1. Introduction

One of the main causes of premature deterioration of asphalt concrete pavement layers is the inadequate quality of road bitumen. In particular, low cohesive strength, high susceptibility to property changes during aging, and insufficient adhesion of bitumen to the surface of aggregates contribute to a decline in the transport and operational performance of asphalt concrete. Another major factor affecting pavement durability is water, which penetrates the pores of the asphalt concrete layer in several ways: through surface infiltration (from top to bottom), capillary rise (migration of water from the lower layers of the road base), or condensation of water vapor (atmospheric moisture diffuses into the pores of asphalt concrete and condenses). Furthermore, the pressure exerted by vehicle wheels accelerates water penetration into these pores [

1,

2,

3,

4,

5,

6,

7].

Adhesion promoters (APs) are essential additives for bitumen, as they ensure strong bonding between bitumen and mineral aggregates, even in the presence of moisture [

8,

9]. Conventional APs are typically amine-based surfactants (e.g., fatty amines, amidoamines, imidazolines, etc.). In recent years, increasing attention has been directed toward bio-based cationic adhesion promoters synthesized from renewable raw materials, which not only enhance adhesion but also improve environmental sustainability and reduce ecological impact [

10,

11].

The incorporation of cationic surfactants into bitumen and asphalt concrete mixes provides several advantages:

Improved adhesion between bitumen and mineral skeleton: Studies demonstrate that adhesion promoters, such as amines or polymeric organic compounds, substantially enhance bonding between mineral materials and bitumen [

12].

Reduced stripping under moisture exposure: Acidic aggregates, such as granite, are more prone to adhesion loss in wet conditions compared to basic aggregates (e.g., limestone, marble). However, the addition of adhesion promoters significantly mitigates this effect by improving wettability and bitumen retention on aggregate surfaces in aqueous environments [

13].

Extended service life of asphalt concrete under intensive operating conditions: The inclusion of specialized anti-stripping agents enhances rutting resistance on wet surfaces while preserving the stability and mechanical strength of asphalt concrete mixes [

14].

Modern research in road construction focuses on identifying environmentally safe and renewable raw materials for synthesizing effective adhesion promoters. Vegetable oils containing fatty acid triglycerides are of particular interest, as they can serve as a basis for obtaining cationic compounds.

Cationic adhesion promoters derived from rapeseed oil combine the advantages of traditional surfactants with the benefits of ecological bioresources. Their use not only improves the adhesion of bitumen to mineral aggregates but also reduces dependence on petrochemical products. Therefore, investigating the properties of such additives and evaluating their effectiveness in bitumen binders and asphalt concrete mixes represent urgent tasks for modern science and practice [

15,

16].

In addition to well-studied rapeseed oil, which is characterized by a high content of unsaturated fatty acids and an established processing technology, other sources are also promising. In particular, amidoamines derived from soybean oil exhibit pronounced cationic properties and high thermal stability, while imidazolines based on tall oil provide long-term adhesive strength under repeated wetting–drying cycles [

1,

17,

18].

Recent studies confirm the effectiveness of bio-based adhesion promoters synthesized from rapeseed, soybean, and tall oils as environmentally safe alternatives to traditional amine compounds. Soybean oil, especially subepoxidized soybean oil, has proven to be an effective source of fatty acids for the synthesis of cationic amine compounds capable of ensuring strong bitumen–aggregate adhesion even in the presence of moisture. Research indicates that soybean oil modification improves water resistance and reduces bitumen aging, while aminoesters and amidoamines derived from tall oil demonstrate stable performance in moisture resistance and compatibility tests with various types of aggregates. At the same time, most existing studies are limited to laboratory experiments and do not cover long-term field observations, aging effects, or comparative evaluations of different bio-based feedstocks under real operating conditions. This creates a research gap that justifies further studies of bio-adhesion promoters derived from various types of plant raw materials to enhance the durability of asphalt concrete pavements [

19,

20,

21,

22].

Table 1 summarizes the results of various studies on the influence of amine-based adhesion additives on asphalt concrete properties, enabling a comparison of their effectiveness in terms of key strength and water-resistance indicators. Amine additives enhance mixture performance: the ITS index reflects the preservation or improvement of strength, while ITSR/TSR values show steady growth, confirming their role in preventing delamination and reducing water sensitivity. Overall, these agents improve bitumen–aggregate adhesion, increase water resistance, and lower the risk of premature pavement failure. For comparison, the table also includes a modifier based on soybean oil and SBR, which, although not a classical amine adhesion additive, exhibits a pronounced adhesion-enhancing effect. Unlike traditional adhesion agents used in small amounts (0.1–0.5%), the bio-modifier Soybean Oil/SBR is added in larger dosages (3–6%), since it performs a dual function—improving bitumen–aggregate bonding and restoring the plasticity of aged binder in reclaimed asphalt mixtures.

Accordingly, the purpose of this study is to investigate and comprehensively evaluate bitumen and hot mix asphalt (HMA) modified with cationic adhesion promoters derived from rapeseed oil, and to compare their effectiveness with that of industrial additives of this type produced in Ukraine and abroad.

