; Kamboozia, N.; Ameri, M.; Mirabdolazimi, S.M. Feasibility of concurrent improvement of pollutants-absorption ability from surface runoff and mechanical performance of asphalt mixtures by using photocatalytic nanomodified porous asphalt. J. Mater. Civ. Eng. 2023, 35, 04023248. [Google Scholar] [CrossRef]

- Porter, F. Zinc Handbook: Properties, Processing, and Use in Design; Marcel Dekker: New York, NY, USA, 1991. [Google Scholar]

- Klingshirn, C. ZnO: Material, physics and applications. Chem. Phys. Chem. 2007, 8, 782–803. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, Y.; Guo, G.; Zhao, B.; Yu, J. Effects of ZnO particle size on properties of asphalt and asphalt mixture. Constr. Build. Mater. 2018, 159, 578–586. [Google Scholar] [CrossRef]

- Neto, V.F.; Silva, I.M.; Lucena, L.C.; Lucena, A.E.; Neto, O.; de Lima, R.K.B. Effect of superficially modified zinc oxide nanoparticles as an additive on the rheological performance of asphalt binder. Road Mater. Pavement Des. 2024, 25, 1211–1228. [Google Scholar] [CrossRef]

- Moezzi, A.; McDonagh, A.M.; Cortie, M.B. Zinc oxide particles: Synthesis, properties and applications. Chem. Eng. J. 2012, 185–186, 1–22. [Google Scholar] [CrossRef]

- Li, R.; Pei, J.; Sun, C. Effect of nano-ZnO with modified surface on properties of bitumen. Constr. Build. Mater. 2015, 98, 656–661. [Google Scholar] [CrossRef]

- Ashish, P.K.; Singh, D. High-and intermediate-temperature performance of asphalt binder containing carbon nanotube using different rheological approaches. J. Mater. Civil Eng. 2018, 30, 04017254. [Google Scholar] [CrossRef]

- Debbarma, K.; Debnath, B.; Sarkar, P.P. A comprehensive review on the usage of nanomaterials in asphalt mixes. Constr. Build. Mater. 2022, 361, 129634. [Google Scholar] [CrossRef]

- Duan, H.; Long, J.; Zhang, H.; Luo, H.; Cao, J. Effects of different carriers for zinc oxide (ZnO) particles on microstructure of ZnO/layered silicate composite and aging resistance of composite modified asphalt. Constr. Build. Mater. 2022, 349, 128773. [Google Scholar] [CrossRef]

- Feng, L.; Zhao, P.; Chen, T.; Jing, M. Comparative study of Octavinyl Oligomeric Sesquisiloxane nanomaterial-modified asphalt using Molecular Dynamics Method. Polymers 2022, 14, 4577. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Ruge-Cárdenas, J.C.; Zafra-Mejía, C.A. The use of zinc oxide in asphalts: Review. Sustainability 2023, 15, 11070. [Google Scholar] [CrossRef]

- Pandhawale, S.S.; Jain, S.; Chandrappa, A.K.; Kari, V. UV aging assessment of asphalt binder: Influence of duration, zinc oxide, and aging condition. Int. J. Pavement Eng. 2024, 25, 2359537. [Google Scholar] [CrossRef]

- Du, P.F.; Ke, N.X.; Zhang, H.L. Effect of nano-zinc oxide on the morphology and ultraviolet aging properties of various bitumens. Pet. Sci. Technol. 2015, 33, 1110–1117. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.; Yu, J.; Tan, B.; Shi, C. Effect of nano-zinc oxide on ultraviolet aging properties of bitumen with 60/80 penetration grade. Mater. Struct. 2015, 48, 3249–3257. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.; Kuang, D. Physical, rheological, and aging properties of bitumen containing organic expanded vermiculite and nano-zinc oxide. J. Mater. Civ. Eng. 2016, 28, 04015203. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, H.; Shi, C.; Li, S. Effect of nano-zinc oxide and organic expanded vermiculite on rheological properties of different bitumens before and after aging. Constr. Build. Mater. 2017, 146, 30–37. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, H.; Xu, G.; Wu, C. Investigation of the aging behaviors of multi-dimensional nanomaterials modified different bitumens by Fourier transform infrared spectroscopy. Constr. Build. Mater. 2018, 167, 536–542. [Google Scholar] [CrossRef]

