A Systematic Approach for Selection of Fit-for-Purpose Low-Carbon Concrete for Various Bridge Elements to Reduce the Net Embodied Carbon of a Bridge Project

Abstract

1. Introduction

2. Performance Requirements for Concrete Bridges

2.1. Performance Requirements Establishment Process

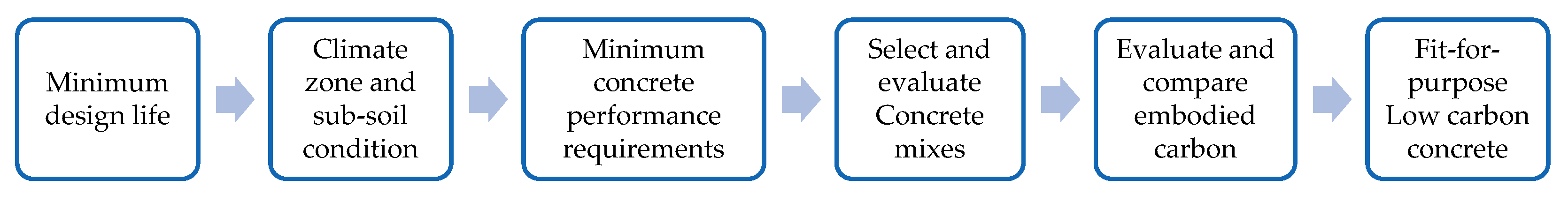

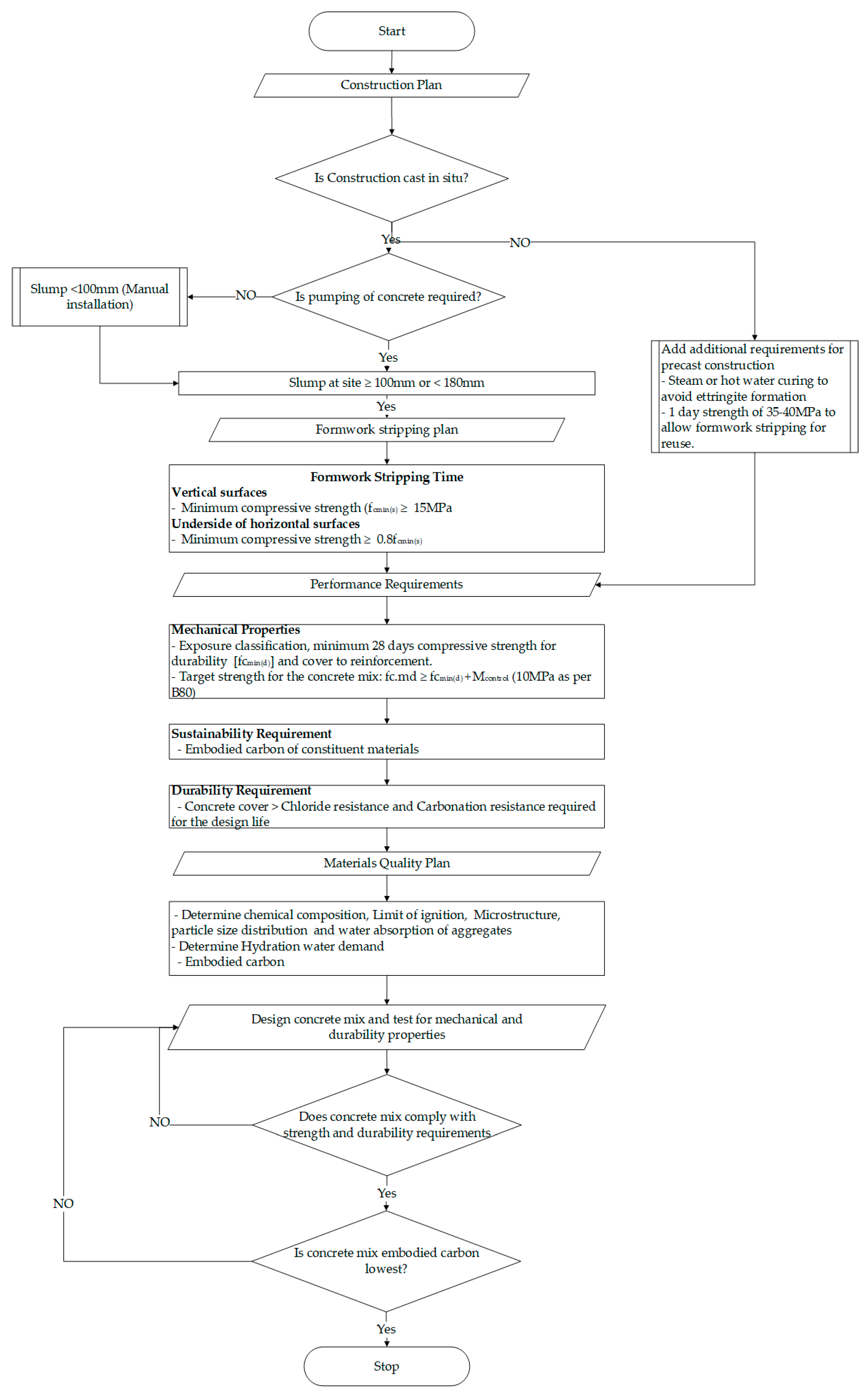

2.2. Design Life

2.3. Material Characteristics

- Aggregates

- ○

- The quantity passing the 75 µm sieve shall not exceed 2% of the total coarse aggregate (by mass).

- ○

- The maximum water absorption shall be 2.5% except for slag aggregate, where the maximum water absorption may be up to 6%.