2. Materials and Methods

2.1. Materials

2.1.1. Bitumen

Bitumen grade 70/100 (Orlen S.A., Płock, Poland) was used in this study. The main physical and mechanical parameters of the unmodified bitumen, determined according to DSTU EN 12591:2017 [

32], are presented in

Table 2.

2.1.2. Adhesion Promoters

The characteristics of the starting reagents and the resulting products, as well as the reaction equation for the amidation of rapeseed oil (RO) with polyamines (PEPA) [

16], are provided below. The synthesis scheme of the adhesion promoter RO-AP is shown in

Figure 1.

The synthesis conditions for the bio-based APs are summarized in

Table 3.

For comparison, two industrial cationic adhesion promoters were selected: Wetfix® BE (Nouryon, Amsterdam, The Netherlands) and Carbazole AK-M (SPETSKONTRAKT, Kyiv, Ukraine). The adhesion promoter, which is industrially produced, was used at a dosage of 0.4 wt. % relative to the bitumen mass.

2.1.3. Mineral Materials

Raw mineral materials were used for the production of hot asphalt concrete mixes with a maximum aggregate size of 20 mm. Granite crushed stone fractions of 5–10 mm and 10–20 mm, as well as crushed stone screenings (0–5 mm fraction), produced by the Klesiv Aggregates Quarry “Technobud” (LLC “KKHK Technobud”, Kyiv, Ukraine), were employed. The physical and mechanical properties of granite screenings and crushed stone are presented in

Table 4 and

Table 5, respectively.

In addition, we used an unactivated filler (mineral powder) of grade I according to DSTU 9246-1:2023 [

43] (

Table 6) which was received from Agrobudservis LLC (Lviv region, Ukraine).

2.2. Methods

2.2.1. Preparation and Testing of Modified Bitumen’s

Bitumen modification was performed with APs in amounts ranging from 0.2 to 1.0 wt. %. Mixing was carried out at 1000 rpm for 30 min, with the temperature maintained at 150 ± 2 °C.

The physical and mechanical properties of the modified bitumen were determined according to the methods listed in

Table 1: penetration at 25 °C (DSTU EN 1426:2018), softening point (DSTU EN 1427:2018), ductility at 25 °C (DSTU 8825:2019), adhesion to glass at 85 °C (DSTU 9169:2021), adhesion to crushed stone (DSTU 8787:2018), and resistance to hardening at 163 °C (mass change, retained penetration at 25 °C, and increase in softening point) according to DSTU B EN 12607-1:2015.

2.2.2. Asphalt Concrete Sample Compaction and Testing

The chip-grain carcass of the asphalt concrete mix was designed using grading curves for dense-graded continuous mixes. The asphalt concrete mix was developed with the following characteristics: hot fine-grained dense-graded asphalt concrete with residual porosity of 2–5%, chip-grain content (>5 mm) of 45–55%, and a maximum grain size of 20 mm (

Table 7).

Two experimental series (No. 1 and No. 2) were carried out to evaluate the compactability and ITSR performance of asphalt concrete samples, which differed in the parameters listed in

Table 8.

The asphalt concrete samples were prepared in a forced action mixer and compacted using a gyratory compactor in accordance with DSTU EN 12697-31:2021 [

45] at a mixture temperature of 150 °C.

The physical and mechanical properties of HMA and asphalt concrete (AC) were determined according to DSTU B V.2.7-319:2016 [

46] and DSTU EN 12697-23:2024 [

47].

The compressive strength at 20 °C and 50 °C of asphalt concrete was measured using mechanical presses at a press-plate movement speed of 3.0 ± 0.1 mm/min. Prior to testing, the samples were conditioned in water for 60 ± 5 min at 20 ± 1 °C and 50 ± 1 °C, respectively. For testing at 50 °C, the samples were first sealed in polyethylene bags to prevent direct contact with water during conditioning.

The average density (AD) of asphalt concrete was determined as follows: the samples were first weighed in air (m), then immersed in water at 20 ± 1 °C for 30 ± 1 min, ensuring that the water level was at least 20 mm above the sample surface. The samples were then weighed in water at 20 ± 1 °C (m1), ensuring no air bubbles adhered to the surface. After weighing, the samples were gently wiped with a soft damp cloth and reweighed in air (m2). The AD (g/cm

3) of each AC sample was calculated according to Equation (1):

where m—mass of the AC sample in air before immersion (g);

—water density (g/cm

3); m1—sample mass after 30 min in water, weighed in water (g); m2—sample mass after 30 min in water, weighed in air (g).

The AD result is reported as the arithmetic mean of three AC samples, rounded to two decimal places.

The method for determining water saturation (W) involves measuring the amount of water absorbed by a cylindrical sample under a specified saturation regime, while swelling (S) is defined as the increase in sample volume after water saturation. After determining AD, the tested samples are immediately placed in a vessel with water maintained at (20 ± 1) °C. The water level above the samples must be at least 3 cm. The vessel is then placed in a vacuum chamber, where a pressure of 2000 Pa is maintained for 1 h.

Afterwards, the pressure is returned to atmospheric, and the samples remain in the same water at (20 ± 1) °C for an additional 30 min. The samples are then removed, weighed in water (m4), wiped with a soft damp cloth, and weighed in air (m3).