- Nazari, H.; Naderi, K.; Nejad, F.M. Improving aging resistance and fatigue performance of asphalt binders using inorganic nanoparticles. Constr. Build. Mater. 2018, 170, 591–602. [Google Scholar] [CrossRef]

- Xu, X.; Guo, H.; Wang, X.; Zhang, M.; Wang, Z.; Yang, B. Physical properties and anti-aging characteristics of asphalt modified with nano-zinc oxide powder. Constr. Build. Mater. 2019, 224, 732–742. [Google Scholar] [CrossRef]

- Fu, Z.; Tang, Y.; Ma, F.; Wang, Y.; Dai, S.J.; Hou, Y.; Li, J. Rheological properties of asphalt binder modified by nano-TiO2/ZnO and basalt fiber. Constr. Build. Mater. 2022, 320, 126323. [Google Scholar] [CrossRef]

- Di, H.; Zhang, H.; Yang, E.; Ding, H.; Liu, H.; Huang, B.; Qiu, Y. Usage of Nano-TiO2 or Nano-ZnO in asphalt to resist aging by NMR spectroscopy and rheology technology. J. Mater. Civ. Eng. 2023, 35, 04022391. [Google Scholar] [CrossRef]

- Han, D.; Hu, G.; Zhang, J. Study on anti-aging performance enhancement of polymer modified asphalt with high linear SBS content. Polymers 2023, 15, 256. [Google Scholar] [CrossRef]

- Staub de Melo, J.V.; Manfro, A.L.; Barra, B.S.; Dell’Antonio Cadorin, N.; Broering, B.W. Evaluation of the rheological behavior and the development of performance equations of asphalt composites produced with titanium dioxide and zinc oxide nanoparticles. Nanomaterials 2023, 13, 288. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Zafra-Mejía, C.A.; Urazán-Bonells, C.F. Aging resistance evaluation of an asphalt mixture modified with zinc oxide. Infrastructures 2024, 9, 81. [Google Scholar] [CrossRef]

- Zhu, Q.; He, Z.; Wang, J.; Wang, S. Morphology, rheology and physical properties investigations of multi-scale nano-zinc oxide modified asphalt binder. Alex. Eng. J. 2024, 89, 31–38. [Google Scholar] [CrossRef]

- He, Z.; Xie, T.; Li, Q.; Wang, P. Physical and antiaging properties of rodlike Nano-ZnO–modified asphalt. J. Mater. Civ. Eng. 2021, 33, 04021316. [Google Scholar] [CrossRef]

- Du, P.; Long, J.; Duan, H.; Luo, H.; Zhang, H. Laboratory performance and aging resistance evaluation of zinc oxide/expanded vermiculite composite modified asphalt binder and mixture. Constr. Build. Mater. 2022, 358, 129385. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Nejad, F.M. The employment of thermodynamic and mechanical methods to evaluate the impact of nanomaterials on moisture damage of HMA. Mater. Struct. 2016, 49, 4483–4495. [Google Scholar] [CrossRef]

- Saltan, M.; Terzi, S.; Karahancer, S. Mechanical behavior of bitumen and hot-mix asphalt modified with zinc oxide nanoparticle. J. Mater. Civ. Eng. 2019, 31, 04018399. [Google Scholar] [CrossRef]

- Fakhri, M.; Shahryari, E. The effects of nano zinc oxide (ZnO) and nano reduced graphene oxide (RGO) on moisture susceptibility property of stone mastic asphalt (SMA). Case Stud. Constr. Mater. 2021, 15, e00655. [Google Scholar] [CrossRef]

- Guo, G.; Zhang, H. The effect of morphology of ZnO particle on properties of asphalt binder and mixture. Int. J. Transp. Sci. Technol. 2022, 11, 437–454. [Google Scholar] [CrossRef]