- ○

- The quantity of clays in fine aggregates shall not exceed 5% by mass, and the quantity of reactive clays shall not exceed 2.0% when the fine aggregate is tested by X-ray diffraction (XRD)/X-ray fluorescence (XRF).

- Alkali–aggregate reaction (AAR) expansion in 21 days, measured by accelerated mortar bar test (AMBT) as per AS 1141.60.1 [11], shall be <0.1% for non-reactive aggregates, between 0.1% to 0.3% for slowly reactive aggregates, and >0.3% for reactive aggregates. For reactive aggregates, blended cement with a minimum of 25% FA or 50% GGBFS is used in production of concrete.

- FA used as SCM in concrete shall be of grade 1 as per AS/NZS 3582.1 [12] with fineness (% passing 45 µm sieve) < 75%, loss of ignition (LOI) < 4%, moisture content < 1% and SO3 content < 3%. Total content of SiO2, Al2O3, and Fe2O3 in FA, determined by XRF tests, shall be >70%. The reactivity of FA, measured as the strength index, shall be >75%.

- GGBFS used as SCM in concrete shall comply with AS 3582.2 [13]. The sulfide sulfur (S), magnesia (MgO), and alumina (Al2O3) content in GGBFS, determined by XRF tests, shall not exceed 1.5%, 15% and 18%, respectively.