Water saturation (W) is calculated as a percentage according to the following Equation (2):

Residual porosity (RP) is determined as the volume of pores contained in asphalt concrete. It is calculated using the measured average density (AD) of the AC and the maximum density (MD) of the asphalt concrete mix according to Equation (3):

The maximum density (MD), corresponding to the real density, was determined by the volumetric (pycnometric) method in accordance with DSTU EN 12697-5:2018 [

48].

The tensile strength ratio (TSR) was determined according to DSTU EN 12697-23:2024 [

47], and the indirect tensile strength ratio (ITSR) according to DSTU EN 12697-12:2018 [

49]

3. Results and Discussion

3.1. Modified Bitumen’s

The influence of the content of different bio-based adhesion promoters on the physical and adhesion properties of bitumen is summarized in

Table 9.

Table 9 shows the effect of various bio-based adhesion promoters (AP10, AP15, AP20, AP40) at different dosages (0.2–1.0 wt. %) on the physical and adhesion properties of bitumen 70/100. The results demonstrate that increasing the AP dosage leads to a gradual improvement in adhesion to both crushed stone and glass, reaching maximum values at 1.0 wt. % for all promoters. Penetration values increase slightly with higher dosages, while the softening point exhibits a minor decreasing trend. Among the tested modifiers, AP20 provided the most balanced performance, achieving high adhesion levels even at 0.2–0.4 wt. %, and was therefore selected for further asphalt mixture testing.

As seen in

Table 9, the adhesion of bitumen to both glass and crushed stone increases with the rise in polyethylene polyamine (PEPA) content in the synthesized adhesion promoters. This trend confirms that the presence of amino groups plays a decisive role in enhancing the interaction between the bitumen binder and mineral aggregates. However, the results also show that when the PEPA content exceeds 20 wt. % (sample AP40), the improvement in adhesion becomes marginal, while the bitumen softening point decreases slightly.

This behavior can be explained by the amphiphilic nature of the synthesized compounds. The amidation of rapeseed oil with PEPA forms molecules containing polar amino groups (-NH-, -NH2) capable of hydrogen and electrostatic interactions with aggregate surfaces, and long hydrocarbon chains compatible with the bitumen matrix. At low PEPA concentrations (10–15 wt. %), the number of polar functional groups is insufficient to ensure strong interfacial bonding. At high PEPA levels (>20 wt. %), the excess of hydrophilic fragments reduces compatibility with the bitumen phase and may cause partial phase separation. Therefore, AP20, which contains approximately 20 wt. % PEPA, provides the optimal balance between hydrophilic and hydrophobic segments, forming a uniform and stable interfacial layer between bitumen and aggregate.

From both a performance and economic standpoint, increasing the PEPA content above 20 wt. % is not justified, since AP20 already ensures sufficiently high adhesion values while maintaining the efficiency of the synthesis process.

The physical and mechanical properties of bitumen modified with the selected adhesion promoters are presented in

Table 10.

Table 10 compares the physical and mechanical properties of virgin bitumen 70/100 with samples modified by the bio-based adhesion promoter AP20 (0.2 and 0.4 wt. %) and two commercial additives (Wetfix

® BE and Carbazole AK-M). The results show that AP20 significantly improves adhesion to both glass and crushed stone, achieving values comparable to or exceeding those of industrial additives. These findings confirm the effectiveness of AP20, particularly at 0.4 wt. %, as a sustainable alternative to conventional adhesion promoters.

3.2. Asphalt Concretes

Research No. 1 (

Table 8) investigated the compaction of asphalt concrete mixes to achieve a given specimen height and average density with a variable number of gyrations. The averaged results for the manufactured asphalt concrete specimens of the corresponding compositions are presented in

Table 11.

The analysis of the results in

Table 11 shows that modification of Orlen 70/100 bitumen with the adhesion promoter AP20 reduces the number of gyrations required to achieve the target density. At the same time, the compressive strength of AC (not subjected to long-term water exposure with adhesive) is somewhat lower, whereas the ITSR is higher compared to unmodified AC. The reduced strength characteristics of AC with adhesive can be attributed to the formation of a thinner binder film covering the mineral materials. This occurs due to improved wettability of mineral surfaces by the adhesive-modified bitumen. As a consequence, a larger proportion of bulk, unstructured bitumen is present in AC, which influences the strength properties. Therefore, the use of AP20 may allow for a slight reduction in the binder content of AC in future applications.

Subsequently, Research No. 2 was carried out with a fixed number of gyrations (70), chosen based on the average number of gyrations required for the unmodified asphalt concrete mix (

Table 12). In this study, all adhesion promoters selected for testing were used at a dosage of 0.4 wt. %.

The analysis of

Table 12 confirms the pattern already observed in

Table 11: the use of adhesion promoters slightly reduces the strength characteristics of AC not subjected to long-term water exposure. Among all adhesion promoters, AP20 causes the least reduction in ultimate compressive strength at both 20 °C and 50 °C, as well as in ITS after 3 days of air storage in the laboratory. An interesting feature seen in both

Table 11 and

Table 12 is that the ITS

15 wet and ITS

3 wet values are consistently higher for AC containing AP20. This indicates that the strength characteristics of AC after prolonged water exposure are clearly improved in HMA by adhesion promoters, with AP20 being the most effective additive in this regard. Moreover, at the same number of gyrations, AC with AP20 shows the lowest residual porosity and water saturation values, along with the highest average density. These results suggest that under the adopted regime, the best compaction of HMA occurs when using AP20, which also demonstrates the energy-saving effect of this additive. In addition, the ITSR value is significantly improved by the incorporation of adhesion promoters. According to this indicator, the effectiveness of the tested promoters decreases in the following order: AP20, Wetfix

® BE, Carbazole AK-M.

