Abstract

The efficient utilization of solar energy technology is significantly enhanced by the application of energy storage, which plays an essential role. Nowadays, a wide variety of applications deal with energy storage. Due to the intermittent nature of solar radiation, phase change materials are excellent options for use in several types of solar energy systems. This overview of the relevant literature thoroughly discusses the applications of phase change materials, including solar collectors, solar stills, solar ponds, solar air heaters, and solar chimneys. Despite the complexity of their availability and high costs, phase change materials are utilized in the majority of solar energy techniques because of the considerable technical improvements they provide. While numerous studies have investigated the progress of phase change materials used in solar energy applications such as photovoltaic systems, it is vital to understand the conceptual knowledge of employing phase change materials in various types of solar thermal energy systems. Investigations into the use of phase change materials in solar applications for the purpose of storing thermal energy are still being carried out to upgrade the overall performance. This paper briefly reviews recently published studies between 2016 and 2023 that utilized phase change materials as thermal energy storage in different solar energy systems by collecting more than 74 examples from the open literature. This study focuses on demonstrating the maturity of phase change materials and their integration into solar energy applications. Based on the findings, proposals for new research projects are made.

1. Introduction

Even though solar energy has been used passively since prehistoric days, its technical application emerged in 2013 [1]. The development of solar thermal collector equipment from 1877 to the current times has improved human living in terms of comfort and economics [2]. Solar energy is a time-dependent renewable source of energy that is inexhaustible and eco-friendly. Among the most often used applications of solar energy is for thermal purposes. On the other hand, thermal energy storage is an efficient way to combat the sporadic and diffuse character of solar energy [3]. Techniques for energy storage can work towards closing the gap between supply and demand for energy. Among the most feasible methods for storing solar energy involves the utilization of specific organic and inorganic substances, which are referred to as phase change materials (PCMs), which enable the latent heat of fusion to be harnessed [4]. To improve the thermal performance of solar heating systems, PCMs can be used as an effective tool. PCMs can effectively store additional thermal energy during the day through fusion and release it at sunset via solidification at a consistent temperature, which leads to a higher storage efficiency.

PCM has a number of benefits. Specifically, its high heat storage capabilities compared to other heat storage materials lead to a decrease in the size of the thermal storage facility [5]. The isothermal phase change feature of PCMs, wherein heat is charged and discharged at a virtually fixed temperature (phase change temperature) matching the phase transition, seems to be another significant benefit. As a consequence, they are perfect for applications involving space heating where thermal comfort can be attained by reducing temperature swings [6]. However, PCMs have a number of demerits such as PCM systems necessitating a long operational time to recuperate the installation cost [7]. Conventional PCMs also have other drawbacks such as low thermal stability, thermal cycling, and low thermal conductivity [8,9]. In addition, the super-cooling effect lowers the PCM’s efficiency, leading to inadequate heat recovery, making it impossible to fix the PCM system without damaging it. To improve PCMs, several investigators have attempted to add various compounds; unfortunately, this has led to lower performance [10,11]. Prior to installation, the PCM’s extremely poor thermal conductivity must be increased since it hinders heat transfer during the solid–liquid transition [12]. Phase segregation may happen in PCM because it may contain many elements, which would undermine its long-term stability [13]. Building envelope organic PCMs have a substantial impact on fire safety. In using organic PCMs in building envelopes, scientists have advised using fire retardants to increase fire safety [14,15].

Despite that there has been a number of attempts to review the implementation of PCMs in different solar energy systems, scholars focused on discussing the concepts of these materials with outlining the influential parameters towards its implications in the solar energy industry. For instance, Nazir et al. (2019) [16] focused on the influences of thermos-physical properties of PCMs such as the melting point, and density and thermal conductivity of the organic, and inorganic materials on their implication in thermal energy storage applications. Additionally, Sikiru et al. (2022) [17] carried out a comprehensive review that provided a thorough examination of the recent advances and impact of PCMs on solar energy systems. Specifically, the authors described how photovoltaic (PV) systems could be improved in terms of performance by integrating heat storage devices into the PV cell energy harvesting. Additionally, it covered the techniques for configuring thermal storage, evaluation of PCM type and hybrid performance, PCM entry requirements, and property testing, as well as advancements in heat and mass transfer fluids for solar energy harvesting and thermal storage mechanisms and their uses. However, both Nazir et al. (2019) [16] and Sikiru et al. (2022) [17] have not covered the potential applications of PCMs in other solar energy fields such as solar air heater, a solar pond, solar collector, solar still, and a solar chimney.

This study discusses the applications of PCMs in solar collectors, solar still, solar ponds, solar air heaters, and solar chimneys. Thoroughly, a variety of technical, research, and development approaches pertaining to PCMs are addressed. Additionally, a full grasp of the characteristics of PCM is outlined to be improved and utilized in a range of applications. The findings of the current investigation may guide future research since they will help scientists understand the numerous advancements made in PCM, which still require further advancement.

2. PCMs in Different Solar Energy Systems

The use of PCMs in solar thermal facilities is meant to boost the intensity of the heat that is stored as a result of the conversion of solar energy. The system elements in which PCMs are deployed are frequently identified in the literature to be traditional thermal energy storage devices, for example water tanks [18,19,20] or systems with a separate tank filled just with PCM [21]. The next sections illustrate the evaluation of the conducted studies on the utilization of PCMs in solar collector systems, solar stills systems, solar bond systems, solar air heater systems, and solar chimney systems. Several aspects will be discussed for each solar energy system including the configuration, studied parameters and highlighting of the most interesting results.

2.1. Solar-Collector-Related Studies

A solar collector system is a technology that harnesses solar power to produce heat or electricity using sun radiation. There are two main types of solar collectors: photovoltaic (PV) (to generate electricity) and thermal (to heat water or air) collectors. A flat plate or a set of tubes that absorb sunlight and transmit the heat to a fluid or air that is pumped through the system make up the fundamental structure of a thermal solar collector [22]. The amount of sunlight available, the angle and orientation of the collector, the type of fluid utilized, and the temperature of the air or water heated, and the system’s insulation all have an impact on how well a solar collector performs. By choosing the right collector design and size, maximizing the orientation and tilt of the collectors to maximize solar radiation, using premium building materials, and limiting heat losses through adequate insulation, enhancing the effectiveness of a solar collector system is attainable [23]. To guarantee optimum efficiency and the system’s longevity, proper system maintenance, including routine collector cleaning of the panels to remove dust or debris is essential [24]. Solar collector systems can offer a clean and sustainable energy source for a number of uses, including electricity generation, hot water production, and residential and commercial heating, with proper design and implementation. Overall, solar collectors can decrease carbon emissions and energy expenses while also raising a property’s value.

This section discusses the recent studies that focused on the utilization of PCMs as thermal energy storage in solar collectors while highlighting the benefits of PCMs, which undoubtedly have influenced their analysis and conclusions.

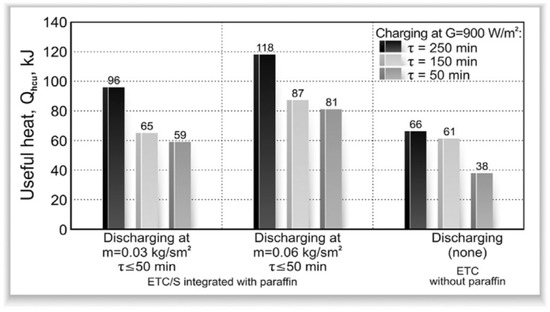

A relatively new proposal for an evacuated tube collector/storage (ETC/S) system including a PCM was proposed in 2016 by Feliński and Sekret [25]. Experiments were carried out to investigate the impact of incorporating commercial-grade paraffin as a PCM in evacuated tubes with heat pipes, with the aim of enhancing the thermal performance of ETC/S systems. The melting temperatures of the hydrocarbons that make up paraffin wax typically range from 47 to 68 °C. The precise melting point of paraffin wax might change depending on the unique makeup of the paraffin wax. Furthermore, the total amount of useable heat as a function of the presence of PCM in ETC/s. By allowing the recovery of heat that had been stored throughout the discharge cycle, the employment of paraffin has augmented the solar thermal operational time. Clearly, it was possible to raise the heating temperature of the medium to a practical level (approximately 45 °C). The findings also demonstrated that the paraffin-combined ETC/S system produced a total amount of useable heat that raised by 45–79% if compared to an ETC (Figure 1). These findings were reported throughout the discharge cycle considering the mass flow rate of the heating fluid.

Figure 1.

Useful heat is received by the heat collection unit throughout the charge and discharge cycles [25].

In 2016, a numerical analysis carried out using an Artificial Neural Networks model was provided by Serale et al. [26]. These simulations were carried out to evaluate the code and get a rough idea of how well the unique notion performed. To assess the efficacy of the slurry phase change materials (PCS) (this is a suspended material of micro-encapsulated phase change material (n-eicosane) in water or in a carrier fluid of water and glycol), and contrast it with that of a conformist solar thermal collector, several (dynamic) boundary conditions including the PCM concentration, location, and orientation were used based on based a flat-plate solar thermal collector. In this regard, solar energy extraction was utilized as a function of the use of slurry phase change materials. The results of the simulations have demonstrated the resilience of the model and its suitability for use in a recent investigation. Additionally, it was demonstrated that the use of PCS as a heat transfer fluid might boost solar energy extraction to varying degrees, depending on the region. Cold regions can get the biggest benefits.

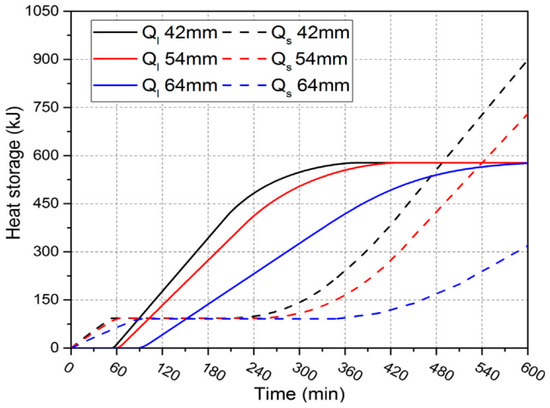

In 2017, Li and Zhai [27] presented a solar collector designed for mid-temperature operations. The PCM in this system, which has a melting temperature of 119 °C and is composed of erythritol and expanding graphite, was put within the aluminum pipes before being located inside the evacuated tubes. To conduct heat from PCM to fluid, the heat pipes were occupied in PCM. Based on thermos-physical property tests, the composite PCM with 3 wt% expanded graphite was selected as a good material for heat storage. It should be noted that heat storage was utilized as a function of tube diameter in this study. The thermal performance of this system was then investigated using both the experimental outfit and the computational model. The exposure tests were performed in August, and the analysis revealed that for mid-temperature consumption, the storage performance extended to 40.17%, according to Figure 2. The experimental data also served to verify the numerical model. For heat storage, a phase transition material composed of 3 weight percent expanded graphite and 97 weight percent erythritol is employed. Latent heat, thermal conductivity, and melting point are all 118.69 °C, 312.2 J/g, and 2.4 W/m K, respectively. In comparison to pure erythritol, the addition of expanded graphite improves thermal conductivity by 241.4%.

