Abstract

Pavement structures are one of the most critical civil infrastructures for the socio-economic development of communities. However, pavement construction demands an elevated financial budget and generates large amounts of environmental impacts. Accordingly, the new trends in daily engineering practices have integrated sustainability criteria verification into traditional pavement design procedures. Thus, this research explores the sustainability implications of asphalt pavement incorporating a Cement-Treated Base (CTB) and Recycled Concrete Aggregate (RCA) within the local context of a Global South country. The environmental and economic performances of four different types of asphalt structures were assessed, each differing in how the CTB is employed. These structures include conventional flexible pavement, semi-rigid pavement, inverted base pavement, and simple composite pavement. Furthermore, each structure is evaluated under four varying contents of coarse RCA (i.e., 0%, 15%, 30%, and 45%) in their asphalt mixtures. This approach results in a comprehensive analysis spanning 16 unique scenarios, providing valuable insights into the interplay between RCA content and CTB inclusion for sustainable infrastructure development. It is important to highlight that the Life-Cycle Assessment and Life-Cycle Cost Analysis methodologies were implemented to perform the environmental and economic inspections, respectively. Overall, this investigation demonstrates that although pavement structures comply with mechanistic design standards, they can yield significantly different cost effectiveness and environmental burdens from each other. Therefore, executing a sustainability-related appraisal is essential for accomplishing definitive infrastructure designs. Consequently, this research effort is expected to be used by stakeholders (e.g., civil engineers, designers, and governmental agencies) to support data-driven decision making in the road infrastructure industry.

1. Introduction

Pavement structures play a crucial role in addressing mobility and connectivity issues among urban, rural, and productive centers [1,2,3]. Among the various types of pavement structures available, conventional flexible pavements (CFPs) stand out as the most adopted [4,5]. Notably, approximately 70% of pavement structures worldwide and ~94–95% in the United States of America and the United Kingdom are CFPs [6,7,8]. Consequently, it becomes essential for governmental agencies to focus on designing appropriate asphalt pavement structures that balance economic and environmental costs [9,10].

In this regard, the incorporation of Cement-Treated Base (CTB) in asphalt pavements has become an increasingly widespread alternative to improve the sustainability of these infrastructures [11,12]. While CFPs typically consist of an asphalt layer over a Granular Base (GB) and Granular Sub-Base (GSB), substituting at least one of these granular layers with a CTB can significantly lower both the environmental impact and the global cost of a paving project [13,14]. CTBs, although generally more expensive and pollutant than both a GB and GSB, offer a significantly higher bearing capacity, which allows for a reduction in the overall pavement thickness, thus triggering sustainability benefits [15,16]. It is important to highlight that CTBs can be integrated into asphalt pavements in three ways, depending on the desired design and performance characteristics. First, the Semi-Rigid Pavement (SRP) approach places the asphalt layer directly over the CTB, which is further supported by a GB underneath [17]. Second, the Inverted Base Pavement (IBP) configuration consists of the asphalt layer placed over a GB, which a CTB then supports [18]. Lastly, the Simple Composite Pavement (SCP) arrangement features the asphalt layer placed directly on top of the CTB, eliminating the need for an additional granular layer [19]. Each of these methods leverages the high bearing capacity of CTBs to optimize the mechanical performance and sustainability of the structure [20,21].

The types of asphalt pavements mentioned above (i.e., CFP, SRP, IBP, and SCP) have in common that their first layer is an asphalt-based material, typically a Hot-Mix Asphalt (HMA) [22,23]. Although HMAs are widely used in industry, they are costly and polluting [24,25]. In this regard, partially substituting coarse Natural Aggregates (NAs) with coarse Recycled Concrete Aggregates (RCAs) is an effective alternative to improve the sustainability of HMAs [26,27]. Environmentally, RCAs reduce the need to extract virgin materials, conserve natural resources, and minimize habitat disruption [28,29]. RCAs also divert construction and demolition waste from landfills, decreasing landfill usage and promoting a circular economy [26,30]. Economically, RCAs can increase the profitability of paving projects by diminishing the demand for expensive virgin aggregates [31,32]. Additionally, if sourced locally, RCAs can yield lower transportation costs than NAs extracted from distant quarries [27,33].

Despite its importance, limited research exists in the literature evaluating the sustainability performance of asphalt pavement structures incorporating (simultaneously) a CTB and RCA. A significant gap remains in comparing their environmental and economic aspects throughout their design life. In order to address this, the present study provides valuable insights through a case study on road infrastructure in Colombia, an emerging economy in the Global South. Specifically, this research focuses on Barranquilla, the largest city in northern Colombia, and examines four different types of asphalt pavement (i.e., CFP, SRP, IBP, and SCP), with each including varying levels of coarse RCA in their HMAs (i.e., 0, 15, 30, and 45%). The resulting 16 scenarios are inspected for their environmental impact and monetary cost using Life-Cycle Assessment (LCA) and Life-Cycle Cost Analysis (LCCA), respectively. The development of a Pareto front further enhances decision making by providing a clear visualization of sustainable design alternatives. Moreover, by focusing on our case study, this work addresses a critical research gap and offers practical insights to promote sustainable road infrastructure development in emerging economies. Thus, this investigation aims to encourage decision makers to adopt sustainable and eco-friendly pavement alternatives for transportation infrastructure development.

The remaining sections of the article can be summarized as follows: Section 2 outlines the case study’s primary attributes and design factors under analysis. Subsequently, Section 3 details the conducted LCA, encompassing comprehensive information regarding the case study and the procedure for the pavement designs. Following this, Section 4 presents the outcomes derived from the respective LCCA. Moving forward, Section 5 deliberates on the economic and environmental elements previously addressed, delving into potential avenues for enhancing the sustainability of pavement options. Lastly, Section 6 summarizes the key discoveries stemming from this investigation.

2. Case Study

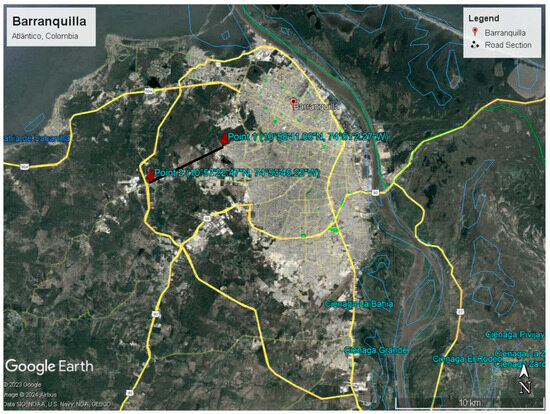

This section presents the contextual background of a case study carried out in Barranquilla City (i.e., the northern region of Colombia). The study centers on a primary road that plays a crucial role in the region’s economic and social growth. This road serves as a key access route to Barranquilla, one of Colombia’s major cities in terms of both population and economic influence within this developing nation. Figure 1 shows the location of the road analyzed in this study. Sixteen flexible pavement structures were designed for the same road (implying the conditions in terms of climate, traffic, subgrade soils, and materials), and the environmental burdens and financial costs associated with their life cycle were estimated using the LCA and LCCA methodologies. Key considerations for the pavement design process for this study include the following aspects:

- Design traffic was estimated through an exhaustive transportation study. The road experiences a high volume of mixed traffic, amounting to 7.8 million equivalent single-axle loads over the design period. The magnitude of this traffic classifies the analyzed roadway as a major roadway according to the Colombian National Institute of Highways (INVIAS, its acronym in the Spanish language), as it exceeds 5 million equivalent single-axle loads over the design period.

- The subgrade soil in this case study is characterized as gravelly sand. It presents a resilient modulus of approximately 76 MPa (≈11,000 psi). This modulus was determined from laboratory tests following the AASHTO T 307 Standard Method [34].

- Barranquilla City has a tropical climate characterized by a mean daily maximum temperature of approximately 32.6 °C (90.7 °F), an average annual relative humidity of 80%, and an annual precipitation of around 900 mm.

