Abstract

This review explores the intersection of Artificial Intelligence (AI) and Generative Design (GD) in engineering within the mechanical, industrial, civil, and architectural domains. Driven by advances in AI and computational resources, this intersection has grown rapidly, yielding over 14,000 publications since 2016. To map the research landscape, this review employed semantic search and Natural Language Processing, parsing 14,355 publications to ultimately select the 88 most relevant studies through clustering and topic modelling. These studies were categorised according to AI and GD techniques, application domains, benefits, and limitations, providing insights into research trends and practical implications. The results reveal a significant growth in the integration of advanced generative AI methods, notably Generative Adversarial Networks for direct design generation, alongside the continued use of genetic algorithms and surrogate models (e.g., Convolutional Neural Networks and Multilayer Perceptrons) to manage computational complexity. Structural and aerodynamic applications were the most common, with benefits including improvements in computational efficiency and design diversity. However, barriers remain, including data generation costs, model accuracy, and interpretability. Research opportunities include the development of generalisable foundation surrogate models, the integration of emerging generative methods such as diffusion models and large language models, and the explicit consideration of manufacturability constraints within generative processes.

1. Introduction

Computational tools have supported engineering design for more than 60 years [1]. They have enabled designers to rapidly and accurately iterate designs, facilitating design space exploration and optimisation. In recent years, computational algorithmic techniques have been developed that automatically synthesise designs. These are known as Generative Design (GD) [2]. GD techniques are attractive, as they enable rapid iteration and design optimisation, with typical goals to minimise the mass of a structure, achieve certain aerodynamic properties, or tailor magnetic flux properties [3,4,5]. These techniques often facilitate large performance increases; for example, Refs. [6,7,8] attained >40%, >50% and >60% mass savings, respectively, in their light-weighting studies when compared to expert designer-derived designs. The use of GD tools has become increasingly popular with the availability of cloud computing to mitigate the usually prohibitive computational cost and the geometric flexibility of Additive Manufacturing (AM), enabling previously infeasible outcomes to be achieved [9,10]. The academic publication rate has responded accordingly, with “Generative Design” the subject of 15,239 articles since 2016 (as recorded at 2024-11-12T15:31:31+00:00) [11].

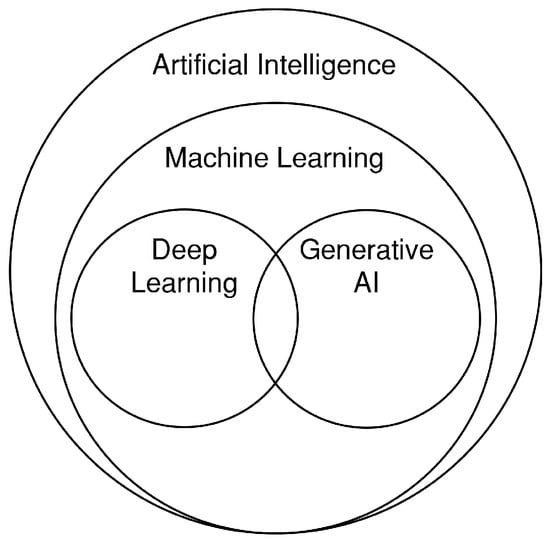

Artificial Intelligence (AI) offers a potential revolution in engineering design [12]. It enables learning from examples to provide generalisations even in scenarios where exact rules are impossible to define. This is in contrast to the deductive reasoning offered by classical computing methods. Since the demonstration of the capabilities of Deep Neural Networks (DNNs) with AlexNet in 2012, there has been a surge in AI research, with the seminal work cited by 134,811 articles at the time of writing and “Artificial Intelligence” the subject of 388,943 articles since 2016 (as recorded at 2024-11-12T15:29:23+00:00) [11,13]. In particular, Generative Artificial Intelligence (GenAI) has experienced an explosion of attention with 8948 articles between 2022 and 2024, compared to 1060 articles in the previous two years (2020–2022) [11]. Unlike traditional AI, which is often designed for analysis, classification, decision-making, or prediction, GenAI is used to produce a completely new output that resembles the data used for training. GenAI offers the ability to significantly enhance the design engineer’s toolkit, thus enabling the rapid creation of detailed designs with very little human input [14]. This review acknowledges the often broad definition of AI and that there are techniques that are considered AI but not Machine Learning (ML). Figure 1 gives relative definitions for some of the relevant AI terms as stated by [15].

Figure 1.

Diagram demonstrating the nested relationships of AI, ML, Deep Learning (DL) and GenAI.

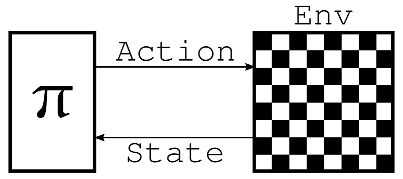

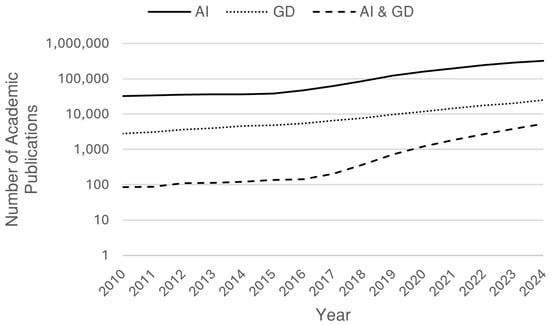

The integration of AI into engineering design is expected to accelerate based on existing trends in the adoption of computational methods for their speed and accuracy [16,17]. The use of AI and the inductive reasoning abilities it provides will enable engineers to tackle both existing and entirely new problems in novel ways [18]. In anticipation of continued development, this review focusses on existing studies at the intersection of GD and AI as presented in Figure 2. Figure 3 demonstrates how the increase in publication rates in the fields of GD and AI corresponds to an increase in the number of studies situated at the intersection of the two fields. The data was collected from [11].

Figure 2.

Venn diagram illustrating the domain of this review.

Figure 3.

Publication trends from 2010 to 2024 for Artificial Intelligence (AI), Generative Design (GD), and their intersection, plotted on a logarithmic scale. The intersection of AI and GD publications demonstrates exponential growth beginning in 2016, following similar acceleration patterns in both individual fields, though with a delay.

The contribution of this review lies in the identification of trends and opportunities in the use of AI techniques for GD applications. The scope of the review covers mechanical, industrial, civil, and architectural design but does not cover material, chemical, electrical, or electronic design. For example, a study that designed specialised power electronic circuits by selecting the appropriate transistor would not be relevant. However, an investigation into the optimal layout of the circuit’s components to reduce packing volume would be included. In addition, the review is solely interested in the use of AI to influence the design process. Studies concerned only with the use of AI for analysis without the results directly informing or being situated in a design process are therefore also excluded. Unlike traditional reviews that rely solely on keyword search and manual filtering, this review applies a Natural Language Processing (NLP)-based methodology, enabling the discovery and thematic grouping of studies that use diverse terminology or span multiple domains.

This paper continues with related work (Section 2) which discusses other reviews that have focused on AI or GD, or both, and why this review is necessary to fill a gap within the existing literature. The methodology (Section 3) is then presented, along with a justification of the steps taken. Section 4 presents the results from each stage of the method, beginning with a meta-analysis of the initial corpus, through the 12 topics identified using NLP to the codes assigned to each of the articles in the final corpus that capture techniques and application themes. Section 5 then discusses the emerging trends in techniques and applications before suggesting opportunities identified within the field. The paper concludes with Section 6, which enumerates the key contributions.

2. Related Work

This section provides justification for the need for a structured review of the literature investigating the intersection of AI and GD. The contributions of a number of existing reviews in the area are discussed, and gaps in their perspectives are highlighted. To better understand these gaps, it is essential to first examine key studies that have explored specific aspects of this intersection. The differences between this review’s method and those of previous works are summarised in Table 1.

Table 1.

Summary of recent literature reviews in AI and engineering design.

Shin et al. [22] reviewed ML techniques in topology optimisation, highlighting the effectiveness of Generative Adversarial Networks (GANs) in generating design solutions that maintain feasibility and diversity, as well as the use of surrogate models to reduce computational costs in iterative design processes. Cheng et al. [23] examined applications of surrogate models in engineering design optimisation, stating their potential to accelerate design cycles by approximating complex simulations whilst also pointing out limitations in model accuracy and generalisability. In contrast to this review, the aforementioned works typically focus on the technical specifics of algorithms or their applications. This work takes a broader perspective to make comparisons between engineering specialities.

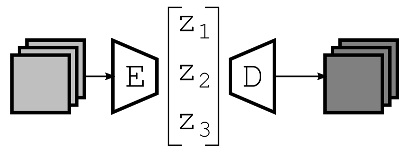

Regenwetter et al. [19] produced a review of deep generative models in engineering design, structured around algorithms, datasets, and representations, with a strong emphasis on GANs and Variational Auto-Encoders (VAEs) to generate design solutions. The authors highlighted key strengths such as the ability of GANs to generate novel solutions and the robustness of VAEs to maintain the structural integrity of the design output. However, their review is based on research conducted up to 2020, and this work aims to capture the work since. As illustrated in Figure 3, the rapid progress in AI and GD requires an updated perspective that captures recent developments and their implications for engineering design.

More recently, Kretzschmar et al. [21] conducted a systematic review of the literature focusing on the applications and capabilities of generative AI in engineering disciplines and product development. They synthesise perspectives from various disciplines, showcasing recent progress and exploring potential future research paths and challenges in applying generative AI to engineering design. Khanolkar et al. [20] examined 108 peer-reviewed studies to investigate how AI techniques are integrated into various stages of the engineering design process. In contrast, this work maps techniques to applications to identify trends. The authors categorised seven distinct AI-based methods and mapped them across five key design stages. Their analysis revealed that the majority of AI applications are concentrated in the conceptual and preliminary design phases.