Figure 2.

Changes in heat storage with several storage tube diameters [27].

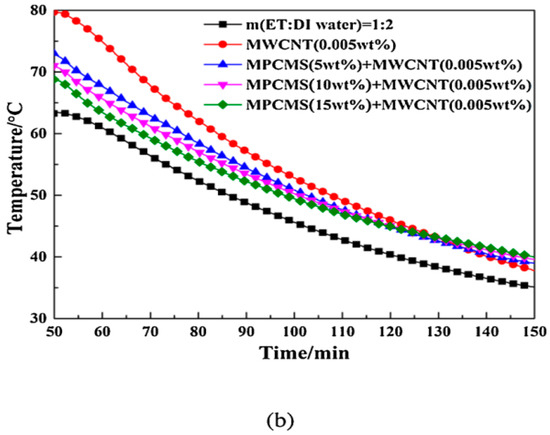

A hybrid slurry made of microencapsulated phase change materials (MPCMs) of paraffin@melamine resin mixed in an ethanol/water mixture-based multi-walled carbon nanotube (MWCNT) nanofluid was developed and testified by Wang et al. (2019) [28]. Temperature changes in PCM in the cases of charging and discharging were identified as a function of concentration. The study found that when PCM melted and the surface of MPCM exhibited high reflectivity, the temperature rise of the hybrid MPCM-MWCNT slurry was lower than that of pure MWCNT nanofluid in the base fluid (an ethanol/water mixture). However, the final temperatures of the hybrid slurries were higher than those of the MWCNT nanofluid during the thermal discharging phase and increased with the amount of MPCM present. The hybrid slurry comprising 15 wt% MPCMs had a comparable terminal temperature that was approximately 4.6 °C greater than the base fluid, as illustrated in Figure 3.

Figure 3.

Temperature changes in MPCM-MWCNT slurries at two stages of (a) charging and (b) discharging with various concentrations [28].

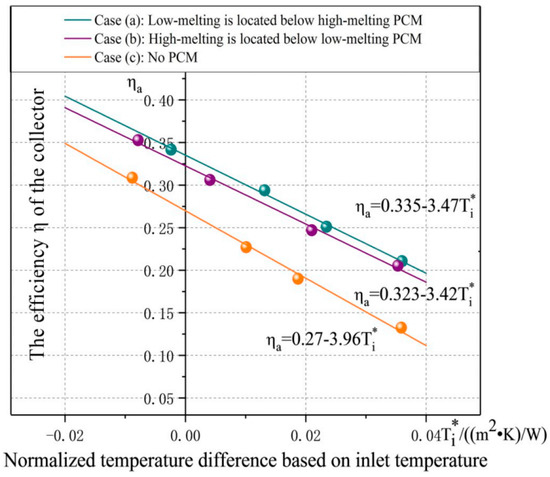

To overcome the phenomenon of overheating and freezing, a brand-new dual-PCM for flat plate solar collectors was suggested by Wang et al. (2019) [29]. Spherical particles were used to encapsulate the PCM, which comprised 20% high-purity graphite and 80% natural grease. The solar collector contained two layers of PCMs, one with 70 °C of phase change temperature (PCT) and the other with 15 °C of PCT. In other words, the PCM liquefies and absorbs heat when exposed to high temperatures, such as when the water temperature raises the PCM’s high melting temperature above 70 °C. This helps prevent the working fluid from becoming overheated. When the low-melting PCM reaches a temperature of less than 15 °C in a low-temperature situation, the PCM solidifies and releases heat to prevent the working fluid from freezing. Furthermore, this study focused on considering the thermal efficiency of the solar collector as a function of inlet collector temperature. They were positioned in the dual-PCM collector’s area beneath the absorber plate. According to the test results, high-temperature conditions can prolong the time it takes for the absorber plate temperature to rise from 60 to 78 °C by 1.6 h. Further, the dual-PCM collector can be employed to prevent freezing and overheating. Figure 4 shows that the performance of the dual-PCM collector was elevated by 24.1% and 19.6%, respectively, when low-melting PCM was positioned beneath high-melting PCM and the contrary situation.

Figure 4.

Proficiencies of the PCM collector and conservative collector [29] ( is the normalized temperature difference based on the inlet temperature ((m2·K)/W); is the ambient temperature (°C), I is the solar radiation intensity.)

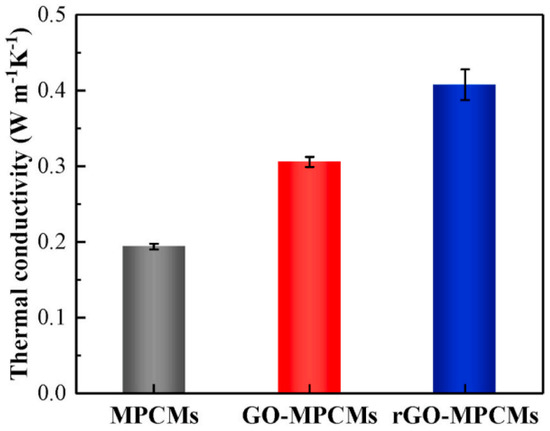

In situ, polymerization was used by Gao et al. (2020) [30] to create the microcapsule, which had an octadecane core and a melamine-formaldehyde (MF) resin shell that had been amended with a reduced form of commercial graphene oxide (rGO) and oleic acid-coated Fe3O4 magnetic nanoparticles in the shell (OA-MNs). In this regard, it is vital to admit that the thermal conductivity of PCM was incorporated as a function of PCM type. According to the experimental findings, introducing rGO significantly improved the thermal conductivity of magnetic PCMs while having no effect on their phase change activity, as shown in Figure 5. In the meantime, the MF resin shell that functioned as a protective shield significantly increased the thermal stability of octadecane in rGO-MPCMs. The photo-thermal conversion performance was further improved by the rGO-MPCMs slurry’s superior optical absorption and thermal storage capabilities compared to MPCMs slurry and deionized water. The rGO-MPCMs in the slurry showed remarkable stability and renewability in the presence of an external magnetic field.

Figure 5.

Thermal conductivities of bulk MPCMs, GO-MPCMs and rGO-MPCMs [30].

A detailed comparative examination of a conventional flat plate solar collector (FPSC) and a prototype with an equivalent thermal storage system via PCM was testified by Palacio et al. in 2020 [31]. Experimental and quantitative methods were used to study the devices’ thermal performance. An experimental setup measured the temperature of the glass cover, absorber plate, and PCM, in addition to the temperature of the ambient air and the water at the inlet and outflow. Palacio et al. in 2020 [31] introduced the thermal collector efficiency as a function of the contract conduction between the absorber and PCM. With this approach, experimental findings were assessed in order to determine how well both collectors performed under identical operating circumstances. Additionally, several trial scenarios were taken into account to enhance the prototype’s thermal efficiency. Analysis was using on two different PCMs (PCM1: Ecopetrol Semirefinada of 60 °C melting point, and PCM2: Rubitherm RT-47 of 41 °C fusion temperature), a contact thermal conduction increase, and collector disposition. According to this study, the contact conduction between the absorber and PCM and the selecting of the PCM are crucial components in enhancing the collector efficacy in comparison to traditional FPSC. Tilting the collector did not significantly improve the latitude of the laboratory investigation.

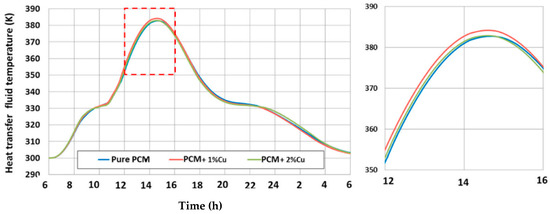

An innovative evacuated tube solar collector (ETSC) featuring a nano-PCM with fins was proposed and investigated by Elarem et al. 2021 [32]. The effectiveness was examined in relation to the adding of copper (Cu) nanoparticles to paraffin wax. Two PCMs were prepared and tested (PCM1: paraffin wax + 1% nano-Cu, and PCM2: paraffin wax + 2% nano-Cu). The simulation of heat transport through the energy storage process was carried out using ANSYS Fluent (Note: ANSYS is a software that provides a range of simulation capabilities, including structural analysis, fluid dynamics, electromagnetics, and system-level simulations). Last but not least, a set of comparative simulations were run to see how well the ETSC performs with and without the solar parabolic trough reflector (SPTR). In this study, the melting of PCM was identified as a function of fin thickness. It has been concluded that the paraffin phase shift heat transmission in the ETSC was significantly affected by the addition of fins. The PCM melts more rapidly as a result of lowering the fin thickness. Additionally, adding 1% Cu to the PCM was the appropriate mass concentration for raising the heat transfer fluid output temperature by 2 K, as shown in Figure 6. Additionally, it was found that a final flow rate of 0.003 kg/s was necessary for the PCM’s entire mass to melt. In reality, Nano-PCM can achieve a greater temperature, although briefly. The heat transfer coefficient between the copper tube and the HTF is improved by including Cu nanoparticles into the PCM. The reason for this is because the Nano-PCM filled Evacuated Tube Solar Collector (ETSC) shows improved energy storage during charging, allowing for a longer duration of hot HTF supply during discharging when solar radiation is at its peak.

Figure 6.

Influence of adding Cu nanoparticles on the heat transfer fluid temperature [32].