- Al-Mistarehi, B.; Al-Omari, A.; Taamneh, M.; Imam, R.; Khafaja, D.A. The effects of adding nano clay and nano zinc oxide on asphalt cement rheology. J. King Saud Univ. Eng. Sci. 2021, 35, 260–269. [Google Scholar] [CrossRef]

- De Sousa Neto, V.F.; de Figueirêdo, L.C.; de Barros, A.G.; de Figueirêdo, A.E.; Filho, P.G. Rheological evaluation of asphalt binder modified with zinc oxide nanoparticles. Case Stud. Constr. Mater. 2022, 17, e01224. [Google Scholar] [CrossRef]

- IDU–Instituto de Desarrollo Urbano. Especificaciones Técnicas Generales de Materiales y Construcción, para Proyectos de Infraestructura Vial y de Espacio Público, para Bogotá DC; IDU: Bogotá, Colombia, 2018. [Google Scholar]

- INVIAS–Instituto Nacional de Vías. Especificaciones Generales de Construcción de Carreteras; INVIAS–Instituto Nacional de Vías: Bogotá, Colombia, 2020. [Google Scholar]

- Huang, H.; Wang, Y.; Wu, X.; Zhang, J.; Huang, X. Nanomaterials for modified asphalt and their effects on viscosity characteristics: A comprehensive review. Nanomaterials 2024, 14, 1503. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.; Yu, J.; Shi, C.; Zhang, D. Influence of surface modification on physical and ultraviolet aging resistance of bitumen containing inorganic nanoparticles. Constr. Build. Mater. 2015, 98, 735–740. [Google Scholar] [CrossRef]

- Zhu, C.; Li, D.; Zhang, H.; Wang, Z.; Li, J. Synergistic effect of surface modified nano-zinc oxide and organic vermiculite on long-term ultraviolet and thermal-oxidative aging resistance of different asphalt binders. Constr. Build. Mater. 2023, 409, 133832. [Google Scholar] [CrossRef]

- Witczak, M.W.; Kaloush, K.; Pellinen, T.; El-Basyouny, M.; Von Quintus, H. Simple Performance Test for Superpave Mix Design; NCHRP Rep. 465; Transportation Research Board: Washington, DC, USA, 2002; p. 114. [Google Scholar]

- Rondón-Quintana, H.A.; Ruge-Cardenas, J.C.; Muniz de Farias, M. Behavior of a hot mix asphalt containing blast furnace slag as aggregate: Evaluation by mass and volume substitution. J. Mater. Civ. Eng. 2019, 31, 04018364. [Google Scholar] [CrossRef]

- Sejin-Garces, J.E.; Ahumada-Navarro, G.; Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Bastidas-Martínez, J.G. Mechanical strength of an hot-mix asphalt using recycled concrete aggregate: Mass and volume proportioning. Road Mater. Pavement Des. 2024, 26, 536–558. [Google Scholar] [CrossRef]

- Kanitpong, K.; Charoentham, N.; Likitlersuang, S. Investigation on the effects of gradation and aggregate type to moisture damage of warm mix asphalt modified with Sasobit. Int. J. Pavement Eng. 2012, 13, 451–458. [Google Scholar] [CrossRef]

- Du, Z.; Zhu, X.Y. Molecular dynamics simulation to investigate the adhesion and diffusion of asphalt binder on aggregate surfaces. Transport. Res. Rec. 2019, 2673, 500–512. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Liu, G.; Pei, J. Effects of material characteristics on asphalt and filler interaction ability. Int. J. Pavement Eng. 2019, 20, 928–937. [Google Scholar] [CrossRef]

- Su, M.; Ding, Q.; Zhang, G.; Zhao, Q. Study on the properties and morphology of nano-ZnO modified asphalt based on Molecular Dynamics and experiments. Coatings 2023, 13, 1163. [Google Scholar] [CrossRef]

- Guo, F.C.; Pei, J.Z.; Zhang, J.P.; Xue, B.; Sun, G.Q.; Li, R. Study on the adhesion property between asphalt binder and aggregate: A state-of-the-art review. Constr. Build. Mater. 2020, 256, 119474. [Google Scholar] [CrossRef]