As shown in

Table 11, the modification of asphalt concrete with AP20 reduced the compressive strength at 20 °C from 5.7 MPa (virgin) to 4.6 MPa at 0.2 wt.% and 5.3 MPa at 0.4 wt.%, while the ITSR values increased from 0.92 to 0.98. Similarly, in

Table 12, the strength at 20 °C decreased slightly from 5.25 MPa (virgin) to 5.02 MPa for the mixture with 0.4 wt.% AP20, whereas the ITSR improved markedly from 0.72 to 0.94. At the same time, the bulk density increased from 2.399 to 2.442 g/cm

3 and the water saturation decreased from 2.45 to 0.93 vol.%, confirming better compaction and tighter aggregate–binder contact.

These results indicate that the improved wettability of mineral particles by AP-modified bitumen facilitates the formation of a more uniform but thinner asphalt film around aggregates. Although the film thickness was not measured directly, the combination of higher density, lower porosity, and reduced water absorption indirectly supports this interpretation. The thinner, well-spread binder film enhances adhesion and moisture resistance but slightly reduces the contribution of bulk bitumen to compressive strength. This behavior is consistent with other studies on amine-based adhesion promoters, where increased aggregate wetting and interfacial bonding led to similar trade-offs between strength and durability performance.

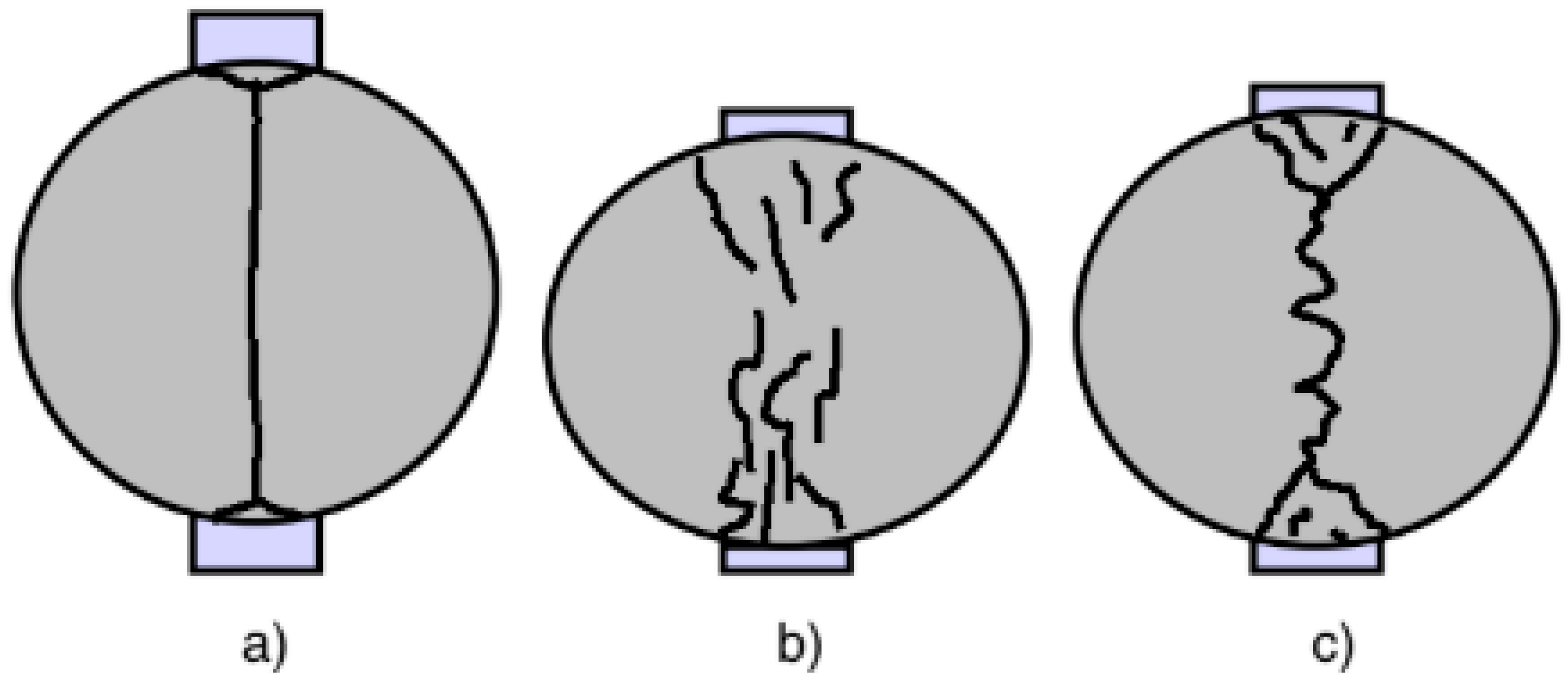

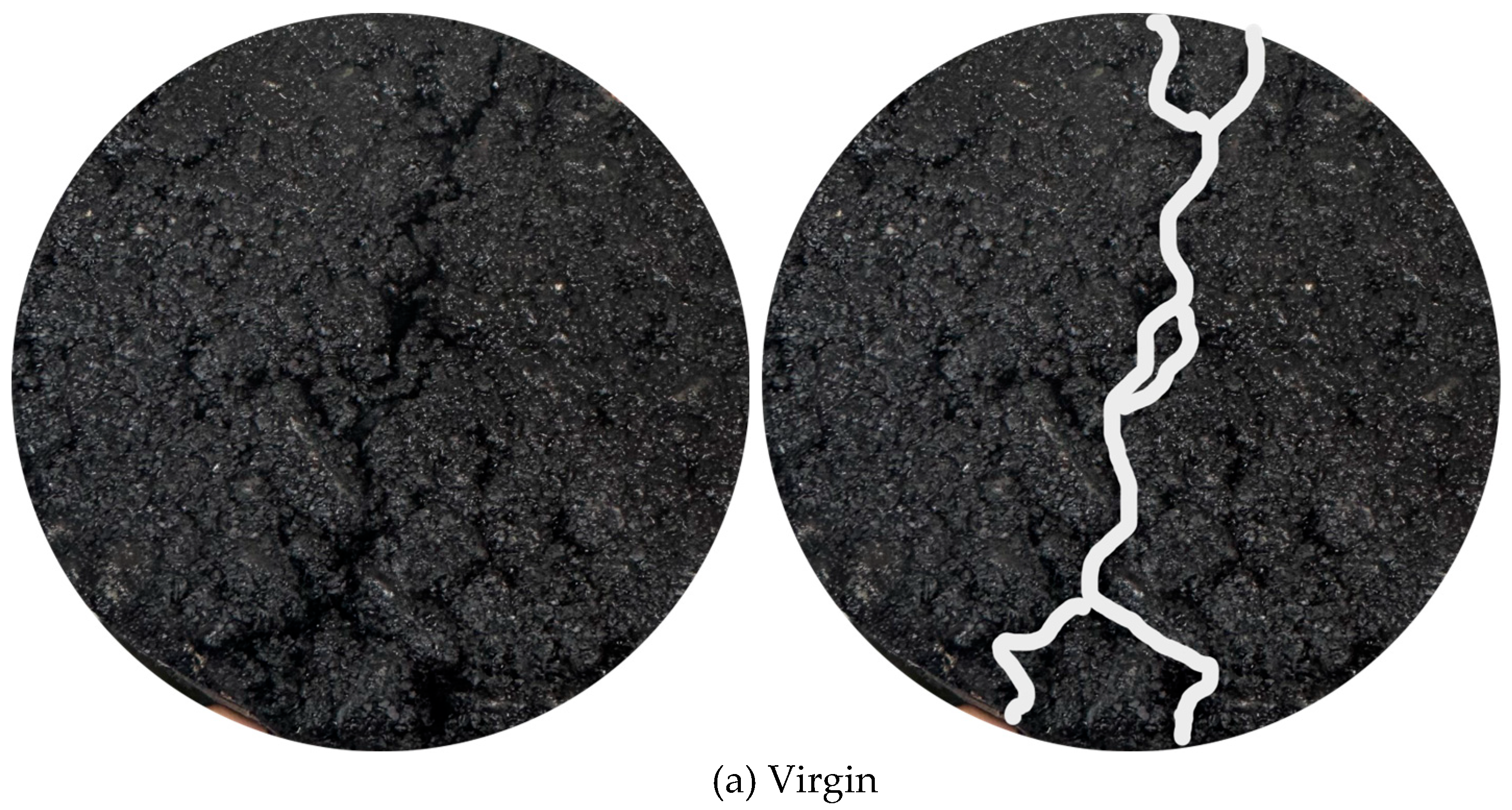

The failed specimens after ITS testing were classified according to DSTU EN 12697-23:2024 [

38] (

