Repair and Treatment of Alkali–Silica Reaction (ASR)-Affected Transportation Infrastructures: Review and Interview

Abstract

1. Introduction

- Review the current practices employed by US state DOTs and international sources for addressing ASR-affected structures;

- Identify commonly used repair and treatment techniques;

- Evaluate the success rates and challenges faced in implementing these strategies;

- Determine the mitigation strategies in new construction.

2. Methodology

2.1. Literature Review

- Locate peer-reviewed and the other published literature or credible research, best practices, and documentation related to the repair and treatment of structures affected by ASR;

- Analyze the various approaches, technologies, and materials used to repair ASR-affected structures;

- Evaluate the performance, advantages, and limitations of different repair and rehabilitation strategies;

- Identify emerging technologies and innovative solutions that show promise for ASR mitigation in new construction;

- Provide insights on best practices and recommendations based on the findings.

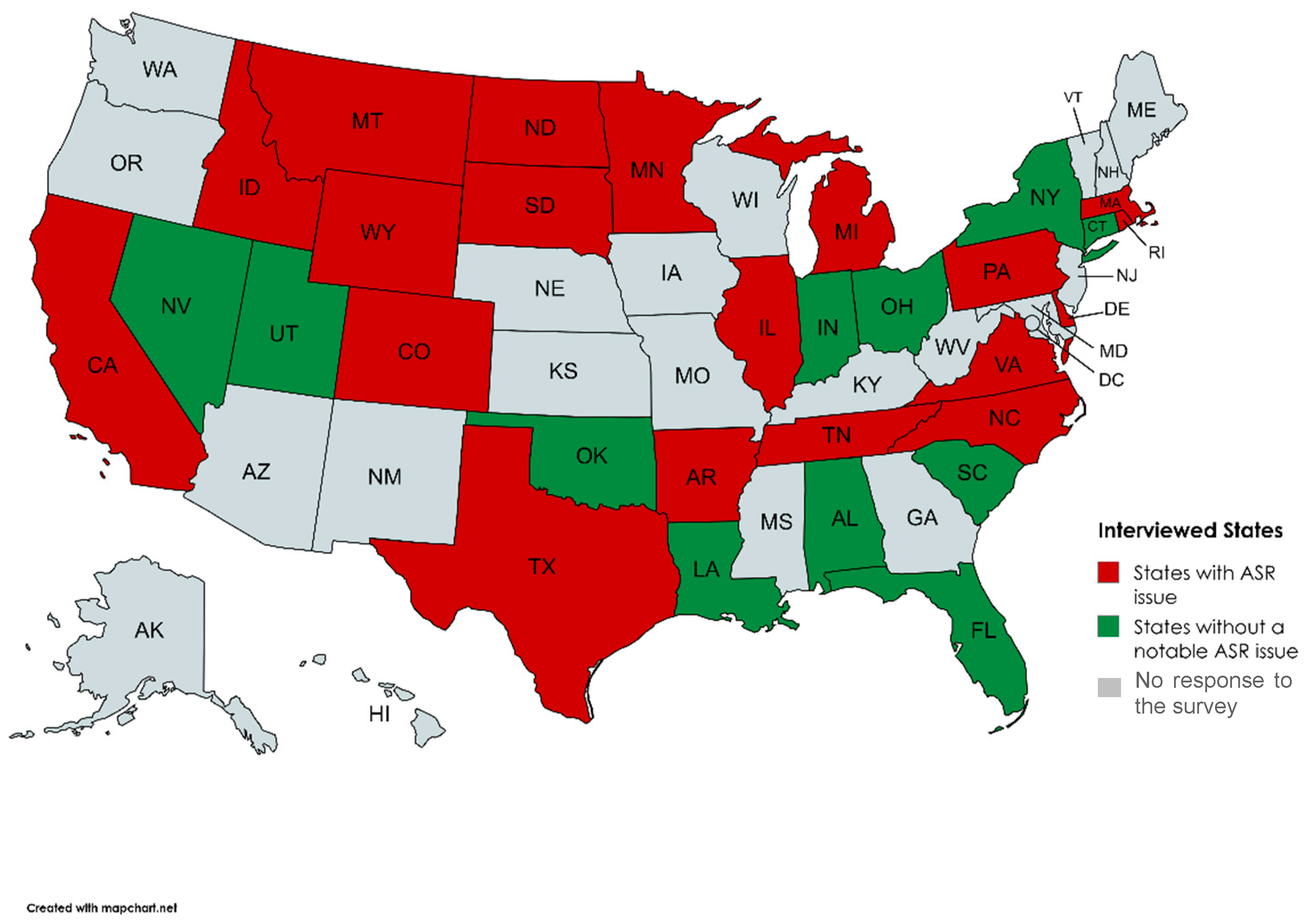

2.2. Survey of State DOTs

- Identify and contact all state DOTs across the country;

- Gather information on their practices, policies, and experiences regarding ASR-affected structures;

- Obtain data on the methods, materials, and techniques used for repair and treatment;

- Analyze the success rates, challenges faced, and lessons learned from their experiences;

- Assess the effectiveness and durability of the implemented strategies;

- Determine the mitigation strategies in new construction.

3. Findings

3.1. Literature Review

3.2. Lessons Learned from the Literature Review

3.3. Interviews with State DOTs

3.4. Lessons Learned from Interviews

3.4.1. Mitigation Strategies: Aggregate Testing

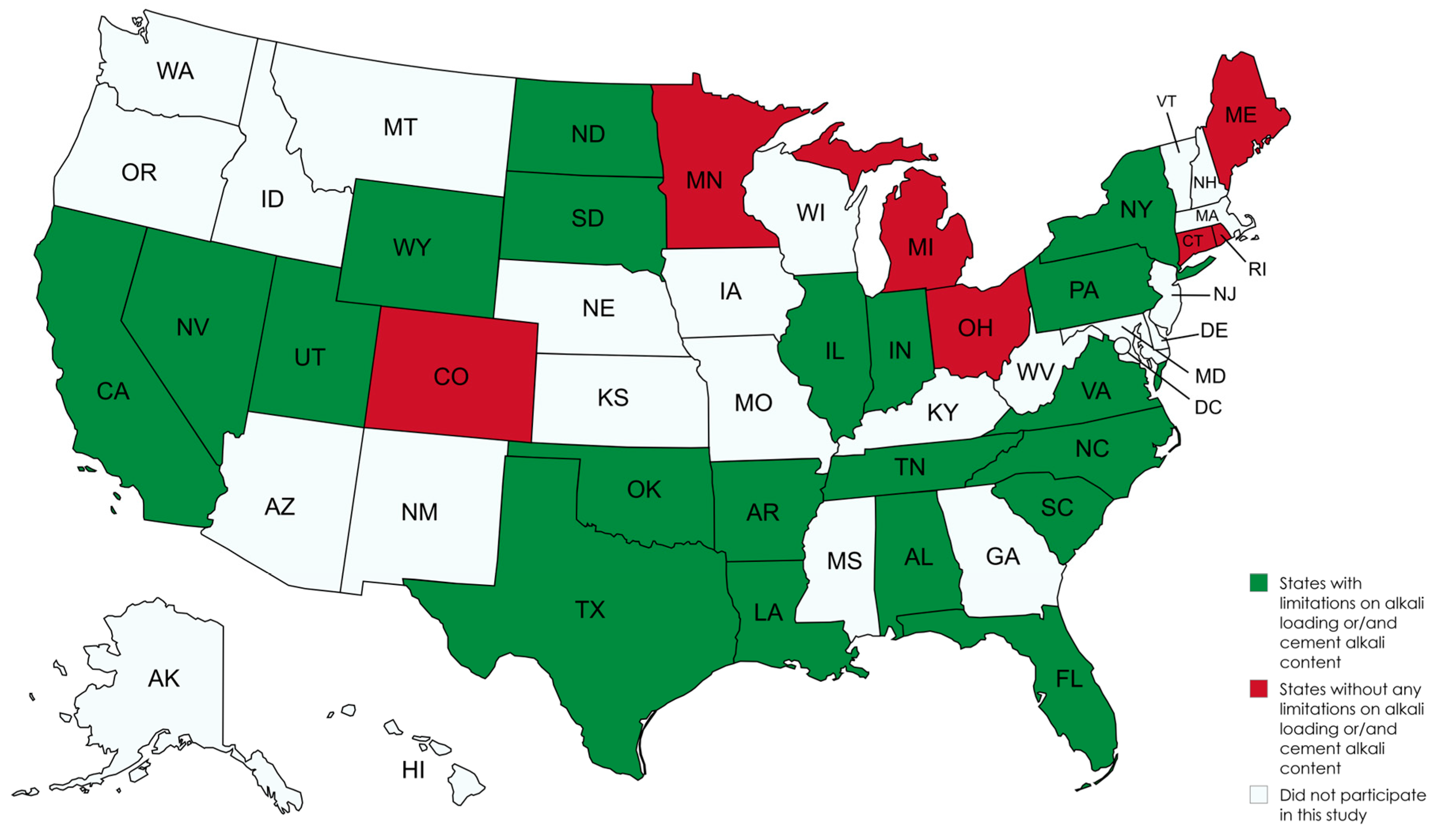

3.4.2. Mitigation Strategies: Cement and SCM Considerations

3.4.3. Mitigation Strategies: Repair Strategies

3.5. Challenges of Each Repair Strategy

3.5.1. Impermeable Surface Coatings

3.5.2. Vapor-Permeable Surface Sealers

3.5.3. Lithium Impregnation

3.5.4. Crack Repairs

3.5.5. CFRP Wraps

4. Translating Laboratory Findings to Field Applications in ASR Mitigation

5. Field Implementation

- For an ASR to occur, sufficient moisture must be present in the concrete. Therefore, a practical repair approach is to minimize moisture within the concrete. Based on the lessons learned from the literature and interviews with the state DOTs, for ASR-affected structural elements, moisture control (e.g., using appropriate vapor-permeable surface sealants) and strengthening (e.g., using FRP wrapping) should be considered, if practical and economical, to gain time until funds are available for replacement.

