Development of a Linking System Between Vehicle’s Computer and Alexa Auto

Abstract

1. Introduction

2. State of the Art

2.1. Voice Assistant and Diagnostic Vehicle System

2.2. Vehicle’s Voice Assistants

3. Materials and Methods

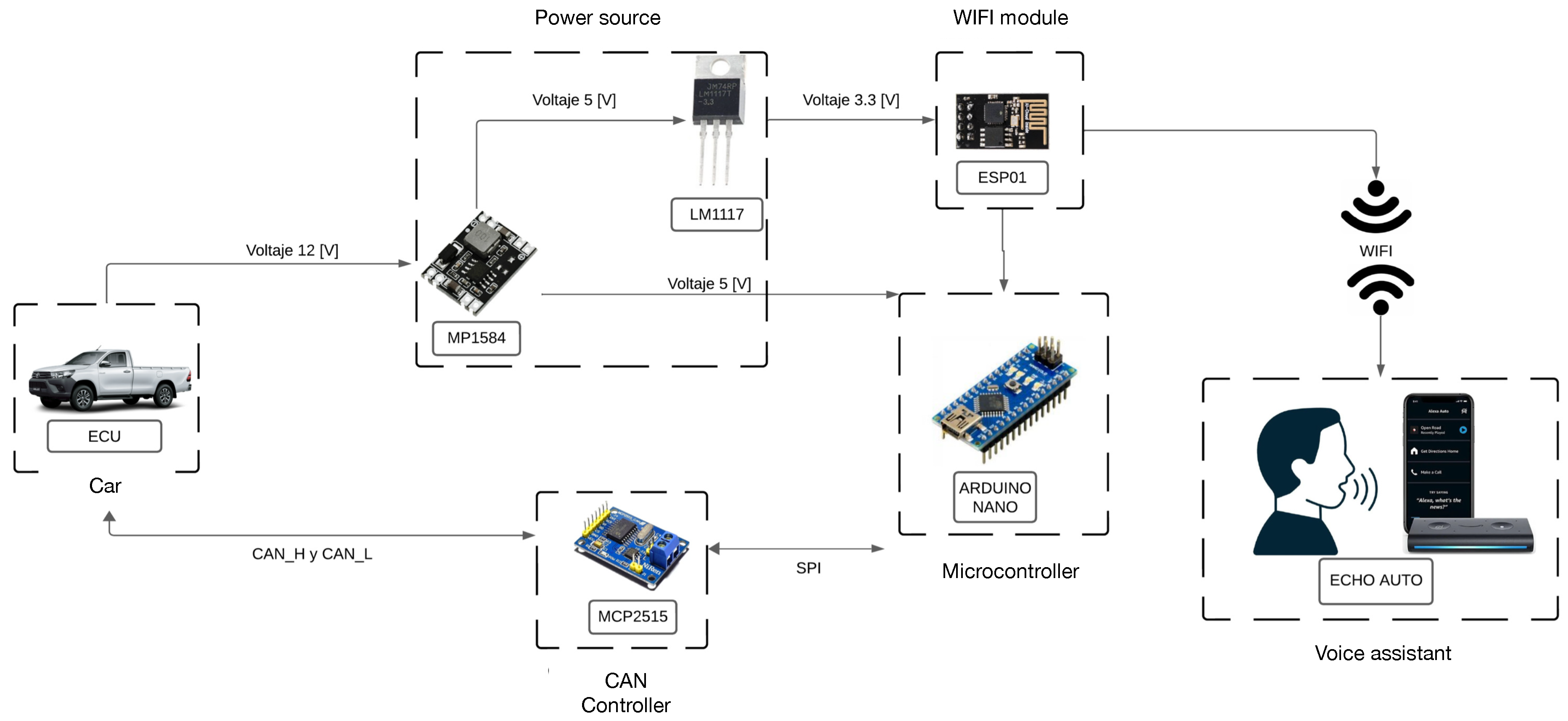

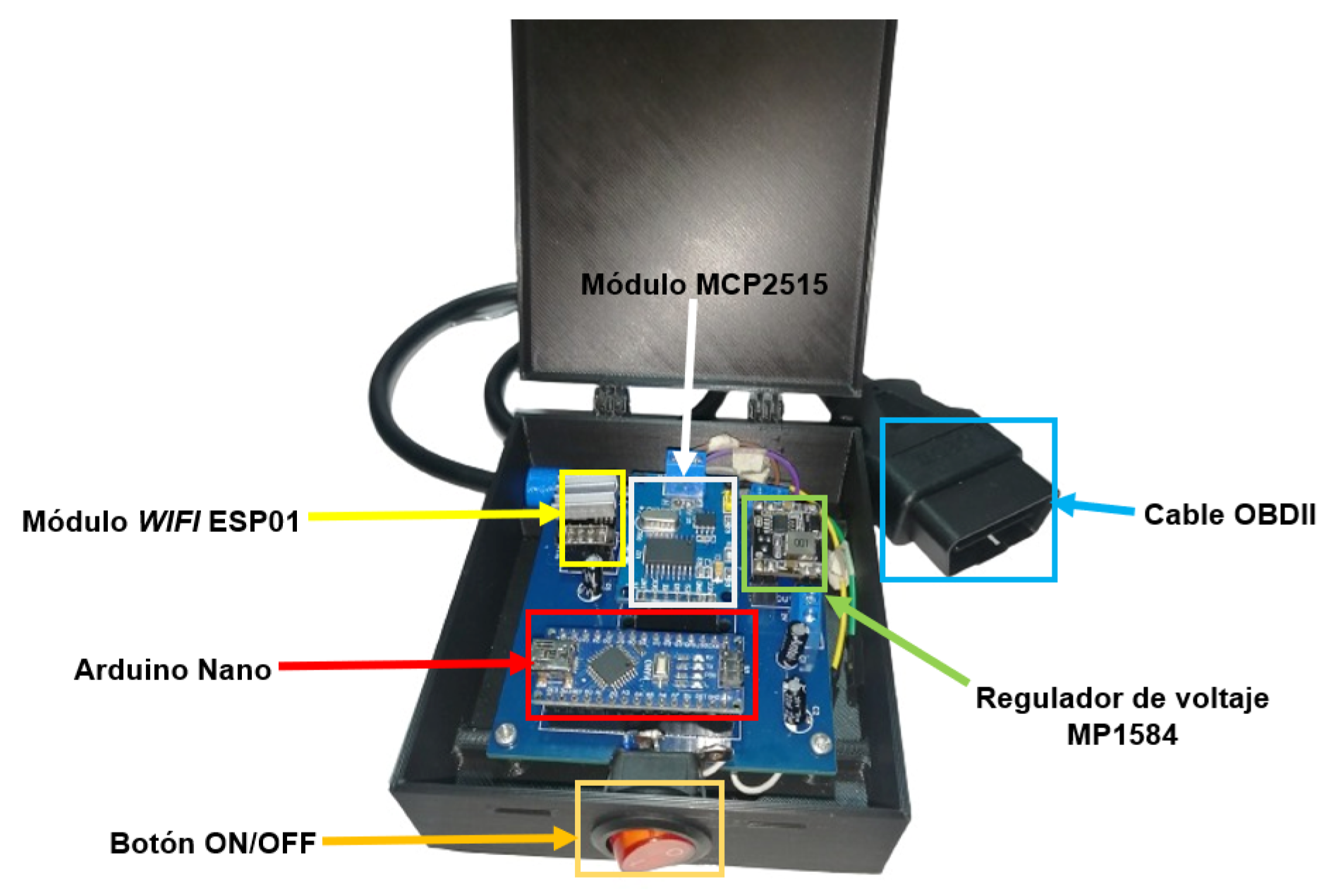

3.1. Hardware

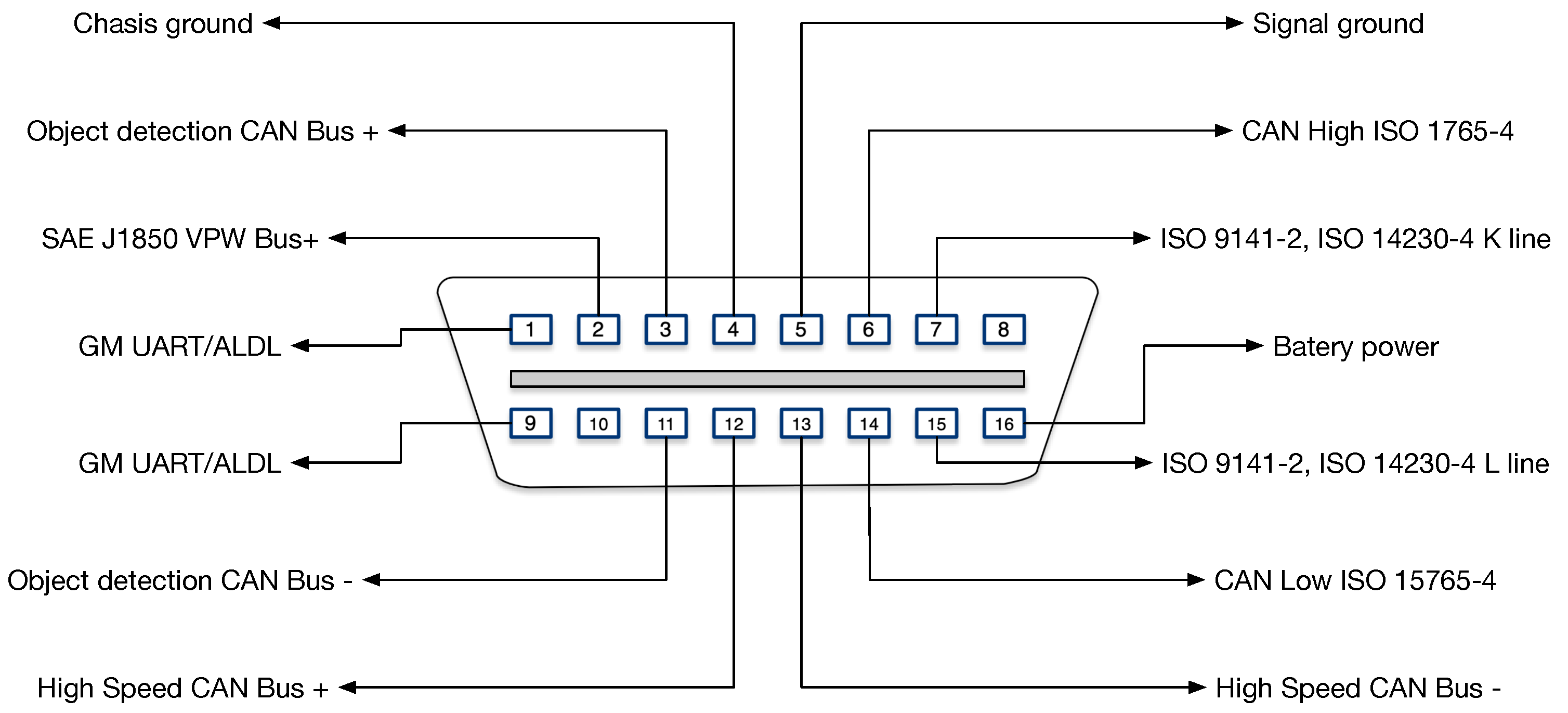

OBD-II Interface Implementation

- CAN_H (Pin 6)/CAN_L (Pin 14) buses

- Battery voltage (Pin 16)

- Chassis ground (Pin 4)

3.2. Software

3.2.1. Variables to Be Monitored

- PID 03—Fuel System Status

- PID 05—Engine Coolant Temperature

- PID 0E—Advance Time

- PID 24—Oxygen sensor

3.2.2. Actuator Selection

- The following message, which is associated with the module PID 7B7, is used to deactivate or unlock doors in block 02 and the first frame. The complete message is 0x7B70201400000000001.

- A message addressed to the same address or PID is used for the activation or locking of doors, changing the bits that correspond to the activation of the respective actuator. The complete message is 0x7B702012011000000000D1.