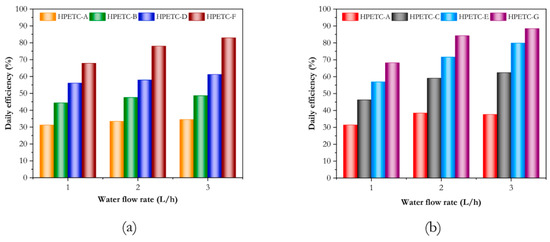

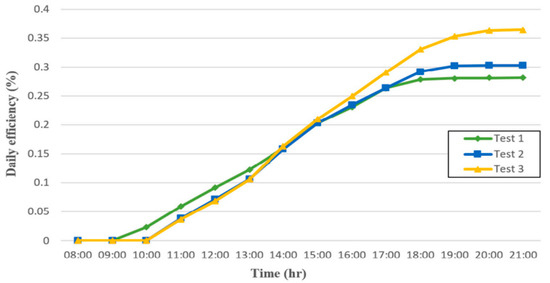

The performance of a heat pipe evacuated tube collector (HPETC) with a new approach, which included either one or both evacuated tubes (ET) and two separate storage tanks that incorporated nano- or micro-enhanced PCMs, was analyzed by Alshukri et al. (2021) [33]. The two separate tanks were filled with improved paraffin wax in the suggested designs, whereas ET was occupied with improved medical paraffin wax (grade-A). These two forms of paraffin wax were improved with either ZnO micro-particles or 5 weight percent CuO nanoparticles (MP-ZnO). In this regard, the collector efficiency was expressed as a function of micro or nanoparticle type. The outcomes demonstrated that the combination of improved paraffin wax with NP-CuO and MP-ZnO yields an efficacy enhancement range of 36.8–50% and 25.43–41.4% correspondingly in both ET and the isolated tanks. In contrast to a standard reference collector without PCM, the combination of improved paraffin wax with NP-CuO and MP-ZnO in the only ET increased efficacy with a range of 33.8–45.7% and 23.8–26.7%, respectively, as illustrated in Figure 7.

Figure 7.

The daily thermal efficiency at three various flow rates for (a) tests 1–3 and (b) tests 4–6 [33].

To overcome the difficulty of solar collectors to immediately store solar energy, Sadeghi et al. (2022) [34] effectively utilized a shape-stabilized phase change material (SSPCM) in a tankless direct-absorption evacuated tube solar collector. The SSPCM utilized in this study consisted of sodium acetate trihydrate (SAT), carboxymethyl-cellulose (CMC), sodium phosphate monohydrate (SPM), and expandable graphite. In this regard, expandable graphite was used to provide the PCM with a shape-stability feature in addition to improving its thermal conductivity. Sadeghi et al. (2022) [34] demonstrated the collector heat gain as a function of flow rate. After determining the appropriate constituent concentrations, the suggested salt hydrate PCM was built utilizing a range of relevant component concentrations and tested through a number of cycles to ensure that it could consistently store heat. The solar system was further refilled in the stagnation mode and then released at flow rates of 10, 27, and 40 (liter per hour) LPH (without water flow). According to the results, the collector-storage system improved thermal efficiency in the stagnation mode from 66% to 82%. Additionally, increasing the flow rate from 10 to 27 LPH did not significantly diminish the heat gain of the collector; however, a decrease in the discharge efficiency occurred after employing a flow rate of 40 LPH.

Yeh et al. (2022) [35] explored a storage-integrated solar thermal collector that had a small footprint and used a compatible phase change material (PCM) for storage. In this study, sodium acetate trihydrate (SAT), a salt hydrate-based composite PCM, was utilized to create a shape-stabilized PCM (SSPCMs) due to its low leakage and excellent thermal conductivity properties. When the built SSPCMs underwent experimental testing, a numerical model was designed to compare the results with the data and estimate the developed SSPCMs’ effective thermal characteristics. Furthermore, a model was used to investigate the (dis)charging behavior of a PCM in a storage-integrated solar thermal collector consisting of an evacuated tube and a double-spiral coil heat exchanger. In this regard, the discharging time was illustrated as a function of geometric optimization. With a minimal outlet temperature of 55 °C, a geometrical optimization has been performed to obtain a 2.6-fold longer discharging time. Furthermore, the circulating water is established to be supportive in rising the PCM charging rate by 9% by transporting heat from the surface of the tube to its center.

Nekoonam and Ghasempour (2022) [36] examined the thermal responses of a solar system with thermal energy storage. To address the PCM’s low thermal conductivity for energy storage and increase the system’s charging and storage efficiencies, a novel technique incorporating the use of sensible-latent materials (encapsulated spherical capsules of PCM and synthetic oil) as the ideal setup with two different options was used (option 1: outlet temperature of the unit with no temperature limitation; option 2: outlet temperature of the unit with threshold restriction). Charging time was considered in this study as a function of the Heat Transfer Fluid (HTF) flow rate. The findings indicated that a 5% rise (reduction) in the input HTF temperature reduced (increased) the charging time by 25% (32%) and enhanced (decreased) the total stored energy by 20% (by 7%). Moreover, a 50% change in the HTF flow rate causes a 12% gain or a 25% drop in charging time. For the first and second optimization scenarios, the best configuration stores 4940 and 4725 kWh of energy during the charge, which is approximately 14% more than the single PCM/sensible investigated situations.

Wen et al. (2022) [37] conducted a detailed performance assessment of an inventive concentrating system made up of a photovoltaic/thermal (PV/T) module with PCM and a solar thermal (ST) collector with thermoelectric generators (TEG) connected in a series. In this technology, the PV/T module produces low-temperature thermal energy in addition to photoelectric power generation, and the ST module and TEG on ST provide the secondary heated water and secondary thermoelectric output. Furthermore, The PV cell’s operational temperature can be lowered by the PCM during the day, and the platform can avoid freezing in the winter by releasing heat at night. The electrical and thermal performance were demonstrated in this study as a function of the Fresnel lens. Theoretical analyses revealed that the PV/T-ST system, which consists of a sequence of the ST and T modules, accomplishes well in terms of thermal and overall performance. Throughout the course of the whole day of activity, the water tank in the PV/T-ST system has a maximum temperature that is approximately 5 °C higher than the PV/T-PV/T system. The electrical and thermal performances using the 1.1-m2 Fresnel lens are also 10.65% and 65.22%, respectively, at 12:30. TEG converts some thermal energy into electrical energy over the day, increasing the quantity of high-grade energy in the system by approximately 321.53 kJ.

By using molecular dynamics modelling, Hatamleh et al. (2022) [38] examined the thermal behavior of glass in the vicinity of PCM (decane). In their research, temperature and density profiles were used to examine the atomic behavior of the structure. Furthermore, heat flow and thermal conductivity were used to examine the simulated structure’s thermal behavior. The quickly altering of PCM was expressed as a function of the design of the structure. According to the numerical findings, fluid particle density and temperature maximums are 0.09643 atoms/cm3 and 1067.51 K, respectively. The structure exhibits a thermal conductivity of 0.74 W/m K and a heat flow of 650.27 W/m2. Overall, incorporating phase change materials in the design can prevent energy loss, lower energy expenses, and facilitate rapid phase changes in the materials, positively impacting the structure’s performance.

Algarni et al. (2020) [39] explored whether a novel evacuated tube solar collector (ETSC) concept that incorporates nano-enhanced PCM (Ne-PCM) (0.33 wt% nano-copper with paraffin wax composite) as a latent heat thermal energy storage system could improve the performance of a conservative evacuated tube collector (ETC). This innovative technology combines the U-pipe of the evacuated tube solar collector (ETSC) with the Ne-PCM to form a single unit (ETSC/Ne-PCM) that can generate heat even when solar intensity is limited or inaccessible. By heat accumulation and the thermal insulation of the evacuated tubes, the new system functions as a thermal promoter, extending the time it takes to produce hot water and reducing temperature swings. Additionally, the effectiveness of FTSC was articulated as a function of the weight percent of Cu/PCM. It was discovered that adding 0.33 weight percent of copper/PCM composite to the ETSC increased its effectiveness by 32%. Moreover, the ETSC/Ne-PCM system with 0.08 L/min can deliver hot water up to 50 °C for roughly 2 h longer than standard ETC systems.

Karami et al. (2023) [40] examined the thermal efficiency of CuO nanofluid, CuO/Al2O3 binary nanofluid, and CuO nanofluid mixed with micro-encapsulated phase transition material in direct absorption solar evacuated tube collectors (MPCM). To simulate the MPCM slurry, two models—single-phase and mixture—were employed. The single-phase model is advised to shorten calculation time owing to the negligible distinction between the two-phase model’s results. The coefficient of performance was justified as a function of the volume % of nanoparticles. It was discovered that 0.06% Al2O3 + 0.002% CuO/water nanofluid and 0.06% Al2O3 + 0.002% CuO/(ethylene glycol) EG nanofluid, which are equivalent to 28.34 K and 36.64 K, respectively, provide the largest changes in outlet temperature. In both water- and EG-based nanofluids, the collector efficiency utilizing binary nanofluids is greater than that of using CuO nanofluids. According to the observations, the addition of MPCM and CuO nanofluid boosts the coefficient of performance by 4.53% and reduces heat loss by 5.84%. Across all working fluids, the combination of MPCM and CuO nanofluid simultaneously had the maximum accuracy.

A PCM of Tritriacontane paraffin is directly incorporated within the heat pipe evacuated tube solar collector (HPETC) and has copper (Cu) porous metal implanted in was developed by Pawar and Sobhansarbandi (2023) [41]. The performance of the suggested system was contrasted against that of a traditional HPETC system under comparable circumstances in order to make comparisons. Taking into account the distinction of fin temperature, output water temperature, energy, exergy efficacy, and cost analysis, each system’s thermal performance was evaluated. The maximum temperature increase was identified as a function of PCM and Cu porous that fill the evacuated tube. The results demonstrated that the evacuated tube filled with PCM + Cu porous metal was able to reach a maximal temperature increase of approximately 21 °C when solar radiation was at its highest amount. The difference in fin temperature between the ordinary evacuated tube and the evacuated tube filled with PCM + Cu porous metal was observed to be 36.1 °C after sunset. Additionally, on 9–11 April, at 10 PM, the highest water outlet temperature differences of 8 °C, 10 °C, and 11 °C, respectively, were discovered between the two designs. The conventional system only recorded a daily energy efficiency maximum of 36.91%, but the suggested scheme showed a maximum energy efficiency of 85.64%.

Studies on phase transition materials for solar collectors are shown in Table 1. Specifically, Table 1 introduces details of configurations, type of study, studied parameters and highlights the most important findings for those studies approximately solar collectors.

