Automating Product Design and Fabrication Within the Furniture Industry

Abstract

1. Introduction

2. State of the Art

3. Methodology

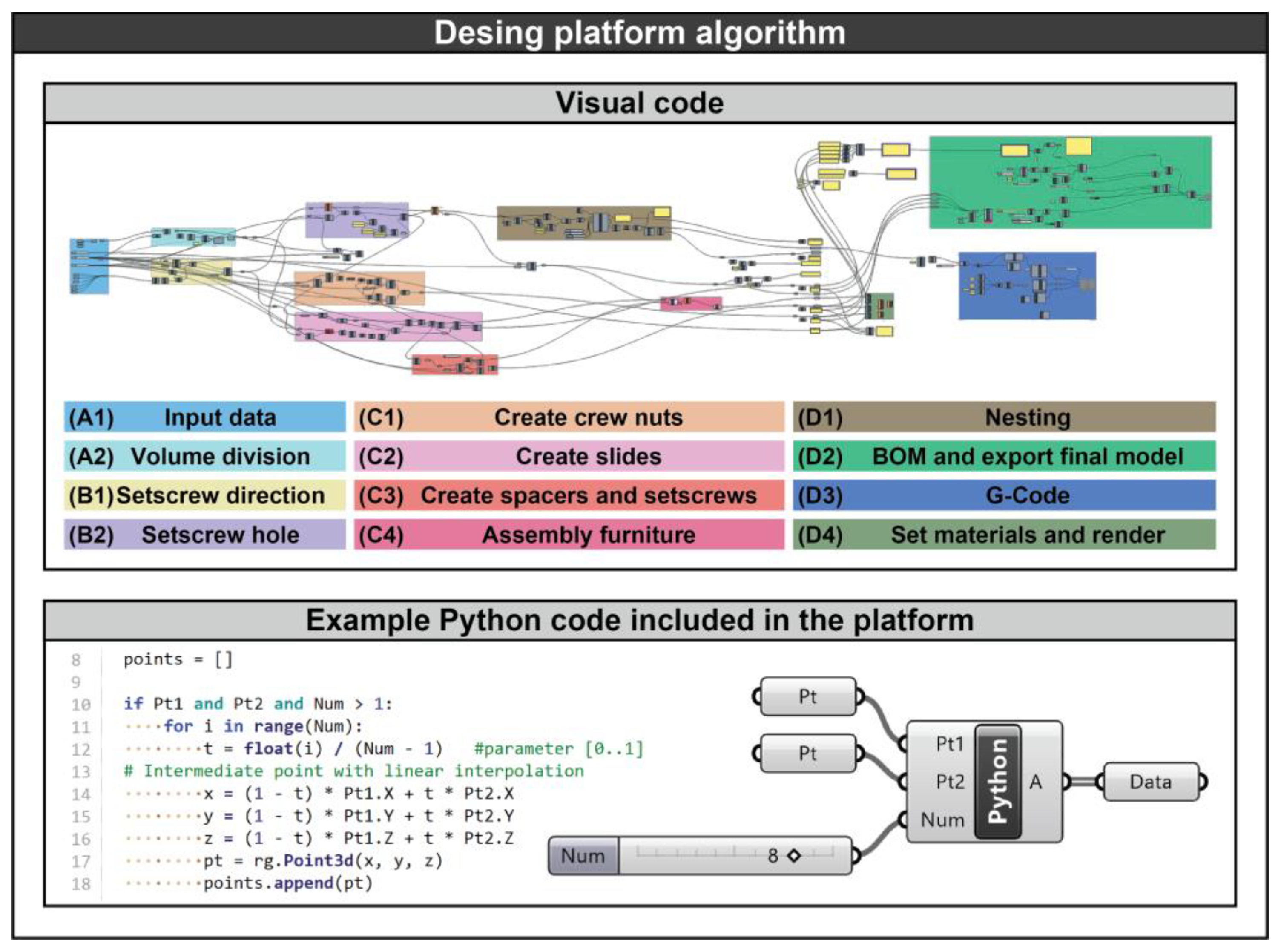

3.1. Algorithm Development and Parameterization

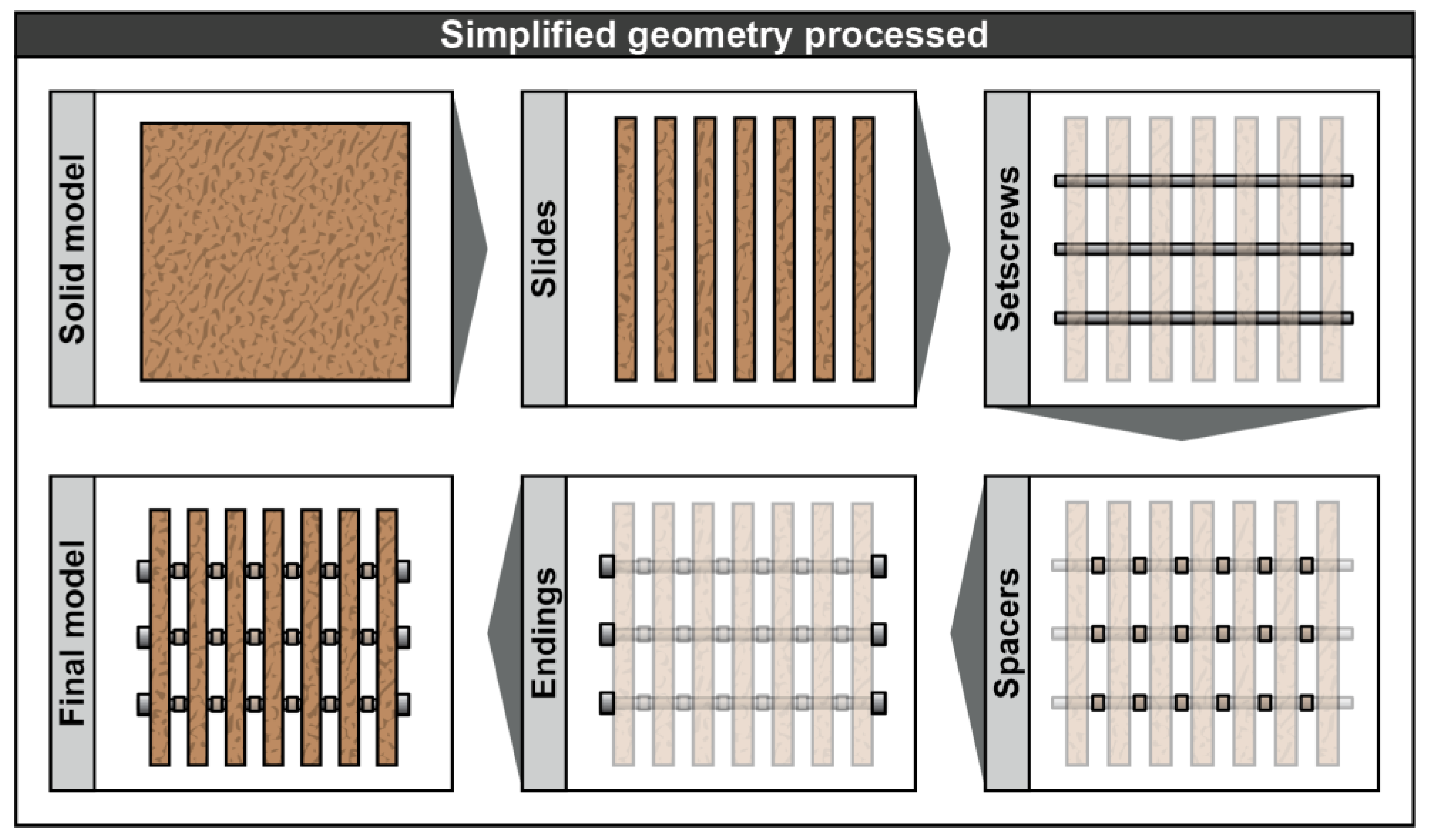

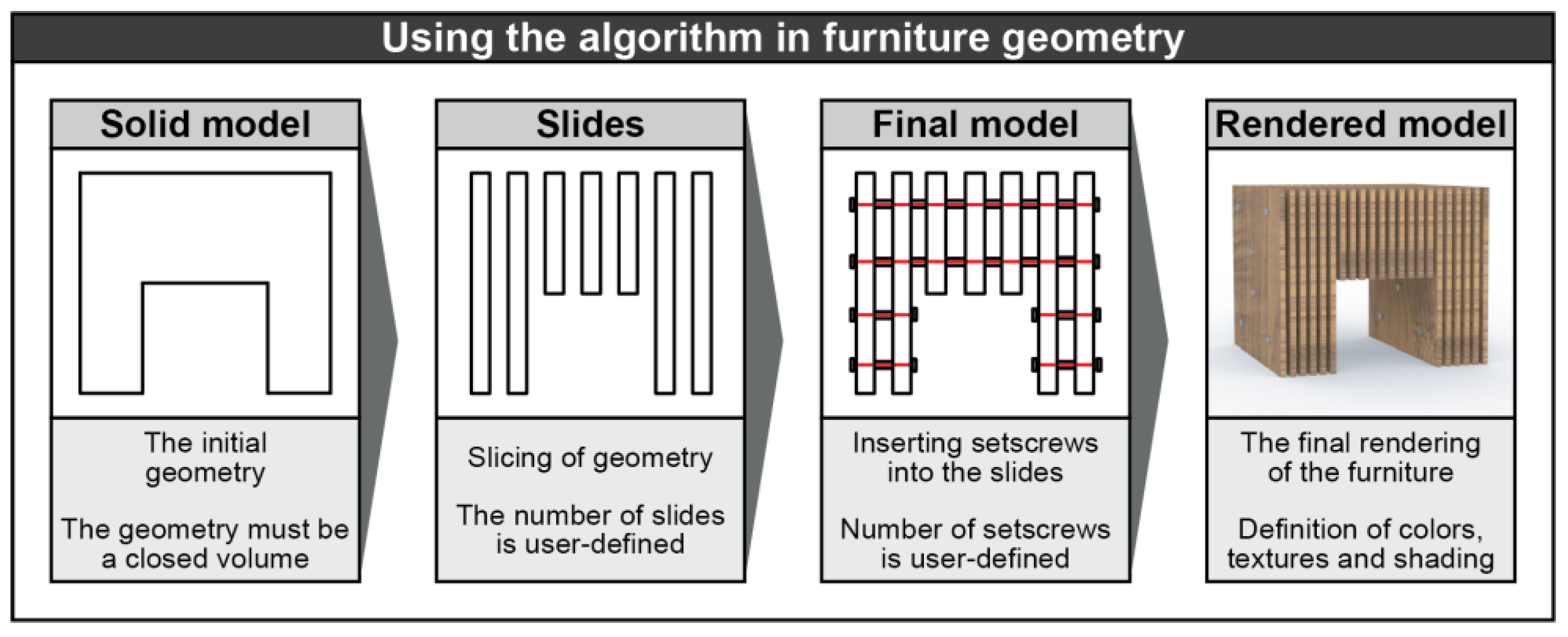

- Stage A (input data, volume division): Initially, the algorithm requires input from the user. The first piece of information is the definition of the 3D geometry that the furniture will be based on. Then, additional data, i.e., number of slices, setscrew radius, guiding points, wood panels thickness, are defined. After the data insertion process, the algorithm leads to dividing the 3D furniture model into slices based on the user’s requirements.

- Stage B (setscrew direction, setscrew holes): The algorithm defines the direction of the setscrews according to the orientation of the slices created. A hole is introduced in each slice at the points at which each setscrew passes through. These holes use the dimensions of the setscrews with the corresponding tolerances for correct and easy assembly. The designer has the option to manually change the paths created if needed.

- Stage C (create screw nuts, create spacers and setscrews, assemble furniture): The algorithm redesigns each part of the furniture in detail, i.e., the threads on the nuts are defined and spacers and setscrews are designed with additional details. Based on the redesigned parts, the 3D modeling of the complete assembly is performed with the parametric characteristics of the furniture.