Figure 2): (a) “clear tensile break,” with a fracture clearly along the diametrical line except for small triangular areas near the loading strips; (b) “deformation,” without a clearly visible tensile break line; (c) “combination,” with a limited tensile break line and larger deformed areas near the loading strips.

In the present study, all specimens failed according to type

Figure 3a or

Figure 3c.

The analysis of

Figure 3 shows that asphalt concrete specimens without adhesion promoters typically fail according to type (c) “combination,” which represents an intermediate form between (a) “clear tensile break” and (b) “deformation.” With the introduction of adhesion promoters, the tendency of AC to fail by combined fracture (c) decreases, and the fracture mode shifts toward type (a) “clear tensile break.” In particular, AC samples containing 0.4 wt. % Carbazole AK-M lie in between types (a) and (c), whereas those modified with 0.4 wt. % Wetfix

® BE or AP20 evidently demonstrate type (a) “clear tensile break.” This behavior is attributed to the increased bond strength between the adhesive-modified bitumen and the mineral skeleton of the mixture, which restricts plastic grain displacement and localizes fracture within the tensile stress zone.

4. Conclusions

This study demonstrated that adhesion promoters synthesized by amidation of rapeseed oil with polyethylene polyamine (PEPA) have a pronounced effect on the properties of bitumen and asphalt concrete. Among the tested formulations, AP20, produced with 20 wt.% PEPA, showed the most balanced and efficient performance.

