3.1. Example 1: Formulation and Design of a Cubic Box

The lengths of three edges of a box are assigned to be the design variables,

,

and

. The performance functions considered here involve the volume, surface area, and weld length of this box, which are defined by,

The design starts with the given values as, , which results in a volume of 6, a surface area of 22, and a weld length of 24. Two scenarios will be investigated here: one with two performance functions; volume and surface area, and the other with three; volume, surface area, and weld length.

3.1.1. Two Performance Requirements: Volume and Surface Area

The goal here is to update the design variables that can reduce the current volume from 6 to 4 and the surface area from 22 to 18. The SOP will be used in the first attempt in which the volume is assigned as the objective and the surface area the constraint. Consequently, the values of

and

are 2 and 4, respectively. The search direction for the objective correction is given by,

while the search direction for constraint correction is given by

On the other hand, the scalar factor

calculated by Equation (12) is found to be,

Therefore, the required changes in the design variables are found to be,

which produces the revised design as

As a result, the volume and the surface area of the revised design are obtained as 4.15 and 18.13, respectively, which are close to the target values of 4 and 20.

The COA is used in the second attempt to solve the same design requirement. However, in this case, both volume and surface area are counted as constraints, and their required changes are set to be,

This approach produces the same revised design as the SOA.

Note that the trade-off design proposed here is based upon the linearized approximation of all functions of concern. Therefore, it is expected that a better trade-off design can be achieved with less amount of adjustment in the performance measurements. To demonstrate this matter, an exercise was performed with the amount of adjustment in volume being reduced in sequence from 2 to 1 and finally to 0.5, and the amount of adjustment in the surface area was reduced from 4 to 2 and to 1. The results are summarized in

Table 1.

3.1.2. Three Performance Requirements: Volume, Surface Area, and Weld Length

A new performance is added to the constraint set in this example, which requires the weld length to be 20. The special feature of this new example is that it is subjected to three equality constraints which are equal to the number of the design variables. Therefore, the constraint set can be directly employed to solve for three design variables. To this end, a root-finding function, fsolve, in Matlab (R2023a) is applied here but failed to generate a solution.

The COA is then employed to reach a revised design,

The new design produces a cube with a volume, a surface area, and a weld length of 1.0, 8.5, and 20. The new design satisfies the linear constraint in the weld length but fails to match the required volume and surface area. A second attempt is made to use the above solution as the initial design to restart the new design revision process. The COA failed as the Jacobian of the constraints is singular at this initial design stated in Equation (21). This is because the gradient of the volume is now linearly dependent on the gradients of the surface area and the weld length at the current design point. Specifically, the linear dependence of gradients can be described as

The MOA was then used to find the revised design with linearly dependent constraint gradients. The trade-off design starts with the design specified in Equation (21). The performance requirements of the volume and the surface area will be included in the composite function defined in Equation (18), while the weld length is kept as an equality constraint. Since the initial design has the weld length matched with the targeted value, it starts with in this case, which leads to . Consequently, the computation of the search direction is simplified as , so does the scalar factor, which is stated in Equation (21) with and . It takes three recursive runs to reach a satisfactory solution. The largest gap between the final and the targeted performances was found in the surface area.

A Matlab built-in function,

fgoalattain [

17], which is a multi-objective goal attainment program, is also applied here to solve the same problem. The volume and the surface area are given as the objectives, with the goals being 2 and 4, respectively. The limit on the weld length is provided as an equality constraint. It takes 10 iterations to reach the solution. The results of these exercises are listed in the last row of

Table 2 for comparison. The goal attainment program produces a result with equal design variables. It performs better in surface area but worse in volume in comparison with the results of the MOA.

3.2. Example 2: Control Problem with Three Targeted Eigenvalues

The goal of this example is to modify the design to achieve multiple targeted changes in the performance requirements. This is done with the recursive use of the Constraint Only Approach (COA).

