Design of Alternatives to Stained Glass with Open-Source Distributed Additive Manufacturing for Energy Efficiency and Economic Savings

Abstract

1. Introduction

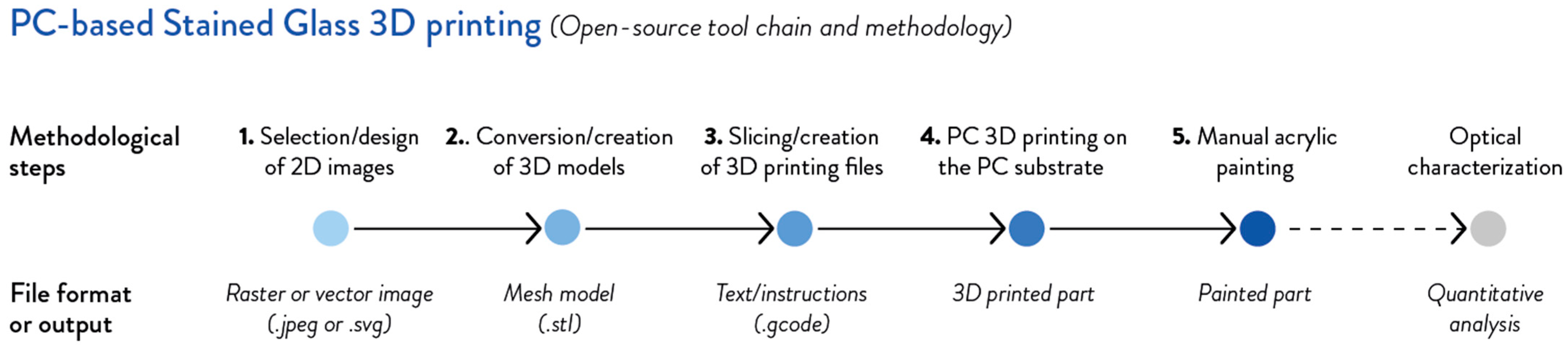

2. Materials and Methods

- Selection or design of the 2D images for the final stained-glass patterns, e.g., sketches, drawings, raster, or vector images, according to the users’ needs and aesthetic choices (Section 2.1).

- Conversion of the 2D images and creation of the 3D models saved in mesh format, i.e., STL, to define the pattern (Section 2.2).

- Slicing of the 3D mesh models of the pattern and generation of the gcode files for its fabrication (Section 2.2).

- Fabrication of the PC-based 3D design on the PC substrate via FFF 3D printing and post-processing of the 3D-printed pattern (Section 2.3).

- Manual coloring of the 3D-printed PC inserts through acrylic painting techniques (Section 2.3).

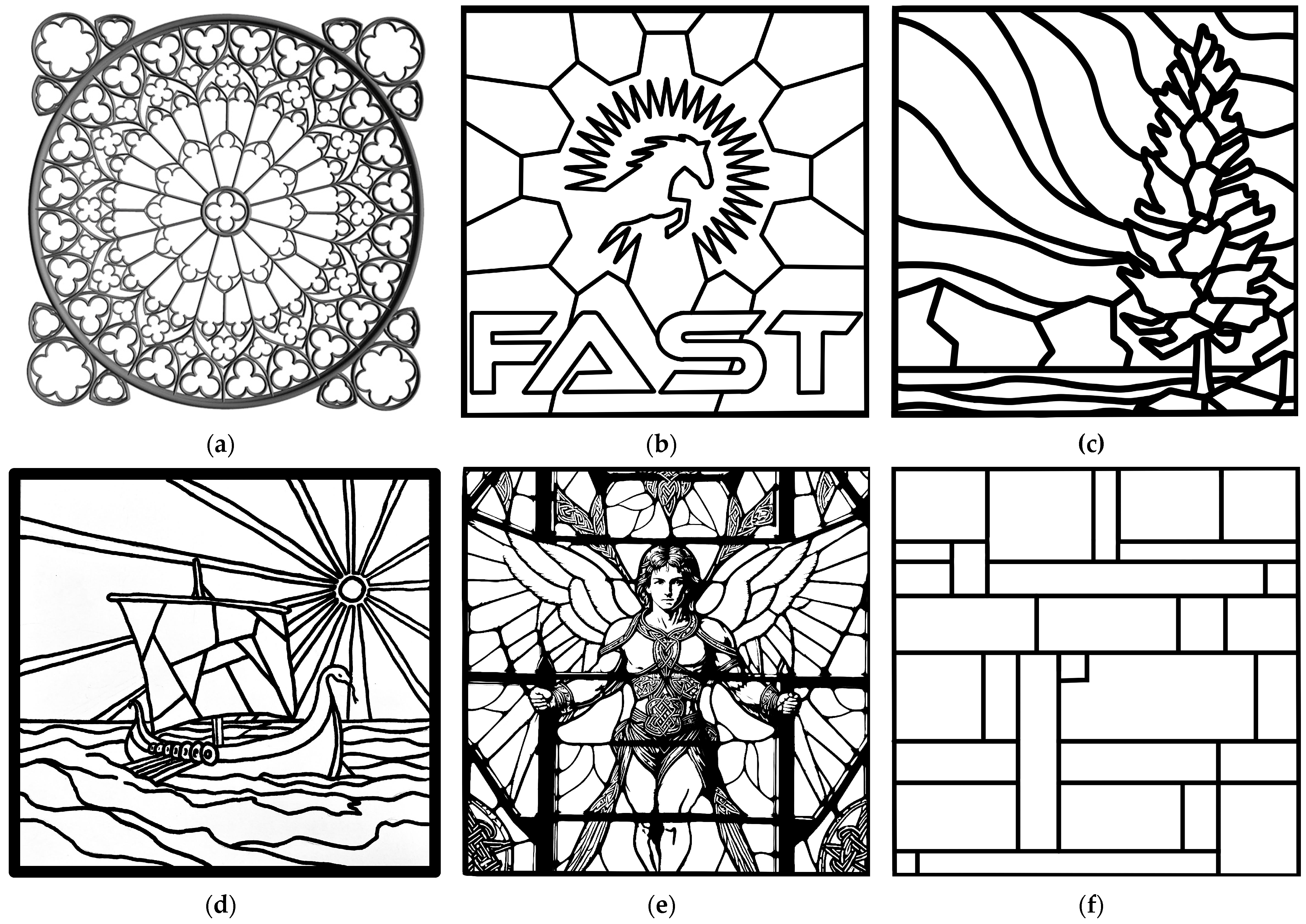

2.1. Phase 1: 2D Image Selection and Design

- AI-generated patterns: novel custom design from an AI image generator (Angel, Figure 2e), saved as a raster image and converted into vector.

