Rice Husk Ash and Waste Marble Powder as Alternative Materials for Cement

Abstract

1. Introduction

2. Materials and Methods

2.1. RHA and WMP

2.2. Properties of Binders

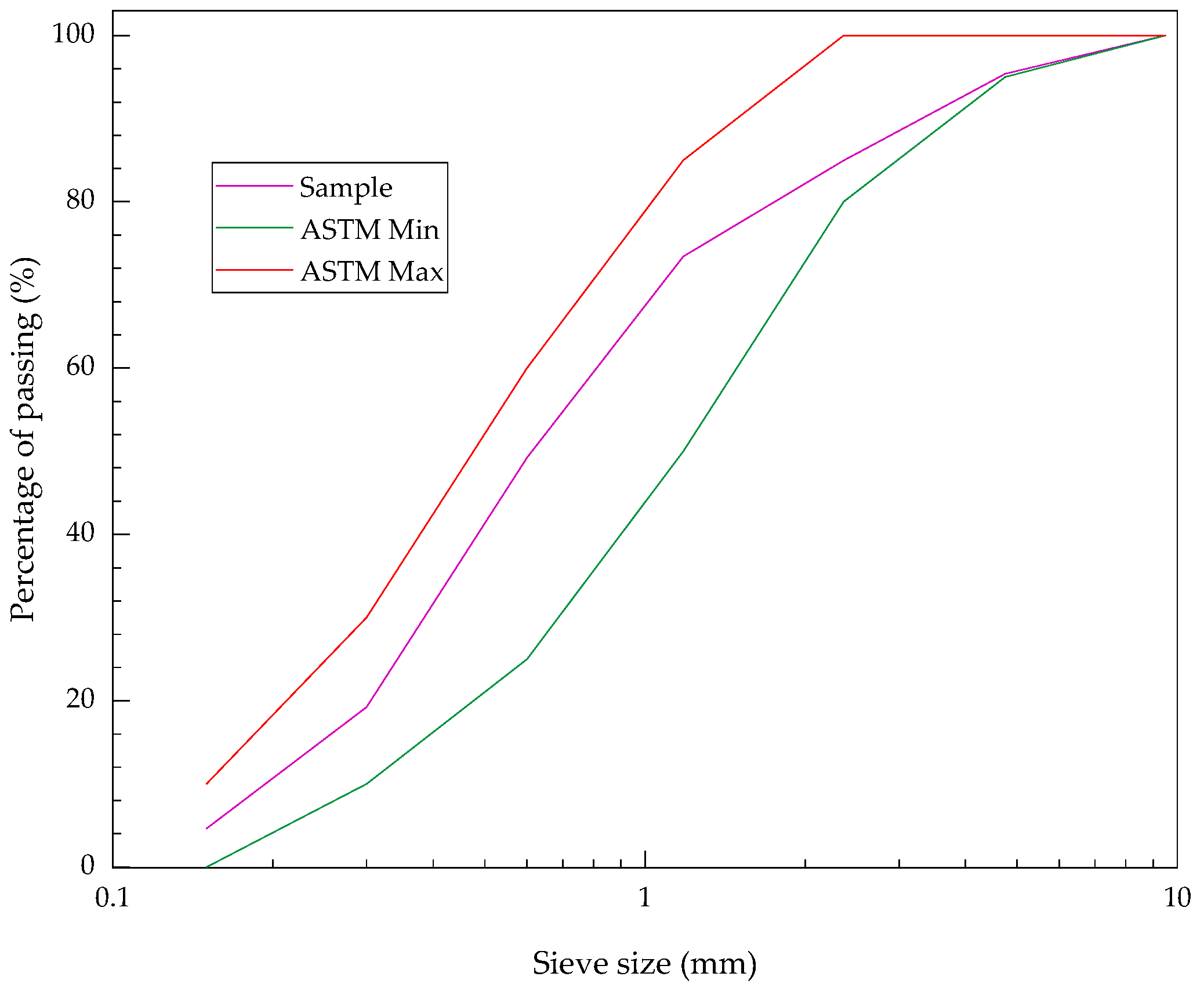

2.3. Fine Aggregates

2.4. Mix Design

2.5. Tests Conducted

3. Results and Discussion

3.1. Fresh Properties

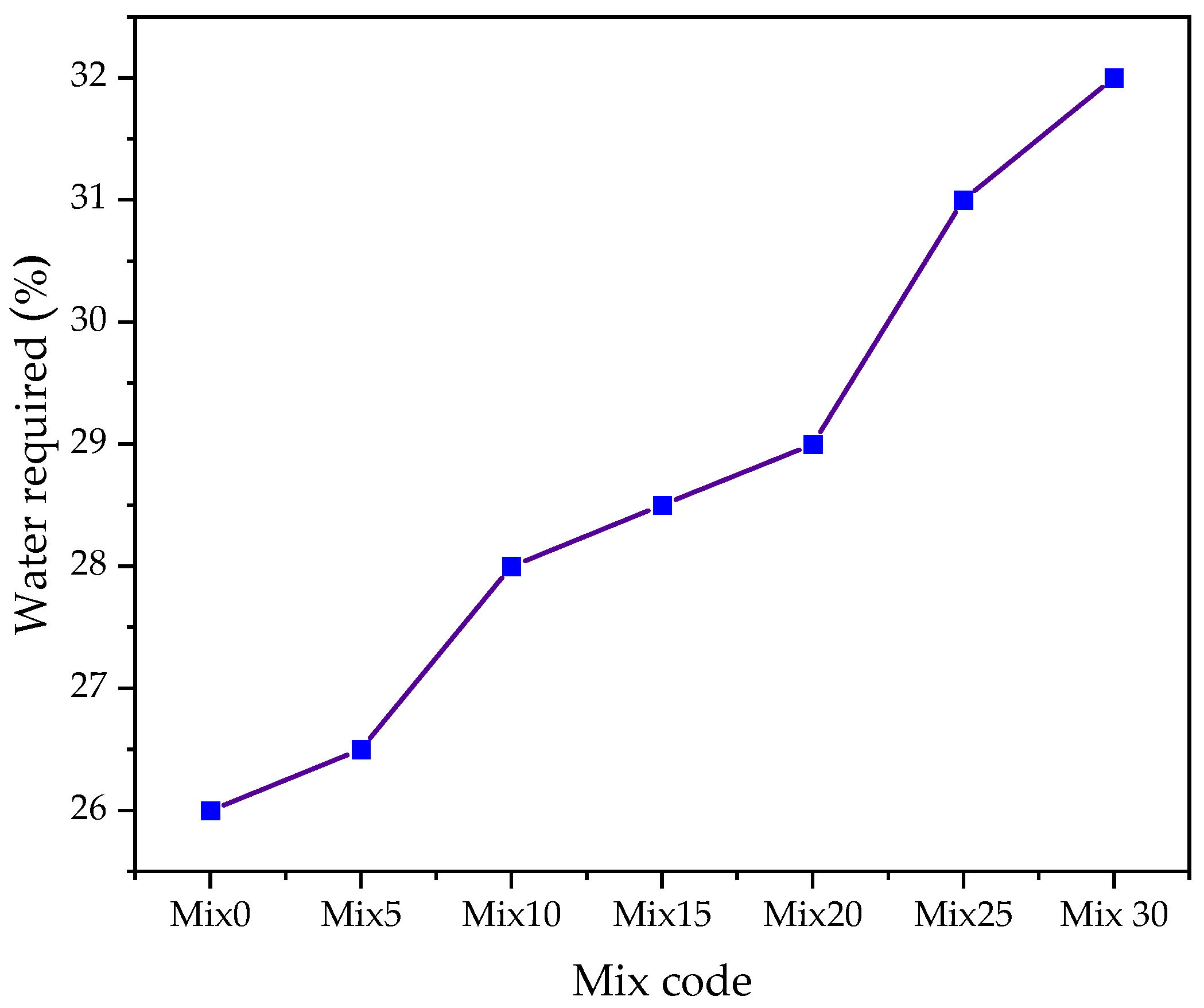

3.1.1. Consistency

3.1.2. Setting Time

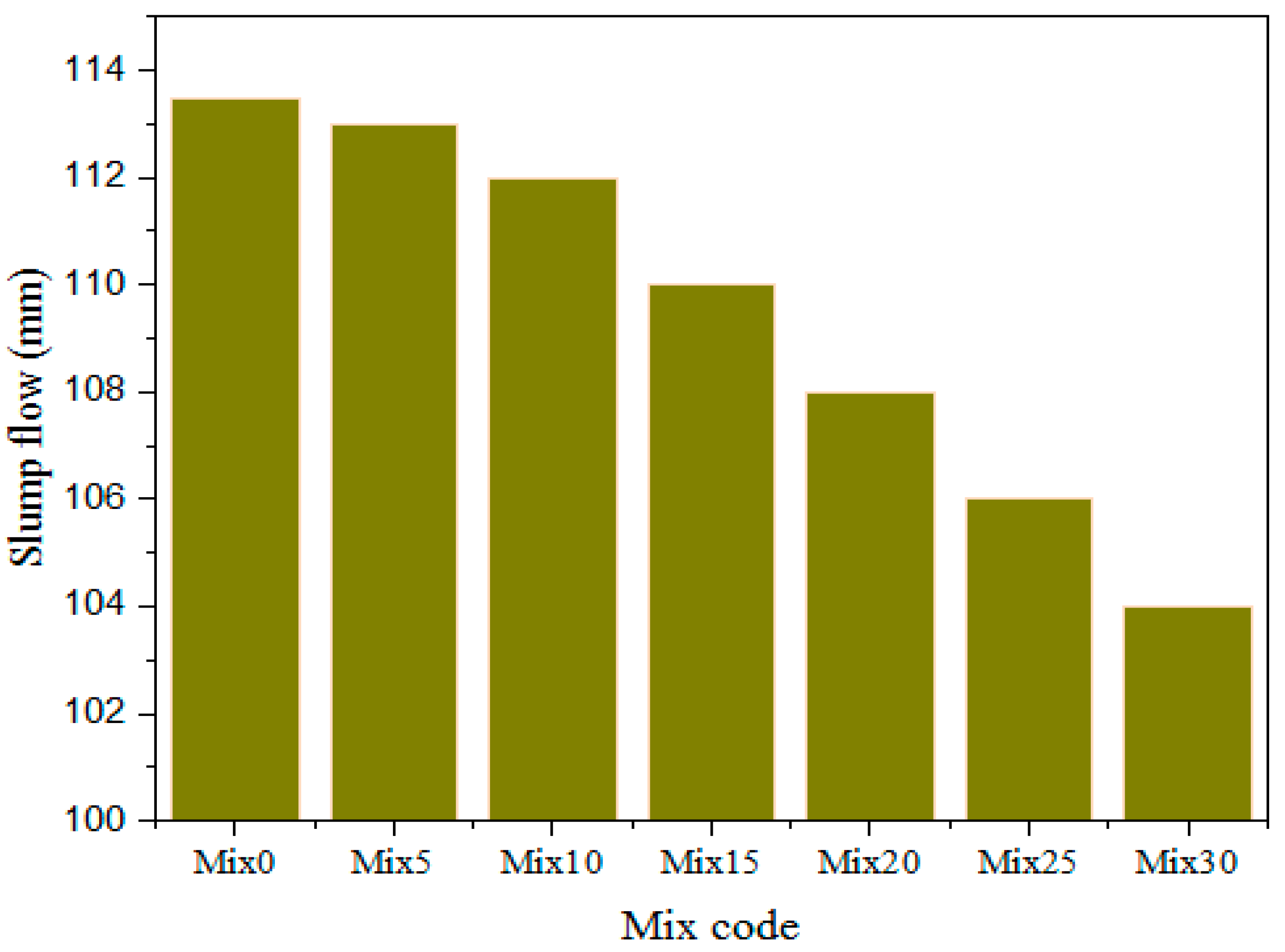