The performance of concern is the eigenvalues of a

matrix equation,

where matrix

D is a matrix of 4 design variables,

,

,

and

, as specified below,

With initial design values,

, and

, the matrix

D is given by,

and the eigenvalue equation yields three eigenvalues,

,

and

. The goal now is to modify

D such that eigenvalues can match with the targeted values;

,

and

. To this end, the performance requirements can be expressed as a set of three equality constraints according to Equation (14):

The required change in this initial design is given by

. The COA is employed here recursively to find the revised design. After four iterations, the revised design can produce eigenvalues close to the targeted values with errors less than 10

−4. The results of this trade-off design process are summarized in

Table 3.

The goal attainment program,

fgoalattain, is again employed here to resolve the above problem. The object in its formulation is to have all three eigenvalues matched with the targeted values. The results are found to be

, which is different from that presented in

Table 3. The solution to the problem studied here is not unique.

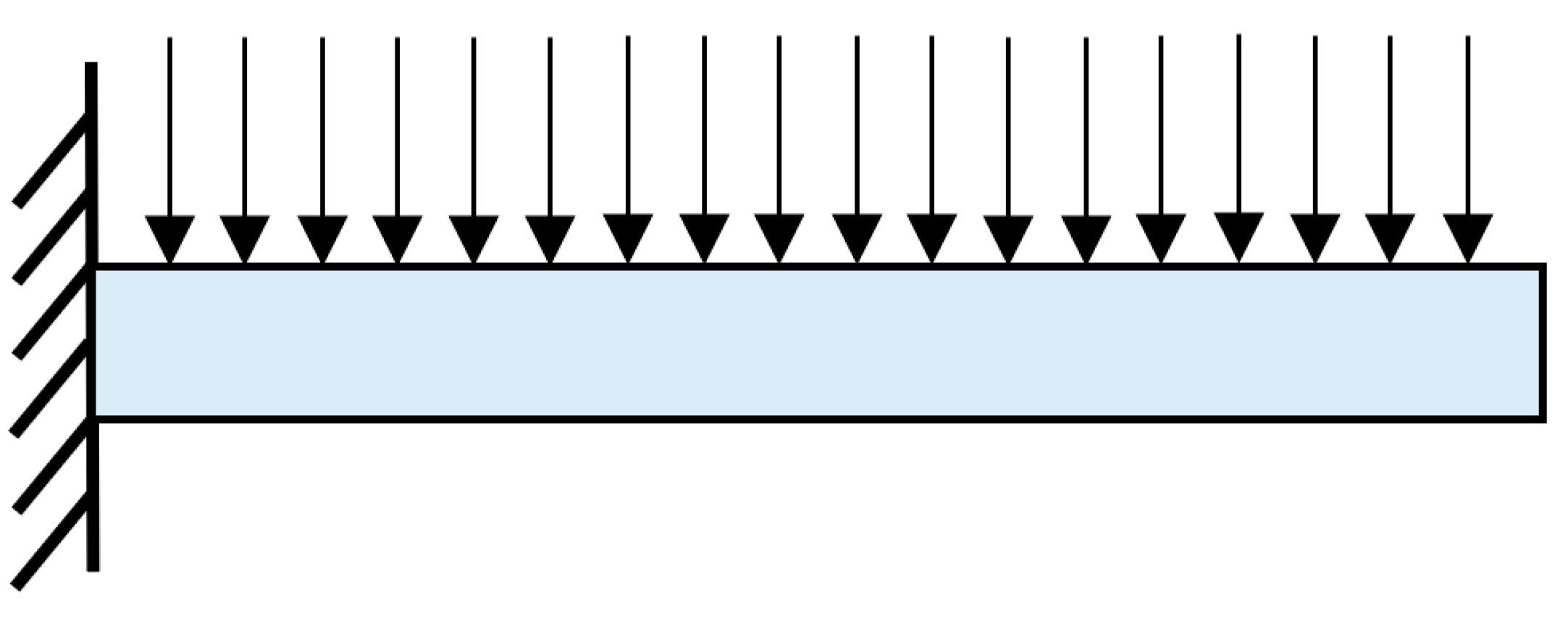

3.3. Example 3: Design Problem of an I-Beam

A design problem of an I-beam is used as a platform to demonstrate the trade-offs between the values of design variables and the design performance requirements. The cantilever I-beam, shown in

Figure 1 and

Figure 2, is required to be as light as possible and be able to support a uniformly distributed load,

, without failure.