2.1.1. Online-Retrieved Patterns

2.1.2. Custom Patterns: Digital-Drawn and Hand-Drawn Images

2.1.3. AI-Generated Pattern

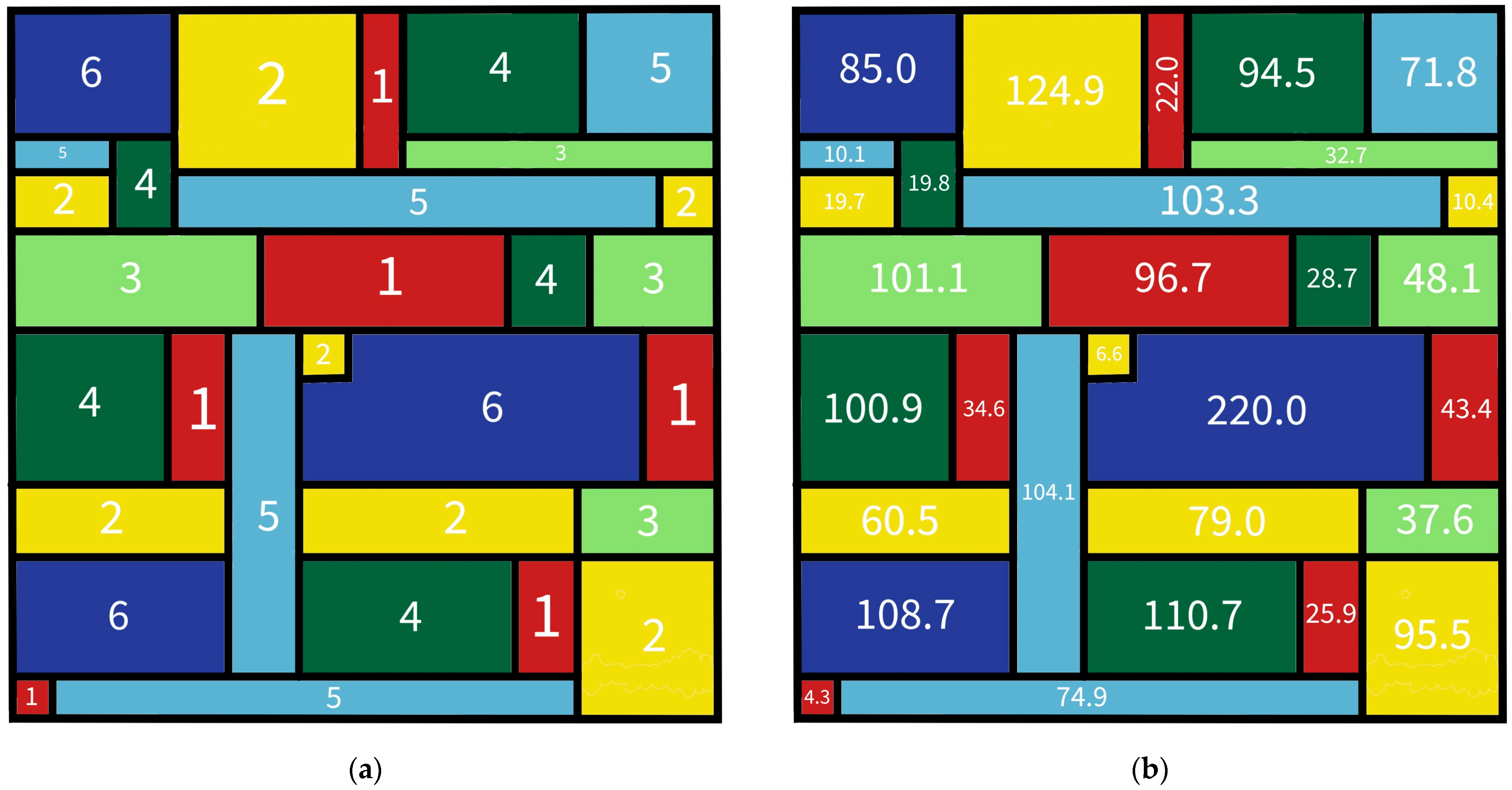

2.1.4. Geometric Validation Image

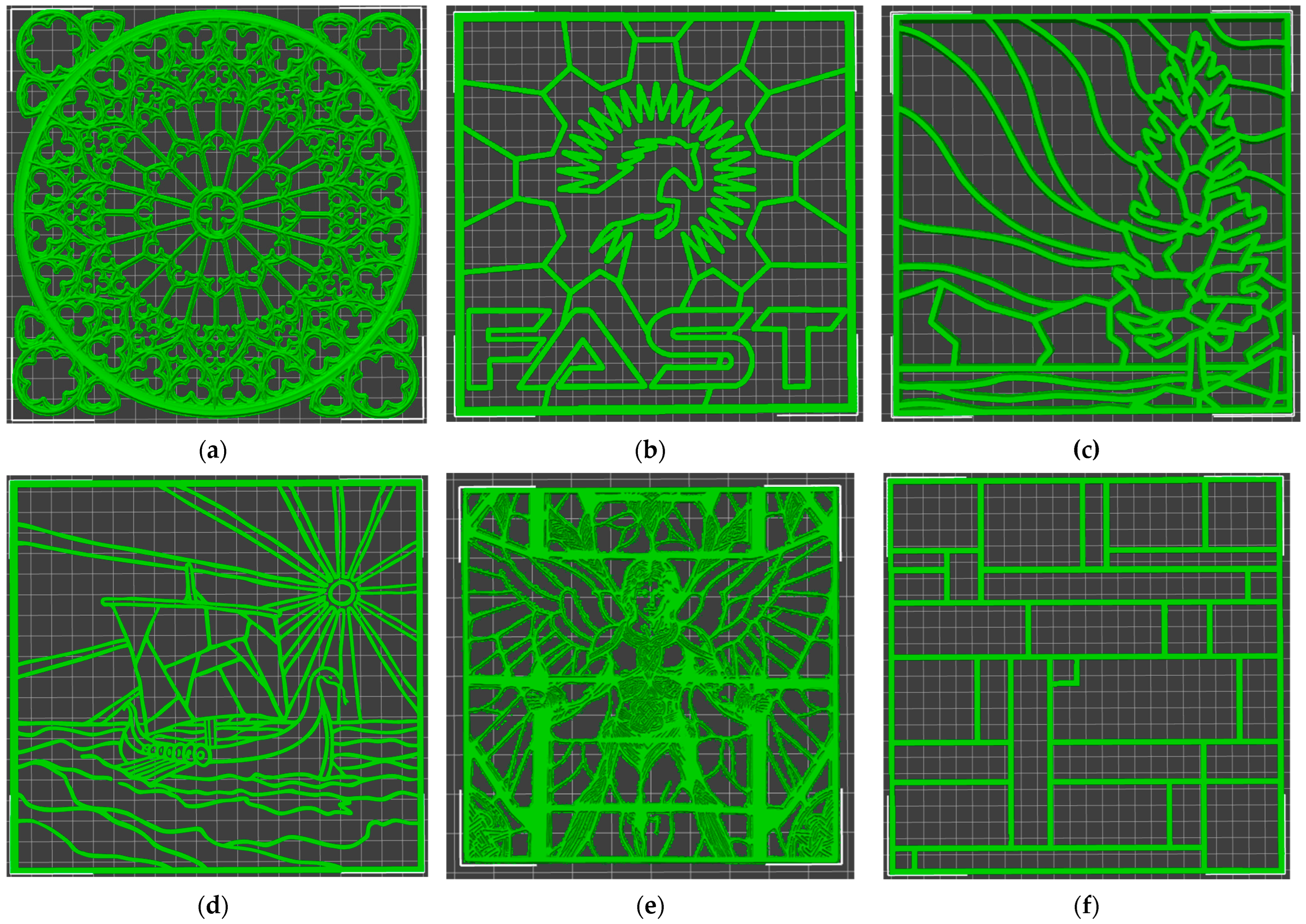

2.2. Phases 2 and 3: Creation of the 3D Mesh Models and 3D Printing Slicing

2.3. Phases 4 and 5: FFF Additive Manufacturing and Painting

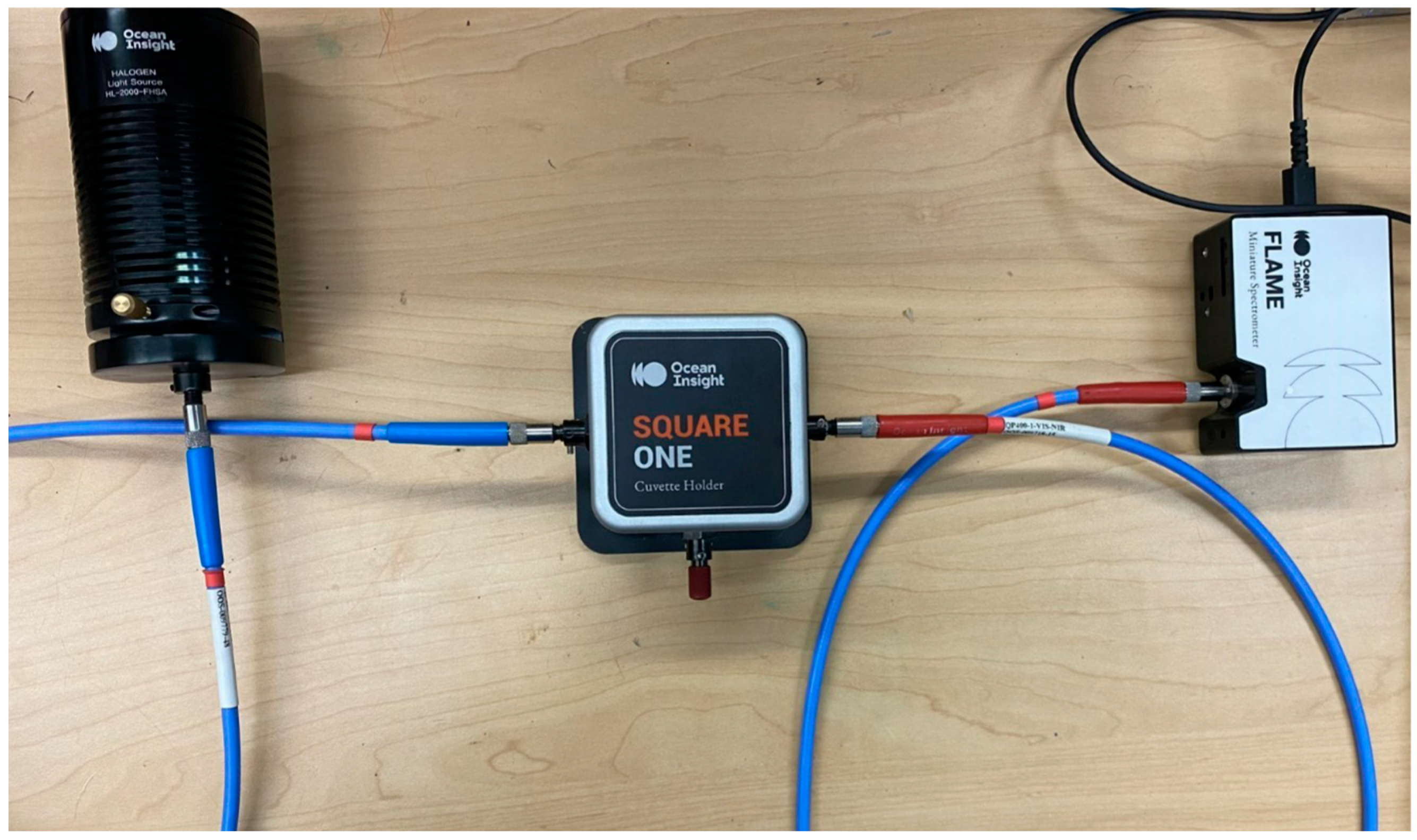

2.4. Optical Spectrum Characterization and Transmission Calculation

2.5. Preliminary Economic Analysis

3. Results and Discussion

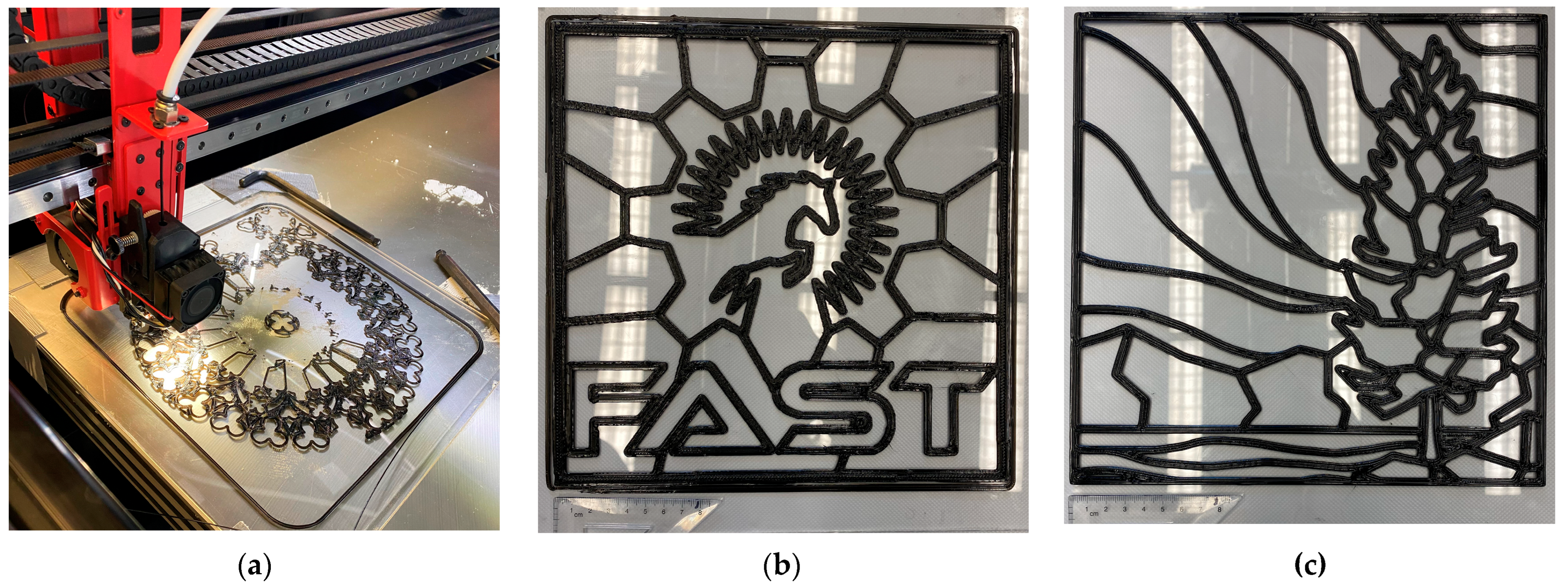

3.1. FFF Additive Manufacturing of the Sample Designs

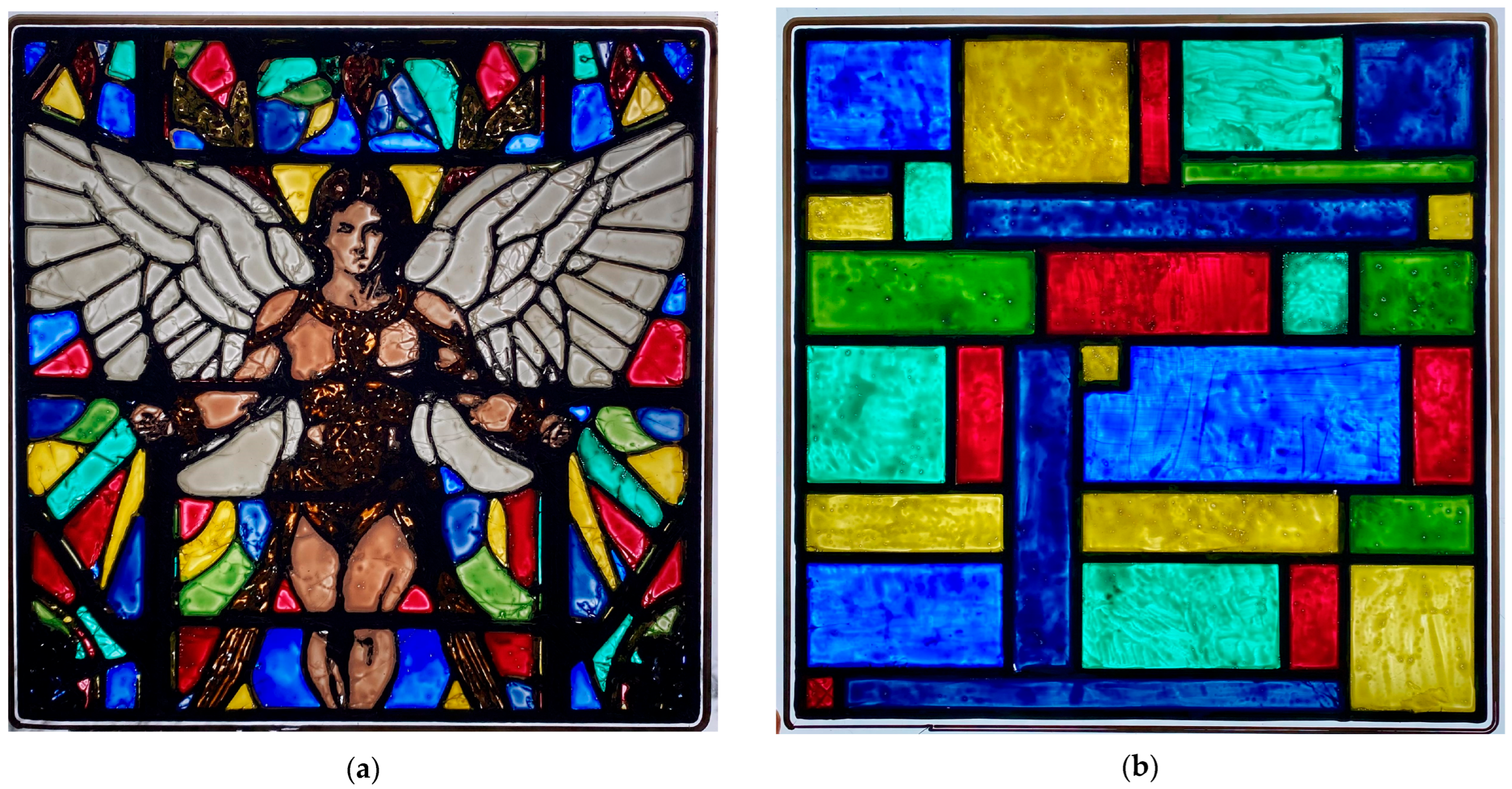

3.2. Fabrication of Stained-Glass Patterns

3.2.1. Online-Retrieved Patterns

3.2.2. Custom Patterns: Digital-Drawn and Hand-Drawn Images

3.2.3. AI-Generated Pattern and Geometric Validation Image

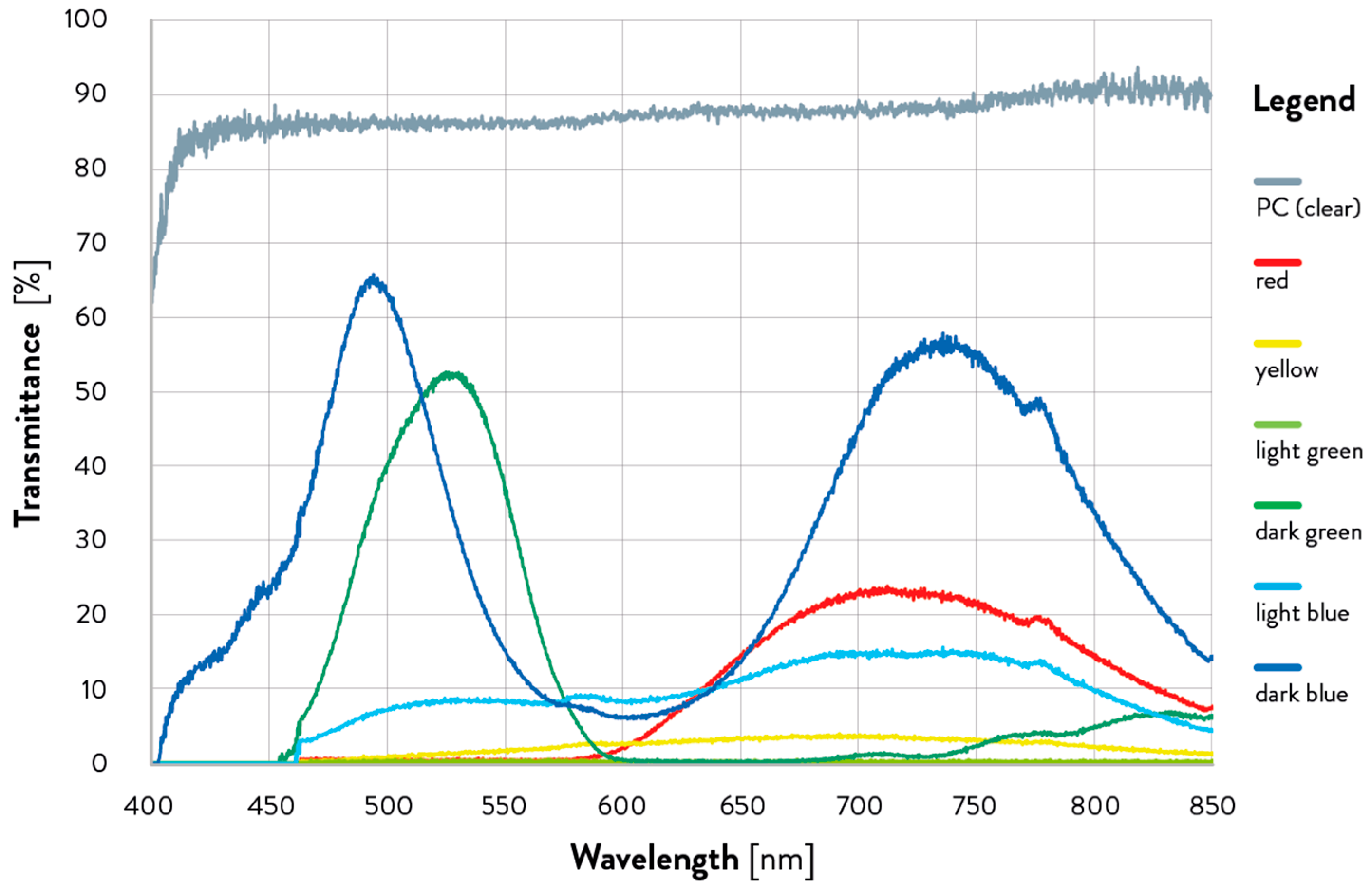