2.4. Exposure Classification and Minimum Requirements

3. Embodied Carbon (EC)

4. Alternative Concrete Mixes with SCMs

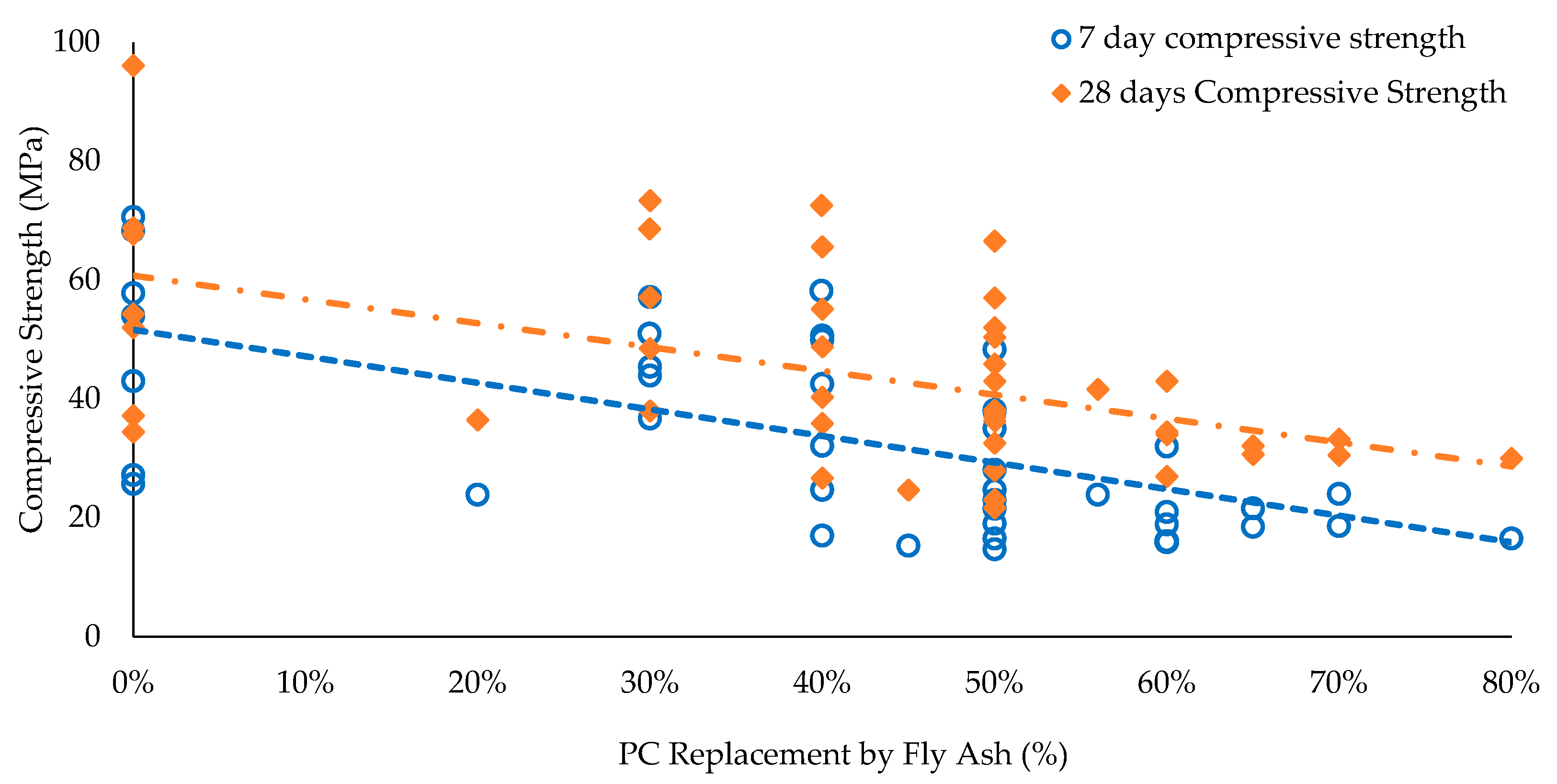

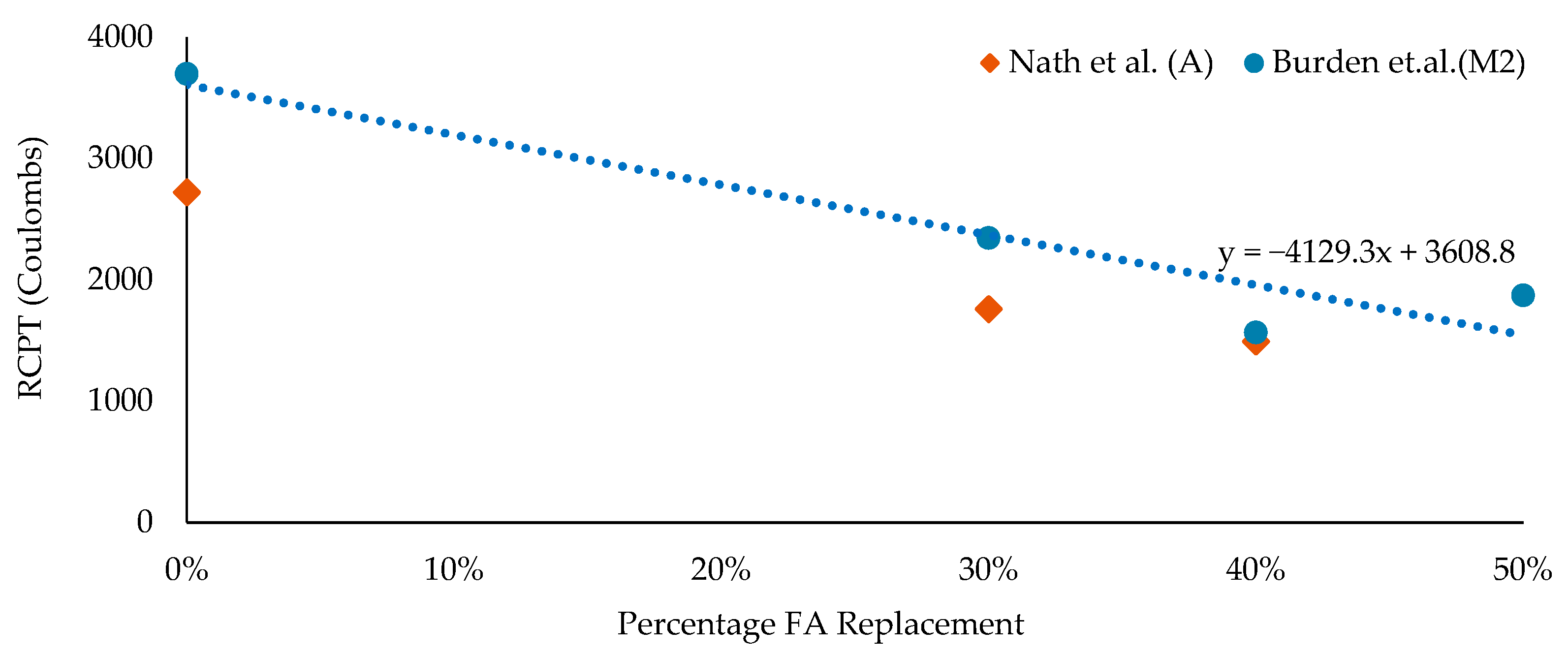

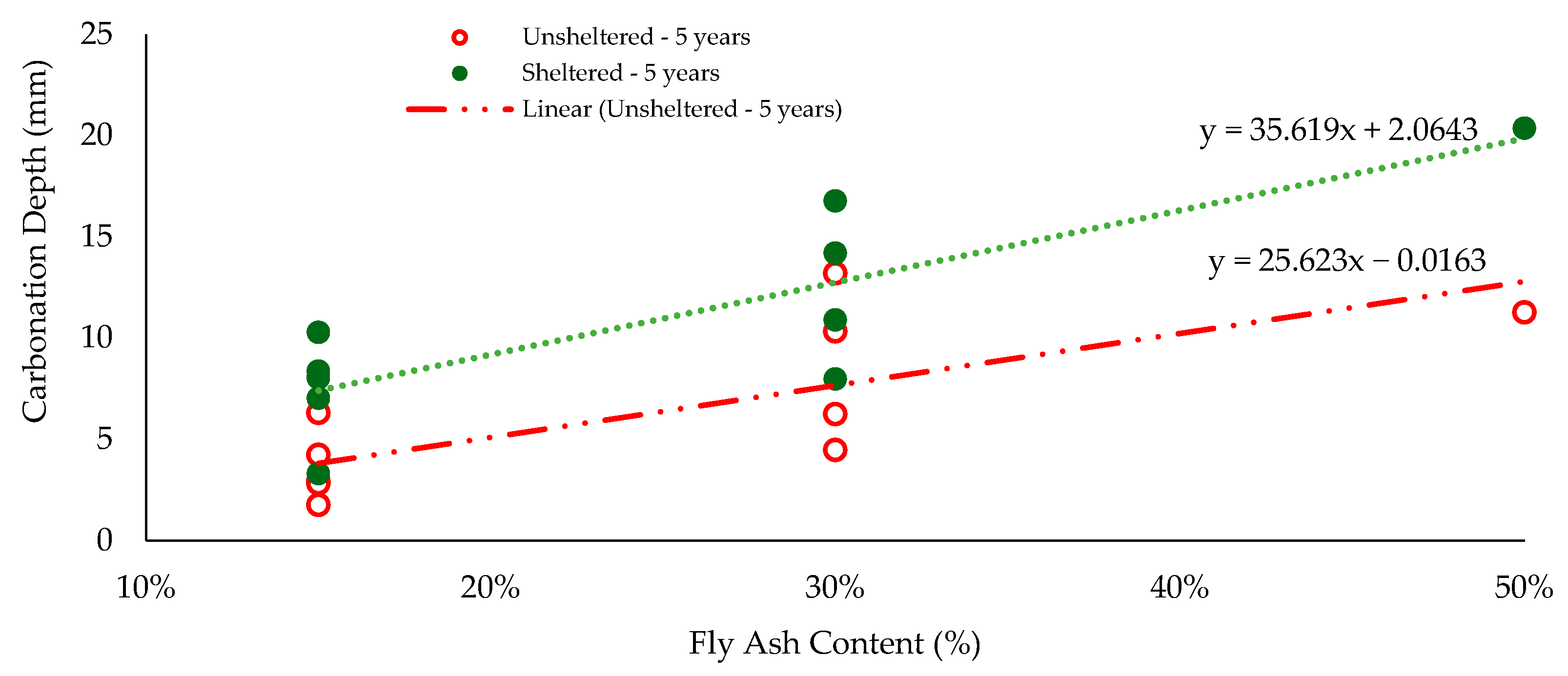