While previous studies provide valuable insights, keyword-based methodologies may naturally limit the scope of identified papers and often rely on predefined search terms, potentially restricting the scope of identified papers by excluding those that use alternative terminology or non-standard phrasing. This limitation highlights the necessity of employing comprehensive search terms and supplementary methodologies to ensure a robust and inclusive review of the literature. Although these approaches have contributed significantly to understanding the AI/GD landscape in engineering, there is still scope to expand the breadth of literature discovery through complementary techniques. To build on these efforts, this review employs an NLP-based topic modelling approach, using document embeddings (via SPECTER2 [24]) and k-means clustering to identify thematically coherent groups of papers. This allows capture of literature where key terms might not be explicitly stated but where the semantic content aligns strongly with our research focus. These insights would likely remain hidden in traditional keyword-based or manually structured reviews. Building on the foundation of existing literature that focusses on specific applications or techniques, this paper synthesises data from a wide range of sources to offer a holistic perspective. By systematically mapping these themes and identifying trending areas, this review not only summarises existing knowledge but also indicates useful technique–application pairings.

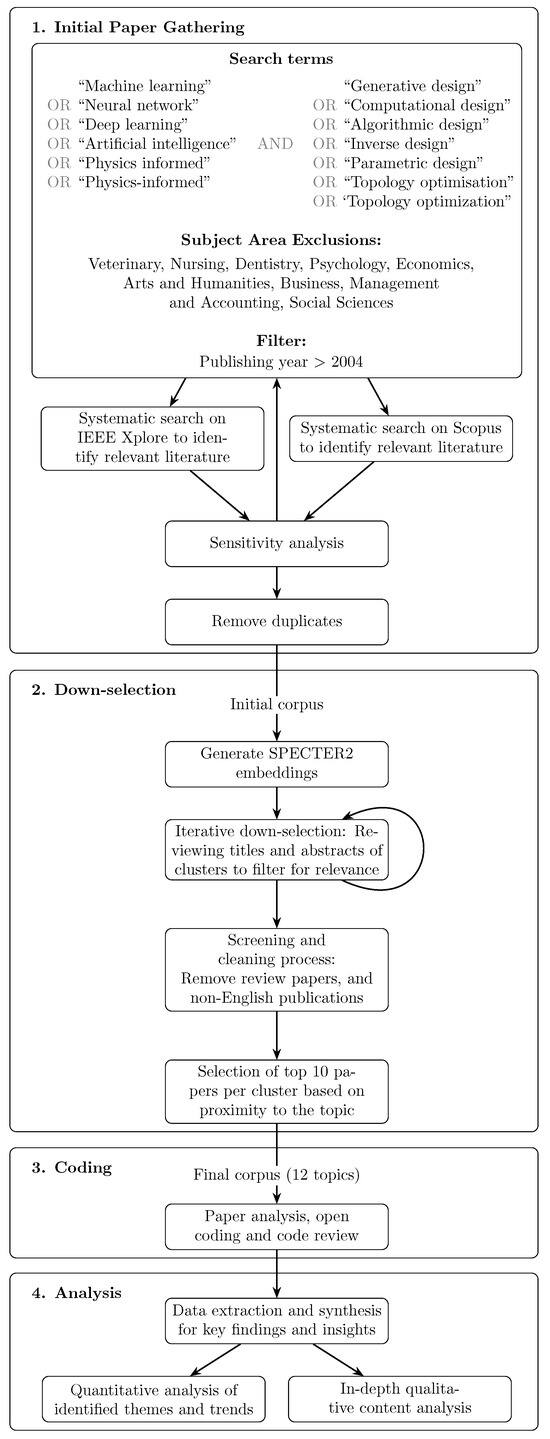

3. Review Methodology

Narrative reviews, while suitable for summarising existing knowledge, lack the scope and specificity necessary to systematically identify and evaluate the breadth and depth of studies in AI and GD [25]. Meta-analyses, on the other hand, would be premature given the heterogeneous nature of the available literature, as the field has yet to mature to a point where comparable statistical measures are widely available [25]. Using modern data science techniques, the research presented in this review employs a structured approach to examine the use of AI and GD. The approach amalgamates suggestions from [25,26,27,28] to leverage NLP and topic modelling and ensure a comprehensive and replicable process that captures a wide range of relevant literature while minimising selection bias [25]. Figure 4 provides a flowchart of the four-step process, which also corresponds to the subsections of this section.

Figure 4.

Flowchart of the review method.

3.1. Initial Paper Gathering

The paper gathering phase curated a corpus of literature from the Scopus and IEEE Xplore databases relevant to AI in GD. These databases were selected for their inclusion of high-impact journals and conference proceedings in AI and GD. For the purposes of this review, the relevance of a paper was evaluated based on whether it provided all the contributions listed below.

- Methodological research aiming to synthesise designs;

- An application of synthesis of “function and form” engineering designs;

- Use of AI techniques to directly inform or perform design synthesis.

Lists of keywords related to AI and GD were created to form a search term that returned relevant articles at the intersection of the two fields. An iterative sensitivity analysis process was then conducted in which multiple searches were performed and the titles and abstracts of the results were reviewed for relevance. This process was repeated until the removal of keywords removed highly relevant papers from the search results and the addition of additional keywords clearly found a high number of low-relevance results. After the iteration was complete, these lists were used to create the initial corpus by searching for papers that include at least one term from each list in the title or abstract. The keywords are displayed in Figure 4. The search for the initial corpus was carried out at 2024-03-16T14:41:36+00:00.

3.2. Down-Selection

An iterative down-selection process was employed to refine the corpus by eliminating less relevant studies. The process was not designed to capture a representative cross-section of the initial corpus, but instead to select the most relevant to our research questions. Initially, a vector embedding representation is created for each paper based on its title and abstract using a language model, SPECTER2 [24]. SPECTER2 is a model that generates dimensional vector representations based on semantic content, capturing the underlying topics and relationships within each document. Two papers that are semantically similar will resolve to two similar vectors. This approach enables the clustering (into topics) and analysis of papers based on their thematic similarity. The use of SPECTER2 embeddings was motivated by the limitations of traditional vectorisation methods (e.g., TF-IDF), which may fail to capture thematic relevance across disciplines, particularly in interdisciplinary fields like AI and GD, where terminology varies widely. The k-means clustering algorithm [29,30] was used to group the articles into a set of topics. K-means clustering is selected for its simplicity, interpretability, and compatibility with our iterative human-in-the-loop refinement process. The number of topics within the topic set was determined using an elbow plot analysis considering an allowed range of 5 to 50 topics [31]. The relevance of each topic was then manually assessed based on the content of its five closest articles (L2 norm and mean cluster point). The articles closest to the centre of the cluster are most relevant to the topic. The topics deemed least relevant were discarded along with those papers that related more strongly to them rather than to any other topic. Re-clustering was then performed upon the remaining papers before the manual evaluation began again. This iterative process increased the specificity of the clustering with each iteration, progressively filtering out less relevant literature. The iterations continued until none of the topics could be discarded as less relevant, indicating that no further significant improvements in cluster cohesion could be achieved.

An inter-rater reliability test was conducted among the three primary researchers to ensure consistency. Each researcher independently assessed a selection of articles based on the relevance to the topic. In cases of disagreement, a discussion was held to reach a consensus and refine the selection, ensuring precision in the final corpus. After confirming agreement between all primary researchers, the 10 most relevant papers (L2 norm closest) for each topic were selected and combined into the final corpus.

3.3. Coding

Following down-selection, techniques, applications and characteristics were extracted from the articles using a standardised form designed to ensure consistency in all coded attributes and to directly address the review’s research questions. The questions in this form were related to three key research areas that guided the review process:

- What are the key trends, drivers, and application areas at the intersection of AI and Generative Design?

- What issues, limitations, and barriers are reported in the existing literature?

- What gaps, emerging opportunities, and future challenges exist for researchers and practitioners?

The form was structured with headings corresponding to these questions and included fields to capture attributes such as AI techniques, GD techniques, application domains, benefits, and limitations. These attributes are explained in Table 2. Each attribute was recorded for every study using an open coding system, allowing researchers to add new codes when necessary or select an existing code if it had already been identified in another study.

Table 2.

Explanation of the terms used to describe study attributes.

Each paper was reviewed by two researchers who independently coded these attributes. In cases of inconsistencies, a third researcher was consulted, and the final coding was determined based on a majority vote. This systematic process not only ensured alignment with the research questions but also improved the reliability and validity of the coding results by incorporating multiple perspectives and minimising individual biases. In the case that a paper was deemed insufficiently relevant after reviewing the full body of text, it was excluded from the final corpus. As described above, relevance was assessed based on whether the paper aligned with the review’s stated domain of the direct influence of AI on engineering function and form in GD.

3.4. Analysis

The analysis used a two-stage approach to draw conclusions from the final corpus. The first stage involved bibliometric analysis to examine trends, distribution, and relationships within the selected articles. This provided quantitative insights into publication years and sources. The most heavily represented sources are reported to provide readers with publishers to watch for similar research in the future.

The second stage was a thematic analysis that aimed to identify recurring themes, contributions, and limitations among the selected articles using the assigned codes. Publication frequency, applications, and prevalent AI and GD techniques are visualised using bar charts and proportional stacked charts to highlight temporal trends and emerging techniques. A pairwise analysis was also performed using the codes assigned to the attributes of the studies to examine how specific AI techniques were used in combination with GD methods. For example, the use of surrogate models with Genetic Algorithms (GAs) and design generation using GANs was quantified and contextualised within broader methodological trends. This dual analysis approach ensured a comprehensive understanding of the landscape of AI and GD, integrating quantitative and qualitative dimensions to effectively address research objectives.

4. Results

This section presents the findings, detailing the progression from the initial corpus selection to the final dataset and its subsequent analysis. The results are structured as follows: trends, methodologies, and insights. The composition of the initial corpus is described first, including bibliometric characteristics and source distributions. This is followed by a description of the systematic down-selection process that refined the dataset to a focused collection of relevant studies. Finally, an analysis of the final corpus highlights emerging themes, AI and GD techniques, application areas, and reported benefits and limitations.