3.3. Optical Transmission Validation

3.4. Economic Analysis

3.5. Potential of 3D-Printed Stained-Glass Alternatives Fabricated Through Open-Source Approaches

3.6. Limitations and Future Work

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rosewell, R. Stained Glass; Bloomsbury Publishing: London, UK, 2012; ISBN 978-1-78200-150-8. [Google Scholar]

- Hunault, M.O.J.Y.; Bauchau, F.; Boulanger, K.; Hérold, M.; Calas, G.; Lemasson, Q.; Pichon, L.; Pacheco, C.; Loisel, C. Thirteenth-Century Stained Glass Windows of the Sainte-Chapelle in Paris: An Insight into Medieval Glazing Work Practices. J. Archaeol. Sci. Rep. 2021, 35, 102753. [Google Scholar] [CrossRef]

- Varieties of Stained Glass. Available online: https://stainedglass.org/learning-resources/varieties-stained-glass (accessed on 20 May 2025).

- Parker, J.M.; Martlew, D. Stained Glass Windows. In Encyclopedia of Glass Science, Technology, History, and Culture; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; pp. 1341–1359. ISBN 978-1-118-80101-7. [Google Scholar]

- Finucane, M.A.; Black, I. CO2 Laser Cutting of Stained Glass. Int. J. Adv. Manuf. Technol. 1996, 12, 47–59. [Google Scholar] [CrossRef]

- Rehren, T.; Freestone, I.C. Ancient Glass: From Kaleidoscope to Crystal Ball. J. Archaeol. Sci. 2015, 56, 233–241. [Google Scholar] [CrossRef]

- Shields, D. Design in Stained Glass. Stud. Ir. Q. Rev. 1952, 41, 209–218. [Google Scholar]

- Yuan, M.; Bonet, J.; Cotte, M.; Schibille, N.; Gratuze, B.; Pradell, T. The Role of Sulphur in the Early Production of Copper Red Stained Glass. Ceram. Int. 2023, 49, 18602–18613. [Google Scholar] [CrossRef]

- Pradell, T.; Molina, G.; Murcia, S.; Ibáñez, R.; Liu, C.; Molera, J.; Shortland, A.J. Materials, Techniques, and Conservation of Historic Stained Glass “Grisailles”. Int. J. Appl. Glass Sci. 2016, 7, 41–58. [Google Scholar] [CrossRef]

