Mechanistic-Empirical Analysis of LDPE-SBS-Modified Asphalt Concrete Mix with RAP Subjected to Various Traffic and Climatic Loading Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Marshall Mix Design for Optimum Binder Content

2.2. Superpave Gyratory Sample Preparation for Performance Test

2.3. Performance Test by Simple Performance Tester

3. Results

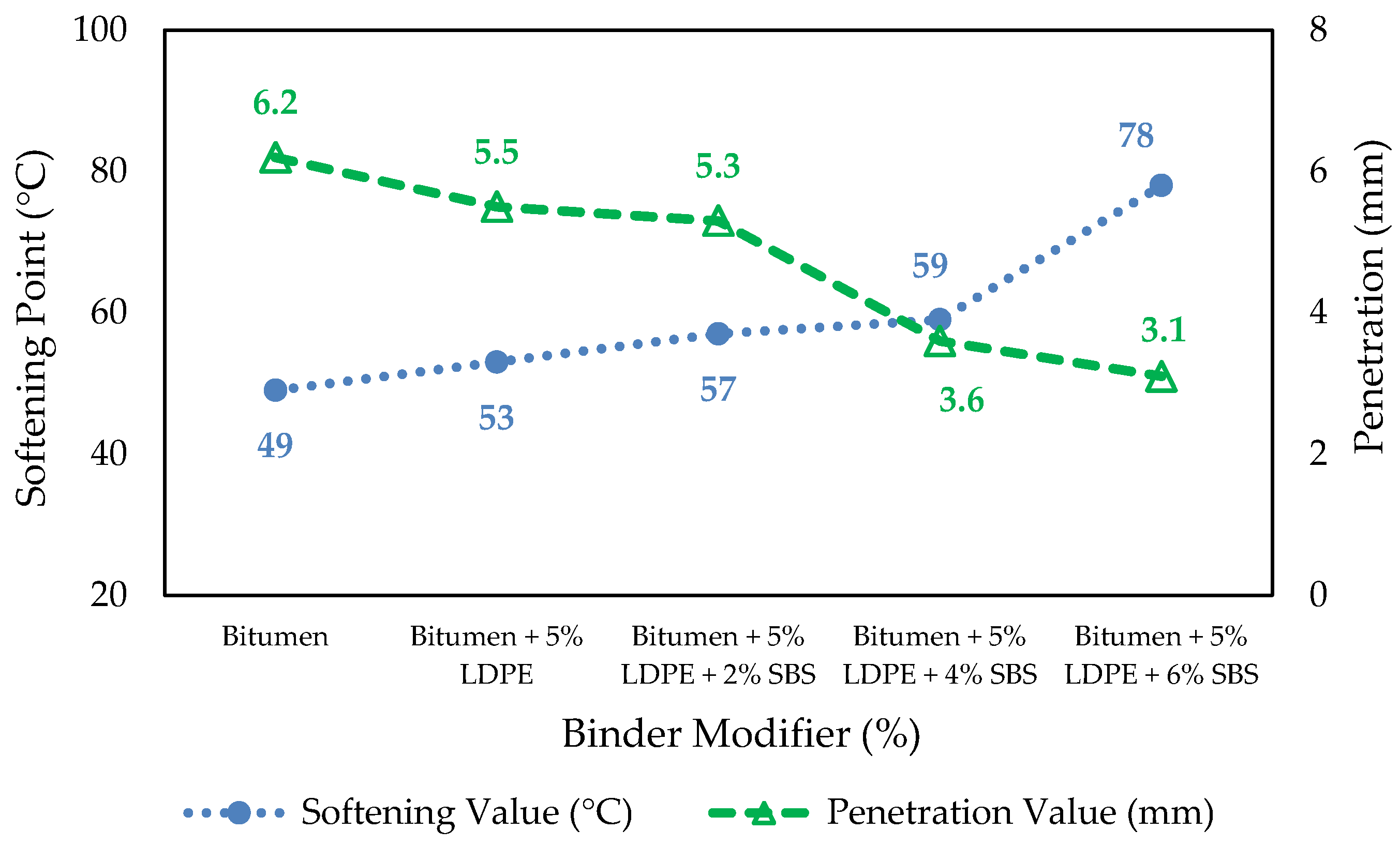

3.1. Consistency Test for Binder

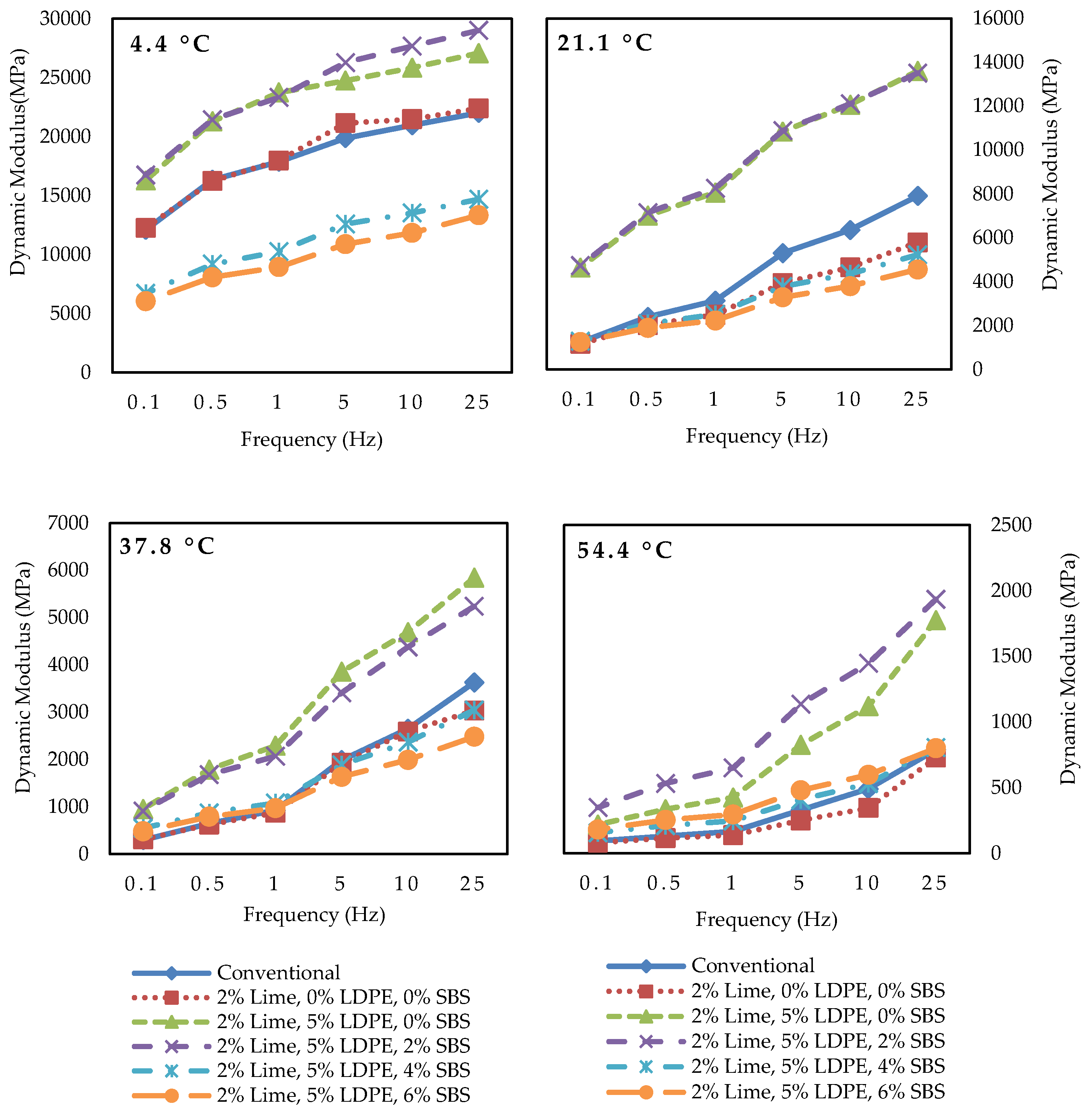

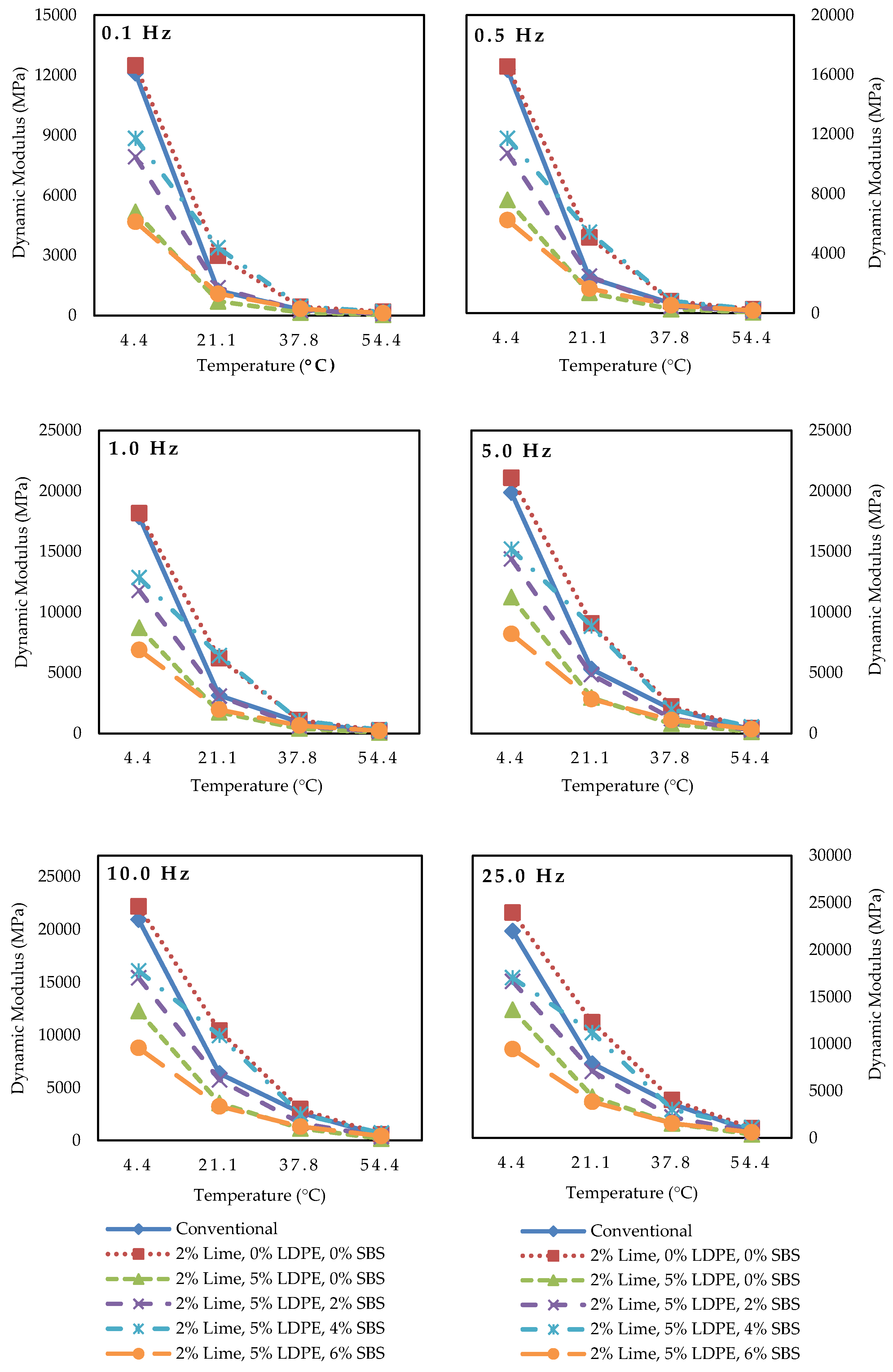

3.2. Evaluating Dynamic Modulus by the Use of SPT