- ASR gel is expansive, and insights from the literature review and interviews with state DOTs indicate that stopping an ASR is challenging. In some cases, reducing moisture in affected elements (e.g., pavements) is difficult. As a result, some DOTs have successfully used rubblization to create space for expansion and prevent crack reflection on the surface. For this reason, the authors recommend rubblizing ASR-affected pavements and repurposing the deteriorated concrete as a new base course.

- One state DOT successfully repaired ASR-affected pavement by minimizing moisture in areas with good drainage. This was achieved by placing an ultra-thin impermeable layer on the pavement surface to reduce moisture infiltration. Transportation agencies may benefit from considering this ultra-thin, gap-graded hot mix asphalt wearing course over a polymer-rich asphalt emulsion overlay on ASR-affected pavement (with good drainage), followed by a 76.2 mm (3-inch) wearing surface.

6. Recommendations

- While several states already rely on SCMs such as fly ash and slag cement, promoting their use through updated guidelines or incentives can help ensure uniform ASR mitigation, especially where alkali limitations are not enforced.

- States should consider transitioning to newer, more reliable test methods for assessing aggregate reactivity. In addition, there is a need for clear guidance on how frequently aggregates from an active quarry should be tested to capture any variability over time.

- Relying solely on aggregate reactivity testing is not sufficient. Testing the job-specific mix design is essential to ensure that the combined effect of cement chemistry, SCMs, and admixtures results in an ASR-resistant concrete under field conditions.

- Facilitating regular knowledge-sharing forums among DOTs can help disseminate best practices and innovations in ASR mitigation, particularly where field performance has been successful.

- A closer connection between research institutions and state transportation agencies is critical. Understanding the practical challenges faced by DOTs can help shape research that is not only scientifically sound but also tailored for successful field implementation. This includes developing solutions that are constructible, cost-effective, and compatible with existing specifications.

7. Conclusions

- The prevention of ASRs is easier and more effective than the repair and rehabilitation of ASR-affected structures. Strategies like aggregate prescreening and using SCMs at appropriate dosages have proven to be successful and cost-effective methods for preventing ASR distress in structures.

- The ultimate solution for any severely ASR-affected structure is replacement. Repairs are completed to extend the service life until the funding becomes available and replacement is programmed.

- The major objective in controlling ASRs in existing field structures is to minimize the amount of water available to the system. Applying silanes in some cases reduces the internal RH and the potential for future expansions. Silane was not effective in pavements and elements that are in contact with moisture continuously without enough time for drying. However, this observation does not automatically translate to all applications of silanes. Moreover, the efficacy of silane treatment on ASRs is difficult to determine especially considering the medium-to-long-term abrasion resistance of such surface treatment.

- The lithium nitrate applied by either vacuum treatment or topically to existing ASRs distressed structures showed no tangible benefit in terms of reducing cracking or expansions.

- The Minnesota DOT reported that the diamond grinding of ASR-affected pavements accelerated the reaction in areas with less ASR distress. Therefore, diamond grinding should be avoided.

- Three states with ASR issues in pavements achieved an extra 5 to 10 years of service life by controlling the moisture ingress with overlays. Therefore, this repair strategy can be considered for the repair and rehabilitation of ASR-affected pavements. For example, the Delaware DOT has used an ultra-thin, gap-graded hot mix asphalt wearing course over a polymer-rich asphalt emulsion overlay on an ASR-affected pavement (with good drainage), followed by a 76.2 mm (3-inch) wearing surface. This approach provided an additional 15 years of service life until now, and the repair has not yet reached the end of its lifespan. Given its promising outcomes, this repair strategy can be considered for the repair and rehabilitation of ASR-affected pavements.

- ASR-affected pavements can be rubblized and used as a base material, thus eliminating expensive removal and disposal costs.

- Any repair strategies like surface sealing or crack sealing are effective in non-active cracks. Crack growth or development compromises many repairs.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASR | Alkali–silica reaction |

| AAR | Alkali–aggregate reaction |

| DOT | Department of Transportation |

| RH | Relative humidity |

| N/S | Not specified |

| CFRP | Carbon Fiber-Reinforced Polymer |

| TFHRC | Turner-Fairbank Highway Research Center |

| SCMs | Supplementary cementitious materials |

| ACMs | Alternative cementitious materials |

| FHWA | Federal Highway Administration |

References

- Shi, Z.; Lothenbach, B. Role of aluminum and lithium in mitigating alkali-silica reaction–a review. Front. Mater. 2022, 8, 796396. [Google Scholar] [CrossRef]

- Rajabipour, F.; Giannini, E.; Dunant, C.; Ideker, J.H.; Thomas, M.D. Alkali–silica reaction: Current understanding of the reaction mechanisms and the knowledge gaps. Cem. Concr. Res. 2015, 76, 130–146. [Google Scholar] [CrossRef]

- Munoz, J.F.; Balachandran, C.; Beyene, M.; Arnold, T. A Novel Approach for the Assessment of ASR Susceptibility of Concrete Mixtures in Airfield Pavements and Infrastructure; United States, Federal Highway Administration, Office of Research: Washington, DC, USA, 2021.

- Brouard, E. Potentially reactive aggregates with a pessimum effect, pessimum effect mechanisms, review of PRP qualification tests and conditions of use of these aggregates. In Proceedings of the 14th International Conference on Alkali Aggregate Reaction, Austin, TX, USA, 20–25 May 2012; p. 10. [Google Scholar]

- Thomas, M.D.; Ahlstrom, G. Methods for Evaluating and Treating ASR-Affected Structures: Results of Field Application and Demonstration Projects: Volume I: Summary of Findings and Recommendations; United States, Federal Highway Administration: Washington, DC, USA, 2013.

- Fournier, B.; Bérubé, M.-A.; Folliard, K.J.; Thomas, M. Report on the Diagnosis, Prognosis, and Mitigation of Alkali-Silica Reaction (ASR) in Transportation Structures; United States, Federal Highway Administration, Office of Pavement Technology: Washington, DC, USA, 2010.

- Shi, Z.; Park, S.; Lothenbach, B.; Leemann, A. Formation of shlykovite and ASR-P1 in concrete under accelerated alkali-silica reaction at 60 and 80 C. Cem. Concr. Res. 2020, 137, 106213. [Google Scholar] [CrossRef]

- Cole, R.; Horswill, P. Alkali-silica reaction: Val de la Mare Dam, Jersey, case history. Proc. Inst. Civ. Eng. 1988, 84, 1237–1259. [Google Scholar] [CrossRef]

- Swamy, R.N. The Alkali-Silica Reaction in Concrete; Blackie: Glasgow, UK, 1992. [Google Scholar]

- Howard, J. Val De La Mare dam, Jersey: Design and installation of a geomembrane lining. Dams Reserv. 2011, 21, 159–163. [Google Scholar] [CrossRef]

- Blackwell, B.; Pettifer, K. Alkali-reactivity of greywacke aggregates in Maentwrog Dam (North Wales). Mag. Concr. Res. 1992, 44, 255–264. [Google Scholar] [CrossRef]

- Hove, G.T. Critical Literature Review on Concrete Crack Repairs. Master’s Thesis, University of Cape Town, Cape Town, South Africa, 2018. [Google Scholar]

- Wouters, J. Evaluation and Repair of Alkali-Silica Reaction Damage to Existing Concrete Wastewater Infrastructure; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 726–735. [Google Scholar]

- Davies, M.J.; Grace, W.R.; Green, W.K.; Collins, F.G. Assessment and Management of a Marine Structure Affected by ASR; CSIRO Division of Building Construction and Engineering: Melbourne, Australia, 1996. [Google Scholar]