4.1. Fly Ash Concrete

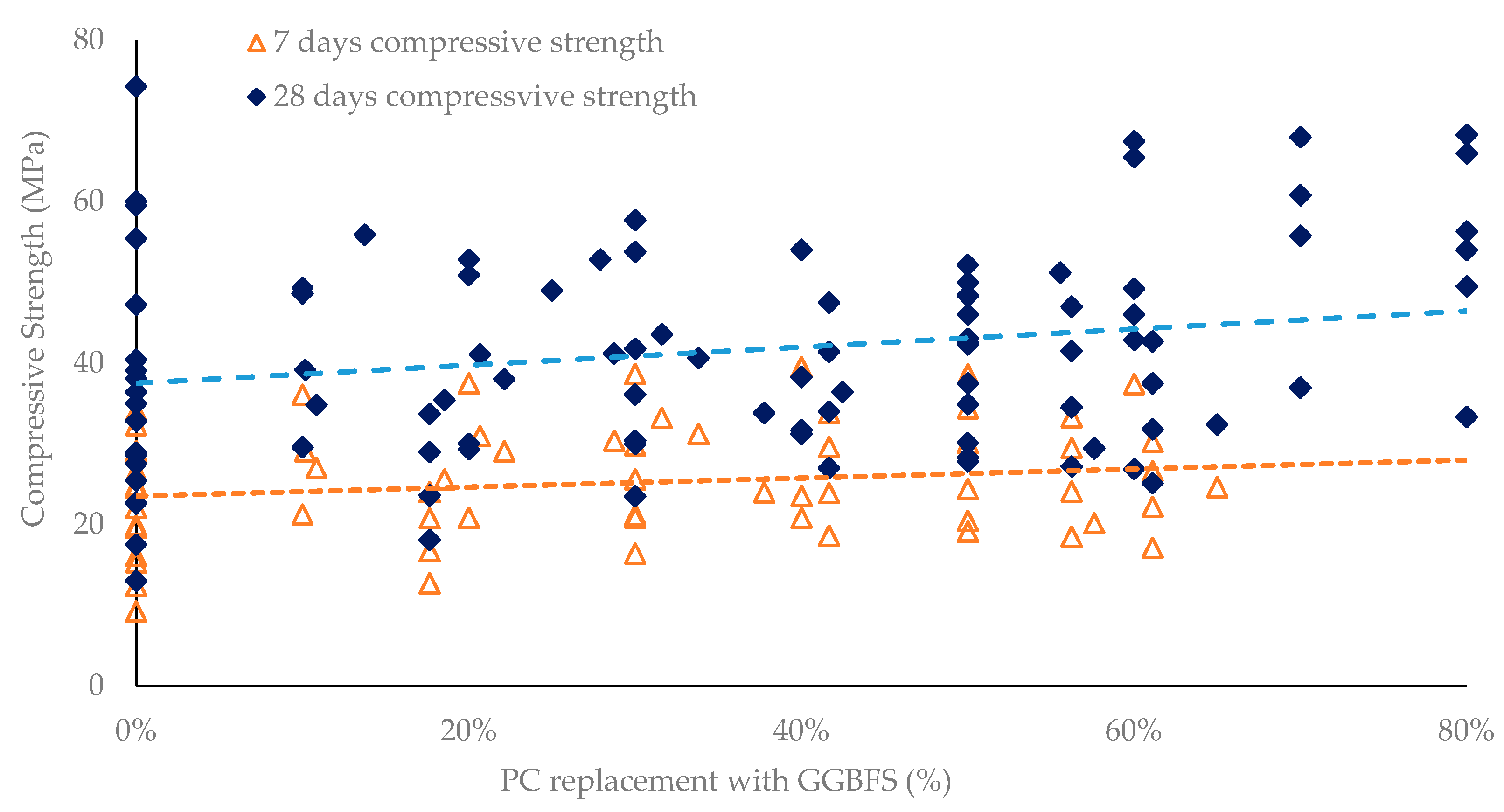

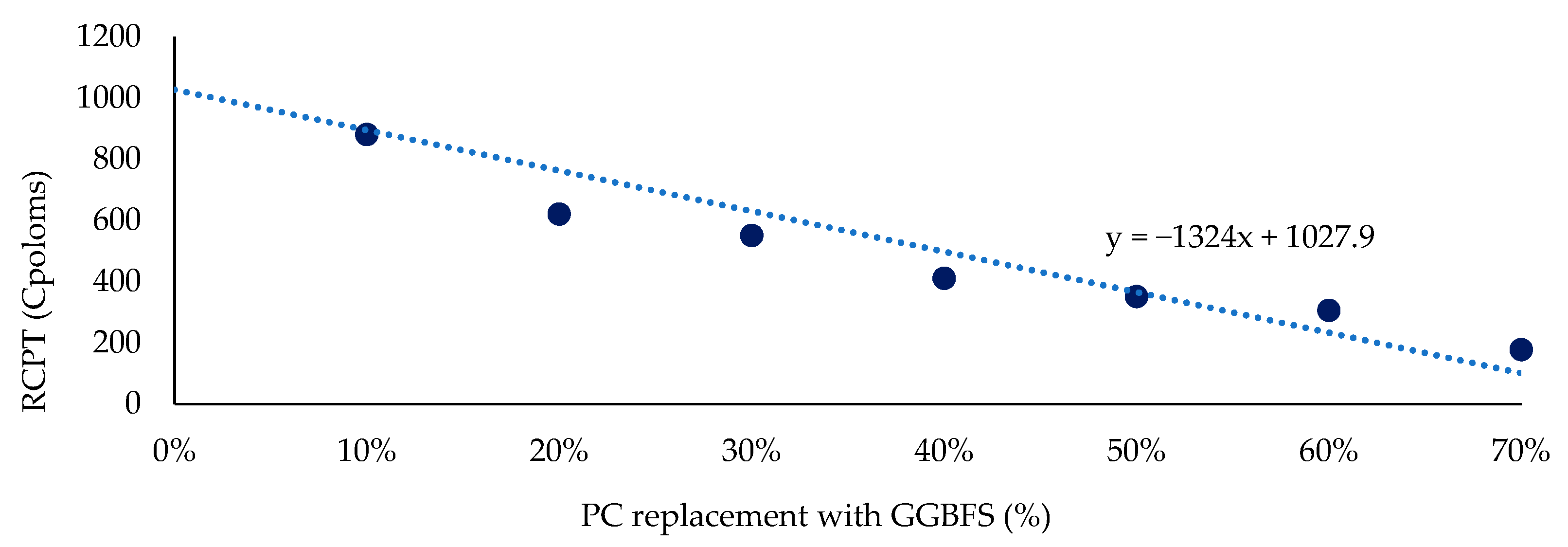

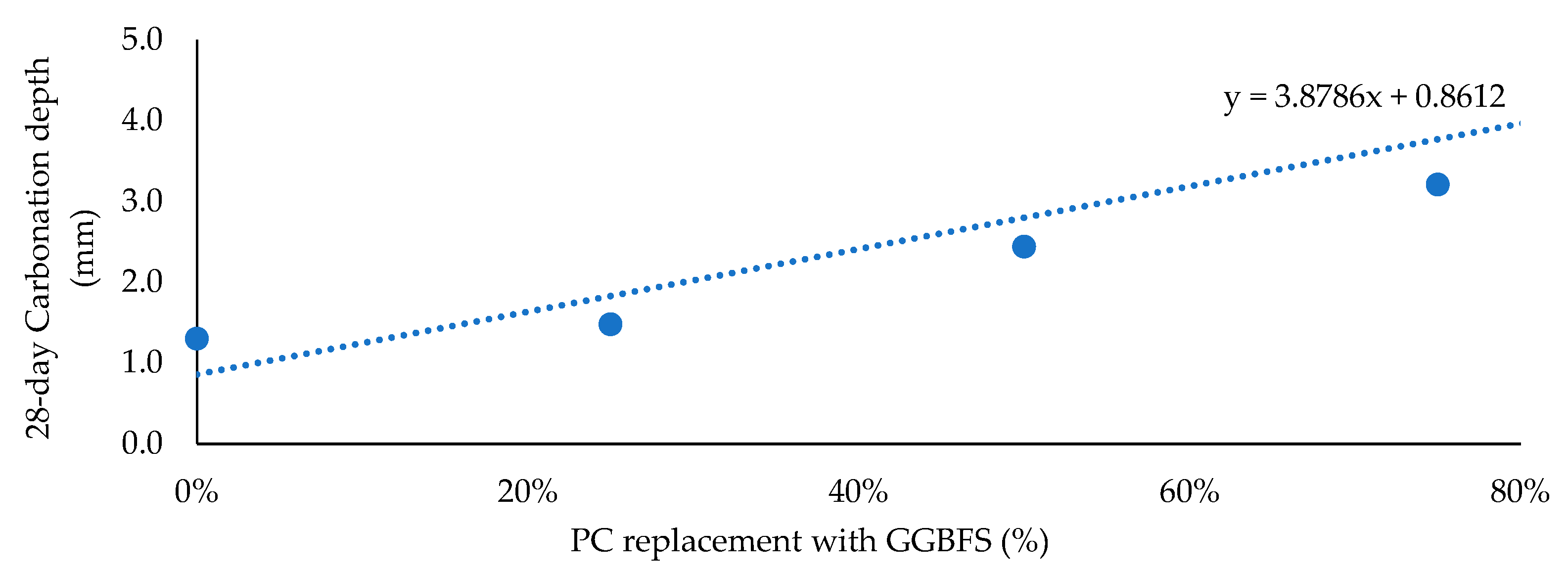

4.2. Granulated Ground Blast Furnace Slag Concrete

4.3. PC, FA, and GGBFS Ternary Blend Concrete

5. Methodology for Selection of a Fit-for-Purpose Low-Carbon Concrete (LCC) for Bridge Elements

- Substructure—Piles, pier, and headstock.

- Superstructure—Bridge girders, decking and deck fittings, such as safety barriers, footpaths, kerbs, medians, etc.