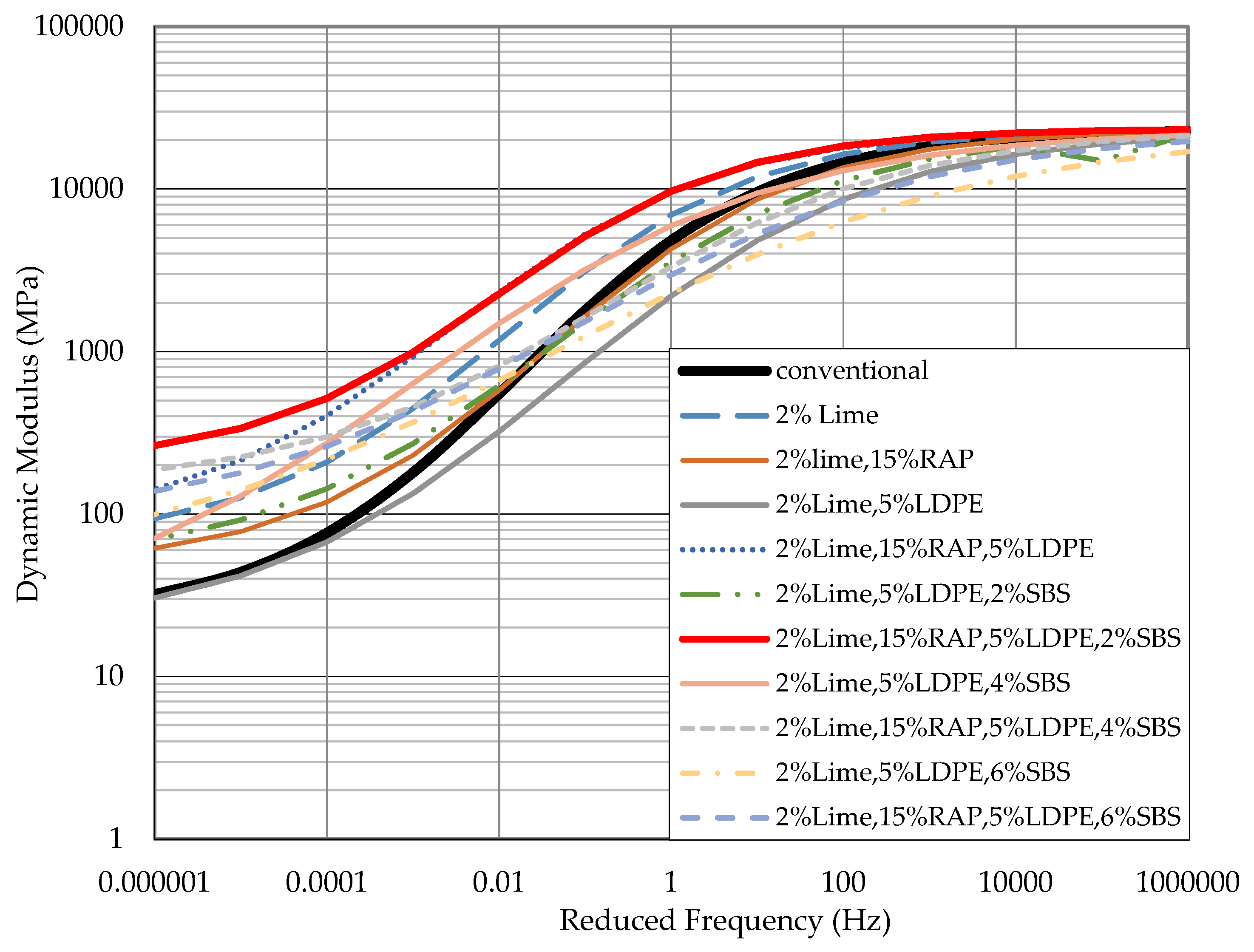

3.3. Development of Master Curves

3.4. MEPDG AASHTOWare

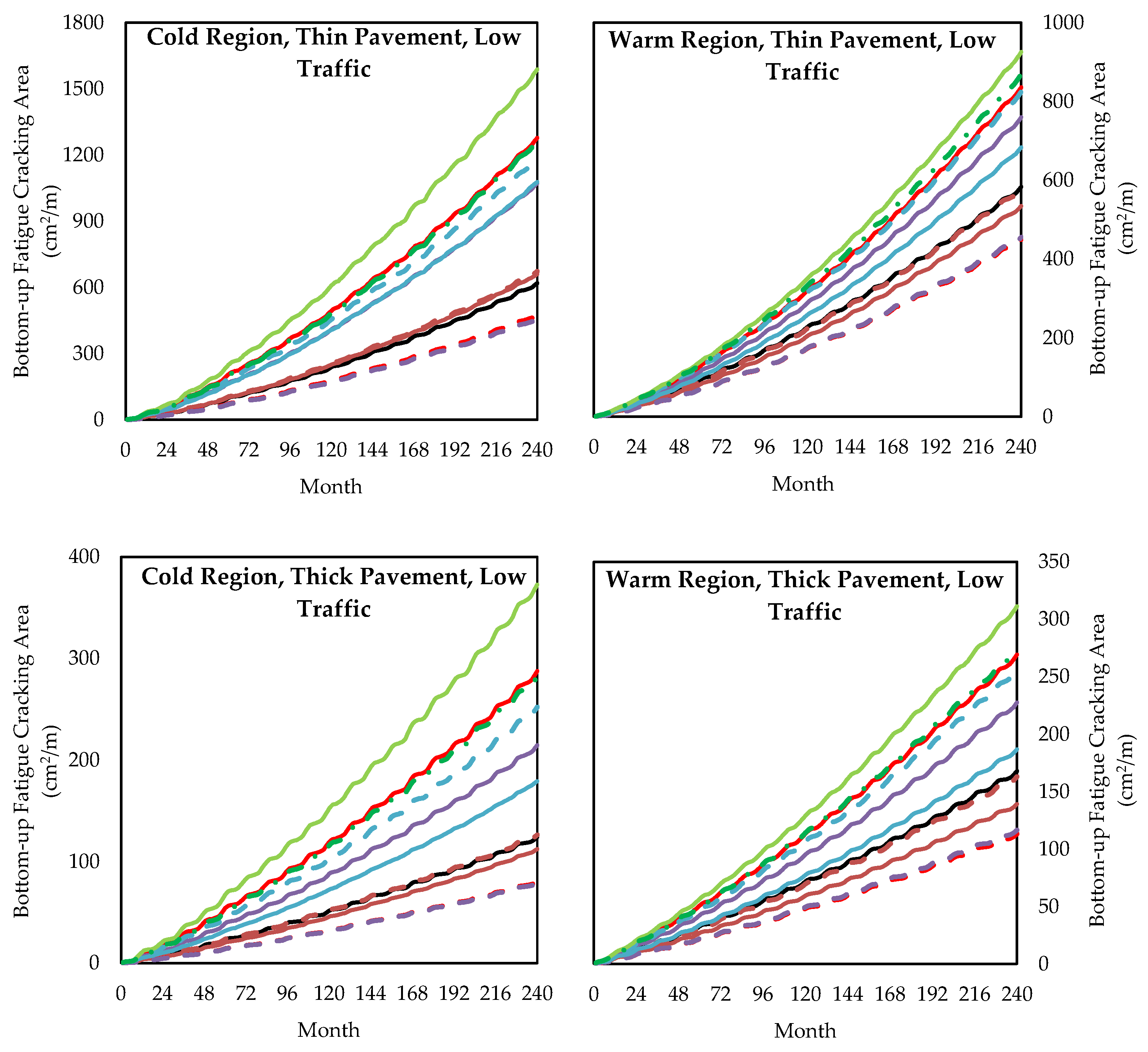

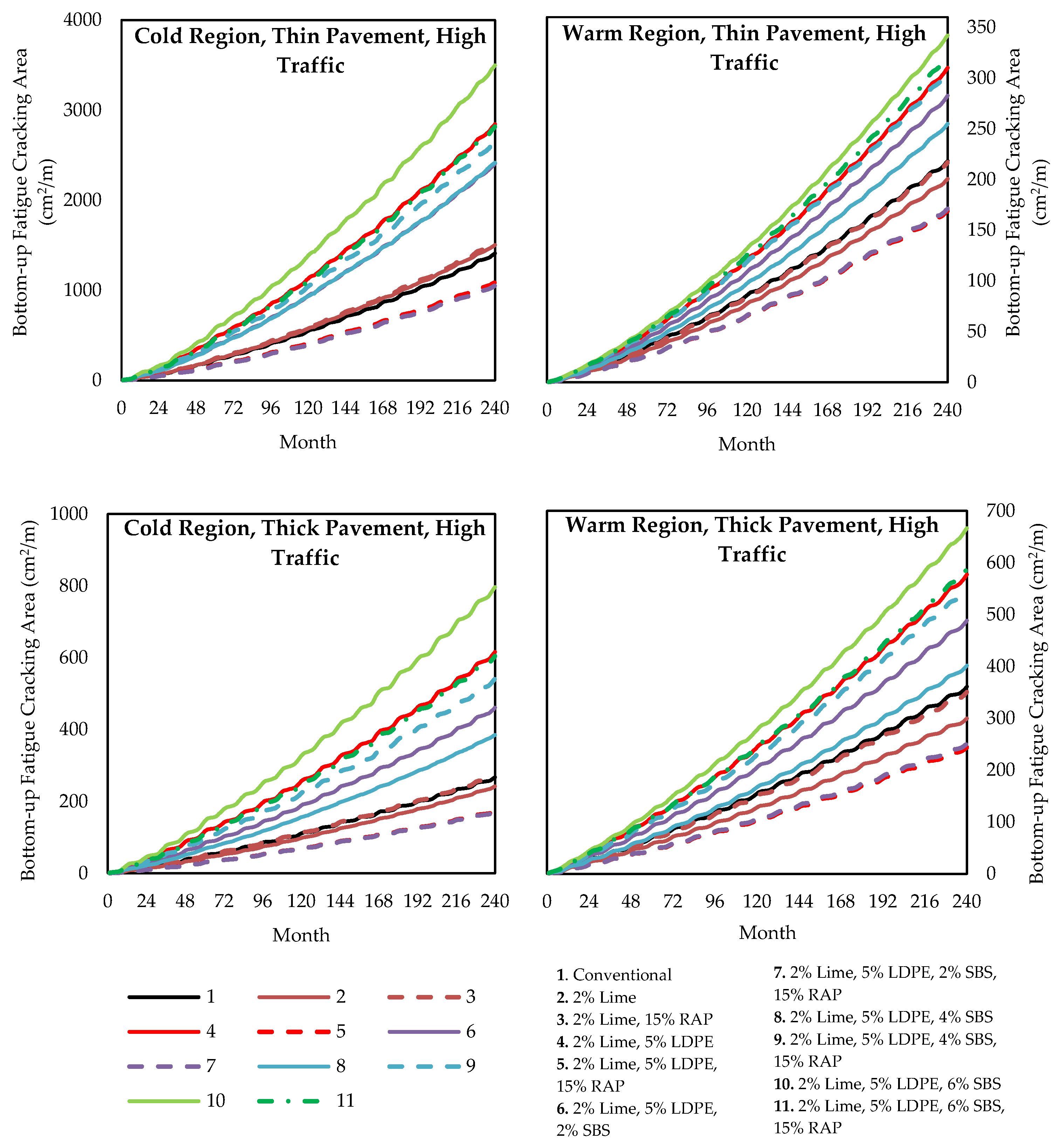

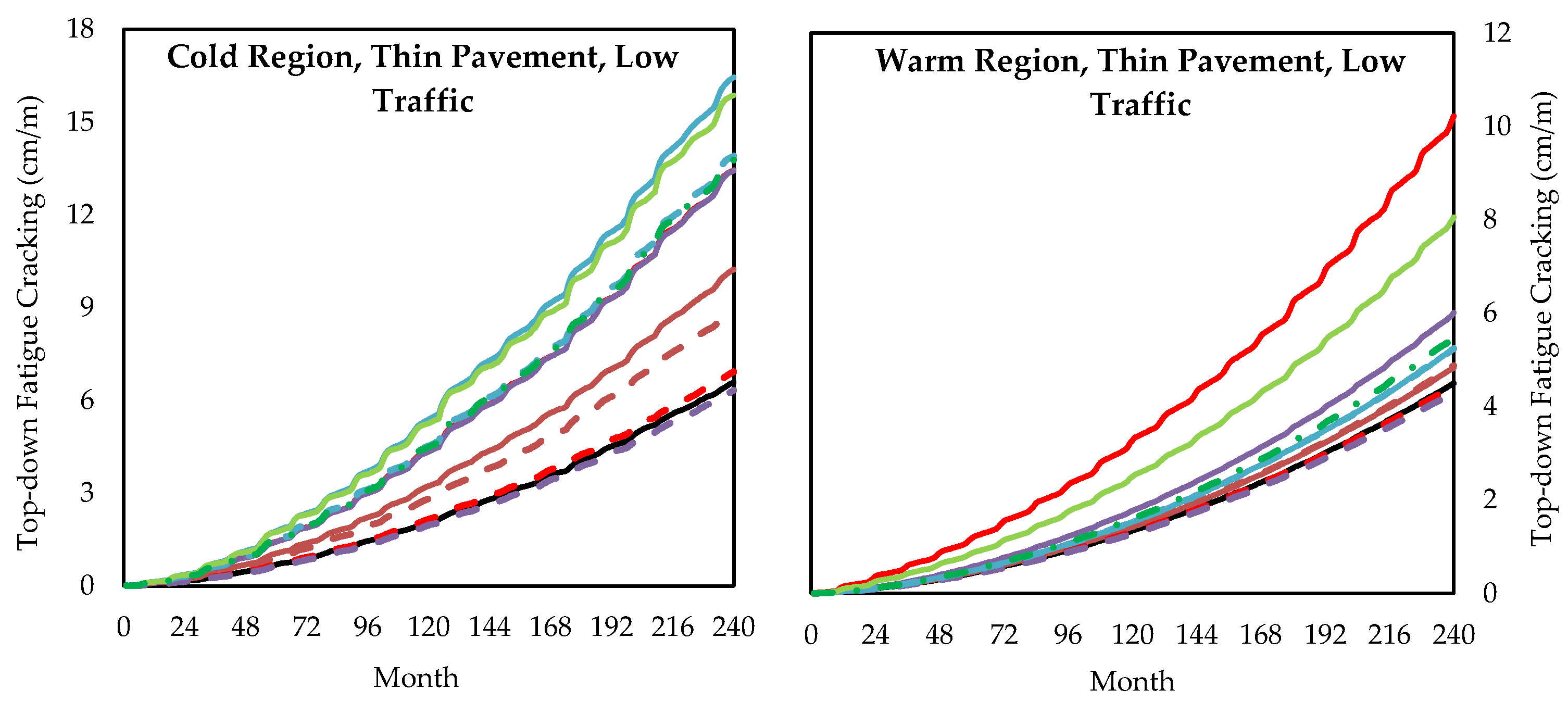

3.4.1. Distress Analysis

- 1.

- New York (cold region): Avg. temperature = 11.8 °C, with 160.3 wet days/year.

- 2.

- Arizona (warm region): Max. temperature = 42 °C, with 68.1 wet days/year.

- 1.

- Thin pavement: 4 in (≈101.6 mm);

- 2.

- Thick pavement: 6 in (≈152.4 mm).

- 1.

- 8 in (≈203 mm) aggregate base (A-1-a);

- 2.

- 8 in (≈203 mm) sub-base (A-1-b);

- 3.

- Semi-infinite subgrade (A-1-a).

- 1.

- Low traffic:

- AADTT (trucks) = 2209;

- AADTT (cars) = 11,076;

- Estimated cumulative truck traffic over 20 years = 9,849,470.

- 2.

- High traffic:

- AADTT (trucks) = 4418;

- AADTT (cars) = 22,152;

- Estimated cumulative truck traffic over 20 years = 19,698,900.

- Urban freeway terrain and facility type;

- Non-truck linear traffic growth rate: 4%;

- Number of lanes: 3;

- Truck distribution: 50% in the design direction and 95% in the design lane;

- Operating speed: 60 mph (≈96.54 Km/h);

- Reliability level: 90% for performance criteria.