- Tordoff, M. Assessment of pre-stressed concrete bridges suffering from alkali-silica reaction. Cem. Concr. Compos. 1990, 12, 203–210. [Google Scholar] [CrossRef]

- Carse, A. The asset management of a long bridge structure affected by alkali-silica reaction. In Proceedings of Concrete’97 Conference, Adelaide, Australia, 14–16 May 1997. [Google Scholar]

- Crampton, D.D.; Todsen, M.J. Case Study: Mitigation of Alkali Silica Reaction in a Signature Stay-Cable Bridge; American Society of Civil Engineers: Reston, VA, USA, 2020; pp. 328–340. [Google Scholar]

- Johnson, D.K.; Warnock, R.L.; Schindler, A.K.; Barnes, R.W. Effectiveness of Silane in Mitigating Alkali-Silica Reaction in the Bibb Graves Bridge; Auburn University, Highway Research Center: Auburn, AL, USA, 2014. [Google Scholar]

- Wood, J.; Angus, E. Montrose Bridge: Inspection, Assessment and Remedial Work to a 65 Year Old Bridge with AAR. Struct. Faults Repair 1995, 95, 6. [Google Scholar]

- Johnson, D.K. Effectiveness of Silane in Mitigating Alkali-Silica Reaction in the Bibb Graves Bridge. Master’s Thesis, Auburn University, Auburn, AL, USA, 2013. [Google Scholar]

- Jensen, V. Alkali–silica reaction damage to Elgeseter Bridge, Trondheim, Norway: A review of construction, research and repair up to 2003. Mater. Charact. 2004, 53, 155–170. [Google Scholar] [CrossRef]

- Skogli, C.E. Assesment of Damages Caused by Alkali-Silica Reactions-Elgseter Bridge, Trondheim. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2015. [Google Scholar]

- Myklebust, E. Assessment of an Existing Bridge Suffering from Alkali-Silica Reaction. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2018. [Google Scholar]

- Sande, S.F.; Christensen, E.S. Evaluation of Externally Reinforced Bridge Exposed to Alkali-Silica Reactions. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2020. [Google Scholar]

- Drimalas, T.; Folliard, K.J.; Thomas, M.D.; Fournier, B.; Bentivegna, A. Study of the effectiveness of lithium and silane treatments on field structures affected by ASR. In Proceedings of the 14th International Conference on Alkali-Aggregate Reaction (ICAAR), Austin, TX, USA, 20–25 May 2012. [Google Scholar]

- Thomas, M.D.; Folliard, K.J.; Fournier, B.; Rivard, P.; Drimalas, T.; Garber, S.I. Methods for Evaluating and Treating ASR-Affected Structures: Results of Field Application and Demonstration Projects: Volume II-Details of Field Applications and Analysis; United States, Federal Highway Administration: Washington, DC, USA, 2013. [Google Scholar]

- Godart, B.; Michel, M.; Fasseu, P. Treatment of structures by waterproof coating. In Proceedings of the 10th International Conference on Alkali-Aggregate Reaction in Concrete, Melbourne, Australia, 18–23 August 1996. [Google Scholar]

- Salamy, R.; Lima, M.; Miller, D. Rehabilitation and CFRP strengthening of ASR affected concrete bridge piers. In Proceedings of the 5th fib Congress, Krakow, Poland, 27–29 May 2019; pp. 3896–3903. [Google Scholar]

- Powers, N.; Frangopol, D.M.; Al-Mahaidi, R.; Caprani, C. Maintenance, Monitoring, Risk and Life-Cycle Performance of Bridges; Taylor & Francis: Abingdon, UK, 2018. [Google Scholar]

- Houde, J.; Lacroix, P.; Morneau, M. Rehabilitation of railway bridge piers heavily damaged by alkali-aggregate reaction. In Proceedings of the 7th ICAAR, Ottawa, ON, Canada, 16–20 August 1987; pp. 163–167. [Google Scholar]

- Imai, H.; Yamasaki, T.; Maehara, H.; Miyagawa, T. The Deterioration by Alkali-Silica Reaction of Hanshin Expressway Concrete Structures-Investigation and Repair. In Proceedings of the 7th International Conference on Concrete Alkali-Aggregate Reactions; The National Academies of Sciences: Ontario, Ottawa, ON, Canada, 1986; pp. 131–135. [Google Scholar]

- Torii, K.; Kumagai, Y.; Okuda, Y.; Ishii, K.; Sato, K. Strengthening Method for ASR Affected Concrete Piers Using Prestressing Steel Wire. In Proceedings of the 11 th International Conference on Alkali-Aggregate Reaction, Quebec City, QC, Canada, June 2000; pp. 1225–1233. [Google Scholar]

- Custódio, J.; Silva, H.; Rodrigues, M.P.; Cabral-Fonseca, S.; Ribeiro, A.B.; Morais, F. Performance of a polymeric coating material applied to a concrete structure affected by internal expansive chemical reactions. Procedia Struct. Integr. 2024, 54, 271–278. [Google Scholar] [CrossRef]

- Ehsani, M.; Day, S.; White, T. Repair of ASR-Damaged Piles. Concr. Int. 2017, 39, 61–65. [Google Scholar]

- Bérubé, M.-A.; Chouinard, D.; Pigeon, M.; Frenette, J.; Rivest, M.; Vézina, D. Effectiveness of sealers in counteracting alkali-silica reaction in highway median barriers exposed to wetting and drying, freezing and thawing, and deicing salt. Can. J. Civ. Eng. 2002, 29, 329–337. [Google Scholar] [CrossRef]

- Deschenes, R., Jr.; Hale, W. Blackwell Rural Transportation Center. Alkali-Silica Reaction Mitigation & Prevention Measures–Phase I; Arkansas Department of Transportation and Mack Blackwell Rural Transportation Center: Fayetteville, AR, USA, 2017; Available online: https://mack-blackwell.uark.edu/Research/mbtc-4000-final-report.pdf (accessed on 25 September 2024).

- Kurtis, K.E.; Stewart, L.K.; Kumar, D. Recommendations for Extension in Service Life of ASR-Affected Concrete, Georgia; Department of Transportation, Office of Performance-Based: Washington, DC, USA, 2024. [Google Scholar]

- Strauss, P.; Schnitter, O. Rehabilitation of a Portland cement concrete pavement cracked by alkali-aggregate reaction. In Proceedings of the 7th ICAAR, Ottawa, ON, Canada, 16–20 August 1987; pp. 210–214. [Google Scholar]

- Heymsfield, E.; Deschenes, R.; Hale, W.M.; Kuss, M.L. Alkali–Silica Reaction Identification and Remediation at Northwest Arkansas Regional Airport. J. Perform. Constr. Facil. 2016, 30, 04015063. [Google Scholar] [CrossRef]

- Basham, K.D. Evaluation of Treatment Options for ASR-Affected Concrete: Final Report, December 11, 2009; Wyoming Department of Transportation: Cheyenne, WY, USA, 2009. [Google Scholar]

- Cavalcanti, A.; Campos, A.; Silveria, E.; Wanderley, E. Rehabilitation of a generating unit affected by alkali-aggregate reaction. In Proceedings of the 11th International Conference on Alkali-Aggregate Reaction in Concrete, Quebec City, QC, Canada, 11–16 June 2000; pp. 11–16. [Google Scholar]

- Resendez, Y.A. Monitoring of an Outdoor Exposure Site: Evaluating Different Treatment Methods for Mitigation of Alkali-Silica Reactivity in Hardened Concrete. Master’s Thesis, The University of Texas at Austin, Austin, TX, USA, 2011. [Google Scholar]

- Blight, G.E.; Alexander, M.G. Alkali-Aggregate Reaction and Structural Damage to Concrete: Engineering Assessment, Repair and Management; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Abdullah, S.R. Experimental investigation of CFRP confined columns damaged by alkali aggregate reaction. Int. J. Integr. Eng. 2012, 4, 49–52. [Google Scholar]

- Abdullah, S.; Shayan, A.; Al-Mahaidi, R. Strain monitoring of CFRP wrapped RC columns damaged by alkali aggregate reaction. In Proceedings of the 14th International Conference on Alkali-Aggregate Reaction in Concrete (ICAAR), Austin, TX, USA, 20–25 May 2012. [Google Scholar]

- Kubat, T.; Al-Mahaidi, R.; Shayan, A. Strain development in CFRP-wrapped circular concrete columns affected by alkali-aggregate reaction. Constr. Build. Mater. 2016, 113, 603–612. [Google Scholar] [CrossRef]

- Kubat, T.; Al-Mahaidi, R.; Shayan, A. Rehabilitation of Alkali-Aggregate Reaction Damaged Bridge Columns Using CFRP Composites; Taylor & Francis: Abingdon, UK, 2014; pp. 848–854. [Google Scholar]