Table 1.

Outline of studies on phase change material for solar collectors.

Table 1 can show that the ETSC’s efficacy was found to rise by 32% with the use of 0.33 weight percent of copper/PCM composite. The prototype with a PCM raised the night outlet temperature by 2 °C and improved the greatest gathered energy by 630 Wh, if compared to the collector without a PCM. By using this collector-storage system, the thermal efficiency during stagnation mode increased from 66% to 82%.

2.2. Solar Still-Related Studies

A solar still system is a device that evaporates and condenses water to purify it using sun energy. A solar still’s basic structure consists of a shallow basin or trough with a transparent cover, typically made of glass or plastic, that lets sunlight in and warms the water inside. Water vapor rises and condenses on the bottom of the lid as it evaporates, gathering there to be collected in a different container [42]. A solar still’s effectiveness is affected by a number of variables, including the quantity of sunshine it receives, the surface area of the basin, the material used for the cover, and the temperature and humidity of the surrounding air [43]. For maximum effectiveness and system longevity, the system must be properly maintained, which includes routinely cleaning the basin and cover. In places where access to clean water is scarce or non-existent, solar still systems can offer a low-cost, long-term alternative for producing drinkable water.

This section attempts to provide a comprehensive review of recent studies that encountered the implications of PCMs in solar stills with a critical analysis of the overall performance.

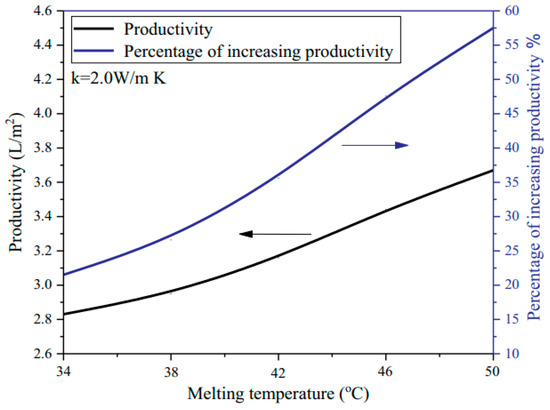

Using a new shape-stabilized phase change material (SSPCM), Cheng et al. (2019) [44] provided an original experiment as well as a simulation model to assess the efficiency of solar still. SSPCM of 5 wt% expanded graphite was specifically used. High thermal conductivity, a steady form, and strong sun absorption were all characteristics of the SSPCM. The SSPCM employed in the investigation had a thermal conductivity of 1.50 W/m K and a solar absorption of 0.94, making it a suitable replacement for the traditional metal absorber plate. Next, a test for solar still with PCM (SSPCM) was conducted. According to the trial findings, as depicted in Figure 8, the SSPCM’s daily productivity was 3.41 L/m2, 43.3% greater than that of the traditional solar still without PCM. The modeling findings demonstrated that when the thermal conductivity of SSPCM improved from 0.2 to 4.0 W/m K, the daily production rose from 42% to 53% compared to that of traditional solar still. The proportion of boosting productivity augmented from 21.5% to 57.5% as the melting temperature of SSPCM rose from 34 to 50 °C.

Figure 8.

The daily output and the increase in daily output of the shape-stabilized PCM (SSPCM) with various melting temperatures [44].

Vigneswaran et al. (2019) [45] conducted an investigation to appraise the thermal efficiency of three passive solar stills of the same size. The first still was a conventional solar still (Still 1), the second was a still with a single PCM (paraffin wax) (Still II), and the third was a still with two PCMs (Still III). The two PCMs utilized in Still III had different temperature ranges for their phase change but similar capacities for latent heat storage. PCM1 and PCM2 had a temperature range for a phase change of 58.03 °C to 64.5 °C and 53.05 °C to 62 °C, respectively. The tests were achieved in Chennai, India from February to May. PCM1 was designed to discharge stored latent heat energy once the solar radiation began to diminish, while PCM2 was intended to discharge heat when PCM1 had almost discharged all the stored energy. The researchers analyzed the thermal performance of the three stills in terms of hourly yield day−1 and exergy performance. The yields of Stills I, II, and III were 3.680, 4.020, and 4.400 L/m2/day, respectively.

Abu-Arabi et al. (2020) [46] conducted a study to evaluate the efficiency of adapted solar still under different scenarios. The solar still was modified and tested in three options: SC connected to an external collector (SCC), solar still with glass cooling (SC), and SCC with PCM (SCCP). In this regard, three PCMs utilized: sodium thiosulfate pentahydrate, sodium acetate trihydrate, and paraffin wax. The results showed that the productivity of the SC, SCC, and SCCP systems (with SAT as PCM) increased from 0.9 to 3.4 mL/min, 2.35 to 10 mL/min, and 3 to 11.9 mL/min, respectively. This is specifically conducted when the solar irradiation increased from 200 to 700 W/m2. The adding of an external collector and PCM improved productivity by 2.4 fold. An increase in the coolant mass flow rate from 0 to 10 kg/s has caused an increase in productivity for all systems. Moreover, an increase in the hot water circulation rate of the external collector has also increased productivity for the SCC and SCCP systems. The best PCM was the one with the greatest melting point and latent heat of fusion, and the ideal mass ratio of basin water to PCM was 2:1.

Incorporating hollow cylindrical pin fins was proposed by Yousef et al. (2019) [47] to improve the heat transfer properties of a PCM storage unit used in a solar still system. These fins functioned as thermal conductivity enhancers (TCEs). The study considered three scenarios: Case 1, a conservative solar still without PCM; Case 2, a solar still with PCM; and Case 3, a solar still with a pin-finned heat sink embedded in the PCM. The efficiency of each scenario was assessed and compared through experimental evaluation under the same climatic conditions. The findings elucidated that the existence of PCM had a negative impact on daytime freshwater productivity, but overall freshwater yield increased significantly. Moreover, the solar still with pin-finned PCM (Case 3) demonstrated superior thermal efficiency compared to both the conservative still (Case 1) and the solar still with only PCM (Case 2). The total daily water productivity was found to be 17% and 7% higher in Case 3 than in Cases 1 and 2, respectively. Additionally, the study showed that the inclusion of PCM in Cases 2 and 3 extended the productivity of distilled water after sunset by roughly 5 and 7 h, respectively.

A unique PCM tube shape was created by Elashmawy et al. (2020) [48] for usage within a tubular solar still with a parabolic solar concentrator. Twelve aluminum tubes with paraffin wax within each serve as a PCM. To improve the thermal qualities, copper rods are placed inside the paraffin wax. The tubular solar still is exposed to stronger sun radiation thanks to a parabolic concentrator solar tracking device. The experimental work was carried out in Ha’il City, Saudi Arabia, which is located at 27.64° N and 41.75° E and is 965 m above sea level. After being coated black, the 12 aluminum tubes were put within the trough. The productivity and device performance in freshwater has significantly improved, with comparatively low production costs. The productivity and performance of the created device are improved by 40.51% and 38.25%, respectively, when PCM tubes are used. When utilizing a device with PCM tubes, the yield, efficiency, and cost per liter are 5.55 L/m2 day, 44.1%, and 0.00782 USD, respectively. In contrast, using a device without PCM tubes yields 3.95 L/m2 day, 31.9% efficiency, and a cost of $0.0163 USD per liter.

Kabeel et al. (2020) [49] conducted experiments to elevate the efficiency of tubular solar still during both daytime and nighttime. They achieved this by adding enhancements to the design and construction, specifically by constructing closed copper tubes filled with PCM (paraffin wax), which suited the basin of the still. The enhancements led to a noteworthy rise in the production of distilled water, where conventional tubular stills produced 4.1–4.31 L/m2/day, while utilizing closed copper tubes filled with PCM increased productivity to 8.82–9.05 L/m2/day during June–August 2019, resulting in a 110–115.1% increase in accumulated productivity under similar conditions. Moreover, daily efficiency also improved, with conventional tubular stills achieving between 32.9% and 33.8%, whereas the utilization of closed copper tubes filled with PCM increased daily performance to 70.9–72.7%, representing a 114.4–115.5% increase in daily performance. Overall, the outcomes demonstrated that the use of copper tubes filled with PCM is a promising option for achieving optimal performance in tubular solar stills.

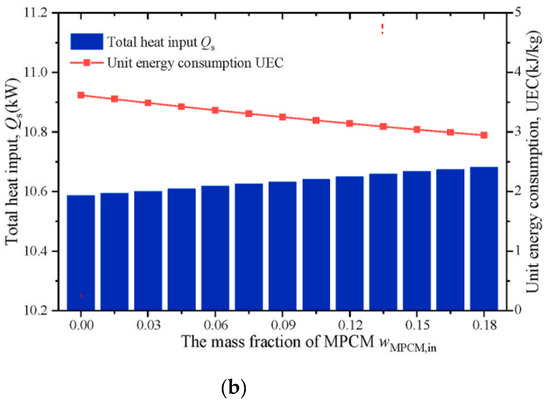

Solar-driven-spray flash evaporation (SFE) desalination unit improved using latent heat fluids was reported by Chen et al. in 2021 [50]. The addition of microencapsulated MPCM (TH-ME 58 (SiO2-paraffin)) in a NaCl aqueous solution improves the working fluid’s thermal energy storage and SFE process. The simulation results indicate that the use of MPCM in droplets can delay the temperature drop during the flash evaporation process due to their higher effective heat capacity. By adding 0.18 mass fraction of MPCM to the flash evaporation fluid, the water production ratio increased by 23.1%, and the specific energy consumption reduced by 18.3%. This is clearly depicted in Figure 9.

Figure 9.

SFE-condensation efficiency for different added solutions of different mass fractions of MPCM (a) the ratio of water production; (b) unit energy consumption [50].

Jahanpanah et al. (2021) [51] studied the impact of low-temperature PCM on the overall efficiency and productivity and basin temperature in a single-slope solar still. A commercialized inorganic salt hydrate + water + Additive PCM (Product number: PGSCR Co. PCM28/315) of 28 °C melting point, low temperature, and latent heat of fusion of 225 kJ kg−1 was chosen for this objective as a cutting-edge method in the industry. Investigations were conducted on three cases: (1) still without PCM, (2) still with 3 kg of PCM, and (3) still with 6 kg of PCM. The operative temperature, hourly and collective productivities, and desalination effectiveness were all observed and computed throughout each experiment. It was discovered that the addition of 6 kg of PCM can raise desalination efficiency from 28.13% to 36.42% while improving production overall by 30.3% (Figure 10). The outcomes demonstrate that the performance of the solar stills might be effectively enhanced by the use of low-temperature PCMs.