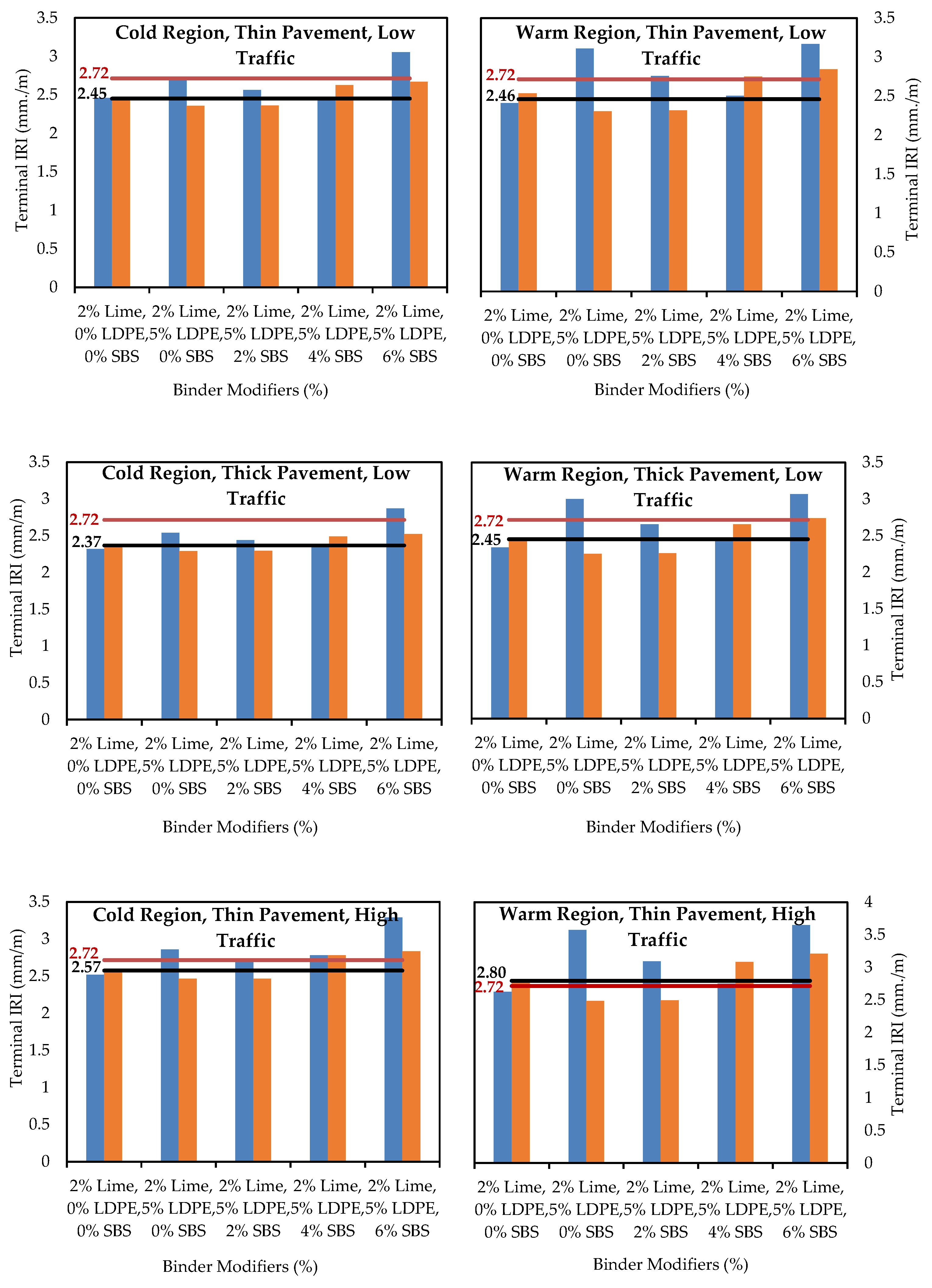

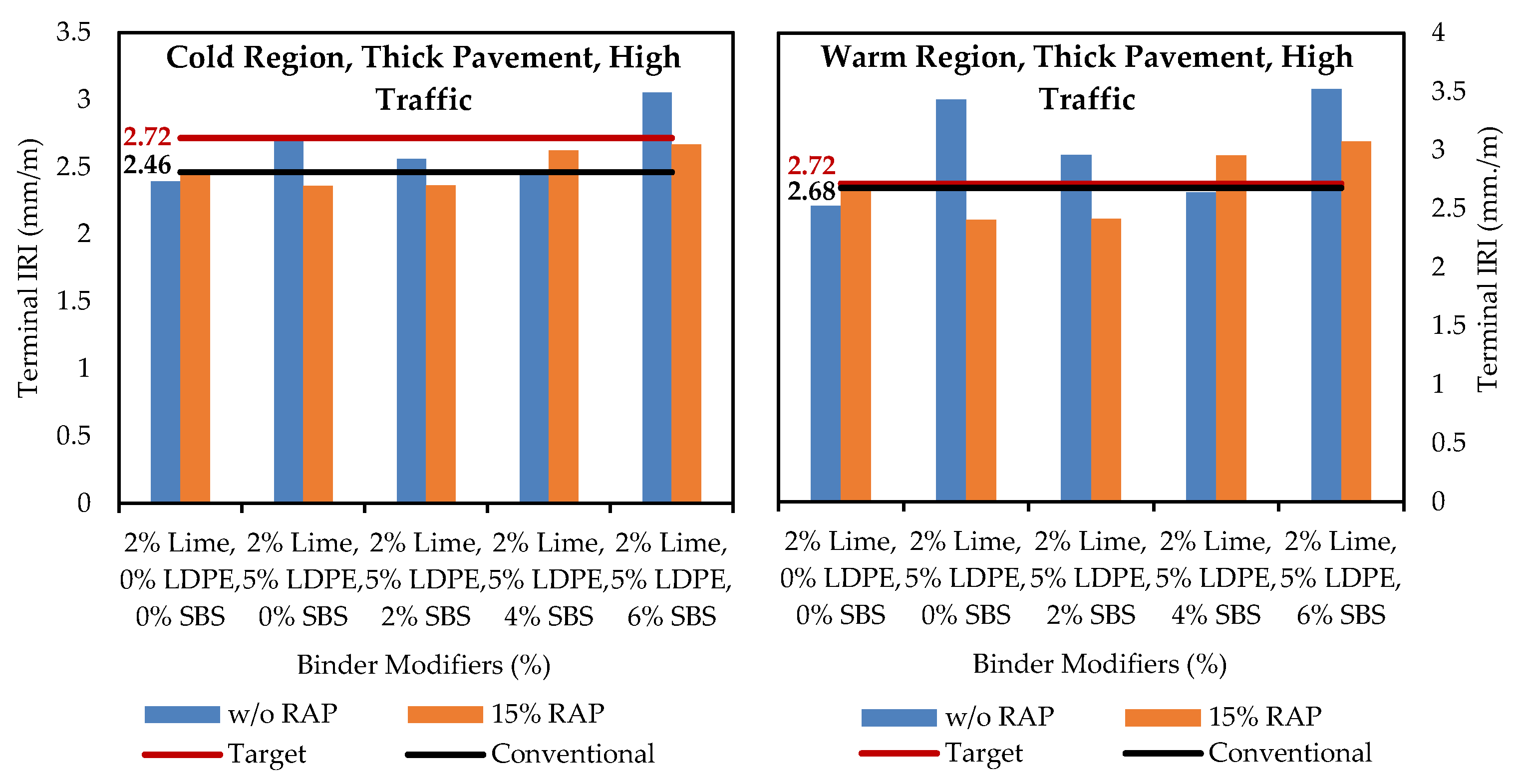

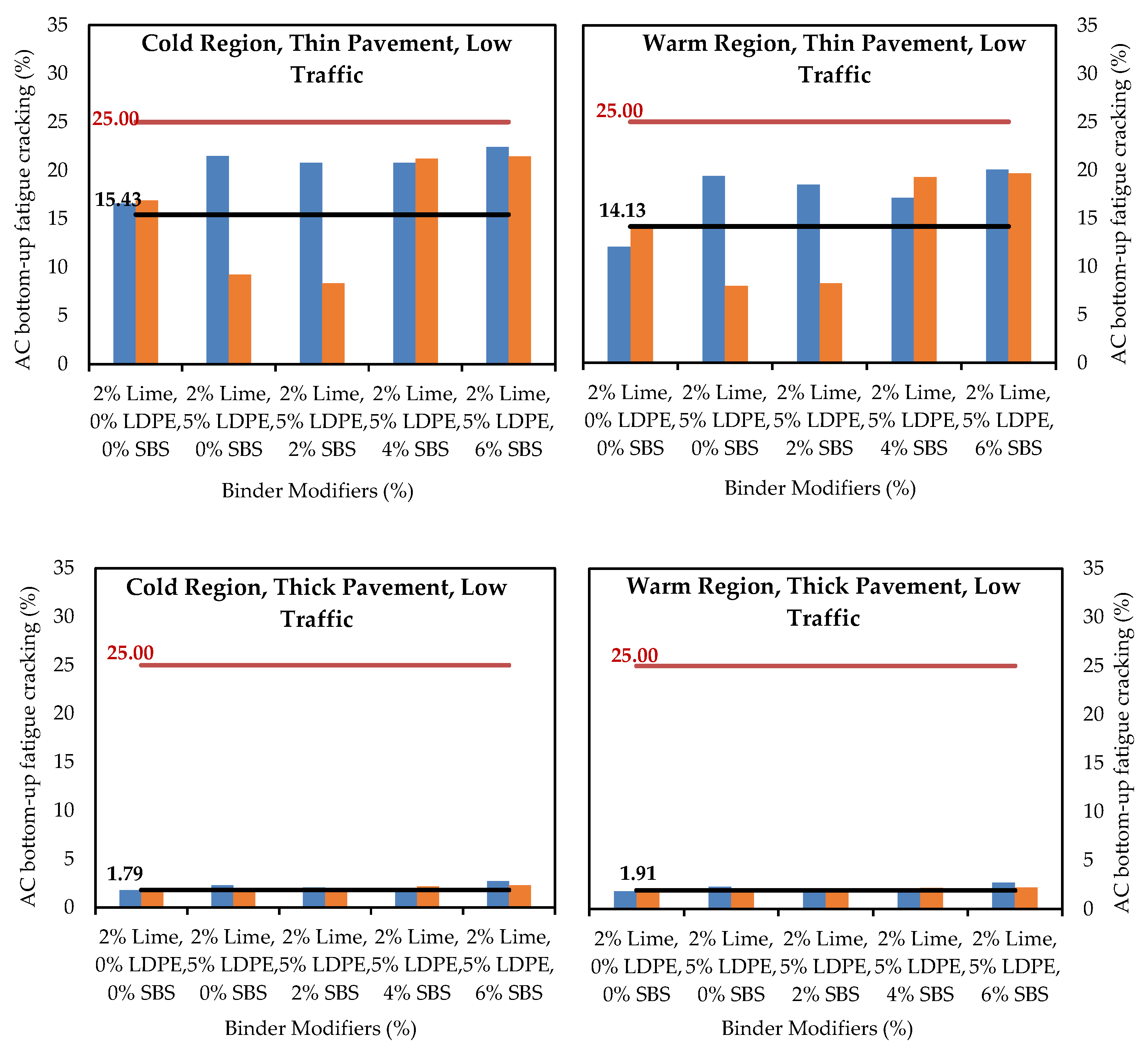

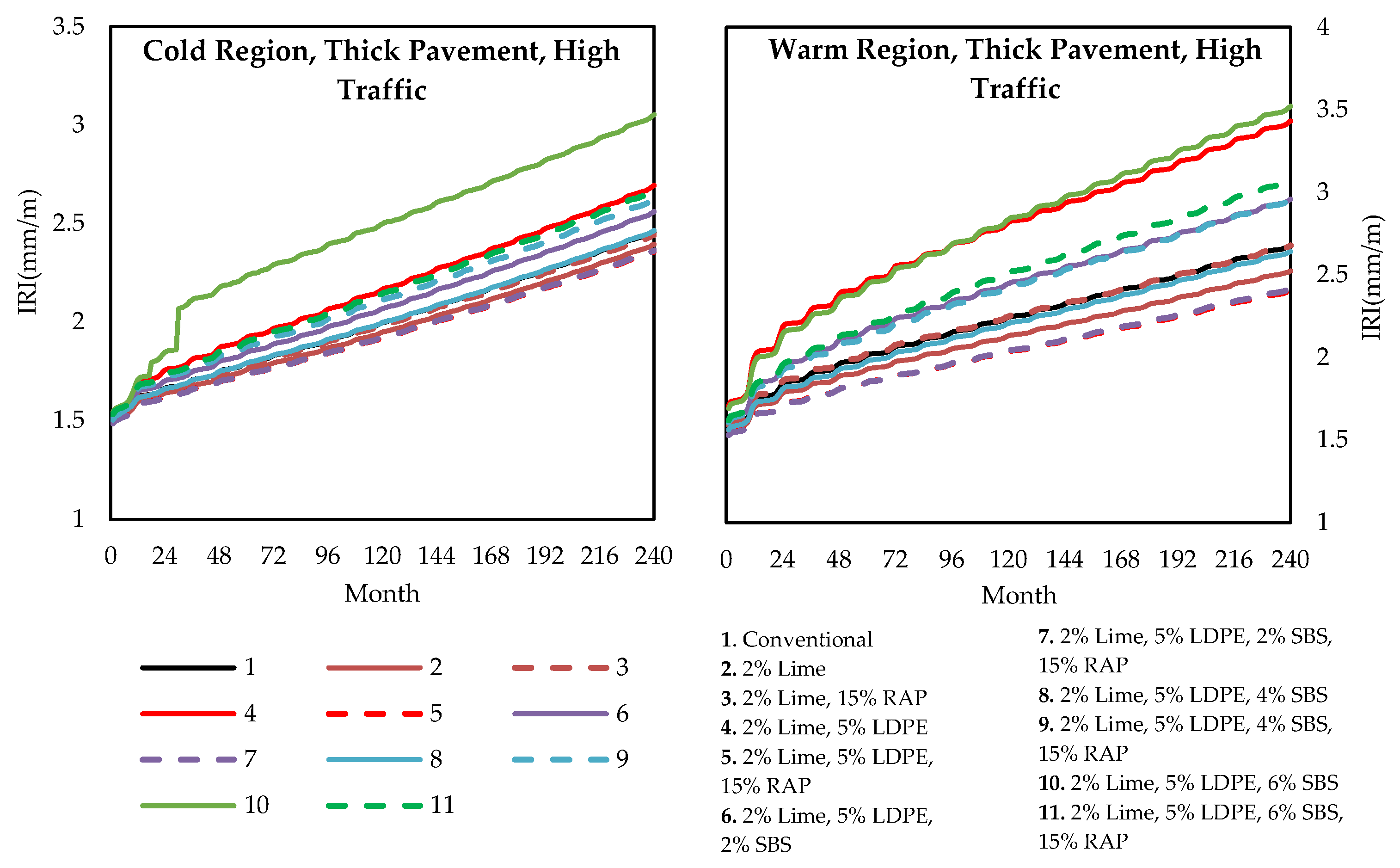

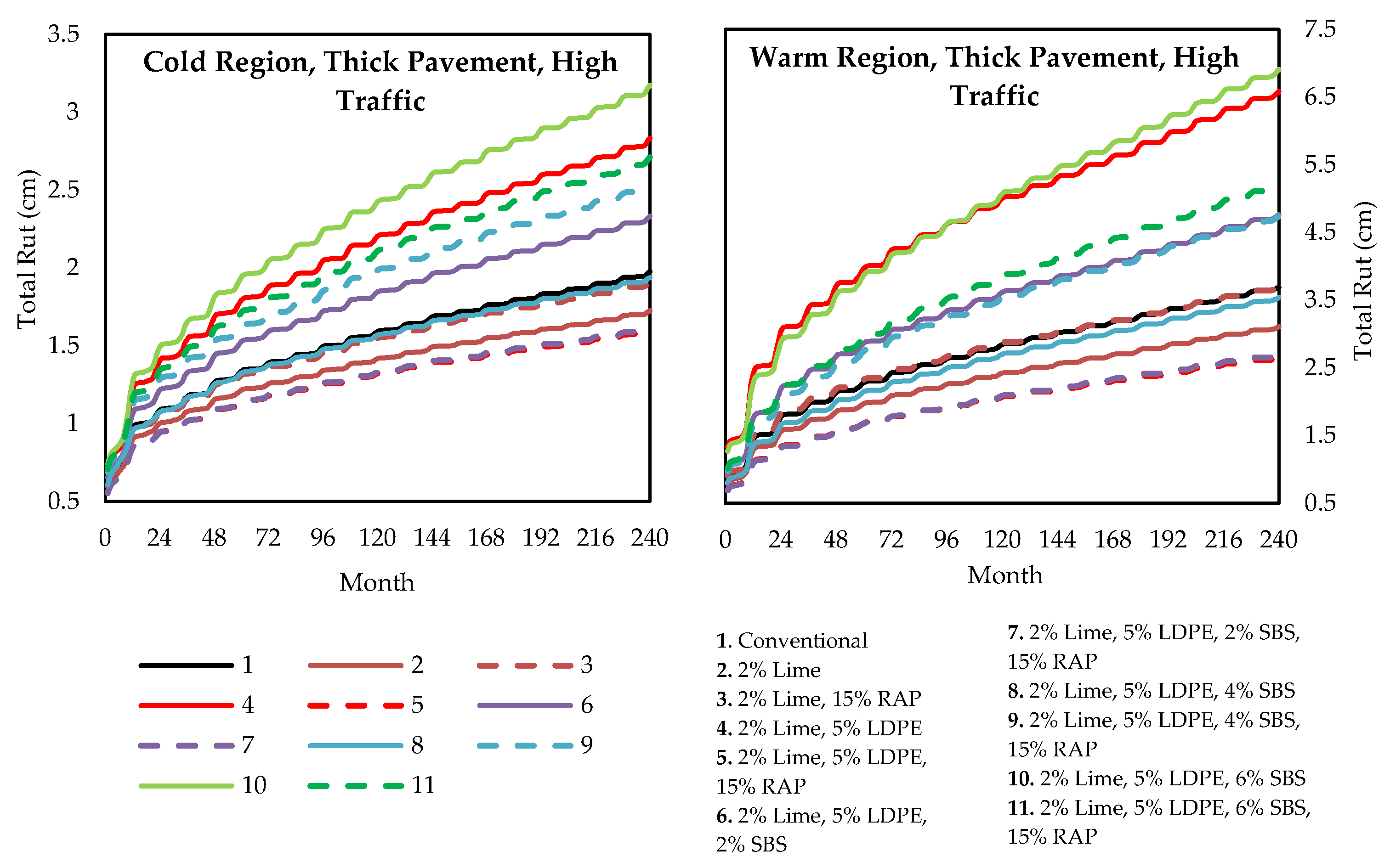

3.4.2. Comparison of Modifier Performance at Different Scenarios

3.4.3. Comparison of Performance Due to Change in Scenario

4. Conclusions

- Dynamic Modulus peaked response over a wide range of testing temperatures and loading frequencies as depicted through a master curve. The dynamic modulus increased by 254.675 MPa compared to conventional samples, representing a 269% increase at the lowest frequency of 0.1 Hz and 54.4 °C, indicating better performance at high strain levels and repeated loading conditions, signifying better fatigue resistance.

- At the highest frequency and temperature of 25 Hz and 54.4 °C, the values were also increased by 1145.55 MPa with a 145% increase indicating better performance in resistance to rutting and permanent deformation, thus suggesting suitability for heavy traffic conditions.

- Enhancement in moisture resistance was also observed as depicted by minimal variation in master curve, indicating lesser temperature susceptibility, respectively,

- The softening point was also increased by approximately 8 °C compared to ARL 60/70 bitumen binder.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled Aggregate from C&D Waste & Its Use in Concrete—A Breakthrough towards Sustainability in Construction Sector: A Review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Xing, C.; Li, M.; Liu, L.; Lu, R.; Liu, N.; Wu, W.; Yuan, D. A Comprehensive Review on the Blending Condition between Virgin and RAP Asphalt Binders in Hot Recycled Asphalt Mixtures: Mechanisms, Evaluation Methods, and Influencing Factors. J. Clean. Prod. 2023, 398, 136515. [Google Scholar] [CrossRef]