- Diab, S.; Soliman, A.; Nokken, M. Exterior strengthening for ASR damaged concrete: A comparative study of carbon and basalt FRP. Constr. Build. Mater. 2020, 235, 117435. [Google Scholar] [CrossRef]

- Giebson, C.; Seyfarth, K.; Stark, J. Influence of acetate and formate-based deicers on ASR in airfield concrete pavements. Cem. Concr. Res. 2010, 40, 537–545. [Google Scholar] [CrossRef]

- Antolik, A.; Jóźwiak-Niedźwiedzka, D. ASR induced by chloride-and formate-based deicers in concrete with non-reactive aggregates. Constr. Build. Mater. 2023, 400, 132811. [Google Scholar] [CrossRef]

- Chatterji, S.; Thaulow, N.; Jensen, A. Studies of alkali-silica reaction. Part 4. Effect of different alkali salt solutions on expansion. Cem. Concr. Res. 1987, 17, 777–783. [Google Scholar] [CrossRef]

- Fournier, B.; Bérubé, M.; Thomas, M.; Smaoui, N.; Folliard, K. Evaluation and Management of Concrete Structures Affected by Alkali-Silica Reaction—A Review. In Proceedings of the 7th CANMET/ACI International Conference on Recent Advances in Concrete Technology, Las Vegas, NV, USA, 26–29 May 2004; pp. 1–60. [Google Scholar]

- Moradllo, M.K.; Sudbrink, B.; Ley, M.T. Determining the effective service life of silane treatments in concrete bridge decks. Constr. Build. Mater. 2016, 116, 121–127. [Google Scholar] [CrossRef]

- Chana, P.; Korobokis, G. The Structural Performance of Reinforced Concrete Affected by Alkali Silica Reaction: Phase II; Transport and Road Research Laboratory: Berkshire, UK, 1992. [Google Scholar]

- Monette, L.J.-G. Effects of the Alkali-Silica Reaction on Unloaded, Statically Loaded and Dynamically Loaded Reinforced Concrete Beams; University of Ottawa: Ottawa, ON, Canada, 1999. [Google Scholar]

- Rivard, P.; Saint-Pierre, F. Assessing alkali-silica reaction damage to concrete with non-destructive methods: From the lab to the field. Constr. Build. Mater. 2009, 23, 902–909. [Google Scholar] [CrossRef]

- Gallias, J. Comparison of Damaging Criteria for Testing Aggregates by Autoclaving Treatment. In Proceedings of the International Conference, Alkali-Aggregate Reaction in Concrete, Quebec City, QC, Canada, June 2000; pp. 949–958, ISBN 2980676209. [Google Scholar]

- Sargolzahi, M.; Kodjo, S.A.; Rivard, P.; Rhazi, J. Effectiveness of nondestructive testing for the evaluation of alkali–silica reaction in concrete. Constr. Build. Mater. 2010, 24, 1398–1403. [Google Scholar] [CrossRef]

- Wang, J.; Humphrey, M.; Bayer, D. Control of ASR expansion by coatings. In Proceedings of the 10th International Conference on Alkali-Aggregate Reaction in Concrete, Melbourne, Australia, 18–23 August 1996. [Google Scholar]

- Snyder, K.A.; Lew, H.S. Alkali-Silica Reaction Degradation of Nuclear Power Plant Concrete Structures: A Scoping Study; National Institute of Standards and Technology (NIST), US Department of Commerce: Gaithersburg, MD, USA, 2013; Document ID-NISTIR 7937.

- Tan, B.; Qu, L.; Xia, Y.; Yang, X.; Su, B.; Wu, J.; Xiao, M. Experimental Study on Improving the Impermeability of Concrete under High-Pressure Water Environments Using a Polymer Coating. Appl. Sci. 2024, 14, 8507. [Google Scholar] [CrossRef]

- Zhou, Q.; Xu, Q. Experimental study of waterproof membranes on concrete deck: Interface adhesion under influences of critical factors. Mater. Des. 2009, 30, 1161–1168. [Google Scholar] [CrossRef]

- Stark, D.; Morgan, B.; Okamoto, P. Eliminating or Minimizing Alkali-Silica Reactivity; National Research Council: Washington, DC, USA, 1993.

- Attanayaka, U.; Ng, S.Y.-C.; Aktan, H. Criteria and Benefits of Penetrating Sealants for Concrete Bridge Decks; Michigan Department of Transportation: Lansing, MI, USA, 2002. [Google Scholar]

- Behravan, A.; Aqib, S.M.; Delatte, N.J.; Ley, M.T.; Rywelski, A. Performance Evaluation of Silane in Concrete Bridge Decks Using Transmission X-ray Microscopy. Appl. Sci. 2022, 12, 2557. [Google Scholar] [CrossRef]

- The Concrete Captain. What Happens If You Put Concrete Sealer on Too Thick? Avoid Common Mistakes. Available online: https://concretecaptain.com/what-happens-if-you-put-concrete-sealer-on-too-thick (accessed on 16 April 2025).

- BASF, High-Performance, Clear, 100% Silane Penetrating Sealer, Hydrozo® 100 Product Data. 2013. Available online: https://www.bestmaterials.com/PDF_Files/h10_tdg.pdf (accessed on 20 September 2024).

- Almusallam, A.; Khan, F.; Dulaijan, S.; Al-Amoudi, O. Effectiveness of surface coatings in improving concrete durability. Cem. Concr. Compos. 2003, 25, 473–481. [Google Scholar] [CrossRef]

- Stokes, D.; Pappas, J.; Thomas, M.; Folliard, K. Field cases involving treatment or repair of ASR affected concrete using lithium. In Proceedings of the 6th CANMET/ACI International Conference on Durability of Concrete, Thessaloniki, Greece, 1–7 June 2002. [Google Scholar]

- Johnston, D.; Surdahl, R.; Stokes, D. A case study of a lithium-based treatment of an ASR-affected pavement. In Proceedings of the 11th International Conference on Alkali-Aggregate Reaction in Concrete, Quebec City, QC, Canada, 11–16 June 2000; pp. 1149–1158. [Google Scholar]

- Folliard, K.; Thomas, M.; Fournier, B.; Resendez, Y.; Drimalas, T.; Bentivegna, A. Evaluation of mitigation measures applied to ASR-affected concrete elements: Preliminary findings from Austin, TX Exposure Site. In Proceedings of the 14th International Conference on Alkali-Aggregate Reaction, Austin, TX, USA, 20–25 May 2012. [Google Scholar]

- Shayan, A.; Xu, A.; Salamy, R. Confinement of AAR expansion in cylindrical reinforced columns by CFRP wrapping. In Proceedings of the 14th International Conference on Alkali-Aggregate Reaction, Austin, TX, USA, 20–25 May 2012. [Google Scholar]

- Sims, F. The application of epoxy resins in bridge construction with particular reference to Rawcliffe Bridge. In Resins and Concrete; Thomas Telford Publishing: London, UK, 2011; pp. 1–16. [Google Scholar]

- Wigum, B.; Thorenfeldt, E. Sheets of Carbon Fibre Reinforced Polymers (CFRP) as a Repair Material in Order to Strengthen and Repair Concrete Damaged by Alkali Aggregate Reaction. In Proceedings of the 12th International Conference on Alkali-Aggregate Reaction in Concrete, Beijing, China, 15–19 October 2004. [Google Scholar]

- Shayan, A.; Xu, A.; Olasiman, R. Factors affecting the expansion and cracking of model bridge piles in seawater, and the effects of mechanical confinement. Road Transp. Res. J. Aust. N. Z. Res. Pract. 2008, 17, 23–37. [Google Scholar]

- Shayan, A.; Xu, A.; Olasiman, R.; Salamy, R. Effectiveness of CFRP wrapping in confining the expansion of AAR-affected concrete. In Proceedings of the 7th Austroads Bridge Conference: Bridges Linking Communities, Auckland, New Zealand, 26–29 May 2009. [Google Scholar]