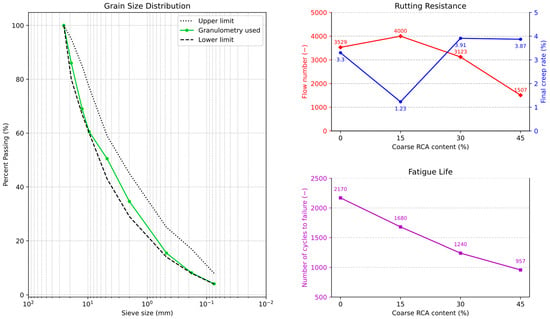

- Conventional road construction materials, both treated and untreated, including GB, GSB, CTB, and HMA (with 25 mm nominal maximum aggregate size), were considered in the design of the pavement structures. The mechanical parameters of these materials were sourced from preceding studies [27,35]. In this regard, Figure 2 shows the characterization of the HMAs in terms of grain size distribution, rutting resistance, and fatigue life. A detailed overview of the material types, composition, resilient modulus, and other properties is presented in Table 1 and Table 2.

Figure 2. Characterization of HMAs. Adapted from [27].

Figure 2. Characterization of HMAs. Adapted from [27]. Table 1. Material characteristics.

Table 1. Material characteristics. Table 2. HMA properties.

Table 2. HMA properties. - In Figure 2, it is noticeable that all HMAs were designed following the same grain size distribution, which is within the regulatory limits established by the Colombian government through INVIAS. On the other hand, this graph shows the rutting resistance from a creep test in terms of the flow number and the final creep rate. According to these results, incorporating 15% of coarse RCA improves the rutting resistance of HMA, whereas higher replacement levels have an adverse effect. In terms of fatigue life, however, a clear trend of deterioration is observed: as the coarse RCA content increases, the HMA exhibits reduced fatigue strength. It is also important to highlight that the results regarding fatigue life were obtained through the indirect tensile test on cylindrical-shaped samples loaded at 50% of the indirect tensile strength measured in dry conditions.

Figure 1.

Location of the road section. Taken from Google Earth ®.

The resilient moduli of the HMAs listed in Table 1 were measured in the laboratory in a previous study conducted by Cantero et al. [27]. These resilient moduli correspond to the following loading conditions: a temperature of 40 °C and frequency of 8 Hz. These loading conditions were selected due to their proximity to the actual field conditions. On one hand, the effective temperature at the surface of the pavement is 40.5 °C, as determined using Equation (1), which is a model proposed by Zheng et al. [36]. On the other hand, the effective frequency of vehicles is 8.1 Hz, as calculated via Equation (2), a model developed by Song et al. [37].

Here, the following hold true:

is the asphalt layer temperature at depth (°C);

is the air temperature (°C), which is 32.6 in this case;

is the depth below the pavement surface (cm), which is 0 at the surface,

is the effective frequency of the vehicles (Hz);

is the speed of the vehicles (km/h), which is 50 in this case.

Pavement Structure Design

Based on the previous data, the sixteen pavement structures were designed following a two-step procedure. Firstly, the thicknesses of the pavement structures were pre-dimensioned to (slightly) exceed a total structural number of 4.44, calculated following the methodology established in the AASHTO-93 Guide for Design of Pavement Structures [38]. Secondly, the preliminary structures were validated through a rational methodology under the fatigue and rutting performance models of the Shell Method [39], considering the recommendations and updates of the Australian Pavement Design Method [40,41]. The performance models commonly used in the study region are described as follows: (i) Equation (3) presents the HMA fatigue model; (ii) Equation (4) the CTB fatigue model; and (iii) Equation (5) the rutting model.

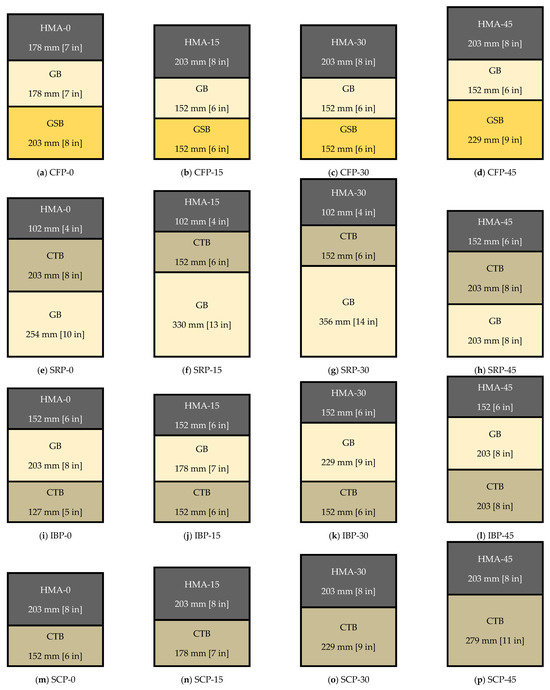

The structural performance was further evaluated through the damage ratio, calculated via Equation (6). This ratio quantifies the relative utilization of the pavement’s structural capacity, with values ≤ 100% indicating compliance with fatigue and rutting performance criteria. In this regard, Table 3 summarizes the results obtained from the design procedure detailed above. Additionally, Figure 3 shows the summary of the designed pavement structures as a basis for environmental and economic analyses throughout their life cycle using the LCA and LCCA methodologies, respectively.

Here, we define the following:

N is the allowable number of repetitions of the standard axle load;

μεt is the load-induced tensile strain at the base of the HMA layer (microstrain);

Vb is the percentage by volume of asphalt binder in the HMA (%);

E is the resilient modulus of the HMA (MPa);

RF is the reliability factor for asphalt fatigue (3.0);

SF is the shift factor between laboratory and in-service fatigue lives, which was assumed to be 6.

Here, the following hold true:

N is the allowable number of repetitions of the standard axle load;

μεt is the load-induced tensile strain at the base of the CTB layer (microstrain);

E is the resilient modulus of the CTB (MPa);

RF is the reliability factor for cemented materials’ fatigue (1.0).

Here, the following hold true:

N is the allowable number of repetitions of the standard axle load;

εz is the load-induced compressive strain at the top of the subgrade (microstrain).

Here, we define the following:

Predicted response represents the computed strain from structural analysis;

Allowable response represents the maximum strain determined using Equations (3)–(5).

Figure 3.

Summary of pavement structures under analysis.

Table 3.

Summary of pavement design methodology results.

Table 3.

Summary of pavement design methodology results.

| Design. | Layer | AASHTO Structural Number | Allowable Response (ε) | Predicted Response (ε) | Damage Ratio (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Material | Thickness (mm) | εt | εz | εt | εz | εt | εz | ||

| CFP-0 | HMA-0 | 178 | 4.93 | 1.84 × 10−4 | 1.84 × 10−4 | 100% | |||

| GB | 178 | ||||||||

| GSB | 203 | ||||||||

| Subgrade | ∞ | 3.41 × 10−4 | 2.74 × 10−4 | 80% | |||||

| CFP-15 | HMA-15 | 203 | 4.83 | 1.90 × 10−4 | 1.70 × 10−4 | 89% | |||

| GB | 152 | ||||||||

| GSB | 152 | ||||||||

| Subgrade | ∞ | 3.41 × 10−4 | 2.85 × 10−4 | 84% | |||||

| CFP-30 | HMA-30 | 203 | 4.48 | 2.19 × 10−4 | 1.95 × 10−4 | 89% | |||

| GB | 152 | ||||||||

| GSB | 152 | ||||||||

| Subgrade | ∞ | 3.41 × 10−4 | 3.11 × 10−4 | 91% | |||||

| CFP-45 | HMA-45 | 203 | 4.55 | 2.51 × 10−4 | 2.15 × 10−4 | 86% | |||

| GB | 152 | ||||||||

| GSB | 229 | ||||||||

| Subgrade | ∞ | 3.41 × 10−4 | 2.83 × 10−4 | 83% | |||||

| SRP-0 | HMA-0 | 102 | 4.47 | 1.84 × 10−4 | ∼0 | ∼0 | |||

| CTB | 203 | 8.58 × 10−5 | 6.61 × 10−5 | 77% | |||||

| GB | 254 | ||||||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.47 × 10−4 | 43% | |||||