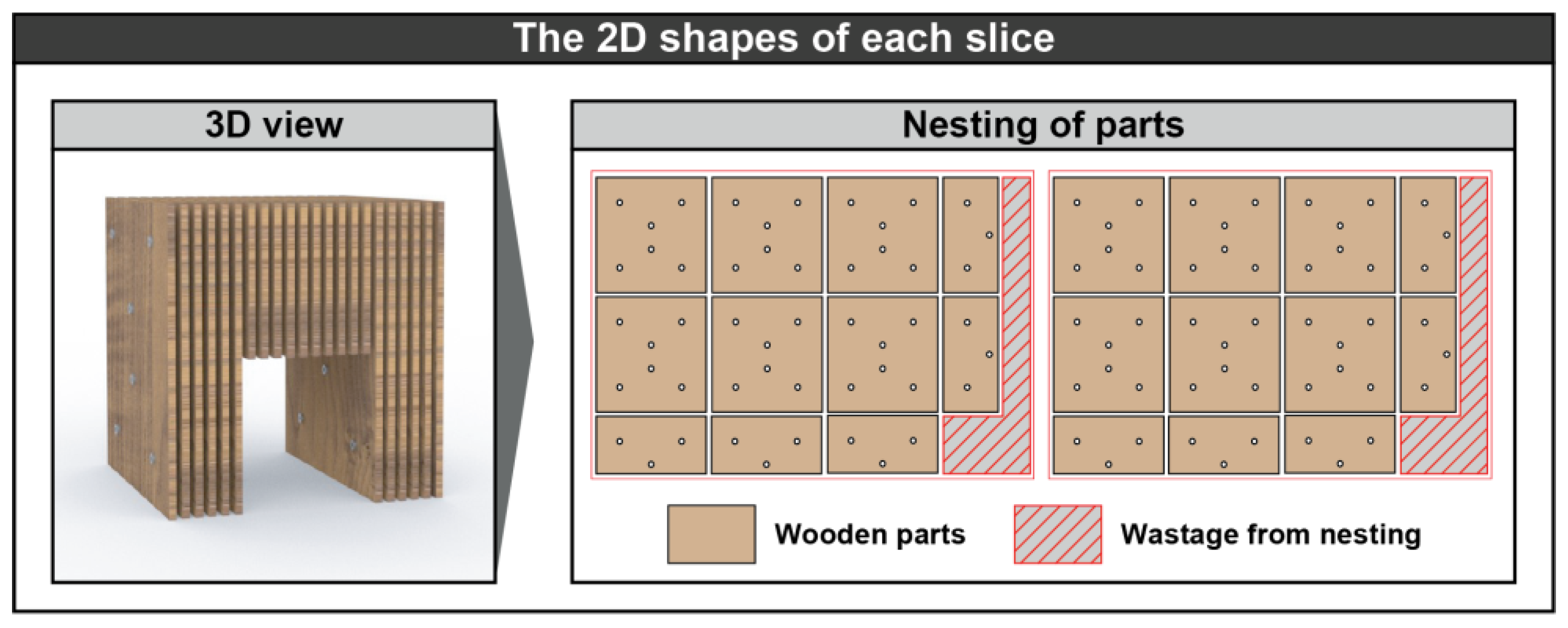

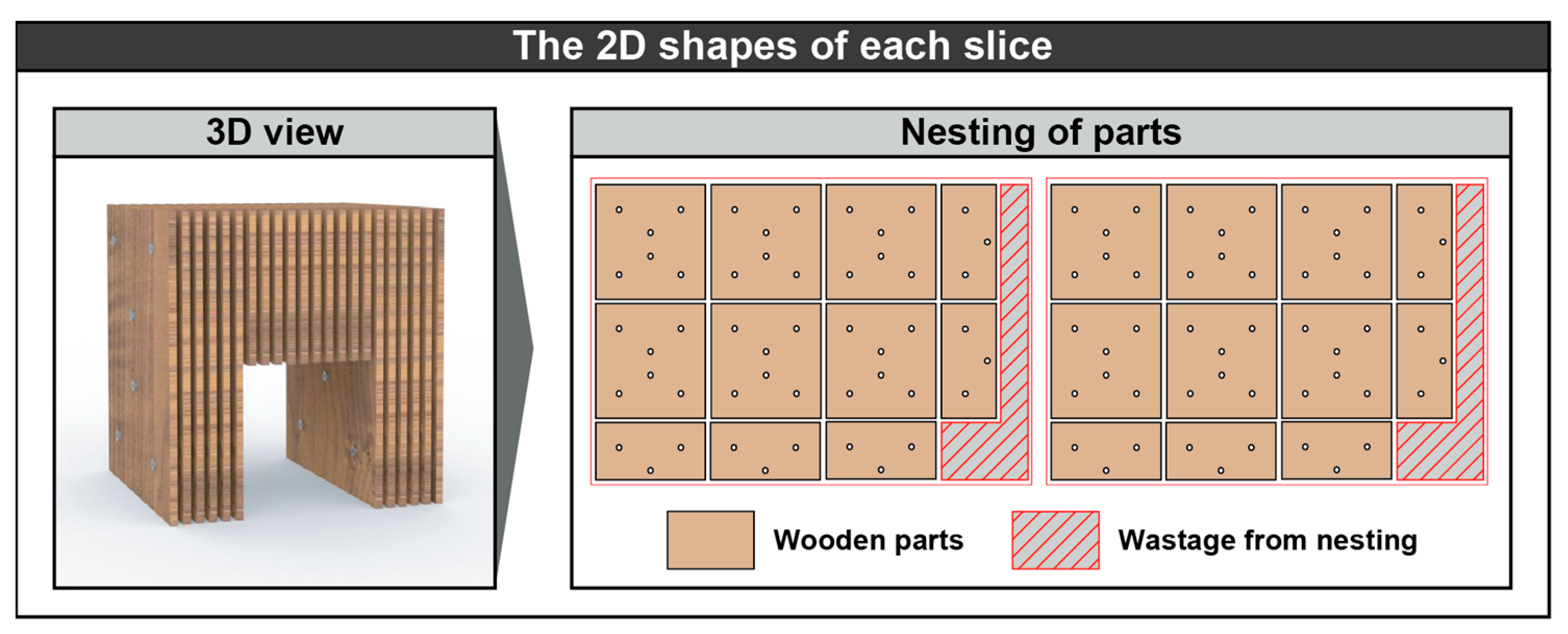

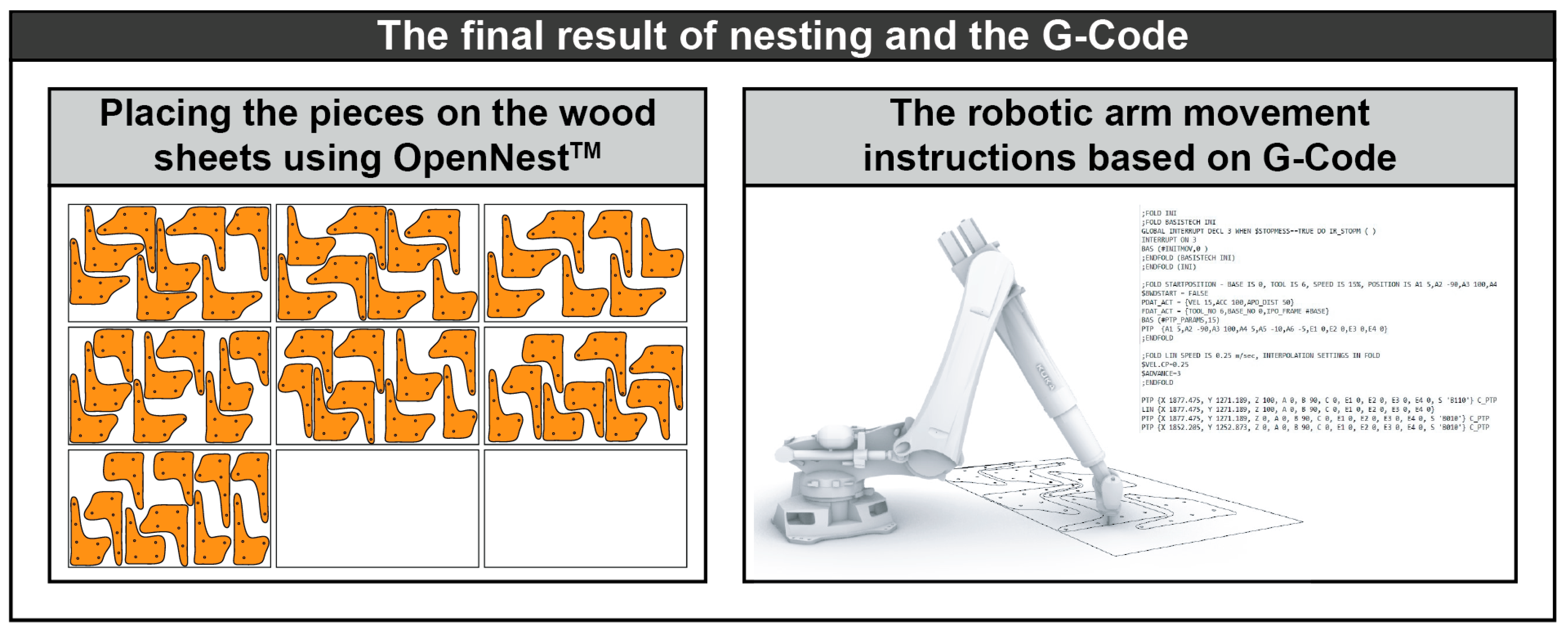

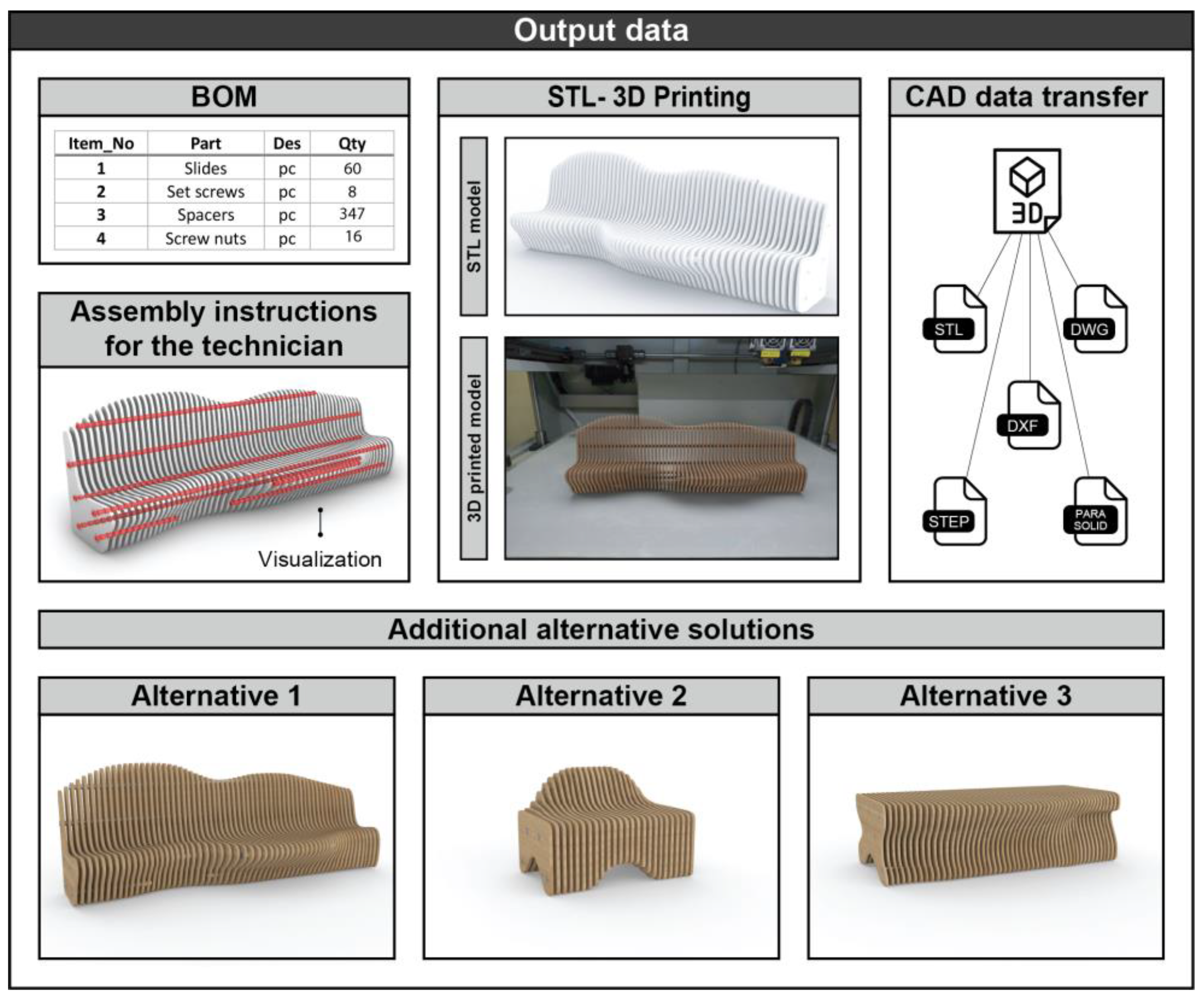

- Stage D (nesting, BOM and export final model, G-Code, set materials and render): The slices are converted from 3D to 2D format and positioned on the plane for the application of the nesting method. The 2D format of the slices is a vector-based geometry on which the G-Code required for the fabrication is created. In addition to the G-Code, a series of exported data is supported by the algorithm, such as 3D CAD models, nesting information, bill of materials (BOM), and export of the final 3D model. Finally, the materials and textures that have been defined from the beginning by the user are applied to create photorealistic renders.