- Li, M.; Xing, C.; Liu, L.; Huang, W.; Meng, Y. Gel Permeation Chromatography-Based Method for Assessing the Properties of Binders in Reclaimed Asphalt Pavement Mixtures. Constr. Build. Mater. 2022, 316, 126005. [Google Scholar] [CrossRef]

- Ma, Y.; Polaczyk, P.; Hu, W.; Zhang, M.; Huang, B. Quantifying the Effective Mobilized RAP Content during Hot In-Place Recycling Techniques. J. Clean. Prod. 2021, 314, 127953. [Google Scholar] [CrossRef]

- Ma, Y.; Polaczyk, P.; Park, H.; Jiang, X.; Hu, W.; Huang, B. Performance Evaluation of Temperature Effect on Hot In-Place Recycling Asphalt Mixtures. J. Clean. Prod. 2020, 277, 124093. [Google Scholar] [CrossRef]

- Zhong, Y.; Wu, P. Economic Sustainability, Environmental Sustainability and Constructability Indicators Related to Concrete- and Steel-Projects. J. Clean. Prod. 2015, 108, 748–756. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and Demolition Waste Generation and Properties of Recycled Aggregate Concrete: A Global Perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Rahman, M.A.; Imteaz, M.; Arulrajah, A.; Disfani, M.M. Suitability of Recycled Construction and Demolition Aggregates as Alternative Pipe Backfilling Materials. J. Clean. Prod. 2014, 66, 75–84. [Google Scholar] [CrossRef]

- Wang, J.; Fang, Z.; Cai, Y.; Chai, J.; Wang, P.; Geng, X. Preloading Using Fill Surcharge and Prefabricated Vertical Drains for an Airport. Geotext. Geomembr. 2018, 46, 575–585. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A Critical Review and Assessment for Usage of Recycled Aggregate as Sustainable Construction Material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Shi, X.; Mukhopadhyay, A.; Zollinger, D.; Grasley, Z. Economic Input-Output Life Cycle Assessment of Concrete Pavement Containing Recycled Concrete Aggregate. J. Clean. Prod. 2019, 225, 414–425. [Google Scholar] [CrossRef]