4.1. Initial Corpus

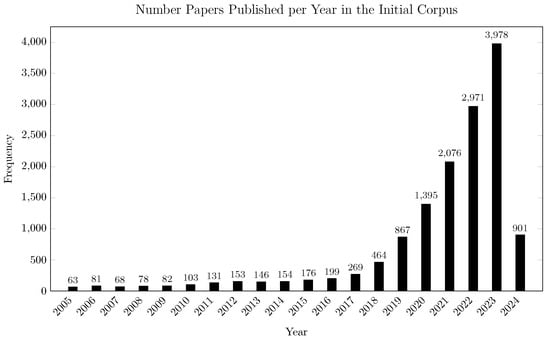

The initial search shown in Figure 4 returned 14,723 papers, which became 14,355 after the removal of duplicates. Meta-analysis of the initial corpus revealed that 69.1% of papers were published after 2021. The year 2024 is not well represented because of data collection occurring during this time. Figure 5 shows the publication rate over time, demonstrating a surge in popularity of the field and therefore its high relevance.

Figure 5.

Bar chart showing the frequency of publication year occurrence in the initial corpus.

The articles were published from 3353 sources, with 4.8% coming from the top five publications that contributed the most papers to the corpus. These top five publications are listed in Table 3.

Table 3.

Number of papers in the initial corpus attributed to the five most contributing publication sources.

4.2. Down-Selection

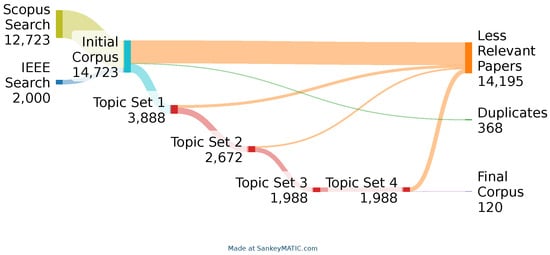

Three down-selection rounds were required following the process described in Section 3.2 before the finishing condition of all topics considered relevant was met. The corpus was then divided into 12 topics, each contributing 10 papers to a final corpus of 120 papers. Figure 6 illustrates this process, demonstrating the steady removal of less relevant studies.

Figure 6.

Sankey diagram of the paper selection process.

The full text of these 120 articles were read in their entirety. A subsequent round of filtering as per the methodology identified 32 as either out of scope or reviews themselves, or the full text was inaccessible. These were discarded from the final corpus, resulting in a corpus of 88. As opposed to comprising a representative cross-section of the initial corpus, these 88 papers were selected as the most relevant to our research questions by the down-selection process. The 12 topics produced by the final down-selection iteration are presented in Table 4 together with the articles related to that set that remained in the final corpus.

Table 4.

Overview of topics and respective papers.

4.3. Trends and Code Analysis

Following the process in Section 3.3, 88 articles were coded. This subsection presents both a meta-analysis of the entire corpus and a view of the themes that emerged in the assigned codes.

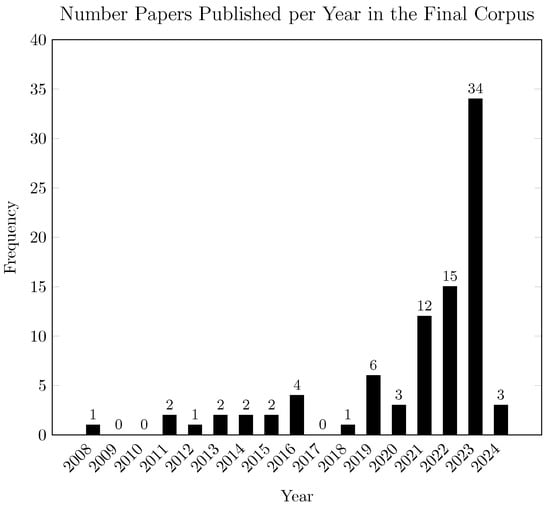

4.3.1. Bibliometric Trend Analysis

The analysis of publication data from the final corpus shows that the publication frequency has increased rapidly, indicating a growing interest in the intersection of AI and GD. Figure 7 demonstrates that 73.9% of articles in the final corpus have been published since the beginning of 2021. Furthermore, the number of authors and affiliated research groups per article increased from 2.81 and 1.52 in 2005 to 4.71 and 2.49 in 2024, respectively.

Figure 7.

Bar chart showing the frequency of publication year occurrence in the final corpus.

The articles in the final corpus come from 54 unique sources (journals/conference proceedings), with 21.6% from the top five most prevalent. Table 5 shows the number of papers from each of these top five. “Proceedings of the ASME Turbo Expo” provides the most papers of any single source. All its contributions from various authors are related to the use of AI surrogate models to reduce computational burden during the design of turbomachinery.

Table 5.

Number of articles in the final corpus attributed to the five most contributing publication sources.

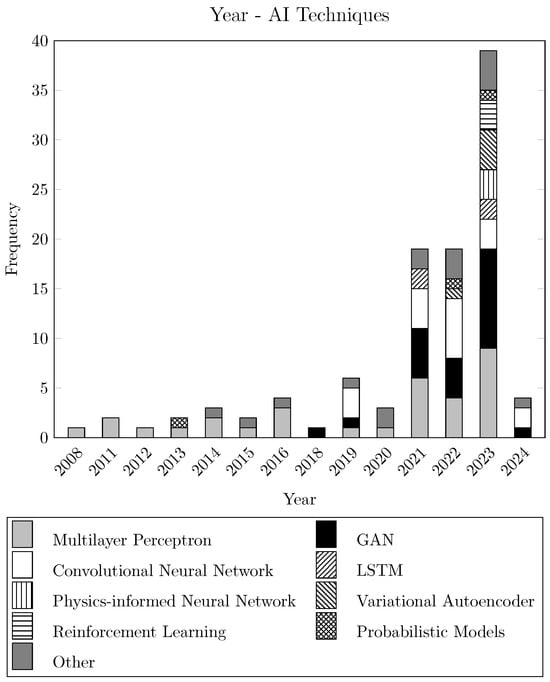

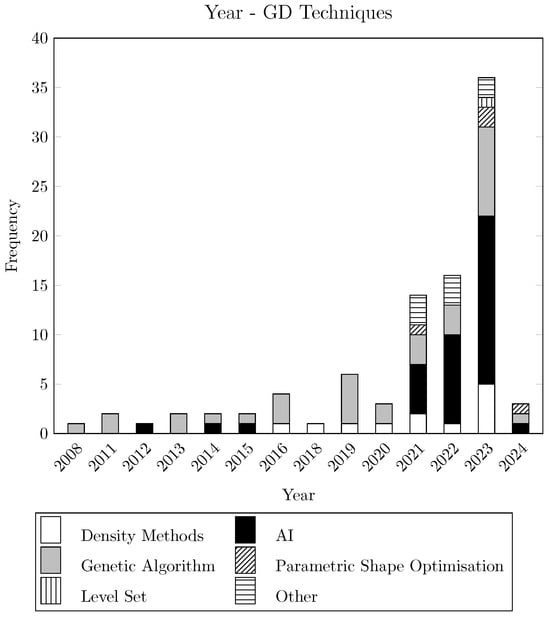

4.3.2. Techniques

This subsection examines the AI and GD techniques employed in the final corpus, their usage over time, and commonly co-occurring codes. Table 6 and Table 7 define and categorise all codes assigned to the two families of techniques.

Table 6.

The AI technique codes that were found in the final corpus. Note that some studies may have used more than one.

Table 7.

The GD technique codes that were found in the final corpus.

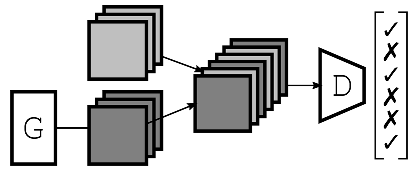

Figure 8 and Figure 9 show trends in the use of AI and GD techniques. Both figures demonstrate the dramatic increase in the use of AI to generate designs directly (direct design), primarily through GANs, since 2021. In contrast, the proportion of studies that used Multilayer Perceptron (MLP) and GA has decreased, illustrating how technological developments have provided new approaches for rapid design space exploration.

Figure 8.

Stacked histogram showing the number of each AI technique from each year. Note that multiple codes can apply to a single paper.

Figure 9.

Stacked histogram showing the number of each GD technique from each year. Note multiple codes can apply to a single paper.

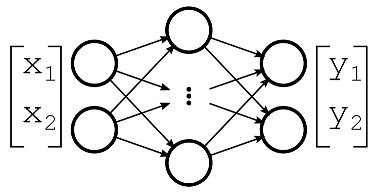

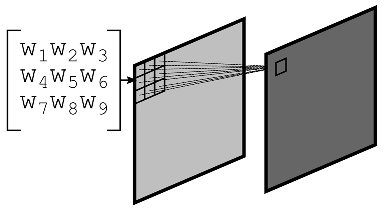

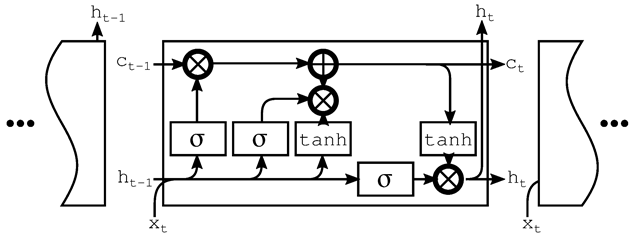

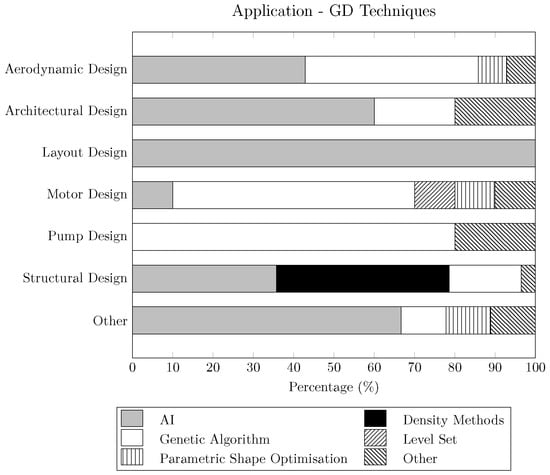

MLP emerged as the most frequently used AI model (32 papers, 34%). Although there has been a modest increase in their implementation over recent years, many contemporary papers have adopted other popular models: GANs (22 papers, 23.4%) and Convolutional Neural Networks (CNNs) (18 papers, 19.1%). Less frequently used models include the VAEs, Long Short-Term Memorys (LSTMs), Physics Informed Neural Networks (PINNs), and RLs, each appearing in <5% of the articles.