3.1.3. Workability

3.2. Mechanical Properties

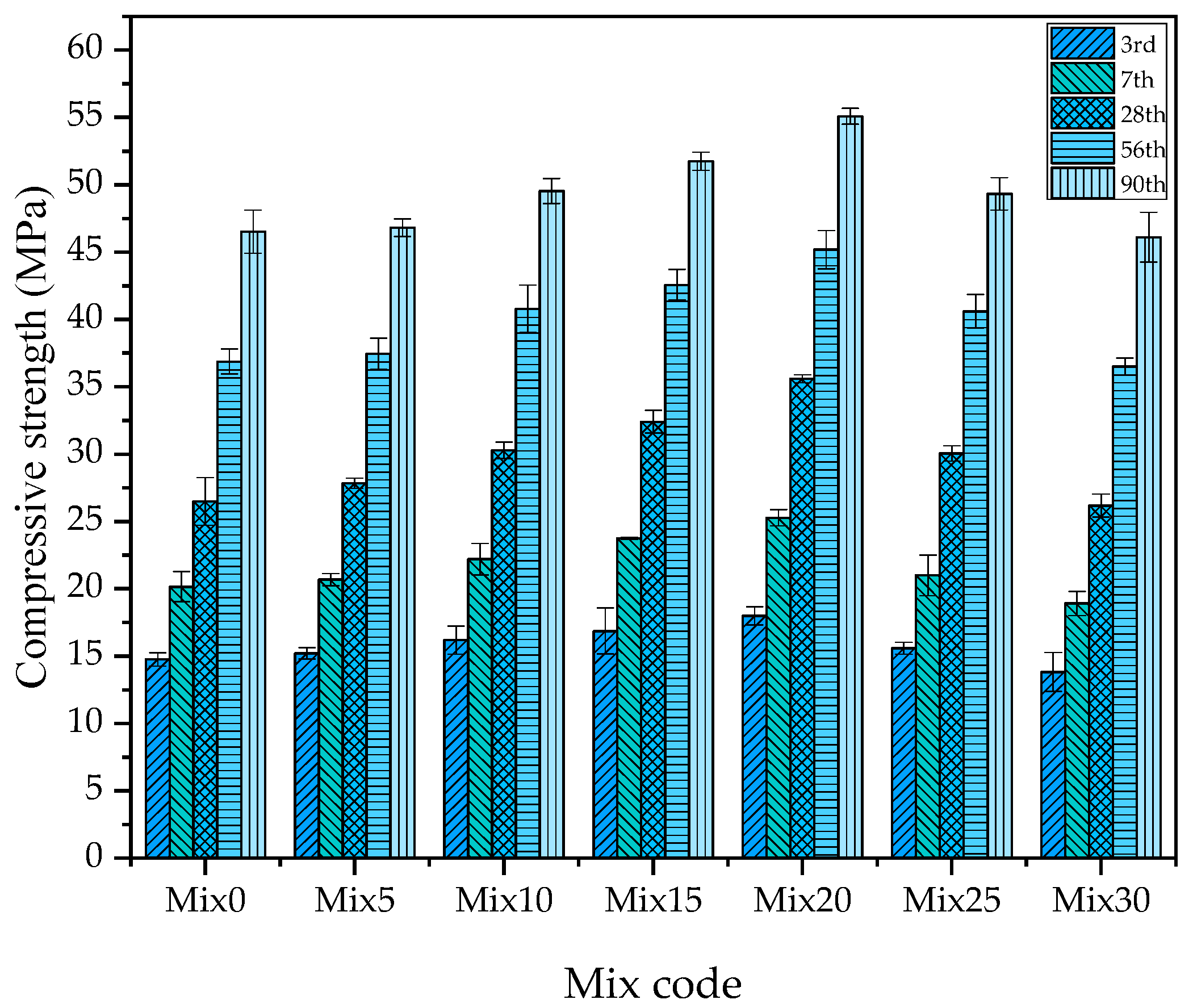

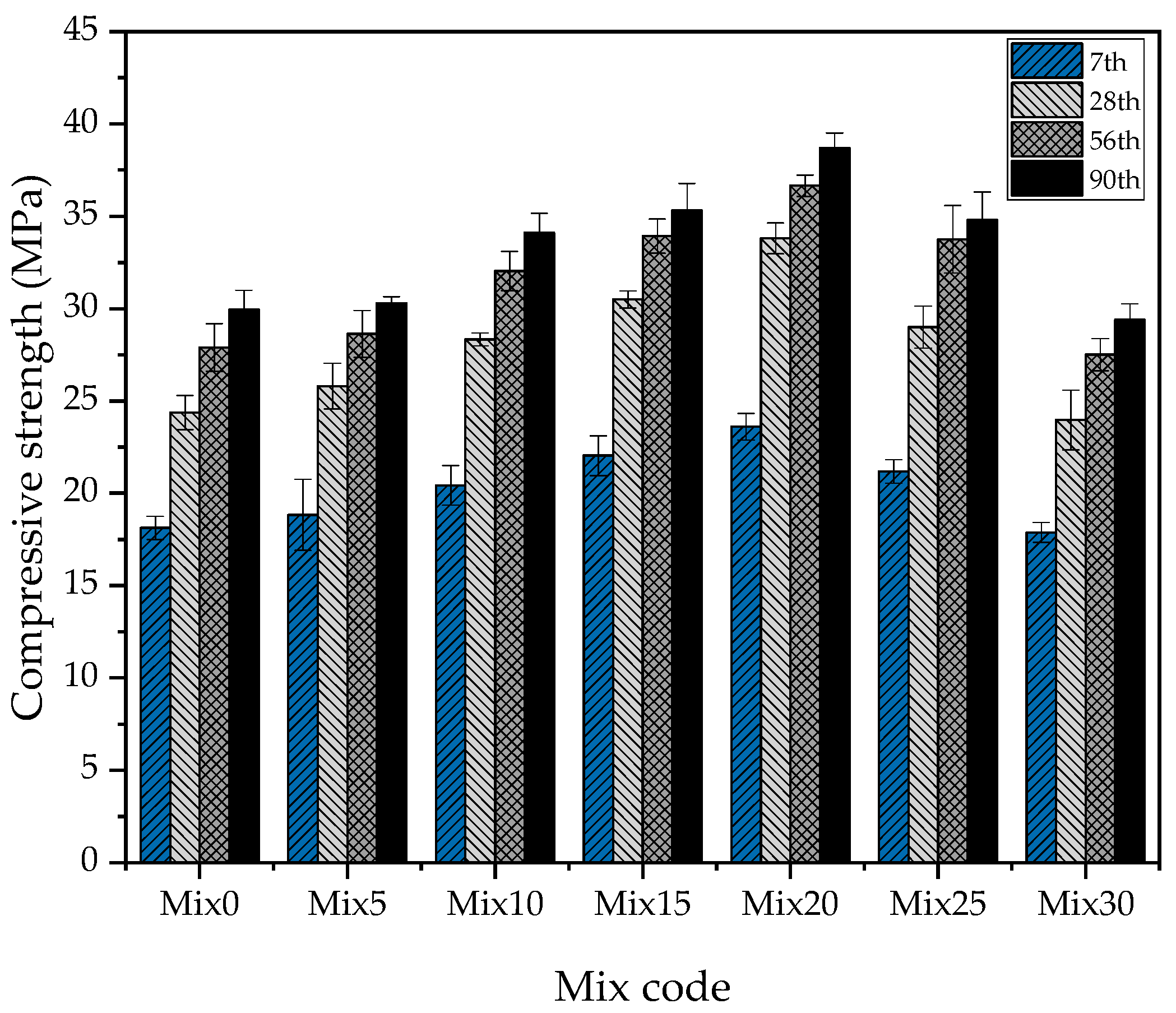

3.2.1. Compressive Strength

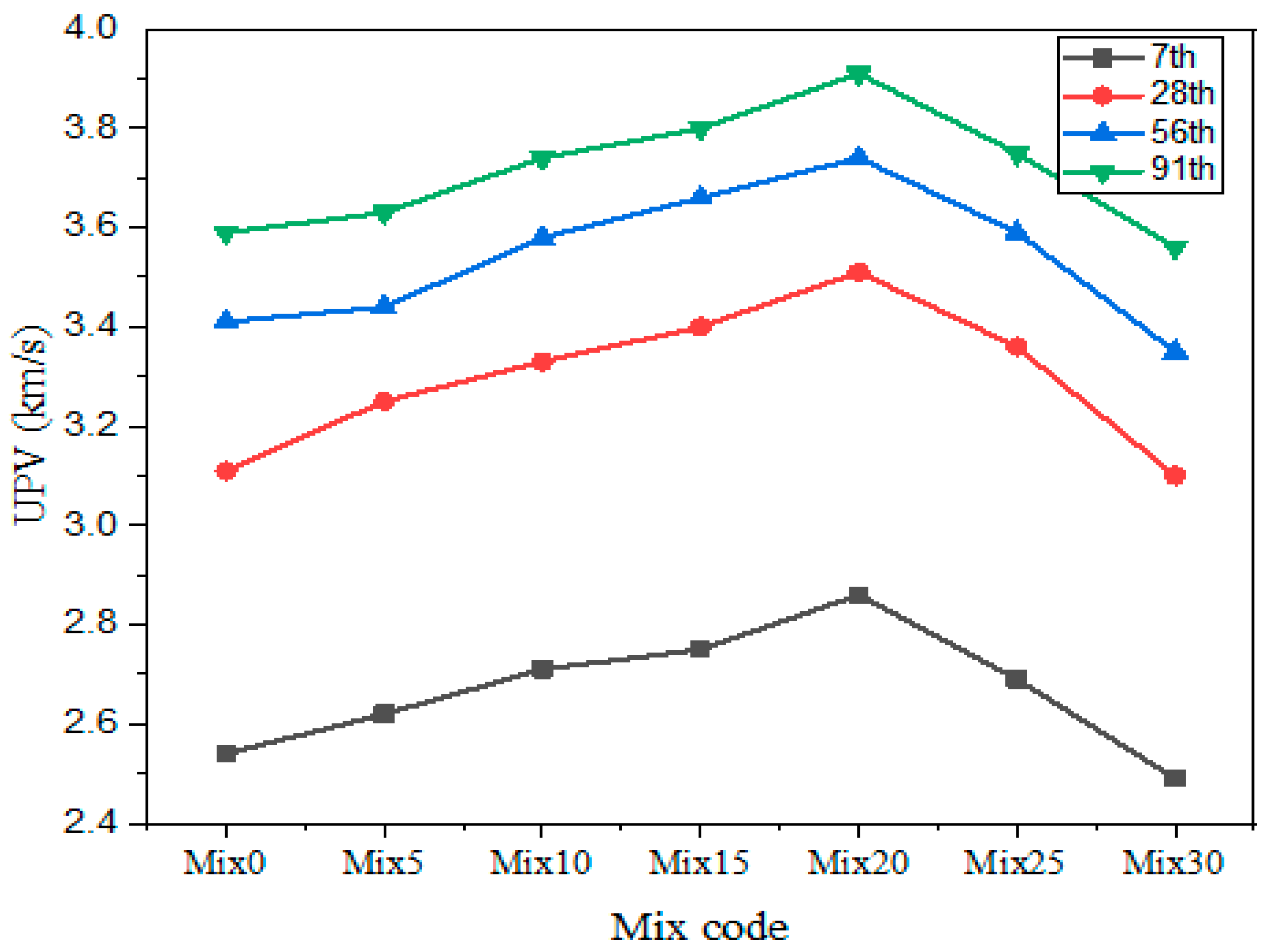

3.2.2. Ultrasonic Pulse Velocity

3.3. Microstructure Properties

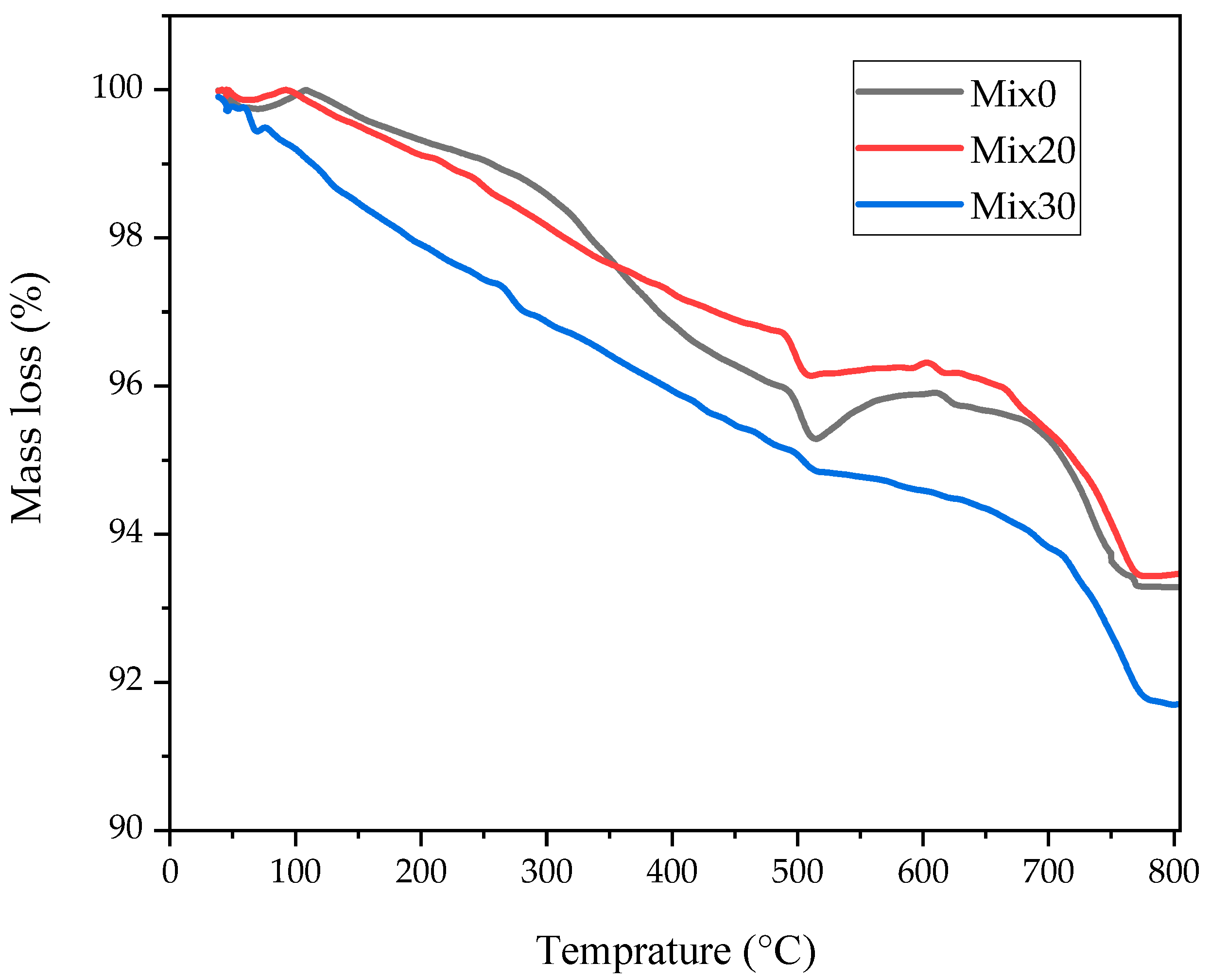

3.3.1. Thermogravimetric Analysis

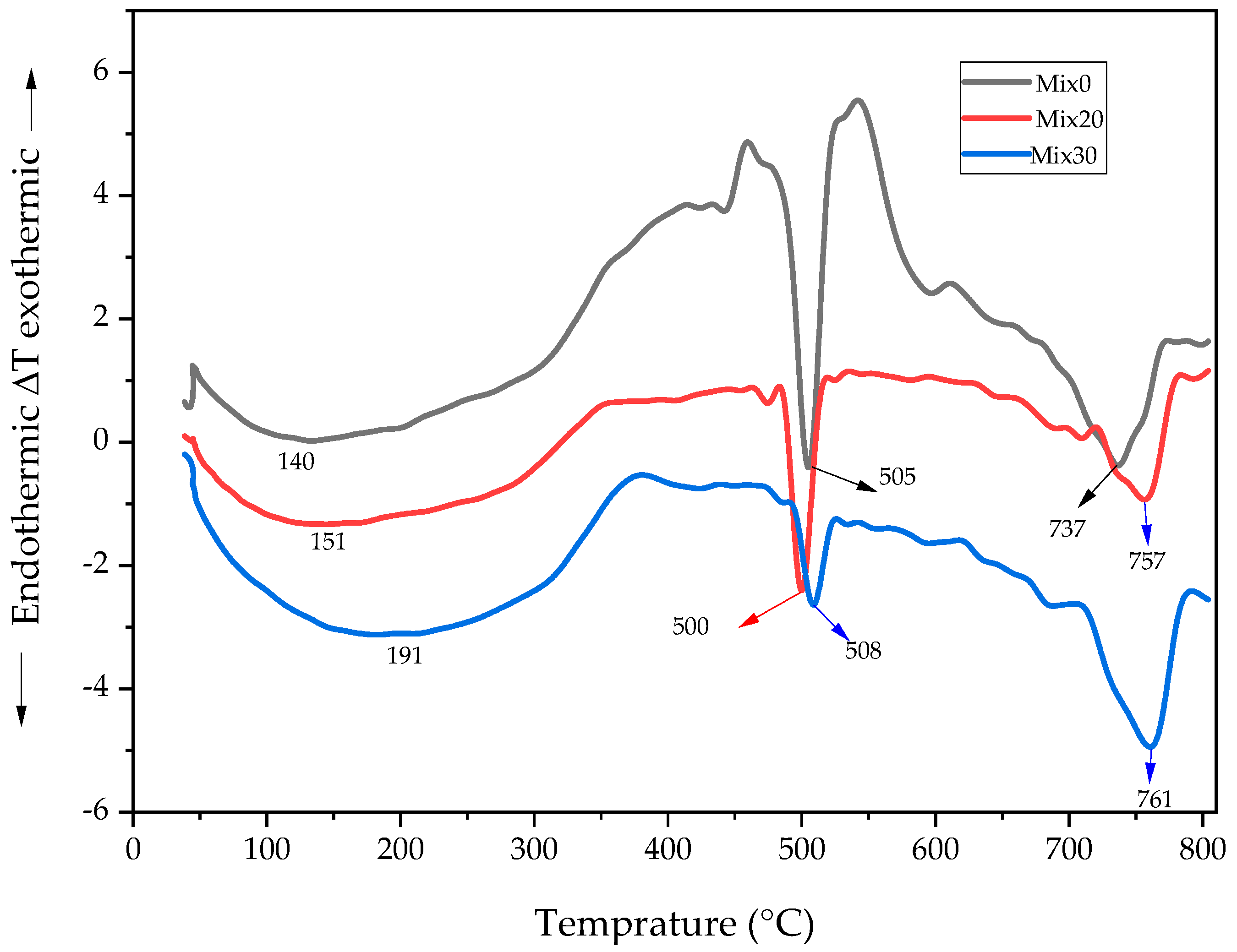

3.3.2. Differential Thermal Analysis