- Verney-Carron, A.; Sessegolo, L.; Chabas, A.; Lombardo, T.; Rossano, S.; Perez, A.; Valbi, V.; Boutillez, C.; Muller, C.; Vaulot, C.; et al. Alteration of Medieval Stained Glass Windows in Atmospheric Medium: Review and Simplified Alteration Model. Npj Mater. Degrad. 2023, 7, 49. [Google Scholar] [CrossRef]

- Vilarigues, M.; Redol, P.; Machado, A.; Rodrigues, P.A.; Alves, L.C.; da Silva, R.C. Corrosion of 15th and Early 16th Century Stained Glass from the Monastery of Batalha Studied with External Ion Beam. Mater. Charact. 2011, 62, 211–217. [Google Scholar] [CrossRef]

- Corrêa Pinto, A.M.; Macedo, M.F.; Vilarigues, M.G. The Conservation of Stained-Glass Windows in Latin America: A Literature Overview. J. Cult. Herit. 2018, 34, 172–181. [Google Scholar] [CrossRef]

- Murcia-Mascarós, S.; Foglia, P.; Santarelli, M.L.; Roldán, C.; Ibañez, R.; Muñoz, A.; Muñoz, P. A New Cleaning Method for Historic Stained Glass Windows. J. Cult. Herit. 2008, 9, e73–e80. [Google Scholar] [CrossRef]