Figure 10.

Daily desalination efficiency of the unit for three test cases [51].

In a study conducted by Gnanavel et al. (2021) [52], the efficiency of solar still was enhanced by incorporating a PCM. The experimental setup consisted of an aluminum basin with and without the phase change material, and tests were conducted from 7 a.m. to 6 p.m. to determine hourly and cumulative productivity. Trimethylolethane and paraffin C18 were used as PCMs, and the results indicated that paraffin C18 resulted in greater productivity. CFD analysis was performed to validate these findings.

The inclined and traditional solar stills were coupled by Hansen et al. (2022) [53] to increase the daily distillation yield as a whole. Both stills store latent heat through the use of paraffin wax. In the course of the day, the PCM stores thermal energy and releases heat as needed. The solar still’s productive yield throughout the night is provided by the thermal energy storage of latent heat. The solar still is connected with external add-ons such as flat, steeped, and fin-shaped absorbers to improve distillation. The experiment was conducted outside, and daily production was assessed. This study determined that fin-shaped absorbers were more productive, and it was combined with PCM to produce a supreme amount of 5.62 L/day of distillate. The inclined still with the fin-shaped absorber was shown to be more creative when paired with basin still, with a production increase of 74.5%, and when coupled to PCM and basin still, with an increase in productivity of 87.96%.

Ajdari and Ameri (2022) [54] constructed an inclined stepped solar still with baffles to study the impact of the input brine flow rate, CuO/graphene oxide (GO) nanocomposite weight percent, a volume ratio of individual nanoparticles in the nanocomposite, existence of paraffin wax as a PCM, and distillate yield on the glass, brine, and bottom temperatures. As a consequence, the freshwater yield increased by 48.12 and 81.59%, respectively, with 0.03 wt% CuO and GO. Freshwater volume rose by 81.59%, thanks to a nanocomposite with a volume ratio of 30/70 for CuO/GO. Additionally, it was discovered that reducing the brine flow rate from 30 to 8 Lh−1 enhanced the productivity of freshwater while raising it to 68 Lh−1 decreased the distillate yield. Last but not least, adding paraffin wax as PCM to the solar still’s stages increased distillate production by 32.8%. In conclusion, it is shown that the CuO/GO nanocomposite is a promising alternative to be used in solar stills to elevate their productivity.

Abdullah et al. (2022) [55] carried out an experimental investigation to enhance the efficiency of the Tray Solar Still (TSS). The rate of heat transfer between the TSS absorber and the saline water has improved. The effectiveness of TSSs with flat and finned absorber forms was therefore examined. Conventional solar stills (CSS), TSS, and finned TSS were the SSs that were examined (FTSS). The finned absorbers were covered with jute wick materials, allowing water from the wick feed to gently rise through the porous material. PCMs of paraffin wax combined with copper oxide nanoparticles have been used to examine the FTSS efficiency for further improving TSS efficiency. The water basin has also been heated using three electric heaters. To occupy the same space as the FTSS and function as a power supply for electric heaters, a photovoltaic cell was constructed adjacent to the back wall of the FTSS. According to the results, using heaters and PCMs with nanoparticles increased FTSS productivity by 166 and 136% as contrasted to that of the CSS, respectively. Moreover, employing electrical heaters and PCMs with nanoparticles simultaneously increased the FTSS’s daily water productivity by 196% over the CSS.

By adding an internal sidewall reflector, hollow circular fins, and a nanoparticle-PCM, Tuly et al. (2022) [56] improved the efficiency of actively modified double-slope solar distiller units. One standard still and four modified stills with the specified connections were utilized in the experiment. According to the findings, the solar still modified with a reflector, fins, and nano-PCM produced a max of 1853 mL per day. The system’s most efficient adaptation was discovered to be the employment of a paraffin wax-Al2O3 nanoparticle mixture (paraffin wax and 3 wt% Al2O3), which offered nearly twice as much cumulative productivity as the pure PCM (just paraffin) scenario. In the situations of pure PCM and nano-PCM, distillate accumulation was superior to the conventional scenario by 61.36% and 92%, respectively. In addition, the combined effect of the circular fin, reflector, and nano-PCM resulted in achieving the highest energy efficiency of 21.56%.

A combined double-slope solar still (DSSS) and PCM-TES w(ere proposed by Afolabi et al. in 2023 [57]. Using vacuum mold-filling processes, PCM was microencapsulated in an epoxy resin composite. Specifically, they used 1.5 wt% of 40 nm sized Zn-nanoparticle and 5 kg paraffin PCM. To determine the impact of TES on productivity, the collected data from the traditional DSSS and DSSS-TES have been evaluated. The DSSS-TES system attained average daily temperatures of 65.2 °C, 77.5 °C, 82.4 °C, 79.5 °C, and 68.4 °C for the glass cover, humid air, salt water, still basin absorber, and TES cavity, respectively. With 7.5 L of potable water every day and a 3 h expansion of the working period, DSSS-TES has produced more. Moreover, rates of condensation and evaporation surged by 105% along with the rise in production. The system’s integration of TES has decreased heat losses, and a microencapsulated insulator has stopped PCM nanocomposite leakages. Desalinated water has not been discovered to contain any metals, microbes, or organic pollutants.

Bacha et al. (2023) [58] introduced an inventive design for tubular solar distillers that enhances productivity while minimizing costs. This was accomplished by replacing the flat absorber with a convex one covered in black jute wick material and incorporating an energy storage reservoir containing paraffin wax beneath the convex absorber. An oil heat exchanger was also included with a solar parabolic concentrator serving as an additional heat source. The effectiveness of this new design was assessed through the creation of two tubular solar distillers and conducting tests in Al-Kharj, Saudi Arabia. The first distiller was a standard tubular solar distiller used as a control, while the second was a modified convex tubular solar distiller (MCVTSD). The outcomes demonstrated the superior productivity of the MCVTSD, which achieved 13.58 L/m2/day. Furthermore, the pioneering configuration has upgraded thermal and exergy efficiencies, and overall productivity by 39.32%, and 4.99%, 233.25%, respectively, compared to the conventional tubular solar distiller.

The evaluation of the studies described in Table 2 shows that the joint effects of circular fin, reflector, and nano-PCM result in a maximum energy efficacy of 21.56%. The overall freshwater yield still significantly increases as a result of PCM, which also has a detrimental effect on daytime freshwater productivity. Moreover, productivity was boosted by 2.4 fold with the inclusion of PCM and an external collector.

Table 2.

Outline of studies on phase change material for solar still.

2.3. Solar Pond-Related Studies

A solar pond system is a device that employs a sizable, shallow pond to gather and store solar energy for use in heating and electricity production, among other things. A solar pond’s basic structure is made up of a number of salt concentration-varying layers that together form a gradient that traps solar energy and warms the water at the pond’s bottom. The heated water can subsequently be used for a variety of purposes, including the production of energy through a turbine, heating of enclosed spaces, and industrial activities. The depth of the pond, the gradient in salinity, the amount of solar radiation, and the surrounding temperature all have an impact on how well a solar pond performs [59]. By choosing the right pond shape and size, maximizing the salinity gradient to optimize thermal stratification, and properly insulating the pond, one can increase the efficiency of a solar pond system [60]. For the system to operate at its best and last as long as possible, it must be properly maintained, which includes monitoring the salinity gradient and routinely clearing the pond of sediment and other waste. Particularly in regions with plenty of sunlight and restricted access to conventional energy sources, solar pond systems can offer a low-cost, environmentally friendly solution for producing thermal energy in a range of applications.

The current section provides a valuable summary of the associated research on PCMs in solar pond systems.

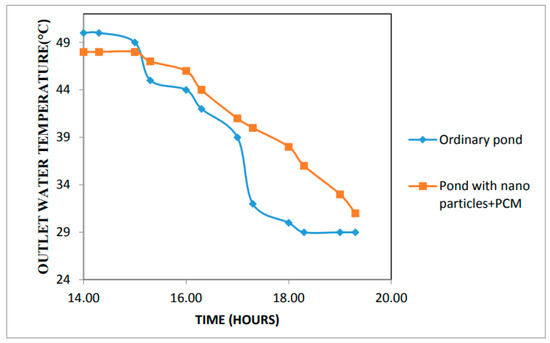

Sarathkumar et al. (2017) [61] added Al2O3 nanoparticles to PCM to enhance the performance of the solar pond. Al2O3 nanoparticles have strong thermal conductivity, and PCM has good heat absorption ability. The time required for solar pond charging and discharging can be greatly decreased, and the rate of heat transfer can be boosted, by the addition of Al2O3 nanoparticles. The copper tube contains a mixture of PCM and Al2O3 nanoparticles. This encapsulation, which consists of PCM mixed with nanoparticles, is positioned in the pond’s LCZ (lower convective zone). In the LCZ, a heat exchanger extracts heat. Power plants can be provided with useful steam to produce electricity. The most usable heat that may be produced is 167 W. Just until evening 6.00 PM could the solar pond without nanoparticles supply water at a warmer temperature. Yet, the solar pond containing Al2O3 nanoparticles was capable of providing hot water until 7.30 PM in the evening. As illustrated in Figure 11, the solar pond containing Al2O3 particles was still capable to produce hot water for 1.5 h after sunset.

Figure 11.

Evaluation of outlet water temperature of two different ponds [61].

Amirifard et al. (2018) [62] combined a solar pond with latent heat storage to improve performance stability. They analyzed three different configurations: two parallel and one series layout and presented the results in terms of temperature changes, thermal energy, and process efficiency. The conducted study evaluated the performance of four PCMs including the n-pentacosane, n-hexacosane, n-docosane and n-tetracoscane. The series layout showed a 6.1% increase in average efficiency of discharging time compared to the pond without PCM, while the parallel layout showed a 5.4% increase.