Of the articles in the final corpus, 35 (39.8%) used their chosen AI technique to directly generate designs. Table 7 shows how, in this case, the papers were assigned ‘AI’ for their GD technique code. GAs were the most commonly used technique traditionally associated with GD, seen in 33 (35.1%) of papers. Density methods for TO such as Solid Isotropic Material with Penalisation (SIMP) were used in 12 (12.8%) of papers.

The pairing of AI and GD techniques (where applicable) was also coded. Of the studies in the final corpus that used AI for direct generation, 19 of the 35 (54.3%) used a GAN, 9 (17.1%) an MLP, 5 (14.3%) a CNN, 3 (8.6%) a PINN, 3 (8.6%) a VAE, 2 (5.7%) an LSTM, 1 (2.9%) a Probabilistic Model (PM) and the remaining 5 (11.4%) used some other niche or hybrid AI approach. The most common AI technique used with a GA was an MLP (16 of 33, 48.5%), with CNNs (8 of 33, 24.2%) and VAEs (3 of 33, 9.1%) the next most popular. The literature in the final corpus did not show a consensus for any particular AI technique which operated well alongside density method techniques for GD, with GANs (3 of 12, 25.0%), CNNs (3 of 12, 25.0%) and MLPs (2 of 12, 16.7%) all used at similar rates. RLs, LSTMs and PINNs were each used only once (8.3%), whilst various other niche AI techniques were applied twice (16.7%).

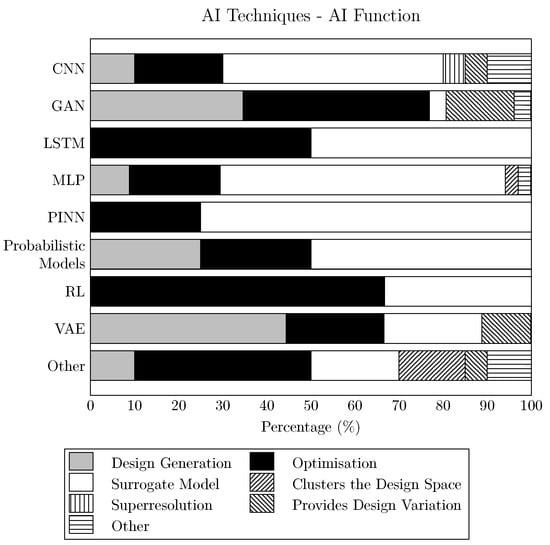

4.3.3. AI Function

The papers in the final corpus were found to use AI for a wide range of different functions. Table 8 lists the function codes and where they appeared in the corpus. A surrogate model was the most common use for AI, appearing in 43 (48.9%) of papers. AI was used for design optimisation in 30 (34.1%) papers, while 14 (15.9%) employed it to generate design solutions. Less common uses included design variation (i.e., generating a range of different designs), design similarity and clustering, and refining coarse simulations (super-resolution). There were also themes in the use of AI for specific functions when a specific GD technique was used. The most common combination was an AI surrogate model paired with a GA, appearing in 28 (31.8%) of articles. This pairing is discussed in detail in Section 5.3.

Table 8.

Description of the various functions performed by AI in the final corpus. Note that some studies may have used more than one.

The most common function of AI techniques for GD used GANs (19 papers, 21.6%) for direct design generation. Second, 10 papers (11.5%) used a CNN as a surrogate model. The third most common combination used MLPs (nine papers, 10.3%) for direct design generation. Figure 10 shows the mapping of the function of different techniques used in AI.

Figure 10.

Stacked histogram showing the proportional use of AI techniques for varying functions.

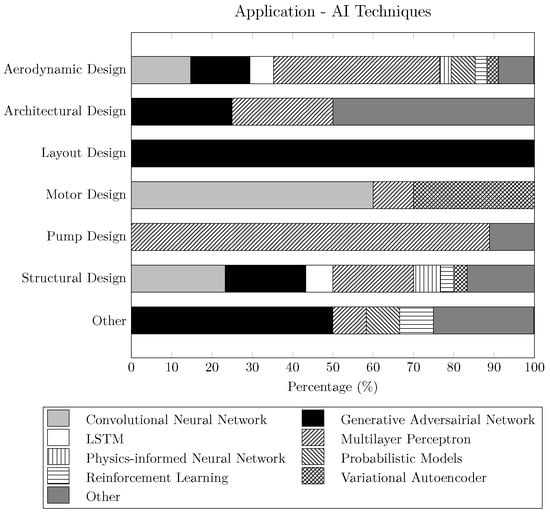

4.3.4. Applications

Table 9 lists the application found in the final corpus. Structural Design (27 papers, 30.7%) and Aerodynamic Design (26, 29.5%) were the two most common areas of application. For these, authors focussed on load-bearing components and aerofoils, respectively. Motor Design was investigated in nine (10.2%) of the papers. Researchers used electromagnetic simulations to create the optimal distribution of metal within motor rotors and stators. Pump Design was considered in nine papers (10.2%), where researchers used Computational Fluid Dynamics (CFD) to optimise the geometry of ducts and impellers. Five (5.7%) articles investigated architectural design, mainly using image generation to create floor plans [66,69]. Similarly, the final three (3.3%) studies focussed on more general layout design problems such as tower crane placement [71]. Figure 11 demonstrates which AI techniques were favoured in each of the identified application areas, whilst Figure 12 shows the favoured GD techniques.

Table 9.

The applications that the studies are focussed upon. This code was only assigned once per study.

Figure 11.

Stacked histogram showing the proportion of different AI techniques used across application areas.

Figure 12.

Stacked histogram showing the proportion of different GD techniques used across application areas.

4.3.5. Benefit Themes

This section summarises the reported benefits of using AI for GD. Table 10 documents the benefits associated with applying AI techniques to GD reported by the articles in the final corpus.

Table 10.

Description of the benefits found for using AI to enhance GD. Note that some studies may have used more than one.

The most widely reported benefit was speed, with 67 (76.1%) articles highlighting computational efficiency during inference. Typically, this was expressed as a time savings during inference compared to a baseline technique. For example, compare CFD with a surrogate model. In three articles, instead of simply saving time, the aim was to make a system fast enough to allow a user to interact with it iteratively in real time [69,95,113]. This category also included papers that reduced computational cost.

The second most commonly cited benefit, observed in 12 (13.6%) of papers, was the promotion of design diversity. Typically, this was achieved by learning a low-dimensional continuous distribution of solutions from a dataset using a VAE or GAN. Subsequently, samples could be sampled at intervals, with the results then optimised using traditional methods such as TO.

Less common benefits included six (5.8%) papers reporting improving the performance (in terms of the quality of the output) of a GD system and three (2.9%) reporting improved interpretability as a result of using AI. One paper reported generalisation as a benefit of their AI method, though this was in the context of improving existing approaches to using AI in TO where generalisation has been a limitation.

4.3.6. Limitation Themes

The articles in the final corpus reported a range of limitations and challenges regarding the application of AI to GD. Table 11 explains the codes assigned to categorise these limitations and references the relevant papers in the corpus.

Table 11.

Description of the limitations associated with using AI techniques for GD. Note that some studies may have used more than one. The code ’N/A’ is used where the paper did not discuss methodological limitations.

The two main categories of limitations that emerged from the analysis were (1) model accuracy and (2) data generation and model training costs.

Data and Training Costs: Training and data costs were mentioned in 50 (56.8%) of the papers. GANs, whilst popular, were reported as difficult to train [47,53,68,111]. A particular issue arises when the generator always fools the discriminator or vice versa, leading to a situation known as mode collapse, where gradients in training are almost zero and no improvement is made. The issue can be addressed using a Wasserstein GAN [126].

The cost of data generation was mentioned in 34 (38.6%) articles. To give an indication of the scale of the issue, Xu et al. [32] used 31,200 CFD simulations using OpenFOAM, and the work carried out by Zan et al. [109] was made possible by using China’s TianHe-1A national supercomputer.

PINNs are attractive for reducing the need for large amounts of data but were also highlighted as having lengthy training processes. Sun et al. [106] implemented a PINN that simultaneously acts as a surrogate model CFD and optimises the design parameters of an aerofoil. The use of a PINN reduced the number of training examples required to 200,000. However, the process was found to be less efficient than adjoint-based optimisation. The authors indicate that improving the PINN training process and hardware improvements could overcome this issue (although hardware improvements would likely also improve the adjoint-based baseline).

Finally, while more of a consideration than a limitation, 15 (17.0%) papers highlighted that souring their data from Finite Element Method (FEM) is a potential source of error, since it involves modelling a pre-existing model. Numerical solvers require significant expertise to enable them to accurately describe physical phenomena, and optimisers GD often do not reconsider parameters such as mesh type at each step [106]. This issue extends to many papers that use TO methods such as SIMP for data generation.

Accuracy and Stability: The accuracy of AI model predictions (usually in the context of surrogate models) was identified as a limitation in 28 (30%) of papers. Several authors specifically attributed inaccuracies to limitations inherent in their models’ loss functions, the metrics used for model training. For example, Ref. [102] employs a CNN UNet architecture for TO, where the model is trained on image representations of boundary conditions and initial stress and strain fields. The model predicts the optimal configuration of a 2D structure using the training data generated through SIMP. Although the loss function evaluates pixel-wise differences between SIMP data and predictions, this approach has notable limitations: minor variations in pixels can significantly impact structural performance (specifically stiffness). For example, altering a single-pixel value could completely compromise the integrity of a thin beam. Multiple articles [94,127,128] emphasise this misalignment between objective functions and loss functions.

Although many articles using AI as a surrogate model cited accuracy as an issue, many did not provide an assessment of its sources [44,84,85,91,110]. Although this is not necessarily an issue if FEM is used to verify the final design, the surrogate is what guides the design process and could limit the effectiveness of the generated designs [62].