- Gagnon-King, D.; Jones, L.; Nabil, S. Interactive Stained-Glass: Exploring a New Design Space of Traditional Hybrid Crafts for Novel Fabrication Methods. In Proceedings of the Seventeenth International Conference on Tangible, Embedded, and Embodied Interaction, Warsaw, Poland, 26 February–1 March 2023; Association for Computing Machinery: New York, NY, USA, 2023; pp. 1–15. [Google Scholar] [CrossRef]

- Cuce, E.; Riffat, S.B. A State-of-the-Art Review on Innovative Glazing Technologies. Renew. Sustain. Energy Rev. 2015, 41, 695–714. [Google Scholar] [CrossRef]

- Somasundaram, S.; Thangavelu, S.R.; Chong, A. Improving Building Efficiency Using Low-e Coating Based Retrofit Double Glazing with Solar Films. Appl. Therm. Eng. 2020, 171, 115064. [Google Scholar] [CrossRef]

- Wolf, S.; Trümpler, S.; Wakili, K.G.; Binder, B.; Baumann, E. Protective Glazing: The Conflict Between Energy- Saving and Conservation Requirements. In Recent Advances in Glass, Stained-Glass, and Ceramic Conservation 2023, Amsterdam, Netherlands, 7–10 October 2013; SPA Uitgevers: Zwolle, The Netherlands, 2013; pp. 99–107. [Google Scholar]

- Uher, C. Thermal Conductivity of Metals. In Thermal Conductivity: Theory, Properties, and Applications; Tritt, T.M., Ed.; Physics of Solids and Liquids; Springer: Boston, MA, USA, 2004; pp. 21–91. ISBN 978-0-387-26017-4. [Google Scholar]

- Lidelöw, S.; Örn, T.; Luciani, A.; Rizzo, A. Energy-Efficiency Measures for Heritage Buildings: A Literature Review. Sustain. Cities Soc. 2019, 45, 231–242. [Google Scholar] [CrossRef]

- How Much Does Installing a Stained Glass Window Cost? Available online: https://www.homeadvisor.com/cost/home-design-and-decor/install-stained-glass/ (accessed on 16 June 2025).

- 2025 Stained Glass Window Cost. Available online: https://www.angi.com/articles/how-much-cost-stained-glass-window.htm (accessed on 16 June 2025).

- Stained Glass Repair Cost: Can Stained Glass Be Repaired and How Much Does It Cost?—Kompareit.Com. Available online: https://www.kompareit.com/homeandgarden/windows-can-stained-glass-be-repaired (accessed on 16 June 2025).

- Frenzel, G. The Restoration of Medieval Stained Glass. Sci. Am. 1985, 252, 126–137. [Google Scholar] [CrossRef]

- Qurraie, B.S.; Beyhan, F. Investigating the Effect of Stained-Glass Area on Reducing the Cooling Energy of Buildings (Case Study: Ankara). CRPASE 2022, 8, 2749. [Google Scholar] [CrossRef]

- Shaik, S.; Maduru, V.R.; Kirankumar, G.; Arıcı, M.; Ghosh, A.; Kontoleon, K.J.; Afzal, A. Space-Age Energy Saving, Carbon Emission Mitigation and Color Rendering Perspective of Architectural Antique Stained Glass Windows. Energy 2022, 259, 124898. [Google Scholar] [CrossRef]

- Golsteijn, C.; van den Hoven, E.; Frohlich, D.; Sellen, A. Hybrid Crafting: Towards an Integrated Practice of Crafting with Physical and Digital Components. Pers. Ubiquitous Comput. 2014, 18, 593–611. [Google Scholar] [CrossRef]

- Zoran, A. Hybrid Craft: Showcase of Physical and Digital Integration of Design and Craft Skills. In Proceedings of the ACM SIGGRAPH Art Gallery, Los Angeles, CA, USA, 9–13 August 2015; Association for Computing Machinery: New York, NY, USA, 2015; pp. 384–398. [Google Scholar] [CrossRef]

- Boisseau, É.; Omhover, J.-F.; Bouchard, C. Open-Design: A State of the Art Review. Des. Sci. 2018, 4, e3. [Google Scholar] [CrossRef]

- Moretti, E.; Zinzi, M.; Belloni, E. Polycarbonate Panels for Buildings: Experimental Investigation of Thermal and Optical Performance. Energy Build. 2014, 70, 23–35. [Google Scholar] [CrossRef]

- Chammas, A.; Quaresma, M.; Mont’Alvão, C. A Closer Look on the User Centred Design. Procedia Manuf. 2015, 3, 5397–5404. [Google Scholar] [CrossRef]

- Petersen, E.E.; Kidd, R.W.; Pearce, J.M. Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market. Technologies 2017, 5, 45. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Romani, A.; Rognoli, V.; Levi, M. Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability 2021, 13, 7269. [Google Scholar] [CrossRef]

- Obi, M.U.; Pradel, P.; Sinclair, M.; Bibb, R. A Bibliometric Analysis of Research in Design for Additive Manufacturing. Rapid Prototyp. J. 2022, 28, 967–987. [Google Scholar] [CrossRef]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific Publishing Company: Singapore, 2009; pp. 568–580. ISBN 978-981-4280-25-9. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Petersen, E.E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Dreessen, K.; Schepers, S.; Leen, D. From Hacking Things to Making Things. Rethinking Making by Supporting Non-Expert Users in a FabLab. Interact. Des. Archit. 2016, 30, 47–64. [Google Scholar] [CrossRef]

- Greenhalgh, S. The Effects of 3D Printing in Design Thinking and Design Education. J. Eng. Des. Technol. 2016, 14, 752–769. [Google Scholar] [CrossRef]

- Pearce, J.; Qian, J.-Y. Economic Impact of DIY Home Manufacturing of Consumer Products with Low-Cost 3D Printing from Free and Open Source Designs. Eur. J. Soc. Impact Circ. Econ. 2022, 3, 1–24. [Google Scholar] [CrossRef]

- Bahar, A.; Belhabib, S.; Guessasma, S.; Benmahiddine, F.; Hamami, A.E.A.; Belarbi, R. Mechanical and Thermal Properties of 3D Printed Polycarbonate. Energies 2022, 15, 3686. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kechagias, J.D. A Comprehensive Investigation of the 3D Printing Parameters’ Effects on the Mechanical Response of Polycarbonate in Fused Filament Fabrication. Prog. Addit. Manuf. 2022, 7, 713–722. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Spiridaki, M.; Kechagias, J.D. Mechanical Performance of Fused Filament Fabricated and 3D-Printed Polycarbonate Polymer and Polycarbonate/Cellulose Nanofiber Nanocomposites. Fibers 2021, 9, 74. [Google Scholar] [CrossRef]