3.2. Input Data

- Material selection, e.g., plywood with different coloring, thickness in mm, material’s panel overall dimensions (i.e., 2.50 m × 1.25 m).

- Definition of the number of slices used for the complete product: This definition was related to the number and size of the spacers designed.

- Selection of the setscrew’s positions: All the properties that relate to the direction of the setscrew, their size (diameter), and their ending are set in this step.

- Default properties are considered for the nesting procedure and all fabrication setup used (algorithms, tooling, manufacturing parameters, etc.).

3.3. Design Automation

3.4. Output Data

4. Case Study

5. Conclusions

- It dramatically shortens the time required to design the final product;

- Geometries of high complexity can be used effectively in furniture design;

- A number of automated downstream facilities can become available, i.e., 3D CAD part modeling and 3D CAD assembly generation, detailed 2D/3D technical drawings, robotic arm/CNC machining code generation, BOM, data transfer among several CAD/CAM systems;

- Several wooden materials can be used via an extensive database for rendering, prototyping, and nesting purposes;

- It supports the new role of the furniture design engineer as a CAD programming expert and the end user is encouraged to participate in the design process, increasing customer satisfaction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, B. The Prospects of Computer Aided Furniture Design and Manufacturing. In Proceedings of the 2021 3rd International Conference on Artificial Intelligence and Advanced Manufacture, Manchester, UK, 23–25 October 2021; pp. 1493–1497. [Google Scholar]

- Manavis, A.; Tzotzis, A.; Tsagaris, A.; Kyratsis, P. A novel computational-based visual brand identity (CbVBI) product design methodology. Machines 2022, 10, 1065. [Google Scholar] [CrossRef]

- Bianconi, F.; Filippucci, M. (Eds.) Digital Wood Design: Innovative Techniques of Representation in Architectural Design; Springer: Berlin/Heidelberg, Germany, 2019; Volume 24. [Google Scholar]

- Caetano, I.; Santos, L.; Leitão, A. Computational design in architecture: Defining parametric, generative, and algorithmic design. Front. Archit. Res. 2020, 9, 287–300. [Google Scholar] [CrossRef]

- Caetano, I.; Leitão, A. Architecture meets computation: An overview of the evolution of computational design approaches in architecture. Archit. Sci. Rev. 2020, 63, 165–174. [Google Scholar] [CrossRef]

- Coenders, J.L. Next generation parametric design. J. Int. Assoc. Shell Spat. Struct. 2021, 62, 153–166. [Google Scholar] [CrossRef]

- Manavis, A.; Minaoglou, P.; Efkolidis, N.; Kyratsis, P. Digital customization for product design and manufacturing: A case study within the furniture industry. Electronics 2024, 13, 2483. [Google Scholar] [CrossRef]

- Ma, J.; Li, Z.; Zhao, Z.L.; Xie, Y.M. Creating novel furniture through topology optimization and advanced manufacturing. Rapid Prototyp. J. 2021, 27, 1749–1758. [Google Scholar] [CrossRef]

- Hu, W.; Liu, N.; Guan, H. Optimal design of a furniture frame by reducing the volume of wood. Drew. Pr. Nauk. Doniesienia Komun. 2019, 62, 85–97. [Google Scholar] [CrossRef]

- Nicolau, A.; Pop, M.A.; Coșereanu, C. 3D printing application in wood furniture components assembling. Materials 2022, 15, 2907. [Google Scholar] [CrossRef] [PubMed]

- Bodenschatz, U.; Rosenthal, M. 3D printing of a wood-based furniture element with liquid deposition modeling. Eur. J. Wood Wood Prod. 2024, 82, 241–244. [Google Scholar] [CrossRef]

- Das, A.K.; Agar, D.A.; Rudolfsson, M.; Larsson, S.H. A review on wood powders in 3D printing: Processes, properties and potential applications. J. Mater. Res. Technol. 2021, 15, 241–255. [Google Scholar] [CrossRef]

- Bourgault, S.; Wiley, P.; Farber, A.; Jacobs, J. CoilCAM: Enabling parametric design for clay 3D printing through an action-oriented toolpath programming system. In Proceedings of the 2023 CHI Conference on Human Factors in Computing Systems, Hamburg, Germany, 23–28 April 2023; pp. 1–16. [Google Scholar]

- Yang, S.; Du, P. The application of 3D printing technology in furniture design. Sci. Program. 2022, 2022, 1960038. [Google Scholar] [CrossRef]

- Pringle, A.M.; Rudnicki, M.; Pearce, J.M. Wood furniture waste–based recycled 3-D printing filament. For. Prod. J. 2018, 68, 86–95. [Google Scholar] [CrossRef]

- Rosenthal, M.; Henneberger, C.; Gutkes, A.; Bues, C.T. Liquid Deposition Modeling: A promising approach for 3D printing of wood. Eur. J. Wood Wood Prod. 2018, 76, 797–799. [Google Scholar] [CrossRef]

- Li, T.; Aspler, J.; Kingsland, A.; Cormier, L.M.; Zou, X. 3D printing—A review of technologies, markets, and opportunities for the forest industry. J. Sci. Technol. For. Prod. Process 2016, 5, 30–46. [Google Scholar]