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PC (GP) | Portland cement (general-purpose cement) |

| SCM | Supplementary cementitious materials |

| FA | Fly ash |

| GGBFS | Granulated ground blast furnace slag |

| DBS | Delithiated beta spodumene |

| LCC | Low-carbon concrete |

| EC | Embodied carbon |

| MPa | Megapascal |

| kg | Kilogram |

| Mt | Million tonnes |

| SEM | Scanning electron microscopy |

| XRF | X-ray fluorescence |

| XRD | X-ray diffraction |

| TGA | Thermogravimetric analysis |

| CIS | Cast-in situ |

| RCPT | Rapid chloride permeability test |

| ATIC | Australian Technical Infrastructure Committee |

| TfNSW | Transport for New South Wales |

References

- DoITRDCSA. National Sustainable Procurement in Infrastructure Guideline. 2025. Available online: https://www.infrastructure.gov.au (accessed on 14 September 2025).

- ITM. Embodied Carbon Measurement for Infrastructure Technical Guidance. 2024. Available online: https://www.infrastructure.gov.au (accessed on 14 September 2025).

- Vdz. Decarbonisation Pathways for the Australian Cement and Concrete Sector. 2021. Available online: https://www.ccaa.com.au (accessed on 30 July 2022).

- Vasikova, I.; Srivastava, H.; Nairn, J. Review of the embodied carbon of Australian concreting materials. In Proceedings of the Concrete 2023, Perth, Australia, 10–13 September 2023. [Google Scholar]

- ATIC. ATIC Spec 43. 2019. Available online: https://www.atic.net.au/wp-content/uploads/2021/01/ATIC-SP43-11July2019.pdf (accessed on 25 February 2024).

- Hanson. ECOTERA High Performance/ Low Carbon Concrete. 2023. Available online: https://epd-australasia.com/wp-content/uploads/2023/11/SP10206-Hanson-EPD-Ecotera-Sydney_Nov23.pdf (accessed on 26 February 2024).

- Boral. Boral—Pre-mix concrete EPD. 2023. Available online: https://www.boral.com.au/ (accessed on 25 February 2024).

- AS 5100.2:2017 Bridge Design (Part 2: Design Loads). Standards Australia. 2017. Available online: www.standards.org.au (accessed on 20 July 2025).

- TfNSW-B80. TfNSW QA Specification B80—Concrete Work for Bridges. 2020. Available online: www.transport.nsw.gov.au (accessed on 11 October 2025).

- MTRS70. Transport and Main Roads Specifications—MRTS70 Concrete. 2022. Available online: https://www.tmr.qld.gov.au/ (accessed on 21 June 2025).

- AS1141.60.1-2014: Potential Alkali-Silica Reactivity—Accelerated Mortar Bar Method. Standards Australia. 2014. Available online: www.standards.org.au (accessed on 10 October 2025).

- AS 3582.1—Supplementary Cementitious for Use with Portland and blended Cement 1: Fly Ash. Available online: www.standards.org.au (accessed on 11 October 2025).

- AS 3582.2—Supplementary Cementitious Materials, Part 2: Slag -Ground Granulated Blast Furnace. 2016. Available online: www.standards.org.au (accessed on 21 June 2025).

- AS 5100.5: 2017 Bridge Design (Part-5 Concrete). Standards Australia. 2017. Available online: www.standards.org.au (accessed on 20 July 2025).

- AS 3582.4—Supplementary Cementitious Materials, Part 4: Pozzolans—Manufactured. Standards Australia. 2022. Available online: www.standards.org.au (accessed on 11 October 2025).

- AusLCI. Construction_Emission_Factor_List_AusLCI1_38_v1. 2022. Available online: https://www.alcas.asn.au/auslci-emissions-factors (accessed on 23 September 2022).

- Circular Ecology. ICE DB Educational V4.0—Dec 2024. 2024. Available online: https://circularecology.com (accessed on 4 May 2025).

- Nath, P.; Sarker, P. Effect of fly ash on the durability properties of high strength concrete. Procedia Eng. 2011, 14, 1149–1156. [Google Scholar] [CrossRef]

- Atis, C.D. High-Volume Fly Ash Concrete with High Strength and Low Drying Shrinkage. J. Mater. Civ. Eng. 2003, 15, 153–156. [Google Scholar] [CrossRef]

- Burden, D. The Durability of Concrete Containing High Levels of Fly Ash—PCA R&D Serial No. 2989. 2006. Available online: https://d1wqtxts1xzle7.cloudfront.net/34756918/durability_flyash1-libre.pdf (accessed on 20 October 2024).

- Bouzoubaa, N.; Bilodeau, A.; Sivasundaram, V.; Chakraborty, A.K. Mechanical properties and durability characteristics of high-volume fly ash concrete made with ordinary Portland cement and blended Portland fly ash cement. Spec. Publ. 2006, 242, 303–320. [Google Scholar]

- Kumar, B.; Tike, G.K.; Nanda, P.K. Evaluation of Properties of High-Volume Fly-Ash Concrete for Pavements. J. Mater. Civ. Eng. 2007, 19, 906–911. [Google Scholar] [CrossRef]

- Huang, C.-H.; Lin, S.-K.; Chang, C.-S.; Chen, H.-J. Mix proportions and mechanical properties of concrete containing very high-volume of Class F fly ash. Constr Build Mater 2013, 46, 71–78. [Google Scholar] [CrossRef]

- Alaka, H.A.; Oyedele, L.O. High volume fly ash concrete: The practical impact of using superabundant dose of high range water reducer. J. Build. Eng. 2016, 8, 81–90. [Google Scholar] [CrossRef]

- von Greve-Dierfeld, S.; Lothenbach, B.; Vollpracht, A.; Wu, B.; Huet, B.; Andrade, C.; Medina, C.; Thiel, C.; Gruyaert, E.; Vanoutrive, H.; et al. Understanding the carbonation of concrete with supplementary cementitious materials: A critical review by RILEM TC 281-CCC. Mater. Struct. Mater. Constr. 2020, 53, 136. [Google Scholar] [CrossRef]