4.3.7. Future Work

The future direction of work reported in the literature can provide insight into opportunities within the field. Table 12 describes the various goals that emerged from the final corpus.

Table 12.

The aims of future work identified in each study. Note that some studies may have more than one. The code ’N/A’ is used where the paper did not discuss future work.

The most frequently reported objective was algorithmic enhancement (33, 37.5%). This target covers the desire to address multiple technical limitations, such as poor output quality or limited performance and scope. Reference [50], for example, discusses the potential for light-weighting performance increases if different TO approaches are incorporated into the existing architecture.

Objectives such as new constraints and additional goals (22,25.0%) involve evaluating the efficacy of methods under further requirements, such as minimum strut widths [52]. Application and domain expansion (21,23.9%) refers to applying the validated approach to a new problem to further assess its effectiveness. For example, Ref. [3] discusses the potential of their surrogate modelling technique to be applied to multi-physics structural design techniques. Many investigations such as [37] and [100] have the specific target to extend to a 3D environment (12, 13.6%), developing workable 3D structures as opposed to 2D schematics.

The issues that the overall literature felt least compelled to address are related to further validation and testing (7, 8.0%) and ensuring outcome manufacturability (3, 3.4%). Meanwhile, 20 (22.7%) of the articles did not include any notes of desired future work.

5. Discussion

The publication data and codes extracted from the final corpus provide the opportunity to evaluate trends and themes in applications and techniques in the field of applying AI to GD. The following subsections discuss these themes, provide the reasoning for them, and establish future studies to advance the field.

5.1. Technique Trends

AI techniques trained on previous designs learn the what not the why. Generated designs are therefore not physically derived. The designs used in training lack context. Some articles addressed this by including context in training. For example, TO included initial stress fields as input to generation or conditional GAN methods in which design parameters such as angle of attack and Mach number were paired with wing profiles in training. Such approaches aim to allow researchers to ensure generation can be physically valid in the future.

Related is the idea that AI/ML methods are optimisers. They produce a single design for a given input. However, in engineering, there are often multiple objectives where the relative importance cannot be specified, so generating a Pareto front is desirable. The modern literature is beginning to reflect this with an increasing frequency of studies that aim to generate multiple solutions.

Future directions and gaps derived from the literature looked at the non-intersection of AI and GD: What is each field doing and using that the other is not?

In this regard, there is a notable lack of papers using Large Language Models (LLMs) for design in our final corpus despite being popular in the field of Generative AI at present. For example, a recent article used LLMs to find better algorithms for bin packing [129]. The discrepancy could be due to the requirement to represent the system as a sequence and the difficulty in handling numeric quantities with precision [130]. In domains where these challenges are not present, such as digital circuit design, where engineers write code using hardware description languages such as Verilog to define designs, there are industrial case studies demonstrating using LLMs for design [131]. Taking a similar approach, Wu et al. [132] presented a workshop paper applying LLMs to design by using them to generate the code underlying Computer Aided Design (CAD) models and more recently incorporating multimodal models [133].

Diffusion models have overtaken GAN in the domain of image generation. Some very recent papers have applied these to TO [134]. We anticipate seeing more work using diffusion models in engineering in the future. We note that diffusion models are not restricted to pixel- and voxel-based representations. Xu et al. [135] used diffusion models to predict the properties of nodes in a hierarchical tree, allowing them to generate B-rep CAD models. Adapting models to data structures that better represent engineering designs could address some of the limitations reported in articles in our corpus, such as the overlap of parts in layout design.

Explainable AI is a significant topic within Generative AI, although it appeared in only one paper from our dataset, where it was used to enhance the design process [82]. The importance of explainability varies depending on the contribution of AI. For surrogate models, accuracy remains the primary consideration. When generating designs, understanding the rationale becomes crucial. For safety-critical applications, such as medical devices, documenting the rationale is part of the required certification process.

Within explainability, separate from the rationale, is the concept of confidence. For tasks like predicting the optimal topology from a load case, the accuracy of the predictions may vary. Current techniques do not provide a measure of the likelihood that their predictions are accurate [51,95].

None of the papers in the final corpus used AI techniques that could not be classified as ML (e.g., expert/rule-based systems or fuzzy-logic systems). This was not explicitly down-selected for. The fact represents both the relative advantages of ML techniques and their ubiquity as topics of research.

5.2. Application Trends

The application of AI in GD spans multiple domains, each with unique challenges and requirements. Aerodynamic design is one of the most prominent areas, with 26 (29.5%) studies exploring its integration with AI and GD. Researchers have focused on improving the performance of fluid-interacting surfaces such as aerofoils and turbine blades. Applications include optimising aircraft wing shapes for improved lift-to-drag ratios [60,104] and improving gas turbine efficiency by refining blade geometries [103,110]. These efforts align with the increasing need for fuel-efficient and high-performance aerodynamic components in the aviation, energy, and automotive industries.

Structural design accounts for the largest share of studies (27 papers, 30.7%) and focusses on load-bearing components in engineering. Applications range from optimising material distribution in mechanical structures [52,54] to improving the weight efficiency of aerospace and automotive parts [73,95]. Several studies aim to develop structures that maintain high strength while minimising material usage [98,102]. A recurring theme in structural applications is the balance between design freedom and manufacturability, particularly in additive manufacturing and topology optimisation [3,100].

Motor design has been another major area of research, with nine studies focussing on the optimisation of electrical machine stators and rotors. Researchers have investigated AI-driven techniques to improve motor efficiency and performance by refining the shapes of magnetic cores and winding patterns [5,80,85]. The objective is often to achieve a higher torque density and reduced energy losses, which is crucial for applications in electric vehicles and industrial automation [79,81].

Pump design has also received significant attention, with nine studies aiming to optimise the efficiency and longevity of fluid actuation devices. These studies include work on centrifugal, axial and mixed-flow pumps, where researchers have sought to minimise turbulence and cavitation [86,91,93]. Applications span water distribution, aerospace fuel systems, and industrial processing, where optimised pump geometries contribute to energy savings and reduced wear [87,88].

Architectural design, represented by five studies, explores AI-driven methods to generate innovative building structures and layouts. These studies typically focus on optimising spatial configurations to improve functionality, aesthetics, and sustainability [66,75]. Applications include the proposal of floor plans and external structures that optimise natural lighting and thermal performance [69,113]. The ability of AI to rapidly generate multiple design alternatives is particularly useful in urban planning and modular construction [76]. Three studies explore layout design primarily in the context of industrial and civil engineering. These studies have focused on optimising 2D layouts for factories, tower crane placements, and floor plans [68,71].

Finally, nine studies investigate niche applications outside the major categories. These include creative product concepts and the generation of product shapes [70,72,114,115]. The diversity underscores the broad applicability of AI in Generative Design across engineering disciplines.

5.3. Technique–Function Pairings

The selection of computational techniques for design and optimisation is often driven by the need to balance computational efficiency with accuracy. Two key pairings emerge from the literature, firstly, GAs with surrogate models and, secondly, GANs for design generation. These pairings are justified by the distinct strengths of each technique and the specific challenges they aim to address.

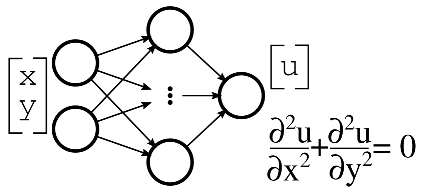

Genetic Algorithms and Surrogate Models: GAs require that the fitness of each member of a population of designs (often a large one) is evaluated every generation. The authors of the studies using GAs were motivated by the speed of surrogate models, which can be orders of magnitude faster than traditional solvers, using them to address the computational burden of GAs. However, many researchers stated the lower accuracy of the surrogate model (9 of 28, 32%, discussed further in Section 4.3.6), the cost to collect the training data (often carried out by running traditional solvers specifically for the purpose), and the cost of training the model as limitations (20 of 28, 71%). Therefore, there is a complex trade-off in determining whether training a surrogate model is worthwhile. Whether the data are available or require generation using FEM, the efficiency of training and the generalisability (and therefore the likelihood of reuse) of the model are important factors. Two papers directly addressed generalisability using ML to accelerate traditional FEM rather than replace it. The FEM is performed at a lower resolution to make it faster. The result can then be directly upscaled [100] or the shape functions of the coarse-resolution elements can be estimated based on the values of the high-resolution elements using ML [3]. One study used PINNs to embed the physics that is being modelled (in the form of a Partial Differential Equation (PDE)) into the loss function to train their network [94]. This eliminated the need for labelled training data but increased the total amount of computational time 34-fold.

CNNs were the dominant approach for surrogate models across multiple fields, from turbine blades [32,103] to TO [95,97], to motor design [81,136]. Seven papers highlighted that the quality and distribution of training data aer crucial when developing a surrogate model. The data, usually generated through FEM simulations, must adequately cover the state space of the system. The process of planning a useful spread is sometimes referred to as ‘Design of Experiments’. Getting this right is an important step; poor data coverage can result in inaccurate surrogate models, while excessive data generation can defeat the surrogate model’s primary purpose of reducing computing costs. Some researchers simply reported that they generated data to “cover the possible…conditions” [97]. Others went into more detail. Popular methods for ensuring this were Latin hypercube sampling [39,109,112] and the D-optimal method [59].

Generative Adversarial Networks for Design: In the cases where AI is used directly as a design method, it is mainly used as an optimisation tool with secondary use for direct generation. Furthermore, seven studies used AI for both generation and as a surrogate model.

GANs were the most commonly used architecture when using AI to directly generate designs (9 of 14, 64%). Here, studies stated their motivation for using a GAN as a desire to create a wider variety of designs [53,54,72,104]. GANs were originally developed for image generation, perhaps explaining why earlier work using GANs in the final corpus (2019) focused on aesthetics [53]. The output of these papers is intended to be the starting point for a downstream process rather than to generate the final geometry. More recently, physical properties such as pressure, stress, and strain have been represented as images and GAN models have been used to generate physics-informed designs [48]. Similarly, GANs have recently been used in more abstract representations such as graph adjacency matrices [69].