- Kariz, M.; Sernek, M.; Kuzman, M.K. Use of wood powder and adhesive as a mixture for 3D printing. Eur. J. Wood Wood Prod. 2016, 74, 123–126. [Google Scholar] [CrossRef]

- Pycka, S.; Roman, K. Comparison of wood-based biocomposites with polylactic acid (PLA) density profiles by desaturation and X-ray spectrum methods. Materials 2023, 16, 5729. [Google Scholar] [CrossRef] [PubMed]

- Sachin, S.R.; Kannan, T.K.; Rajasekar, R. Effect of wood particulate size on the mechanical properties of PLA biocomposite. Pigment Resin Technol. 2020, 49, 465–472. [Google Scholar] [CrossRef]

- Jasiński, W.; Szymanowski, K.; Nasiłowska, B.; Barlak, M.; Betlej, I.; Prokopiuk, A.; Borysiuk, P. 3D Printing Wood–PLA Composites: The Impact of Wood Particle Size. Polymers 2025, 17, 1165. [Google Scholar] [CrossRef] [PubMed]

- Kechagias, J.D.; Zaoutsos, S.P.; Chaidas, D.; Vidakis, N. Multi-parameter optimization of PLA/Coconut wood compound for Fused Filament Fabrication using Robust Design. Int. J. Adv. Manuf. Technol. 2022, 119, 4317–4328. [Google Scholar] [CrossRef]

- Fountas, N.A.; Kechagias, J.D.; Zaoutsos, S.P.; Vaxevanidis, N.M. Experimental and statistical study on the effects of fused filament fabrication parameters on the tensile strength of hybrid PLA/wood fabricated parts. Procedia Struct. Integr. 2022, 41, 638–645. [Google Scholar] [CrossRef]

- Sultana, J.; Rahman, M.M.; Wang, Y.; Ahmed, A.; Xiaohu, C. Influences of 3D printing parameters on the mechanical properties of wood PLA filament: An experimental analysis by Taguchi method. Prog. Addit. Manuf. 2024, 9, 1239–1251. [Google Scholar] [CrossRef]

- Vigneshwaran, K.; Venkateshwaran, N. Statistical analysis of mechanical properties of wood-PLA composites prepared via additive manufacturing. Int. J. Polym. Anal. Charact. 2019, 24, 584–596. [Google Scholar] [CrossRef]

- Malagutti, L.; Mazzanti, V.; Mollica, F. Tensile properties of FDM 3D-printed wood flour filled polymers and mathematical modeling through classical lamination theory. Rapid Prototyp. J. 2022, 28, 1834–1842. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue behavior of PLA-wood composite manufactured by fused filament fabrication. J. Mater. Res. Technol. 2020, 9, 8507–8516. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kariz, M.; Šernek, M.; Kuzman, M.K. Effects of sandwich core structure and infill rate on mechanical properties of 3D-printed wood/PLA composites. Int. J. Adv. Manuf. Technol. 2021, 115, 3233–3242. [Google Scholar] [CrossRef]

- Kain, S.; Ecker, J.V.; Haider, A.; Musso, M.; Petutschnigg, A. Effects of the infill pattern on mechanical properties of fused layer modeling (FLM) 3D printed wood/polylactic acid (PLA) composites. Eur. J. Wood Wood Prod. 2020, 78, 65–74. [Google Scholar] [CrossRef]

- Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J.; Jorba-Peiro, J.; Travieso-Rodriguez, J.A. Study of the manufacturing process effects of fused filament fabrication and injection molding on tensile properties of composite PLA-wood parts. Int. J. Adv. Manuf. Technol. 2020, 108, 1725–1735. [Google Scholar] [CrossRef]

- Kananathan, J.; Samykano, M.; Kadirgama, K.; Ramasamy, D.; Rahman, M.M. Comprehensive investigation and prediction model for mechanical properties of coconut wood–polylactic acid composites filaments for FDM 3D printing. Eur. J. Wood Wood Prod. 2022, 80, 75–100. [Google Scholar] [CrossRef]

- Efkolidis, N.; Minaoglou, P.; Aidinli, K.; Kyratsis, P. Computational design used for jewelry. In Proceedings of the 10th International Symposium on Graphic Engineering and Design, Novi Sad, Serbia, 14–16 November 2020; pp. 12–14. [Google Scholar]

- Manavis, A.; Kakoulis, K.; Kyratsis, P. A brief review of computational product design: A brand identity approach. Machines 2023, 11, 232. [Google Scholar] [CrossRef]

- Manavis, A.; Minaoglou, P.; Tzetzis, D.; Efkolidis, N.; Kyratsis, P. Computational design technologies for interior designers: A case study. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 5th International Conference on Computing and Solutions in Manufacturing Engineering (CoSME’20), Brasov, Romania, 7–10 October 2020; IOP Publishing Ltd.: Bristol, UK, 2021; Volume 1009, p. 012037. [Google Scholar]

- Minaoglou, P.; Kakoulis, K.; Manavis, A.; Kyratsis, P. Computational wearables design: Shoe sole modeling and prototyping. Int. J. Mod. Manuf. Technol. (IJMMT) 2023, 15, 143–151. [Google Scholar] [CrossRef]