The design variables are those specifying the cross-sectional dimensions of the beam. They are defined as

, the width of the beam minus the web thickness,

, the web thickness,

, the height minus the thickness of both flanges and

, the total height of the beam. Based on the definition of the variables, the cross sections area, the moment of inertia

I, and the area of the moment,

, are expressed as:

and

The total distributed load

on the beam is equal to the summation of the externally distributed load and the weight density per unit length. Thus, the total distributed load is given by

where

is the density of the beam per unit volume, and

A is the cross-sectional area. The performance requirements in this I-beam design problem include the total weight, the maximal deflection at the free end,

, the maximal bending stress,

, and the maximal shear stress at the fixed end,

, and the two fundamental frequencies,

and

.

For this example, the length of the beam

is set to be 40 inches, and the uniformly distributed load

P is set at 25 lbf/in. The beam is made of steel with Young’s modulus

E of 3

psi and a density

ρ of

lbf/in

3. The maximum allowable yielding stress

is equal to 12 kpsi, the maximal deflections

, is 0.1 inches, and maximum shear stess

, is 1500 lbf/in

2. These performance measurements are expressed as

The fundamental frequencies are calculated from the eigenvalues of the I-beam. To this end, the I-beam is discretized into two Euler beam elements, based upon which an eigenvalue matrix equation is built as follows

where the inputs are

and

, the stiffness and the mass matrices, and the output is

and

are the pair of the

ith eigenvalue and eigenvector. Here the eigenvector is normalized. That is

. The equations of the first and second fundamental frequencies can then be defined as,

The gradients of the frequencies with respect to the design variables can then be found by differentiating Equation (22) as

By careful examination, the above equation reveals that the gradient vectors of distinct eigenvalues of the I-beam problem are linearly independent of each other.

Three trade-off design examples are reported separately in

Section 3.3.2,

Section 3.3.3 and

Section 3.3.4. They are carried out using the result of an optimal design run as the initial design point. The optimal design run is reported in

Section 3.3.1. Example 1 in

Section 3.3.2 deals with three targeted constraint functions. Example 2 in

Section 3.3.3 deals with four constraints, among which two constraints exhibit linearly dependent gradients. Example 3 in

Section 3.3.4 works with five constraints. The challenge in Example 3 is that the number of the targeted constraints is greater than the number of the design variables. To demonstrate its effectiveness, the MOA will be used to solve Examples 2 and 3.

3.3.1. Initial Design Optimization

The design process starts with an optimization problem to minimize the weight subjected to constraints on deflection, normal stress, shear stresses, and geometry. The geometry constraint ensures that the thickness of the flange is greater than 0.25 inches and the bounds of the dimensions are in the range between 0.5 and 5 inches. The mathematical formulation of the design optimization problem is expressed below

subject to:

and the geometry constraint and the bounds

All performance constraints are weighted equally in the optimization process, which is normalized with respect to their upper limits.

The initial optimization was solved using the Matlab built-in function, fmincon, with the initial guess (2, 0.25, 1, 2). The optimal design was found to be (0.7469, 0.5, 3.1583, 3.6583). This result produces an I-beam with a weight of 25.55 lbs, a deformation of 0.0875 inches, a yielding stress of 12 kpsi, and a shear stress of 757.5 lbf/in2. More specifically, the yielding stress of the final design hits the upper bound, the design variable, , which is the thickness of the web, hits the lower bound, and the geometry constraint, or the difference between and hits the bound. Thus, the thickness of the flange also reaches the lower bound. In short, the four design variables of the I-beam problem are subjected to three tight constraints, , , and , at the optimal solution.

3.3.2. Example 1: Trade-Offs with Three Performance Functions

The goal of this example is to modify the optimal design to have three selected performance functions matched exactly with the targeted values. The first case will consider the maximal deflection, the maximal yielding stress, and the geometry constraint, while the second case will replace the geometry constraint with the constraint on the first natural frequency.