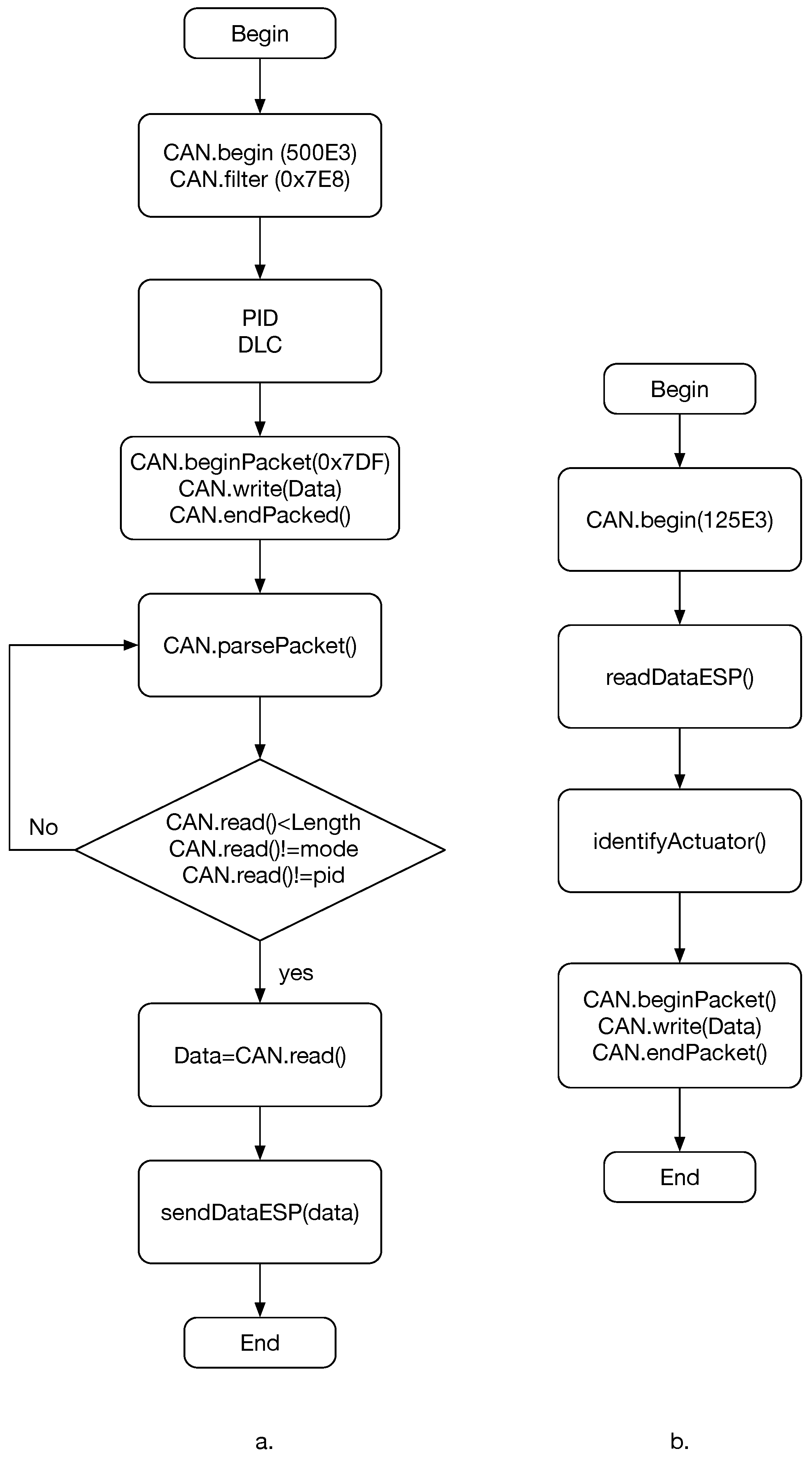

3.2.3. Arduino Nano Programming

3.2.4. ESP01 Board Programming

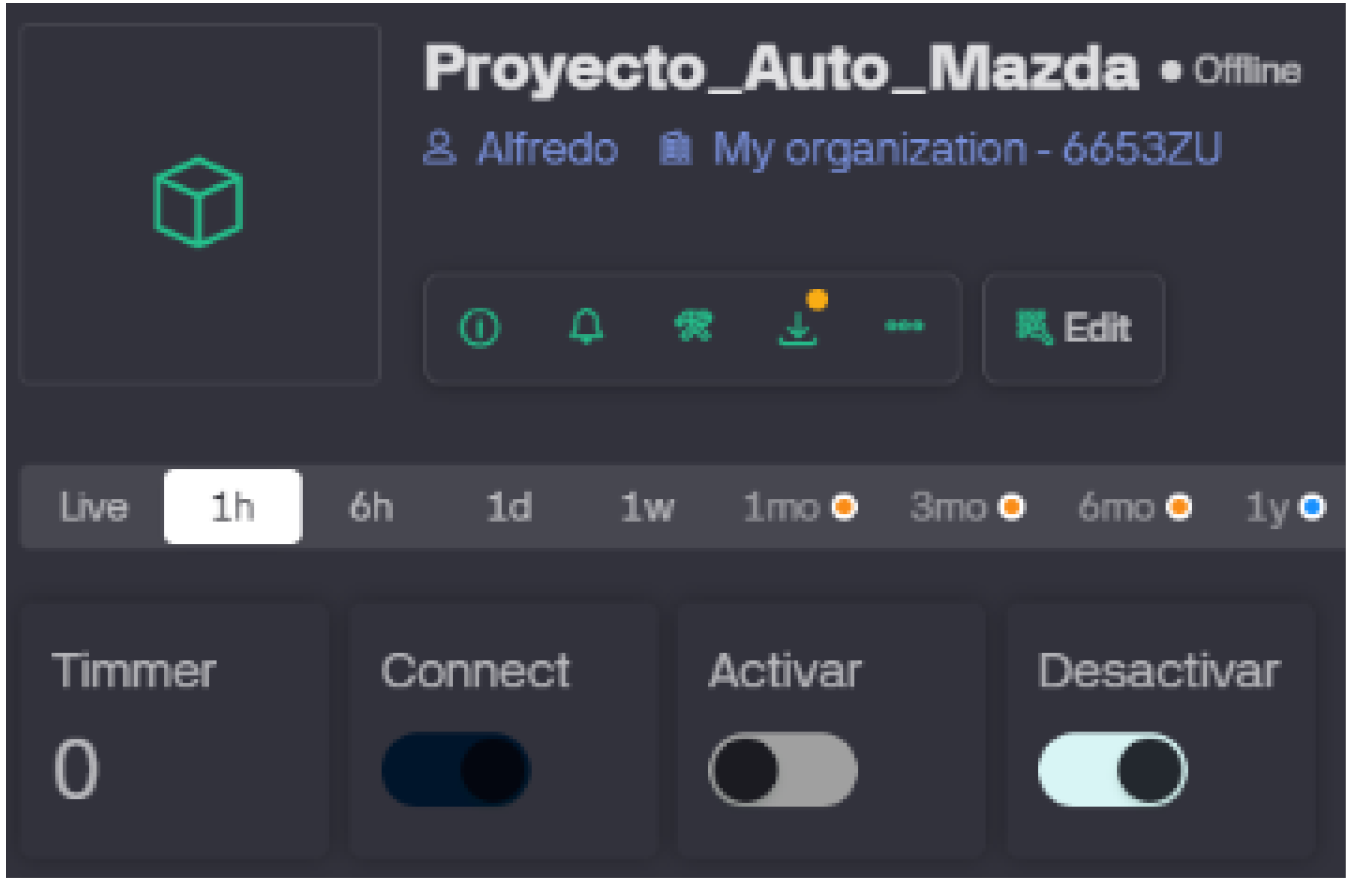

3.2.5. Car Variables on Blynk Platform

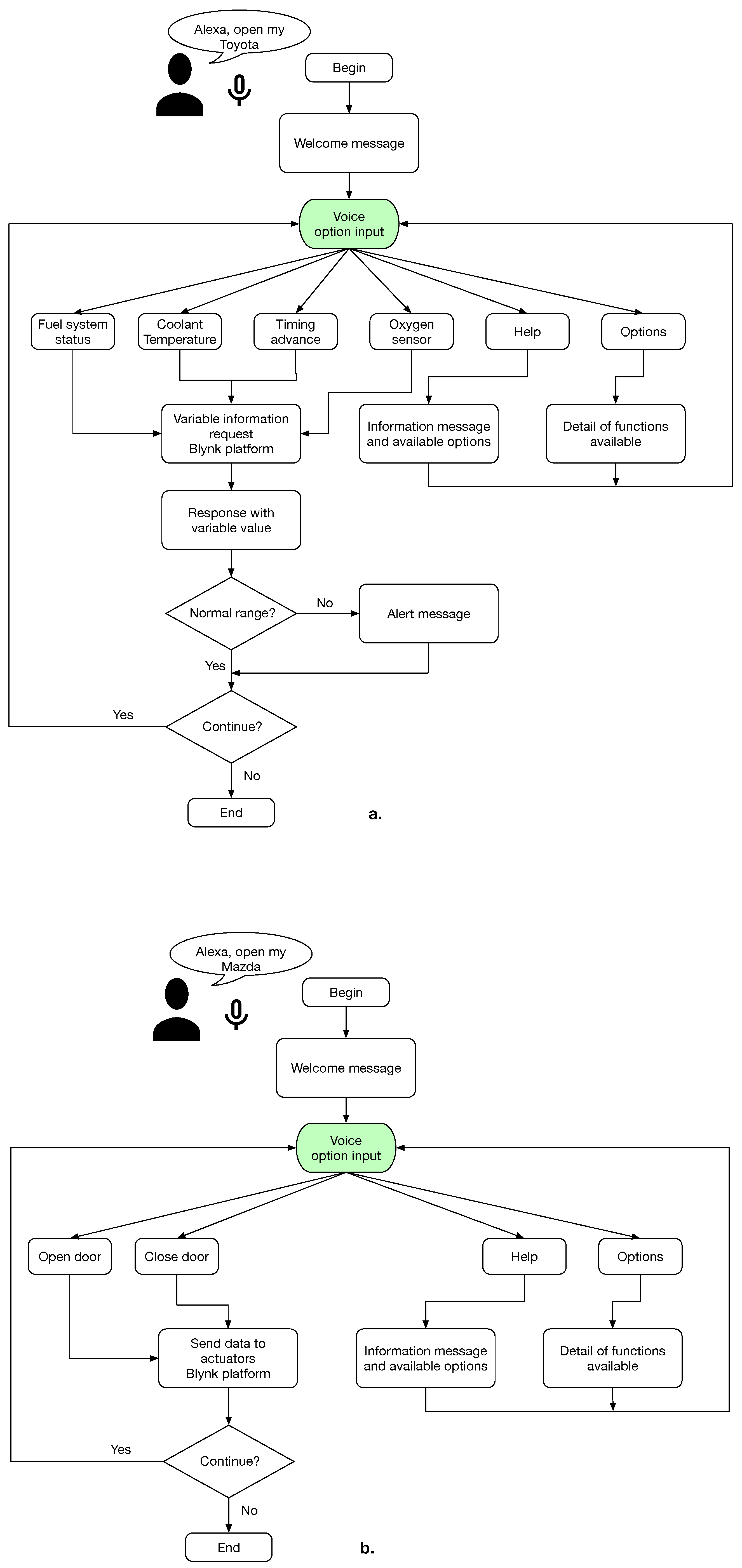

3.2.6. Alexa Skill

4. Test and Results

4.1. Functional Tests of the Sensor Reading Skill

4.1.1. Sensor Read Test with the Vehicle Stopped

- The engine is on, but the vehicle is not running.