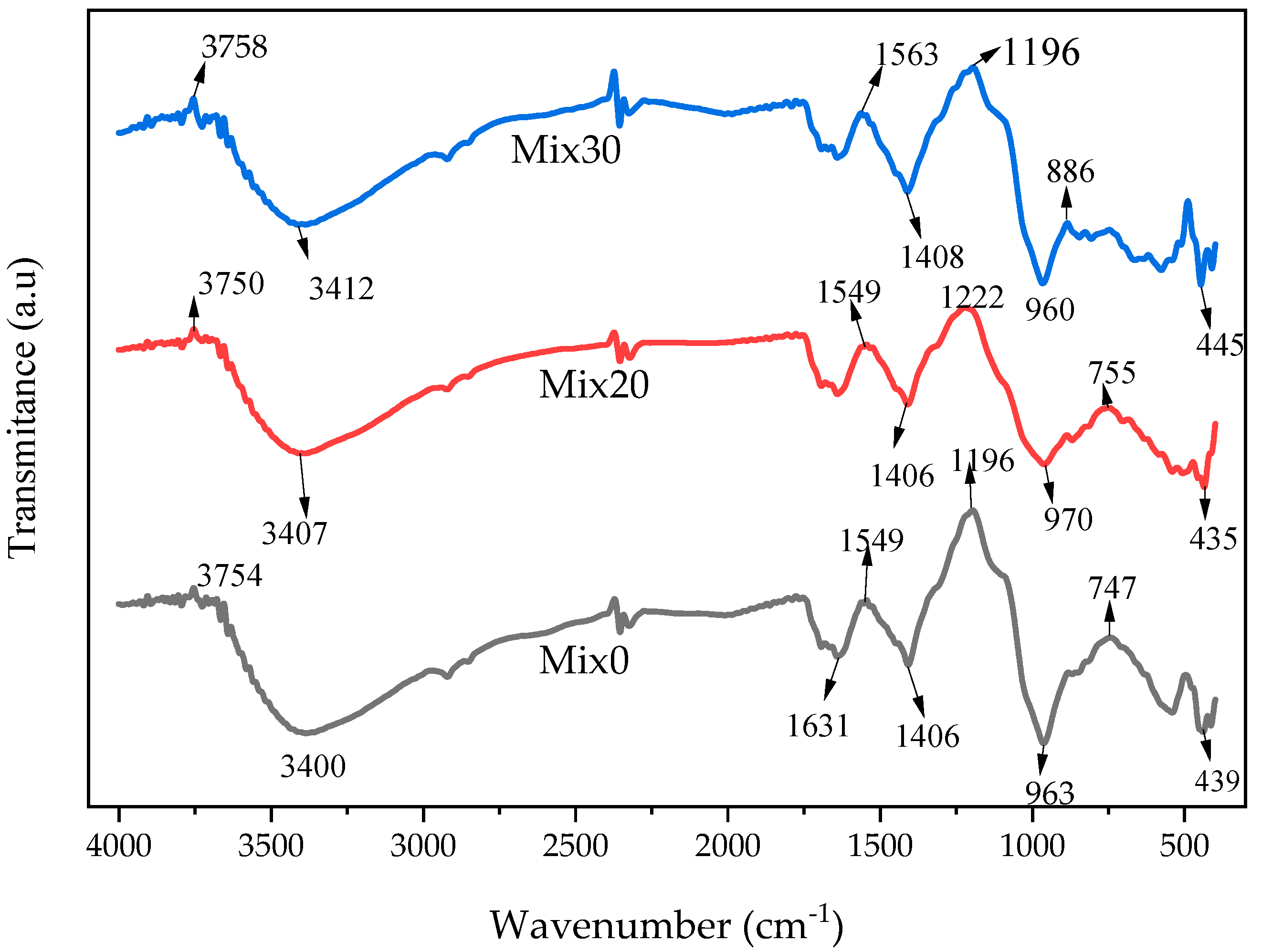

3.3.3. Fourier Transformation Infrared Spectroscopy

3.4. Durability Properties

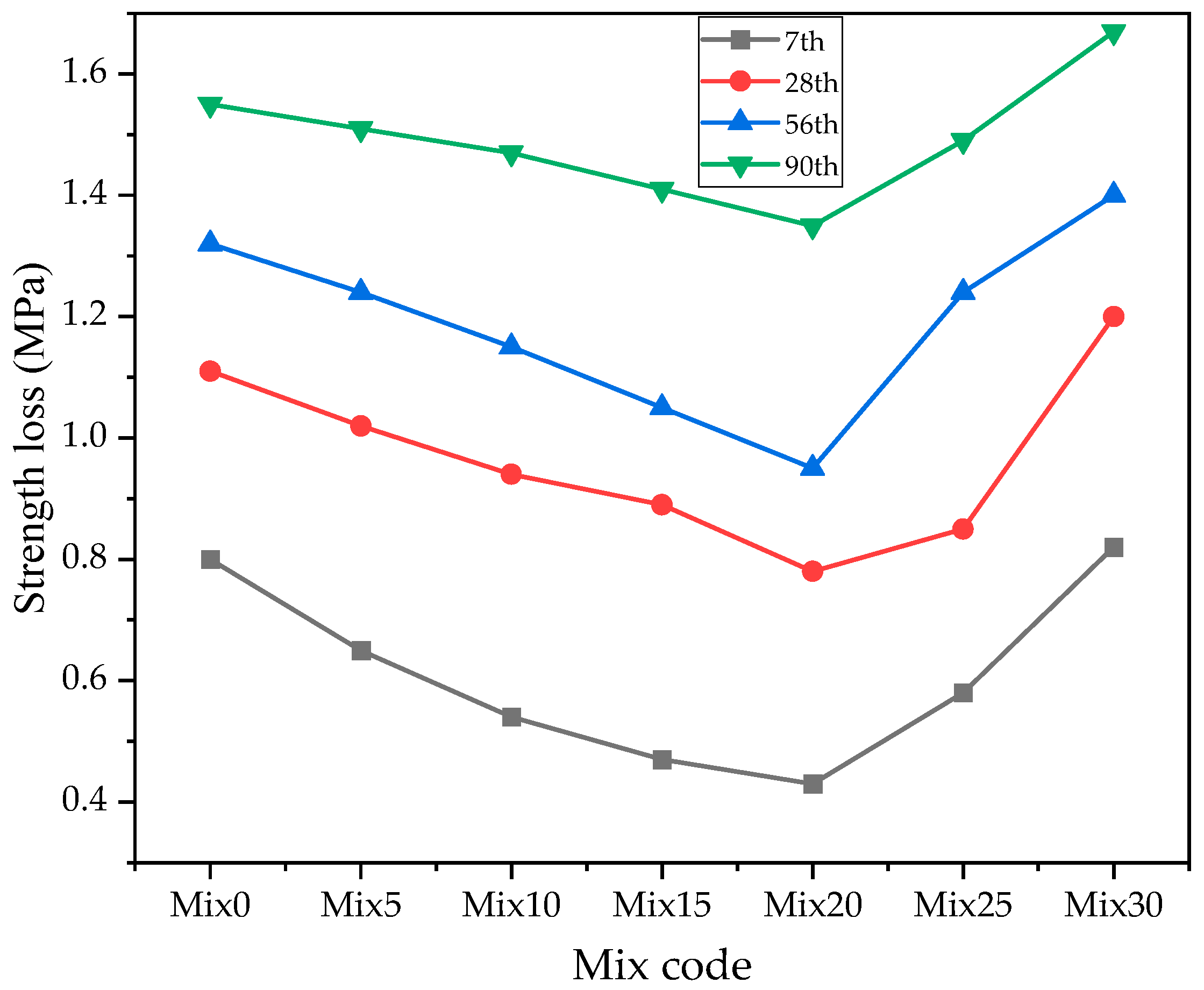

3.4.1. Sulfate Attack Resistance

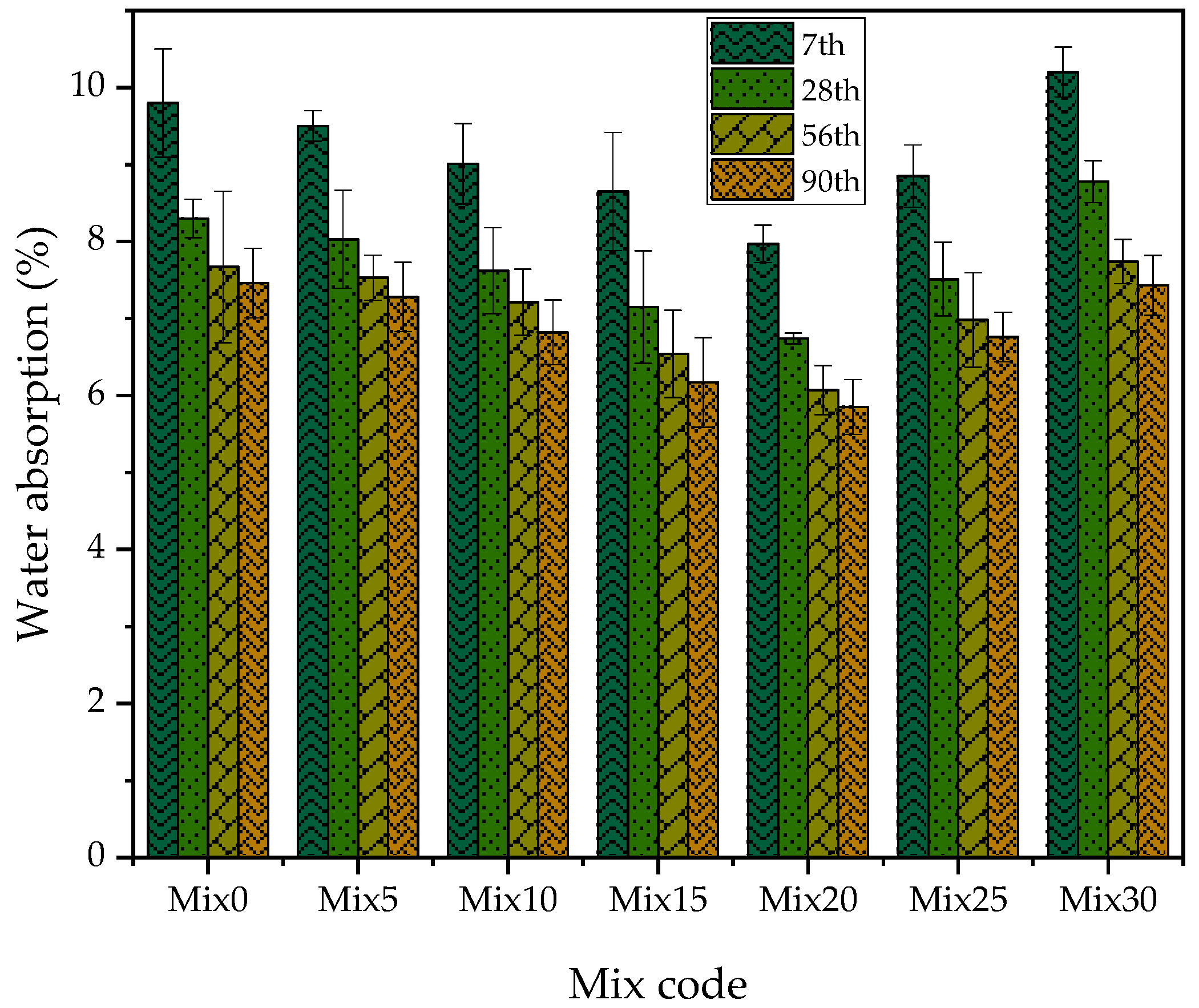

3.4.2. Water Absorption

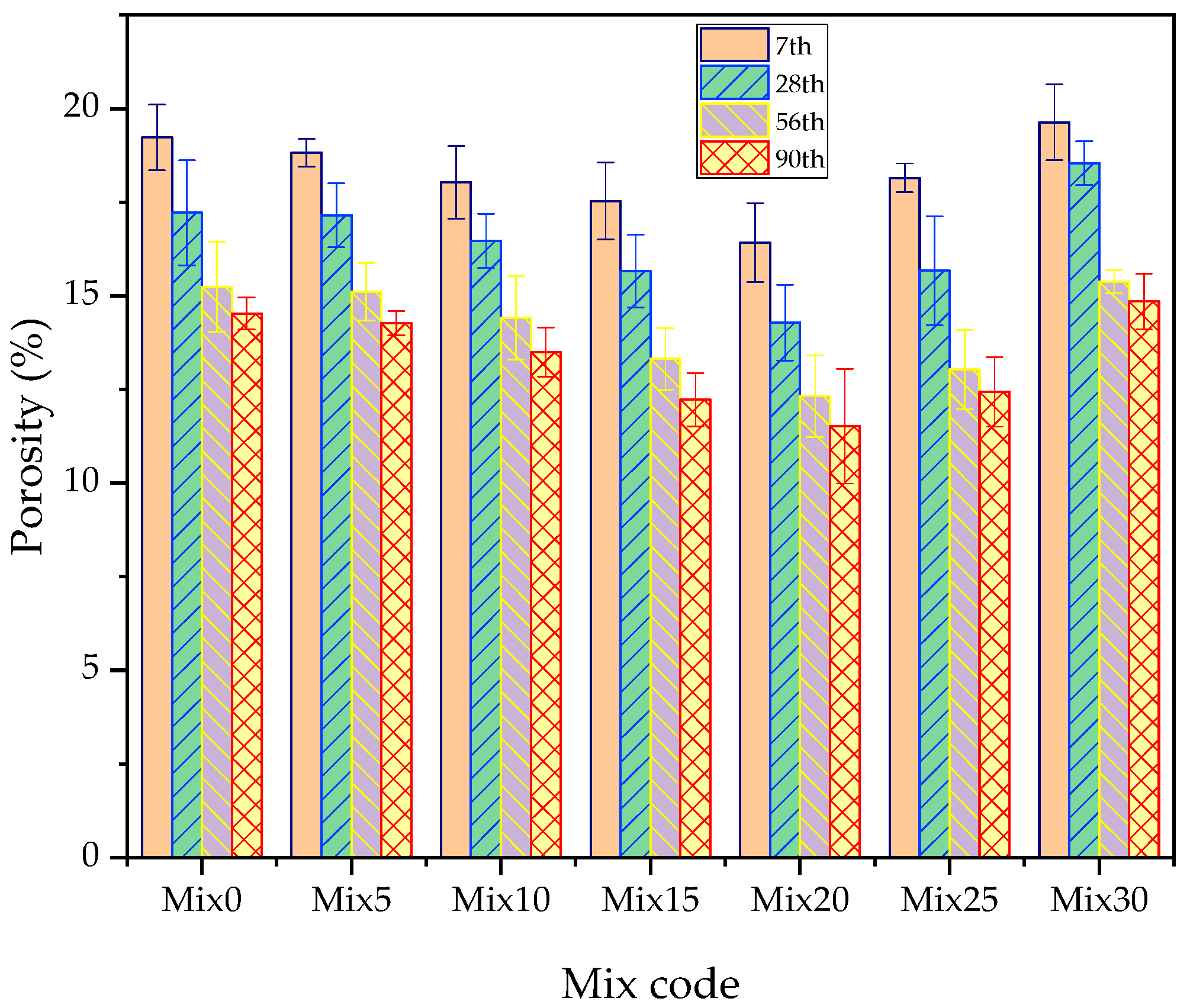

3.4.3. Porosity

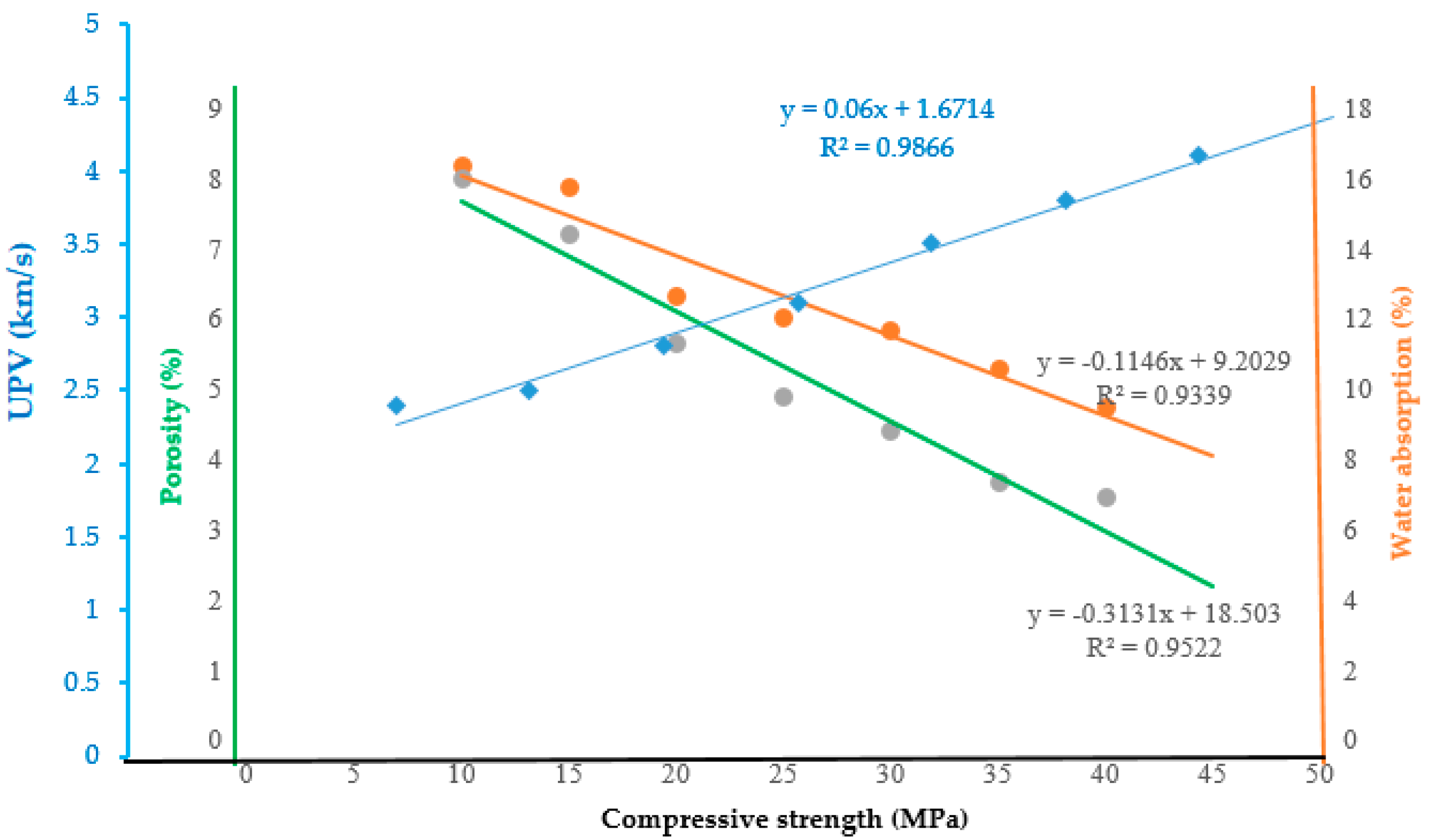

3.5. Correlation Analysis

4. Conclusions

- Workability and setting time: The incorporation of RHA and WMP led to reduced workability and shorter setting times, attributed to their higher specific surface area compared to cement. The initial and final setting times exhibited a linear decline, with reductions of up to 28% and 22%, respectively. Additionally, workability decreased by 9.25% at 30% replacement (Mix30).

- Mechanical properties: Compressive strength and UPV improved with replacement levels up to 20%, due to the formation of additional C-S-H gel, which enhanced matrix uniformity and densification. At 20% replacement (Mix20), compressive strength reached its peak increase of 26.33%, while UPV improved by 9.44% after 90 days of curing compared to the control mix. However, beyond 20% replacement, a decline in both compressive strength and UPV was observed, indicating a loss of matrix homogeneity.

- Durability: Sulfate resistance significantly improved with increasing replacement levels, peaking at 20% replacement due to pore refinement, reduced porosity, and enhanced C-S-H formation. The inclusion of RHA and WMP resulted in a 12.9% increase in sulfate resistance at Mix20 after 91 days compared to the control mix. Additionally, water absorption and porosity were at their lowest at 20% replacement; however, beyond this level, both properties increased, suggesting a threshold for optimal durability performance.