- Santero, N.J.; Masanet, E.; Horvath, A. Life-Cycle Assessment of Pavements. Part I Crit. Rev. Resour. Conserv. Recycl. 2011, 55, 801–809. [Google Scholar] [CrossRef]

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An Empirical Study of Perceptions towards Construction and Demolition Waste Recycling and Reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

- Menaria, Y.; Sankhla, R. Use of Waste Plastic in Flexible Pavements-Green Roads. Open J. Civ. Eng. 2015, 5, 299–311. [Google Scholar] [CrossRef]

- Fanijo, E.O.; Kolawole, J.T.; Babafemi, A.J.; Liu, J. A Comprehensive Review on the Use of Recycled Concrete Aggregate for Pavement Construction: Properties, Performance, and Sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An Overview of Chemical Additives Present in Plastics: Migration, Release, Fate and Environmental Impact during Their Use, Disposal and Recycling. J. Hazard Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef]

- Sarwar, S.; Shaibur, M.R.; Akter, S. Conversion of Waste Plastic (Low Density Polyethylene) to Alternative Resources. Case Stud. Constr. Mater. 2023, 19, e02339. [Google Scholar] [CrossRef]

- Ahmed, T.; Shahid, M.; Azeem, F.; Rasul, I.; Shah, A.A.; Noman, M.; Hameed, A.; Manzoor, N.; Manzoor, I.; Muhammad, S. Biodegradation of Plastics: Current Scenario and Future Prospects for Environmental Safety. Environ. Sci. Pollut. Res. 2018, 25, 7287–7298. [Google Scholar] [CrossRef]

- Xin, J.; Akiyama, M.; Frangopol, D.M. Sustainability-Informed Management Optimization of Asphalt Pavement Considering Risk Evaluated by Multiple Performance Indicators Using Deep Neural Networks. Reliab. Eng. Syst. Saf. 2023, 238, 109448. [Google Scholar] [CrossRef]

- Pierce, L.M.; Ginger, M. Implementation of the AASHTO Mechanistic-Empirical Pavement Design Guide and Software; Transportation Research Board: Washington, DC, USA, 2014. [Google Scholar] [CrossRef]

- AASHTO. Top-Down Cracking Enhancement to the MEPDG, 3rd Edition Manual of Practice; AASHTO: Washington, DC, USA, 2021.

- Tran, N.; Robbins, M.M.; Rodezno, C.; Timm, D.H.; Tran, T. Pavement ME Design, Impact of Local Calibration, Foundation Support, Design and Reliability Thresholds; NCAT Report 17-08; NCAT: Greensboro, NC, USA, 2017.

- Habib, A. AASHTOWare Pavement ME User Manual; Virginia Department of Transportation: Richmond, VA, USA, 2017.

- Malpass, D.B. Introduction to Industrial Polyethylene; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Pugin, K.G. The Use of Polymer Materials in the Composition of Asphalt Concrete; Materials Research Forum: Millersville, PA, USA, 2022; pp. 150–155. [Google Scholar] [CrossRef]

- Yassoub, N.; Mohammed, A.S. Effect of Density of the Polyethylene Polymer on the Asphalt Mixtures. J. Babylon Univ. Eng. Sci. 2014, 22, 674–683. [Google Scholar]

- Nizamuddin, S.; Boom, Y.J.; Giustozzi, F. Sustainable Polymers from Recycled Waste Plastics and Their Virgin Counterparts as Bitumen Modifiers: A Comprehensive Review. Polymers 2021, 13, 3242. [Google Scholar] [CrossRef]

- Hameed, A.; Al-Busaltan, S.; Dulaimi, A.; Kadhim, M.A.; Al-Yasari, R. Evaluating Modified Asphalt Binder Comprising Waste Paper Fiber and Recycled Low-Density Polyethylene. J. Phys. Conf. Ser. 2021, 1973, 012237. [Google Scholar] [CrossRef]

- Alghrafy, Y.M.; Abd Alla, E.-S.M.; El-Badawy, S.M. Rheological Properties and Aging Performance of Sulfur Extended Asphalt Modified with Recycled Polyethylene Waste. Constr. Build. Mater. 2021, 273, 121771. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, S.; Upadhyay, N. Composition Based Physicochemical Analysis of Modified Bitumen by HDPE/LDPE. Orient. J. Chem. 2019, 35, 1167–1173. [Google Scholar] [CrossRef]

- Du, Z.; Jiang, C.; Yuan, J.; Xiao, F.; Wang, J. Low Temperature Performance Characteristics of Polyethylene Modified Asphalts—A Review. Constr. Build. Mater. 2020, 264, 120704. [Google Scholar] [CrossRef]

- Dong, F.; Yu, X.; Liu, S.; Wei, J. Rheological Behaviors and Microstructure of SBS/CR Composite Modified Hard Asphalt. Constr. Build. Mater. 2016, 115, 285–293. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Luo, H.; Wang, X.; Xing, B. Investigation of the Rheological Properties and Storage Stability of CR/SBS Modified Asphalt. Constr. Build. Mater. 2015, 74, 235–240. [Google Scholar] [CrossRef]

- Kanny, K.; Mohan, T.P. Rubber Nanocomposites with Nanoclay as the Filler. In Progress in Rubber Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2017; pp. 153–177. [Google Scholar] [CrossRef]

- Kim, T.W.; Baek, J.; Lee, H.J.; Choi, J.Y. Fatigue Performance Evaluation of SBS Modified Mastic Asphalt Mixtures. Constr. Build. Mater. 2013, 48, 908–916. [Google Scholar] [CrossRef]

- Airey, G. Rheological Properties of Styrene Butadiene Styrene Polymer Modified Road Bitumens⋆. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Liu, X.; Duan, H. A Novel Method for Determining the Time-Temperature Superposition Relationship of SBS Modified Bitumen: Effects of Bitumen Source, Modifier Type and Aging. Constr. Build. Mater. 2021, 280, 122549. [Google Scholar] [CrossRef]

- Liu, J.; Yan, K.; Liu, W.; Zhao, X. Partially Replacing Styrene-Butadiene-Styrene (SBS) with Other Asphalt Binder Modifier: Feasibility Study. Constr. Build. Mater. 2020, 249, 118752. [Google Scholar] [CrossRef]

- Hong, Z.; Yan, K.; Ge, D.; Wang, M.; Li, G.; Li, H. Effect of Styrene-Butadiene-Styrene (SBS) on Laboratory Properties of Low-Density Polyethylene (LDPE)/Ethylene-Vinyl Acetate (EVA) Compound Modified Asphalt. J. Clean. Prod. 2022, 338, 130677. [Google Scholar] [CrossRef]

- Tayfur, S.; Ozen, H.; Aksoy, A. Investigation of Rutting Performance of Asphalt Mixtures Containing Polymer Modifiers. Constr. Build. Mater. 2007, 21, 328–337. [Google Scholar] [CrossRef]

- Omrani, H.; Ghanizadeh, A.R.; Tanakizadeh, A. Effect of SBS Polymer and Anti-Stripping Agents on the Moisture Susceptibility of Hot and Warm Mix Asphalt Mixtures. Civ. Eng. J. 2017, 3, 987–996. [Google Scholar] [CrossRef]

- Yang, Q.; Lin, J.; Wang, X.; Wang, D.; Xie, N.; Shi, X. A Review of Polymer-Modified Asphalt Binder: Modification Mechanisms and Mechanical Properties. Clean. Mater. 2024, 12, 100255. [Google Scholar] [CrossRef]

- Modarres, A. Investigating the Toughness and Fatigue Behavior of Conventional and SBS Modified Asphalt Mixes. Constr. Build. Mater. 2013, 47, 218–222. [Google Scholar] [CrossRef]

- Bai, M. Investigation of Low-Temperature Properties of Recycling of Aged SBS Modified Asphalt Binder. Constr. Build. Mater. 2017, 150, 766–773. [Google Scholar] [CrossRef]

- Kök, B.V.; Çolak, H. Laboratory Comparison of the Crumb-Rubber and SBS Modified Bitumen and Hot Mix Asphalt. Constr. Build. Mater. 2011, 25, 3204–3212. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Analysis of Styrene-Butadiene-Styrene Polymer Modified Bitumen Using Fluorescent Microscopy and Conventional Test Methods. J. Hazard Mater. 2008, 150, 424–432. [Google Scholar] [CrossRef]

- Özen, H. Rutting Evaluation of Hydrated Lime and SBS Modified Asphalt Mixtures for Laboratory and Field Compacted Samples. Constr. Build. Mater. 2011, 25, 756–765. [Google Scholar] [CrossRef]

- Abed, A.H.; Bahia, H.U. Enhancement of Permanent Deformation Resistance of Modified Asphalt Concrete Mixtures with Nano-High Density Polyethylene. Constr. Build. Mater. 2020, 236, 117604. [Google Scholar] [CrossRef]

- Little, D.N.; Petersen, J.C. Unique Effects of Hydrated Lime Filler on the Performance-Related Properties of Asphalt Cements: Physical and Chemical Interactions Revisited. J. Mater. Civ. Eng. 2005, 17, 207–218. [Google Scholar] [CrossRef]

- Mohan, H.M.; Obaid, H.A. Laboratory Examination for the Effect of Adding Hydrated Lime on the Moisture Damage Resistance of Asphalt Concrete Mixtures. Kufa J. Eng. 2014, 5, 1–12. [Google Scholar] [CrossRef]

- Singh, B.; Prasad, D.; Kant, R.R. Effect of Lime Filler on RCA Incorporated Bituminous Mixture. Clean. Eng. Technol. 2021, 4, 100166. [Google Scholar] [CrossRef]

- Hussain, M.A. Performance Evaluation of Flexible Pavement against Rutting. Int. J. Adv. Struct. Geotech. Eng. 2015, 4, 2319–5347. [Google Scholar]

- Federal Highway Administration Research and Technology. Reclaimed Asphalt Pavement; National Asphalt Pavement Association: Lanham, MD, USA, 2023. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/97148/046.cfm#:~:text=Reclaimed%20asphalt%20pavement%20(RAP)%20is,obtain%20access%20to%20buried%20utilities (accessed on 24 July 2025).