- Liu, W.; Md Ishak, S.M.; Yahaya, M.F. Enhancing Mobility and Sustainability: An Origami-Based Furniture Design Approach for Young Migrants. Sustainability 2025, 17, 164. [Google Scholar] [CrossRef]

- Caymaz, G.F.Y.; Yardımlı, S.; Turan, B.O.; Tarım, A. Wooden structures within the context of parametric design: Pavilions and seatings in urban landscape. J. Archit. Res. Dev. 2018, 2, 34–54. [Google Scholar] [CrossRef][Green Version]

- Hamza Hamad, S. The influence of parametric design tools on increasing creativity in the furniture design process. Eurasian J. Sci. Eng. 2020, 6, 199–211. [Google Scholar] [CrossRef]

- Haghnazar, R.; Ashjazadeh, Y.; Hauptman, J.; Nasir, V. A computational design integrated digital fabrication framework for mass customization in industry 5.0 manufacturing with non-standard natural materials. Results Eng. 2024, 23, 102400. [Google Scholar] [CrossRef]

- Felek, S.Ö. Parametric modelling in furniture design a case study: Two door wardrope. Eur. J. Res. Dev. 2022, 2, 62–74. [Google Scholar] [CrossRef]

- Symeonidou, I. Furniture Design with Digital Media. Comput. Better Tomorrow 2018, 417, 417–426. [Google Scholar]

- Capone, M.; Lanzara, E. Parametric kerf bending: Manufacturing double curvature surfaces for wooden furniture design. In Digital Wood Design: Innovative Techniques of Representation in Architectural Design; Springer: Berlin/Heidelberg, Germany, 2019; pp. 415–439. [Google Scholar]

- Ashraf, S. Proposing digital design methodology for furniture products by integrating generative design approach to conventional process. J. Technol. Syst. 2023, 5, 1–21. [Google Scholar] [CrossRef]

- Zahra, N. Role of artificial intelligence technology in the development of furniture design Process. Int. Des. J. 2023, 13, 503–520. [Google Scholar] [CrossRef]

- Barros, M.; Duarte, J.P.; Chaparro, B.M. Integrated generative design tools for the mass customization of furniture. In Design Computing and Cognition’12; Springer: Dordrecht, The Netherlands, 2014; pp. 285–300. [Google Scholar]

- Bi, M.; Tran, P.; Xia, L.; Ma, G.; Xie, Y.M. Topology optimization for 3D concrete printing with various manufacturing constraints. Addit. Manuf. 2022, 57, 102982. [Google Scholar] [CrossRef]

- Karimova, D.E.; Shamatov, J.I. Modern materials for furniture design. Int. J. Integr. Educ. 2022, 5, 305. Available online: https://www.neliti.com/publications/407576/modern-materials-for-furniture-design (accessed on 23 September 2025).

- García-Dominguez, A.; Claver, J.; Sebastián, M.A. Integration of additive manufacturing, parametric design, and optimization of parts obtained by fused deposition modeling (FDM). A methodological approach. Polymers 2020, 12, 1993. [Google Scholar] [CrossRef] [PubMed]

- Kontovourkis, O.; Tryfonos, G. Integrating parametric design with robotic additive manufacturing for 3D clay printing: An experimental study. In Proceedings of the International Symposium on Automation and Robotics in Construction (ISARC), Berlin, Germany, 20–25 July 2018; Volume 35, pp. 1–8. [Google Scholar]

- Taher, A.; Aşut, S.; van der Spoel, W. An integrated workflow for designing and fabricating multi-functional building components through additive manufacturing with clay. Buildings 2023, 13, 2676. [Google Scholar] [CrossRef]

| When Designing Only 1 Furniture | When 10 Furniture Designs Are Implemented | |||

|---|---|---|---|---|

| Design method | Traditional | Algorithmic | Traditional | Algorithmic |

| Algorithm design | - | 20 h | 20 h | |

| Computing time | - | 1 m | - | 10 m |

| Traditionally design time | 8.5 h | - | 85 h | - |

| Total time | 8.5 h | 20 h 1 min | 85 h | 20 h 10 min |

| Algorithmic | Traditional | |||

| Material waste | Automatic reduction via nesting | Using external tools for nesting | ||

| Design model accuracy | High accuracy | Unpredictable accuracy | ||

| Total cost | Can be calculated during parameter definition | By experience | ||

| Integration into industry | Yes | No | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aidinli, K.; Minaoglou, P.; Kyratsis, P.; Efkolidis, N. Automating Product Design and Fabrication Within the Furniture Industry. Designs 2025, 9, 116. https://doi.org/10.3390/designs9050116

Aidinli K, Minaoglou P, Kyratsis P, Efkolidis N. Automating Product Design and Fabrication Within the Furniture Industry. Designs. 2025; 9(5):116. https://doi.org/10.3390/designs9050116

Chicago/Turabian StyleAidinli, Kyriaki, Prodromos Minaoglou, Panagiotis Kyratsis, and Nikolaos Efkolidis. 2025. "Automating Product Design and Fabrication Within the Furniture Industry" Designs 9, no. 5: 116. https://doi.org/10.3390/designs9050116

APA StyleAidinli, K., Minaoglou, P., Kyratsis, P., & Efkolidis, N. (2025). Automating Product Design and Fabrication Within the Furniture Industry. Designs, 9(5), 116. https://doi.org/10.3390/designs9050116