As stated in [19], image-based representations have limitations. In the papers in our final corpus, researchers recorded issues such as pixelation, aliasing, and fuzzy edges. As such, a recurring theme is how to produce crisp outputs. Post-processing is one option that uses noise-reduction neural networks [67] or hand-coded rules [66]. This issue is avoided by choosing an alternate representation in Wang et al. [104], Yi and Deng [105], Kumar and Vadlamani [137]. All of them use vectors of 2D points to represent the wing cross-sections. Khan et al. [138] were motivated by needing to generate smooth geometry for ship hulls and investigated alternative ways to represent their geometry in a way that was better integrated with the parametric designs commonly used in research and industry. The authors devised a domain-specific system for distributing points across the surface of the hulls and created a tensor of their positions in 3D space. They also then calculated and appended geometric moments (mean location, skew, kurtosis, etc.) to enrich the geometric representation. The tensors generated by a GAN trained on this richer representation could be used to create a parametric NURBS surface.

GANs comprise two networks trained adversarially. The generator mimics the training data, and the discriminator differentiates the training data from the output of the generator. An article also extended the approach to provide a mechanism for enforcing constraints [47,52]. A second discriminator that identified physical inconsistencies was added in parallel to the first, rewarding the generator for physically plausible designs. This approach incentivised meeting the geometric constraints rather than enforcing them. The authors reported that including the second discriminator could detrimentally affect other aspects of the design as the loss signals from the discriminators could essentially compete.

A comparison across domains reveals that AI–GD technique pairings are closely influenced by domain-specific characteristics such as the nature of the data, design constraints and performance objectives. For example, in aerodynamic design, MLPs are frequently applied to approximate high-cost CFD simulations, enabling efficient design iteration [139]. In motor design, CNNs dominate due to their ability to process spatial simulation data such as magnetic flux [82,136]. VAEs are also used in this context due to their ability to encode complex spatial data into a lower-dimensional latent space, enabling structured exploration and variation of designs. In contrast, in applications that require design exploration or creativity, such as layout design, GANs are adopted to produce diverse and novel solutions. These patterns suggest that technique selection is not uniform across applications, but instead aligns with the functional role within the process. Also within the same domain, multiple AI–GD techniques are often applied, each offering distinct advantages depending on the nature of the design task and available data, illustrating that technique selection within a domain is often driven by trade-offs between model complexity, data availability and the design task in hand.

Furthermore, the timeline of published studies shows that newer generative techniques have increasingly expanded into more constrained domains. From 2021 onwards, GANs began appearing not only in creative fields but also in domains like structural and aerodynamic design. This shift shows a growing maturity and reliability of generative models.

5.4. Opportunities

This review has focused on the intersection of AI and GD within engineering. Looking beyond the intersection, what is relevant in AI and not yet being used in GD, we can make predictions about potential areas for future work. The remainder of this subsection therefore develops opportunities for future research within the field.

The field could also benefit from better approaches to handling combinatorial complexity [140]. Neural-guided search presents a promising direction, particularly in adapting diffusion models and transformers to engineering structures. However, this requires solving the challenge of translating between neural/pixel-based representations and engineering-specific formats. Current research is exploring ways to bridge this gap while maintaining the utility of the generated designs.

Following trends in the fields of text and image generation, it seems likely that diffusion models will begin to be used for Generative Design within engineering [141,142]. However, a significant challenge remains: many of the modern tools (GANs, diffusion models, and transformers) are designed for images/voxels and sequences, driven by the abundance of text and images available on the internet. These formats are not commonly used to represent designs in industry. However, diffusion models are not limited to image generation, so future work should either develop diffusion models for engineering data or standardise methods to represent engineering data in image formats.

The first papers using the mechanisms of LLMs (transformers and self-attention) with engineering data are being published, and we predict that this field will grow rapidly, following the trend of general AI development [132,133,143,144]. These model architectures use a sequence representation, which can be problematic for engineering designs. One way to overcome this, and to make use of pre-training, is to use LLMs to generate code that describes a parametric design. Although the design is not a sequence, the code can be represented as one. This is sometimes referred to as a program-centric approach. Researchers have used approaches based on GA to search for mathematical proofs. There is also the opportunity to fine-tune LLMs to produce better programmes using RL as discussed in [145]. This approach could allow AI systems to better learn the why as well as the what. An investigation in this direction would likely require integration with a simulation tool such as a physics engine or a Computer Aided Manufacturing (CAM) studio.

The real-world feasibility of the results of GD poses a significant barrier to its widespread adoption [9]. The lack of studies that aim to use AI to improve the manufacturability of GD results is therefore a significant omission. Applying manufacturing constraints to the GD process is a non-trivial task, requiring the capturing of complex logical and geometric relationships. AI tools such as MLPs are particularly suited to problems of this nature. A potential investigation could focus, for example, on the integration of an MLP manufacturability checker into the final stages of a GD optimisation. Adjacent is the lack of consideration for the use of standard components within designs. This would enable GD to produce more economically feasible system-level outcomes.

5.5. Evaluation of Our Approach

In this paper, we used a novel combination of SPECTER2 embeddings and k-means clustering to identify articles relevant to topics of interest. The method proved useful in identifying papers across fields using different terminology.

A limitation of the method is that disparate papers are connected by a chain of closely related papers, approximating a continuum. As such, drawing a line between sufficiently relevant and less relevant papers is a challenge.

Secondly, this approach represents the distance between two papers with a single scalar number (the L2 norm of the difference in SPECTER2 embeddings). However, papers may share similarities across multiple dimensions—they could employ similar methods but focus on different application areas, or vice versa. In the future, it may be possible to cluster papers on several metrics that correspond to the attributes (technique, AI function, etc.) related to the research questions and structure of the review. Embeddings based on the whole text rather than just the title and abstract may be beneficial but are more labour-intensive to generate and require more computing resources.

Further, the k-means method can struggle to form meaningful clusters for high-dimensional vectors since the range in L2 norm may be small compared to the absolute value. The SPECTER2 embeddings used in this review are 768-dimensional. To confirm that this did not overly impact the results of this review, a dimension-reduction procedure (UMAP [146]) was used to project the embeddings into ten dimensions. Both the low- and high-dimensional embeddings were clustered, and the output was found to be sufficiently similar.

A sensitivity analysis was performed to validate the robustness of the selection process. The initial search terms shown in Figure 4 were varied, and the results of different search strategies were compared. Using the same comprehensive search term with multiple keywords related to AI and GD carried out at 2024-09-29T08:25:43+00:00, a total of 17,988 papers were retrieved. The overlap between the IEEE and Scopus databases was 25.61% and 79.52%, respectively, resulting in a combined overlap of 74.40% without weighting for database size. This provides confidence that the final corpus used in this review is indicative of wider literature at the time of writing.

The embeddings were based on the title, abstract, and keywords of the articles, not the full text. Abstracts may omit methodological details, how the article positions itself within the literature, limitations, and discussion points. As a result, these factors may not be represented by the embeddings used to group and select the articles for this review.

This review is also limited to the uses of AI for GD represented in the academic literature. In recent years, a number of commercial GD toolchains have been released. Most notable is Autodesk’s Dreamcatcher [147]. A number of these use the term AI to explain their tool’s operation. Although this is likely the broader use of AI and not referring to the use of ML or neural networks as part of the generation process, more work is required to determine the contribution of AI to industrial GD tools. However, this will be difficult due to their proprietary nature.

6. Conclusions

This structured review examined the intersection of AI and GD in engineering design, analysing 88 articles to map the state of the field and identify emerging trends and opportunities. The review provides the following contributions:

- A comprehensive survey of trends in the use of AI and GD techniques in a wide range of applications. The key findings from this are:

- There has been a significant increase in research activity at this intersection, with 72.7% relevant articles published since 2021 compared to the period from 2008 to 2020. This reflects both growing interest in the field and technological advancement.

- The analysis reveals two primary applications of AI in GD: as surrogate models to accelerate existing optimisation processes and for direct design generation.

- Although MLPs remains the most commonly used AI technique (34% of the articles), there has been a shift toward modern approaches like GANs (23.4%) and CNNs (19.1%) in the past 5 years. MLPs in recent research tended to be used as components in larger systems. This evolution mirrors broader trends in AI research, although with a lag between advances in general AI and their application to engineering design.

- The review identified persistent challenges across the field. Data generation and training costs were cited as limitations in 56.8% of the articles, while model accuracy concerns were raised in 30%. These challenges particularly affect surrogate modelling approaches, where researchers must carefully balance the computational costs of training against potential performance benefits.

- Identification of opportunities and priorities for further research on the use of AI to enhance GD:

- Training of foundation surrogate models capable of generalising to multiple scenarios could address limitations in computational cost and accuracy.

- The development of GenAI systems capable of synthesis using structured engineering data formats.

- Investigation into the use of unsupervised learning systems to better capture and reproduce the physical meaning behind design features.

- Improvement in the manufacturability of GD outcomes.

Author Contributions

Conceptualization, B.H., O.P., J.R., E.B., M.G. and J.G.; Methodology, O.P., J.R., E.B., M.G. and J.G.; Software, O.P., J.R., E.B. and J.G.; Validation, O.P., J.R. and E.B.; Formal Analysis, O.P., J.R. and E.B.; Investigation, O.P., J.R. and E.B.; Data Curation, O.P., J.R. and E.B.; Writing—original draft, O.P., J.R. and E.B.; Writing—review and editing, O.P., J.R., E.B., M.G., J.G., D.B., A.N. and B.H.; Visualization, O.P., J.R. and E.B.; Supervision, B.H., M.G., J.G., D.B. and A.N.; Project administration, B.H., O.P., J.R., E.B. and M.G.; Resources, B.H.; Funding acquisition, B.H. All authors have read and agreed to the published version of the manuscript.

Funding

EPSRC DTP 2020-2021 University of Bristol Grant Ref EP/T517872/1 and UKRI CDT in Interactive AI at the University of Bristol EP/S022937/1.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

There are no competing interests to declare.