- Huy Vu, Q.; Pham, G.; Chonier, A.; Brouard, E.; Rathnarajan, S.; Pillai, R.; Gettu, R.; Santhanam, M.; Aguayo, F.; Folliard, K.J.; et al. Impact of different climates on the resistance of concrete to natural carbonation. Constr. Build. Mater. 2019, 216, 450–467. [Google Scholar] [CrossRef]

- Borges, P.H.R.; Costa, J.O.; Milestone, N.B.; Lynsdale, C.J.; Streatfield, R.E. Carbonation of CH and C-S-H in composite cement pastes containing high amounts of BFS. Cem. Concr. Res. 2010, 40, 284–292. [Google Scholar] [CrossRef]

- Hussain, F.; Kaur, I.; Hussain, A. Reviewing the influence of GGBFS on concrete properties. Mater. Today Proc. 2020, 32, 997–1004. [Google Scholar] [CrossRef]

- Richardson, D.N. Scholars’ Mine Scholars’ Mine Strength and Durability Characteristics of a 70% Ground Strength and Durability Characteristics of a 70% Ground Granulated Blast Furnace Slag (GGBFS) Concrete Mix Granulated Blast Furnace Slag (GGBFS) Concrete Mix. 2006. Available online: https://scholarsmine.mst.edu/civarc_enveng_facwork (accessed on 20 October 2024).

- CCAA. 2018-CCAA TECH_NOTE_78_-_Ground_Slag. 2018. Available online: https://www.ccaa.com.au (accessed on 20 October 2024).

- Megat Johari, M.A.; Brooks, J.J.; Kabir, S.; Rivard, P. Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr. Build. Mater. 2011, 25, 2639–2648. [Google Scholar] [CrossRef]

- ACI Committee 233. ACI 233R-17—Guide to the Use of Slag Cement in Concrete and Mortar. American Concrete Institute. 2017. Available online: http://concrete.org/Publications. (accessed on 20 October 2024).

- Oner, A.; Akyuz, S. An experimental study on optimum usage of GGBS for the compressive strength of concrete. Cem. Concr. Compos. 2007, 29, 505–514. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N. Bond, durability and microstructural characteristics of ground granulated blast furnace slag based recycled aggregate concrete. Constr. Build. Mater. 2019, 212, 578–595. [Google Scholar] [CrossRef]

- Topçu, I.B.; Boĝa, A.R. Effect of ground granulate blast-furnace slag on corrosion performance of steel embedded in concrete. Mater. Des. 2010, 31, 3358–3365. [Google Scholar] [CrossRef]

- Elchalakani, M.; Aly, T.; Abu-Aisheh, E. Sustainable concrete with high volume GGBFS to build Masdar City in the UAE. Case Stud. Constr. Mater. 2014, 1, 10–24. [Google Scholar] [CrossRef]

- Ganesh, P.; Murthy, A.R. Tensile behaviour and durability aspects of sustainable ultra-high performance concrete incorporated with GGBS as cementitious material. Constr. Build. Mater. 2019, 197, 667–680. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. In Construction and Building Materials; Elsevier: Amsterdam, The Netherlands, 2016; Volume 105, pp. 423–434. [Google Scholar] [CrossRef]

- Kanavaris, F.; Gibbons, O.; Walport, E.; Shearer, E.; Abbas, A.; Orr, J.; Marsh, B. Reducing the embodied carbon of lightweight aggregate concrete for structural applications. Proc. Inst. Civ. Eng. Eng. Sustain. 2021, 175, 75–83. [Google Scholar] [CrossRef]

- Hooton, R.D. Canadian use of ground granulated blast-furnace slag as a supplementary cementing material for enhanced performance of concrete. Can. J. Civ. Eng. 2000, 27, 754–760. [Google Scholar] [CrossRef]

- Bhat, A.V.; Tengli, S.K. Behaviour of ground granulated blast furnace slag concrete in marine environment under chloride attack. Int. J. Innov. Technol. Explor. Eng. 2019, 9, 1659–1664. [Google Scholar] [CrossRef]

- Huyen Vu, T.; Yang, Y.; Cao, T.; Srivastava, H.; Sirivivatnanon, V. Machine Learning-Based Prediction of Chloride Resistance in Low-Carbon Concretes Using Experimental Data. In Proceedings of the Concrete 2025 Proceeding, Adelaide, Australia, 7–10 September 2025. [Google Scholar]

- Srivastava, H.K.; Sathorn, S.; Vimonsatit, V.; Clark, S. A Systematic Approach for Optimising Water to Binder Ratio for Low Carbon Concrete. In Proceedings of the ISEC 2025 Proceeding, Seoul, Republic of Korea, 26–27 August 2025; Volume 12. [Google Scholar] [CrossRef]

- French, D.; Chaves, I.; Smith, G.; Borgert, J. Optimizing Prestressed Concrete Mix designs for Lower Carbon Emissions. In Proceedings of the Concrete 2023 Proceeding, Perth, Australia, 10–13 September 2023. [Google Scholar]

| Exposure Classification | Surface and Exposure Environment |

|---|---|

| A |

|

| |

| B1 |

|

| B2 |

|

| C1 |

|

| C2 |

|

| Exp. | fcmin (MPa) | Binder (PC + SCM) (kg/m3) | W/B | fc at Completion of Curing (MPa) | Water Curing Duration (Days) | Heat Curing Period (°C·Hours) |