- Romani, A.; Levi, M.; Pearce, J.M. Recycled Polycarbonate and Polycarbonate/Acrylonitrile Butadiene Styrene Feedstocks for Circular Economy Product Applications with Fused Granular Fabrication-Based Additive Manufacturing. Sustain. Mater. Technol. 2023, 38, e00730. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; He, S.; Lu, L. Binary Image Carving for 3D Printing. Comput.-Aided Des. 2019, 114, 191–201. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, W.; Guo, J.; Cao, J.; Zhang, Y.J. Orientation Field Guided Line Abstraction for 3D Printing. Comput. Aided Geom. Des. 2018, 62, 253–262. [Google Scholar] [CrossRef]

- Bedel, A.; Coudert-Osmont, Y.; Martínez, J.; Nishat, R.I.; Whitesides, S.; Lefebvre, S. Closed Space-Filling Curves with Controlled Orientation for 3D Printing. Comput. Graph. Forum 2022, 41, 473–492. [Google Scholar] [CrossRef]

- Powell, A. Democratizing Production through Open Source Knowledge: From Open Software to Open Hardware. Media Cult. Soc. 2012, 34, 691–708. [Google Scholar] [CrossRef]

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Addison-Wesley Professional: Boston, MA, USA, 2014; ISBN 978-0-13-337390-5. [Google Scholar]

- Bow Pearce, E.; Pearce, J.; Romani, A. 3D Printable Designs for Alternatives to Stained Glass for Energy Efficiency and Economic Savings. Available online: https://doi.org/10.17605/OSF.IO/WQ5PF (accessed on 28 May 2025).

- NOTRE DAME. 3D CAD Model Library on GrabCAD. Available online: https://grabcad.com/library/notre-dame-4 (accessed on 16 June 2025).

- FAST Logo Black and White. Available online: https://www.appropedia.org/File:FASTlogobw.png (accessed on 16 June 2025).

- GIMP—GNU Image Manipulation Program. Available online: https://www.gimp.org/ (accessed on 16 June 2025).

- Inkscape—Draw Freely. Available online: https://inkscape.org/ (accessed on 16 June 2025).

- Krita: Digital Painting. Creative Freedom. Available online: https://krita.org/en/ (accessed on 16 June 2025).

- AUTOMATIC1111 Stable Diffusion Web UI 2022. Available online: https://github.com/AUTOMATIC1111/stable-diffusion-webui (accessed on 29 May 2025).

- ImageJ. Available online: https://imagej.net/ij/ (accessed on 16 June 2025).

- PrusaSlicer—Firmware & Downloads. Available online: https://help.prusa3d.com/downloads/prusaslicer?versions=all (accessed on 16 June 2025).

- BIG-Meter—Modix Large 3D Printers. Available online: https://www.modix3d.com/big-meter/ (accessed on 5 May 2025).

- Operating Manual for Modix Printers. Available online: https://www.appropedia.org/Operating_Manual_for_Modix_printers (accessed on 17 May 2025).

- PC Filament 1.75 Mm 3D Printer Filament—CC3D. Available online: https://cc3dglobal.com/product/white-pc-filament-1-75-mm-3d-printer-filament/ (accessed on 16 June 2025).

- 20 Pack 12 x 12 x.02 Inch Clear Plastic Craft Polycarbonate Sheet Thin Clear Plastic Sheet Flexible Transparent Plastic Sheet. Available online: https://www.amazon.ca/Polycarbonate-Flexible-Transparent-Projects-Replacement/dp/B09XZZG8SH (accessed on 16 June 2025).

- Software, Ocean Optics. Available online: https://www.oceanoptics.com/software/ (accessed on 16 June 2025).

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-Cycle Economic Analysis of Distributed Manufacturing Withopen-Source 3-D Printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Electricity Rates|Ontario Energy Board. Available online: https://web.archive.org/web/20250604200203 (accessed on 29 May 2025).

- Transparent 3mm 4mm 5mm 8mm Solid Polycarbonate Sheets for Greenhouse. Available online: https://yunai888.en.made-in-china.com/product/uwCtIAPjrzWd/China-Transparent-3mm-4mm-5mm-8mm-Solid-Polycarbonate-Sheets-for-Greenhouse.html (accessed on 16 June 2025).

- Costanzo, V.; Nocera, F.; Evola, G.; Buratti, C.; Lo Faro, A.; Marletta, L.; Domenighini, P. Optical Characterization of Historical Coloured Stained Glasses in Winter Gardens and Their Modelling in Daylight Availability Simulations. Sol. Energy 2022, 243, 22–34. [Google Scholar] [CrossRef]

- Elbadawi, M.; Basit, A.W.; Gaisford, S. Energy Consumption and Carbon Footprint of 3D Printing in Pharmaceutical Manufacture. Int. J. Pharm. 2023, 639, 122926. [Google Scholar] [CrossRef] [PubMed]

- Tempered Double Pane Glazing Glass Price. Available online: https://jinjingglass.en.made-in-china.com/product/WdqAnZKyLBRG/China-Tempered-Double-Pane-Glazing-Glass-Price.html (accessed on 16 June 2025).

- Balletti, C.; Ballarin, M.; Guerra, F. 3D Printing: State of the Art and Future Perspectives. J. Cult. Herit. 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Bourgeois, I.; Ascensão, G.; Ferreira, V.; Rodrigues, H. Methodology for the Application of 3D Technologies for the Conservation and Recovery of Built Heritage Elements. Int. J. Archit. Herit. 2024, 19(7), 1200–1211. [Google Scholar] [CrossRef]

- Garcia-Espinel, J.D.; González, J.M.L.-G.; Torres, M.F. 3D Heritage: Preserving Historical and Cultural Heritage Through Reality Capture and Large-Scale 3D Printing. In Decoding Cultural Heritage: A Critical Dissection and Taxonomy of Human Creativity Through Digital Tools; Moral-Andrés, F., Merino-Gómez, E., Reviriego, P., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 377–394. ISBN 978-3-031-57675-1. [Google Scholar]

- Yu, J. The Application of 3D Printing Technology in Sculpture. In Proceedings of the the 2020 International Conference on Machine Learning and Big Data Analytics for IoT Security and Privacy, Shanghai, China, 6 November 2020; MacIntyre, J., Zhao, J., Ma, X., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 755–759. [Google Scholar] [CrossRef]

- KurtH3 How to 3D Print a Stained “Glass” Window—Instructables. Available online: https://www.instructables.com/How-to-3D-Print-a-Stained-Glass-Window/ (accessed on 5 March 2025).