- The ambient noise is approximately 61 dB.

- The revolutions per minute is 656 rpm.

- The car is in a neutral position.

- The accelerator is not being pressed.

- Fuel system status

- Coolant temperature

- Timing advance

- Oxygen sensor

4.1.2. Sensor Read Test with the Vehicle Running

- The engine is on and the vehicle is running.

- The windows are closed.

- The ambient noise is approximately 63 dB.

- The vehicle is at an average speed of 30–40 km/h.

- Fuel system status

- Coolant temperature

- Timing advance

- Oxygen sensor

4.2. Skill Test for Locking/Unlocking Door

- The engine is on, but the vehicle is not running.

- The approximate ambient noise is 50 dB.

- The revolutions per minute is 750 rpm.

- The vehicle is in parking mode.

- The accelerator is not being pressed.

- Lexical ambiguity: Minimal phonetic differentiation between critical verbs (“lock”/“unlock”);

- Environmental noise: Background interference during command utterance;

- User articulation variability: Non-uniform pronunciation across test participants.

5. Conclusions

Performance Validation Revealed High Accuracy

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Williams, K.J.; Peters, J.C.; Breazeal, C.L. Towards leveraging the driver’s mobile device for an intelligent, sociable in-car robotic assistant. In Proceedings of the 2013 IEEE Intelligent Vehicles Symposium (IV), Gold Coast, QLD, Australia, 23–26 June 2013; pp. 369–376. [Google Scholar] [CrossRef]

- Gonzalez, P. LOS COCHES QUE MEJOR… TE HABLAN. Tecnologia HC: Madrid, Spain, 2022. Available online: https://hackercar.com/los-coches-que-mejor-te-hablan/ (accessed on 15 April 2025).

- Surface Vehicle Standard—OBD II Scan Tool; SAE International: Warrendale, PA, USA, 2014.

- Road Vehicles—Communication Between Vehicle and External Equipment for Emissions-Related Diagnostics, 5th ed.; International Organization for Standardization: Geneva, Switzerland, 2020.

- Katreddi, S.; Kasani, S.; Thiruvengadam, A. A Review of Applications of Artificial Intelligence in Heavy Duty Trucks. Energies 2022, 15, 7457. [Google Scholar] [CrossRef]

- Braun, M.; Mainz, A.; Chadowitz, R.; Pfleging, B.; Alt, F. At Your Service: Designing Voice Assistant Personalities to Improve Automotive User Interfaces. In Proceedings of the 2019 CHI Conference on Human Factors in Computing Systems (CHI ’19), Glasgow, UK, 4–9 May 2019; pp. 1–11. [Google Scholar] [CrossRef]

- Tobisch, V.; Funk, M.; Emfield, A. Dealing with Input Uncertainty in Automotive Voice Assistants. In Proceedings of the 12th International Conference on Automotive User Interfaces and Interactive Vehicular Applications (AutomotiveUI ’20), Virtual, 21–22 September 2020; pp. 161–168. [Google Scholar] [CrossRef]

- Damaj, I.W.; Yousafzai, J.K.; Mouftah, H.T. Future Trends in Connected and Autonomous Vehicles: Enabling Communications and Processing Technologies. IEEE Access 2022, 10, 42334–42345. [Google Scholar] [CrossRef]

- Reséndiz, M. Sistema Inteligente de Monitoreo y Caracterización de Gases Generados por Vehículos Operados Bajo Diferentes Modos de Manejo. Master’s Thesis, Universidad Autónoma de Querétaro, Santiago de Querétaro, Mexico, 2024. [Google Scholar]

- Calleja Lecanda, J. Aplicación de Asistente Virtual para la Búsqueda de Aparcamiento en Ciudades Inteligentes. Bachelors’s Thesis, Universidad de Cantabria, Cantabria, España, 2021. [Google Scholar]

- Bodero Jiménez, J.; Wong Caicedo, K. Diseño e Implementación de un Sistema de Conectividad para el Monitoreo en Tiempo Real de los Sistemas Funcionales de un Automóvil. Ph.D. Thesis, Universidad Politécnica Salesiana, Quito, Ecuador, 2021. [Google Scholar]

- Zhou, X.; Zheng, Y. Research on Personality Traits of In-Vehicle Intelligent Voice Assistants to Enhance Driving Experience. In Proceedings of the HCI in Mobility, Transport, and Automotive Systems, Copenhagen, Denmark, 23–28 July 2023; Krömker, H., Ed.; Springer: Cham, Switzerland, 2023; pp. 236–244. [Google Scholar]

- Ramírez Grajales, M. Asistentes de voz se Perfilan Como Aliados de la Revolución Automotriz. FORBES. 2021. Available online: https://forbes.com.mx/forbes-life/auto-asistentes-de-voz-aliados-revolucion-automotriz/ (accessed on 17 April 2025).