The first case was solved by the SOA, in which the deformation is set as the objective function, while the yielding stress and the difference between

and

, which is referred to as the geometry constraint, were set as the targeted equality constraints. The initial design is set at

, which is the optimal design result obtained from

Section 3.3.1. The SOA takes four iterations to produce a revised design,

, which results in a deformation of 0.1 inches, yielding stress of 12 Kpsi, and the difference between

and

of 0.5 inches. Therefore, it accurately meets all the desired requirements. The same problem is solved by the COA, which produces the same result.

The second case will continue the previous study, with its starting design point setting as . In this case, though, the existing geometry constraint in the existing constraint set will be replaced by the constraint imposed upon the first fundamental frequency, which is required to be 80 Hz. The SOA took four iterations to match closely to the targeted constraints. The final design is , which results in a first fundamental frequency of 80 hertz, a deformation of 0.1 inches, a yielding stress of 12 Kpsi, and a difference between and of 0.807 inches. It is important to note that the geometry constraint is higher than the previous targeted value; however, the geometry constraint is not being imposed in this case. Therefore, it accurately meets all the desired performance requirements.

This case is also solved by using the COA. In this approach, the first fundamental frequency, deformation, and yielding stress are all set as constraints. Like Example 1, the results produced by the COA are the same as those by the SOA. The results of these two cases are summarized in

Table 4.

3.3.3. Example 2: Trade-Offs with Four Performance Functions

The goal for this example is to demonstrate the use of MOA to handle situations where the gradients of involved functions are not all linearly independent of each other. Neither the SOA nor the COA can work in these cases. This example will consider four performance functions, including the first, the second fundamental frequencies, the maximal deflection, and the maximal stress constraints. Note that the gradient of the second fundamental frequency, which is newly added to the problem formulation, is parallel to the gradient of the first fundamental frequency, as indicated by Equation (23).

The MOA will be employed in this case, in which the objective function is made of both first and second fundamental frequencies, and the constraints include the maximal deflection and the maximal stress. The approach starts with an initial design at , which is the result obtained at the end of Example 1. After two iterations, the approach reaches a design with an acceptable result. The design is , which results in a first fundamental frequency of 79.172 Hz and a second fundamental frequency of 500.1311 Hz and achieves the targeted constraints: the maximal deflection, 0.1 inches, and the maximal stress, 12 Kpsi.

For comparison, this problem is also solved using the goal attainment function in Matlab,

fgoalattain. The goal is to enforce the two fundamental frequencies to be the same as the respective targeted values. To this end, the

EqualityGoalCount option is selected as an input parameter for this run. The optimization was terminated after 20 iterations because the maximal constraint violation was less than

. The results are listed in

Table 4, which are close to those obtained by the MOA.

3.3.4. Example 3: Trade-Off with Five Performance Functions

Example 2 is repeated here with the same objective and the same initial design. However, one more equality constraint on geometry, , is added back to the constraint set. Therefore, the number of the targeted functions is now 5, which is higher than the number of the design variables. The problem will be solved by the MOA as well as the goal attainment program, fgoalattain. The targeted objectives will be the fundamental frequencies 1 and 2.

The MOA takes three iterations to reach the design , which results in a first fundamental frequency of 79.172 Hz, a second fundamental frequency of 500.131 Hz and achieves the targeted constraints; the maximal deflection, 0.1 inches, the maximal stress, 12 Kpsi, and the newly added constraint, . On the other hand, the goal-attainment program produces the final design at after seven iterations. The new design satisfies the targeted constraint values and produces the two fundamental frequencies of 79.26 Hz and 500.73 Hz.

The results of all seven examples investigated in this I-beam problem are summarized in

Table 4. The four design variables of the I-beam problem are related to the sectional geometry, while the performance requirements involve the weight, the maximal deflection, the maximal stress, the thickness of the flange, and the first two fundamental frequencies. The active performance constraints considered in each case are indicated by the bold numbers in

Table 4. The results show that adding the deflection and the first frequency requirements in the constraint set will not affect the value of the design variable

, which is the height of the beam. Frequency 2 can be added as a new performance requirement without causing too many changes in the design variables. On the other hand, adding the geometry constraint as a new requirement will increase about 30% the values of the design variables

and

which are related to the width of the flange and the depth of the web. The weight of the I-beam remains stable throughout this trade-off study, which is not considered here as a constraint.