- Thermal and structural analysis: TGA demonstrated minimum mass loss in hardened mortar at 20% cement replacement. The FTIR analysis corroborated these findings, revealing a denser internal structure with increased C-S-H formation and a reduction in C-H as the replacement percentages rose to 20%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krishna, N.K.; Sandeep, S.; Mini, K.M. Study on concrete with partial replacement of cement by rice husk ash. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016. [Google Scholar]

- Bouchhima, L.; Rouis, M.J.; Choura, M. Correlation of Ultrasound Pulse Velocity with Mechanical Properties and Water Absorption in Phosphogypsum-wade Sand-Lime-Cement Building Bricks produced under a static compaction of 20 MPa. Int. J. Latest Technol. Eng. Manag. Appl. Sci. IJLTEMAS 2015, 4, 1–5. [Google Scholar]

- Cosentino, I.; Liendo, F.; Arduino, M.; Restuccia, L.; Bensaid, S.; Deorsola, F.; Ferro, G.A. Nano CaCO3 particles in cement mortars towards developing a circular economy in the cement industry. Procedia Struct. Integr. 2020, 26, 155–165. [Google Scholar]

- Thwe, E.; Khatiwada, D.; Gasparatos, A. Life cycle assessment of a cement plant in Naypyitaw, Myanmar. Clean. Environ. Syst. 2021, 2, 100007. [Google Scholar]

- Worku, M.A.; Taffese, W.Z.; Hailemariam, B.Z.; Yehualaw, M.D. Cow dung ash in mortar: An experimental study. Appl. Sci. 2023, 13, 6218. [Google Scholar] [CrossRef]

- Getachew, E.M.; Yifru, B.W.; Taffese, W.Z.; Yehualaw, M.D. Enhancing mortar properties through thermoactivated recycled concrete cement. Buildings 2023, 13, 2209. [Google Scholar] [CrossRef]

- Yehualaw, M.D.; Alemu, M.; Hailemariam, B.Z.; Vo, D.H.; Taffese, W.Z. Aquatic weed for concrete sustainability. Sustainability 2022, 14, 15501. [Google Scholar] [CrossRef]

- Nebiyu, W.M.; Nuramo, D.A.; Ketema, A.F. Experimental Study of Recycled Aggregate Concrete Produced from Recycled Fine Aggregate. In Proceedings of the Advances of Science and Technology: 9th EAI International Conference, ICAST 2021, Hybrid Event, Bahir Dar, Ethiopia, 27–29 August 2021; Proceedings, Part II. Springer: Cham, Switzerland, 2022. [Google Scholar]

- Rajput, J.; Yadav, R.; Chandak, R. The effect of rice husk ash used as supplementary cementing material on strength of mortar. Int. J. Eng. Res. Appl. 2013, 3, 133–136. [Google Scholar]

- Hailemariam, B.Z.; Yehualaw, M.D.; Taffese, W.Z.; Vo, D.H. Optimizing Alkali-Activated Mortars with Steel Slag and Eggshell Powder. Buildings 2024, 14, 2336. [Google Scholar] [CrossRef]

- Nega, D.M.; Yifru, B.W.; Taffese, W.Z.; Ayele, Y.K.; Yehualaw, M.D. Impact of partial replacement of cement with a blend of marble and granite waste powder on mortar. Appl. Sci. 2023, 13, 8998. [Google Scholar] [CrossRef]

- Endale, S.; Taffese, W.Z.; Vo, D.H.; Yehualaw, M.D. Rice husk ash in concrete. Sustainability 2023, 15, 137. [Google Scholar]

- Ephraim, M.E.; Akeke, G.A.; Ukpata, J.O. Compressive strength of concrete with rice husk ash as partial replacement of ordinary Portland cement. Sch. J. Eng. Res. 2012, 1, 32–36. [Google Scholar]

- Ali, T.; Saand, A.; Bangwar, D.K.; Buller, A.S.; Ahmed, Z. Mechanical and durability properties of aerated concrete incorporating rice husk ash (RHA) as partial replacement of cement. Crystals 2021, 11, 604. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Dorostkar, F.; Ahmadi, M. Rice husk ash as a partial replacement of cement in high strength concrete containing micro silica: Evaluating durability and mechanical properties. Case Stud. Constr. Mater. 2017, 7, 73–81. [Google Scholar]

- Lezzerini, M.; Luti, L.; Aquino, A.; Gallello, G.; Pagnotta, S. Effect of marble waste powder as a binder replacement on the mechanical resistance of cement mortars. Appl. Sci. 2022, 12, 4481. [Google Scholar] [CrossRef]

- Chandrakar, R.; Singh, A. Cement replacement in concrete with marble dust powder. Int. Res. J. Eng. Technol. 2017, 4, 1409–1411. [Google Scholar]

- Bakar, R.A.; Yahya, R.; Gan, S.N. Production of high purity amorphous silica from rice husk. Procedia Chem. 2016, 19, 189–195. [Google Scholar]

- Ramezanianpour, A.; Pourbeik, P.; Mahdikhani, M.; Moodi, F. Mechanical properties and durability of concretes containing rice husk ash as supplementary cementing material. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010. [Google Scholar]

- Alex, J.; Dhanalakshmi, J.; Ambedkar, B. Experimental investigation on rice husk ash as cement replacement on concrete production. Constr. Build. Mater. 2016, 127, 353–362. [Google Scholar]

- Neville, A.M.; Brooks, J.J. Concrete Technology; Longman Scientific & Technical England: London, UK, 1987; Volume 438. [Google Scholar]

- ASTM C618-22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2022.

- Snellings, R.; Mertens, G.; Elsen, J. Supplementary cementitious materials. Rev. Mineral. Geochem. 2012, 74, 211–278. [Google Scholar]

- Zain, M.F.M.; Islam, M.N.; Mahmud, F.; Jamil, M. Production of rice husk ash for use in concrete as a supplementary cementitious material. Constr. Build. Mater. 2011, 25, 798–805. [Google Scholar]

- ASTM C33-07; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C29; Standard Test Method for Bulk Density (Unit Weight) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C128-07; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM C566-97; Standard Test Method for Total Evaporable Moisture Content of Aggregate by Drying. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM C117-04; Standard Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing. ASTM International: West Conshohocken, PA, USA, 2003.

- ASTM C109/C109M-02; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM C187; Standard Test Method for Amount of Water Required for Normal Consistency of Hydraulic Cement Paste. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM C191-08; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C1437; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM C1012/C1012M; Standard Test Method for Length Change of Hydraulic Cement Mortars Exposed to a Sulfate Solution. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C597-16; Standard Test Method for Pulse Velocity through Concrete. ASTM International: West Conshohocken, PA, USA, 2018.

- Mohseni, E.; Yazdi, M.A.; Miyandehi, B.M.; Zadshir, M.; Ranjbar, M.M. Combined effects of metakaolin, rice husk ash, and polypropylene fiber on the engineering properties and microstructure of mortar. J. Mater. Civ. Eng. 2017, 29, 04017025. [Google Scholar]

- Thiedeitz, M.; Ostermaier, B.; Kränkel, T. Rice husk ash as an additive in mortar–Contribution to microstructural, strength and durability performance. Resour. Conserv. Recycl. 2022, 184, 106389. [Google Scholar] [CrossRef]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; Salleh, M.A.M. Contribution of rice husk ash to the properties of mortar and concrete: A review. J. Am. Sci. 2010, 6, 157–165. [Google Scholar]

- Madhava Krishna Reddy, G.; Sreenivasulu Gopu, M.G.K.; Sashidhar, C. Experimental Studies on Blended Concrete with Chemically Cured Coarse Aggregate. Int. J. Eng. Technol. Sci. Res. 2017, 4, 202–2013. [Google Scholar]

- Mounika, G.; Baskar, R.; Sri Kalyana Rama, J. Rice husk ash as a potential supplementary cementitious material in concrete solution towards sustainable construction. Innov. Infrastruct. Solut. 2022, 7, 51. [Google Scholar]

- Srinivasreddy, A.B.; McCarthy, T.; Lume, E. Effect of rice husk ash on workability and strength of concrete. In Proceedings of the 26th Biennial Concrete Institute of Australia’s National Conference, Gold Coast, Australia, 16–18 October 2013. [Google Scholar]

- Pathan, V.G.; Pathan, M.G. Feasibility and need of use of waste marble powder in concrete production. IOSR J. Mech. Civ. Eng. 2014, 6, 23–26. [Google Scholar]

- Rao, B.K. Study on marble powder as partial replacement of cement in normal compacting concrete. IOSR J. Mech. Civ. Eng. (IOSR-JMCE) 2016, 13, 1–5. [Google Scholar]

- De Sensale, G.R. Effect of rice-husk ash on durability of cementitious materials. Cem. Concr. Compos. 2010, 32, 718–725. [Google Scholar] [CrossRef]

- Ulubeyli, G.C.; Artir, R. Properties of hardened concrete produced by waste marble powder. Procedia Soc. Behav. Sci. 2015, 195, 2181–2190. [Google Scholar]

- Meziani, M.; Chelouah, N.; Amiri, O.; Leklou, N. Blended cement hydration assessment by thermogravimetric analysis and isothermal calorimetry. In Proceedings of the MATEC Web of Conferences, Reykjavik, Iceland, 12 August 2018; EDP Sciences: Les Ulis, France, 2018. [Google Scholar]