References

- Schmit, L.A. Structural Design by Systematic Synthesis. In Proceedings of the Second National Conference on Electronic Computation; ASCE: Reston, VA, USA, 1960. [Google Scholar]

- Caetano, I.; Santos, L.; Leitão, A. Computational Design in Architecture: Defining Parametric, Generative, and Algorithmic Design. Front. Archit. Res. 2020, 9, 287–300. [Google Scholar] [CrossRef]

- Huang, M.; Cui, T.; Liu, C.; Du, Z.; Zhang, J.; He, C.; Guo, X. A Problem-Independent Machine Learning (PIML) Enhanced Substructure-Based Approach for Large-Scale Structural Analysis and Topology Optimization of Linear Elastic Structures. Extrem. Mech. Lett. 2023, 63, 102041. [Google Scholar] [CrossRef]

- Wang, Z.; Melkote, S.; Rosen, D.W. Generative Design by Embedding Topology Optimization into Conditional Generative Adversarial Network. J. Mech. Des. 2023, 145, 111702. [Google Scholar] [CrossRef]

- Parekh, V.; Flore, D.; Schops, S. Variational Autoencoder-Based Metamodeling for Multi-Objective Topology Optimization of Electrical Machines. IEEE Trans. Magn. 2022, 58, 7500604. [Google Scholar] [CrossRef]

- Shrestha, P.R.; Timalsina, D.; Bista, S.; Shrestha, B.P.; Shakya, T.M. Generative Design Approach for Product Development. In Proceedings of the the 7th International Conference on Engineering, Applied Sciences and Technology: (ICEAST2021), Bangkok, Thailand, 1–3 April 2021; p. 020008. [Google Scholar] [CrossRef]

- Mihály, C.; Ildikó, D.M. Mass Reduction of the Upright of a Racing Car with Innovative Methods. Acta Polytech. Hung. 2024, 21, 253–264. [Google Scholar] [CrossRef]

- Ntintakis, I.; Stavroulakis, G.E.; Sfakianakis, G.; Fiotodimitrakis, N. Utilizing Generative Design for Additive Manufacturing. In Recent Advances in Manufacturing Processes and Systems; Dave, H.K., Dixit, U.S., Nedelcu, D., Eds.; Springer Nature: Singapore, 2022; pp. 977–989. [Google Scholar] [CrossRef]

- Peckham, O.; Elverum, C.W.; Hicks, B.; Goudswaard, M.; Snider, C.; Steinert, M.; Eikevåg, S.W. Investigating and Characterizing the Systemic Variability When Using Generative Design for Additive Manufacturing. Appl. Sci. 2024, 14, 4750. [Google Scholar] [CrossRef]

- Research, S. Global Generative Design Market Size, Trends, Forecast to 2030. Available online: https://straitsresearch.com/report/generative-design-market (accessed on 12 November 2024).

- Elsevier. Scopus—Document Search. Available online: https://www.scopus.com/search/form.uri?display=basic&zone=header&origin=#basic (accessed on 1 November 2024).

- Yüksel, N.; Börklü, H.R.; Sezer, H.K.; Canyurt, O.E. Review of Artificial Intelligence Applications in Engineering Design Perspective. Eng. Appl. Artif. Intell. 2023, 118, 105697. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet Classification with Deep Convolutional Neural Networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- He, Z.; Wang, Y.H.; Zhang, J. Generative AIBIM: An Automatic and Intelligent Structural Design Pipeline Integrating BIM and Generative AI. Inf. Fusion 2025, 114, 102654. [Google Scholar] [CrossRef]

- Sengar, S.S.; Hasan, A.B.; Kumar, S.; Carroll, F. Generative Artificial Intelligence: A Systematic Review and Applications. Multimed. Tools Appl. 2024. [Google Scholar] [CrossRef]

- BendsOe, M.P. Optimal Shape Design as a Material Distribution Problem. Struct. Optim. 1989, 1, 193–202. [Google Scholar] [CrossRef]

- Bernal, M.; Haymaker, J.R.; Eastman, C. On the Role of Computational Support for Designers in Action. Des. Stud. 2015, 41, 163–182. [Google Scholar] [CrossRef]

- Jenis, J.; Ondriga, J.; Hrcek, S.; Brumercik, F.; Cuchor, M.; Sadovsky, E. Engineering Applications of Artificial Intelligence in Mechanical Design and Optimization. Machines 2023, 11, 577. [Google Scholar] [CrossRef]

- Regenwetter, L.; Nobari, A.H.; Ahmed, F. Deep Generative Models in Engineering Design: A Review. J. Mech. Des. 2022, 144, 071704. [Google Scholar] [CrossRef]

- Khanolkar, P.M.; Vrolijk, A.; Olechowski, A. A Case Study of the Decision Making Behind the Automation of a Composites Based Design Process. Proc. Des. Soc. 2023, 3, 49–58. [Google Scholar] [CrossRef]

- Kretzschmar, M.; Dammann, M.P.; Schwoch, S.; Braun, F.; Saske, B.; Paetzold-Byhain, K. Evaluating the Role of Generative AI in Product Development and Design—A Systematic Review. In Proceedings of the DS 130: Proceedings of NordDesign 2024, Reykjavik, Iceland, 12–14 August 2024; pp. 21–30. [Google Scholar] [CrossRef]

- Shin, S.; Shin, D.; Kang, N. Topology Optimization via Machine Learning and Deep Learning: A Review. J. Comput. Des. Eng. 2023, 10, 1736–1766. [Google Scholar] [CrossRef]

- Cheng, H.; Yi, W.; Ji, L. Multi-Point Optimization Design of High Pressure-Ratio Centrifugal Impeller Based on Machine Learning. In Proceedings of the Volume 2D: Turbomachinery, Virtual, Online, 21–25 September 2020; p. V02DT38A009. [Google Scholar] [CrossRef]

- Singh, A.; D’Arcy, M.; Cohan, A.; Downey, D.; Feldman, S. SciRepEval: A Multi-Format Benchmark for Scientific Document Representations. In Proceedings of the 2023 Conference on Empirical Methods in Natural Language Processing, Singapore, 6–10 December 2023; pp. 5548–5566. [Google Scholar] [CrossRef]

- Asmussen, C.B.; Møller, C. Smart Literature Review: A Practical Topic Modelling Approach to Exploratory Literature Review. J. Big Data 2019, 6, 93. [Google Scholar] [CrossRef]

- Aguirre, A.M.G.; Robledo, S.; Zuluaga, M. Topic Modeling: Perspectives From a Literature Review. IEEE Access 2023, 11, 4066–4078. [Google Scholar] [CrossRef]

- Wong, A.; Cheng, F.W.Y.; Keung, A.; Hercules, Y.; Garcia, M.A.; Lim, Y.W.; Pham, L. An Iterative Approach to Topic Modelling. arXiv 2024, arXiv:2407.17892. [Google Scholar] [CrossRef]

- Li, D.; Wu, K.; Lei, V.L. Applying Topic Modeling to Literary Analysis: A Review. Digit. Stud. Lang. Lit. 2024, 1, 113–141. [Google Scholar] [CrossRef]

- Lloyd, S. Least Squares Quantization in PCM. IEEE Trans. Inf. Theory 1982, 28, 129–137. [Google Scholar] [CrossRef]

- MacQueen, J. Some Methods for Classification and Analysis of Multivariate Observations. In Proceedings of the Fifth Berkeley Symposium on Mathematical Statistics and Probability, Volume 1: Statistics, Berkeley, CA, USA, 21 June–18 July 1965; University of California Press: Berkeley, CA, USA, 1967; Volume 5, pp. 281–298. [Google Scholar]

- Arvai, K. Zenodo Kneed. 2020. Available online: https://doi.org/10.5281/zenodo.6496267 (accessed on 14 January 2025).

- Xu, J.; Wang, L.; Yuan, J.; Shi, J.; Wang, Z.; Zhang, B.; Luo, Z.; Tan, A.C. A Cost-Effective CNN-BEM Coupling Framework for Design Optimization of Horizontal Axis Tidal Turbine Blades. Energy 2023, 282, 128707. [Google Scholar] [CrossRef]

- Li, Y.; Yi, Y.K. Optimal Shape Design Using Machine Learning for Wind Energy and Pressure. J. Build. Eng. 2023, 70, 106337. [Google Scholar] [CrossRef]

- Gisbert, F.; Cadrecha, D.; Quintanal, J.; Sotillo, A.; Pueblas, J.; Serrano, A.; Puente, R.; Corral, R. Adapting Artificial Neural Networks Training Algorithms to Adjoint-Based Aerodynamic Shape Optimization. In Proceedings of the Volume 13D: Turbomachinery—Multidisciplinary Design Approaches, Optimization, and Uncertainty Quantification, Boston, MA, USA, 26–30 June 2023; Radial Turbomachinery Aerodynamics. Unsteady Flows in Turbomachinery: Boston, MA, USA, 2023; p. V13DT34A021. [Google Scholar] [CrossRef]

- Xu, X.; Huang, X.; Bi, D.; Zhou, M. A Combined Artificial-Intelligence Aerodynamic Design Method for a Transonic Compressor Rotor Based on Reinforcement Learning and Genetic Algorithm. Appl. Sci. 2023, 13, 1026. [Google Scholar] [CrossRef]

- Ghosh, S.; Anantha Padmanabha, G.; Peng, C.; Andreoli, V.; Atkinson, S.; Pandita, P.; Vandeputte, T.; Zabaras, N.; Wang, L. Inverse Aerodynamic Design of Gas Turbine Blades Using Probabilistic Machine Learning. J. Mech. Des. 2021, 144, 021706. [Google Scholar] [CrossRef]

- Zhou, H.; Yu, K.; Luo, Q.; Luo, L.; Du, W.; Wang, S. Design Methods and Strategies for Forward and Inverse Problems of Turbine Blades Based on Machine Learning. J. Therm. Sci. 2022, 31, 82–95. [Google Scholar] [CrossRef]