- Hernández Mejía, R. La Prealimentación Como Técnica de Diseño de Experiencia de Usuario Aplicada a Indicadores Vitales Propios de un Panel de Instrumentos Automotriz Manejado por Asistente Virtual. Ph.D. Thesis, CIATEQ A.C., Santiago de Querétaro, México, 2023. [Google Scholar]

- Road Vehicles—Controller Area Network (CAN)—Part 2: High-Speed Medium Access Unit; International Organization for Standardization: Geneva, Switzerland, 2016.

- Diagnostic Connector—Equivalent to ISO/DIS 15031-3; SAE International: Warrendale, PA, USA, 2012.

- Battery Test Guide for 12V Automotive Starting, Lighting, and Ignition Systems; SAE International: Warrendale, PA, USA, 2020.

- Duan, J.; Xiao, J.; Zhang, M. Framework of CANopen Protocol for a Hybrid Electric Vehicle. In Proceedings of the 2007 IEEE Intelligent Vehicles Symposium, Istanbul, Turkey, 13–15 June 2007; pp. 906–911. [Google Scholar] [CrossRef]

- Andrade, R.d.; Santos, M.M.D.; Justo, J.F.; Yoshioka, L.R.; Hof, H.J.; Kleinschmidt, J.H. Security architecture for automotive communication networks with CAN FD. Comput. Secur. 2023, 129, 103203. [Google Scholar] [CrossRef]

- Kumar, B.; Ramesh, J. Improved Automotive CAN Protocol Based on Payload Reduction and Selective Bit Stuffing. Circuits Syst. 2016, 7, 3415–3429. [Google Scholar] [CrossRef]

- Road Vehicles—Diagnostic Communication over Controller Area Network (DoCAN)—Part 4: Requirements for Emissions-Related Systems, 3rd ed.; International Organization for Standardization: Geneva, Switzerland, 2021.

- Woo, S.; Jo, H.J.; Lee, D.H. A Practical Wireless Attack on the Connected Car and Security Protocol for In-Vehicle CAN. IEEE Trans. Intell. Transp. Syst. 2015, 16, 993–1006. [Google Scholar] [CrossRef]

- Sánchez Vela, L.; Molano Clemente, M.; Fabela Gallegos, M.; Martínez Madrid, M.; Hernánez, J.; Vázquez Vega, D.; Flores Centeno, O. Revisión Documental del Protocolo CAN Como Herramienta de Comunicación y Aplicación en Vehículos; Instituto Mexicano del Transporte, Ed.; Secretaria de Comunicaciones y Transporte: Sanfandila, Qro, 2016; Available online: https://imt.mx/archivos/Publicaciones/PublicacionTecnica/pt474.pdf (accessed on 10 April 2025).

- Jung, D.H.; Jeong, G.M.; Ahn, H.S.; Ryu, M.; Tomizuka, M. Remote Diagnostic Protocol and System for U-Car. In Proceedings of the Ubiquitous Convergence Technology, Jeju Island, Republic of Korea, 5–6 December 2006; Stajano, F., Kim, H.J., Chae, J.S., Kim, S.D., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 60–68. [Google Scholar]

- Bencs, P.; Alktranee, M. The potential of vehicle cooling systems. J. Phys. Conf. Ser. 2021, 1935, 012012. [Google Scholar] [CrossRef]

- González Calleja, D. Mantenimiento de Sistemas de Refrigeración y Lubricación de los Motores Térmicos; Paraninfo, Ed.; Artedis: Madrid, Spain, 2015; e-book: 9788428352048. [Google Scholar]

- Madriz Meza, F. Módulo de Control de Avance de Encendido. Ph.D. Thesis, Instituto Tecnológico de Costa Rica, Cartago, Costa Rica, 2004. [Google Scholar]

- Díaz, E. Sensores y actuadores en el sistema de admisión y escape con equipos de diagnóstico automotriz. Cotopaxi Tech 2022, 2, 66–78. [Google Scholar]

- Litnevskyi, S. Manual de Usuario de Excel Mazda SkyActiv OBD-II calc (FORScan). FORScan Forum. 2021. Available online: https://www.forscan.org/forum/viewtopic.php?t=3379 (accessed on 15 April 2025).