- Zhou, Z.; Sofi, M.; Lumantarna, E.; San Nicolas, R.; Hadi Kusuma, G.; Mendis, P. Strength development and thermogravimetric investigation of high-volume fly ash binders. Materials 2019, 12, 3344. [Google Scholar] [CrossRef]

- Wang, W.; Meng, Y.; Wang, D. Effect of rice husk ash on high-temperature mechanical properties and microstructure of concrete. Kem. U Ind. Časopis Kemičara I Kem. Inženjera Hrvat. 2017, 66, 157–164. [Google Scholar]

- Alarcon-Ruiz, L.; Platret, G.; Massieu, E.; Ehrlacher, A. The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem. Concr. Res. 2005, 35, 609–613. [Google Scholar] [CrossRef]

- Ahmed, A.; Ameer, S.; Abbas, S.; Abbass, W.; Razzaq, A.; Mohamed, A.M.; Mohamed, A. Effectiveness of ternary blend incorporating rice husk ash, silica fume, and cement in preparing ASR resilient concrete. Materials 2022, 15, 2125. [Google Scholar] [CrossRef] [PubMed]

- Amaran, R.; Ravi, R. Effect of cactus on the rheological properties of cement. Int. J. Chem. Sci. 2016, 14, 203–210. [Google Scholar]

- Horgnies, M.; Chen, J.; Bouillon, C. Overview about the use of Fourier transform infrared spectroscopy to study cementitious materials. WIT Trans. Eng. Sci. 2013, 77, 251–262. [Google Scholar]

- Malathy, R.; Shanmugam, R.; Chung, I.M.; Kim, S.H.; Prabakaran, M. Mechanical and microstructural properties of composite mortars with lime, silica fume and rice husk ash. Processes 2022, 10, 1424. [Google Scholar] [CrossRef]

- Luo, Y.-B.; Zhang, Y.-J. Investigation of sticky-rice lime mortar of the Horse Stopped Wall in Jiange. Herit. Sci. 2013, 1, 26. [Google Scholar] [CrossRef]

- Ylmen, R.; Jäglid, U. Carbonation of Portland cement studied by diffuse reflection Fourier transform infrared spectroscopy. Int. J. Concr. Struct. Mater. 2013, 7, 119–125. [Google Scholar] [CrossRef]

- Thomas, B.S. Green concrete partially comprised of rice husk ash as a supplementary cementitious material—A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 3913–3923. [Google Scholar] [CrossRef]

- Varadharajan, S.; Jaiswal, A.; Verma, S. Assessment of mechanical properties and environmental benefits of using rice husk ash and marble dust in concrete. In Structures; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Chanu, N.M.; Devi, T.K. Contribution of rice husk ash to the properties of cement mortar and concrete. Int. J. Eng. Res. Technol. 2013, 2, 1–7. [Google Scholar]

- Ibrahim, I.A.; Ahmad, E.; Dulawat, S.; Garko, M.N.; Ibrahim, U.S.; Ubayi, S.S.; Ibrahim, M.A. A review on the impact of rice husk ash and marble waste powder on concrete properties. Int. J. Mech. Civ. Eng. 2024, 7, 145–159. [Google Scholar] [CrossRef]

- Shaladi, R.J.; Johari, M.A.M.; Ahmad, Z.A.; Mijarsh, M.J. The influence of palm oil fuel ash heat treatment on the strength activity, porosity, and water absorption of cement mortar. Environ. Sci. Pollut. Res. 2022, 29, 72493–72514. [Google Scholar]

- Nugroho, M.S.; Ma’arif, F.; Widodo, S.; Rachmi, D.; Fajriani, Q.; Suryadwanti, N.; Setiawan, W. The effect of mortar mixture variations on the compressive strength and ultrasonic pulse velocity. INERSIA Lnformasi Dan Ekspose Has. Ris. Tek. Sipil Dan Arsit. 2022, 18, 225–234. [Google Scholar] [CrossRef]

| Materials | BET Surface Area (m2/kg) | Specific Gravity (g/cm3) |

|---|---|---|

| OPC | 1000 [21] | 3.15 |

| RHA | 3160.35 | 1.87 |

| WMP | 2938.89 | 2.63 |

| Oxides | Amout of Oxides for Binders (%) | ||

|---|---|---|---|

| OPC | RHA | WMP | |

| SiO2 | 21.03 | 93.96 | 6.08 |

| Al2O3 | 6.16 | <0.01 | <0.01 |

| Fe2O3 | 2.58 | 0.5 | <0.01 |

| CaO | 64.67 | 0.56 | 51.82 |

| MgO | 2.62 | 0.42 | 0.38 |

| Na2O | 0.61 | <0.01 | 0.06 |

| K2O | 0.61 | 0.98 | <0.01 |

| MnO | - | 0.26 | 0.12 |

| P2O5 | - | 0.58 | 0.10 |

| TiO2 | - | 0.28 | 0.05 |

| H2O | - | 0.82 | 0.05 |

| SO3 | 2.06 | - | - |

| LOI | 1.34 | 40.33 | |

| SiO2 + Al2O3 + Fe2O3 | 29.77 | 94.46 | 6.08 |

| Aggregate Properties | Standard | Unit | Result | Allowable Range |

|---|---|---|---|---|

| Bulk density | ASTM C29 [26] | kg/m3 | 1655.80 | 1200–1750 |

| Specific gravity | ASTM C128 [27] | - | 2.74 | 2.3–2.9 |

| Fineness modules and gradation | ASTM C 33 [25] | - | 2.73 | 2.3–3.2 |

| Water absorption | ASTM C128 [27] | % | 2.53 | <5 |

| Moisture content | ASTM C566 [28] | % | 2.39 | 0–10 |

| Silt content | ASTM C117 [29] | % | 1.72 | <5 |

| Mix Code | % of Replacement (RHA + WMP) | Cement (kg) | RHA (kg) | WMP (kg) | Sand (kg) | Water (Liter) | Number of Cubes |

|---|---|---|---|---|---|---|---|

| Mix0 | 0 | 5.1 | 0 | 0 | 14.03 | 2.47 | 51 |

| Mix5 | 5 | 4.85 | 0.15 | 0.10 | 14.03 | 2.47 | 51 |

| Mix10 | 10 | 4.59 | 0.31 | 0.20 | 14.03 | 2.47 | 51 |

| Mix15 | 15 | 4.34 | 0.46 | 0.31 | 14.03 | 2.47 | 51 |

| Mix20 | 20 | 4.08 | 0.61 | 0.41 | 14.03 | 2.47 | 51 |

| Mix25 | 25 | 3.83 | 0.77 | 0.51 | 14.03 | 2.47 | 51 |

| Mix30 | 30 | 3.57 | 0.92 | 0.61 | 14.03 | 2.47 | 51 |

| Test Category | Property | Test Standard |

|---|---|---|

| Workability | ASTM C1437 [33] | |

| Fresh | Setting time | ASTM C191 [32] |

| Consistency | ASTM C187 [31] | |

| Compressive strength | ASTM C109 [30] | |

| Hardened | Homogeneity | ASTM C597 [36] |

| Durability | Sulfate attack resistance | ASTM C1012 [35] |

| Absorption capacity | ASTM C642-06 [34] | |

| Porosity | ASTM C642-06 [34] | |

| Thermal decomposition | ||

| Microstructure | Mineralogical composition |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeshiwas, M.D.; Yehualaw, M.D.; Habtegebreal, B.T.; Nebiyu, W.M.; Taffese, W.Z. Rice Husk Ash and Waste Marble Powder as Alternative Materials for Cement. Infrastructures 2025, 10, 78. https://doi.org/10.3390/infrastructures10040078

Yeshiwas MD, Yehualaw MD, Habtegebreal BT, Nebiyu WM, Taffese WZ. Rice Husk Ash and Waste Marble Powder as Alternative Materials for Cement. Infrastructures. 2025; 10(4):78. https://doi.org/10.3390/infrastructures10040078

Chicago/Turabian StyleYeshiwas, Mezgebu Debas, Mitiku Damtie Yehualaw, Betelhem Tilahun Habtegebreal, Wallelign Mulugeta Nebiyu, and Woubishet Zewdu Taffese. 2025. "Rice Husk Ash and Waste Marble Powder as Alternative Materials for Cement" Infrastructures 10, no. 4: 78. https://doi.org/10.3390/infrastructures10040078

APA StyleYeshiwas, M. D., Yehualaw, M. D., Habtegebreal, B. T., Nebiyu, W. M., & Taffese, W. Z. (2025). Rice Husk Ash and Waste Marble Powder as Alternative Materials for Cement. Infrastructures, 10(4), 78. https://doi.org/10.3390/infrastructures10040078