Experimentally, a salt-gradient solar pond (SGSP) subjected to a solar simulator was provided for thermal evaluation by Ines et al. (2019) [63]. Environmental chambers were used for the experiments. To compare the integration and absence of ultra violet (UV) filters, two experimental prototype solar ponds were constructed in Italy. Additionally, illustrative findings demonstrating the impact of the simulator spectrum on an SGSP’s temperature distribution and the consequences of thermal performance have been examined. Due to its higher potential to store latent heat, the PCM has been utilized in this study as a material that can absorb and release significant amounts of energy during solidification and melting. The outcome demonstrated that the solar pond with PCM (Plexiglas Poly (methyl methacrylate)) is capable of serving as a hot water source for home presentations by simultaneously gathering and storing solar energy. As demonstrated in Figure 12, the difference in temperature has decreased due to the pond’s highest temperature being lower with PCM while the lowest temperature was roughly identical in both ponds.

Figure 12.

Temperature fluctuations of SGSP without and with PCM throughout the operational time [63] (a) without phase change materials, (b) with phase change materials.

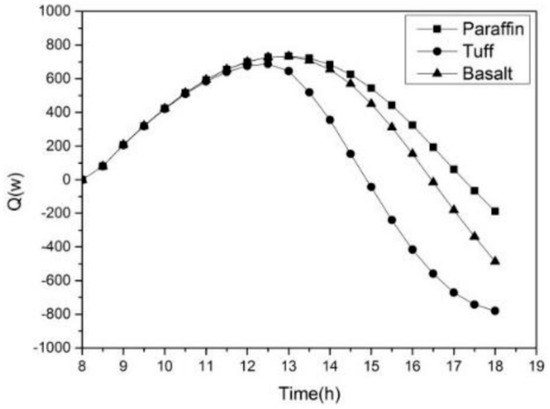

A one-dimensional model for transient heat transfer utilizing PCM was proposed by Beik et al. (2019) [64]. The convection, conduction, and radiation heat exchange with the ambient was used to determine the UCZ temperature. Paraffin Wax was utilized as PCM in the LCZ to extend the effects. According to numerical findings, a sizable amount of energy is wasted in this configuration due to reflection, walls, convection, and evaporation. Only 6% of the available solar radiation was stored, which can be improved with better insulation. Additionally, this study establishes optimal guidelines for the depth-to-radius ratio of the system, beyond which heat loss can be neglected. Moreover, the application of PCM in the solar pond yielded more stable temperatures during heat extraction, as indicated by both experimental and numerical findings.

Wang et al. (2020) [65] evaluated the effect of incorporating composite PCM heat storage capsules into the heat storage layer of a salt-gradient solar pond on its thermal efficiency, using both numerical and experimental methods. The solar pond with PCM capsules (paraffin wax 50 and paraffin wax 60) exhibited a smaller temperature range during the phase change process compared to the conventional solar pond, but not during the non-phase transition process. Moreover, the inclusion of PCM phase change units has reduced the flow rate of the heat storage zone. The high latent heat of the PCM has a more pronounced suppressive influence on the flow. Consequently, adding PCM to the solar pond has an optimistic influence on preserving a fixed temperature and steadiness within a certain temperature range.

Rghif et al. (2021) [66] conducted a numerical investigation to determine the impact of a layer of PCM (paraffin wax) and the Dufour effect on the thermal efficiency of a salt-gradient solar pond (SGSP). The analysis considered two cases, the first case with an SGSP without a PCM layer, and the second case with an SGSP having a PCM layer located at its bottom. The findings of the simulation showed that the SGSP with a PCM layer had a lower temperature and thermal efficiency and higher heat losses across the saline water-free surface compared to the SGSP without a PCM layer. In Case 1, elevating the dimensionless Dufour coefficient from 0 to 0.8 resulted in a drop in the storage zone’s dimensionless temperature from 0.894 to 0.764 and a drop in thermal storage efficacy from 37.41% to 31.85%. Similar to Case 1, Case 2 saw a reduction in the dimensionless temperature of the storage zone from 0.800 to 0.688 and a drop in the thermal storage efficacy from 33.32% to 28.66% for the same variation spectrum in the dimensionless Dufour coefficient.

A pond combined with paraffin wax PCM (RT35 HC) and a conventional one were planned, constructed, and tested by Colarossi et al. (2022) [67] to compare their respective performances. The average temperature in the pond with the RT35 HC is, according to the results, roughly 4 °C cooler over 10 days (equivalent to a 5.7% decrease). After that, a second experiment was run to compare two melting temperatures (RT35 HC and RT44 HC). According to the findings, a greater melting temperature makes it possible to smooth out temperature peaks. Due to the release of latent heat, a lower melting temperature ensures a greater and more stable temperature at night, making the application suitable in cases where a fixed temperature need at the outlet fluid is present.

In the LCZ of a small solar pond, Colarossi and Principi (2022) [68] demonstrated an innovative application of PCMs. Aluminum cylinders that have been stacked on the bottom contained paraffin wax (RT-35 HC). Both with and without the PCM, the solution’s deep temperature is being tracked. With a laser shadowgraph approach, the stability of the pond is examined in order to see how thermal convection affects the surfaces. Findings indicate that after a 6 h heating cycle, the LCZ of the solar pond with PCM is approximately 3 °C cooler than the reference example. The shadowgraph study demonstrates that the reference case’s increased thermal convection damages the interface to the point of failure. The solar pond is more stable, according to PCM testing.

Wang et al. (2022) [69] investigated the effect of adding steel wires to paraffin in the composite PCM on heat transfer performance. The study found that adding 10 wt% of steel wires significantly improved the heat transfer coefficient, with a greatest value of 18.17 W m−2 °C−1 and an increase of 18.84% during melting, and a maximum value of 21.59 W m−2 °C−1 and an increase of 20.88% during freezing. In addition, an experimental study was conducted in a solar pond with 20 PCM capsule tubes added. According to the study, the addition of RT 50 and RT 60 paraffin waxes to the solar pond reduced day-night temperature differences by 2.87 °C and 2.53 °C, respectively, compared to the conditions without any PCM. Moreover, the inclusion of RT 50 and RT 60 resulted in exergy increments of 9.34% and 14.13%, respectively. This implies that adding PCM to the solar pond improved the quality of the thermal energy produced.

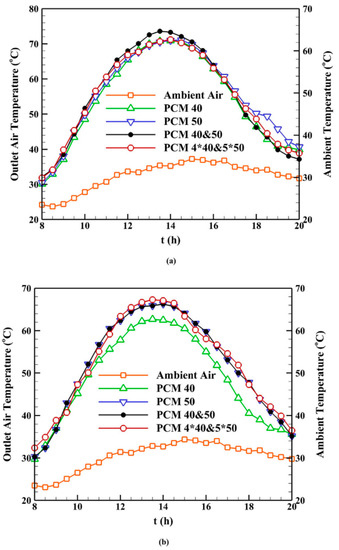

In 2022, Reza et al. [70] carried out a study to compare the thermal and salinity characteristics of two pilot salt-gradient solar ponds with and without a PCM made of paraffin wax. They looked at three distinct heat extraction techniques and discovered that instability can occur at the upper and lower salinity gradient limits. The findings demonstrated that the PCM-equipped salt-gradient solar pond outperformed the pond without the PCM in terms of average outlet temperature for the internal heat exchanger, thermal and salinity stability, and temperature drop during heat extraction. The minimum and maximum temperatures of the pond were controlled by PCM, which increased evaporation (8.4%) and enhanced thermal efficiency during rapid or prolonged heat extraction. The research additionally indicated that while heat extraction from the non-convective zone (NCZ) can affect the stability of the NCZ, heat extraction from the convective layer is preferable to that from the NCZ.

In summary, it can be stated that the maximum increase in outlet water temperature from the solar pond was 6.5% for using PCM than the case without using PCM. This is already indicated by Beik et al. (2019) [64] and demonstrated in Figure 13.

Figure 13.

Heat extraction of the ponds with and without PCM and ponds’ temperature against operational time [64].

A review of the research included in Table 3 demonstrates that adding PCM units to the solar pond improved its stability and capacity to sustain a constant temperature. Moreover, utilizing the PCM in the solar pond results in a temperature that is more consistently stable while the heat is being extracted. Additionally, the average efficiency of discharging time for the series arrangement reveals a 6.1% increase in the pond without phase change material (PCM). Moreover, this increase for the parallel layout is roughly 5.4%.

Table 3.

Outline of studies on phase change material for the solar pond.

2.4. Solar Air Heater-Related Studies

In order to heat air for applications such as room heating and ventilation, a solar air heater system employs solar energy. A flat plate or a group of tubes serving as the basic building blocks of a solar air heater are used to absorb sunlight and transmit heat to the air being circulated within the system. The heated air can then be utilized in place of or as an addition to conventional heating systems. The amount of sunshine available, the direction and tilt of the collector, the airflow rate, and the surrounding temperature all have an impact on how well a solar air heater performs [71]. By choosing the right collector type and size, adjusting the collectors’ orientation and tilt to maximize solar radiation, and reducing heat losses through adequate insulation, it is possible to increase the efficiency of a solar air heater system. For the system to operate at its best and last as long as possible, proper maintenance is required, including routine air filter replacement and collector cleaning [72]. In a number of applications, solar air heater systems can offer an affordable, environmentally friendly alternative for space heating and ventilation, especially in regions with ample sunlight and high heating demands.

There are profound advantages and a few limitations and shortcomings of the current utilization of PCMs as thermal energy storage in solar air heaters. This section covers a broad range of topics related to PCMs, including their thermal properties, applications, and challenges.

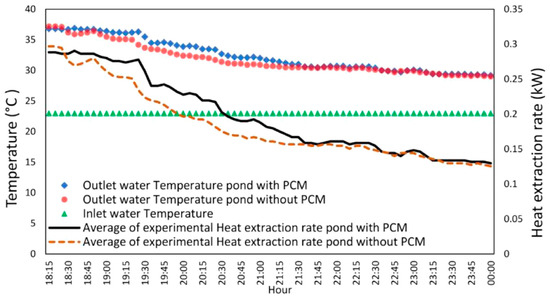

Research on the thermal efficiency of a v-corrugated plate solar air heater and a flat plate solar air heater with and without PCM (paraffin wax) at various mass flow rates of 0.062, 0.028, and 0.009 kg/s was undertaken by Kabeel et al. (2016) [73]. They also looked into the impact of changing the PCM’s thickness beneath the absorber plate. According to the experimental results, the flat plate solar air heater with the same mass flow rate of 0.062 kg/s had a temperature of 1–5.5 °C for 2.5 h after sunset while the v-corrugated plate solar air heater’s outlet temperature was 1.5–7.2 °C greater than the surrounding temperature when PCM was used. Furthermore, the outcomes presented in Figure 14 indicate that the v-corrugated plate solar air heater equipped with PCM had a 12% higher daily performance than the one without PCM. Moreover, when the mass flow rate was 0.062 kg/s, the v-corrugated plate solar air heater with PCM showed a 15% and 21.3% improvement in daily performance compared to the flat plate solar air heater with and without PCM, respectively.