| SRP-15 | HMA-15 | 102 | 4.47 | 1.90 × 10−4 | ∼0 | ∼0 | |||

| CTB | 152 | 8.58 × 10−5 | 8.02 × 10−5 | 93% | |||||

| GB | 330 | ||||||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.78 × 10−4 | 52% | |||||

| SRP-30 | HMA-30 | 102 | 4.44 | 2.19 × 10−4 | ∼0 | ∼0 | |||

| CTB | 152 | 8.58 × 10−5 | 8.11 × 10−5 | 95% | |||||

| GB | 356 | ||||||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.80 × 10−4 | 53% | |||||

| SRP-45 | HMA-45 | 152 | 4.45 | 2.51 × 10−4 | ∼0 | ∼0 | |||

| CTB | 203 | 8.58 × 10−5 | 6.52 × 10−5 | 76% | |||||

| GB | 203 | ||||||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.46 × 10−4 | 43% | |||||

| IBP-0 | HMA-0 | 152 | 4.53 | 1.84 × 10−4 | 1.81 × 10−4 | 98% | |||

| GB | 203 | ||||||||

| CTB | 127 | 8.58 × 10−5 | 5.76 × 10−5 | 67% | |||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.61 × 10−4 | 47% | |||||

| IBP-15 | HMA-15 | 152 | 4.45 | 1.90 × 10−4 | 1.85 × 10−4 | 97% | |||

| GB | 178 | ||||||||

| CTB | 152 | 8.58 × 10−5 | 5.87 × 10−5 | 68% | |||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.58 × 10−4 | 46% | |||||

| IBP-30 | HMA-30 | 152 | 4.47 | 2.19 × 10−4 | 2.17 × 10−4 | 99% | |||

| GB | 229 | ||||||||

| CTB | 152 | 8.58 × 10−5 | 5.34 × 10−5 | 62% | |||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.47 × 10−4 | 43% | |||||

| IBP-45 | HMA-45 | 152 | 4.45 | 2.51 × 10−4 | 2.33 × 10−4 | 93% | |||

| GB | 203 | ||||||||

| CTB | 203 | 8.58 × 10−5 | 4.92 × 10−5 | 57% | |||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.30 × 10−4 | 38% | |||||

| SCP-0 | HMA-0 | 203 | 4.44 | 1.84 × 10−4 | 1.23 × 10−5 | 7% | |||

| CTB | 152 | 8.58 × 10−5 | 6.77 × 10−5 | 79% | |||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.53 × 10−4 | 45% | |||||

| SCP-15 | HMA-15 | 203 | 4.46 | 1.90 × 10−4 | 7.75 × 10−6 | 4% | |||

| CTB | 178 | 8.58 × 10−5 | 6.08 × 10−5 | 71% | |||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.39 × 10−4 | 41% | |||||

| SCP-30 | HMA-30 | 203 | 4.45 | 2.19 × 10−4 | 1.61 × 10−6 | 1% | |||

| CTB | 229 | 8.58 × 10−5 | 5.00 × 10−5 | 58% | |||||

| Subgrade | ∞ | 3.41 × 10−4 | 1.18 × 10−4 | 35% | |||||

| SCP-45 | HMA-45 | 203 | 4.50 | 2.51 × 10−4 | ∼0 | ∼0 | |||

| CTB | 279 | 8.58 × 10−5 | 4.17 × 10−5 | 49% | |||||

| Subgrade | ∞ | 3.41 × 10−4 | 9.99 × 10−5 | 29% | |||||

In order to systematically evaluate the environmental and economic implications of incorporating a CTB and RCA, the CFP-0 structure (i.e., a conventional flexible pavement composed of HMA without RCA content and GB and GSB layers) was established as the benchmark. This configuration represents a commonly used pavement design that excludes recycled or stabilized materials. The remaining 15 structures were assessed relative to CFP-0 to quantify the potential benefits or trade-offs associated with incorporating CTB and RCA at replacement levels of 15%, 30%, and 45%. This comparative approach provides a consistent baseline for evaluating sustainability improvements in terms of cost effectiveness and environmental impact.

3. Life-Cycle Assessment (LCA)

The LCA methodology is employed to evaluate the environmental impacts caused by the various pavement structure alternatives. This process follows the guidelines outlined in ISO 14040 and ISO 14044 [42,43]. Likewise, as far as possible, the pavement LCA framework developed by the Federal Highway Administration (FHWA) is also embraced [44]. The implementation of LCAs is separated into four stages: (i) defining the goal and scope, (ii) conducting the Life-Cycle Inventory (LCI) analysis, (iii) performing the Life-Cycle Impact Assessment (LCIA), and (iv) the interpretation phase. It is essential to highlight that the attributional LCAs performed in this research were conducted with the aid of SimaPro 9.4 software [45,46].

3.1. Goal and Scope Definition Phase

The primary objective of the LCA developed in this study is to assess the environmental burdens associated with sixteen different pavement structures. In this case study, the functional unit is defined as the construction of a road section measuring 1 km in length and 7.3 m in width. Considering that all the alternatives are asphalt pavements and require the same maintenance and rehabilitation activities, this research does not evaluate them. In this regard, the LCA methodology is implemented under the cradle-to-laid approach, which was proposed by the FHWA [44] and has been widely used in the road infrastructure industry [47,48,49]. Following the outlined approach, the system boundaries in this research are divided into five stages: (i) raw material extraction/production, (ii) the transportation of raw materials to the processing plant, (iii) composite material production, (iv) the transportation of materials to the construction site, and (v) pavement construction activities.

3.2. LCI Analysis Phase

The LCI for this study was adapted from previous investigations, primarily based on primary data, as referenced in [26,27]. Thus, the LCI is summarized in Table 4, which outlines the SimaPro Unit Processes utilized to model the five stages defined within the system boundaries. From Table 4, it is clear that all the unit processes were taken from two databases, i.e., Ecoinvent and USLCI. The Ecoinvent database was produced by the Swiss Center for Life Cycle Inventories and has had several versions released to the public [50,51]. In this research, Ecoinvent was used in its 3.9 version, which was recently released in 2022. The USLCI was the second adopted database; the US National Renewable Energy Laboratory developed USLCI, and its last version was released in 2021 [52].

Table 4.

LCI embraced in this investigation. Adapted from [26,27].

3.3. LCIA Phase

In this study, the BEES+ v.4.08 model was used as the impact assessment method to categorize environmental impacts. BEES+ was created by the National Institute of Standards and Technology in the United States of America [53]. BEES+ employs 13 different categories to classify environmental burdens, namely ACidification (AC), ECotoxicity (EC), EUtrophication (EU), Global Warming (GW), Habitat Alteration (HA), Human Health Cancer (HHC), Human Health Criteria Air Pollutants (HHCAPs), Human Health NonCancer (HHNC), Indoor Air Quality (IAQ), Natural Resource Depletion (NRD), Ozone Depletion (OD), SMog (SM), and Water Intake (WI) [54]. BEES+ is widely used because it has standard weights to carry out the weighing process of the characterization results [35,55]. Table 5 presents these weights.

Table 5.

Impact categories used in the BEES+ model. Adapted from SimaPro 9.4 and [35].

3.4. Interpretation Phase

Table 6 presents the characterization results of the LCAs. In this table, the green color and red color are used to represent the less and more contaminating pavement structures, respectively. Meanwhile, the yellow/orange color range is employed for intermediate states. From Table 6, the following conclusions are worthy to be mentioned: (i) the construction of the considered asphalt pavements does not emit appreciable amounts of volatile organic compounds into the atmosphere; (ii) for most of the impact categories, CFP-15, CFP-30, SCP-0, and SCP-15 are the alternatives that generate the lowest environmental burdens; and (iii) depending on the analyzed impact category, the CFP-45, SRP-45, IBP-45, and SCP-45 alternatives exhibit the most elevated contaminating potential.

Table 6.

Characterization results.