| Identifier (11 Bits, Request) | Data Bytes | |||

|---|---|---|---|---|

| Number of bytes of additional data | Service (01 = show data) | PID code (00 = show PIDs) | No used (ISO 15765-2) | |

| 7DF | 02 | 01 | 00 | |

| Identifier (11 Bits, Reply) | Data Bytes | |||||||

|---|---|---|---|---|---|---|---|---|

| Number of bytes of additional data | Request Service, add 40 h | PID code (00 = show PIDs) | Byte data 0 | Byte data 1 | Byte data 2 | Byte data 3 | No used (ISO 15765-2) | |

| 7E8 | 06 | 41 | 00 | BE | 1F | A8 | 13 | |

| PID | Description | Min | Max | Equation | Units |

|---|---|---|---|---|---|

| 03 | Fuel status system | - | - | - | Table 4 |

| 05 | Coolant engine’s temperature | −40 | 215 | A-40 | |

| 0E | Advance time | −64 | 63.5 | Before | |

| 24 | Sensor (fuel–air ratio) | 0 | <2 | Ratio |

| Value | Status |

|---|---|

| 0 | Engine OFF |

| 1 | Circuit open, low engine’s temperature |

| 2 | Circuit close, use oxygen sensor for fuel mix |

| 4 | Circuit open, high engine load or fuel outage due to slowdown |

| 8 | Circuit open, fail system |

| 16 | Circuit close, oxygen sensor used but there is a feedback system fault |

| ID | Bloq | Message | Data Bytes | Check SUM | ||||

|---|---|---|---|---|---|---|---|---|

| 07 | B7 | 02 | 01 | 40 | 00 | 00 | 00 | 01 |

| Test | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Car status with Alexa system | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| OBDLink EX device | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| error | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Test | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Coolant temperature with Alexa system | 45 | 45 | 45 | 46 | 46 |

| OBDLink EX device | 45 | 45 | 45 | 46 | 46 |

| error | 0% | 0% | 0% | 0% | 0% |

| Test | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Timing advance with Alexa system | 10 | 10 | 10 | 11 | 10 | 10 | 10 | 11 | 10 | 10 |

| OBDLink EX device | 9 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| error | 11.11% | 0% | 0% | 10% | 0% | 0% | 0% | 10% | 0% | 0% |

| Test | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Oxygen sensor with Alexa system | 14.72 | 14.75 | 14.73 | 14.71 | 14.75 |

| OBDLink EX device | 14.72 | 14.76 | 14.73 | 14.72 | 14.76 |

| error | 0% | 0.06% | 0% | 0.06% | 0.06% |

| Test | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Car status whith Alexa system | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| OBDLink EX device | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| error | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Test | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Coolant temperature with Alexa system | 81 | 81 | 80 | 81 | 81 |

| OBDLink EX device | 81 | 80 | 80 | 80 | 81 |

| error | 0% | 1.25% | 0% | 1.25% | 0% |

| Test | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Timing advance with Alexa system | 29 | 41 | 37 | 42 | 42 | 40 | 42 | 38 | 42 | 40 |

| OBDLink EX device | 30 | 40 | 37 | 42 | 41 | 40 | 41 | 38 | 42 | 41 |

| error | 3.33% | 2.5% | 0% | 0% | 2.44% | 0% | 2.44% | 0% | 0% | 2.44% |

| Test | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Oxygen sensor with Alexa system | 14.82 | 14.60 | 14.77 | 14.77 | 14.56 |

| OBDLink EX device | 14.81 | 14.62 | 14.71 | 14.76 | 14.54 |

| error | 0.06% | 0.14% | 0.41% | 0.06% | 0.14% |

| Test | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Total (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Door close | S | S | S | S | S | X | S | S | S | S | 90% |

| Door open | S | S | X | S | S | S | S | S | S | X | 80% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayala Taco, J.P.; Cerón, K.S.; Bautista, A.L.; Ibarra Jácome, A.; Arcos Avilés, D. Development of a Linking System Between Vehicle’s Computer and Alexa Auto. Designs 2025, 9, 84. https://doi.org/10.3390/designs9040084

Ayala Taco JP, Cerón KS, Bautista AL, Ibarra Jácome A, Arcos Avilés D. Development of a Linking System Between Vehicle’s Computer and Alexa Auto. Designs. 2025; 9(4):84. https://doi.org/10.3390/designs9040084

Chicago/Turabian StyleAyala Taco, Jaime Paúl, Kimberly Sharlenka Cerón, Alfredo Leonel Bautista, Alexander Ibarra Jácome, and Diego Arcos Avilés. 2025. "Development of a Linking System Between Vehicle’s Computer and Alexa Auto" Designs 9, no. 4: 84. https://doi.org/10.3390/designs9040084

APA StyleAyala Taco, J. P., Cerón, K. S., Bautista, A. L., Ibarra Jácome, A., & Arcos Avilés, D. (2025). Development of a Linking System Between Vehicle’s Computer and Alexa Auto. Designs, 9(4), 84. https://doi.org/10.3390/designs9040084