Figure 14.

An assessment of daily performance between v-corrugated and flat plate solar air heaters vs. the mass flow rates with and without PCM [73].

El Khadraoui et al. (2017) [74] developed an indirect forced convection solar dryer using PCM (paraffin wax). A solar air panel heats the drying agent directly, while a drying chamber and a solar energy accumulator (a solar air collector with a PCM cavity) are also part of the system. The objective of this study was to investigate the feasibility of using a solar air heater with PCM to store solar energy during the day and release it at night. The solar dryer was tested both with and without PCM while under no load. The solar energy accumulator’s daily energy effectiveness was estimated to be 33.9%, compared to its daily energy efficiency of 8.5%. The findings show that after employing the solar energy accumulator, the drying chamber’s temperature stayed 4–16 °C above the surrounding air throughout the night. Moreover, when using the solar dryer with PCM, the relative humidity in the drying chamber was 17–34.5% lower than the ambient relative humidity.

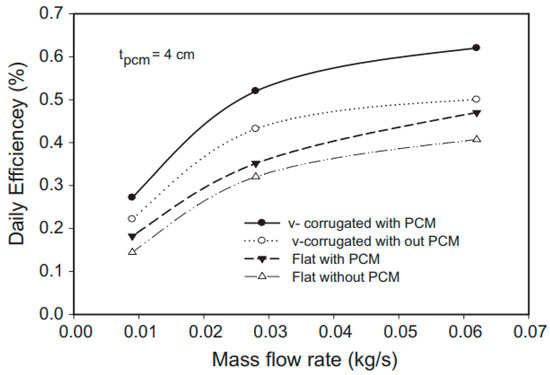

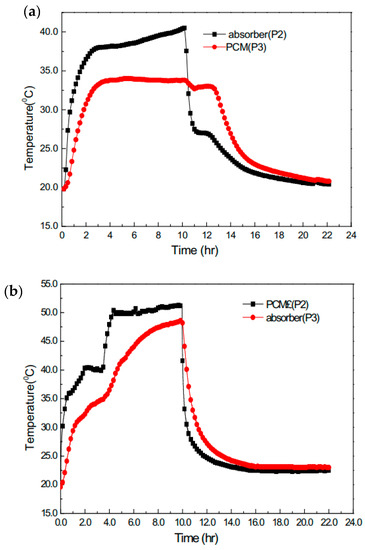

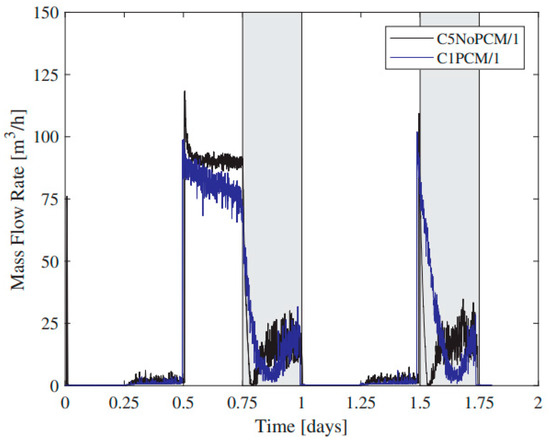

A double-pass solar air heater was studied by Salih et al. (2019) [75] using a series of rectangular capsules filled with PCM made of paraffin wax. The innovative system was tested during the charge/discharge process using an indoor projector simulator, and the three-dimensional forced convection turbulent flow in the double-pass solar heater was solved using a model based on a SIMPLE solver. As shown in Figure 15, the results revealed that raising the air flow rate caused the melting duration to take longer and the paraffin melting temperature to drop. For different sun intensities of 825 W/m2, 725 W/m2, and 625 W/m2 at the same airflow speed of 0.6 kg/min, it was discovered that the heater’s best discharging period and air temperature increase were 3 h with 17.95–3 °C, 2 h with 14–3 °C, and 1.25 h with 11–2.5 °C.

Figure 15.

The mean temperature in the DP-SAH with PCM versus air MFR for various solar irradiance of 825 W/m2 [75].

The thermal efficiency of solar air heaters was studied in experiments by Abuşka et al. (2019) [76] to determine the effects of employing PCM and honeycomb as an internal fin structure in the PCM panel. A total of 6 different air mass flow rates, ranging from 0.008 to 0.048 kg/s, were used during the tests. A total of 2 distinct configurations of the heat storage material were tested. The Type I heater (which utilized PCM with a honeycomb core) and the Type II heater (which used solely PCM). The third heater (Type III), which served as a reference, had a flat absorber plate without PCM. The findings revealed that for mass flow rates of 0.032, 0.04, and 0.048 kg/s, the Type I and II heaters with PCM’s average daytime thermal performance improved from 8.4% to 9.0%, while for mass flow rates of 0.008, 0.016, and 0.024 kg/s, it declined from 0.8% to 8.0%. The heater without honeycomb was more effective by 0.1% to 4.4% per day when compared to the heaters with PCM, according to the comparison. The Type I and II heaters with PCM were more effective, ranging from 2.6% to 22.3%, when the daily thermal performance was taken into account, especially at high mass flow rates.

The study conducted by Raj et al. (2019) [77] aimed to improve the thermal efficiency of the double-pass solar air heater system (DPSAHS) by incorporating PCM with thermal lag. Additionally, they investigated the impact of metallic macro-encapsulation on the heat storage and recovery of the PCM coupled with the DPSAHS. The study investigates the impact of encapsulation geometry on the storage and discharge of organic paraffin wax PCM. The research found that rectangular and cylindrical macro-encapsulates equipped with DPSAHS had an average encapsulation performance of 47.2% and 67%, respectively. The study also compared the performance of DPSAHS with and without PCM storage. The analysis showed that the DPSAHS with PCM storage improved operational time at a slightly higher construction cost.

SunilRaj et al. (2020) [78] conducted an experiment on a solar air heater with a V-trough solar thermal collector integrated with PCM (paraffin wax) blended with Al2O3 nanomaterials at a fill ratio of 0.90, and a drying chamber. The experiment aimed to test the efficiency of the system in drying 0.5 kg capsicum, and the results demonstrated a significant enhancement in moisture removal. The researchers determined that the design of the system is uncomplicated and exhibits excellent thermal efficiency. The research was carried out under sunny conditions in Bengaluru (12.96° N, 77.63° E) and demonstrated that the daily thermal efficiency of the air heater with thermal storage system ranged from 12% to 65%.

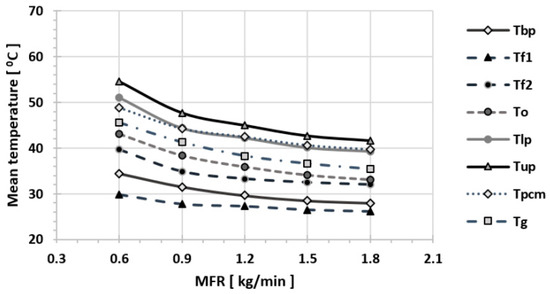

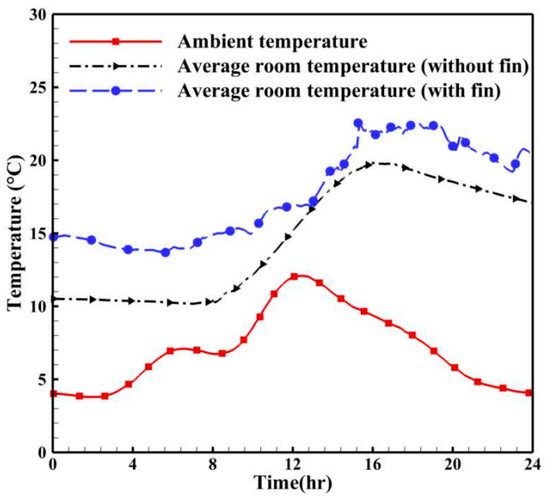

In order to assess the temperature responsiveness and competence of a standard solar air heater (SAH) with SAH fitted with a PCM constructed of paraffin packs, Ameri et al. (2021) [79] conducted an experiment. The experiment looked at how the use of PCM, its melting temperature, and the layout of slabs of PCM with various melting points affected the thermal responsiveness of SAHs. On a Board, four distinct combinations of 2 kinds of paraffin wax with various melting temperatures between 40 °C and 50 °C were fitted. In Kerman, Iran, the experiment was carried out at two separate air mass flow rates. The findings demonstrated that utilizing PCM increased the SAH’s daily thermal efficiency from 53.1% to 62.6%. Using PCM with a greater melting point temperature, SAHs’ outlet temperatures rose by over 5 °C, and their daily efficiency increased by approximately 3%. (Figure 16). The experiment also showed that the configuration with evenly distributed PCM types with various melting points had the best daily thermal efficiency and produced an enhanced thermal efficiency of approximately 5%.

Figure 16.

The variation of outlet temperatures in different scenarios for air mass flow rates of (a) 0.006 kg/s and (b) 0.01 kg/s, data acquired on 20 July 2019, and 21 July 2019 [79].