|---|---|---|---|---|---|---|

| A | 25 | 280 | - | 17.5 | 3 | As required |

| B1 | 32 | 330 | 0.50 | 22.4 | 7 | 350 |

| B2 | 40 | 400 | 0.45 | 28.0 | 7 | 350 |

| C1 | 50 | 420 | 0.40 | 28.0 | 14 | 420 |

| C2 | 50 | 420 | 0.36 | 35.0 | 14 | 420 |

| Exp. | fcmin,d (MPa) | Bmin (kg/m3) | W/B | Dmax (m2/s) | ||||

|---|---|---|---|---|---|---|---|---|

| CIP | P | CIP | P | CIP | P | NT 443 | NT 443 | |

| A | 25 | 32 | 320 | 320 | 0.40 | 0.28 | N/A | N/A |

| B1 | 32 | 40 | 320 | 320 | 0.40 | 0.28 | N/A | N/A |

| B2 | 40 | 50 | 370 | 370 | 0.32 | 0.28 | 3.5 × 10−12 | 8.0 × 10−12 |

| C1 | 50 | 60 | 420 | 420 | 0.32 | 0.28 | 2.0 × 10−12 | 4.0 × 10−12 |

| C2 | 55 | 60 | 420 | 420 | 0.32 | 0.28 | 2.0 × 10−12 | 4.0 × 10−12 |

| SCM Limits | |||

|---|---|---|---|

| Concrete Mix | FA | GGBFS | SF |

| Binary blends | 25–40% | 30–70% | 4–10% |

| Ternary blends | 25–30% | 20–35% | - |

| 25–35% | - | 4–10% | |

| - | 50–65% | 4–10% | |

| Exposure Classification | Required Cover (mm) and Characteristic Strength (MPa) | |||

|---|---|---|---|---|

| 25 MPa | 32 MPa | 40 MPa | ≥50 MPa | |

| A | 45 | 35 | 30 | 30 |

| B1 | 50 | 45 | 40 | |

| B2 | 60 | 50 | ||

| C1 | 70 | |||

| C2 | 80 | |||

| Concrete Constituents | Embodied Carbon (kg CO2e/kg) | Source |

|---|---|---|

| General (Portland) purpose (GP) cement | 0.905 | AusLCI database [16] |

| Fly ash (FA) | 0.020 | AusLCI database |

| Granulated ground blast furnace slag (GGBFS) | 0.195 | AusLCI database |

| Silica fume (Amorphous Silica) | 0.014 | AusLCI database |

| Fine aggregate | 0.004 | AusLCI database |

| Coarse aggregate | 0.011 | AusLCI database |

| Tap water, at user, Australia | 0.00045 | AusLCI database |

| Plasticizer and superplasticizers | 1.88 | ICE database [17] |

| Charge Passed (Coulombs) | Chloride Ion Penetrability |

|---|---|

| >4000 | High |

| 2000–4000 | Moderate |

| 1000–2000 | Low |

| 100–1000 | Very low |

| <100 | Negligible |

| Target Strength (MPa) | Concrete Mix | Binder Content | EC | Curing | ||

|---|---|---|---|---|---|---|

| PC | FA | GGBFS | (kg/m3) | (kg CO2e/m3) | ||

| CIS 50–28 days | 100% | - | - | 450 | 407 | Water curing |

| 60% | 40% | - | 450 | 248 | ||

| 50% | 50% | - | 450 | 208 | ||

| 40% | - | 60% | 450 | 216 | ||

| 30% | - | 70% | 450 | 184 | ||

| 30% | 20% | 50% | 450 | 168 | ||

| 30% | 30% | 40% | 450 | 169 | ||

| Precast 60–28 days 35–1 day | 100% | - | - | 570 | 516 | Heat-accelerated curing |

| 75% | 25% | - | 600 | 410 | ||

| 70% | 30% | - | 600 | 384 | ||

| Bridge Component | Concrete Quantity | Embodied Carbon (kgCO2e/m3) | Bridge Structure Embodied Carbon (kgCO2e/m3) | |||

|---|---|---|---|---|---|---|

| m3 | PCC | LCC | PCC | LCC | Change | |

| Superstructure—CIS (40 MPa) concrete @ 25% | 0.25 | 407 | 168 | 102 | 42 | −60 |

| Superstructure—precast (50 MPa) concrete @ 15% | 0.15 | 516 | 384 | 77 | 58 | −20 |

| Substructure (40 MPa) concrete @ 60% | 0.60 | 407 | 168 | 244 | 101 | −143 |

| 423 | 200 | −223 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srivastava, H.K.; Vimonsatit, V.; Clark, S.M. A Systematic Approach for Selection of Fit-for-Purpose Low-Carbon Concrete for Various Bridge Elements to Reduce the Net Embodied Carbon of a Bridge Project. Infrastructures 2025, 10, 274. https://doi.org/10.3390/infrastructures10100274

Srivastava HK, Vimonsatit V, Clark SM. A Systematic Approach for Selection of Fit-for-Purpose Low-Carbon Concrete for Various Bridge Elements to Reduce the Net Embodied Carbon of a Bridge Project. Infrastructures. 2025; 10(10):274. https://doi.org/10.3390/infrastructures10100274

Chicago/Turabian StyleSrivastava, Harish Kumar, Vanissorn Vimonsatit, and Simon Martin Clark. 2025. "A Systematic Approach for Selection of Fit-for-Purpose Low-Carbon Concrete for Various Bridge Elements to Reduce the Net Embodied Carbon of a Bridge Project" Infrastructures 10, no. 10: 274. https://doi.org/10.3390/infrastructures10100274

APA StyleSrivastava, H. K., Vimonsatit, V., & Clark, S. M. (2025). A Systematic Approach for Selection of Fit-for-Purpose Low-Carbon Concrete for Various Bridge Elements to Reduce the Net Embodied Carbon of a Bridge Project. Infrastructures, 10(10), 274. https://doi.org/10.3390/infrastructures10100274