Modification of bitumen with 0.2–0.4 wt.% AP20 increased adhesion to glass from 26.1% to 85.1% and to crushed stone from 3.0 to 5.0 points. In asphalt concrete, the incorporation of 0.4 wt.% AP20 improved the indirect tensile strength ratio (ITSR) from 0.72 to 0.94 (an increase of about 30%) under short-term conditioning and from 0.92 to 0.98 (an increase of about 7%) under long-term conditioning. The bulk density of asphalt concrete rose by approximately 1.8%, while water saturation decreased by about 62%, indicating more efficient compaction and enhanced resistance to moisture damage.

A slight (3–5%) decrease in compressive strength after AP addition was observed and attributed to the formation of a more uniform and thinner bitumen film around the mineral particles. This structural change improves wettability and adhesion at the aggregate–binder interface without compromising overall durability.

Overall, AP20 outperformed commercial adhesion promoters such as Wetfix® BE and Carbazole AK-M in terms of ITSR, density, and moisture resistance while maintaining adequate mechanical strength. Increasing the PEPA content beyond 20 wt.% was found to be economically unjustified, as AP20 already provided optimal adhesion performance with a minimal additive dosage.

These findings confirm that rapeseed oil-based adhesion promoters, particularly AP20, represent effective, sustainable, and cost-efficient alternatives to traditional amine-based additives in road construction.

5. Patents

Gunka, V.M.; Poliak, O.Ye.; Hrynchuk, Yu.M.; Sidun, Iu.V. Utility Model Patent No. 159700, Ukraine. Method for Obtaining an Adhesion Additive for Bitumen Based on Renewable Raw Materials; Lviv Polytechnic National University: Lviv, Ukraine, 13 November 2024; Published 25 June 2025.

Author Contributions

Conceptualization, V.G., I.S. and O.P.; methodology, V.G. and I.S.; software, N.D.; validation, V.G., A.O. and A.K.; formal analysis, V.G., Y.B. and I.S.; investigation, V.G., I.S. and O.P.; resources, I.S. and Y.D.; data curation, V.G. and O.P.; writing—original draft preparation, V.G., I.S. and O.P.; writing—review and editing, A.K., N.D. and Y.B.; visualization, I.S. and A.O.; supervision, V.G.; project administration, V.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Research Foundation of Ukraine (Grant No. 2023.05/0026).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Acknowledgments

We would like to thank the laboratory “SUPERPAVE R&D LAB” (Lviv Polytechnic National University, Ukraine).

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HMA | Hot mix asphalt |

| AC | Asphalt concrete |

| AD | Average density |

| APs | Adhesive promoters |

| ITS | Indirect tensile strength |

| ITSR | Indirect tensile strength ratio |

| MD | Maximum density |

| PEPA | Polyethylene polyamine |

| RO | Rapeseed oil |

| RTFOT | Rolling thin-film oven test |

| W | Water-saturation |

References

- Oliviero Rossi, C.; Teltayev, B.; Angelico, R. Adhesion promoters in bituminous road materials: A review. Appl. Sci. 2017, 7, 524. [Google Scholar] [CrossRef]

- Pstrowska, K.; Gunka, V.; Sidun, I.; Demchuk, Y.; Vytrykush, N.; Kułażyński, M.; Bratychak, M. Adhesion in bitumen/aggregate system: Adhesion mechanism and test methods. Coatings 2022, 12, 1934. [Google Scholar] [CrossRef]

- Hung, A.M.; Goodwin, A.; Fini, E.H. Effects of water exposure on bitumen surface microstructure. Constr. Build. Mater. 2017, 135, 682–688. [Google Scholar] [CrossRef]

- Gunka, V.; Astakhova, O.; Hrynchuk, Y.; Sidun, I.; Reutskyy, V.; Mirchuk, I.; Poliak, O. A Review of Road Bitumen Modification Methods. Part 1—Physical Modification. Chem. Chem. Technol. 2024, 18, 295–304. [Google Scholar] [CrossRef]

- Omar, H.A.; Yusoff, N.I.M.; Mubaraki, M.; Ceylan, H. Effects of moisture damage on asphalt mixtures. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 600–628. [Google Scholar] [CrossRef]

- Kohut, A.; Poliak, O.; Sidun, I.; Onyshchenko, A.; Besaha, K.; Gunka, V. A Review of Road Bitumen Modification Methods. Part 2—Chemical Modification. Chem. Chem. Technol. 2025, 19, 141–156. [Google Scholar] [CrossRef]

- Pyrig, Y.; Galkin, A. Comparative evaluation of the bitumen binders adhesion by the methods normalized by national standards of Ukraine. Bull. Kharkov Natl. Automob. Highw. Univ. 2019, 86, 202–212. [Google Scholar] [CrossRef]

- Sidun, I.; Solodkyy, S.; Vollis, O.; Stanchak, S.; Bidos, V. Adhesion of bituminous binders with aggregates in the context of surface dressing technology for road pavements treatment. Theory Build. Pract. 2021, 3, 92–99. [Google Scholar] [CrossRef]