- Lee, L.S.; Jain, R. The role of FRP composites in a sustainable world. Clean Technol. Environ. Policy 2009, 11, 247–249. [Google Scholar] [CrossRef]

| Structure | Time to Distress | Cause and Damage | Repair Strategies | Repair Effectiveness | Ref. |

|---|---|---|---|---|---|

| Val De La Mare Dam, Jersey, UK Construction: 1958–1962 | 9 years (1971) | Cause: -Aggregates with reactive silica and cement alkali content of up to 0.95% Na2Oeq. Damage -Cracking and differential displacement in mass concrete blocks. | In 1974: -Anchoring into underlaying rock with post-tensioned steel bars. Pressure relief drainage holes were also drilled. -Polymer grout was used to seal cracks. In 2011: -Lining with polyvinyl chloride (PVC) geomembrane and geotextile. The liner was bonded with epoxy resin and stainless-steel strips. | 1975 to 2010: -Expansion continued; -One anchor failed; -Grout ineffective in sealing cracks; -Service life extended; 2011 to date: -No further updates are available. | [8,9,10] |

| Maentwrog Dam, UK Construction: 1926–1928 | N/S * | Cause: -Use of greywacke reactive aggregates. Damage -Cracking and seepage. | In 1944: -After minimal success in reducing leakage, the upstream face was reinforced using the gunite method. In 1958–1978: -The gunite layer was removed, and the upstream face was covered with glass fiber-reinforced bitumen; -Several grouting attempts were made. In 1983: -Cracks on the upstream face were sealed using an underwater elastomeric sealant. | In 1992: The dam had to be replaced due to severe ASR damage. | [11] |

| Gravity Dam, India Construction: 1962 | 25 years | Damage -Cracks on the upstream face; -The structural stability of the dam was not compromised, but its serviceability was affected. | In late 1980s: -Cracks on the upstream face were sealed with epoxy grout and then painted with epoxy. In late 1990s: -Various repair products were employed; -A specialized repair mortar was applied as a cementitious slurry to the pre-saturated surfaces of the existing structures. | Late 1990s to date: -No further updates are available. | [12] |

| Wastewater Treatment Plant, OK, USA | N/S | Damage -Widespread map cracking; -Large cracks; -Out-of-plane displacements. | -A structural retrofit was implemented; -Large ring beams were designed and dowelled into the existing basin walls; -Existing cracks were sealed by applying a robust epoxy-based coating; -Large cracks were sealed with epoxy injection. | -The coating is expected to last around 20 years, and, with one additional reapplication, the overall service life of the structure is expected to extend over 35 years; -The overall repair cost was 22.8% of the replacement cost; -No further updates are available. | [13] |

| Marine Structure, Western Australia Construction: 1962 | 39 years (1992) | Damage -Cracks measuring 0.4 to 0.6 mm in width; -The cracks varied in depth from 50 to 150 mm and were most severe at the ends of the beams; -About 50% of the transverse beams and 20% of the longitudinal beams exhibited these cracks. | -A trial silane coating was applied to one of the transverse beams. | -The silane coating effectively reduced the rate of expansion; -The silane coating was not sufficient to resolve the problem entirely; -Replacing the affected components was determined to be the most effective solution. | [14] |

| Structure | Time to Distress | Cause and Damage | Repair Strategies | Repair Effectiveness | Ref. |

|---|---|---|---|---|---|

| 7 pre-stressed post-tensioned single-span UK Bridge Construction: 1974/75 | 7 years | -ASR cracking in precast prestressed concrete beams; -The strength of the beams had not been compromised. | -Cracks treated with epoxy (1984/85); -One bridge was painted with a protective coating (1987). | -Crack repair ineffective; -Structure remained in service; -No further updates are available. | [15] |

| Long Bridge, Australia Construction: 1979 | 13 years | Cause: -Marine environment contributed to ASR. Damage -Severe ASR cracking in piles; -Crack widths ranged from 0.1 mm to a maximum of 8 mm; -Crack orientation being vertical, aligned with the axis of the pile. | -Piles with individual crack widths in the range of 2–3 mm where ASR expansion had nearly ceased were selected for repair; -Circular reinforced concrete jackets were used. | -No further updates are available. | [16] |

| Great River Bridge, IA, USA Construction: 1992 | <1 year | Damage -ASR in reinforced concrete pylons; -Crack widths ranged from 0.5 mm to 0.8 mm; -In 2003, the maximum measured centerline crack widths reached approximately 7.6 mm. | -Breathable coating was applied. | -The cost of the repair was approximately 7% of the bridge’s replacement cost; -No further updates are available. | [17] |

| Bibb Graves Bridge, AL, USA Construction: 1931 | 25 years (1956) | Cause: -Use of siliceous gravel coarse aggregate and predominantly siliceous natural sand fine aggregate. Damage -ASR in the reinforced concrete arch. | -Water blasting and silane sealer application; -A hydrophobic penetrating sealer was applied (2010); -Cracks were filled with flexible sealant (2010); -Epoxy flood coat applied at the top of the arches (2010). | -Not effective, expansion and cracking continued. | [18] |

| Montrose New Bridge, Montrose, Scotland Construction: 1931 | 29 years (1960) | Damage -ASR cracks in superstructure. | -Cracks injected with epoxy resin and repair areas sealed with epoxy mortar (1979); -Reinforcing the bridge with straps, plates, and tensioned through-bolts to provide full containment (1994). | -Not effective, expansion and cracking continued; -Bridge was removed from service in 2004. | [19,20] |

| Elgeseter Bridge, Norway Construction: 1951 | 40 years (1990s) | Damage -Vertical cracks in the columns; -Horizontal displacement of columns; -Closure of the expansion joint. | -Expansion joint, which had closed, was repaired with epoxy concrete (1995); -Columns were treated using different silanes (1999); -One row of columns was repaired using CFRP ** (2003); -The most critical beams were rehabilitated using CFRP (2013); -New membranes were applied to the driving lanes and pedestrian sections (2014 & 2015). | -The repairs completed before 2000 were not effective; -ASR remains a significant concern for this infrastructure. | [21,22,23,24] |

| Highway Bridge Columns, TX, USA Construction: 1990s | 5–7 years | Damage -ASR cracks in substructure. | -Different repair techniques as field testing:

| -Lithium impregnation exacerbated ASR expansion; -Topical silane applied over a blasted surface did not reduce expansion; -Sodium silicate applied over a blasted surface, topical silane applied over the original painted surface, and lithium vacuum impregnation effectively controlled expansion. | [25] |

| Series of bridges, ME, USA Construction: N/S | N/S * | Damage -ASR cracks in the substructure. | -ASR was treated using various surface treatment products, including 100% silane, 40% water-based silane, elastomeric coating, and electrochemical lithium (2010); -One severely deteriorated column was reinforced with four layers of CFRP. | -The lithium treatment appeared to increase expansion in the treated elements; -Silane treatment was not effective in reducing RH ***; -Silane treatment on a slender circular column may have reduced expansion; -It was too early to draw definitive conclusions. | [26] |

| 4-span continuous reinforced concrete slab bridge structure, France Construction: 1976 | 10 years (1986) | Damage -ASR damage in both superstructure and substructure. | -Cracks were repaired with an epoxy resin mortar (1990); -A coating system was applied (e.g., cold impregnation, a bituminous membrane, asphalt, and a gravel-coated wearing course) (1990); -The underside of the deck, piers, and abutments were coated with a polymer-modified cement mortar (1990). | -The waterproofing effort was unsuccessful. | [27] |

| Four railway bridges, Victoria, Australia Construction: 1957–1958 | N/S | Damage -ASR and Delayed Ettringite Formation (DEF) in the piers; The cracks varied in width and length, ranging from 0.1 mm to 10 mm. | -CFRP was used for severely affected piers; -Cracks were filled with epoxy injection; -Following the application of CFRP, a protective and waterproofing coating was added. | 2019 to date: -Repair remains fully functional and has not encountered any issues. | [28,29] |

| Railway Bridge, Montreal, Canada Construction: N/S | N/S | Damage -Piers showed significant damage due to ASR. | -Holes were drilled into the piers to insert steel columns to transfer the bridge loads to deeper, undamaged concrete. | -The repair cost was only 10% of the cost of replacing the bridge with a new structure; -No further updates are available. | [30] |

| Hanshin Expressway, Japan Construction: 1979 | 4 years (1982) | Damage -ASR damage was identified in the concrete piers. | -Piers were dried to a moisture level below 80%; -Cracks were filled with epoxy resin injected under pressure. Two surface repair methods were used (one involved epoxy resin coating, and the other, silane impregnation, was followed by polymer cement for protection). | -Repair was effective in controlling ASR. | [31] |

| Toyokawa Highway Bridge, Japan Construction: 1979 | 21 years (1990) | Damage -ASR damage was identified in the concrete columns and beams; -Cracks widened progressively over time. | -Prestressing steel wire known as the PC confined method was applied. | -A significant reduction in the expansion rate was observed. | [32] |

| Bridge at the interchange of I-10 and I-45 in Houston, TX, USA Construction: Late 1990s | 7 years (2006) | Damage -The columns of the bridge were identified as suffering from ASR. | -The treatment methods evaluated included lithium nitrate applications (via vacuum and electrochemical processes) and various coatings/sealers such as sodium silicate and a silane/siloxane blend. | -Lithium treatments were not effective; -The effectiveness of silane depended on the surface preparation; -For other repair techniques, the results were inconclusive as the degree of the ASR and the state of the ASR in the treated elements had an impact on the treatment performance. | [26] |