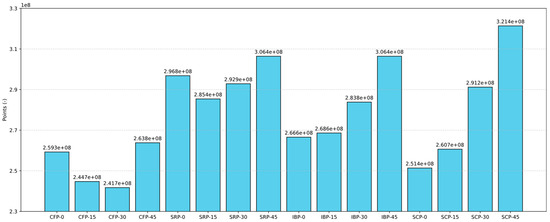

In order to rank each of the alternatives, a weighing process was carried out using the weight introduced in Table 5. Therefore, obtaining a weighted “point/score” of potential environmental damage is possible. The higher this score, the greater the environmental impact linked to the assessed alternative [53,54]. The results associated with the weighting process are presented in Figure 4. From this graph, it is feasible to determine that the pavement structures are located from lowest to highest pollution potential in the following order: CFP-30, CFP-15, SCP-0, CFP-0, SCP-15, CFP-45, IBP-0, IBP-15, IBP-30, SRP-15, SCP-30, SRP-30, SRP-0, SRP-45, IBP-45, and SCP-45. The preceding confirms that CTBs do not (necessarily) offer environmental advantages over traditional granular layers. These results from Figure 4 are congruent with Table 6. More detailed findings can be found, such as (i) regarding the most contaminating alternative (i.e., SCP-45), the less contaminating alternative (i.e., CFP-30) yields a 24.78% smaller environmental burden; (ii) the optimal content of coarse RCA was 30% and 15% for the CFP and SRP structures, respectively; and (iii) for the other types of structures (i.e., IBP and SCP), the RCA did not show overall environmental savings. Thus, it is clear that the simultaneous inclusion of RCA and a CTB inside an asphalt pavement should be carried out within the framework of a comprehensive environmental analysis.

Figure 4.

Results of the weighting process.

4. Life-Cycle Cost Analysis (LCCA)

In order to evaluate the economic advantages of the studied alternatives, an LCCA was conducted. These tools enable the execution of an economic analysis, facilitating a comprehensive evaluation of pavement alternatives across their complete life cycle, being able to consider not only the initial construction cost but also integrating an assessment of sustained operational and maintenance costs throughout an extended timeframe [56,57,58]. In order to perform an LCA-LCCA integration, the same stages from the LCA (see Table 4) are employed in the LCCA, namely: raw material extraction, transport to the processing facility, composite material production, transport to the construction site, and pavement-related activities.

LCCAs essentially represent the sum of initial expenses and discounted future costs across all phases of the life cycle, primarily focusing on agency and user costs [58,59,60]. In this instance, the LCCA was performed according to the specified LCA considerations, which include the design period, functional unit, system boundaries (encompassing stages and sub-stages), production rates, and predetermined distances. As these are pavement structures characterized by comparable maintenance and rehabilitation conditions, the analysis exclusively considers initial costs, obviating the necessity to discount future values or employ financial indicators such as the net present value.

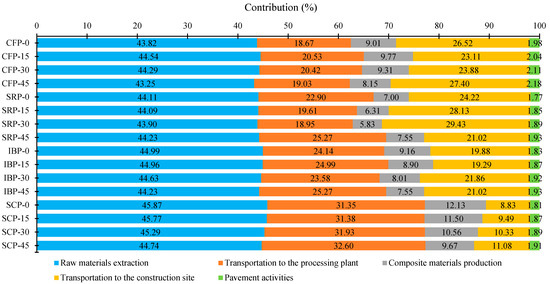

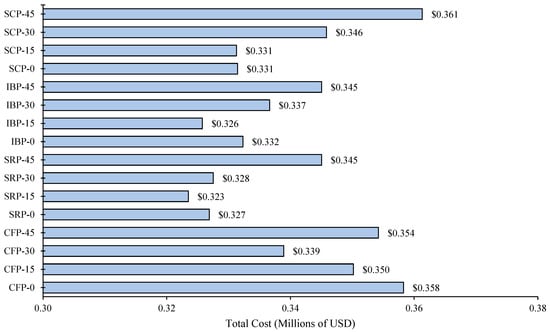

Table 7 shows the unitary costs of each material considered in the study. These costs are the official prices of the Colombian government, which are publicly reported by the unitary price database from INVIAS for the study area [61]. It is important to highlight that for the currency conversion, an exchange rate equal to COP 4200 = USD 1 was assumed, which is valid at the time of conducting this study, i.e., the first half of the year 2025. The costs related to each assessed alternative, presented separately for each of the sub-stages, are detailed in Table 8. Additionally, Figure 5 provides a schematic representation of their respective contributions to the total cost of the alternative. Finally, the total costs of each alternative are summarized in Figure 6.

Table 7.

Unit prices adopted in this research in USD.

Table 8.

Partial and total costs of each alternative.

Figure 5.

Contribution to the total cost of each alternative.

Figure 6.

Total costs of the pavement structure alternatives.

According to Table 7 and Figure 5, the variability of costs among the alternatives is significantly different depending on the stage. Transportation to the construction site exhibits the highest variability, with a coefficient of variation of 34.57%, reflecting a strong influence of logistical factors such as transportation distances and the volume of materials required. In terms of average costs, raw material extraction is the most expensive stage, followed by transportation to the processing plant and composite material production. These stages account for a significant portion of the total cost and vary widely across designs due to factors such as the properties of the materials used (e.g., RCA and CTB content) and the associated logistics. In contrast, construction activities are the least expensive and least variable stage among those evaluated.

The extraction of raw materials is the dominant stage across all the evaluated designs, with a contribution ranging from 42.76% to 45.87%. This reflects the significant influence of material usage, whether virgin or recycled, on the overall project cost. On the other hand, transportation to the processing plant exhibits notable variation, with contributions ranging from 17.09% to 32.60%, being higher in designs such as those in the SCP series, likely due to elevated logistical requirements or associated transportation volumes. Composite material production, while contributing less overall (between 5.83% and 12.13%), reaches higher values in alternatives with greater proportions of the CTB, such as SCP. Transportation to the construction site also shows significant variability, contributing between 19.29% and 30.66%, highlighting the importance of logistics in specific designs, such as those with high RCA contents (i.e., 45%).

SRP-15 stands out as the most economical option, positioning it as an efficient alternative from an economic perspective. This can be attributed to its reduced thickness in the CTB layer and an optimized asphalt mixture with an intermediate RCA content (i.e., 15%). Designs such as IBP-0 and SRP-0 also exhibit competitive costs. Conversely, the most expensive alternatives include SCP-45, whose cost reflects the impact of intensive CTB use.

The analysis also reveals that the use of RCA can reduce costs in specific stages, particularly in raw material extraction and composite material production. Nevertheless, these reductions do not always translate into lower total costs, as they can be offset by increases in subsequent stages or design-related factors. On the other hand, alternatives in the SCP series, which integrate CTBs with higher thicknesses, show higher costs compared to configurations like SRP, where the CTB is used more efficiently to reduce costs without compromising structural performance.

5. Discussion

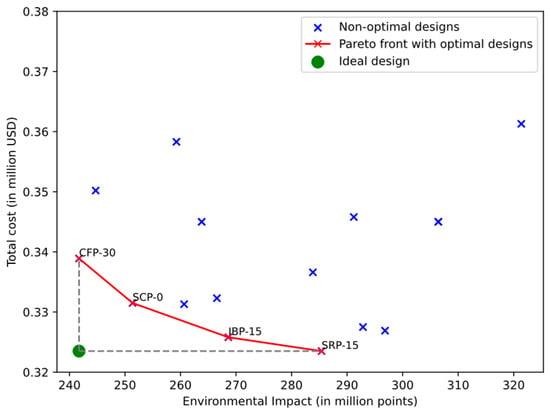

Figure 4 and Figure 6 comprise the results from the LCA and LCCA, respectively. From these graphs, it is evident that the environmental impacts do not follow the same trends as the financial costs, which complicates decision making. Thus, the findings of this research are dissected below, aiming to make them explicit.

From an economic standpoint, the control design (i.e., CFP-0) is less convenient than almost all other alternatives (except for SCP-45). The preceding is to be expected, since the integration of a CTB and RCA into asphalt pavements is usually motivated by financial reasons. It is well known that the inclusion of these materials reduces the total construction costs of the structure, which increases the profitability of road infrastructure projects [62,63]. A closer look reveals that the inclusion of a CTB (in all types of structures evaluated, i.e., SRP, IBP, and SCP) can generate monetary benefits. Nonetheless, RCA follows a more complicated trend, in which there is an optimal dosage of coarse RCA (30% for CFP and 15% for the other types of structures) that minimizes the total costs but, when exceeded, increases them drastically. Additionally, the fact that the most cost-effective design was the SRP-15 reinforces the conclusion that the simultaneous implementation of a CTB and RCA in asphalt pavement is an effective strategy for achieving economic savings. An unexpected but equally valuable finding is that CFPs allow for the incorporation of a higher content of coarse RCA into the HMAs than CTB-modified structures.