- Yin, Y.P.; Chen, H.X.; Kuang, D.L.; Song, L.F.; Wang, L. Effect of chemical composition of aggregate on interfacial adhesion property between aggregate and asphalt. Constr. Build. Mater. 2017, 146, 231–237. [Google Scholar] [CrossRef]

- Al-Rawashdeh, A.S.; Sargand, S. Performance assessment of a warm asphalt binder in the presence of water by using surface free energy concepts and nanoscale techniques. J. Mater. Civ. Eng. 2014, 26, 803–811. [Google Scholar] [CrossRef]

- Modarres, A.; Rahmanzadeh, M. Application of coal waste powder as filler in hot mix asphalt. Constr. Build. Mater. 2014, 66, 476–483. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I. The influence of the mineral filler on the adhesion between aggregates and bitumen. Int. J. Adhes. Adhes. 2015, 58, 53–58. [Google Scholar] [CrossRef]

- Lim, S.M.; He, M.; Hao, G.; Ng, T.C.A.; Ong, G.P. Recyclability potential of waste plastic-modified asphalt concrete with consideration to its environmental impact. Constr. Build. Mater. 2024, 439, 137299. [Google Scholar] [CrossRef]

- Kodsangma, A.; Thajai, N.; Punyodom, W.; Worajittiphon, P.; Jantrawut, P.; Ruksiriwanich, W.; Sommano, S.R.; Sringarm, K.; Thanakkasaranee, S.; Rachtanapun, P.; et al. Mechanical properties and water resistance improvement of thermoplastic modified starch, carboxymethyl cellulose, and zinc oxide nanometal particles by reactive blending. Int. J. Biol. Macromol. 2023, 253(Part 3), 126783. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Rondón-Quintana, H.A. Assessment of asphalt binder content, temperature and loading rate in indirect tensile strength and resilient modulus tests of a hot-mix asphalt—Comparison with Marshall design method. Constr. Build. Mater. 2024, 426, 136158. [Google Scholar] [CrossRef]

- Farhan, F.K.; Al-Ramadhan, Z.; Hussein, W.A.A.A. Electrical and mechanical properties of ZnO/(UPE-PMMA) blend nanocomposites. Int. J. Compos. Mater. 2017, 7, 46–50. [Google Scholar]

- Nawaz, A.; Farhan, A.; Maqbool, F.; Ahmad, H.; Qayyum, W.; Ghazy, E.; Rahdar, A.; Díez-Pascual, A.M.; Fathi-karkan, S. Zinc oxide nanoparticles: Pathways to micropollutant adsorption, dye removal, and antibacterial actions—A study of mechanisms, challenges, and future prospects. J. Molec. Struct. 2024, 1312(Part 1), 138545. [Google Scholar] [CrossRef]

- Bakhori, S.K.M.; Mahmud, S.; Mohamad, D.; Masudi, S.M.; Seeni, A. Surface morphological and mechanical properties of zinc oxide eugenol using different types of ZnO nanopowder. Mater. Sci. Eng. C 2019, 100, 645–654. [Google Scholar] [CrossRef]

- Arif, M.; Rauf, A.; Akhter, T. A comprehensive review on crosslinked network systems of zinc oxide-organic polymer composites. Int. J. Biol. Macromol. 2024, 274 Pt 1, 133250. [Google Scholar] [CrossRef]

- Barman, M.; Ghabchi, R.; Singh, D.; Zaman, M.; Commuri, S. An alternative analysis of indirect tensile test results for evaluating fatigue characteristics of asphalt mixes. Constr. Build. Mater. 2018, 166, 204–213. [Google Scholar] [CrossRef]

- Bastidas-Martinez, J.G.; Camapum de Carvalho, J.; Cristhiane, L.L.; Muniz de Farias, M.; Rondón-Quintana, H.A. Effects of iron ore tailing on performance of hot-mix asphalt. J. Mater. Civ. Eng. 2022, 34, 04021405. [Google Scholar] [CrossRef]