| Curved prestressed reinforced concrete bridge, Portugal Construction: 1998 | 11 years (2009) | Damage -Severe cracking was observed in certain piers due to ASR and DEF. | -A coating system applied consisted of a polymer-modified cementitious layer and a water-based acrylic layer (2021). | -Coating was not effective in areas exposed to moisture. | [33] |

| Barron River Bridge, Queensland, Australia Construction: 1977 | 23 years (2000) | Damage -Severe cracking was observed in certain piers. | -A special wrapping system consisting of laminates of carbon or glass fabric that were saturated with resin was applied; | -The repair is still functional; -The repair cost 37.5% of the reinforced concrete encasement. | [34] |

| Location | Repair Strategies | Repair Effectiveness | Ref. |

|---|---|---|---|

| Canada | -Four different types of sealers: two silanes, one oligosiloxane, and one polysiloxane were applied on different sections of two highway median barriers (1991). | -Different performances were observed among different sealers; -The effectiveness of oligosiloxane- and polysiloxane-based sealers to control ASR expansion was limited to one or two years. | [35] |

| MA, USA | -A total of 30% lithium nitrate, applied both topically (in single, double, and quadruple applications) and by vacuum impregnation (single and double applications) (2005); -Lithium silicate and silane treatments (20% and 40% alcohol-based, and 40% water-based) were also applied (2005); -An elastomeric paint was applied over the existing silane (2010). | -Lithium treatment was ineffective; -Silane-based treatments were effective. | [26] |

| Interstate 49 in Northwest Arkansas, USA | -Three commercially available products including silane, elastomeric breathable vapor, and boiled linseed oil were applied to different sections (2013). | -Silane treatments effectively reduced expansion; -Linseed oil and elastomeric paint treatments yielded inconclusive results. | [26,36] |

| Interstate 89 in VT, USA | -Barrier walls were treated with three different sealers: 100% silane, 40% water-based silane, and 40% alcohol-based silane, as well as an elastomeric coating (2011). | -No definitive conclusions about the performance of each sealer could be drawn; -It was deemed too early to draw any meaningful conclusions; -No further updates are available. | [26] |

| GA, USA | -Different sealers, including 100% silane, water-based silane, alcohol-based silane, and three proprietary slurry products, were applied. | -No conclusions could be drawn about the effectiveness of the treatments; -No further updates are available. | [37] |

| Location | Time to Distress | Repair Strategies | Repair Effectiveness | Ref. |

|---|---|---|---|---|

| South Africa Construction: 1969 | 6 years | -Different approaches were tested:

| -Replacing the pavement with high-quality concrete was the most effective repair strategy; -Undersealing had limited success in controlling vertical movement; -The freezing method was less successful than the concrete replacement method; -Geofabric-reinforced asphalt overlays showed limitations in handling environmental stresses and accelerated traffic loading. | [38] |

| Airport Runway Pavement, AR, USA Construction: 1998 | 4 years (2002) | -Various surface sealants were tested including elastomeric coating, linseed oil, and silane coating (2008). | -RH * varied with ambient conditions; -Silane and linseed oil had minimal effect in ASR control; -Elastomeric paint was ineffective; -Ultimately, the runway was replaced (2012). | [39] |

| Air Service Apron Pavement, WY, USA Construction: 1997 | 5 years | -Various chemical surface treatments and sealers including sodium tartrate, siloxane, silane, lithium nitrate, a combination of lithium nitrate with silane and siloxane, and boiled linseed oil were applied (2006). | -The repair was ineffective; -The apron was replaced (2008). | [40] |

| AR, USA | N/S ** | -Two different silane-based sealers including 100% silane and 40% water-based silane were applied to the pavement. | -It was deemed too early to draw any meaningful conclusions; -No further updates are available. | [26] |

| DE, USA | N/S | -Pavement was treated by topical application of 30% lithium nitrate (2009). | -The repair was ineffective. | [26] |

| Structure | Time to Distress | Repair Strategies | Repair Effectiveness | Ref. |

|---|---|---|---|---|

| Generating Unit, Brazil Construction: 1972–1997 | <10 years | -Structural modifications were applied; -The accumulated stress was released by cutting some elements; -Turbine parts were repositioned. | -Repair was effective; -No further updates are available. | [41] |

| Specimen | Experimental Program | Repair Strategies | Repair Effectiveness | Ref. |

|---|---|---|---|---|

| Bridge decks | -A total of 60 bridge deck elements were constructed; -A total of 29 decks made with reactive fine aggregate, 29 decks made with reactive coarse aggregate, and two non-reactive slabs. | A series of treatment methods and materials were evaluated, including the following:

| -Silane was effective; -Concrete overlays with a two-layer waterproofing membrane were effective; -Other treatments were not effective. | [42] |

| Concrete columns | -A total of 36 spirally reinforced concrete columns were constructed; -Half of the columns were made with reactive fine aggregate, while the other half used reactive coarse aggregate. |

| -Electrochemical treatment with lithium nitrate did not yield any benefits; -Both types of silane were effective in reducing column expansion; -The outcomes for columns treated with CFRP wraps and the eliminator membrane were inconclusive. | [42] |

| Specimen | Experimental Program | Repair Strategies | Repair Effectiveness | Ref. |

|---|---|---|---|---|

| Concrete beams | -A series of large beams (“large” is not defined) were fabricated; -One set of samples was tested in a mild climate with seasonal rain; -The other set was exposed to a climate having summer rainfall and dry cool winters. | -A total of 19 surface treatments were tested; - Treatments included acrylic PVA, magnesium fluosilicate, polyurethane, and silicone; -Silane and silicone were applied as pore liner penetrants. | -Surface treatments were not effective; -After four years of exposure, the silane retained its effectiveness, while the silicone lost its impact. | [43] |

| Concrete columns | -Two types of reinforced concrete (RC) columns, circular and square, were prepared for testing; -The specimens were kept in an environment at 8 °C and 100% RH for up to six months. | Two confinement approaches were applied to the damaged columns:

| -CFRP was effective in maintaining the load capacity of these columns | [44,45] |

| Circular concrete columns | -A total of 26 columns, using reactive aggregates, were prepared; -The columns were wrapped with one or two layers of CFRP at different stages of expansion. | -CFRP was applied at various intervals after casting and monitored both radial and axial expansion. | -CFRP wrapping significantly reduces both radial and axial expansion; -The efficiency of reducing ASR expansion depended on both the timing of the CFRP wrapping and the number of layers applied to the column. | [46,47] |

| Concrete cylinders | -Concrete cylinders with reactive aggregates were cast; -Wrapping was applied at different stages of ASR expansion; -Key parameters such as expansion, stiffness damage index (SDI), and compressive strength were measured. | -CFRP and Basalt Fiber-Reinforced Polymer (BFRP) wraps were applied. | -Both wrapping systems were effective. | [48] |

| DOT | ASR Severity | Aggregates | ASR Mitigation Strategies | Effectiveness |

|---|---|---|---|---|

| Alabama | Not significant | -Limestone and sandstone in the north and river gravel in the south. | -Cement alkali content limit: ≤0.6% Na2Oeq. -Concrete alkali loading limit: ≤2.4 Kg/m3 (4.00 lb/yd3). -Aggregate reactivity tests: None. -SCMs: Fly ash is primarily used. | -Satisfied with their outcomes. |

| Arkansas | Moderate | -Reactive fine river gravel. | -Cement alkali content limit: ≤0.6% Na2Oeq. -Aggregate reactivity tests: ASTM C1260 and ASTM C1567. -SCMs (since the mid-90s): Primarily fly ash capped at 20%. | -Not satisfied with reactivity tests. -Aiming to increase fly ash content to 25% for better ASR mitigation. |

| California | Moderate to severe | -Moderately to highly reactive aggregates. | -Cement alkali content limit: ≤0.6% Na2Oeq. -Aggregate reactivity tests: ASTM C1293, ASTM C1260. -SCMs (since the mid-90s): Fly ash, metakaolin, silica fume, and Ground Granulated Blast-Furnace Slag (GGBFS), natural pozzolans and blended SCMs. | -Satisfied with their outcomes. |

| Colorado | Moderate | -Most aggregates are reactive. -Slightly reactive aggregates found around the Denver Metro area. | -Cement alkali content limit: No limits. Used to be ≤0.6% Na2Oeq. -Aggregate reactivity tests: ASTM C1260, ASTM C1567. -SCMs (since the mid-80s): Minimum of 20% Class F, natural pozzolans (e.g., volcanic ash). | -The experience with fly ash has been mixed, while earlier projects encountered air issues. -Newer mixes incorporating up to 50% pozzolans have been more successful. |

| Connecticut | Not significant | -No known reactive aggregates. -The typical aggregates used include trap rock, various broken and crushed stones, and some gravel. | -Cement alkali content limit: No limits. -Aggregate reactivity tests: petrographic analysis for new sources. -SCMs (since 1990s): Slag (20–30%) and recycled glass known as “Pozzotive”. | -Satisfied with their outcomes. |