From an environmental point of view, the RCA-modified HMAs are just suitable in CFP and SRP in a limited replacement amount (30% as maximum). For the other types of structures, the environmental impacts drastically augment with rising RCA content, which is arguably associated with the greater consumption of asphalt binder by the porous structure of these recycled aggregates. It is also interesting that the most economically profitable alternative (i.e., SRP-15) is one of the most polluting, while the design with the lower potential environmental burdens (i.e., CFP-30) is at a midpoint of cost effectiveness. These adversarial tendencies are common in sustainability analysis, where efforts to reduce environmental damage yield increased monetary costs [55,64]. In order to explain these trends in more detail, a Pareto front is shown in Figure 7.

Figure 7.

Pareto front obtained from the LCA-LCCA integration.

The Pareto front consists of solutions that are not dominated by each other but that outperform all other solutions in the search space [65,66,67]. In the case of a 2D Pareto front where both the x-axis and y-axis represent criteria to be minimized (such as in the case of minimizing environmental impacts and monetary costs), the Pareto front consists of the points located toward the bottom-left region of the graph [68,69]. A solution belongs to the Pareto front if no other solution in the search space achieves a lower value for one objective without increasing the value of the other [70,71]. Graphically, the Pareto front forms the boundary of the feasible solutions, with no points below or to the left of it, ensuring that every point on this front represents an optimal trade-off between the two objectives [72,73]. In Figure 7, it is evident that the Pareto front obtained from the LCA-LCCA integration is composed of four optimal designs, namely CFP-30, SCP-0, IBP-15, and SRP-15. Respectively, the CFP-30 and SRP-15 alternatives are the best solutions in terms of environmental burden and total costs. Further optimal designs (i.e., IBP-15 and SRP-15) are midpoints in terms of sustainable performance. Accordingly, it is also possible to determine that the optimal content of coarse RCA is 0% for the SCP, 30% for the CFP, and 15% for the other types of structures (i.e., IBP and SRP). From a sustainability standpoint, it can be concluded that (i) the RCA-modified HMAs are preferred to be used in CFP, where relatively elevated amounts of coarse RCA (i.e., up to 30% via the replacement of coarse NAs) can be used to achieve environmental savings and higher profitability ratios; (ii) the RCA-modified HMAs may also be utilized in IBP and SRP structures but in fewer quantities (i.e., 15%); (iii) SCP structures are already sustainable by the mere fact of incorporating a CTB and do not need to employ RCA-modified HMAs, since the inclusion of coarse RCA induces more increased costs and more contaminating potential; (iv) if the goal is to maximize the consumption of RCA (e.g., with the aim of reducing the amount of waste sent to landfills), it is advisable to construct CFPs, thereby avoiding the need for a CTB; and (v) the simultaneous use of a CTB and RCA in asphalt pavements is a viable strategy to build more eco-friendly and budget-conscious road infrastructure projects; however, the design process of the structure must be careful and meticulous to prevent incurring counterproductive effects (e.g., as occurred in the SCPs).

Figure 7 also contains an “ideal design”, which is an imaginary point in the search space consisting of the projection of the lowest environmental impact obtained (i.e., from the CFP-30 design) and the lowest total cost obtained (i.e., from the SRP-15 design). The area generated by the intersection of this point (and its projections) with the Pareto front represents the region of theoretically feasible alternatives that were not explored in this research but could hypothetically be achieved under other design settings. In this regard, identifying the characteristics of these “possible ideal solutions” (that would enhance the sustainability performance of the designs proposed herein) is a crucial topic for further investigation.

5.1. Limitations of the Study

One of the principal limitations of this study stems from its decision to exclude the maintenance and rehabilitation activities, use, and end-of-life phases from the environmental and economic evaluations. This exclusion is primarily justified by the fact that all the pavement alternatives analyzed are asphalt-based structures, inherently requiring comparable post-construction activities throughout their service life. By adopting a cradle-to-laid approach within the integrated LCA-LCCA framework, the study deliberately narrows its focus to the stages from the sourcing of raw materials to the initial construction, where the influence of incorporating a CTB and RCA is most pronounced. While this methodological choice effectively isolates the sustainability impacts attributable to material selection and design configurations (thus aligning with the study’s primary objective of assessing RCA and CTB implications), it also limits the comprehensiveness of the life-cycle perspective. In real-world applications, factors such as differential maintenance needs, varying rehabilitation frequencies, and potential durability advantages or disadvantages of certain structures could further differentiate the alternatives over their entire lifespan. Hence, although reasonable within the scope of the current investigation, this simplification suggests that future research expanding the analysis to encompass full life-cycle stages would provide a more holistic understanding of the long-term sustainability performance of asphalt pavements incorporating RCA and a CTB.

5.2. Generalizability of Results

The generalizability of the main findings from this case study requires careful consideration of contextual aspects. While the LCA and LCCA methodologies provide valuable insights for pavement engineering and sustainable infrastructure development, certain elements are inherently tied to the field conditions of Barranquilla City or cities with similar characteristics, for example, factors such as the climate, raw material availability, and local socio-economic considerations, among others.

The overall methodology and processes for conducting LCA and LCCA, following the ISO standards and FHWA guidelines, can be applicable in diverse settings. In the same way, these findings can serve as a foundation for comparative studies in different locations or contexts. Nonetheless, the environmental burdens associated with material types, extraction, and transportation are heavily influenced by regional factors and local availability. Similarly, the viability of alternative pavement structures is subject to local cost variations, technological progress, and regional socio-economic development.

Considering the results of this research, it can be stated that the qualitative findings, particularly the observed environmental and economic trends, may hold similarities and applicability to other cities in developing countries with similar climatic, technological, and socio-economic conditions. However, the quantitative results or calculated absolute values may not align precisely with those of distinct case studies because these results depend on the actual, estimated, and/or measured databases of the specific study analyzed, which even vary over time.

The preceding arguments lead to the conclusion that while the general approach and methodology are transferable, the specific outcomes should be interpreted with consideration for the unique characteristics of each geographical and socio-economic context. Therefore, the difficult task of establishing desirable consensus and generalizable arguments will depend largely on the development of more and more frequent, rigorous, and varied research in this important field of pavement engineering.

5.3. Methodological Reproducibility

The integration of LCA and LCCA within a single analytical framework represents a significant methodological advantage in this research, as it enables a holistic evaluation of both environmental and economic performances across diverse pavement design scenarios. This dual-framework approach is particularly suitable for assessing the sustainability implications of incorporating a CTB and RCA in asphalt pavement structures, as it captures the trade-offs and synergies between ecological impacts and financial feasibility over the infrastructure’s lifespan. By applying the integrated LCA-LCCA methodology across 16 systematically varied pavement configurations, the study ensures methodological reproducibility through standardized data inputs, consistent boundary conditions, and a comparative structure that supports transparent scenario analysis. Nevertheless, while robust, this framework may face limitations in accounting for regional variability in construction practices, material sourcing, and long-term maintenance patterns (the latter were even outside the scope of this investigation), which can influence real-world outcomes. Future research can enhance reproducibility and contextual sensitivity by incorporating dynamic data modeling, stochastic Life-Cycle Inventories, and region-specific economic indicators, thus extending the applicability and precision of sustainability appraisals in pavement design.

6. Summary and Conclusions

The primary objective of this research was to evaluate the sustainability performance of asphalt pavement structures integrating a CTB and RCA in a case study set in a Global South country. Accordingly, this study aimed to assess both the environmental and economic implications of 16 unique pavement configurations, combining various coarse RCA contents and structural designs. The conclusions derived from this investigation, based on rigorous LCA-LCCA integration, are summarized below:

- The SRP-15 design was identified as the most cost-effective configuration, demonstrating significant economic advantages due to its optimized use of coarse RCA (at 15% replacement of NAs) and reduced CTB thickness. Nonetheless, from an environmental perspective, CFP-30 emerged as the least impactful design, indicating that the optimal solution depends on the prioritization of cost or environmental impact.