- Zhang, J.; Guo, C.; Chen, T.; Zhang, W.; Yao, K.; Fan, C.; Liang, M.; Guo, C.; Yao, Z. Evaluation on the Mechanical Performance of Recycled Asphalt Mixtures Incorporated with High Percentage of RAP and Self-Developed Rejuvenators. Constr. Build. Mater. 2021, 269, 121337. [Google Scholar] [CrossRef]

- Moniri, A.; Ziari, H.; Aliha, M.R.M.; Saghafi, Y. Laboratory Study of the Effect of Oil-Based Recycling Agents on High RAP Asphalt Mixtures. Int. J. Pavement Eng. 2021, 22, 1423–1434. [Google Scholar] [CrossRef]

- Esfandiarpour, S.; Shalaby, A. Effect of Local Calibration of Dynamic Modulus and Creep Compliance Models on Predicted Performance of Asphalt Mixes Containing RAP. Int. J. Pavement Res. Technol. 2018, 11, 517–529. [Google Scholar] [CrossRef]

- Izaks, R.; Haritonovs, V.; Klasa, I.; Zaumanis, M. Hot Mix Asphalt with High RAP Content. Procedia Eng. 2015, 114, 676–684. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Vukosavljevic, D. Laboratory Investigation of Cracking Resistance of Hot-Mix Asphalt Field Mixtures Containing Screened Reclaimed Asphalt Pavement. J. Mater. Civ. Eng. 2011, 23, 1535–1543. [Google Scholar] [CrossRef]

- Kim, S.; Sholar, G.A.; Byron, T.; Kim, J. Performance of Polymer-Modified Asphalt Mixture with Reclaimed Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2009, 2126, 109–114. [Google Scholar] [CrossRef]

- Mcdaniel, R.S.; Anderson, R.M. Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Method Technician’s Manual; National Academy Press: Washington, DC, USA, 2001. [Google Scholar]

- Widyatmoko, I. Mechanistic-Empirical Mixture Design for Hot Mix Asphalt Pavement Recycling. Constr. Build. Mater. 2008, 22, 77–87. [Google Scholar] [CrossRef]

- Pradyumna, T.A.; Mittal, A.; Jain, P.K. Characterization of Reclaimed Asphalt Pavement (RAP) for Use in Bituminous Road Construction. Procedia Soc. Behav. Sci. 2013, 104, 1149–1157. [Google Scholar] [CrossRef]

- Shannon, C.; Lee, W.; Williams, C.; Tang, S. Development of Quality Standards for Inclusion of High Recycled Asphalt Pavement Content in Asphalt Mixtures; Public Policy Center: Washington, DC, USA, 2012. [Google Scholar]

- Ali, Z.K.; Jasim, A.F. A Scenario-Based Case Study Approach to Pavement Rehabilitation Using Life Cycle Analysis of Recycled Asphalt Materials. Eng. Technol. Appl. Sci. Res. 2025, 15, 22072–22080. [Google Scholar] [CrossRef]

- Leiva-Villacorta, F.; Cerdas-Murillo, A. Performance Evaluation of Recycled Fibers in Asphalt Mixtures. Constr. Mater. 2024, 4, 839–855. [Google Scholar] [CrossRef]

- Do, T.C.; Nguyen, T.H.; Nguyen, V.L. Experimental Study on the Resistance of Asphalt Mixtures to Permanent Deformation and Its Relation to Mechanical Behavior of Pavement Structures. Case Stud. Constr. Mater. 2025, 22, e04248. [Google Scholar] [CrossRef]

- Zahid, A.; Ahmed, S.; Irfan, M. Experimental Investigation of Nano Materials Applicability in Hot Mix Asphalt (HMA). Constr. Build. Mater. 2022, 350, 128882. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Ruge, J.C.; Herrera Cano, C.E. Mechanical Performance of an Asphalt Stabilized Base with Natural Asphalt, Hydrated Lime and Portland Cement. Constr. Build. Mater. 2024, 446, 137938. [Google Scholar] [CrossRef]

- ASTM D5821; Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C131; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D4791; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2019.

- BS 812; Testing Aggregates—Methods for Determination of Aggregate Impact Value (AIV). British Standards Institution: London, UK, 1990.

- ASTM C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C142; Standard Test Method for Clay Lumps and Friable Particles in Aggregates. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D92; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D70; Standard Test Method for Density of Semi-Solid Bituminous Materials (Pycnometer Method). ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D36; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D113; Standard Test Method for Ductility of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D6926; Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus. ASTM International: West Conshohocken, PA, USA, 2016.

- The Editors of Encyclopaedia Britannica. Properties of Hydrated Lime. Encyclopedia Britannica. 2025. Available online: www.britannica.com (accessed on 17 October 2025).

- Awodiji Chioma, B.T.; Onyebuchi, D.J.; Chibuike, N.; Olujide, A.O.; Joan, A.I. Reactions of Hydrated Lime-Saw Dust Ash Blend on the Strength Properties of Cement Concrete. Glob. J. Res. Eng. 2019, 19, 29–39. [Google Scholar]

- Mansour, A.; Hamdy, A.; Saber, D.; El-Meniawy, M.A.; Abdelhaleim, A.M.; Abdelnaby, A.H. Mechanical Properties and Corrosion Behavior of Sugarcane Bagasse Fiber Reinforced Low Density Polyethylene Composites. Egypt. Int. J. Eng. Sci. Technol. 2021, 36, 63–71. [Google Scholar]

- BPF. Polyethylene (Low Density) LDPE, LLDPE. Available online: https://www.bpf.co.uk/plastipedia/polymers/LDPE.aspx (accessed on 24 July 2025).

- Singh, A.; Gupta, A. Revisiting MSCR Test Parameters for LDPE-Modified Asphalt Binders. Constr. Build. Mater. 2025, 494, 143353. [Google Scholar] [CrossRef]

- Junaid, M.; Jiang, C.; Eltwati, A.; Khan, D.; Alamri, M.; Eisa, M.S. Statistical Analysis of Low-Density and High-Density Polyethylene Modified Asphalt Mixes Using the Response Surface Method. Case Stud. Constr. Mater. 2024, 21, e03697. [Google Scholar] [CrossRef]

- ASTM D2172; Standard Test Methods for Quantitative Extraction of Asphalt Binder from Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D6925; Standard Test Method for Preparation and Determination of the Relative Density of Asphalt Mix Specimens by Means of the Superpave Gyratory Compactor. ASTM International: West Conshohocken, PA, USA, 2015.

- AASHTO T312; Standard Method of Test for Preparing and Determining the Density of Asphalt Mixture Specimens by Means of the Superpave Gyratory Compactor. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- AASHTO TP62-07; Standard Method of Test for Determining Dynamic Modulus of Hot-Mix Asphalt Concrete Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2009.

- AASHTO TP79-09; Standard Method of Test for Determining the Dynamic Modulus and Flow Number for Asphalt Mixtures Using the Asphalt Mixture Performance Tester (AMPT). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2009.

| Density (Kg/m3) | Molar Mass (g/mol) | Melting Point (°C) | Color | Texture | Sol. in H2O | Sol. in HCl |

|---|---|---|---|---|---|---|

| 2240 | 74.09 | 580 | White | Smooth | Partial | Partial |

| Properties | Values |

|---|---|

| Density (Kg/m3) | 917–930 |

| Reactivity | Non-reactive |

| Long-term thermal exposure (°C) | 65 |

| Short-term thermal exposure (°C) | 90 |

| Color | Opaque |

| Tensile Strength (MPa) | 9 |

| Thermal coefficient of expansion (×10−6) | 100–220 |

| Melt flow rate (g/s) | 0.033 at 190 °C |

| Flexural strength (MPa) | 7 |

| Flexural Modulus (MPa) | 175 |

| Strain at breakage (%) | 150 |

| Izod impact strength (J/m2) | 500 |

| Hardness shore D | 45 |

| Properties | Values |

|---|---|

| Styrene to Butadiene ratio | 0.43 |

| Grade | YH-791H |

| Structure | Linear |

| Styrene solution’s Viscosity (Pa. s) at 25 °C | 2.24 at 5% |

| Volatility (%) | <1.0 |

| Tensile strength (MPa) | 20 |

| Melt flow rate (g/s) | 0.166 × 10−3 |

| Hardness shore A | 76 |

| Test Type | Results (%) | Specification (%) | Standards | |

|---|---|---|---|---|

| Fractured Particles | 98.67 | >90 | ASTM D5821 | |

| Los Angeles Abrasion | 24.56 | <45 | ASTM C131 | |

| Flakiness Index | 11.41 | <15 | ASTM D4791 | |

| Elongation Index | 3.86 | <15 | ASTM D4791 | |

| Impact Value | 16.62 | <30 | BS 812 | |

| Crushing Value | 20.58 | <30 | BS 812 | |

| Water Absorption | Fine Aggregate | 2.37 | <3 | ASTM C128 |

| Coarse Aggregate | 0.56 | <3 | ASTM C127 | |

| Specific Gravity | Fine Aggregate | 2.67 | - | ASTM C128 |

| Coarse Aggregate | 2.70 | - | ASTM C127 | |

| Clay Percentage | Fine Aggregate | 2.78 | - | ASTM C142 |

| Coarse Aggregate | 0.56 | - | ASTM C142 | |

| Test Description | Result | Specification | Standard |

|---|---|---|---|

| Penetration Test (mm) | 6.2 | 60–70 | ASTM 5 |

| Flash Point (°C) | 258 | Min. 232 | ASTM D92 |

| Fire Point (°C) | 273 | Min. 270 | ASTM D92 |

| Specific Gravity | 1.00 | 0.97–1.02 | ASTM D70 |

| Softening Point (°C) | 49 | 49–56 | ASTM D36-06 |

| Ductility Test (cm) | 111 | Min. 100 | ASTM D113-99 |

| Parameters | Value | Criteria | Remarks |

|---|---|---|---|

| OBC (%) | 4.26 | 4 | - |

| Unit Weight (KN/m3) | 23.63 | - | - |

| VMA (%) | 13.90 | >13 | Pass |

| VFA (%) | 71.50 | 65–75 | Pass |

| Stability (KN) | 11.02 | >8.006 | Pass |

| Flow (mm) | 2.62 | 2.0–3.5 | Pass |

| Sieve Size (mm) | Passing Range for NHA-B for ACWC 1 (%) | Selection for Study (%) | Retained Proportion on Each Sieve (%) | Retained Wt. of Sample (gm) | Retained Wt. with 2% Lime (gm) | Retained Wt. with 15%RAP & 2% Lime (gm) |