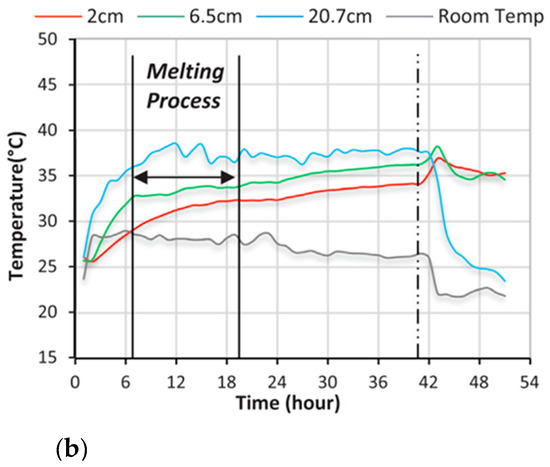

Mahdi and colleagues (2021) conducted numerical simulations to investigate the melting/solidification process in a metal foam containing PCM for both sequential and simultaneous operational modes. Specifically, Mahdi et al. (2021) [80] used organic phase change material paraffin wax type RT70HC (RUBITHERM). The composite was included in a rectangular compound that heated a room as a space heater after being cooled by air flowing through a central channel. As a result of quicker charging rates than mode II, the results showed that modes I (8 h charging and 8 h discharging separately) and III (2 h charge and 14 h simultaneous charging-discharging) both reached full melting (2 h charging and 2 h discharging separately, repeated for 16 h). The temperature distribution in Mode III was more uniform, leading in consistent heat transfer between the PCM and cooling fluid. Increasing the porosity of the metal foam had a negative impact on the rate of liquid development, resulting in complete PCM melting in 6.5 h for 90% porosity and 78% melting in 8 h for 95% porosity. Moreover, by increasing the air flow rate from 0.01 kg/s to 0.03 kg/s, the final mean temperature of the PCM was reduced from 69.9 °C to 66.4 °C.

Madhulatha et al. (2021) [81] utilized ANSYS FLUENT to optimize TESS design through numerical analysis. The researchers evaluated three diverse PCMs, including paraffin wax, n-octadecane, and calcium chloride hexahydrate (CaCl2·6H2O), and examined inline, staggered, and circular arrangements of tubes in the TESS. They altered the air intake temperature to TESS from 40 °C to 125 °C and adjusted the mass flow rate of air velocity at the inlet from 3.5 to 5.5 m s−1 in steps of 0.5 m s−1. The results introduced the average tube wall temperature, average surface heat transfer coefficient, average PCM temperature in tubes, and average heat absorbed by PCM. When comparing staggered and inline grid arrangements, tubes in staggered arrangements were found to increase heat absorbed by PCM by 10.45% and 48.03%, respectively, with paraffin wax and CaCl2·6H2O as PCMs, while there was an insignificant 0.09% improvement with n-octadecane.

Dinesh et al. (2022) [82] carried out a study to test the efficacy of a baffled solar-based air heater (SAH-BP) with organic PCM backup. The investigation was carried out over two similar solar days in February 2021 and interacted with operating modes, namely baffled SAH without organic PCM (SAH-BP) and baffled SAH with organic PCM. The organic PCM was stored underneath the absorber, and the baffle plates were connected over the absorber surface in an alternate sequential manner. The trials were kept at a constant flow rate of 0.18 kg/s and the organic PCM utilized was regular commercial-grade paraffin. The findings demonstrated that the baffled SAH’s energy efficiency was increased by 11.25% by adding organic PCM.

The energy consumption (EC) of a conference hall in Riyadh that had a timetable of occupancy from 8 a.m. to 12 p.m. was evaluated by Abu-Hamdeh et al. in 2022 [83]. The installation of an economizer and heat recovery equipment allowed for the development of software that changes the active and inactive hours in accordance with the mechanical ventilation timetable. In the first method, the injection of cold air into the indoor area in the summer was adjusted in the range of 3–12 (i.e., ACH = 3, 6, 9 and 12) by constructing programming on the air change (ACH) parameter. The findings showed that the economizer’s effectiveness was more apparent with a lower ACH value. The economizer’s performance was lower than expected, despite the improvement in ACH, leading to a maximum decrease of 3.07% in EC. In the second method, a program was developed to limit the use of heat recovery to the temperature difference between the interior and exterior of the building. By using this method, EC was decreased by 34% in the summer and 95% in the winter. Yet, the yearly EC drop was capped at 35% because of the significant amount of cooling load. In the third procedure, HS29 PCM was introduced to the structure, and it was found that while it occasionally performed poorly during the winter, it performed admirably throughout the summer. The approach utilized has ultimately decreased annual EC by 5.6%.

An experiment was carried out by Palacio and colleagues (2022) [84] to investigate the effectiveness of a double-channel solar air heater (SAH) with and without a PCM used as a thermal energy storage system. In order to include macro-encapsulated PCM (Rubitherm RT 45) in the absorber plate, one of two similar prototypes was adjusted. The three weather conditions that were tested in the study were clear skies with strong solar radiation, partly cloudy skies, and clear skies with a large decrease in solar radiation at noon. The experiment demonstrated that the double-channel solar air heater (SAH) with a PCM as a thermal energy storage system had maximum outlet temperatures of 82 °C, 62 °C, and 79.5 °C for the three cases studied, respectively. In contrast, the SAH without PCM consistently had an outlet temperature that was 10 °C lower than the SAH with PCM. The PCM enabled the system to maintain heating during day irradiation transients and extend it after dusk without affecting thermal efficiency.

Chaatouf et al. (2022) [85] conducted a study on a solar air heater (SAH) integrated with a PCM storage unit to optimize its efficiency for drying apricots. The SAH was analyzed under real meteorological conditions in Eastern Morocco using the computational fluid dynamics (CFD) method and a C++ UDF (User-Defined Function) subroutine written in the C++ programming language ((Note: C++ UDF is a type of function used in CFD, such as ANSYS Fluent, to extend the functionality of the software beyond the built-in capabilities). To meet the drying needs of apricots, the SAH was subjected to testing with natural and forced convection and optimization based on different tilts and air velocities. Results showed that without PCM, the SAH produced high temperatures above 70 °C that could negatively affect product quality. However, with a PCM layer (paraffin RT RT58), the temperature decreased throughout the day and increased after sunset, with an optimal combination of 1 m/s air velocity and 4 cm PCM thickness for forced convection. For natural convection, a 60° tilt was found to be appropriate for enhancing the mass flow rate, which significantly affected the outlet temperature of SAH and the melting process of PCM. In the drying chamber, these two ideal instances were further examined.

Verma et al. (2022) [86] used a transient computational iterative solution procedure to predict the thermal efficiency of a solar air heater with PCM (paraffin wax RT42) using differential airflow arrangements. The finite volume method was employed to solve the governing differential equations. The researchers used the first-order upwind advection scheme to stimulate air temperatures. The findings demonstrated that the PCM integrated into the solar air heater enabled large thermal energy storage, instantaneous and prolonged thermal backups, and air heat gain as corresponding to the daytime and changeable air flow rate configurations. The highest thermal performance was 63% at 0.05 kg/s total mass flow rate. The airflow rate settings that can deliver an outlet air temperature of at least 303 K during the night were also found by the researchers.

Sharol et al. (2022) [87] conducted an experimental analysis to investigate the effect of incorporating a thermal energy storage material inside the tube of a double-pass solar air heater with a cross-matrix absorber (DPSAH-CMA) on its thermal efficiency. The researchers tested the SAH under different operating conditions both indoors and outdoors. Results showed that the DPSAH-CMA with PCM (paraffin wax) was able to buffer thermal energy more effectively, with a rate of −0.81 °C min−1, compared to the one without PCM at a mass flow rate of 0.005 kg/s. The PCM also led to an increase in the cumulative heat rate of the DPSAH-CMA, with an extreme value of 1548.54 W at the greatest solar radiation of 900 W m−2. The maximum storage performance of the DPSAH-CMA with PCM was at the matching greatest mass flow rate and was inversely related to solar radiation values. When comparing the performance of the two SAHs under outdoor conditions, the DPSAH-CMA with PCM attained the greatest thermal performance, outperforming the DPSAH-CMA without PCM by 17%. Moreover, the DPSAH-CMA’s exergy efficiency was found to be 23% with PCM and 15% without PCM, as per Sharol et al. (2022) [87].

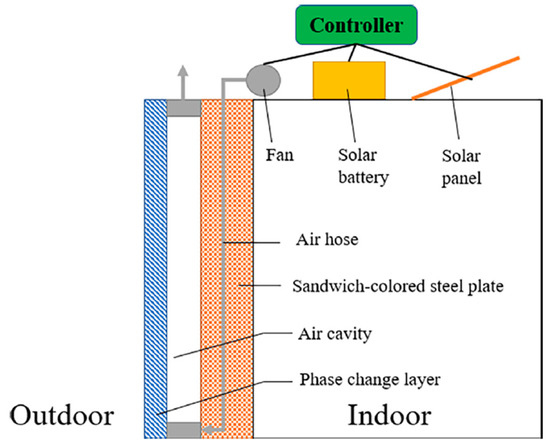

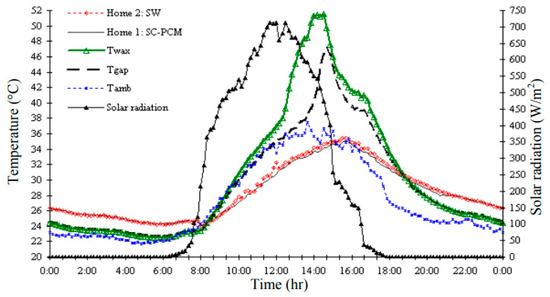

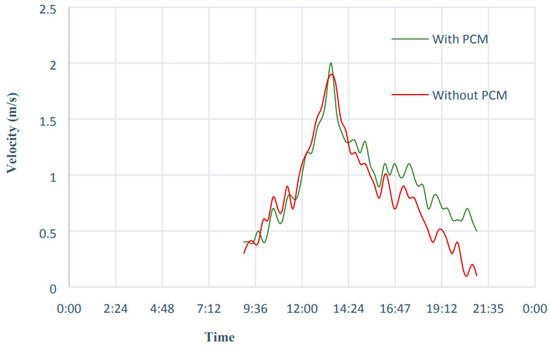

Unidirectional flow, PCM-rod (ZN-110H), and spiral tubes were used in an experiment by Luo et al. (2002) [88] to increase the thermal performance of an evacuated tube solar air heater. Using an experimental test platform, the thermal efficiency of the SAH-PCM was assessed. ANSYS software was utilized to examine the temperature and flow fields in the vacuum tube, and an environmental assessment was performed. The numerical study identified the ideal PCM-rod size and estimated the spiral tube’s heat augmentation coefficient to be 1.1. The results of the experimental testing showed that the SAH-PCM could effectively prevent outlet temperature swings, albeit at the expense of a 31.5 °C lower average outlet temperature. The rate of heat loss was decreased by 58.5%, and PCM’s thermal efficiency could increase to 844.9%. Moreover, the operation hours at night were extended by over 3 h. These findings demonstrate that phase change materials and spiral tubes, as well as unidirectional flow structural design, can enhance the thermal efficiency of the air heater.