- Incorporating RCA into HMA reduces costs up to an optimal threshold (30% for CFP and 15% for SRP). Beyond these levels, costs and environmental impacts increase significantly due to the higher asphalt binder demand associated with the RCA’s porous structure.

- SCP designs, which employ thicker CTB layers, exhibit higher total costs and environmental burdens compared to other configurations. This indicates that excessive reliance on a CTB, even with RCA integration, may not yield overall sustainability benefits.

- The Pareto front analysis identified CFP-30, IBP-15, SRP-15, and SCP-0 as optimal designs balancing environmental impacts and monetary costs. Notably, these configurations demonstrate that sustainability-focused strategies must carefully integrate both material and design considerations to avoid counterproductive outcomes.

- The analysis of cost distribution revealed that raw material extraction and transportation account for the largest share of total costs, regardless of the pavement configuration. The preceding highlights the critical roles of logistics and material sourcing in sustainable pavement design, suggesting that optimizing supply chain strategies and promoting local sourcing could significantly reduce both costs and environmental impacts.

It is worth noting that the findings from this investigation are context specific, influenced by the local climate, material availability, and socio-economic conditions of Barranquilla City (i.e., the northern region of Colombia). Nevertheless, the methodology and observed trends offer valuable insights applicable to other regions with similar conditions, supporting sustainable decision making in pavement engineering.

Author Contributions

Conceptualization, J.D. and R.P.-M.; methodology, O.G.-B. and G.M.-A.; software, R.P.-M.; validation, G.M.-A., C.A. and M.M.; formal analysis, O.G.-B., R.C., J.D. and R.P.-M.; investigation, O.G.-B., R.C., J.D. and R.P.-M.; resources, G.M.-A.; data curation, R.C.; writing—original draft preparation, O.G.-B., R.C., J.D. and R.P.-M.; writing—review and editing, G.M.-A., C.A. and M.M.; visualization, O.G.-B., R.C., J.D. and R.P.-M.; supervision, G.M.-A., C.A. and M.M.; project administration, J.D. and G.M.-A.; funding acquisition, G.M.-A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors express their sincere gratitude to the Universidad del Norte and the Administrative Department of Science, Technology, and Innovation (COLCIENCIAS) for supporting this investigation through “Research Project 745/2016, Contract 037-2017, No. 1215-745-59105”. Furthermore, Carlos Acosta acknowledges the financial support provided by the Colciencias-Fulbright Scholarship—2018 Cohort.

Data Availability Statement

Some or all of the data, models, or code supporting this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AASHTO | American Association of State Highway and Transportation Officials |

| AC | ACidification |

| CFP | Conventional flexible pavement |

| CTB | Cement-Treated Base |

| EC | ECotoxicity |

| EU | EUtrophication |

| FHWA | Federal Highway Administration |

| GB | Granular Base |

| GSB | Granular Sub-Base |

| GW | Global Warming |

| HA | Habitat Alteration |

| HHC | Human Health Cancer |

| HHCAPs | Human Health Criteria Air Pollutants |

| HHNC | Human Health NonCancer |

| HMA | Hot Mix Asphalt |

| IAQ | Indoor Air Quality |

| IBP | Inverted Base Pavement |

| ISO | International Organization for Standardization |

| LCA | Life-Cycle Assessment |

| LCCA | Life-Cycle Cost Analysis |

| LCI | Life-Cycle Inventory |

| LCIA | Life-Cycle Impact Assessment |

| NA | Natural Aggregate |

| NRP | Natural Resource Depletion |

| OAC | Optimal asphalt content |

| OD | Ozone Depletion |

| RCA | Recycled Concrete Aggregate |

| SCP | Simple Composite Pavement |

| SM | SMog |

| SRP | Semi-Rigid Pavement |

| VFA | Voids filled with asphalt |

| VMA | Voids in mineral aggregate |

| VTM | Voids in the total mix |

| WI | Water Intake |

References

- Cervero, R.; Guerra, E.; Al, S. Chapter 7: Transit-Oriented Development. In Beyond Mobility: Planning Cities for People and Places; Island Press: Washington, DC, USA, 2017; pp. 109–141. [Google Scholar]

- Shamdasani, Y. Rural Road Infrastructure & Agricultural Production: Evidence from India. J. Dev. Econ. 2021, 152, 102686. [Google Scholar] [CrossRef]

- Urazán-Bonells, C.F.; Rondón-Quintana, H.A.; Zafra-Mejía, C.A. Correlation between Sectoral GDP and the Values of Road Freight Transportation in Colombia. Economies 2024, 12, 205. [Google Scholar] [CrossRef]

- Norouzi, Y.; Ghasemi, S.H.; Nowak, A.S.; Jalayer, M.; Mehta, Y.; Chmielewski, J. Performance-Based Design of Asphalt Pavements Concerning the Reliability Analysis. Constr. Build. Mater. 2022, 332, 127393. [Google Scholar] [CrossRef]

- Wang, H.-P.; Guo, Y.-X.; Wu, M.-Y.; Xiang, K.; Sun, S.-R. Review on Structural Damage Rehabilitation and Performance Assessment of Asphalt Pavements. Rev. Adv. Mater. Sci. 2021, 60, 438–449. [Google Scholar] [CrossRef]

- Kumar, P.; Shukla, S. Flexible Pavement Construction Using Different Waste Materials: A Review. Mater. Today Proc. 2022, 65, 1697–1702. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A Review of the Use of Recycled Solid Waste Materials in Asphalt Pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Qiao, Y.; Dawson, A.R.; Parry, T.; Flintsch, G.; Wang, W. Flexible Pavements and Climate Change: A Comprehensive Review and Implications. Sustainability 2020, 12, 1057. [Google Scholar] [CrossRef]

- Duque, J.; Martinez-Arguelles, G.; Nuñez, Y.; Peñabaena-Niebles, R.; Polo-Mendoza, R. Designing Climate Change (CC)-Resilient Asphalt Pavement Structures: A Comprehensive Literature Review on Adaptation Measures and Advanced Soil Constitutive Models. Results Eng. 2024, 24, 103648. [Google Scholar] [CrossRef]

- Guerrero-Bustamante, O.; Camargo, R.; Dawd, I.; Duque, J.; Polo-Mendoza, R.; Javier, G.; Diaz, J.; Daza, O.; Cucunuba, J.; Acosta, C. Implementation of Crumb Rubber (CR) in Road Pavements: A Comprehensive Literature Review. Infrastructures 2024, 9, 223. [Google Scholar] [CrossRef]

- Chhabra, R.S.; Naga, G. Stabilization of Cement-Treated Base Mixes Incorporating High Reclaimed Asphalt Pavement Materials Using Stabilizer Rich in SiO2 and Al2O3. Constr. Build. Mater. 2023, 365, 130089. [Google Scholar] [CrossRef]

- Bressi, S.; Primavera, M.; Santos, J. A Comparative Life Cycle Assessment Study with Uncertainty Analysis of Cement Treated Base (CTB) Pavement Layers Containing Recycled Asphalt Pavement (RAP) Materials. Resour. Conserv. Recycl. 2022, 180, 106160. [Google Scholar] [CrossRef]

- Pham, P.N. Utilization of Rubber Aggregates in Cement-Treated Bases: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1289, 012076. [Google Scholar] [CrossRef]

- Chakravarthi, S.; Shankar, S. Utilization of Recycled Aggregates in Cement-Treated Bases: A State-of-the-Art Review. Innov. Infrastruct. Solut. 2021, 6, 191. [Google Scholar] [CrossRef]

- Ismail, A.; Baghini, M.S.; Karim, M.R.; Shokri, F.; Al-Mansob, R.A.; Firoozi, A.A.; Firoozi, A.A. Laboratory Investigation on the Strength Characteristics of Cement-Treated Base. Appl. Mech. Mater. 2014, 507, 353–360. [Google Scholar] [CrossRef]

- Priastiwi, Y.A.; Sukamta; Hidayat, A.; Hafidz, M.; Widyandika, R.; Wiguna, E. Study Optimization Cement Content of Cement Treated Base (CTB) Using Compressive Strength Parameter. IOP Conf. Ser. Earth Environ. Sci. 2023, 1203, 012036. [Google Scholar] [CrossRef]

- Jiang, B.; Xu, L.; Cao, Z.; Yang, Y.; Sun, Z.; Xiao, F. Interlayer Distress Characteristics and Evaluations of Semi-Rigid Base Asphalt Pavements: A Review. Constr. Build. Mater. 2024, 431, 136441. [Google Scholar] [CrossRef]

- Papadopoulos, E.; Santamarina, J.C. Inverted Base Pavements: Construction and Performance. Int. J. Pavement Eng. 2019, 20, 697–703. [Google Scholar] [CrossRef]

- SHRP S2-R21-RR-2: Composite Pavement Systems, Volume 1, HMA/PCC Composite Pavements. In Strategic Highway Research Program (SHRP 2); Transportation Research Board: Washington, DC, USA, 2013; pp. 1–135.