- Ghosh, S.; Andreoli, V.; Padmanabha, G.A.; Peng, C.; Atkinson, S.; Pandita, P.; Vandeputte, T.; Zabaras, N.; Wang, L. A Probabilistic Machine Learning Framework for Explicit Inverse Design of Industrial Gas Turbine Blades. In Proceedings of the Volume 9B: Structures and Dynamics—Fatigue, Fracture, and Life Prediction; Probabilistic Methods; Rotordynamics; Structural Mechanics and Vibration, Virtual, Online, 7–11 June 2021; p. V09BT27A003. [Google Scholar] [CrossRef]

- Zeinalzadeh, A.; Pakatchian, M. Evaluation of Novel-Objective Functions in the Design Optimization of a Transonic Rotor by Using Deep Learning. Eng. Appl. Comput. Fluid Mech. 2021, 15, 561–583. [Google Scholar] [CrossRef]

- Bohara, R.P.; Linforth, S.; Thai, H.T.; Nguyen, T.; Ghazlan, A.; Ngo, T. Multi-Objective Bulk Scale Optimisation of an Auxetic Structure to Enhance Protection Performance. Eng. Struct. 2023, 280, 115729. [Google Scholar] [CrossRef]

- Nasrullah, A.I.H.; Puji Santosa, S.; Widagdo, D.; Arifurrahman, F. Structural Lattice Topology and Material Optimization for Battery Protection in Electric Vehicles Subjected to Ground Impact Using Artificial Neural Networks and Genetic Algorithms. Materials 2021, 14, 7618. [Google Scholar] [CrossRef]

- Liu, K.; Xu, Z.; Detwiler, D.; Tovar, A. Optimal Design of Cellular Material Systems for Crashworthiness. In Proceedings of the SAE 2016 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2016. SAE Technical Paper 2016-01-1396. [Google Scholar] [CrossRef]

- Liu, K.; Tovar, A.; Nutwell, E.; Detwiler, D. Thin-Walled Compliant Mechanism Component Design Assisted by Machine Learning and Multiple Surrogates. In Proceedings of the SAE 2015 World Congress & Exhibition, Detroit, MI, USA, 21–23 April 2015. SAE Technical Paper 2015-01-1369. [Google Scholar] [CrossRef]

- Choi, J.; Kim, H.; Noh, T.; Kang, Y.J.; Noh, Y. Digital Twin Data-Driven Multi-Disciplinary and Multi-Objective Optimization Framework for Automatic Design of Negative Stiffness Honeycomb. Int. J. Precis. Eng. Manuf. 2023, 24, 1453–1472. [Google Scholar] [CrossRef]

- Bucher, M.J.J.; Kraus, M.A.; Rust, R.; Tang, S. Performance-Based Generative Design for Parametric Modeling of Engineering Structures Using Deep Conditional Generative Models. Autom. Constr. 2023, 156, 105128. [Google Scholar] [CrossRef]

- Venugopal, V.; Anand, S. Structural and Thermal Generative Design Using Reinforcement Learning-Based Search Strategy for Additive Manufacturing. Manuf. Lett. 2023, 35, 564–575. [Google Scholar] [CrossRef]

- Almasri, W.; Danglade, F.; Bettebghor, D.; Adjed, F.; Ababsa, F. A Data-Driven Topology Optimization Approach to Handle Geometrical Manufacturing Constraints in the Earlier Steps of the Design Phase. Procedia CIRP 2023, 119, 377–383. [Google Scholar] [CrossRef]

- Kazemi, H.; Seepersad, C.C.; Alicia Kim, H. Multiphysics Design Optimization via Generative Adversarial Networks. J. Mech. Des. 2022, 144, 121702. [Google Scholar] [CrossRef]

- Fei, Y.; Liao, W.; Huang, Y.; Lu, X. Knowledge-Enhanced Generative Adversarial Networks for Schematic Design of Framed Tube Structures. Autom. Constr. 2022, 144, 104619. [Google Scholar] [CrossRef]

- Kallioras, N.A.; Lagaros, N.D. MLGen: Generative Design Framework Based on Machine Learning and Topology Optimization. Appl. Sci. 2021, 11, 12044. [Google Scholar] [CrossRef]

- Hertlein, N.; Buskohl, P.R.; Gillman, A.; Vemaganti, K.; Anand, S. Generative Adversarial Network for Early-Stage Design Flexibility in Topology Optimization for Additive Manufacturing. J. Manuf. Syst. 2021, 59, 675–685. [Google Scholar] [CrossRef]

- Almasri, W.; Bettebghor, D.; Ababsa, F.; Danglade, F.; Adjed, F. Deep Learning Architecture for Topological Optimized Mechanical Design Generation with Complex Shape Criterion. In Advances and Trends in Artificial Intelligence. Artificial Intelligence Practices; Fujita, H., Selamat, A., Lin, J.C.W., Ali, M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; Volume 12798, pp. 222–234. [Google Scholar] [CrossRef]

- Oh, S.; Jung, Y.; Kim, S.; Lee, I.; Kang, N. Deep Generative Design: Integration of Topology Optimization and Generative Models. J. Mech. Des. 2019, 141, 111405. [Google Scholar] [CrossRef]

- Oh, S.; Jung, Y.; Lee, I.; Kang, N. Design Automation by Integrating Generative Adversarial Networks and Topology Optimization. In Proceedings of the Volume 2A: 44th Design Automation Conference, Quebec City, QC, Canada, 24–28 June 2018; p. V02AT03A008. [Google Scholar] [CrossRef]

- Antunes, A.P.; Azevedo, J.L.F. An Aerodynamic Optimization Computational Framework Using Genetic Algorithms. J. Braz. Soc. Mech. Sci. Eng. 2016, 38, 1037–1058. [Google Scholar] [CrossRef]

- Sun, G.; Sun, Y.; Wang, S. Artificial Neural Network Based Inverse Design: Airfoils and Wings. Aerosp. Sci. Technol. 2015, 42, 415–428. [Google Scholar] [CrossRef]

- Pehlivanoglu, Y.V. Direct and Indirect Design Prediction in Genetic Algorithm for Inverse Design Problems. Appl. Soft Comput. 2014, 24, 781–793. [Google Scholar] [CrossRef]

- Thinakaran, K.; Rajasekar, R. Design of Airfoil Using Backpropagation Training with Combined Approach. In Innovative Design, Analysis and Development Practices in Aerospace and Automotive Engineering; Bajpai, R.P., Chandrasekhar, U., Arankalle, A.R., Eds.; Springer: New Delhi, India, 2014; pp. 295–306. [Google Scholar] [CrossRef]

- Lee, S.; Lee, D.H.; Kim, K.H.; Park, T.C.; Lim, B.J.; Kang, Y.S. Multi-Disciplinary Design Optimization and Performance Evaluation of a Single Stage Transonic Axial Compressor. J. Mech. Sci. Technol. 2013, 27, 3309–3318. [Google Scholar] [CrossRef]

- Ulaganathan, S.; Asproulis, N. Surrogate Models for Aerodynamic Shape Optimisation. In Surrogate-Based Modeling and Optimization; Koziel, S., Leifsson, L., Eds.; Springer: New York, NY, USA, 2013; pp. 285–312. [Google Scholar] [CrossRef]

- Astrua, P.; Piola, S.; Silingardi, A.; Bonzani, F. Multi-Objective Constrained Aero-Mechanical Optimization of an Axial Compressor Transonic Blade. In Proceedings of the Volume 8: Turbomachinery, Parts A, B, and C, Copenhagen, Denmark, 11–15 June 2012; pp. 241–252. [Google Scholar] [CrossRef]

- Wang, X.; Hirsch, C.; Kang, S.; Lacor, C. Multi-Objective Optimization of Turbomachinery Using Improved NSGA-II and Approximation Model. Comput. Methods Appl. Mech. Eng. 2011, 200, 883–895. [Google Scholar] [CrossRef]

- Mengistu, T.; Ghaly, W. Aerodynamic Optimization of Turbomachinery Blades Using Evolutionary Methods and ANN-based Surrogate Models. Optim. Eng. 2008, 9, 239–255. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, X.; Yu, C. How Does AI Promote Design Iteration? The Optimal Time to Integrate AI into the Design Process. J. Eng. Des. 2023, 1–28. [Google Scholar] [CrossRef]

- Agius, S.; Farrugia, P.; Francalanza, E. Designing for Human Factors: Development and Evaluation of a Harmonistic Knowledge-Based Design Decision Support Tool. Proc. Des. Soc. 2023, 3, 1367–1376. [Google Scholar] [CrossRef]

- Aalaei, M.; Saadi, M.; Rahbar, M.; Ekhlassi, A. Architectural layout generation using a graph-constrained conditional Generative Adversarial Network (GAN). Autom. Constr. 2023, 155, 105053. [Google Scholar] [CrossRef]

- Li, K.; Ye, W. A Generative Adversarial Active Learning Method for Mechanical Layout Generation. Neural Comput. Appl. 2023, 35, 19315–19335. [Google Scholar] [CrossRef]

- Chen, R.; Zhao, J.; Yao, X.; Jiang, S.; He, Y.; Bao, B.; Luo, X.; Xu, S.; Wang, C. Generative Design of Outdoor Green Spaces Based on Generative Adversarial Networks. Buildings 2023, 13, 1083. [Google Scholar] [CrossRef]

- Zhang, C.; Tao, M.X.; Wang, C.; Fan, J.S. End-to-end Generation of Structural Topology for Complex Architectural Layouts with Graph Neural Networks. Comput.-Aided Civ. Infrastruct. Eng. 2024, 39, 756–775. [Google Scholar] [CrossRef]

- Ghasemi, P.; Yuan, C.; Marion, T.; Moghaddam, M. Are Generative Adversarial Networks Capable of Generating Novel and Diverse Design Concepts? An Experimental Analysis of Performance. Proc. Des. Soc. 2023, 3, 633–644. [Google Scholar] [CrossRef]

- Li, R.; Chi, H.L.; Peng, Z.; Chen, J. Tower Crane Layout Planning Through Generative Adversarial Network. In ECPPM 2022—eWork and eBusiness in Architecture, Engineering and Construction 2022, 1st ed.; CRC Press: London, UK, 2023; pp. 382–388. [Google Scholar] [CrossRef]