- Pyrih, Y.I.; Halkin, A.V. Features of the influence of adhesive promoters on bitumen of different structural and rheological types Modern technologies and methods of calculations in construction. Mod. Technol. Calc. Methods Constr. 2022, 18, 89–97. [Google Scholar] [CrossRef]

- Zhang, J.; Apeagyei, A.K.; Airey, G.D.; Grenfell, J.R. Influence of aggregate mineralogical composition on water resistance of aggregate-bitumen adhesion. Int. J. Adhes. Adhes. 2015, 62, 45–54. [Google Scholar] [CrossRef]

- Poliak, O.; Gunka, V. Properties of bitumen modified with adhesive additives based on renewable raw materials. Visnyk KhPI. 2024, 2, 45–49. [Google Scholar] [CrossRef]

- Ye, Y.; Hao, Y.; Zhuang, C.; Shu, S.; Lv, F. Evaluation on improvement effect of different anti-stripping agents on pavement performance of granite–asphalt mixture. Materials 2022, 15, 915. [Google Scholar] [CrossRef] [PubMed]

- Cui, S.; Blackman, B.R.; Kinloch, A.J.; Taylor, A.C. Durability of asphalt mixtures: Effect of aggregate type and adhesion promoters. Int. J. Adhes. Adhes. 2014, 54, 100–111. [Google Scholar] [CrossRef]

- Tripathi, P. Optimization of Different Anti Stripping Agents in Asphalt Concrete Mixes. Int. J. Eng. Res. Technol. IJERT 2020, 9, 671–676. [Google Scholar]

- Nadirov, R.; Ketegenov, T.; Batkal, A.; Kalugin, S.; Teltayev, B.; Caputo, P.; Rossi, C.O.; Kamunur, K.; Assylkhanov, Z.; Osserov, T. Sustainable adhesion additive improving road bitumen properties with rapeseed oil waste. Sustainability 2025, 17, 1472. [Google Scholar] [CrossRef]

- Gunka, V.; Poliak, O.; Hrynchuk, Y.; Stadnik, V.; Demchuk, Y.; Besaha, K.; Galkin, A.; Pyrig, Y. Sustainable Bitumen Modification Using Bio-Based Adhesion Promoters. Sustainability 2025, 17, 7187. [Google Scholar] [CrossRef]

- Caputo, P.; Porto, M.; Calandra, P.; De Santo, M.P.; Oliviero Rossi, C. Effect of epoxidized soybean oil on mechanical properties of bitumen and aged bitumen. Molecular Crystals and Liquid Crystals 2018, 675, 68–74. [Google Scholar] [CrossRef]

- Schilling, P.; Schreuders, H.G. Tall Oil Based Amino Esters as Anti-Stripping Agents for Asphalt. U.S. Patent No. 4,806,166; U.S. Patent and Trademark Office, 21 February 1989. Available online: https://patents.google.com/patent/US4806166A (accessed on 21 February 1989).

- Bearsley, S.R.; Haverkamp, R.G. Adhesive properties of tall oil pitch modified bitumen. Road Mater. Pavement Des. 2017, 8, 449–465. [Google Scholar] [CrossRef]

- Kuang, D.; Jiao, Y.; Ye, Z.; Lu, Z.; Chen, H.; Yu, J.; Liu, N. Diffusibility enhancement of rejuvenator by epoxidized soybean oil and its influence on the performance of recycled hot mix asphalt mixtures. Materials 2018, 11, 833. [Google Scholar] [CrossRef] [PubMed]

- Babagoli, R.; Ameli, A. Influence of soybean oil on binder and warm mixture asphalt properties. Adv. Mater. Sci. Eng. 2021, 1, 6860878. [Google Scholar] [CrossRef]

- Raihan, P.M.S.; Diaz, R.V.; Wan, L. Warm Mix Asphalt: Natural Additives and Sustainable Technologies for Reducing Environmental Pollution. World J. Eng. Technol. 2025, 13, 764–790. [Google Scholar] [CrossRef]

- Hurley, G.C.; Prowell, B.D. Evaluation of Evotherm for use in warm mix asphalt. NCAT Rep. 2006, 2. [Google Scholar]

- Tayebali, A.A.; Knappe, D.R.; Mandapaka, V.L. Effect of Prolonged Heating on the Asphalt-Aggregate Bond Strength of HMA Containing Liquid Anti-Strip Additives; Technical Report FHWA/NC/2007-08; North Carolina State University, Department of Civil, Construction, and Environmental Engineering: Raleigh, NC, USA, 2008. [Google Scholar]

- Cook, T.J.; Lawrie, J.J. Benchmarking for North Carolina Public Transportation Systems: Final Report; Technical Report FHWA/NC/2006-33; North Carolina State University: Raleigh, NC, USA, 2006. [Google Scholar]

- Valentin, J.; Vavřička, J.; Valentova, T. Influence of Various Adhesion Promoters on Asphalt Behavior by Assessment of Water Sensitivity. In Proceedings of the International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 25–27 June 2013; pp. 735–744. [Google Scholar]

- Valentová, T.; Altman, J.; Valentin, J. Impact of asphalt ageing on the activity of adhesion promoters and the moisture susceptibility. Transp. Res. Procedia 2016, 14, 768–777. [Google Scholar] [CrossRef]