- Daheshpour, A.E.; Hayati, P. Analytical-Field Investigation of the Effect of Elastic Modulus Parameter of the Cement Treated Base (CTB) According to FAA Manual on the Airfield Concrete Block Pavement (ACBP) Performance. Case Stud. Constr. Mater. 2025, 22, e04120. [Google Scholar] [CrossRef]

- Ai, X.; Pei, Z.; Xu, M.; Fan, L.; Tu, L.; Yang, J.; Feng, D.; Yi, J. Micromechanical Behavior of Cement-Treated Base Materials Incorporating Recycled Crushed Aggregates Arising from C&D Waste Powder Based on DEM. Constr. Build. Mater. 2023, 403, 133100. [Google Scholar] [CrossRef]

- Sravanthi, B.; Radhakrishnan, V.; Andrews, J.K.; Saudagar, A.S.R. Comparative Study on the Performance of Cement Treated Base Layer Materials and Fly Ash-Based Geopolymer Base Layer Materials. Innov. Infrastruct. Solut. 2025, 10, 3. [Google Scholar] [CrossRef]

- Yadav, N.; Kumar, R.; Jethy, B. Influence of Supplementary Cementitious Materials along with Construction and Demolition Waste in Pavement Cement-Treated Sub-Base Applications. Innov. Infrastruct. Solut. 2024, 9, 65. [Google Scholar] [CrossRef]

- Milad, A.; Babalghaith, A.M.; Al-Sabaeei, A.M.; Dulaimi, A.; Ali, A.; Reddy, S.S.; Bilema, M.; Yusoff, N.I.M. A Comparative Review of Hot and Warm Mix Asphalt Technologies from Environmental and Economic Perspectives: Towards a Sustainable Asphalt Pavement. Int. J. Environ. Res. Public Health 2022, 19, 14863. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Zhu, Y.; Zhang, H. A Review of Sustainability in Hot Asphalt Production: Greenhouse Gas Emissions and Energy Consumption. Appl. Sci. 2024, 14, 10246. [Google Scholar] [CrossRef]

- Covilla-Varela, E.; Turbay, E.; Polo-Mendoza, R.; Martínez-Arguelles, G.; Cantero-Durango, J. Recycled Concrete Aggregates (RCA)-Based Asphalt Mixtures: A Performance-Related Evaluation with Sustainability-Criteria Verification. Constr. Build. Mater. 2023, 403, 133203. [Google Scholar] [CrossRef]

- Cantero-Durango, J.; Polo-Mendoza, R.; Martinez-Arguelles, G.; Fuentes, L. Properties of Hot Mix Asphalt (HMA) with Several Contents of Recycled Concrete Aggregate (RCA). Infrastructures 2023, 8, 109. [Google Scholar] [CrossRef]

- Xu, X.; Luo, Y.; Sreeram, A.; Wu, Q.; Chen, G.; Cheng, S.; Chen, Z.; Chen, X. Potential Use of Recycled Concrete Aggregate (RCA) for Sustainable Asphalt Pavements of the Future: A State-of-the-Art Review. J. Clean. Prod. 2022, 344, 130893. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Y.; Yang, H.; Xiang, Y.; Ye, Z.; Li, W.; Hu, C. Enhancing Self-Healing of Asphalt Mixtures Containing Recycled Concrete Aggregates and Reclaimed Asphalt Pavement Using Induction Heating. Constr. Build. Mater. 2024, 439, 137361. [Google Scholar] [CrossRef]

- Neupane, R.P.; Devi, N.R.; Imjai, T.; Rajput, A.; Noguchi, T. Cutting-Edge Techniques and Environmental Insights in Recycled Concrete Aggregate Production: A Comprehensive Review. Resour. Conserv. Recycl. Adv. 2025, 25, 200241. [Google Scholar] [CrossRef]

- Cheng, H.; Wang, Y.; Liu, J.; Poon, C.-S.; Ren, P.; Liu, Y.; Chen, Z. The Long-Term Re-Cementation of Recycled Concrete Aggregate in Road Sub-Base and Its Impacts on Pavement Performance. Transp. Geotech. 2024, 49, 101431. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Reyes-Lizcano, F.A.; Rondón-Quintana, H.A. Use of Recycled Concrete Aggregates in Asphalt Mixtures for Pavements: A Review. J. Traffic Transp. Eng. 2022, 9, 725–741. [Google Scholar] [CrossRef]

- Espino-Gonzalez, C.U.; Martinez-Molina, W.; Alonso-Guzman, E.M.; Chavez-Garcia, H.L.; Arreola-Sanchez, M.; Sanchez-Calvillo, A.; Navarrete-Seras, M.A.; Borrego-Perez, J.A.; Mendoza-Sanchez, J.F. Asphalt Mixes Processed with Recycled Concrete Aggregate (RCA) as Partial Replacement of the Natural Aggregate. Materials 2021, 14, 4196. [Google Scholar] [CrossRef]

- AASHTO T 307-99; Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012; pp. 1–40.

- Polo-Mendoza, R.; Mora, O.; Duque, J.; Turbay, E.; Martinez-Arguelles, G.; Fuentes, L.; Guerrero, O.; Perez, S. Environmental and Economic Feasibility of Implementing Perpetual Pavements (PPs) against Conventional Pavements: A Case Study of Barranquilla City, Colombia. Case Stud. Constr. Mater. 2023, 18, e02112. [Google Scholar] [CrossRef]

- Zheng, Y.X.; Cai, Y.C.; Zhang, Y.M. Study on Temperature Field of Asphalt Concrete Pavement. In Proceedings of the GeoHunan International Conference: Emerging Technologies for Material, Design, Rehabilitation, and Inspection of Roadway Pavements, Hunan, China, 9–11 June 2011; pp. 266–273. [Google Scholar]

- Song, Y.; Yang, C.H.; Hong, S.K.; Hwang, S.J.; Kim, J.H.; Choi, J.Y.; Ryu, S.K.; Sung, T.H. Road Energy Harvester Designed as a Macro-Power Source Using the Piezoelectric Effect. Int. J. Hydrog. Energy 2016, 41, 12563–12568. [Google Scholar] [CrossRef]

- AASHTO. AASHTO Guide for Design of Pavement Structures; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1993; pp. 1–622. [Google Scholar]

- Hunter, R.; Self, A.; Read, J. The Shell Bitumen Handbook, 6th ed.; ICE Publishing: Bristol, UK, 2015; ISBN 978-0-7277-5837-8. [Google Scholar]

- Austroads. AP-G17/04: Pavement Design—A Guide to the Structural Design of Road Pavements; Austroads: Sydney, Australia, 2006. [Google Scholar]

- Austroads. Guide to Pavement Technology Part 2: Pavement Structural Design; Austroads: Sydney, Australia, 2017. [Google Scholar]

- BS EN ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- BS EN ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Harvey, J.T.; Meijer, J.; Ozer, H.; Al-Qadi, I.L.; Saboori, A.; Kendall, A. FHWA-HIF-16-014: Pavement Life Cycle Assessment Framework; FHWA: Washington, DC, USA, 2016.