| Delaware | Severe | -Limestone aggregates sourced from Maryland and Pennsylvania. -Reactive sands. | -Cement alkali content limit: ≤1.25% Na2Oeq. -Concrete alkali loading limit: ≤1.50 Kg/m3 (2.5 lb/yd3). -Aggregate reactivity tests: ASTM C1260 and ASTM C1567. -SCMs (since mid-1990s): 40% fly ash and 50% slag in standard mixes, 35–40% fly ash or 65% slag for higher alkali cements. | -Discrepancies have been observed between ASTM C1260 and ASTM C1293. -ASTM C1260 test producing false positives. -Incorporating SCMs helped the state to reduce the ASR issues. |

| Florida | Not significant | -Predominantly limestone. | -Cement alkali content limit: ≤0.6% Na2Oeq. -SCMs (since the mid-80s): Primarily fly ash Class F with typical replacement levels between 18% and 20%, though this can go up to 50%. | -Satisfied with their outcomes. |

| Idaho | Moderate to severe | -Fine and coarse reactive aggregates. | -Cement alkali content limit: ≤0.6% Na2Oeq. -Concrete alkali loading limit: ≤1.80 Kg/m3 (3 lb/yd3) (was removed since contractors could not meet that standard). -Aggregate reactivity tests: AASHTO T380 and CRD C662, which accounts for lithium. -SCMs: Fly ash, lithium, and slag in the northern regions. | -The state is satisfied with the aggregate reactivity testing methods. -The current test methods are unreliable for job mix evaluation. -Despite including 20–25% fly ash in the mixes, ASR issues persist. |

| Illinois | Moderate | -Reactive fine aggregates. -Coarse aggregates are crushed limestone or dolomitic limestone. | -Cement alkali content limit: ≤ 0.4% Na2Oeq for very reactive aggregates, 0.6% Na2Oeq for reactive aggregates, no limits for nonreactive aggregates. -Concrete alkali loading limit: Indirectly considered by limiting maximum cement content. -Aggregate reactivity tests: ASTM C1260. -SCMs (since mid-1980s): Class C and F fly ash and Grade 100 slag cement. | -The use of Class F fly ash is on the rise, as it is deemed effective in countering ASR. |

| Indiana | Not significant | -Limestone, dolomitic limestone, and natural sand. -Did not exhibit reactive tendencies. | -Adhering to AASHTO M240. -Aggregate reactivity tests: No standard tests. -SCMs: Fly ash (28%) and slag (30%). | -Satisfied with their outcomes. |

| Louisiana | ASR: Not significant ACR: Significant | -Chert river gravel as the main aggregates. -Limestone from Mexico, Kentucky, and Missouri. | -Cement alkali content limit: ≤0.6% Na2Oeq. -Producing low-permeability concrete. -Aggregate reactivity tests: switching to AASHTO T380, AASHTO TP 144 (T-FAST). -SCMs (since mid-1980s): Slag, fly ash, or a combination, ternary systems (slag, class F fly ash + class C fly ash). -The state mandates that nearly all mixes contain at least 50% SCMs. | -Since introducing these SCMs, the state has reported no ASR issues. -ASTM C1260 has produced many false positives. |

| Maine | Severe | -Gravel with non-reactive to moderately reactive. | -Cement alkali content limit: No limits. -Aggregate reactivity tests: ASTM C1567, looking at AASHTO TP 144 (T-FAST). -SCMs (since 2000s): primarily 50% slag. | -Inconsistent results from ASTM C1567. |

| Michigan | Severe | -Coarse aggregates are primarily limestone and carbonate types. -Fine aggregates are reactive. | -Cement alkali content limit: No limits. -Aggregate reactivity tests: ASTM C1567, C1260, and C1293. -SCMs (since 1980s, mandated in 2012): Slag is used more often than fly ash. | -N/A * |

| Minnesota | Mild | -Quartzite, granite, basalt, carbonate rocks and natural gravel. -Fine aggregates are reactive. | -Cement alkali content limit: No limits (used to be 0.60% Na2Oeq). -Concrete alkali loading limit: ≤1.80 Kg/m3 (3 lb/yd3) (removed). -Aggregate reactivity tests: Modified ASTM C1567 and modified ASTM C1260. -SCMs (since 1970s): 30% Class C fly ash, 20% Class F fly ash, or 35% slag. | -Satisfied with their outcomes. |

| Nevada | Not significant | -Northern region primarily composed of volcanic rock sources. -The southern regions are dominated by limestone and some basalt. | -Cement alkali content limit: ≤0.6% Na2Oeq. -Concrete alkali loading limit: Indirectly considered by limiting maximum cement content. -Aggregate reactivity tests: AASHTO T303. -SCMs (since early 2010s): Southern region primarily utilizes fly ash, while the northern region uses Class N pozzolans, such as calcined clay and metakaolin. -Applying epoxy or polymer overlays on newly constructed concrete bridge decks. | -Satisfied with their outcomes. |

| New York | Not significant | -Limestone, dolomite, sandstone, granite, trap rock, marble, and argillite. -Aggregate sources include some reactive materials from across the Northeast. -Reactivity classification of many sources remains unclear. | -Cement alkali content limit: ≤0.7% Na2Oeq for reactive aggregates. If cement alkali content exceeds 0.7% with reactive aggregates, SCMs must be used. -Begun to consider alkali loading. -Aggregate reactivity tests: In-house petrographic evaluation of aggregates. Third-party testing (AASHTO TP 144 (T-FAST)). -SCMs (Since mid-1990s): Fly ash, silica fume, and slag cement. -Moving towards PEM. | -ASTM C1260 gives false positives or negatives. -Satisfied with their outcomes. |

| North Carolina | Mild to Moderate | -Aggregates with different levels of reactivity. | -Cement alkali content limit: ≤1% Na2Oeq. If cement alkali content exceeds 0.6%, SCMs must be used. -Aggregate reactivity tests: AASHTO T380, AASHTO TP 144 (T-FAST), modified T-FAST. -SCMs: Began using SCMs in early 2000s. | -Satisfied with their outcomes. |

| North Dakota | Mild | -Glacially deposited aggregates and dolomite. -Non-reactive for the most part. -Reactive sand used in pavements. | -Cement alkali content limit: ≤0.6% Na2Oeq. -Aggregate reactivity tests: ASTM C1260 and ASTM C1567. They have considered AASHTO TP 144 (T-FAST). -SCMs (Since 1980s): Class F fly ash at 20–30% (25% typical). | -Satisfied with their outcomes. |

| Ohio | Not significant | -Gravels, limestone, dolomite, and lightweight aggregate (expanded shale). -Non-reactive aggregates for the most part. | -Cement alkali content limit: No limits. -Aggregate reactivity tests: ASTM C1293. -SCMs (Since 1990s): Fly ash (up to 25%), slag cement (up to 30%), and silica fume. | -Satisfied with their outcomes. |

| Oklahoma | Not significant | -Mostly limestone. | -Cement alkali content limit: ≤ 0.95%Na2Oeq. -Aggregate reactivity tests: ASTM C1260. -SCMs: Fly ash (up to 20%), slag cement (up to 50%), and silica fume (up to 10%). | -Satisfied with their outcomes. |

| Pennsylvania | Mild to Moderate | -Carbonate, sedimentary, and metamorphic rocks. -Significant amounts of gravel used. -ASR issues with sedimentary rocks and certain natural sands. | -Cement alkali content limit: ≤1.25%Na2Oeq. -Pay attention to alkali loading, yet no requirement. -Aggregate reactivity tests: AASHTO T303 and ASTM C1293. ASTM C1778 for job mix evaluation. Exploring AASHTO TP 144 (T-FAST). -SCMs (Since 1990s): Class F and C fly ash, slag cement, and silica fume. -Lithium admixtures were also used. | -False negatives with AASHTO T303. -Satisfied with their outcomes. |

| Rhode Island | Moderate | -Mostly mildly reactive granitic aggregates. -One highly reactive source exists. | -Cement alkali content limit: No limits. -Aggregate reactivity tests: ASTM C1567. -SCMs (since mid-1990s): Mainly silica fume and fly ash. In some cases, slag cement. SCMs used since the mid-1990s for strength (silica fume). SCMs for ASR mitigation since 2008. | -Too early to determine effectiveness. |

| South Carolina | Not significant | -Mostly granite. | -Cement alkali content limit: ≤0.6% Na2Oeq. -Aggregate reactivity tests: None. -SCMs (since 1990s): Fly ash (up to 20%). | -Satisfied with their outcomes. |