- Mehdinazar, M.; Arabani, M. Estimating moisture sensitivity of asphalt mixtures with using Wetfix and ZycoTherm as anti-stripping additives. In Proceedings of the 10th International Congress on Civil Engineering, Berlin, Germany, 21–25 September 2014. [Google Scholar]

- El Badawy, A.; Rahim, A. Evaluation of Nanoclay Additives for Improving Resistance to Moisture Damage in Hot Mix; Technical Report No. 22–56; San Jose State University, College of Business, Mineta Transportation Institute: San Jose, CA, USA, 2023. [Google Scholar]

- Eltwati, A.; Putra Jaya, R.; Mohamed, A.; Jusli, E.; Al-Saffar, Z.; Hainin, M.R.; Enieb, M. Effect of warm mix asphalt (WMA) antistripping agent on performance of waste engine oil-rejuvenated asphalt binders and mixtures. Sustainability 2023, 15, 3807. [Google Scholar] [CrossRef]

- Chen, Y.; Li, X.; Tian, X. Performance Evaluation of Soybean Oil/SBR Reclaimed Asphalt and Mixtures. Buildings 2024, 14, 2085. [Google Scholar] [CrossRef]

- DSTU EN 12591:2017; Bitum and Bitumen Binders. Technical Requirements for Road Bitumen. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2017. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=72959 (accessed on 1 October 2017).

- DSTU EN 1426:2018; Bitumen and Bituminous Binders. Determination of the Depth of the Needle Permeability (Penetration). State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=78299 (accessed on 1 June 2019).

- DSTU EN 1427:2018; Bitumen and Bitumen Binders. Determination of Softening Temperature by Ring and Bullet Method. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=78301 (accessed on 1 June 2019).

- DSTU 8825:2019; Bitumen and Bitumen Binders. Method of Determination of Stretchability. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2019. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=82135 (accessed on 1 January 2020).

- DSTU 9169:2021; Bitumen and Bitumen Binders. Determination of Adhesion to Mineral Material. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2021. Available online: https://online.budstandart.com/ua/catalog/doc-page?id_doc=97049 (accessed on 1 August 2022).

- DSTU 8787:2018; Bitumen and Bituminous Binders. Method for Determining Adhesion to Crushed Stone. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2018. Available online: https://online.budstandart.com/ua/catalog/doc-page?id_doc=77885 (accessed on 1 June 2019).

- DSTU EN 12607-1:2015; Bitumen and Bituminous Binders. Determination of Resistance to Hardening Under the INFLUENCE of Heat and Air. Part 1. RTFOT Method. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2015. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=63683 (accessed on 1 July 2016).

- DSTU B V.2.7-232:2010; Building Materials. Sand for Construction Works. Test Methods. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2010. Available online: https://online.budstandart.com/ua/catalog/doc-page?id_doc=26321 (accessed on 1 January 2011).

- DSTU B V.2.7-71-98; Crushed Stone and Gravel from Dense Rock Formations and Industrial Waste for Construction Works. Methods of Physical and Mechanical Testing. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 1998. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=6621 (accessed on 1 January 1999).

- DSTU B V.2.7-210:2010; Building Materials. Sand from Crushed Igneous Rock Screenings for Construction Works. Technical Conditions. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2010. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=26741 (accessed on 1 August 2011).

- DSTU B V.2.7-75-98; Building Materials. Crushed Stone and Gravel, Dense Natural, for Building Materials, Products, Structures and Works. Technical Conditions. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 1998. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=4674 (accessed on 1 January 1999).

- DSTU 9246-1:2023; Fillers for Asphalt Concrete Mixtures and Materials Treated with Bituminous Binder. Technical Conditions. Part 1. Filler. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2023. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=104340 (accessed on 1 April 2024).

- DSTU 8772:2018; Mineral Powder for Asphalt Concrete Mixtures. Test Methods. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2018. Available online: https://online.budstandart.com/ua/catalog/doc-page?id_doc=81717 (accessed on 1 January 2019).

- DSTU EN 12697-31:2021; Bituminous Mixtures. Test Methods. Part 31. Sample Preparation with a Gyratory Compactor. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2021. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=95578 (accessed on 1 April 2022).

- DSTU B V.2.7-319:2016; Asphalt Concrete Mixtures and Asphalt Concrete for Roads and Airfields. Test Methods. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2016. Available online: https://online.budstandart.com/ua/catalog/doc-page?id_doc=65403 (accessed on 1 April 2017).

- DSTU EN 12697-23:2024; Bituminous Mixtures. Test Methods. Part 23. Determination of Indirect Tensile Strength of Bituminous Samples. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2024. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=110149 (accessed on 1 April 2025).

- DSTU EN 12697-5:2018; Bituminous Mixtures. Test Methods for Hot Asphalt Mixtures. Part 5. Determination of Maximum Density. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=81757 (accessed on 1 January 2020).

- DSTU EN 12697-12:2018; Bituminous Mixtures. Test Methods. Part 12. Determination of Water Resistance of Asphalt Concrete Samples. State Standard of Ukraine (DSTU): Kyiv, Ukraine, 2018. Available online: https://online.budstandart.com/ua/catalog/doc-page?id_doc=81761 (accessed on 1 January 2020).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).