- PRé Sustainability. SimaPro Flow Tutorial; 2023. Available online: https://simapro.com/wp-content/uploads/2023/12/SimaPro-Flow-tutorial.pdf (accessed on 15 May 2025).

- PRé Sustainability. SimaPro Database Manual—Methods Library Table; 2020. Available online: https://simapro.com/wp-content/uploads/2020/10/DatabaseManualMethods.pdf (accessed on 15 May 2025).

- Mattinzioli, T.; Sol-Sánchez, M.; Martínez, G.; Rubio-Gámez, M. A Parametric Study on the Impact of Open-Source Inventory Variability and Uncertainty for the Life Cycle Assessment of Road Bituminous Pavements. Int. J. Life Cycle Assess. 2021, 26, 916–935. [Google Scholar] [CrossRef]

- Huang, Y.; Spray, A.; Parry, T. Sensitivity Analysis of Methodological Choices in Road Pavement LCA. Int. J. Life Cycle Assess. 2013, 18, 93–101. [Google Scholar] [CrossRef]

- Li, H.; Jiang, J.; Li, Q. Economic and Environmental Assessment of a Green Pavement Recycling Solution Using Foamed Asphalt Binder Based on LCA and LCCA. Transp. Eng. 2023, 13, 100185. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. Overview and Methodology—Data Quality Guideline for the Ecoinvent Database Version 3; The Ecoinvent Centre: St. Gallen, Switzerland, 2013. [Google Scholar]

- Moreno Ruiz, E.; Valsasina, L.; FitzGerald, D.; Symeonidis, A.; Turner, D.; Müller, J.; Minas, N.; Bourgault, G.; Vadenbo, C.; Ioannidou, D.; et al. Documentation of Changes Implemented in the Ecoinvent Database v3.7 & v3.7.1 (2020.12.17); Ecoinvent Association: Zürich, Switzerland, 2020. [Google Scholar]

- NREL. The U.S. Life-Cycle Inventory Database Project—Helping Us Find Answers to Environmental Impact Concerns; National Renewable Energy Laboratory: Golden, CO, USA, 2005.

- Curran, M.A.; Overly, J.G.; Hofstetter, P.; Muller, R.; Lippiatt, B.C. NISTIR 6865: BEES 2.0—Building for Environmental and Economic Sustainability; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2002; pp. 1–38.

- Gloria, T.P.; Lippiatt, B.C.; Cooper, J. Life Cycle Impact Assessment Weights to Support Environmentally Preferable Purchasing in the United States. Environ. Sci. Technol. 2007, 41, 7551–7557. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Martinez-Arguelles, G.; Peñabaena-Niebles, R. A Multi-Objective Optimization Based on Genetic Algorithms for the Sustainable Design of Warm Mix Asphalt (WMA). Int. J. Pavement Eng. 2023, 24, 2074417. [Google Scholar] [CrossRef]

- Rayjada, S.P.; Ghosh, J.; Raghunandan, M. Assessment, Quantification and Propagation of Uncertainty in Seismic Life-Cycle Cost Analysis. Struct. Infrastruct. Eng. 2024, 1–20. Available online: https://www.tandfonline.com/doi/full/10.1080/15732479.2024.2391037?af=R (accessed on 15 May 2025). [CrossRef]

- Clemmensen, A.; Wang, H. Airfield Pavement Condition Prediction with Machine Learning Models for Life-Cycle Cost Analysis. Int. J. Pavement Eng. 2024, 25, 2322529. [Google Scholar] [CrossRef]

- Suwarto, F.; Parry, T.; Airey, G. Review of Methodology for Life Cycle Assessment and Life Cycle Cost Analysis of Asphalt Pavements. Road Mater. Pavement Des. 2024, 25, 1631–1657. [Google Scholar] [CrossRef]

- Ilyas, M.; Kassa, F.M.; Darun, M.R. Life Cycle Cost Analysis of Wastewater Treatment: A Systematic Review of Literature. J. Clean. Prod. 2021, 310, 127549. [Google Scholar] [CrossRef]

- Degieter, M.; Gellynck, X.; Goyal, S.; Ott, D.; De Steur, H. Life Cycle Cost Analysis of Agri-Food Products: A Systematic Review. Sci. Total Environ. 2022, 850, 158012. [Google Scholar] [CrossRef]

- INVIAS. Análisis de Precios Unitarios—Sector Transporte; Instituto Nacional de Vias: Bogotá, Colombia, 2024; pp. 1–7.

- Riekstins, A.; Haritonovs, V.; Straupe, V.; Izaks, R.; Merijs-Meri, R.; Zicans, J. Comparative Environmental and Economic Assessment of a Road Pavement Containing Multiple Sustainable Materials and Technologies. Constr. Build. Mater. 2024, 432, 136522. [Google Scholar] [CrossRef]

- Narayan, K.; Aryal, R.; Joshi, B.R.; Shahi, P.B. Thickness and Cost Comparison of Cement Treated and Granular Base for Flexible Pavement: A Case Study of Pathlaiya-Nijgadh Section of East-West Highway of Nepal. J. Eng. Technol. Plan. 2022, 3, 10–17. [Google Scholar] [CrossRef]

- Hashemi Sohi, F.S.; Mansour, S.; Dehghanian, A. Multi-Objective Optimization for Selecting Sustainable Materials with Simultaneous Consideration of Several Components in a Product. Int. J. Sustain. Eng. 2022, 15, 107–121. [Google Scholar] [CrossRef]

- Yao, H.; Xu, Z.; Hou, Y.; Dong, Q.; Liu, P.; Ye, Z.; Pei, X.; Oeser, M.; Wang, L.; Wang, D. Advanced Industrial Informatics towards Smart, Safe and Sustainable Roads: A State of the Art. J. Traffic Transp. Eng. 2023, 10, 143–158. [Google Scholar] [CrossRef]

- Akbari, M.; Asadi, P.; Givi, M.K.B.; Khodabandehlouie, G. Chapter 13—Artificial Neural Network and Optimization. In Advances in Friction-Stir Welding and Processing; Woodhead Publishing Series in Welding and Other Joining Technologies; Woodhead Publishing Ltd.: Sawston, UK, 2014; pp. 543–599. [Google Scholar]

- Besseris, G. Non-Linear Saturated Multi-Objective Pseudo-Screening Using Support Vector Machine Learning, Pareto Front, and Belief Functions: Improving Wastewater Recycling Quality. Appl. Sci. 2024, 14, 9971. [Google Scholar] [CrossRef]

- Kang, S.; Li, K.; Wang, R. A Survey on Pareto Front Learning for Multi-Objective Optimization. J. Membr. Comput. 2024, 1–7. Available online: https://link.springer.com/article/10.1007/s41965-024-00170-z (accessed on 15 May 2025). [CrossRef]

- Legriel, J.; Guernic, C.L.; Cotton, S.; Maler, O. Approximating the Pareto Front of Multi-Criteria Optimization Problems. In Proceedings of the International Conference on Tools and Algorithms for the Construction and Analysis of Systems, Paphos, Cyprus, 20–29 March 2010; pp. 69–83. [Google Scholar]

- Tušar, T.; Filipic, B. Visualization of Pareto Front Approximations in Evolutionary Multiobjective Optimization: A Critical Review and the Prosection Method. IEEE Trans. Evol. Comput. 2015, 19, 225–245. [Google Scholar] [CrossRef]

- Cibulski, L.; Mitterhofer, H.; May, T.; Kohlhammer, J. PAVED: Pareto Front Visualization for Engineering Design. Comput. Graph. Forum 2020, 39, 405–416. [Google Scholar] [CrossRef]

- Petchrompo, S.; Coit, D.W.; Brintrup, A.; Wannakrairot, A.; Parlikad, A.K. A Review of Pareto Pruning Methods for Multi-Objective Optimization. Comput. Ind. Eng. 2022, 167, 108022. [Google Scholar] [CrossRef]

- Bejarano, L.A.; Espitia, H.E.; Montenegro, C.E. Clustering Analysis for the Pareto Optimal Front in Multi-Objective Optimization. Computation 2022, 10, 37. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).