- By Faux Stained Glass Effect, With 3D Printing And Epoxy—Hackaday. Available online: https://hackaday.com/2021/04/22/faux-stained-glass-effect-with-3d-printing-and-epoxy/ (accessed on 22 May 2025).

- Toronto Based 3D Printing Service Company Creates a Stained Glass Window out of 100% Plastic. Available online: https://customprototypes.ca/blog/toronto-based-3d-printing-service-company-creates-a-stained-glass-window-out-of-10089991592657516849e6744e94e5940d3ea60f047fd6ba2f5bb1206c368e04806-plastic/ (accessed on 5 March 2025).

- Zhong, S.; Pearce, J.M. Tightening the Loop on the Circular Economy: Coupled Distributed Recycling and Manufacturing with Recyclebot and RepRap 3-D Printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Romani, A.; Levi, M. Large-Format Material Extrusion Additive Manufacturing for Circular Economy Practices: A Focus on Product Applications with Materials from Recycled Plastics and Biomass Waste. Sustainability 2024, 16, 7966. [Google Scholar] [CrossRef]

- The Longevity of Acrylics: An Interview with Mark Golden—Brad Teare. Available online: https://bradteare.com/280-the-longevity-of-acrylics-an-interview-with-mark-golden/ (accessed on 17 June 2025).

- Jones, F.N.; Mao, W.; Ziemer, P.D.; Xiao, F.; Hayes, J.; Golden, M. Artist Paints—An Overview and Preliminary Studies of Durability. Prog. Org. Coat. 2005, 52, 9–20. [Google Scholar] [CrossRef]

- Stained Glass Orchid—Thingiverse. Available online: https://www.thingiverse.com/thing:3080869 (accessed on 16 June 2025).

- Woern, A.L.; McCaslin, J.R.; Pringle, A.M.; Pearce, J.M. RepRapable Recyclebot: Open Source 3-D Printable Extruder for Converting Plastic to 3-D Printing Filament. HardwareX 2018, 4, e00026. [Google Scholar] [CrossRef]

- Home of HueForge. Available online: https://shop.thehueforge.com/ (accessed on 16 June 2025).

- Brooks, S. Image-Based Stained Glass. IEEE Trans. Vis. Comput. Graph. 2006, 12, 1547–1558. [Google Scholar] [CrossRef]

- Stained Glass Window Generator. Available online: https://deepai.org/machine-learning-model/stained-glass-generator (accessed on 28 May 2025).

| Sample and Nomenclature | Design Category | 2D Design (Origin) | Image Format |

|---|---|---|---|

| Notre Dame Rose Window [52] (SG01) | Online patterns (Section 2.1.1) | Retrieved design (3D model, online) | JPEG (raster) |

| Online FAST Logo [53] (SG02) | Online patterns (Section 2.1.1) | Retrieved design (2D image, online) | SVG (vector) |

| Digitally Created Northern Lights (SG03) | Custom patterns (Section 2.1.2) | Digital drawing (digitally hand-drawn) | SVG (vector) |

| Viking Boat (SG04) | Custom patterns (Section 2.1.2) | Pencil sketch drawing (digital acquisition) | JPEG (raster) |

| AI-created Angel (SG05) | AI-generated patterns (Section 2.1.3) | AI-generated image (text prompt) | JPEG (raster) |

| Digitally Created Geometric (SG06) | Geometric validation (Section 2.1.4) | Digital image (path design) | SVG (vector) |

| Parameters for Bitmap Creation | Value |

|---|---|

| Detection Mode | Auto-trace |

| Filter Iterations | 4 |

| Error Threshold | 2.0 |

| Speckles | 1000 |

| Smooth Corners | 1.000 |

| Optimize | 0.000 |

| 3D Printing Parameter | Unit | Value |

|---|---|---|

| Nozzle diameter | mm | 0.8 |

| 3D printing temperature | °C | 245 |

| Build plate temperature | °C | 105 |

| 3D printing speed | mm/s | 60 |

| 3D printing speed (initial layer) | mm/s | 30 |

| Extrusion flow | % | 100 |

| Number of perimeters | // | 3 |

| Layer height | mm | 0.8 |

| Layer height (initial layer) | mm | 0.5 |

| Number of bottom/top layers | // | 3 |

| Infill percentage | % | 100 |

| N. Color | Color | Transmission (%) | Area in the Geometric Validation Design (mm2) |

|---|---|---|---|

| 1 | Red | 7.5 | 226.9 |

| 2 | Yellow | 1.7 | 396.4 |

| 3 | Light green | 0.1 | 219.2 |

| 4 | Dark green | 7.6 | 354.7 |

| 5 | Light blue | 6.9 | 364.3 |

| 6 | Dark blue | 21.3 | 413.6 |

| Sample | 3D Printed Path | PC Substrate | Total Cost (USD) | |||

|---|---|---|---|---|---|---|

| Nominal Weight (g) | Nominal Time (min) | Material Cost (USD) | Energy Cost (USD) | Sheet Cost (USD) | ||

| SG01 | 30.2 | 57 | 0.58 | 0.14 | 0.39 | 1.11 |

| SG02 | 29.8 | 44 | 0.58 | 0.11 | 0.39 | 1.07 |

| SG03 | 33.2 | 32 | 0.64 | 0.08 | 0.39 | 1.11 |

| SG04 | 30.4 | 32 | 0.59 | 0.08 | 0.39 | 1.06 |

| SG05 | 39.0 | 74 | 0.75 | 0.18 | 0.39 | 1.32 |

| SG06 | 21.0 | 20 | 0.41 | 0.05 | 0.39 | 0.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bow Pearce, E.; Pearce, J.M.; Romani, A. Design of Alternatives to Stained Glass with Open-Source Distributed Additive Manufacturing for Energy Efficiency and Economic Savings. Designs 2025, 9, 80. https://doi.org/10.3390/designs9040080

Bow Pearce E, Pearce JM, Romani A. Design of Alternatives to Stained Glass with Open-Source Distributed Additive Manufacturing for Energy Efficiency and Economic Savings. Designs. 2025; 9(4):80. https://doi.org/10.3390/designs9040080

Chicago/Turabian StyleBow Pearce, Emily, Joshua M. Pearce, and Alessia Romani. 2025. "Design of Alternatives to Stained Glass with Open-Source Distributed Additive Manufacturing for Energy Efficiency and Economic Savings" Designs 9, no. 4: 80. https://doi.org/10.3390/designs9040080

APA StyleBow Pearce, E., Pearce, J. M., & Romani, A. (2025). Design of Alternatives to Stained Glass with Open-Source Distributed Additive Manufacturing for Energy Efficiency and Economic Savings. Designs, 9(4), 80. https://doi.org/10.3390/designs9040080