|---|---|---|---|---|---|---|

| 19 | 100 | 100 | 0 | 0.00 | 0.00 | 0.00 |

| 12.5 | 75–90 | 82.5 | 17.5 | 1223.08 | 1223.08 | 1039.62 |

| 9.5 | 60–80 | 70 | 12.5 | 873.63 | 873.63 | 742.58 |

| 4.75 | 40–60 | 50 | 20 | 1397.80 | 1397.80 | 1188.13 |

| 2.38 | 20–40 | 30 | 20 | 1397.80 | 1397.80 | 1188.13 |

| 1.18 | 5–15 | 10 | 20 | 1397.80 | 1397.80 | 1188.13 |

| 0.075 | 3–8 | 5.5 | 4.5 | 314.51 | 314.51 | 267.33 |

| Pan | 0 | 0 | 5.5 | 384.40 | 238.40 | 202.64 |

| Total | 100 | 6989.02 | 6843.02 | 5816.57 | ||

| Binder Modifier | Distress Type | |||||

|---|---|---|---|---|---|---|

| Terminal IRI (mm/m) | AC Bottom-Up Fatigue Cracking (%) | AC Top-Down Fatigue Cracking (mm/m) | Permanent Deformation | |||

| Total (mm) | AC Only (mm) | |||||

| Conventional | 0.085 | −1.300 | −46.547 | 12.446 | 14.732 | |

| Without RAP | 2% Lime, 0% LDP, 0% SBS | 0.003 | −4.520 | −101.442 | 9.652 | 12.192 |

| 2% Lime, 5% LDPE, 0% SBS | 0.453 | −2.130 | −46.873 | 27.178 | 29.718 | |

| 2% Lime, 5% LDPE, 2% SBS | 0.210 | −2.290 | −121.105 | 17.780 | 20.320 | |

| 2% Lime, 5% LDPE, 4% SBS | 0.018 | −3.680 | −178.697 | 10.922 | 13.970 | |

| 2% Lime, 5% LDPE, 6% SBS | 0.107 | −2.380 | −114.809 | 26.670 | 29.210 | |

| With RAP | 2% Lime, 0% LDP, 0% SBS | 0.092 | −2.910 | −79.360 | 12.954 | 15.240 |

| 2% Lime, 5% LDPE, 0% SBS | −0.060 | −1.250 | −54.846 | 6.604 | 9.144 | |

| 2% Lime, 5% LDPE, 2% SBS | −0.053 | −0.090 | −46.214 | 7.112 | 9.398 | |

| 2% Lime, 5% LDPE, 4% SBS | 0.146 | −1.960 | −144.258 | 15.748 | 18.288 | |

| 2% Lime, 5% LDPE, 6% SBS | 0.202 | −1.810 | −136.959 | 17.780 | 20.320 | |

| Binder Modifier | Distress Type | |||||

|---|---|---|---|---|---|---|

| Terminal IRI (mm/m) | AC Bottom-Up Fatigue Cracking (%) | AC Top-Down Fatigue Cracking (mm/m) | Permanent Deformation | |||

| Total (mm) | AC Only (mm) | |||||

| Conventional | 0.083 | −1.300 | 98.699 | 12.192 | 13.716 | |

| Without RAP | 2% Lime, 0% LDP, 0% SBS | 0.018 | −4.520 | 118.536 | 9.652 | 11.430 |

| 2% Lime, 5% LDPE, 0% SBS | 0.464 | −2.130 | 83.849 | 26.670 | 28.702 | |

| 2% Lime, 5% LDPE, 2% SBS | 0.215 | −2.290 | 37.996 | 17.272 | 19.050 | |

| 2% Lime, 5% LDPE, 4% SBS | 0.050 | −3.680 | 55.965 | 11.176 | 13.208 | |

| 2% Lime, 5% LDPE, 6% SBS | 0.194 | −2.380 | 75.538 | 26.670 | 28.702 | |

| With RAP | 2% Lime, 0% LDP, 0% SBS | 0.095 | −2.910 | 98.858 | 12.446 | 14.224 |

| 2% Lime, 5% LDPE, 0% SBS | −0.042 | −1.250 | 158.005 | 7.366 | 9.144 | |

| 2% Lime, 5% LDPE, 2% SBS | −0.037 | −0.090 | 158.582 | 7.366 | 9.398 | |

| 2% Lime, 5% LDPE, 4% SBS | 0.165 | −1.960 | 17.785 | 15.494 | 17.526 | |

| 2% Lime, 5% LDPE, 6% SBS | 0.220 | −1.810 | 7.951 | 17.780 | 19.304 | |

| Binder Modifier | Distress Type | |||||

|---|---|---|---|---|---|---|

| Terminal IRI (mm/m) | AC Bottom-Up Fatigue Cracking (%) | AC Top-Down Fatigue Cracking (mm/m) | Permanent Deformation | |||

| Total (mm) | AC Only (mm) | |||||

| Conventional | 0.221 | −1.300 | −71.444 | 18.034 | 20.320 | |

| Without RAP | 2% Lime, 0% LDP, 0% SBS | 0.110 | −4.520 | −167.864 | 13.970 | 16.510 |

| 2% Lime, 5% LDPE, 0% SBS | 0.718 | −2.130 | −84.683 | 38.100 | 40.640 | |

| 2% Lime, 5% LDPE, 2% SBS | 0.386 | −2.290 | −209.930 | 25.146 | 27.940 | |

| 2% Lime, 5% LDPE, 4% SBS | 0.129 | −3.680 | −308.572 | 16.002 | 19.050 | |

| 2% Lime, 5% LDPE, 6% SBS | 0.363 | −2.380 | −204.743 | 37.338 | 40.132 | |

| With RAP | 2% Lime, 0% LDP, 0% SBS | 0.230 | −2.910 | −128.839 | 18.288 | 21.082 |

| 2% Lime, 5% LDPE, 0% SBS | 0.021 | −1.250 | −84.570 | 9.906 | 12.700 | |

| 2% Lime, 5% LDPE, 2% SBS | 0.031 | −0.090 | −70.450 | 10.414 | 12.954 | |

| 2% Lime, 5% LDPE, 4% SBS | 0.301 | −1.960 | −246.099 | 22.606 | 25.146 | |

| 2% Lime, 5% LDPE, 6% SBS | 0.376 | −1.810 | −235.578 | 25.400 | 27.940 | |

| Binder Modifier | Distress Type | |||||

|---|---|---|---|---|---|---|

| Terminal IRI (mm/m) | AC Bottom-Up Fatigue Cracking (%) | AC Top-Down Fatigue Cracking (mm/m) | Permanent Deformation | |||

| Total (mm) | AC Only (mm) | |||||

| Conventional | 0.217 | −1.300 | 117.317 | 17.018 | 19.050 | |

| Without RAP | 2% Lime, 0% LDP, 0% SBS | 0.130 | −4.520 | 138.380 | 13.716 | 15.748 |

| 2% Lime, 5% LDPE, 0% SBS | 0.738 | −2.130 | 128.340 | 37.338 | 39.370 | |

| 2% Lime, 5% LDPE, 2% SBS | 0.398 | −2.290 | 51.613 | 24.130 | 26.162 | |

| 2% Lime, 5% LDPE, 4% SBS | 0.177 | −3.680 | 77.342 | 16.002 | 18.288 | |

| 2% Lime, 5% LDPE, 6% SBS | 0.469 | −2.380 | 127.690 | 37.338 | 39.370 | |

| With RAP | 2% Lime, 0% LDP, 0% SBS | 0.234 | −2.910 | 117.924 | 17.780 | 19.558 |

| 2% Lime, 5% LDPE, 0% SBS | 0.046 | −1.250 | 180.240 | 10.414 | 12.446 | |

| 2% Lime, 5% LDPE, 2% SBS | 0.053 | −0.090 | 181.081 | 10.668 | 12.700 | |

| 2% Lime, 5% LDPE, 4% SBS | 0.332 | −1.960 | 26.296 | 22.098 | 23.876 | |

| 2% Lime, 5% LDPE, 6% SBS | 0.405 | −1.810 | 11.703 | 24.892 | 26.924 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haris, M.; Naseem, A.; Ahmed, S.; Kashif, M.; Naseem, A. Mechanistic-Empirical Analysis of LDPE-SBS-Modified Asphalt Concrete Mix with RAP Subjected to Various Traffic and Climatic Loading Conditions. Infrastructures 2025, 10, 288. https://doi.org/10.3390/infrastructures10110288

Haris M, Naseem A, Ahmed S, Kashif M, Naseem A. Mechanistic-Empirical Analysis of LDPE-SBS-Modified Asphalt Concrete Mix with RAP Subjected to Various Traffic and Climatic Loading Conditions. Infrastructures. 2025; 10(11):288. https://doi.org/10.3390/infrastructures10110288

Chicago/Turabian StyleHaris, Muhammad, Asad Naseem, Sarfraz Ahmed, Muhammad Kashif, and Ahsan Naseem. 2025. "Mechanistic-Empirical Analysis of LDPE-SBS-Modified Asphalt Concrete Mix with RAP Subjected to Various Traffic and Climatic Loading Conditions" Infrastructures 10, no. 11: 288. https://doi.org/10.3390/infrastructures10110288

APA StyleHaris, M., Naseem, A., Ahmed, S., Kashif, M., & Naseem, A. (2025). Mechanistic-Empirical Analysis of LDPE-SBS-Modified Asphalt Concrete Mix with RAP Subjected to Various Traffic and Climatic Loading Conditions. Infrastructures, 10(11), 288. https://doi.org/10.3390/infrastructures10110288