- Bharath, G.; Reddy, K.S.; Tandon, V.; Reddy, M.A. Aggregate gradation effect on the fatigue performance of recycled asphalt mixtures. Road Mater. Pavement Des. 2021, 22, 165–184. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Ruge-Cárdenas, J.C.; Reyes-Lizcano, F.A.; Bastidas-Martínez, J.G.; Zafra-Mejía, C.A. Mechanical resistance of hot-mix asphalt using phosphorite as filler. J. Mater. Civ. Eng. 2023, 35, 04023274. [Google Scholar] [CrossRef]

| Test (Standard), Unit | Requirement | Value |

|---|---|---|

| Abrasion in Los Angeles machine (AASHTO T96), in % | 25% maximum | 22.7 |

| Micro-Deval (AASHTO T327), % | 20% maximum | 18.6 |

| 10% of fines—dry (DNER-ME 096), kN | 110 kN minimum | 122.5 |

| 10% of fines—wet (DNER-ME 096), kN | 82.5 kN minimum | 108.9 |

| Soundness of aggregate (AASHTO T104), in % | 18.0% maximum | 5.30 |

| Specific gravity (fine aggregate; AASHTO T84), in - | - | 2.652 |

| Absorption (fine aggregate; AASHTO T84), in % | - | 1.65 |

| Specific gravity (coarse aggregate; AASHTO T85), in - | - | 2.671 |

| Absorption (coarse aggregate; AASHTO T85), in % | - | 1.88 |

| Fractured particles (ASTM D5821), in % | 85% minimum | 92.7 |

| Test (Standard), Unit | Requirement | Value |

|---|---|---|

| Virgin asphalt | ||

| Penetration (ASTM D5), in dmm | 60–70 | 61.6 |

| Softening point (ASTM D36), in °C | 48–54 | 48.7 |

| Ductility (ASTM D113), in cm | 100 minimum | 128 |

| Viscosity at 135 °C (ASTM D 4402), in Poises | 4 minimum | 4.72 |

| Penetration Index (NLT 181), in - | −1.2 at +0.6 | −1.05 |

| Specific gravity (AASHTO T 228), in - | - | 1.024 |

| Flash and fire points (ASTM D92), in °C | 230 minimum | 288 |

| After Rolling Thin Film Oven Test | ||

| Mass loss (ASTM D2872), in % | 0.8 maximum | 0.22 |

| Penetration (ASTM D5), in % | 50 minimum | 82.8 |

| Increase in softening point (ASTM D36), in °C | 9 maximum | 2.3 |

| Test | Parameter | Asphalt Mix Type | |||

|---|---|---|---|---|---|

| Control | HMA-25 | HMA-50 | HMA-100 | ||

| ITS | ITSD (kPa) | 3 | 3 | 3 | 3 |

| ITSC (kPa) | 3 | 3 | 3 | 3 | |

| Cantabro | CL (%) | 3 | 3 | 3 | 3 |

| RM | RM (MPa) | 3 | - | 3 | 3 |

| Static creep | Displacement (mm) | 3 | - | 3 | 3 |

| Fatigue | Nf (-) to σ = 150 kPa | 3 | - | 3 | 3 |

| Fatigue | Nf (-) to σ = 250 kPa | 3 | - | 3 | 3 |

| Fatigue | Nf (-) to σ = 350 kPa | 3 | - | 3 | 3 |

| Comparison | S | S/F | Va |

|---|---|---|---|

| FT | |||

| Control (AC = 5.5%) vs. 25% (AC = 5.0%) | 0.92 | 5.26 | 187.7 * |

| Control (AC = 5.5%) vs. 50% (AC = 5.0%) | 1.57 | 0.001 | 105.9 * |

| Control (AC = 5.5%) vs. 100% (AC = 5.0%) | 3.51 | 1.91 | 1316.3 * |

| Comparison | ITSD | ITSC | CL |