| South Dakota | Moderate to Severe | -Coarse aggregates are crushed ledge rock, limestone, granite, and natural round river rock. Fine aggregates are natural sand. | -Cement alkali content limit: ≤0.6%Na2Oeq. -Aggregate reactivity tests: ASTM C1260 and ASTM C1567. -SCMs (since 1990s): Class C and F fly ash with a 20 to 25% replacement for cement. | -Problems observed with Class C fly ash. -Positive experience with Class F fly ash. |

| Tennessee | Moderate | -Granite, limestone, and gravel. -For the most part, aggregates are not reactive. | -Cement alkali content limit: ≤0.6% Na2Oeq for pavements only. -Aggregate reactivity tests: None specified. Has explored ASTM C1293. Considering AASHTO TP 144. -SCMs (since 1990s): Not mandatory, however, about 60% of their concretes contain SCMs. Class F fly ash (25%) or slag cement (35%) is primarily used. | -False positives and negatives with ASTM C1260. -Exploring new alternatives. |

| Texas | Mild (less than 1% of structures) | -Limestone and silicious gravels and sands. | -Concrete alkali loading limit: ≤2.1 Kg/m3 (3.5 lb/yd3). -Aggregate reactivity tests: None. -SCMs: Used since the late 1990s. | -Satisfied with their outcomes. |

| Utah | Not significant | -Non-reactive for the most part. | -Cement alkali content limit: ≤0.8% Na2Oeq. -Aggregate reactivity tests: ASTM C1260 and ASTM C1567. Tests performed by concrete producers. -SCMs: Fly ash and natural pozzolan for the most part at dosages of 20–40%. Used since the late 1990s. | -Satisfied with their outcomes. |

| Wyoming | Severe | -Very reactive. | -Cement alkali content limit: ≤0.65% Na2Oeq (old). -Concrete alkali loading limit: ≤2.4 Kg/m3 (4.00 lb/yd3) (new). -Aggregate reactivity tests: ASTM C1567. -SCMs (since late 1980s): Mainly fly ash (20–25%). Plans to increase the maximum dosage to 30%. Slag cement and natural pozzolan are emerging. -Lithium nitrate admixture. | -Positive results for lithium nitrate in combination with fly ash. -Working on improvements. |

| DOT | ASR-Affected Elements | ASR Repair Strategies | Effectiveness |

|---|---|---|---|

| Alabama | N/A * | N/A | N/A |

| Arkansas | -Primarily concrete pavements and median barrier walls; -No significant damage to its bridge infrastructure. | -Epoxy patches; -Milling and overlaying with ultra-thin bonded wearing courses. | -Epoxy patches failed; -Milling + overlay gave positive results, especially for pavement repairs. |

| California | -Column and footpath. | -Full replacement rather than repairs. | -The best remediation action. |

| Colorado | -Pavements, bridge decks, piers, columns, and abutments. | -Rubblizing pavements and covering them with asphalt; -In the case of a bridge, complete replacement is considered. | -Satisfied with their outcomes. |

| Connecticut | N/A | N/A | N/A |

| Delaware | -Pavements, bridge decks, piers, columns, abutments, footings, and parapets. | -Applying ultra-thin overlays such as NovaChip. | -Satisfied with their outcomes by getting more than 20 years of extra service life. |

| Florida | N/A | N/A | N/A |

| Idaho | -Bridge decks, footings, parapets. | -Replacement is preferred; -Where replacement is impractical, try to keep moisture away from affected structures by applying polyester overlays and silane. | -The repairs prolong the life of structures until they reach a point of irreparable damage. |

| Illinois | -Pavements, bridge decks, parapets | -Moisture management employing sealing applications on bridge parapets; -Milling pavements for overlay with hot mix asphalt | -Limited extension of service life, typically lasting between five to ten years. |

| Indiana | N/A | N/A | N/A |

| Louisiana | -ACR issues: Pavements, bridge decks, footings. | -Rubblization and overlay; -Dewatering and CFRP wraps; -Hydro-blasting and applying dense concrete overlays, or fiber-reinforced materials. | -Repairs are temporary solutions; -Replacement is the ultimate decision. |

| Maine | -Pavements and median barrier walls. | -Applying 100% silane, 40% water-based silane, elastomeric coatings, and lithium nitrate; -Important traffic areas are prioritized for replacement. | -Strategies were unsuccessful; -Replacement is typically the best option. |

| Michigan | -Bridges and roadways. | -Silane waterproofing is applied especially on decks; -Epoxy overlays. | -Data on long-term effectiveness are limited; -Replacing components has become the most common solution. |

| Minnesota | -Pavements. | -Full-depth replacements of severely damaged concrete; -Penetrating sealers; -Diamond grinding; -Lithium treatment. | -Full-depth replacement seems to work. It is under long-term evaluation; -Penetration sealers and lithium were ineffective; -Diamond grinding exacerbated the ASR issue. |

| Nevada | N/S ** | -Replacement of older structures, aged 50 to 70 years. | N/S |

| New York | N/A | N/A | N/A |

| North Carolina | -Areas experiencing wet–dry cycles such as bent caps; -Columns and piers. | -Deck overlay (latex-modified concrete, polymer concrete, or thin epoxy overlay) to limit water infiltration. -Wide cracks injected with epoxy, epoxy-coated jackets, and silane. -Decision depends on the severity, often leaning towards replacement. | -Too early to determine the effectiveness of epoxy-coated jackets. |

| North Dakota | -Primarily pavements (did not receive mitigation), footings, and parapets; -Typically observed at the end of service life, eliminating the need for repairs. | -Pavement rubblization; -Patching; -Replacement. | -Pavement rubblization is highly successful. |

| Ohio | N/A | N/A | N/A |

| Oklahoma | N/A | N/A | N/A |

| Pennsylvania | -Primarily pavements. | -Cost-based analysis to decide whether to repair or replace (moderately to severely affected structures); -If damage is too severe, then replacement; -For pavements, asphalt overlays are used to reduce water infiltration. | -Pavement overlay successful (20 to 25 years’ service life extension); -Challenges in determining the best repair strategies and scope of work. |

| Rhode Island | -Structural elements, particularly abutments. | -Penetrating sealers; -Remove affected concrete and replace it with higher-quality concrete. | -Penetrating sealers showed promise in slowing ASR progression; -Surface preparation and regular reapplication of sealers are challenges; -Effectiveness of strategies remains to be fully assessed. |

| South Carolina | N/A | N/A | N/A |

| South Dakota | -Bridge decks, barriers, and pavements. | -Topical lithium treatments; -Typically leaning towards replacement, especially for decks and pavements. | -Topical lithium: Minimal benefits and high cost. |

| Tennessee | -Bridge railings (ASR exacerbated by deicing salts) | -No formal repair strategies were implemented. | N/A |

| Texas | -Different structural elements like columns. | -Crack sealing; -Silane treatments; -CFRP wraps for columns; -Removal and replacement in rare cases; -Structural capacity of the affected element is assessed and managed until the end of service life. | -Success of these methods over time is difficult to determine (structures not actively monitored). -Repairs can help slow down ASR progression, but challenges remain with moisture retention in larger structures. -Applying sealers can be ideal if load capacity is intact. -Texas considers CFRP wraps the best solution for circular columns. On rectangular columns, full confinement was not achieved. -Wraps are effective in waterproofing and managing visible cracking. -Prevention is the most effective approach. |

| Utah | N/A | N/A | N/A |

| Wyoming | -Pavements and structural elements. | -Epoxy injection; -Silane/Siloxane sealers; -For small structures suffering from moderate to severe ASR, repair if moisture can be kept out, otherwise replace; -For larger structures, repairs should be re-applied until funds are available for replacement. | -Moderate success (5–10 years of service life extension). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behravan, A.; Arce, G.; Ozyildirim, H.C.; Spradley, E.; Davenport, C. Repair and Treatment of Alkali–Silica Reaction (ASR)-Affected Transportation Infrastructures: Review and Interview. Infrastructures 2025, 10, 101. https://doi.org/10.3390/infrastructures10040101

Behravan A, Arce G, Ozyildirim HC, Spradley E, Davenport C. Repair and Treatment of Alkali–Silica Reaction (ASR)-Affected Transportation Infrastructures: Review and Interview. Infrastructures. 2025; 10(4):101. https://doi.org/10.3390/infrastructures10040101

Chicago/Turabian StyleBehravan, Amir, Gabriel Arce, H. Celik Ozyildirim, Emily Spradley, and Cooper Davenport. 2025. "Repair and Treatment of Alkali–Silica Reaction (ASR)-Affected Transportation Infrastructures: Review and Interview" Infrastructures 10, no. 4: 101. https://doi.org/10.3390/infrastructures10040101

APA StyleBehravan, A., Arce, G., Ozyildirim, H. C., Spradley, E., & Davenport, C. (2025). Repair and Treatment of Alkali–Silica Reaction (ASR)-Affected Transportation Infrastructures: Review and Interview. Infrastructures, 10(4), 101. https://doi.org/10.3390/infrastructures10040101