|---|---|---|---|

| Control (AC = 5.5%) vs. HMA-25 (AC = 5.0%) | 20.4 * | 51.5 * | 1.50 |

| Control (AC = 5.5%) vs. HMA-50 (AC = 5.0%) | 52.0 * | 794.4 * | 1.59 |

| Control (AC = 5.5%) vs. HMA-100 (AC = 5.0%) | 31.0 * | 59.5 * | 0.53 |

| HMA-25 (AC = 5.0%) vs. HMA-50 (AC = 5.0%) | 26.0 * | 270.1 * | 2.96 |

| HMA-25 (AC = 5.0%) vs. HMA-100 (AC = 5.0%) | 17.8 * | 19.2 * | 0.11 |

| HMA-50 (AC = 5.0%) vs. HMA-100 (AC = 5.0%) | 8.3 * | 2.7 | 1.54 |

| Comparison | 2.5 Hz | 5.0 Hz | 10.0 Hz |

|---|---|---|---|

| FT | |||

| Control vs. HMA-50 | 118.1 * | 53.1 * | 11.0 * |

| Control vs. HMA-100 | 37.5 * | 4.0 | 0.03 |

| HMA-50 vs. HMA-100 | 2.3 | 37.4 * | 18.0 |

| Comparison | 350 kPa | 250 kPa | 150 kPa |

|---|---|---|---|

| FT | |||

| Control vs. HMA-50 | 3523.9 * | 31.10 * | 28.20 * |

| Control vs. HMA-100 | 21.71 * | 4.49 | 43.36 * |

| HMA-50 vs. HMA-100 | 91.66 * | 3.56 | 0.43 |

| Test | Parameter | Qualitative Value | ||

|---|---|---|---|---|

| Control | HMA-50 | HMA-100 | ||

| Marshall | S (kN) | 1 | 3 | 2 |

| S/F (kN/mm) | 2 | 3 | 1 | |

| ITS | ITSD (kPa) | 1 | 2 | 3 |

| ITSC (kPa) | 1 | 3 | 2 | |

| TSR (%) | 1 | 3 | 2 | |

| Cantabro | CL (%) | 2 | 1 | 3 |

| Resilient Modulus | RM (MPa) | 1 | 3 | 2 |

| Static creep | D (mm) | 3 | 2 | 1 |

| DR (mm/s) | 3 | 2 | 1 | |

| Fatigue | Nf (-) to σ = 150 kPa | 1 | 2 | 3 |

| Fatigue | Nf (-) to σ = 250 kPa | 1 | 3 | 2 |

| Fatigue | Nf (-) to σ = 350 kPa | 1 | 3 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rondón-Quintana, H.A.; Forero-Rubiano, K.T.; Valderrama-Agudelo, Y.S.; Bastidas-Martínez, J.G.; Zafra-Mejía, C.A. Zinc Oxide as a Filler in a Hot-Mix Asphalt: Impact on Mechanical Properties. Infrastructures 2025, 10, 110. https://doi.org/10.3390/infrastructures10050110

Rondón-Quintana HA, Forero-Rubiano KT, Valderrama-Agudelo YS, Bastidas-Martínez JG, Zafra-Mejía CA. Zinc Oxide as a Filler in a Hot-Mix Asphalt: Impact on Mechanical Properties. Infrastructures. 2025; 10(5):110. https://doi.org/10.3390/infrastructures10050110

Chicago/Turabian StyleRondón-Quintana, Hugo Alexander, Karem Tatiana Forero-Rubiano, Yohan Sebastián Valderrama-Agudelo, Juan Gabriel Bastidas-Martínez, and Carlos Alfonso Zafra-Mejía. 2025. "Zinc Oxide as a Filler in a Hot-Mix Asphalt: Impact on Mechanical Properties" Infrastructures 10, no. 5: 110. https://doi.org/10.3390/infrastructures10050110

APA StyleRondón-Quintana, H. A., Forero-Rubiano, K. T., Valderrama-Agudelo, Y. S., Bastidas-Martínez, J. G., & Zafra-Mejía, C. A. (2025). Zinc Oxide as a Filler in a Hot-Mix Asphalt: Impact on Mechanical Properties. Infrastructures, 10(5), 110. https://doi.org/10.3390/infrastructures10050110